A kind of preparation method of aluminum foil for automobile radiator

A technology of automobile radiator and aluminum foil, which is applied in the field of aluminum alloy casting to achieve the effect of improving casting structure, improving intermediate segregation and porosity, and reducing emulsion residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

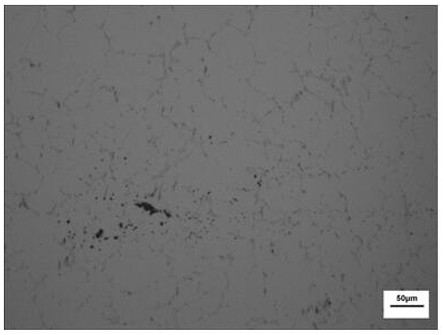

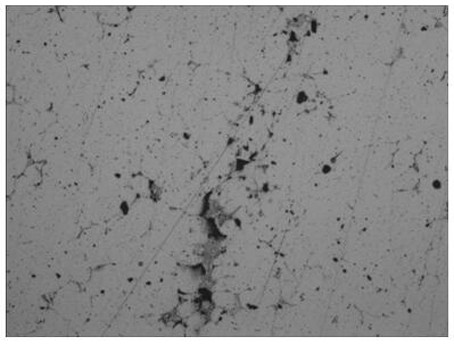

Image

Examples

Embodiment 1

[0042] The chemical composition and preparation method of a 0.099mm thick "H22" state 7072 alloy aluminum foil for automobile radiators.

[0043] S1. Preparation of aluminum melt:

[0044] A radiating fin for a 7072 alloy automobile radiator, the percentage content of alloying elements is: Si: 0.05%; Fe: 0.35%; Cu: 0.05; Zn: 1.0%; Ti: 0.025%; other individual impurities ≤ 0.03%, total ≤0.15%, the rest is Al.

[0045] In order to ensure the chemical composition of the 7072 alloy, the aluminum melt is prepared by feeding electrolytic aluminum liquid with Fe ≤ 0.16%, Si ≤ 0.04% and aluminum ingot with aluminum content ≥ 99.7%, and no waste is added. In this way, the element Si content in the 7072 alloy is guaranteed to be in the range of 0.05-0.1%. The Fe element is added in the form of aluminum-iron master alloy or 90% iron powder, and the Zn element is added in the form of zinc ingot.

[0046] The electrolytic aluminum liquid with Fe≤0.16% and Si≤0.04% is pre-refined in the ...

Embodiment 2

[0061] A chemical composition and preparation method of 0.12mm thick "O" state 7072 alloy aluminum foil for automobile radiators.

[0062] S1. A heat dissipation fin for a 7072 alloy automobile radiator, the percentage content of alloy elements is: Si: 0.05%; Fe: 0.45%; Cu: 0.05; Zn: 1.0%; Ti: 0.020%; other single impurities ≤ 0.03% , the total ≤0.15%, and the rest is Al.

[0063] All the other are with embodiment 1;

[0064] S2. During continuous rolling, the specific pass distribution is: 19-9.0-7.0mm, and the rest are the same as in Example 1.

[0065] S3. The homogenization annealing process is the same as in Example 1.

[0066] S4. The distribution scheme of the cold rolling pass is: 7.0mm→4.2mm→2.5mm→1.5mm→0.9mm→0.53mm→0.31mm→edge trimming→0.18mm→0.12mm→slitting. The total deformation of the billet in the cold rolling step was 98.3%.

[0067] Middle pass processing rate ≥ 40%, finished product pass processing rate 33%, all the other are the same as embodiment 1.

[...

Embodiment 3

[0071] The chemical composition and preparation method of a 0.095mm thick "H22" state 7072 alloy aluminum foil for automobile radiators.

[0072] S1. Preparation of aluminum melt:

[0073] A radiating fin for a 7072 alloy automobile radiator, the percentage content of alloying elements is: Si: 0.08%; Fe: 0.30%; Cu: 0.08; Zn: 0.9%; Ti: 0.020%; other individual impurities ≤ 0.03%, total ≤0.15%, the rest is Al.

[0074] In order to ensure the chemical composition of the 7072 alloy, the aluminum melt is prepared by feeding electrolytic aluminum liquid with Fe ≤ 0.16%, Si ≤ 0.04% and aluminum ingot with aluminum content ≥ 99.7%, and no waste is added. In this way, the element Si content in the 7072 alloy is guaranteed to be in the range of 0.05-0.1%. The Fe element is added in the form of aluminum-iron master alloy or 90% iron powder, and the Zn element is added in the form of zinc ingot.

[0075]The electrolytic aluminum liquid with Fe≤0.16% and Si≤0.04% is pre-refined in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com