Preparation method of aluminum foil for automobile radiator

A technology of automobile radiator and aluminum foil, applied in the field of aluminum alloy casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

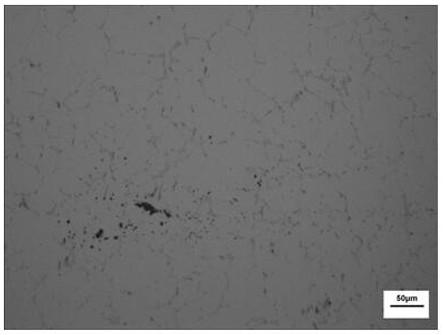

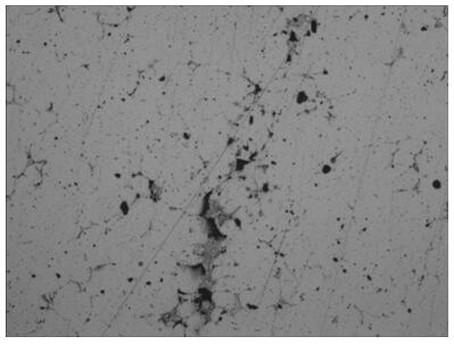

Image

Examples

Embodiment 1

[0042] The chemical composition and preparation method of a 0.099mm thick "H22" state 7072 alloy aluminum foil for automobile radiators.

[0043] S1. Preparation of aluminum melt:

[0044] A radiating fin for a 7072 alloy automobile radiator, the percentage content of alloying elements is: Si: 0.05%; Fe: 0.35%; Cu: 0.05; Zn: 1.0%; Ti: 0.025%; other individual impurities ≤ 0.03%, total ≤0.15%, the rest is Al.

[0045] In order to ensure the chemical composition of the 7072 alloy, the aluminum melt is prepared by feeding electrolytic aluminum liquid with Fe ≤ 0.16%, Si ≤ 0.04% and aluminum ingot with aluminum content ≥ 99.7%, and no waste is added. In this way, the element Si content in the 7072 alloy is guaranteed to be in the range of 0.05-0.1%. The Fe element is added in the form of aluminum-iron master alloy or 90% iron powder, and the Zn element is added in the form of zinc ingot.

[0046] The electrolytic aluminum liquid with Fe≤0.16% and Si≤0.04% is pre-refined in the ...

Embodiment 2

[0061] A chemical composition and preparation method of 0.12mm thick "O" state 7072 alloy aluminum foil for automobile radiators.

[0062] S1. A heat dissipation fin for a 7072 alloy automobile radiator, the percentage content of alloy elements is: Si: 0.05%; Fe: 0.45%; Cu: 0.05; Zn: 1.0%; Ti: 0.020%; other single impurities ≤ 0.03% , the total ≤0.15%, and the rest is Al.

[0063] All the other are with embodiment 1;

[0064] S2. During continuous rolling, the specific pass distribution is: 19-9.0-7.0mm, and the rest are the same as in Example 1.

[0065] S3. The homogenization annealing process is the same as in Example 1.

[0066] S4. The distribution scheme of the cold rolling pass is: 7.0mm→4.2mm→2.5mm→1.5mm→0.9mm→0.53mm→0.31mm→edge trimming→0.18mm→0.12mm→slitting. The total deformation of the billet in the cold rolling step was 98.3%.

[0067] Middle pass processing rate ≥ 40%, finished product pass processing rate 33%, all the other are the same as embodiment 1.

[...

Embodiment 3

[0071] The chemical composition and preparation method of a 0.095mm thick "H22" state 7072 alloy aluminum foil for automobile radiators.

[0072] S1. Preparation of aluminum melt:

[0073] A radiating fin for a 7072 alloy automobile radiator, the percentage content of alloying elements is: Si: 0.08%; Fe: 0.30%; Cu: 0.08; Zn: 0.9%; Ti: 0.020%; other individual impurities ≤ 0.03%, total ≤0.15%, the rest is Al.

[0074] In order to ensure the chemical composition of the 7072 alloy, the aluminum melt is prepared by feeding electrolytic aluminum liquid with Fe ≤ 0.16%, Si ≤ 0.04% and aluminum ingot with aluminum content ≥ 99.7%, and no waste is added. In this way, the element Si content in the 7072 alloy is guaranteed to be in the range of 0.05-0.1%. The Fe element is added in the form of aluminum-iron master alloy or 90% iron powder, and the Zn element is added in the form of zinc ingot.

[0075]The electrolytic aluminum liquid with Fe≤0.16% and Si≤0.04% is pre-refined in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com