Patents

Literature

103results about How to "Large expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moon-white Song-dynasty official and brother kiln glaze material, moon-white Song-dynasty official and brother kiln porcelain and preparation method of porcelain

The invention relates to moon-white Song-dynasty official and brother kiln porcelain, a moon-white Song-dynasty official and brother kiln glaze material and a preparation method of the porcelain. The moon-white Song-dynasty official and brother kiln porcelain comprises a porcelain body and a glaze layer, wherein a preform body for preparing the porcelain body consists of the following materials by weight percent: 30% of stone-layer porcelain clay, 40% of Mudaikou purple gold clay and 30% of Yuandi porcelain clay; the glaze material for preparing the glaze layer consists of the following materials by weight percent: 20%-35% of Baoxi Wutou glaze clay, 7%-10% of quartz powder, 2%-5% of Mudaikou purple gold clay, 18%-23% of limestone, 15%-20% of potassium feldspar, 17%-10% of kaolin and 8%-10% of talcum powder. The preparation method comprises the following steps: forming paste, drying the porcelain body, performing biscuit firing, applying internal and external glaze and performing glaze firing on the basis of the raw materials. The moon-white Song-dynasty official and brother kiln porcelain is pure and mild in glaze color, good in thermal stability and high in overall quality.

Owner:龙泉市建春青瓷厂

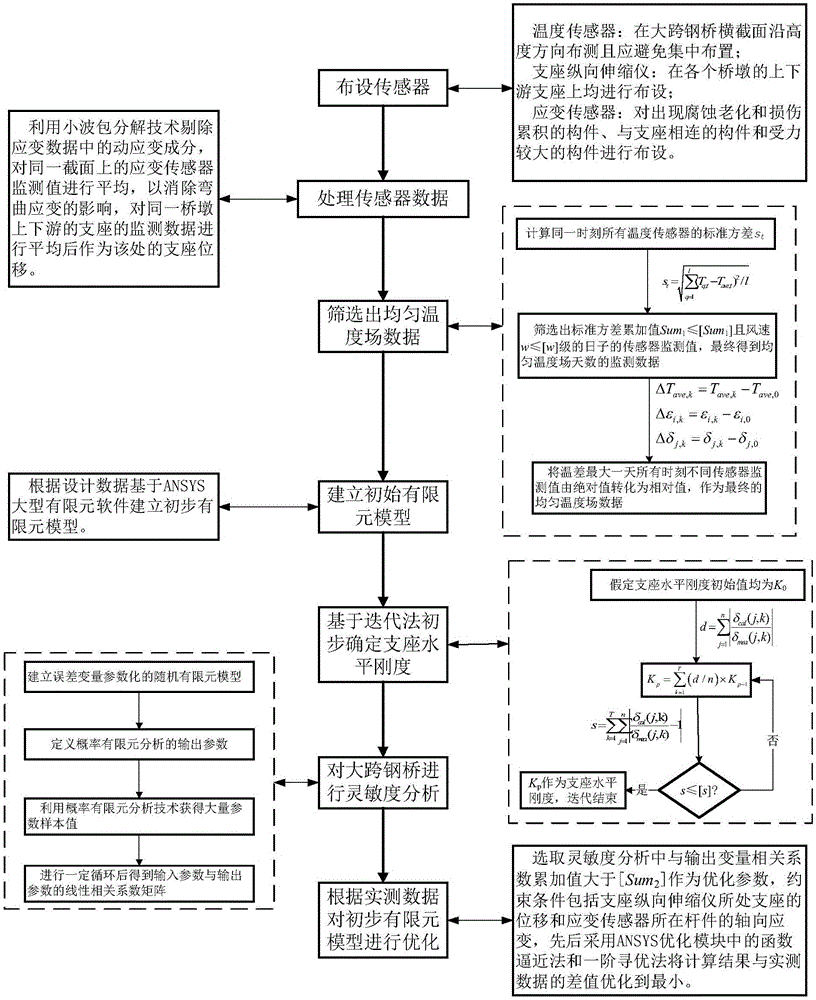

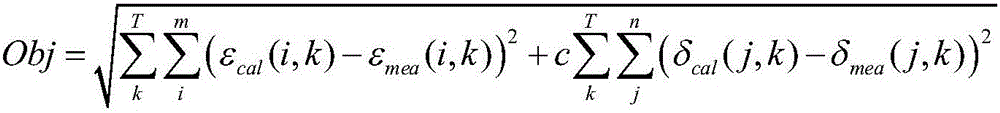

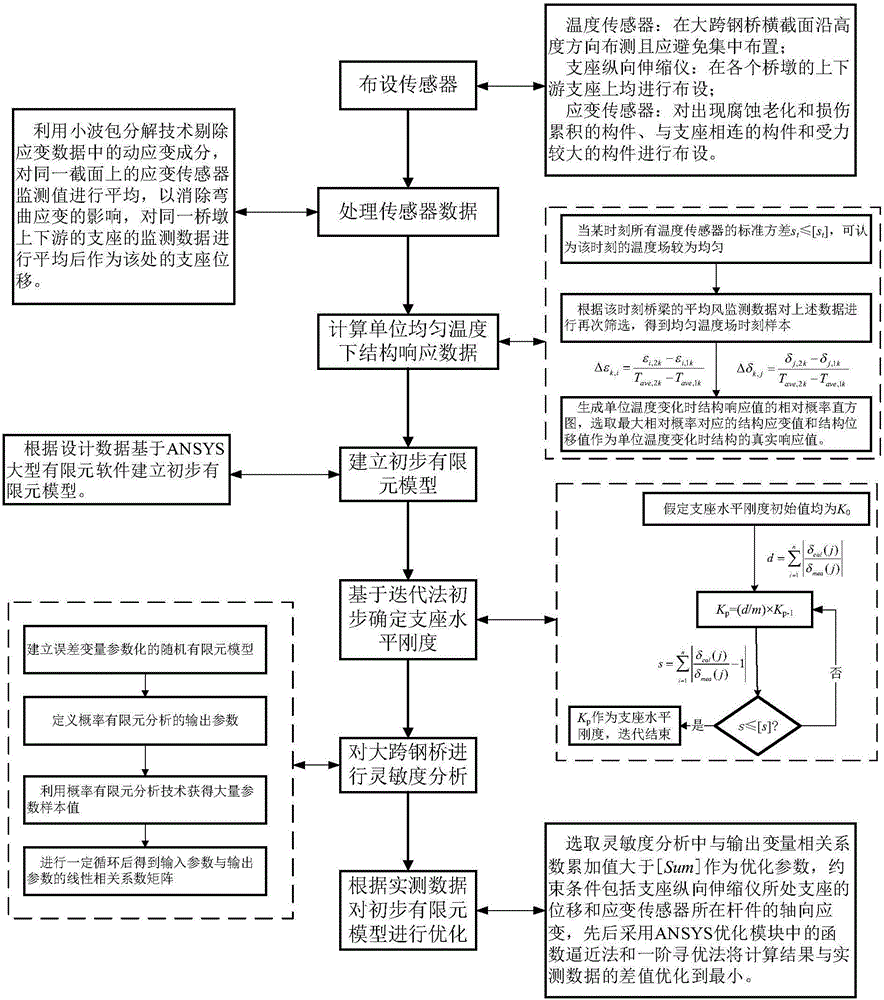

