Method for improving corrosion resistance of carbon fiber reinforced aluminum matrix composite

A composite material and reinforced aluminum-based technology, which is applied in the field of improving the corrosion resistance of carbon fiber-reinforced aluminum-based composite materials, can solve the problems of long preparation period, complicated preparation process, and high production cost, and achieve short preparation period, simple preparation process, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific Embodiment 1: This embodiment is a method for improving the corrosion resistance of carbon fiber reinforced aluminum matrix composite materials. The preparation method is carried out according to the following steps:

[0025] 1. Weighing: Weigh 0.05-3% yttrium element powder and 97-99.5% aluminum alloy according to the mass fraction;

[0026] 2. Mixed melting: use high-temperature heating to melt the aluminum alloy weighed in step 1 and add yttrium element powder for stirring to obtain an aluminum-yttrium alloy melt;

[0027] 3. Forming: Preheat the carbon fiber mold, and then use the pressure infiltration method to infiltrate the aluminum-yttrium alloy melt obtained in step 2 to obtain a composite material;

[0028] 4. Heat treatment: heat the composite material obtained in step 3 for heat preservation, control the heat preservation temperature to 300-400° C., and heat preservation time to 0.5h-12h, then furnace cool to room temperature to obtain a carbon fibe...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: Step 1 weighs 0.1% yttrium element powder and 99.9% aluminum alloy according to the mass fraction. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: Step 1 weighs 0.2% yttrium element powder and 99.8% aluminum alloy according to the mass fraction. Others are the same as in the first or second embodiment.

PUM

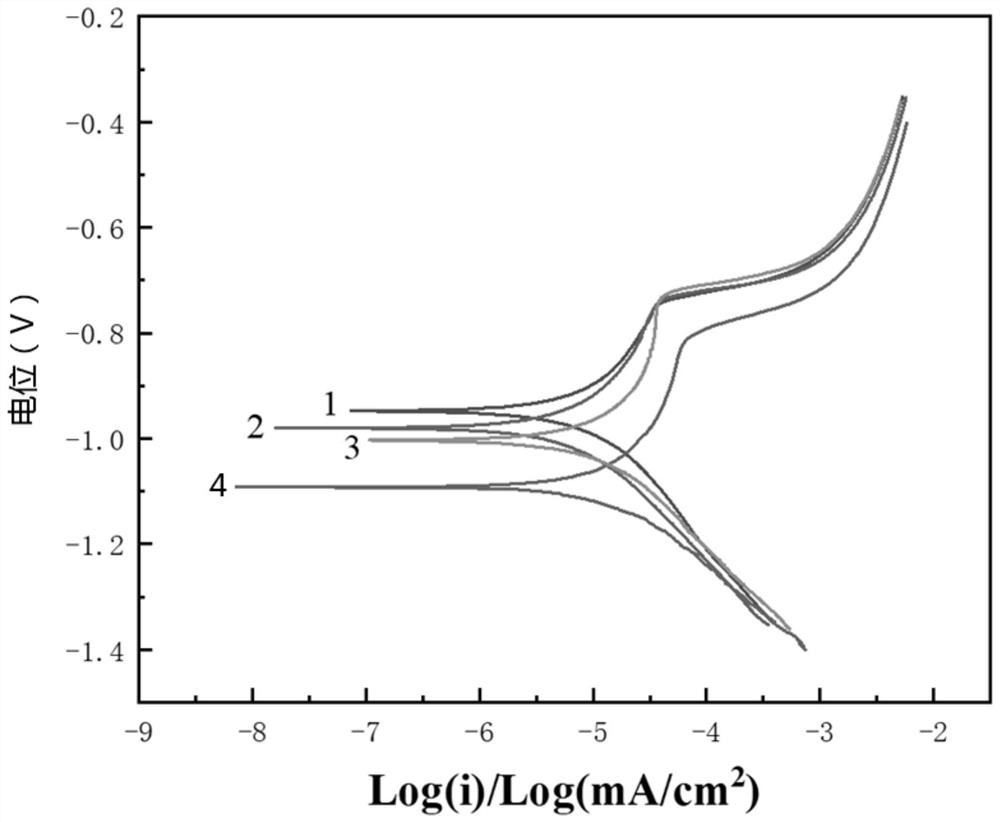

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com