Method for carrying out hot-dipping on aluminum-zinc alloy on steel surface

A steel surface, hot infiltration technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve problems such as difficult to handle large workpieces, and achieve low production cost, low temperature and simple process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

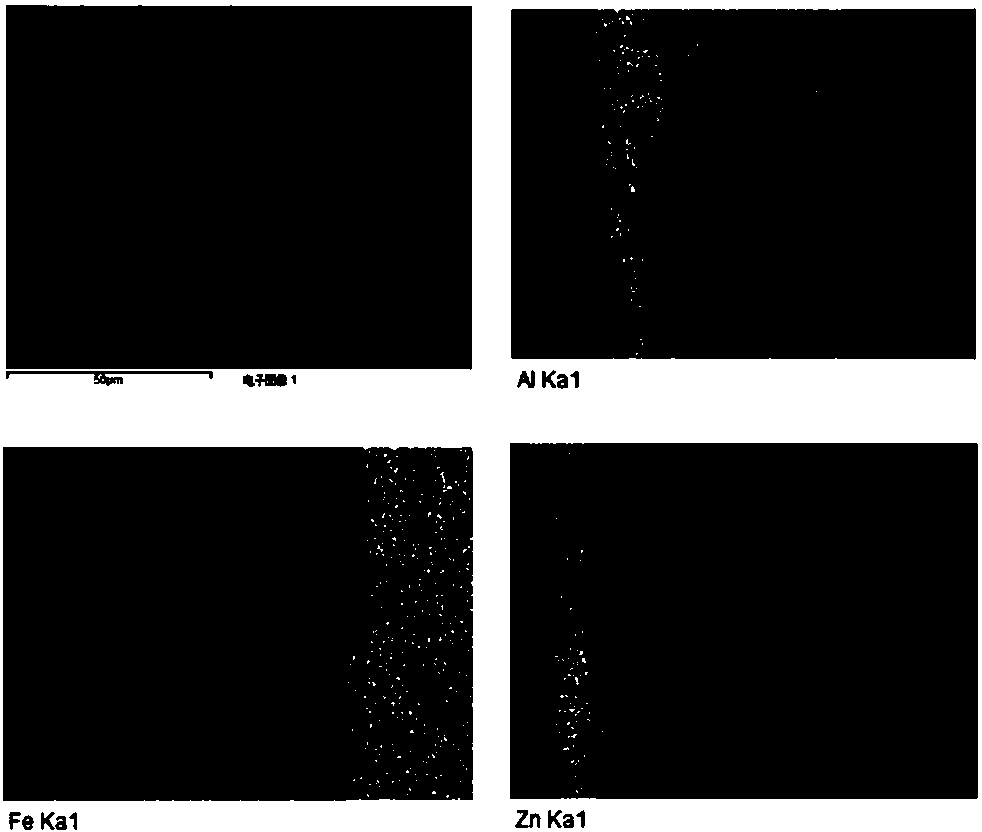

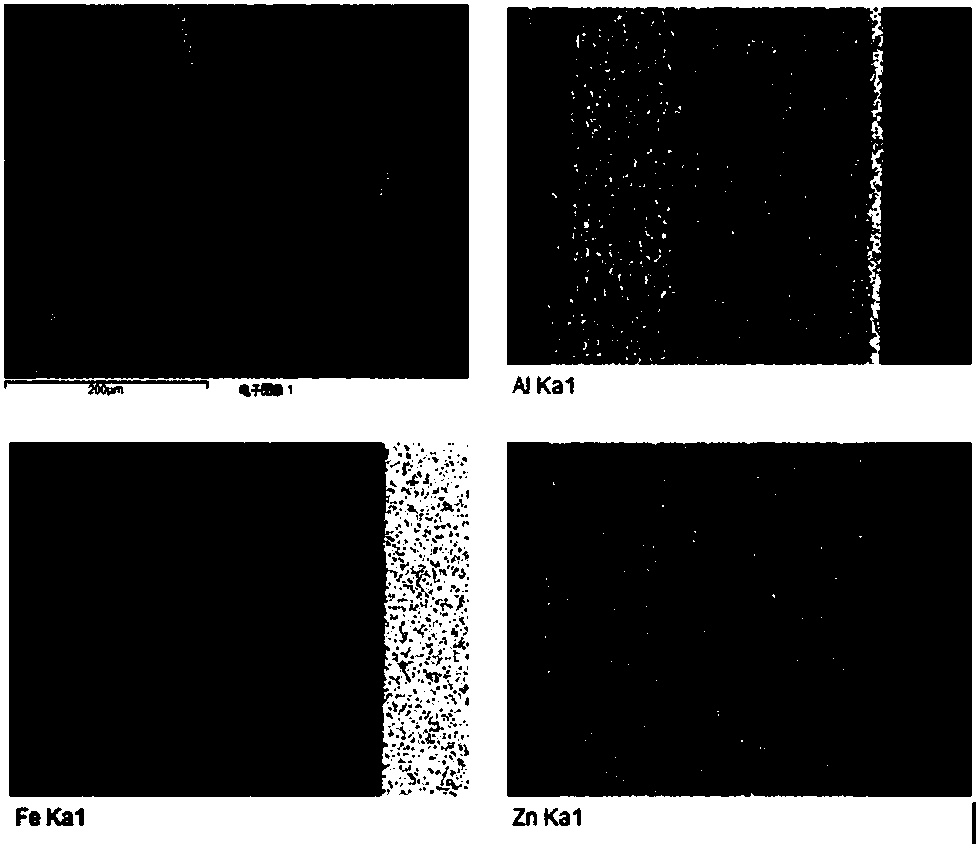

[0028] The Q345 steel plate is immersed in the alloy solution at 480°C after the fluxing treatment. The composition of the alloy solution is Zn-5%Al-2%Mg-0.2%RE (RE is mixed rare earth containing cerium), and the hot dipping time is 2 minutes. . The cross-sectional morphology and the surface distribution of the main components of the hot-impregnated layer are shown in figure 1 . The inner layer is an aluminum-zinc-iron alloy layer (the average atomic ratio of aluminum-iron-zinc elements is about 46:35:19), with a thickness of about 55 μm, and the outer layer is a zinc-aluminum alloy layer, with a