Preparation method of zinc sulfide (ZnS)/cadmium telluride (CdTe) quantum dot sensitization titanium dioxide (TiO2) nano film

A quantum dot sensitization, nano-film technology, applied in photosensitive equipment, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of unstable quantum dots, no photocathode protection effect, low photoelectric efficiency of thin films, etc. Photogenerated cathodic protection effect, reduced defect density, improved crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

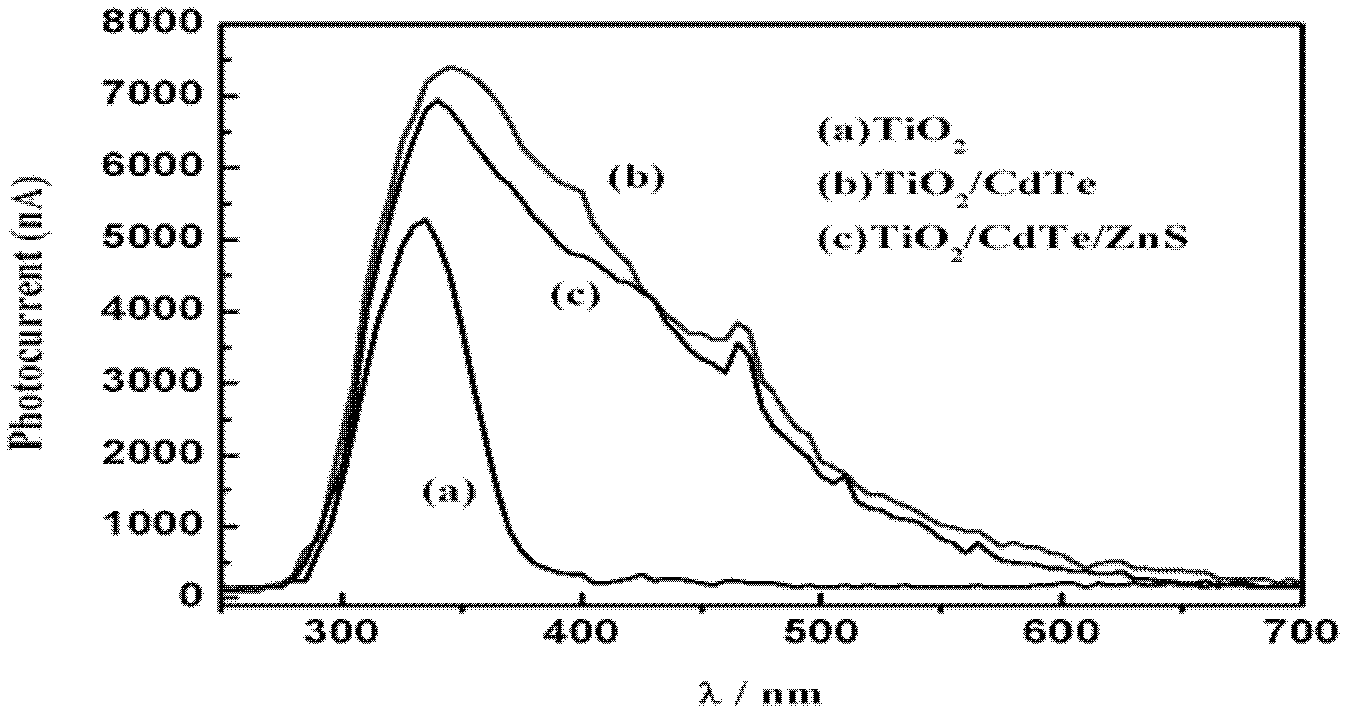

[0030] According to the above technical scheme (specific steps), prepare ZnS / CdTe quantum dot sensitized TiO 2 Nano film, and test the cathodic protection effect of the film as a photoanode on 403 stainless steel.

[0031] A rectangular pure titanium foil with a thickness of 0.1 mm is used as a sample, its length is 15 mm, and its width is 10 mm. After the surface of the sample was polished by No. 400-1500 water abrasive paper, it was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes respectively.

[0032] Weigh 4.5g NH 4 F, dissolve in 333mL deionized water, add 500mL glycerol, and mix well. At room temperature, using platinum as the counter electrode, anodize at 20V for 30min in the above solution. Then the sample was placed in a muffle furnace and calcined at 450 °C for 2 h and cooled to room temperature with the furnace, that is, TiO was prepared on the Ti surface. 2 nanotube array film.

