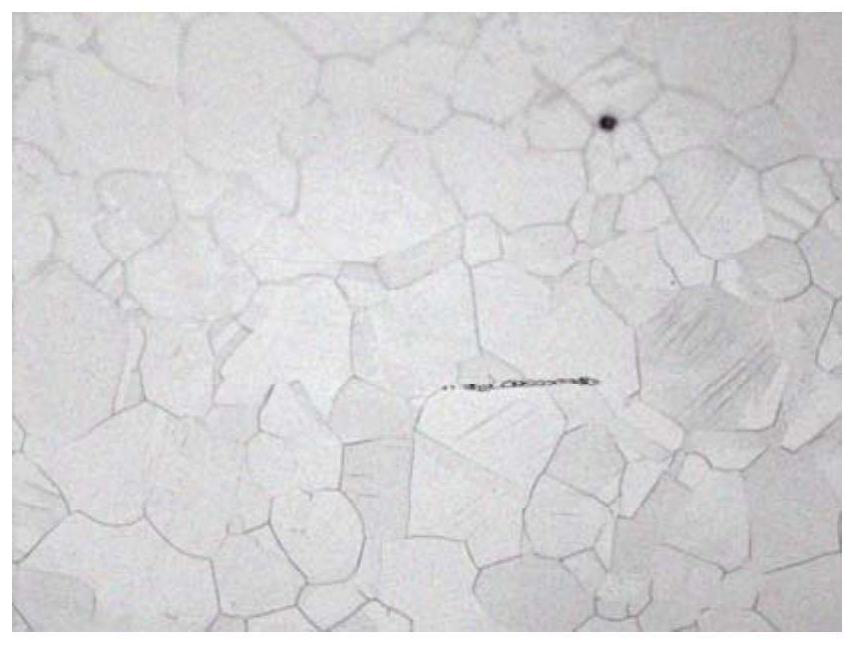

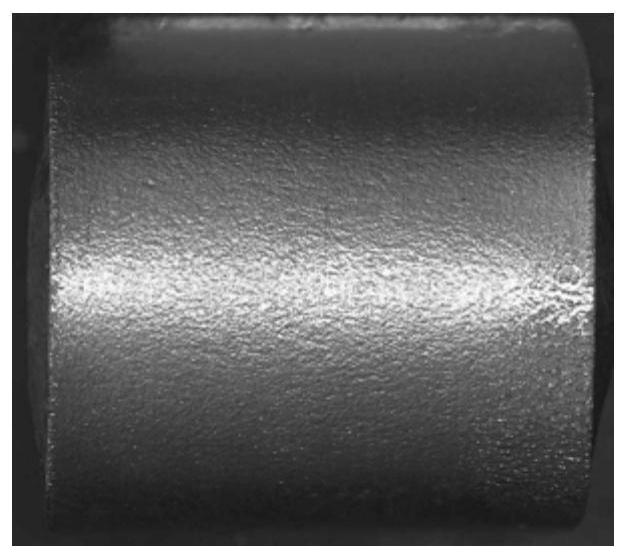

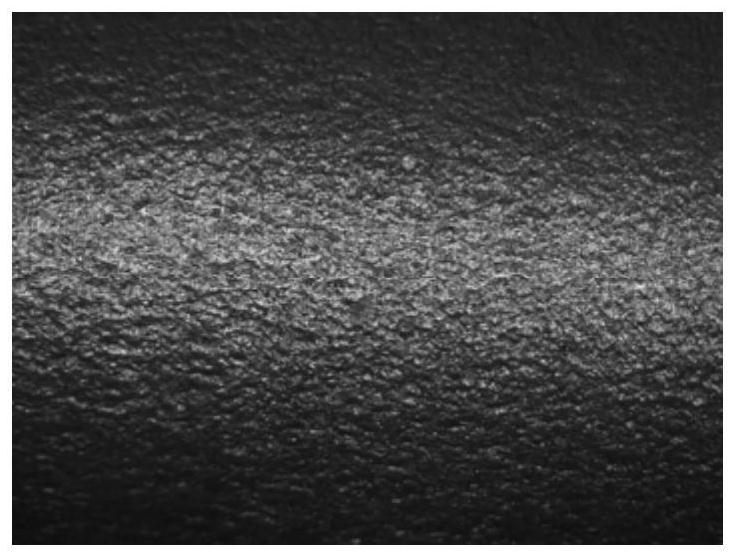

High-carbon low-ferrite-content austenitic stainless steel plate and production method thereof

An austenitic stainless steel and production method technology, applied in the field of iron and steel materials, can solve the problems of high ferrite content, poor intergranular corrosion resistance, and increased production costs, and achieve good comprehensive performance, good mechanical properties, and optimized distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below by embodiment the present invention will be further described.

[0058] In the embodiment of the present invention, according to the component ratio of the technical solution, electroslag remelting, heating, forging, homogenization heat treatment, rolling, and grain boundary engineering control are carried out;

[0059] (1) Electroslag remelting:

[0060] a) In the slag removal stage, the arc is automatically started, and the power supply parameter current and voltage are gradually increased from 6000-7000A, 74V to 16000-17000A, 86V, and the slag removal time is 105-115min; after that, enter the current and voltage raising stage, and the power supply parameters The current and voltage continue to increase step by step to 25000-26000A, 101V;

[0061] b) Remelting stage: the target melting speed is 1100kg / h~1300kg / h, the remelting time is 15~20 hours, and the power supply parameters current and voltage are gradually reduced from 25000-26000A and 101V to 19000-20000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com