thickness of about 10 μm. Compared with the Zn-5%Al-2%Mg-0.2%RE coating (with no penetration layer structure) converted into the same thickness, the time for rust spots to appear in the neutral salt spray test is extended to 1.5 times.

Embodiment 2

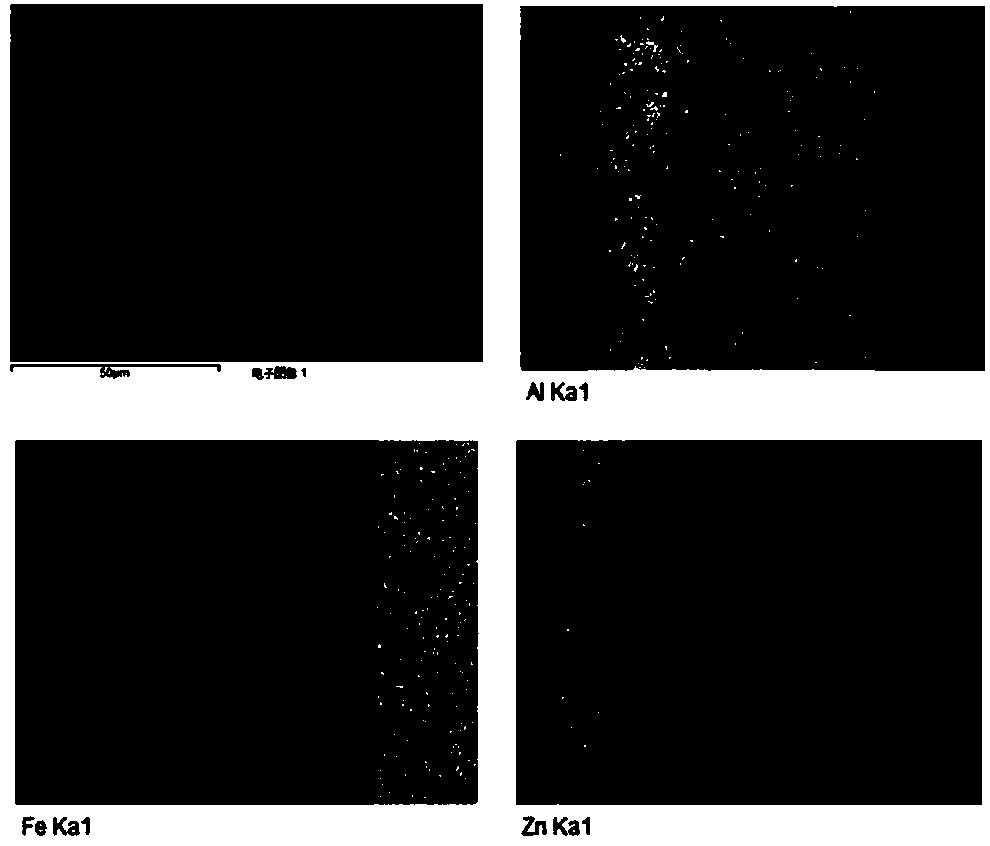

[0030] The Q235 steel plate is immersed in the Zn-6%Al-3%Mg-0.1%RE alloy liquid, and the temperature of the alloy liquid is 470°C. The impregnation time is 2min, and the cross-sectional morphology and main component surface distribution of the obtained alloy layer are shown in figure 2 . The inner layer is an Al-Zn-Fe alloy layer (the average atomic ratio of Al-Fe-Zn elements is about 47:36:18), with a thickness of about 80 μm, and the outer layer is a zinc-aluminum alloy layer, with a thickness of about 11 μm. Compared with the Zn-6%Al-3%Mg-0.1%RE coating (no permeation layer structure was formed), the time to appear rust spots in the neutral salt spray test was extended to 1.4 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com