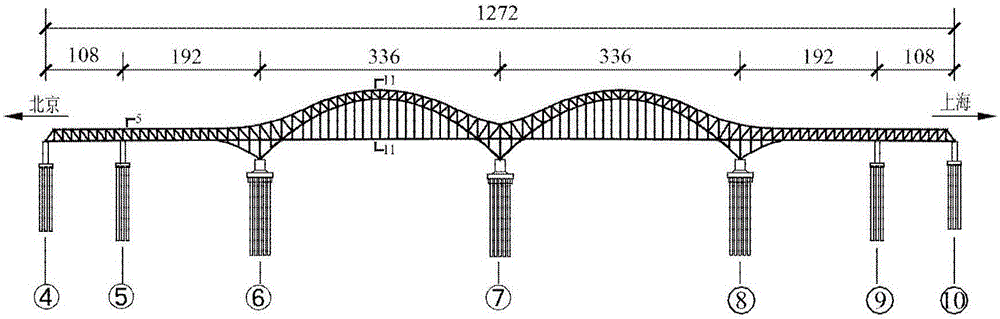

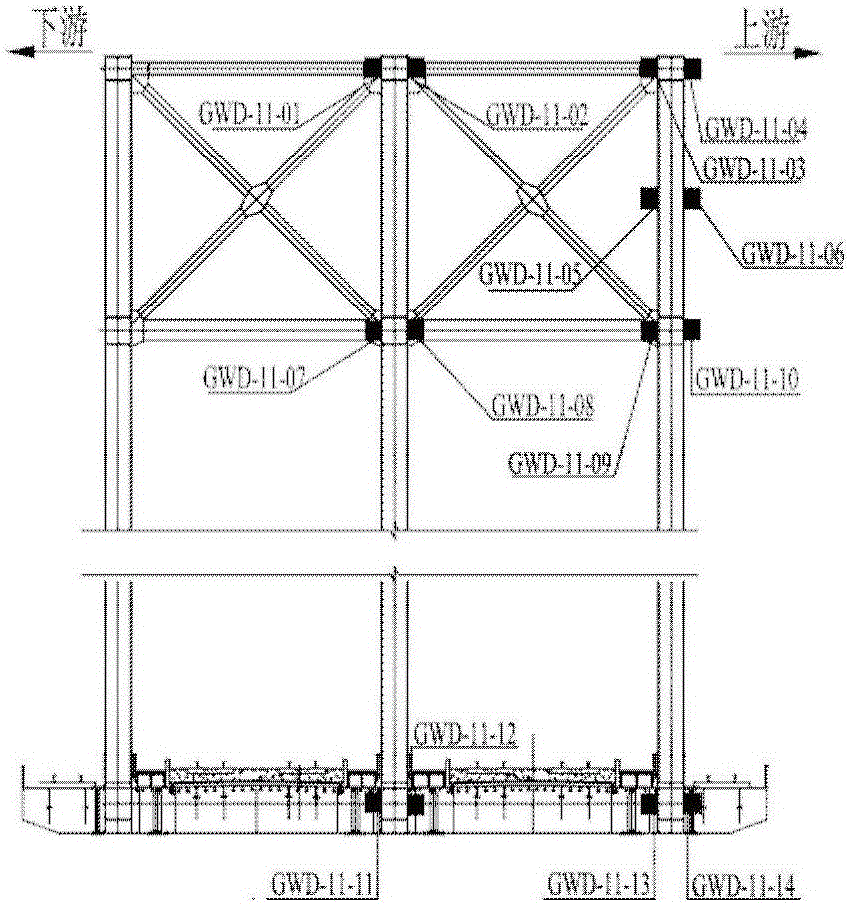

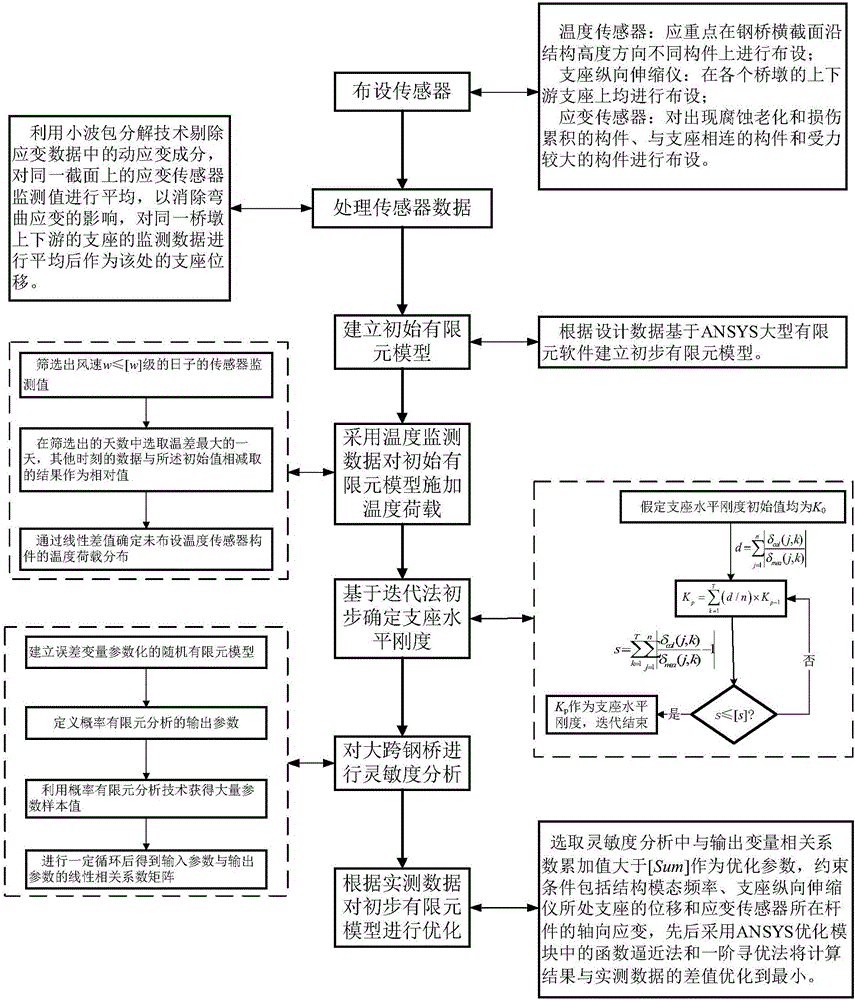

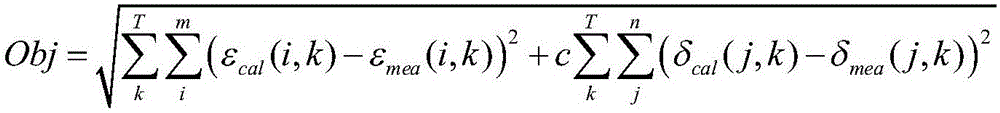

Finite element model correction method for large-span steel bridge based on uniform temperature response monitoring value

ActiveCN105956216AAvoid errorsInput and output are clearGeometric CADDesign optimisation/simulationTemperature responseModal data

The invention discloses a finite element model correction method for a large-span steel bridge based on a uniform temperature response monitoring value, and the method comprises the following steps: 1), carrying out the analysis of yearly monitoring data of the large-span steel bridge, and finding a response law of a structure under the action of a uniform temperature field; 2), building a preliminary finite element model according to design data; 3), preliminarily determining the horizontal rigidness of a steel bridge supporting seat through employing an iteration method; 4), carrying out the sensitivity analysis of the large-span bridge based on the temperature response data of the large-span bridge, and determining a design variable with the higher coefficient of association with actual measurement data; 5), carrying out the optimization analysis of a large-span bridge finite element model through reducing the difference between a finite element model calculation result and the actual measurement data. Compared with a commonly used finite element model correction method based on a power response result (test modal data), the method is simple and accurate, is lower in cost, and is good in safety.

