Multi-layer material brazing aluminum material with excellent internal and external corrosion performance and preparation method of multi-layer material brazing aluminum material

A technology of corrosion performance and multi-layer materials, which is applied in welding equipment, chemical instruments and methods, welding/cutting media/materials, etc., can solve the problems of failure of durability of heat exchanger and failure of anti-corrosion performance at the same time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

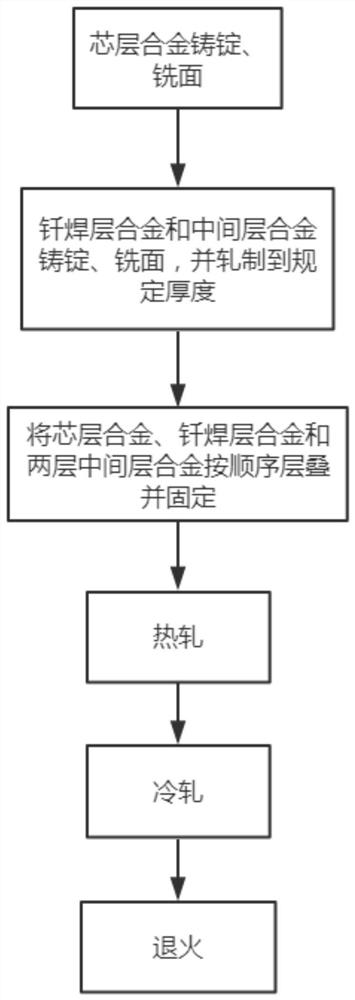

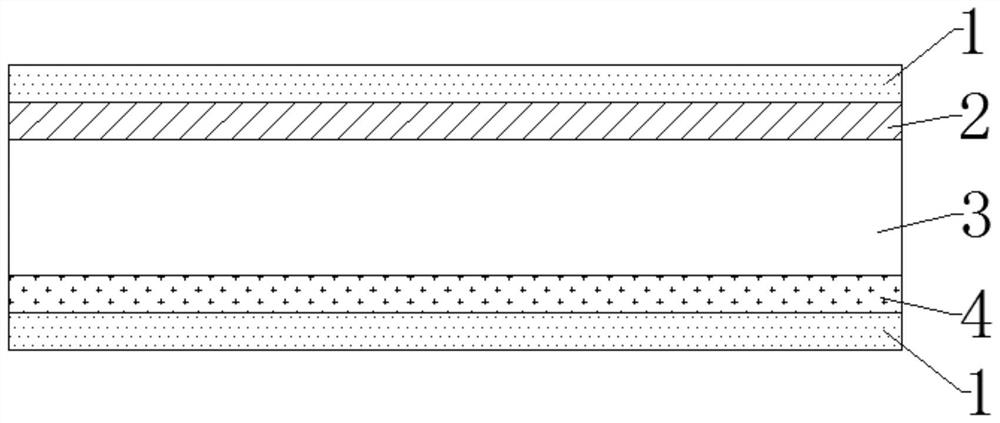

[0033] The present invention will be described in detail below with reference to the drawings, such as figure 1 The shown flow chart first explains the preparation method of the multilayer material brazed aluminum material according to the present invention, which is mainly realized through the following steps:

[0034] (1) Cast the ingot of core alloy 3, the casting temperature range is 675-700℃, use AlTiB to refine the grain structure of the ingot and ensure good processing performance, core alloy 3 may be processed according to the final shape and requirements of the product Homogenizing treatment, heating temperature range is 520-605℃, holding time is more than 2-6 hours;

[0035] (2) The ingot of the core layer alloy 3 is milled, and the surface defects such as impurities, segregation and oxidation on the surface of the ingot are milled on both sides in the width direction to prevent affecting the subsequent first intermediate layer alloy 2 and second intermediate layer alloy 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com