Black chromium plating solution, composite plating layer and preparing method thereof

A composite coating and electroplating solution technology, which is applied in the field of electroplating products, can solve the problems of light color of trivalent black chromium coating, single color of workpiece products, and failure to satisfy consumers, and achieve good plating ability, good decoration, and good coverage effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

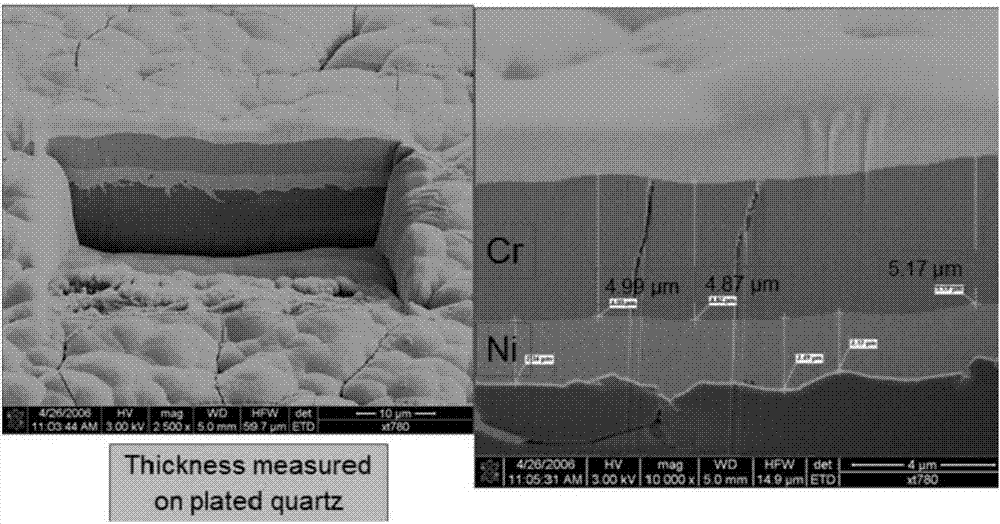

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of preparation method of composite coating, comprises the steps:

[0055] (1) Provide the substrate and pretreat the substrate:

[0056] The base material adopts electroplating grade ABS injection molded parts.

[0057] Place the base material in an ultrasonic degreasing solution containing 50g / L of ENPREP 142 alkaline degreasing agent, and perform immersion degreasing treatment at a temperature of 45±5°C for 5 minutes. After triple water washing, place the degreased substrate in a roughening solution containing 400g / L chromic anhydride and 400g / L sulfuric acid, and immerse it for 11min at a temperature of 67±3°C to form micropores on the surface of the substrate shape structure. After six-way water washing, place the roughened substrate in a solution containing 75 g / L of hydrochloric acid and 6 g / L of hydroxylamine sulfate, and immerse it for 2 minutes at room temperature to reduce hexavalent chromium ions to trivalent chromium ...

Embodiment 2

[0072] The present embodiment provides a kind of preparation method of composite coating, comprises the steps:

[0073] (1) A substrate is provided, and the substrate is pretreated, and the steps of the pretreatment are the same as in Example 1.

[0074] (2) Electroplating forms a bright copper layer on the substrate, and carries out copper microetching to the bright copper layer:

[0075] Place the pretreated base material obtained in step (1) into copper sulfate 220g / L, sulfuric acid 65g / L, chloride ion 90PPM, CUPROSTAR 1560 leveler 0.5ml / L, CUPROSTAR 1560 carrier 0.6ml / L and CUPROSTAR 1560 cylinder opening agent 8ml / L copper plating electroplating solution, at a temperature of 27±3°C and a current density of 3±0.5A / dm 2 Electroplating for 40min under certain conditions, triple washing to form a bright copper layer with a thickness of 20±5μm.

[0076] The substrate on which a bright copper layer has been formed is placed in a mixture of sulfuric acid 40g / L and ENTEK Microe...

Embodiment 3

[0088] The present embodiment provides a kind of preparation method of composite coating, comprises the steps:

[0089] (1) A substrate is provided, and the substrate is pretreated, and the steps of the pretreatment are the same as in Example 1.

[0090] (2) Electroplating forms a bright copper layer on the substrate, and carries out copper microetching to the bright copper layer:

[0091] Place the pretreated base material obtained in step (1) into copper sulfate 180g / L, sulfuric acid 75g / L, chloride ion 90PPM, CUPROSTAR 1560 leveler 0.5ml / L, CUPROSTAR 1560 carrier 0.6ml / L and CUPROSTAR 1560 cylinder opening agent 8ml / L copper plating electroplating solution, at a temperature of 27±3°C and a current density of 3±0.5A / dm 2 Electroplating for 40min under certain conditions, triple washing to form a bright copper layer with a thickness of 20±5μm.

[0092] The substrate on which the bright copper layer has been formed is placed in a mixture of sulfuric acid 25g / L and ENTEK Micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com