Owner:SOUTHEAST UNIV

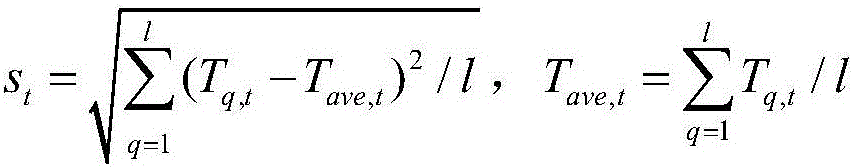

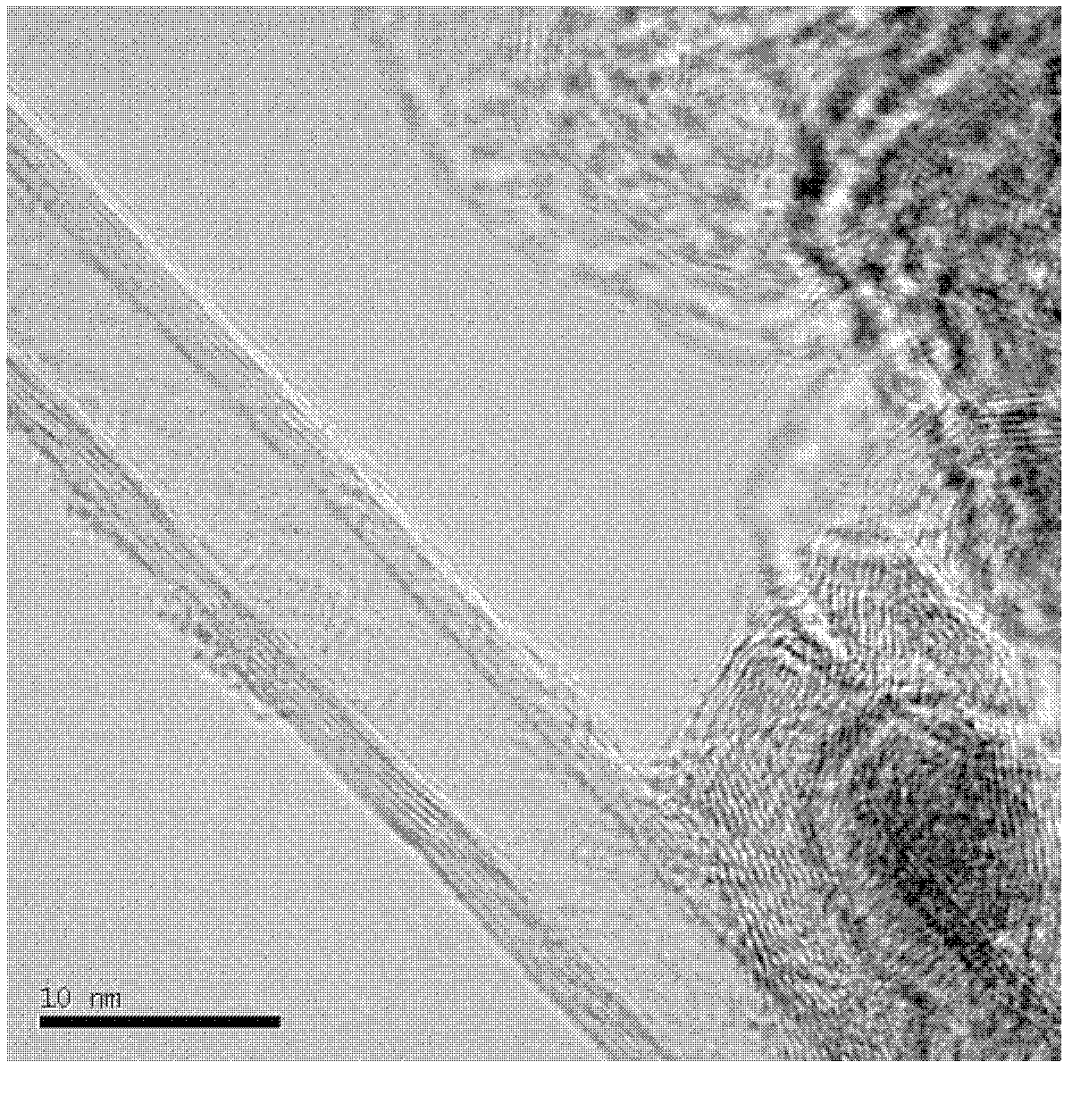

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

Unit temperature response monitoring value based correction method for finite element model of large-span steel bridge

ActiveCN105930571AInput and output are clearImprove stabilityGeometric CADDesign optimisation/simulationTemperature responseElement model

The invention discloses a unit temperature response monitoring value based correction method for a finite element model of a large-span steel bridge. The method comprises the following major steps of 1) analyzing annual monitoring data of the large-span steel bridge and determining static strain and displacement generated by unit uniform temperature change based on a relative probability histogram of a structure response value during unit temperature change; 2) establishing a primary finite element model according to design data; 3) preliminarily determining the horizontal stiffness of a steel bridge support by adopting an iterative method; 4) performing sensitivity analysis on the large-span steel bridge based on actual measurement data of displacement at the large-span steel bridge support and strain in a key position, and determining a design variable with a relatively high coefficient of correlation with the actual measurement data; and 5) performing optimization analysis on the finite element model of the large-span steel bridge by reducing a difference value of a finite element calculation result and the actual measurement data. Compared with a generally adopted finite element model correction method based on dynamic response results of test modal data and the like, the method has the advantages of simplicity, accuracy, relatively low expense and high security.

