High-strength aluminum alloy composite plate for gas-carrying soldering and cladding material

A technology of cladding material and aluminum alloy, which is applied in the field of high-strength aluminum alloy clad plate and cladding material for carrier gas brazing, can solve problems such as low production efficiency, achieve high production efficiency, improve strength and erosion resistance, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

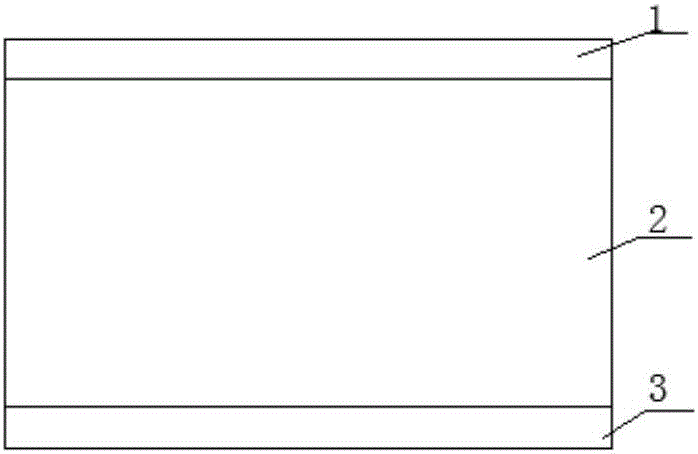

Embodiment 1

[0064] The invention provides an aluminum alloy composite plate and cladding material for carrier gas brazing (CAB) containing Mg on the water-contacting side, which can improve the strength of the alloy under the premise of ensuring the corrosion performance of the material and not affecting the welding effect of carrier gas brazing . This embodiment is a three-layer aluminum alloy composite heat exchanger plate, its structure is as follows figure 1 As shown, the middle core material 2 is AA3003Mod alloy, the upper skin material 1 is AA4045, and the cladding material 3 on the water-contacting side is AA7072Mod. Among them, the AA4045 alloy contains 10.4% Si; the core material AA3003 contains 1.4% Mn, 0.6% Si, 0.7% Fe, 0.2% Cu, 0.1% Ti, and the rest is Al and unavoidable impurities; AA7072Mod alloy contains 1.2% Zn, 0.5% Mn, 0.45% Mg, 0.2% Si, 0.3% Fe, 0.02% Ti, and the rest are Al and unavoidable impurities.

[0065] The present embodiment carries out according to the follo...

Embodiment 2

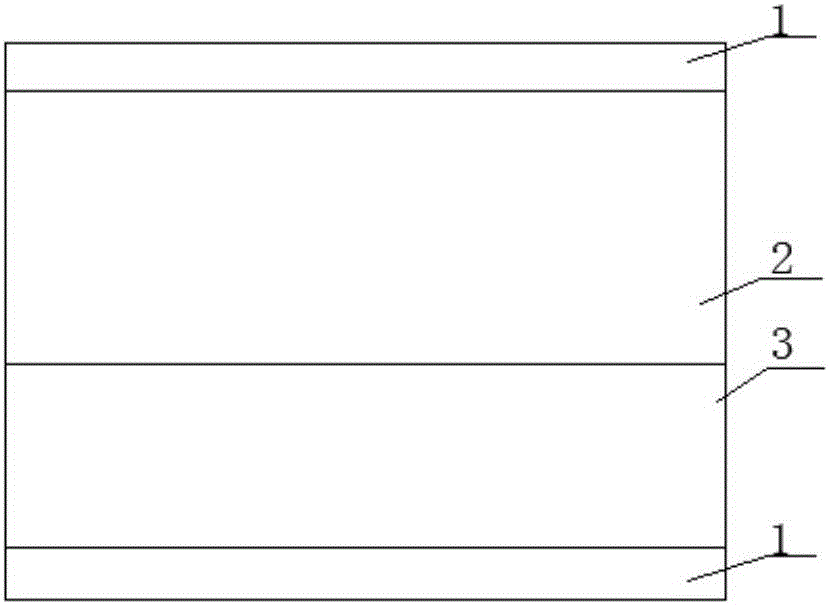

[0078] This embodiment is a four-layer aluminum alloy composite heat exchanger plate, its structure is as follows figure 2 As shown, the upper skin material 1 is AA4045, the middle core material 2 is AA3003 alloy, the third layer of water-touching side cladding material 3 is AA7072Mod, and the lower skin material is also AA4045 as the upper skin material 1. Among them, the AA4045 alloy contains 10.4% Si; the core material AA3003 contains 1.5% Mn, 0.6% Si, 0.5% Fe, 0.2% Cu, 0.15% Ti, and the rest are Al and unavoidable impurities; AA7072Mod alloy contains 1.1% Zn, 0.3% Mn, 0.30% Mg, 0.5% Si, 0.6% Fe, 0.05% Ti, and the rest are Al and unavoidable impurities.

[0079] The present embodiment carries out according to the following steps:

[0080] 1) Alloy melting and casting: AA4045, AA7072 and AA3003 are cast by semi-continuous casting, and the ingot size is 450×1120×5100mm.

[0081] 2) Homogenization: AA3003 is homogenized at 600±10°C for 12-15 hours.

[0082] 3) Composite ho...

Embodiment 3

[0091] The invention provides an aluminum alloy composite plate and cladding material for carrier gas brazing (CAB) containing Mg on the water-contacting side, which can improve the strength of the alloy under the premise of ensuring the corrosion performance of the material and not affecting the welding effect of carrier gas brazing . This embodiment is a three-layer aluminum alloy composite heat exchanger plate, its structure is as follows figure 1 As shown, the middle core material 2 is AA3003 alloy, the upper skin material 1 is AA4045, and the cladding material 3 on the water-contacting side is AA7072Mod. Among them, the AA4045 alloy contains 10.4% Si; the core material AA3003 contains 1.4% Mn, 0.6% Si, 0.7% Fe, 0.2% Cu, 0.1% Ti, and the rest is Al and unavoidable impurities; AA7072Mod alloy contains 0.8% Zn, 0.6% Mn, 0.6% Mg, 0.6% Si, 0.7% Fe, 0.05% Cr, and the rest are Al and unavoidable impurities.

[0092] The present embodiment carries out according to the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com