Electroless nickel-tin-phosphorus alloy bath

An electroless nickel plating and alloying technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as not conforming to the development trend, carbon dioxide corrosion, positive corrosion potential, etc., to improve the scope of application, increase Non-magnetic, ability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

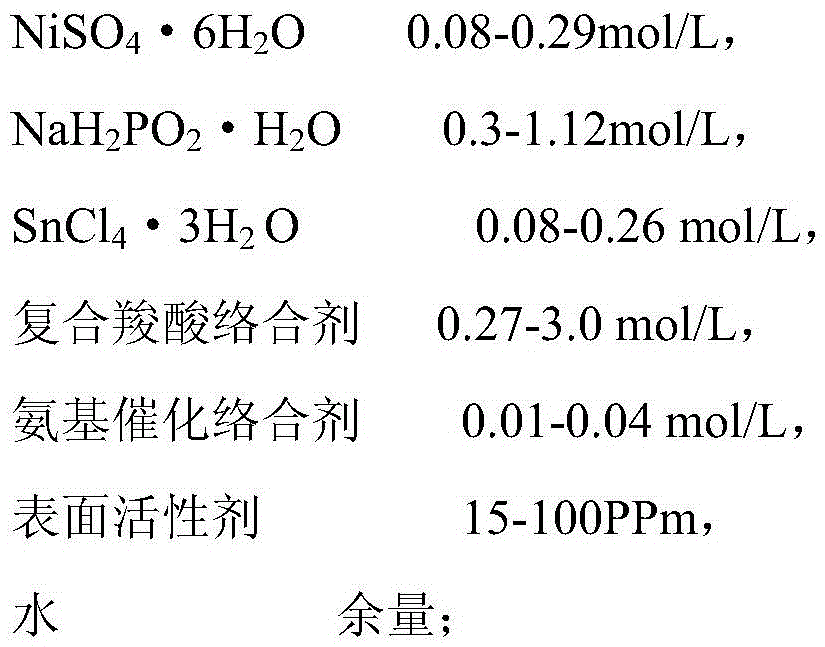

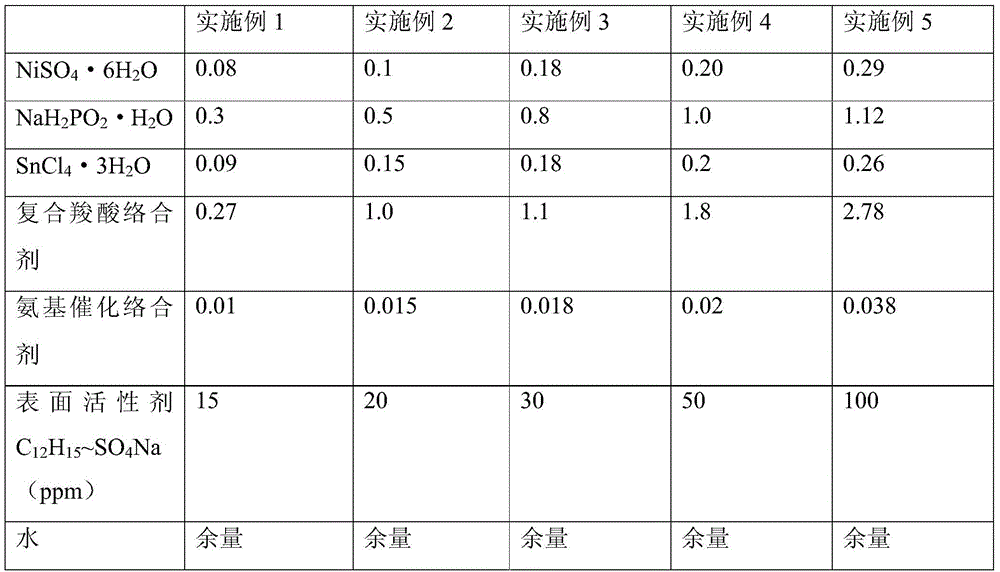

[0079] The composition of table 1 embodiment 1-5 chemical plating multifunctional nickel-tin-phosphorus alloy plating solution

[0080]

[0081] Wherein: the compound carboxylic acid complexing agent used in embodiment 1 consists of: hydroxypropionic acid and hydroxysuccinic acid are mixed 0.15mol / L by the amount concentration of substance 1:1, propionic acid 0.02mol / L, 2-hydroxypropane- 1,2,3-Triacetic acid sodium salt 0.08mol / L, KNaC 4 h 4 o 6 4H 2 O0.02mol / L;

Embodiment 2

[0082] The composite carboxylic acid complexing agent used in embodiment 2 consists of: hydroxypropionic acid and hydroxysuccinic acid mix 0.5mol / L by substance amount concentration 2:1, propionic acid 0.3mol / L, 2-hydroxypropane-1, 2,3-Triacetic acid sodium salt 0.1mol / L, KNaC 4 h 4 o 6 4H 2 O0.1mol / L;

Embodiment 3

[0083] The composite carboxylic acid complexing agent used in embodiment 3 consists of: hydroxypropionic acid and hydroxysuccinic acid mixed 0.8mol / L according to the amount concentration of substance 1:2, propionic acid 0.2mol / L, 2-hydroxypropane-1, 2,3-Triacetic acid sodium salt 0.08mol / L, KNaC 4 h 4 o 6 4H 2 O0.02mol / L;

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com