Owner:SOUTHEAST UNIV

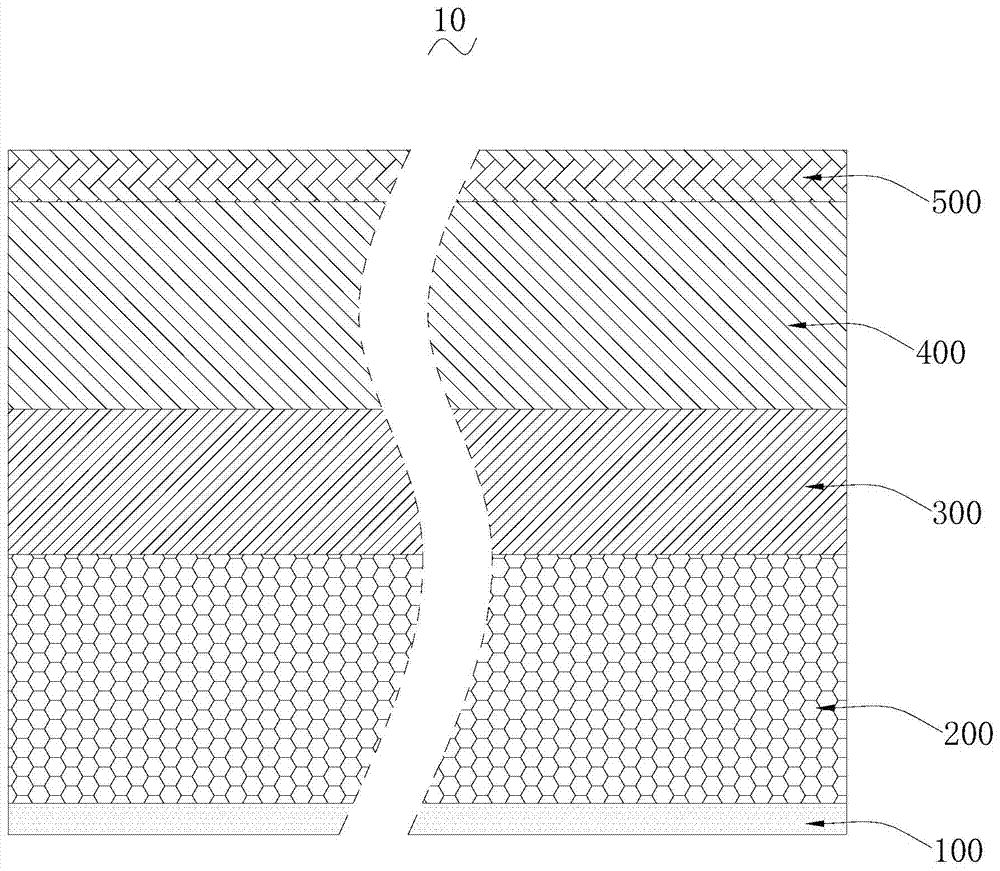

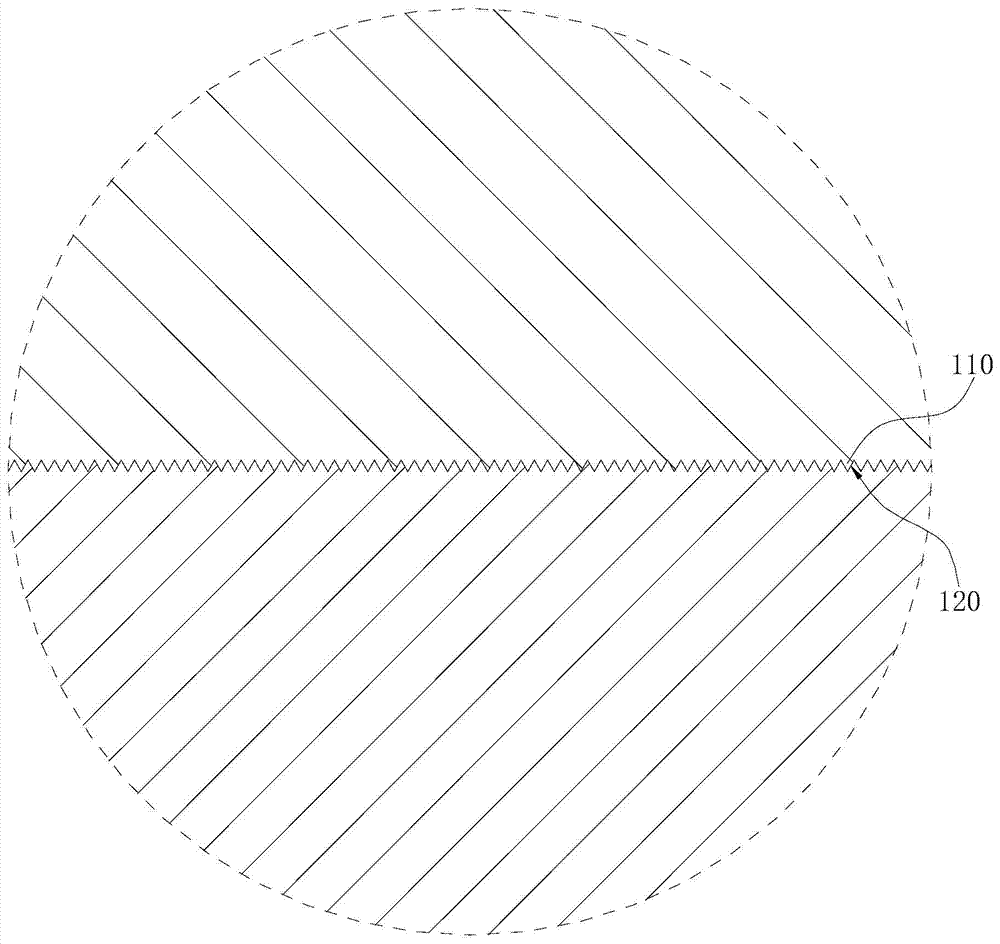

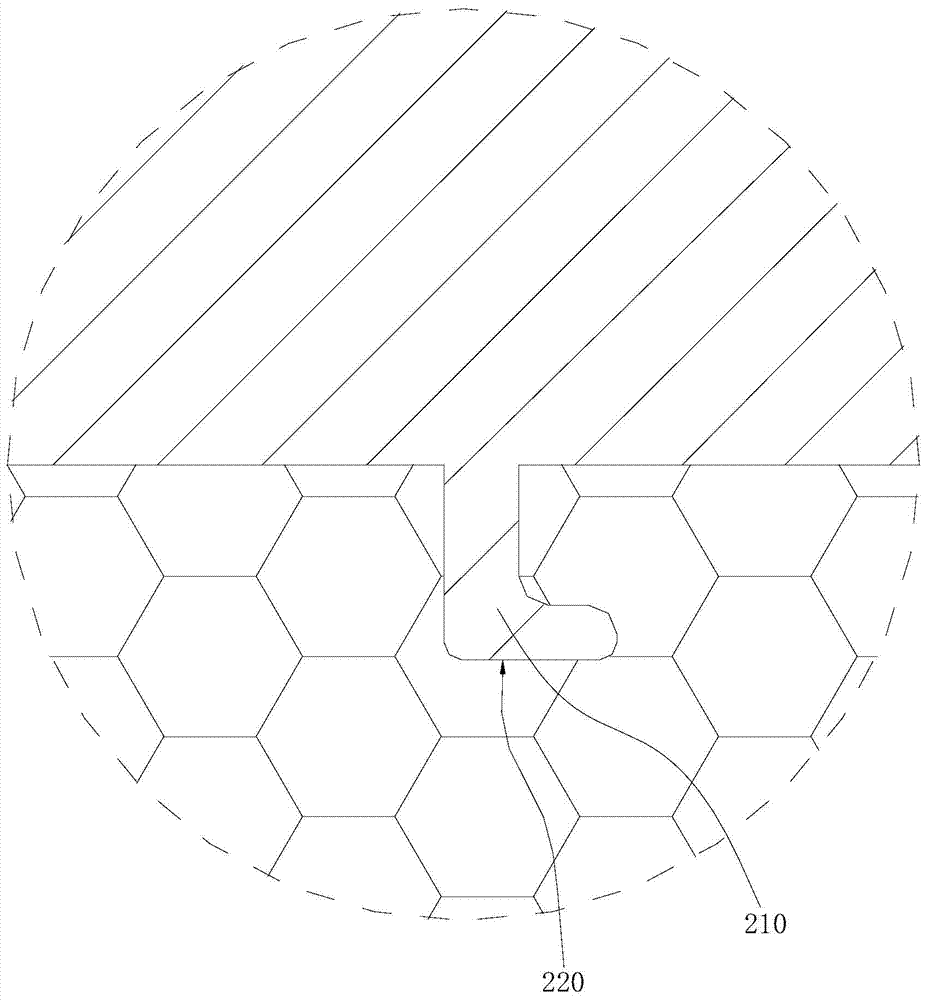

Heat radiating material and LED lamp

ActiveCN104708868AImprove insulation performanceImprove cooling effectSynthetic resin layered productsNatural mineral layered productsFiberCarbon fibers

The invention relates to a heat radiating material and an LED lamp. The heat radiating material comprises an insulation layer, a heat conduction layer, a heat transferring layer, a heat radiating layer and a protection layer. The heat conduction layer comprises the following components in parts by weight: 80 to 95 parts of graphene, 0.1 to 20 parts of a carbon nano-tube and 0.1 to 20 parts of nano carbon fibers; the heat radiating layer comprises the following components in parts by weight: 47 to 50 parts of copper, 49 to 52 parts of aluminum, 0.2 to 0.7 part of magnesium, 0.2 to 0.7 part of iron, 0.2 to 0.5 part of manganese, 0.1 to 0.3 part of titanium, 0.05 to 0.1 part of chromium and 0.1 to 0.3 part of niobium. The heat radiating material is provided with the insulation layer, the heat conduction layer, the heat transferring layer, the heat radiating layer and the protection layer which are sequentially laminated, so that the heat radiating material has advantages of good insulation property, low expansion coefficient, large heat conduction coefficient, good heat radiating effect and light weight.

