Aluminum heat exchanger

A heat exchanger, strip technology, used in heat exchange equipment, indirect heat exchangers, heat exchanger shells, etc., can solve problems such as flat tube leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described below with reference to the drawings.

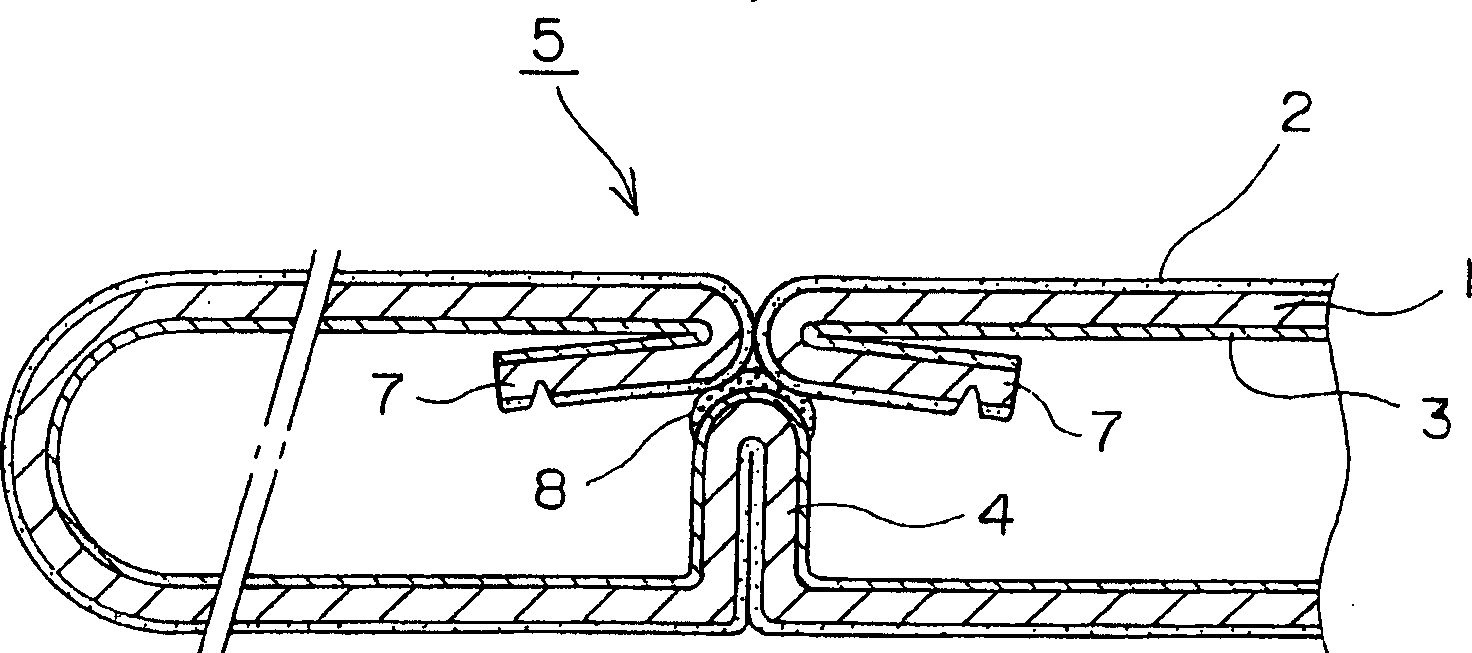

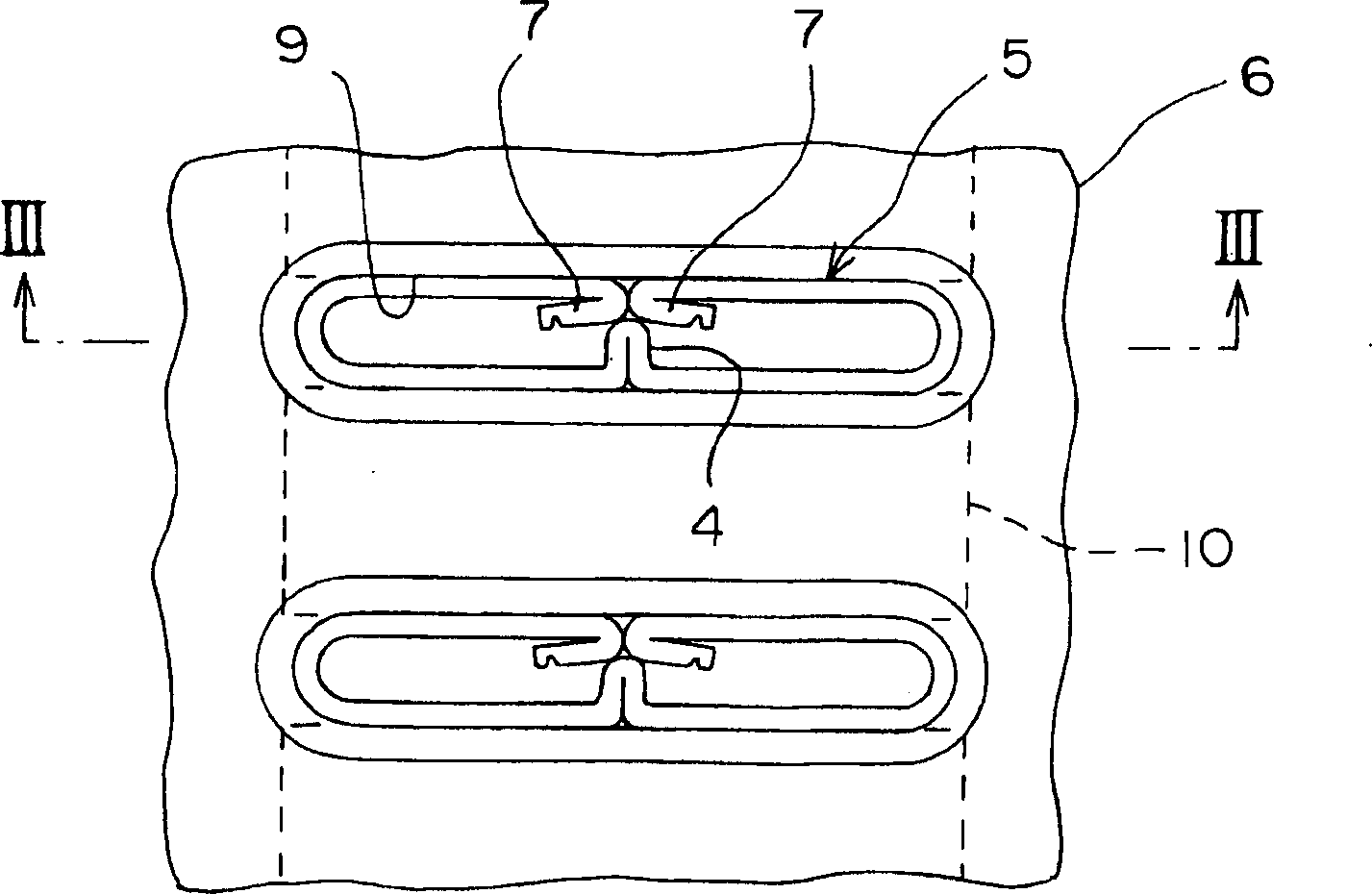

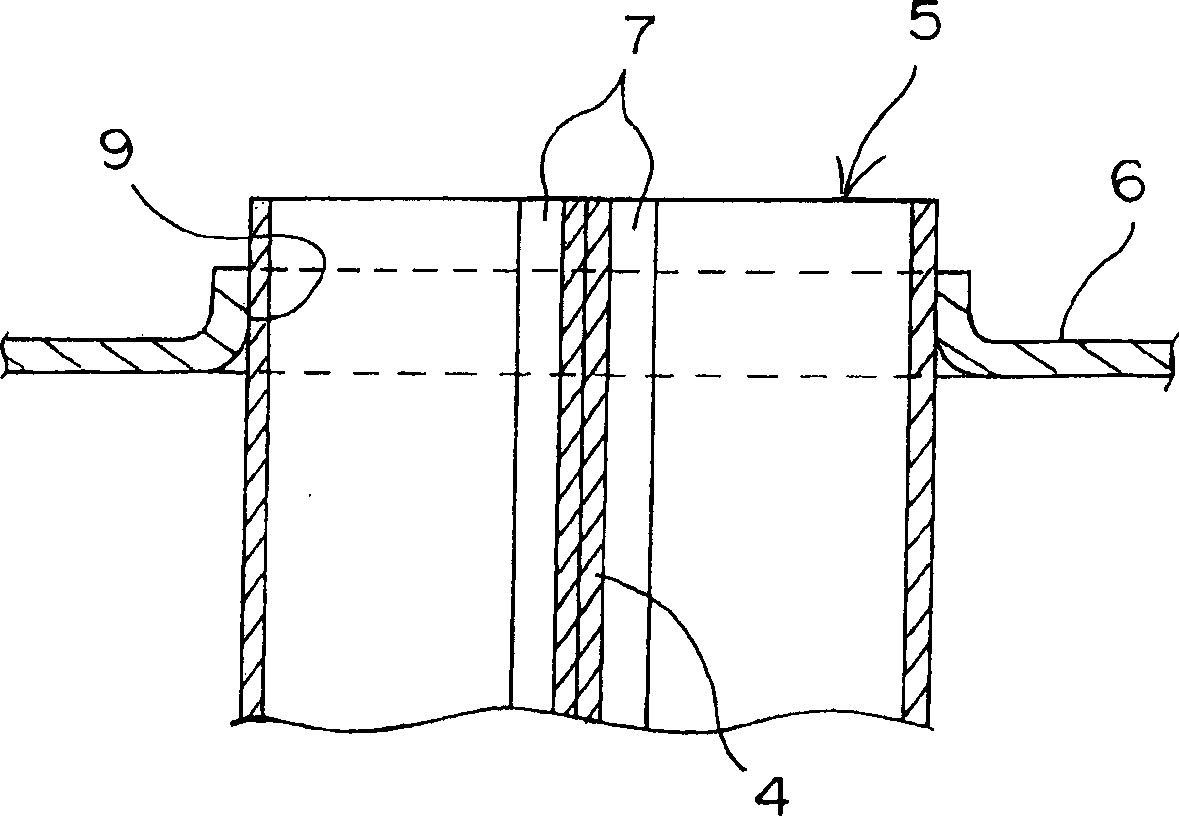

[0022] figure 1 An enlarged view showing flat tubes for an aluminum heat exchanger according to the present invention, showing relevant parts before brazing; figure 2 Represents a plan view of the heat exchanger, showing its assembled state; image 3 means along figure 2 The schematic sectional view obtained by the line III-III in ; and Figure 4 Denotes a front view showing the relevant part of the heat exchanger.

[0023] Such as Figure 4 As shown in , the heat exchanger has a plurality of flat tubes 5 arranged parallel to each other at a certain interval, and corrugated fins 10 arranged between the flat tubes 5 , and both ends of the corresponding flat tubes 5 are inserted into the tube sheet 6 The tube is inserted into the hole; the core is thus assembled.

[0024] Such as figure 1 with 2 As shown in , the flat tube 5 is formed, for example, by bending a strip mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com