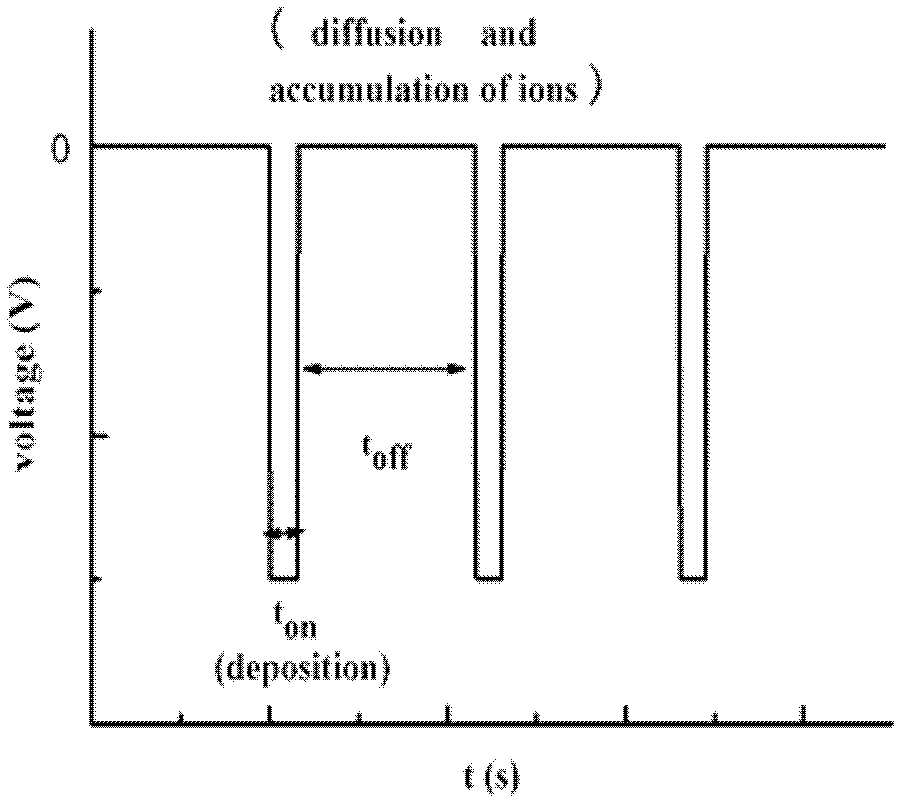

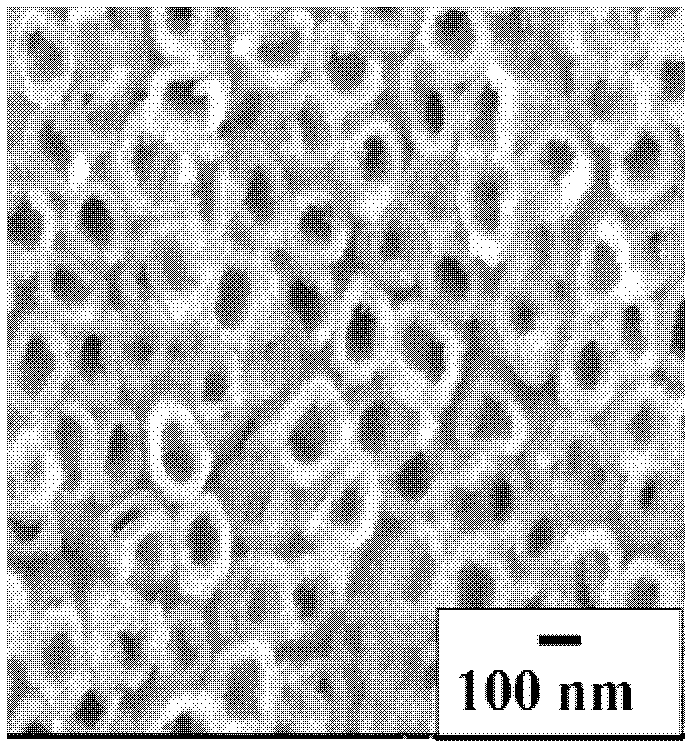

[0033] Using the constant voltage pulse el...

Embodiment 2

[0041] According to the above technical scheme (specific steps), prepare ZnS / CdTe quantum dot sensitized TiO 2 Nano film, and test the cathodic protection effect of the film as a photoanode on 403 stainless steel.

[0042] A rectangular pure titanium foil with a thickness of 0.1 mm is used as a sample, its length is 10 mm, and its width is 10 mm. After the surface of the sample was polished by No. 400-No. 1500 water-grinding paper, it was ultrasonically cleaned in acetone, absolute ethanol and deionized water for 8 minutes respectively.

[0043] Weigh 4.5g of ammonium fluoride, dissolve it in 333mL of deionized water, add 500mL of glycerol, and mix well. At room temperature, using platinum as the counter electrode, anodize at 20V for 30min in the above solution. The samples were then calcined at 450 °C for 2 h in a muffle furnace and cooled to room temperature with the furnace.

[0044] Using the constant voltage pulse electrodeposition method, using the Autolab PGSTAT30 el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com