Owner:东莞市闻誉实业有限公司

Steel bridge finite element model correction method based on non-uniform temperature response monitoring value

ActiveCN105956218AAvoid errorsInput and output are clearGeometric CADDesign optimisation/simulationTemperature responseElement model

The invention discloses a steel bridge finite element model correction method based on a non-uniform temperature response monitoring value. The method mainly includes the steps of: 1) analyzing the year-round monitoring data of a steel bridge, and finding out the response rule of structure under the action of a non-uniform temperature field, 2) establishing an initial finite element model according to design data, 3) preliminarily determining the horizontal stiffness of a steel bridge bearing by iteration method, 4) performing sensitivity analysis on the steel bridge on the basis of steel bridge temperature response data, and determining a design variable having a high correlation coefficient with actually measured data, and 5) conducting optimization analysis on the steel bridge finite element model by reducing the difference between a finite element calculation result and the actually measured data. Compared with the universally adopted finite element model correction method based on experimental modal data and other dynamic response results, the method provided by the invention has the advantages of simplicity and accuracy, low cost and good safety.

Owner:SOUTHEAST UNIV

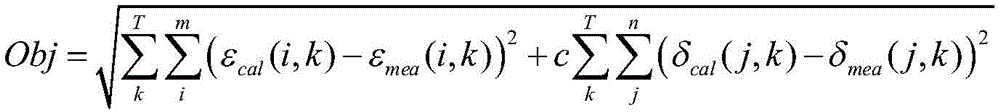

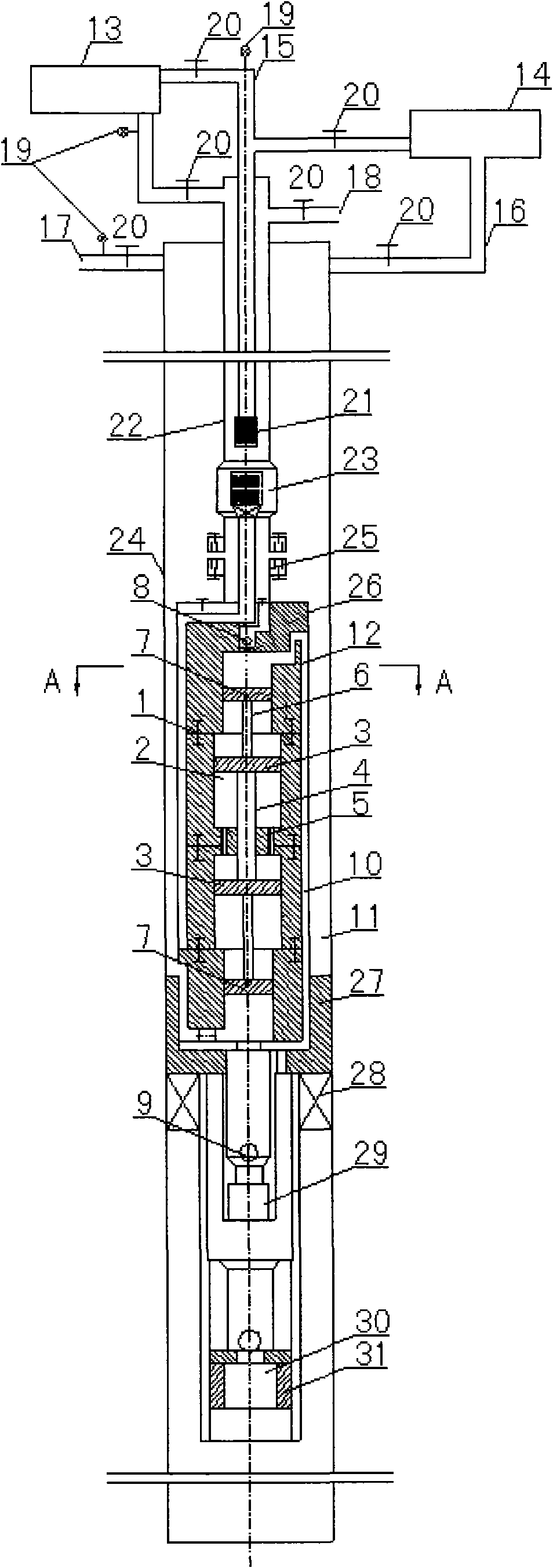

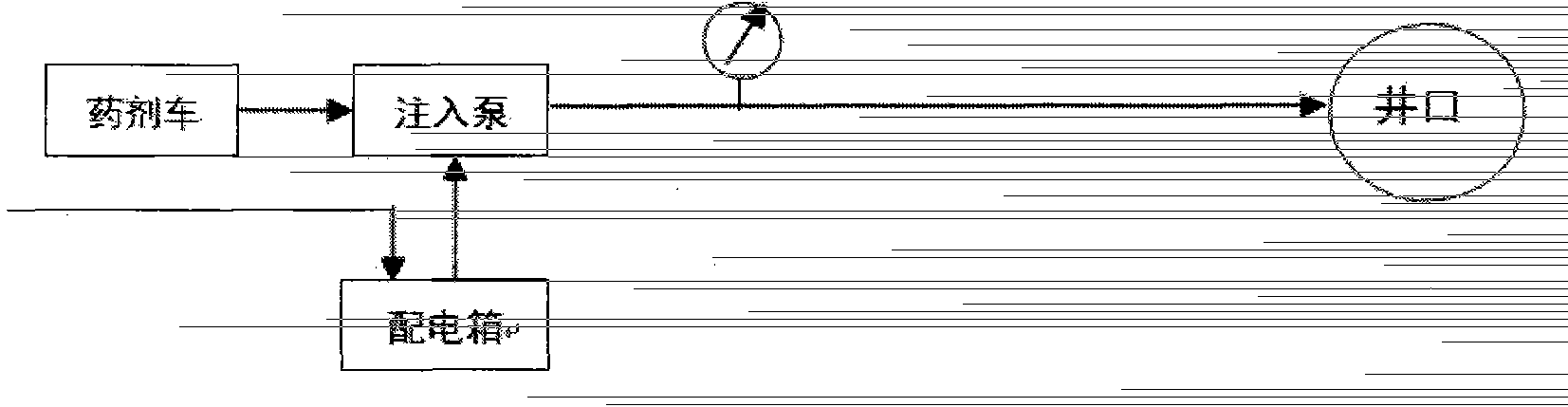

Deep well gas injection supercharging mechanical oil production method and device

InactiveCN101566057ASolve the problem of insufficient lifting capacityIncreased lifting capacityFluid removalProduct gasOil production

The invention provides a deep well gas injection supercharging mechanical oil extraction method and device, which belongs to the method or equipment technique field for extracting oil from well, and solves insufficient lifting ability problem of prior mechanical oil extraction method and device, the method uses a deep well gas injection supercharging oil extraction device, and specifically includes the steps of: connecting a sealing base, a supercharging oil extraction pump, a pump fastening rack, a packer, a filter tube valve and a filter tube to the oil conduit, placing the oil conduit into the well bore casing tube, and fastening the pump-fastening rack; injecting liquid into the annular spacing between the oil conduit and casing tube, testing pressure and relieving pressure; injecting gas into the annular spacing between the oil conduit and the air injection tube, discharging liquid from the gas injection tube; installing wellhead equipment, adjusting pressure and air flow of pumped air, sampling humidity and oil content of analysis gas, calculating quantity of production. The method and device provided by the invention use gas as power medium for periodic duty recyclablely, which causes the lifting pressure up to 2-5 times of gas pressure, and the process flow is simple and is suitable for oil extraction of deep well and mechanical oil extraction of thick oil well.

