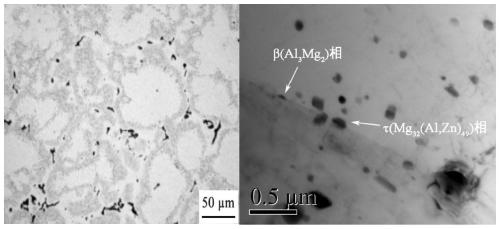

Al-Mg alloy with high intergranular corrosion resistance and preparation method thereof

An intergranular corrosion and alloy technology, applied in the field of materials, can solve problems such as limited equipment size and inability to prepare large-scale samples, and achieve the effect of optimizing intergranular corrosion resistance and reducing potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

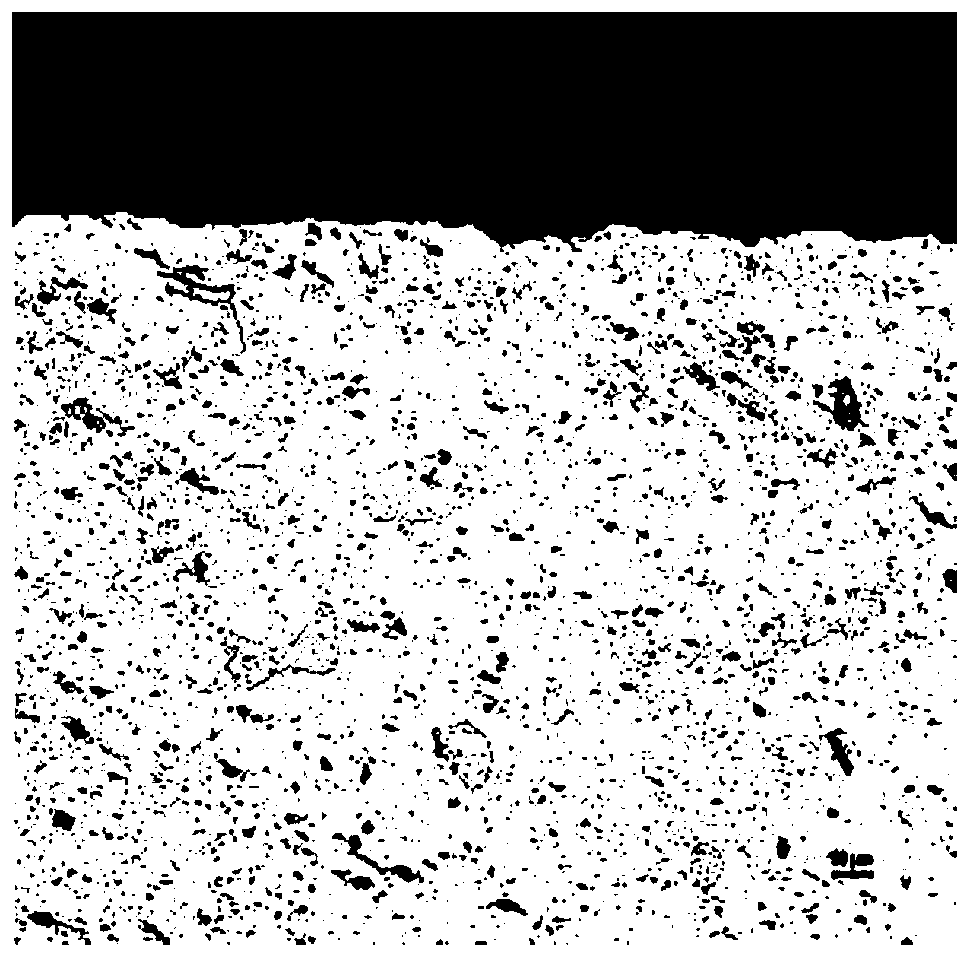

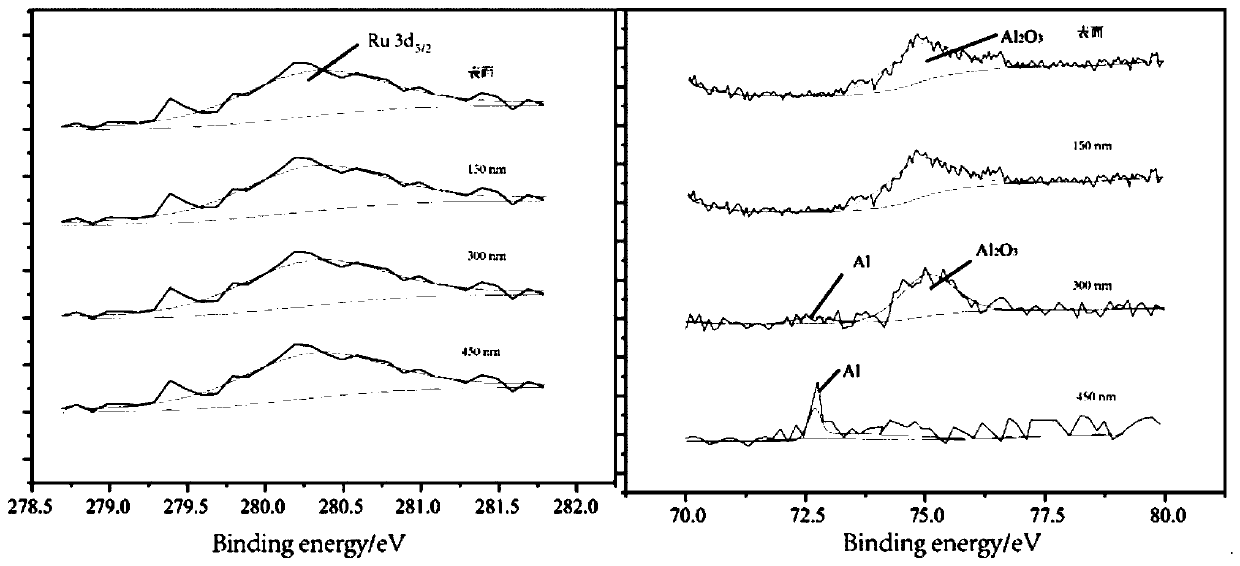

Method used

Image

Examples

Embodiment 1

[0034] 1) Take Mg: 3.5wt%, Mn: 0.3wt%, Zn: 0.2wt%, Ti: 0.09wt%, Ru: 0.05wt% according to the weight percentage of the constituent elements, and the balance is Al. Melt the above materials in a melting furnace at a melting temperature of 780°C until melting;

[0035] 2) After the alloy melt is added with multiple refining agents and degassing agents, it is refined and degassed and slag removed, and then allowed to stand for 8 minutes;

[0036] 3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 15 Hz for 30 s, and then water-cooling to form an ingot;

[0037] 4) The ingot is subjected to homogenization treatment, the homogenization temperature is 560° C., and the time is 48 hours. After the treatment is completed, it is water quenched at room temperature.

Embodiment 2

[0039] 1) Take Mg: 4.2wt%, Mn: 0.6wt%, Zn: 0.25wt%, Ti: 0.09wt%, Ru: 0.05wt% according to the weight percentage of the constituent elements, and the balance is Al. Melt the above materials in a melting furnace at a melting temperature of 760°C until melting;

[0040] 2) After the alloy melt is added with multi-element refining agent and degassing agent, it is refined and degassed and slag removed, and then allowed to stand for 8 minutes;

[0041] 3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 15 Hz for 30 s, and then water-cooling to form an ingot;

[0042] 4) The ingot is subjected to homogenization treatment, the homogenization temperature is 570° C., and the time is 18 hours. After the treatment, it is water quenched at room temperature.

Embodiment 3

[0044] 1) Take Mg: 4.2wt%, Mn: 0.6wt%, Zn: 0.3wt%, Ti: 0.15wt%, Ru: 0.08wt% according to the weight percentage of the constituent elements, and the balance is Al. Melt the above materials in a melting furnace at a melting temperature of 800°C until melting;

[0045] 2) After the alloy melt is added with multiple refining agents and degassing agents, it is refined and degassed and slag removed, and then allowed to stand for 8 minutes;

[0046] 3) Pouring the alloy melt into a cylindrical mold in an electromagnetic stirring device, performing low-frequency electromagnetic stirring at 15 Hz for 30 s, and then water-cooling to form an ingot;

[0047] 4) The ingot is subjected to homogenization treatment, the homogenization temperature is 550° C., and the time is 48 hours. After the treatment, it is water quenched at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com