Inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, anti-fouling/underwater coatings, alkali metal silicate coatings, etc., can solve problems such as easy reunion and insufficient long-term algae resistance, and achieve overcoming easy reunion, Improve the effect of cathodic protection and extend the effect of shielding path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

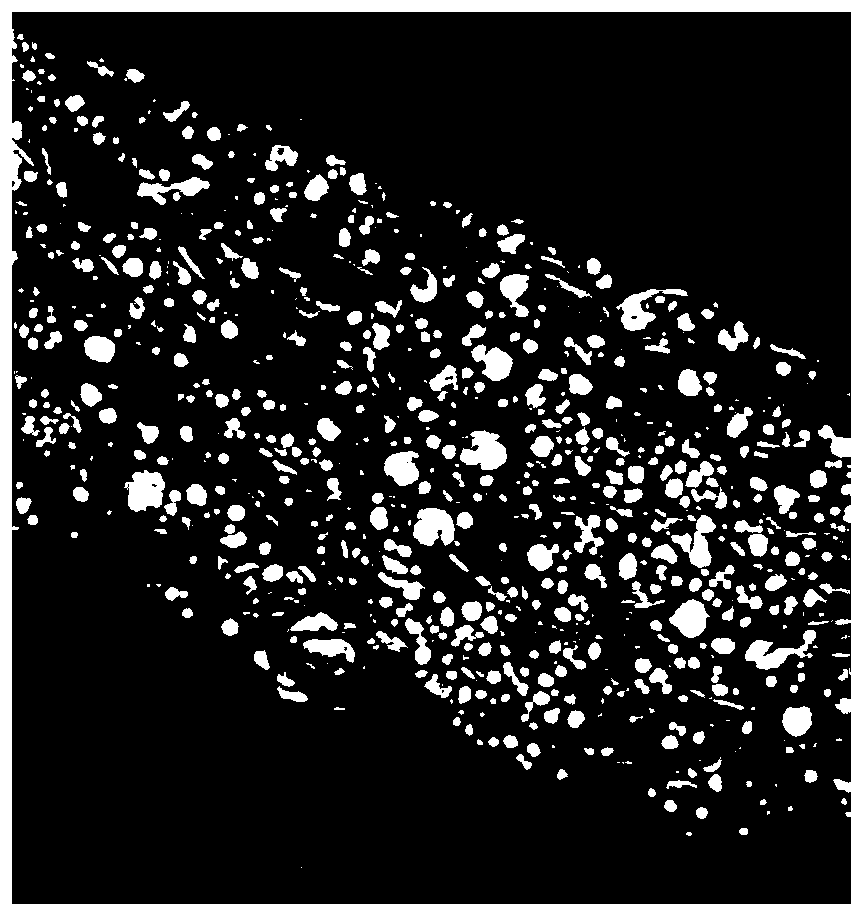

Image

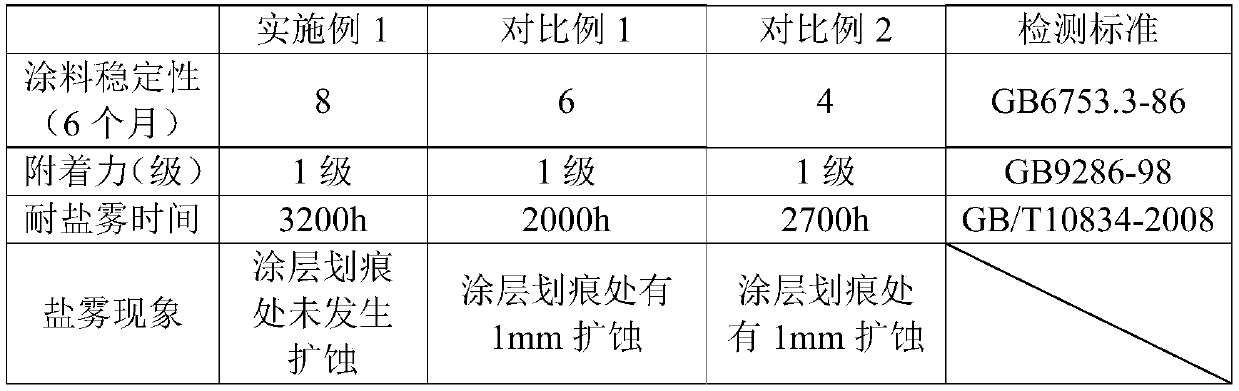

Examples

Embodiment 1

[0029] The present embodiment provides a kind of inorganic graphene antibacterial anti-algae zinc-rich anticorrosion coating, which is prepared according to the following steps:

[0030] (1) Preparation of silicate solution: take raw materials potassium hydroxide, silica sol and water, wherein the molar ratio of potassium hydroxide, silica sol and water is 1:10:6. Pre-mix and dissolve potassium hydroxide and water to obtain a potassium hydroxide solution, then gradually add the potassium hydroxide solution dropwise to the silica sol under rapid stirring, and react for 1 hour at a water bath temperature of 50°C to prepare a silicate High modulus potassium silicate solution with a modulus of 4.5.

[0031] (2) Preparation of stable high modulus silicate: according to the mass ratio of high modulus potassium laurate solution: silane coupling agent: silicon acrylic emulsion is 1:0.5%: (2% ~ 5%) ratio, weigh Silane coupling agent KH-560 and silicon acrylic emulsion are slowly added...

Embodiment 2

[0037] The present embodiment provides a kind of inorganic graphene antibacterial anti-algae zinc-rich anticorrosion coating, which is prepared according to the following steps:

[0038] (1) Preparation of silicate solution: take raw materials sodium hydroxide, potassium hydroxide, silica sol and water, wherein the molar ratio of sodium hydroxide, potassium hydroxide, silica sol and water is 0.3:0.7:14:10. Sodium hydroxide, potassium hydroxide and water are premixed and dissolved to obtain a mixed solution, and then, under rapid stirring, the mixed solution is gradually added dropwise to the silica sol, and the reaction time is 1 hour at a water bath temperature of 50 ° C. The prepared modulus is 6.5 Silicate solution.

[0039] (2) Preparation of stable high modulus silicate: according to the mass ratio of high modulus sodium silicate solution: silane coupling agent: silicon acrylic emulsion is 1:0.5%: (2% ~ 5%), weigh Silane coupling agent KH-560 and silicone acrylic emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com