Owner:CHINA PETROLEUM & CHEM CORP

Diversified carbon-dioxide flooding oil extraction method

The invention relates to the technical field of oil extraction of oil fields, in particular to a diversified carbon-dioxide flooding oil extraction method. By adjusting parameters including minimum mixed-phase pressure, injection ratio, injection pressure, injection speed and the like of liquid carbon dioxide and water and utilizing alternative injection and flooding of the carbon dioxide and the water to perform crude oil extraction, the oil extraction speed and the recovery efficiency are improved.

Owner:PANJIN DAOBOER PETROLEUM NEW TECH DEV

Konjac fermented food and beverage and preparation method thereof

The invention provides konjac fermented food and beverage and a preparation method thereof, and relates to the technical field of food and beverage processing. The preparation method comprises the following steps: preparing konjac fluid, preparing primary seed fluid, preparing secondary seed fluid, inoculating and fermenting, and preparing a finished product. The konjac fermented food and beverage have the advantages that konjac glucomannan (KGM) is high molecular polysaccharide, has an effect of promoting growth of bifidobacterium of human intestinal tracts, so that the structure of intestinal flora can be effectively improved. Lactic acid bacteria are normal flora of a human body, and the probiotics represented by the lactic acid bacteria is necessary to the human body, and are beneficial bacteria with critical physiological functions, so that animal growth can be promoted, normal flora of gastrointestinal tracts can be regulated, the micro-ecological balance can be maintained, the gastrointestinal tract functions can be improved, body immunity is improved. Carbon sourced substances are required when lactic acid bacteria ferment, starch is the carbon source for growth and metabolism of microorganisms, and 10 to 30 percent of the konjac is starch, so that the konjac can be effectively used as the carbon sourced substance in lactic acid bacteria fermentation. Therefore, the content of effective components of konjac is taken, and the process of lactic acid bacteria fermentation is introduced, so that the konjac fermented food and beverage can be a perfect combination of the two advantages technologically.

Owner:西藏月王藏药科技有限公司

Fire stopping ring core material and preparation method and use thereof

The invention discloses a fire stopping ring core material and a preparation method and use thereof. The fire stopping ring core material consists of a core material solidifying agent, a flame-retarding agent, a carbonizing agent, a carbonization catalyst, a foaming agent, an expansible material, a reinforcing body, glue and other materials. The fire stopping ring core material disclosed by the invention has the advantages of environment protection, convenience and low cost; and at a certain temperature, the fire stopping ring core material can be used for quick plugging, the expansion factor of the fire stopping ring core material is high and the fire resistant time is long.

Owner:GUANGDONG LIANSU TECH INDAL

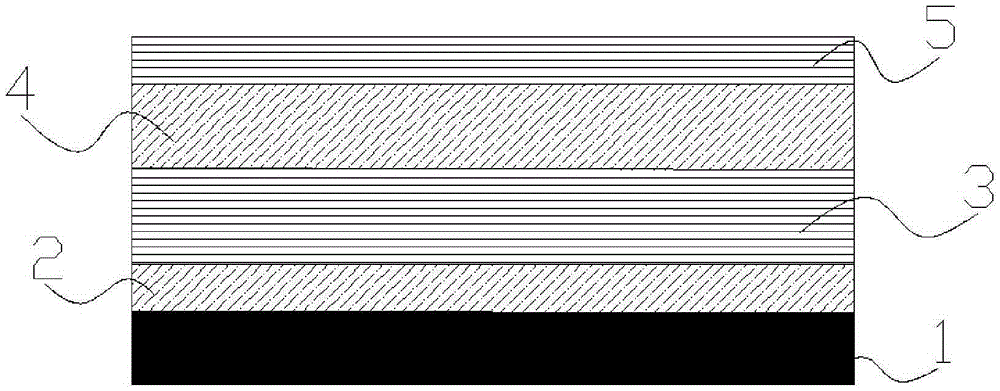

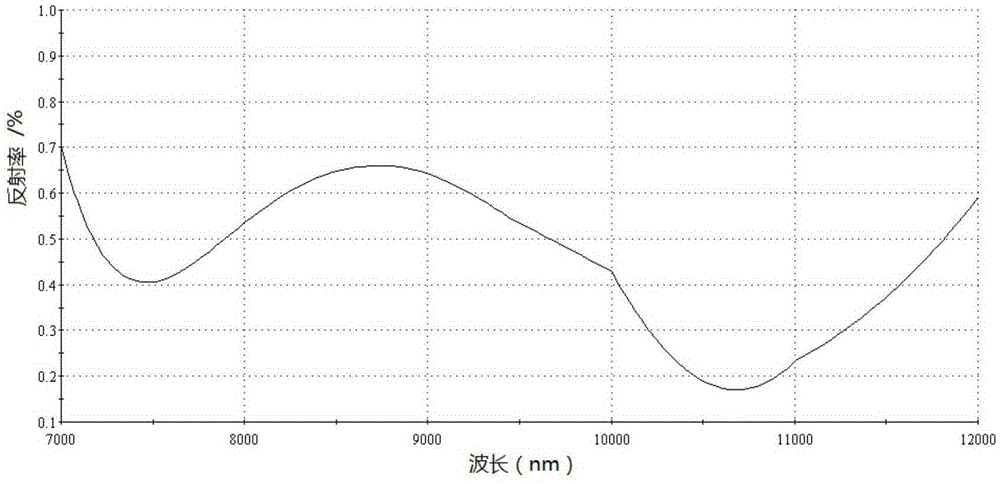

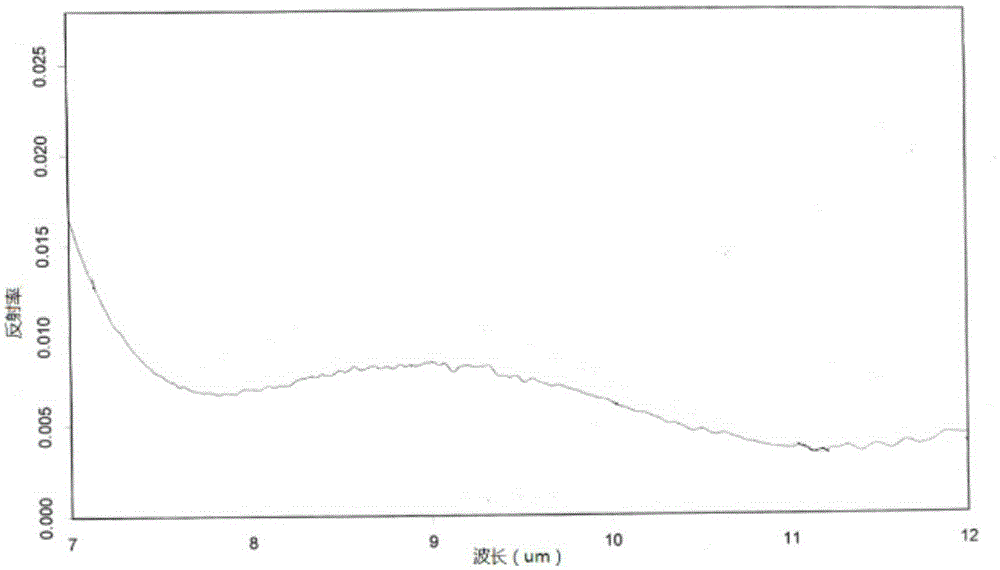

Ge-As-Se infrared glass with anti-reflection film and preparation method thereof

ActiveCN105388542AImprove permeabilityReduce surface residual reflectivityOptical elementsYtterbium fluorideZinc sulfide

