Method for preparing aluminum-based amorphous layer by jointly adopting hot spraying and electron beam remelting technologies

An amorphous layer, thermal spraying technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of limiting the corrosion resistance of the coating, unable to prepare the coating, etc., to achieve short processing time, eliminate the Defect structure, the effect of strong amorphous forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

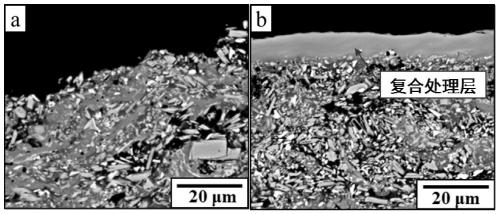

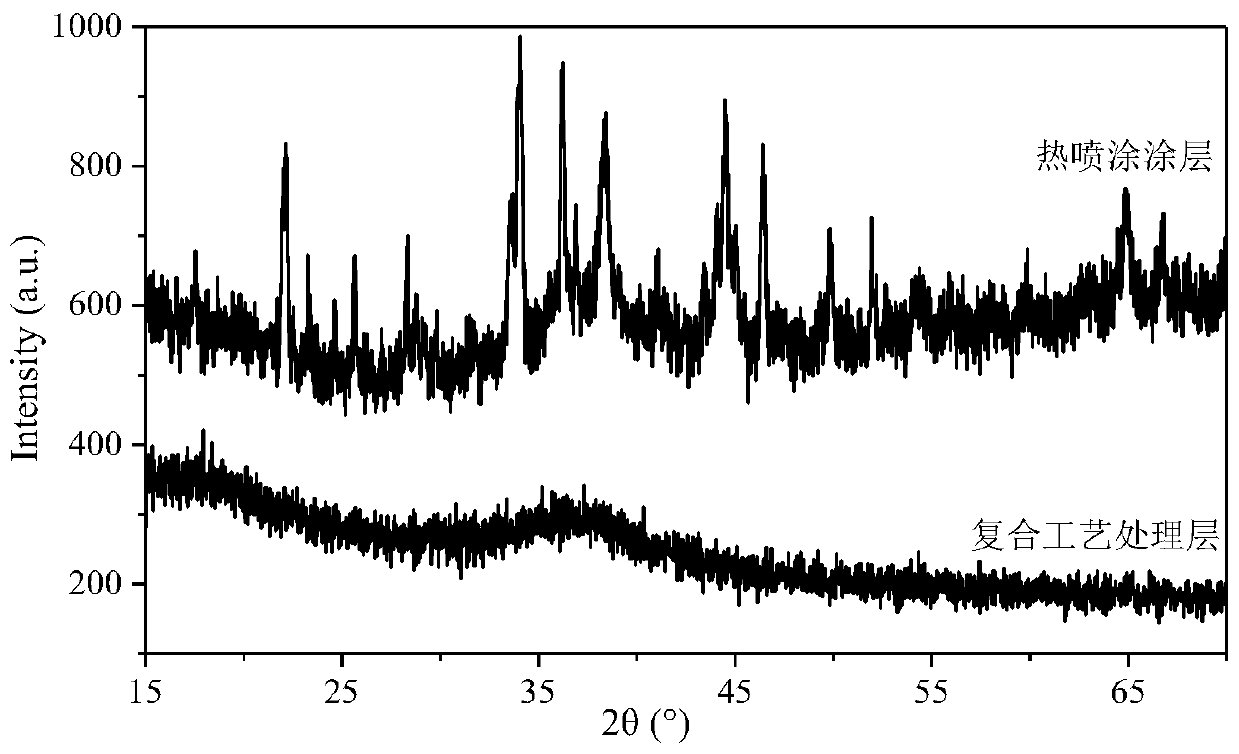

[0032] The HOPE-I high-current pulsed electron beam device was used to remelt the thermal sprayed AlCoCe coating to prepare the amorphous alloy treatment layer. The testing process is as follows:

[0033] (1) Prepare Al by vacuum induction melting furnace 86 co 7.6 Ce 6.4 Alloy, and use gas atomization technology to prepare alloy powder in vacuum metal atomization powder making furnace, vacuum degree ≤ 1.0×10 -3 Pa, the melting temperature is 1350°C, the atomizing gas is argon, and the pressure is 4MPa;

[0034] (2) Use acetone and absolute ethanol to clean the surface of the Q235 steel substrate to remove oil stains; then remove the attachments and oxide scales on the surface of the Q235 steel substrate by sandblasting, and the surface derusting level reaches Sa 2.5. After the end, dry the surface with dry gas blow off;

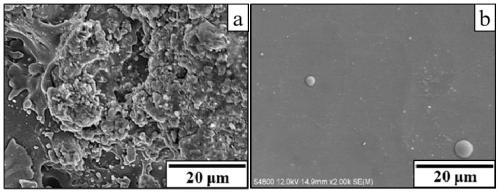

[0035] (3) Using supersonic flame thermal spraying equipment to deposit alloy powder on the surface of Q235 steel substrate to form Al 86 co 7.6 Ce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com