Method for protecting components of a primary system of a boiling water reactor in particular from stress corrosion cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

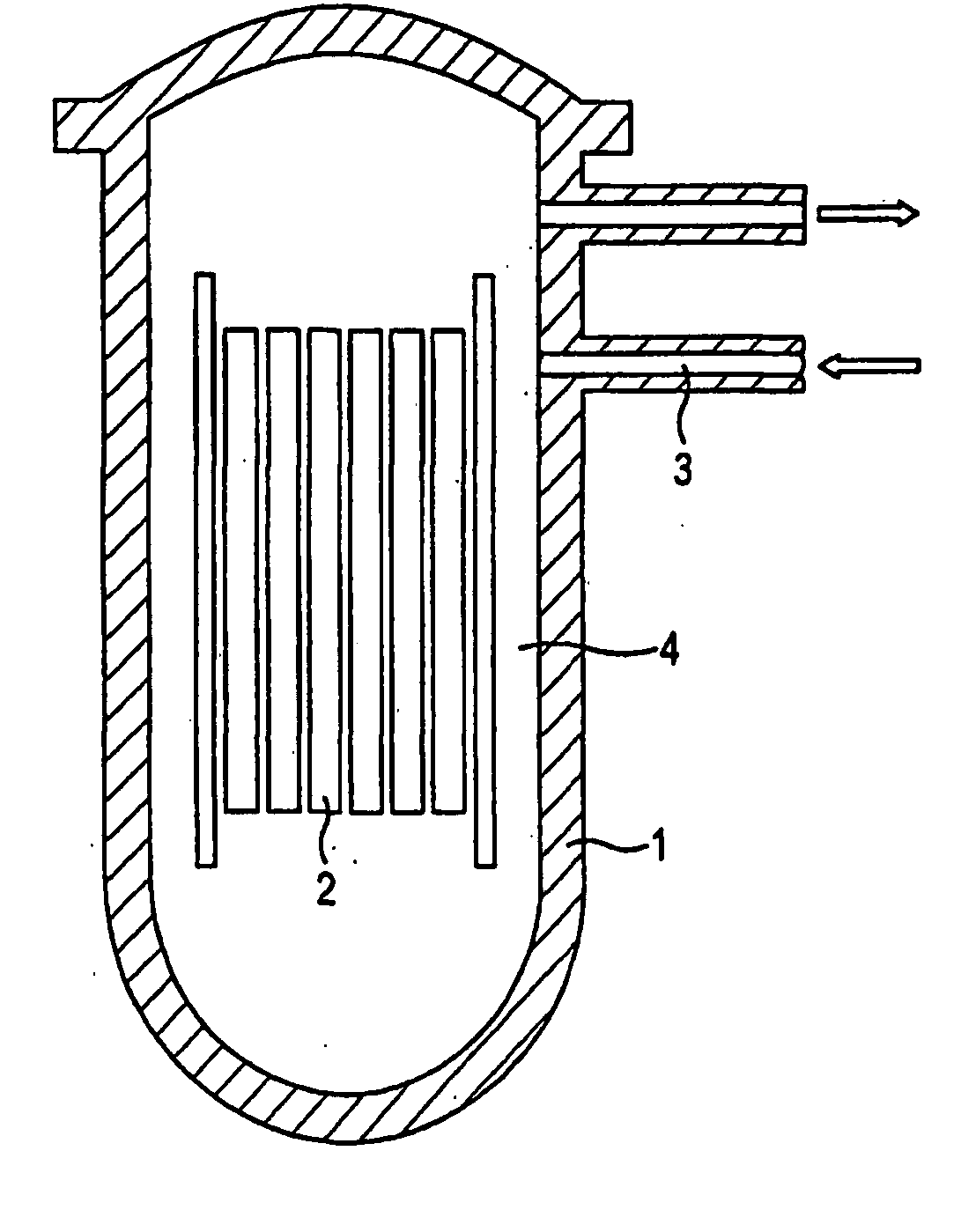

[0022] Referring now to the figures of the drawing in detail and first, particularly, to FIG. 1 thereof, there is shown a highly simplified illustration of a boiling water reactor. A pressure vessel 1 of the reactor houses fuel assemblies 2 or fuel elements. An alcohol of the above-mentioned type, preferably methanol, is injected into a feedline 3, which continues inside the pressure vessel in the form of an annular distributor line, to protect against corrosion and in particular against stress corrosion cracking (IGSCC). The reactor is in an operating state in which the components of the reactor, i.e. for example the pressure vessel 1 and the non-illustrated core grid, which usually consist of CrNi steel or an Ni-base alloy, are bright or are covered only with a native oxide layer. The former case occurs, for example, if an oxide layer has been removed from the component surfaces during maintenance work. The quantity injected into the feedline 3 is such that a concentration of from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molality | aaaaa | aaaaa |

| Molality | aaaaa | aaaaa |

| Osmolality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com