The invention discloses Ge-As-Se infrared glass with an anti-reflection film and a preparation method thereof. The Ge-As-Se infrared glass with the anti-reflection film comprises a Ge-As-Se infrared glass base layer, the Ge-As-Se infrared glass base layer is composed of 12% of Ge, 28% of As and 60% of Se by weight, and a first ytterbium fluoride layer, a first zinc sulfide layer, a second ytterbium fluoride layer and a second zinc sulfide layer are deposited on the Ge-As-Se infrared glass base layer successively. The Ge-As-Se infrared glass of the invention can effectively prevent the anti-reflection film from falloff, and the reflectivity of the infrared glass is reduced.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of jade cracked ice glazed porcelain

InactiveCN107417110ASoft glaze lusterJade texture effect is goodCeramic materials productionClaywaresCeramic glazeWollastonite

The invention discloses a preparation method of jade cracked ice glazed porcelain. The preparation method comprises the steps of preparing a biscuit of the porcelain, applying glaze of 0.8-2mm to the surface of the biscuit to make a green body, and firing the green body to prepare the porcelain. The following raw materials of the glaze are added according to parts by weight: 70-80 parts of anorthite, 15-20 parts of barium carbonate, 0-0.5 part of zinc oxide, 0-0.5 part of zirconium oxide, 5-10 parts of wollastonite, 10-15 parts of boron oxide, 20-30 parts of neodymium oxide, 0-1 part of white mica and 5-10 parts of titanium stones. In the preparation method, the expansion coefficient of a glaze layer is greater than the coefficient of thermal expansion of the biscuit and in the firing process, as the expansion coefficients are different, the tensile stress of the porcelain occurs, the glaze splits and cracks are formed; meanwhile, the glaze layer can generate silicate neodymium crystals, so that small crystal patterns show up in the ice cracks, and therefore, the ornamental value is improved.

Owner:任合超

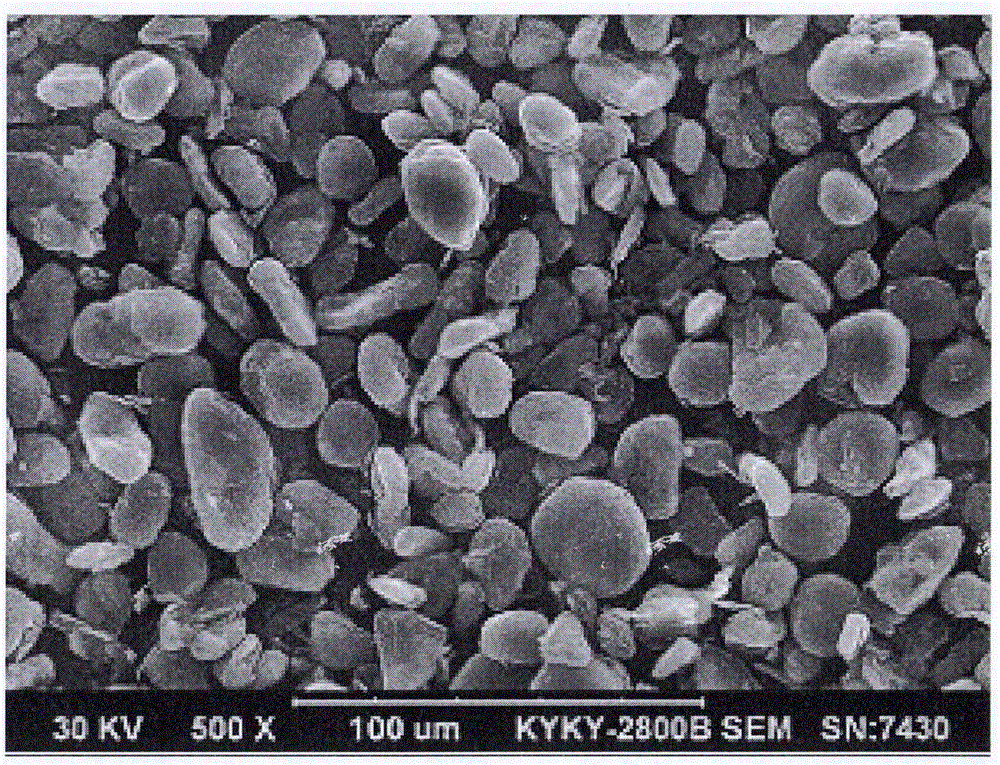

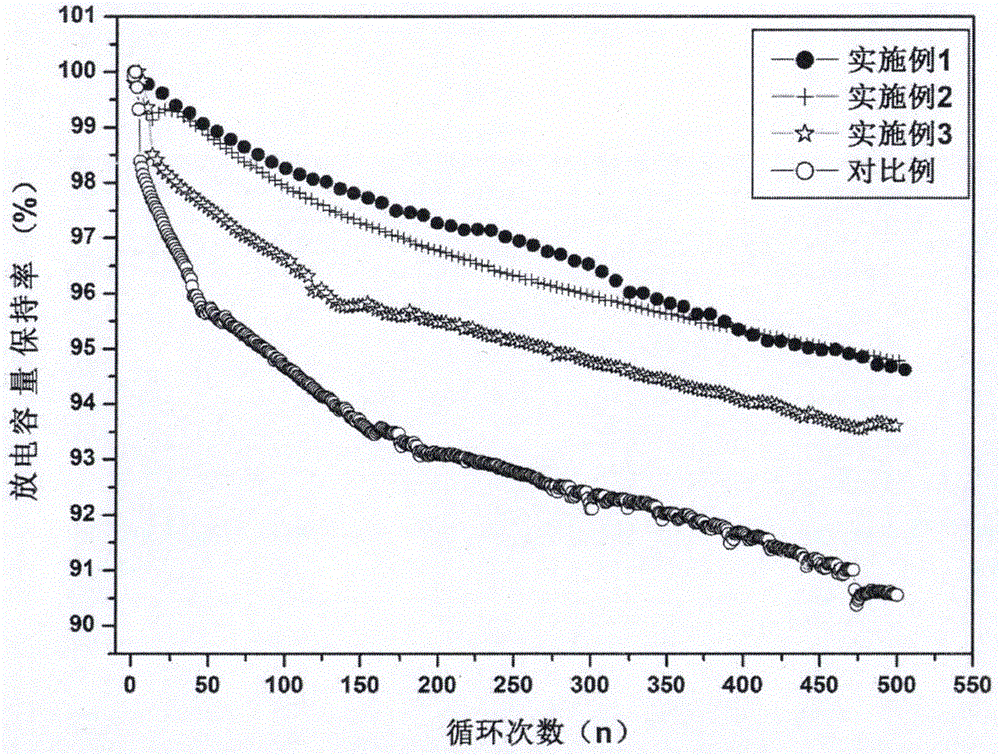

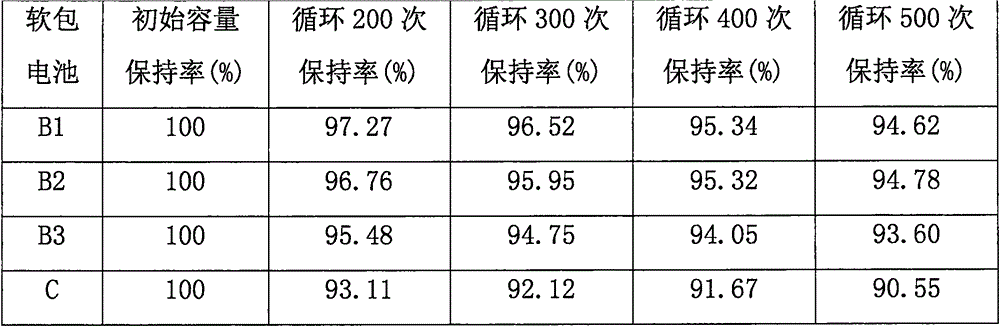

Preparation method of silicon dioxide composite material for negative electrode of lithium-ion battery

