Rare earth polishing liquor for organic alkaline corrosive medium

A corrosive medium and rare earth polishing technology, which is applied in the field of polishing liquid, can solve problems such as chip reliability reduction, pH instability, and partial punch-through effect of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-4

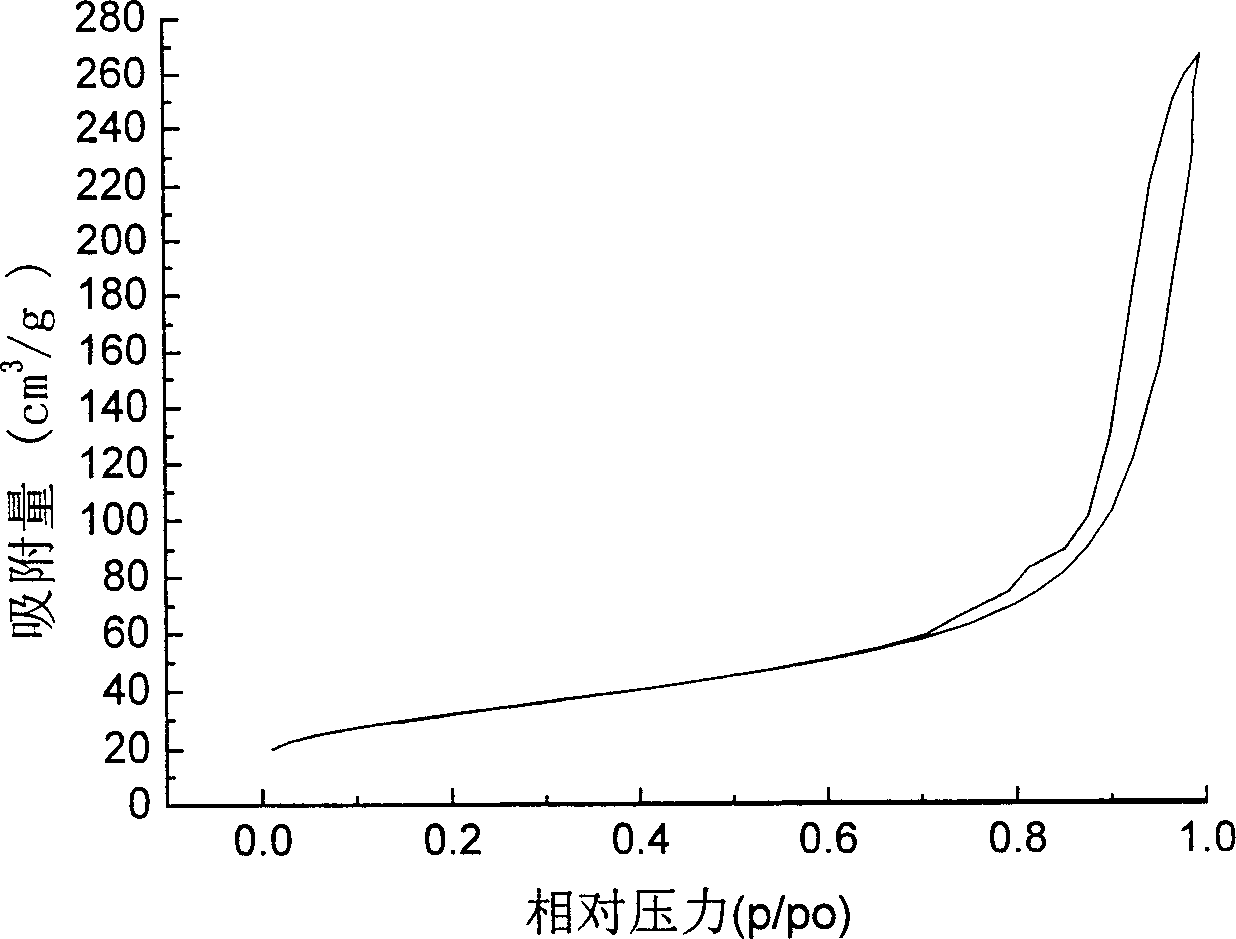

[0036] Example 1-4: Dissolve solid ceria powder in distilled water at normal temperature and pressure to form a solution of 0.5% to 5% (weight percent), and add 0.05% and 0.10% by weight to this solution respectively. , 1.0% organic base triethanolamine to adjust the pH value of the solution, and the mixed solution was stirred evenly to obtain the polishing solution. The rare earth polishing solution of this group was subjected to the same polishing test as the comparative example, and the test results are shown in Table 1.

[0037] Component content and test results

example 5-8

[0038] Example 5-8: At normal temperature and pressure, according to the steps of Example 1, first prepare a solution containing 2% cerium dioxide powder and 0.10% organic base triethanolamine, and then add 0%, 0.25%, 0.5% by weight , 1.0% oxidant potassium ferricyanide, stir the mixture evenly to get the polishing solution of this group. Then the polishing test was carried out as before, and the test results are listed in Table 2.

[0039] Component content and test results

example 9-12

[0040] Example 9-12: At normal temperature and pressure, the steps of Example 2 are used to prepare a solution of 2% cerium oxide powder, 0.10% triethanolamine, and 0.25% potassium ferricyanide, and the weight percentage Add 5%, 10%, and 15% pro-oxidant hydrogen peroxide into the mixed solution, and stir the mixed solution evenly to obtain the polishing solution of this group. The polishing test is the same as before, and the representative results are listed in Table 1.

[0041] Component content and test results

[0042] The prepared polishing liquid of each example compares with the comparative example polishing liquid that formula keeps secret, and finds that the polishing roughness when only having basic composition nano-abrasive and organic base in the polishing liquid example 1-4 of the present invention is 0.733-0.757nm, slightly inferior The polishing roughness of the comparative example is 0.727nm. However, in the polishing process of monocrystalline silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com