InactiveCN105895880AUniform depositionHigh tap densityCell electrodesSecondary cellsCarbon nanotubeDistilled water

The invention provides a preparation method of a silicon dioxide composite material for a negative electrode of a lithium-ion battery. The method comprises three processes, namely preparation of a [carbon nanotube / silicon dioxide] composite material, preparation of a silicon dioxide precursor and preparation of the silicon dioxide composite material. Ethyl alcohol, distilled water, ammonium hydroxide, hexadecyl trimethyl ammonium bromide, acid-treated carbon nanotube, ethyl orthosilicate, deionized water and absolute ethyl alcohol are utilized in the preparation process of the [carbon nanotube / silicon dioxide] composite material. The carbon nanotube in the prepared silicon dioxide composite material has relatively high conductivity, large specific surface area and relatively large expansion coefficient as an inner core; the expansion effect of the silicon dioxide in the charging and discharging process of the lithium-ion battery can be reduced; the structure stability of the silicon dioxide composite material is improved; and the cycle performance of the silicon dioxide composite material is finally improved.

Owner:赵晓锋

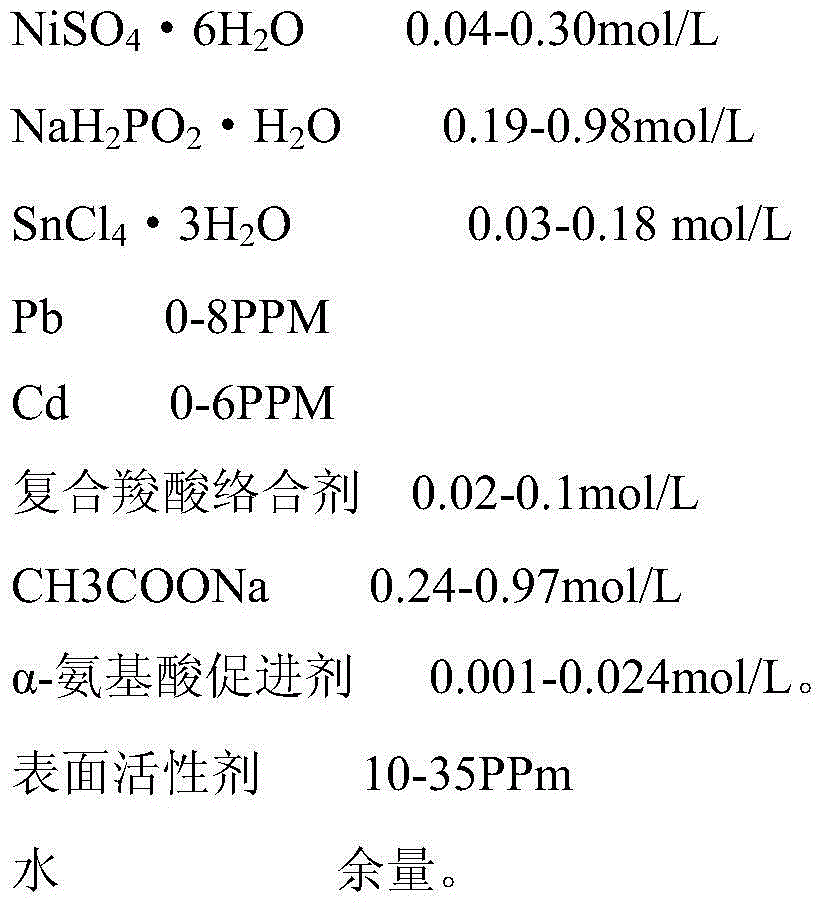

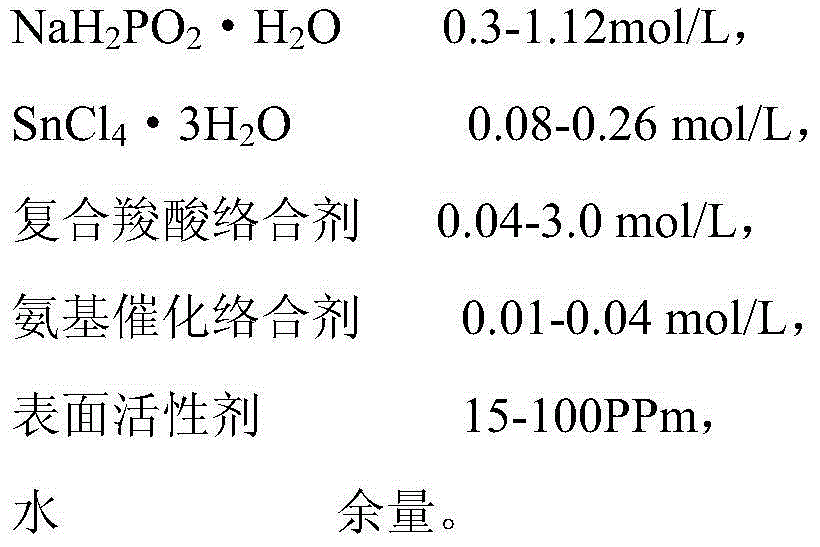

Chemical-plated multifunctional nickel-tin-phosphorus alloy plating solution and plating layer thereof

ActiveCN104018142ASolve the problem of plating speedImprove stabilityLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention belongs to the field of chemical plating solutions, and in particular relates to a chemical-plated multifunctional nickel-tin-phosphorus alloy plating solution and a plating layer thereof. The plating solution is composed of the following components: 0.08-0.29mol / L of NiSO4.6H2O, 0.3-1.12mol / L of NaH2PO2.H2O, 0.08-0.26mol / L of SnCl4.3H2O, 0.04-3.0mol / L of composite carboxylic acid complexing agent, 0.01-0.04mol / L of amino catalytic complexing agent, 15-100PPm of surfactant and the balance of water. The plating solution is free from Pb and Cd heavy metal ions and more environment-friendly and has high stability and high deposition speed. Due to the increase of the Sn ions, the ductility of the plating layer is greatly improved, the hydrogen sulfide, chloride and carbon dioxide corrosive resistance of the plating layer is improved, the corrosion potential is more negative, the conductivity is better, and the plating layer can be used as a better invisible material.

Owner:林忠华

Glaze used for medium-temperature ceramic product and ceramic preparation method applying glaze

The invention discloses glaze used for a medium-temperature ceramic product and a ceramic preparation method applying the glaze and belongs to the technical field of ceramic preparation. The glaze used for the medium-temperature ceramic product is prepared from the following raw materials in parts by weight: 60-80 parts of glass powder, 20-40 parts of quartz, 3-12 parts of feldspar, 1-8 parts of clay, 1-6 parts of kaolin and 1-6 parts of zirconium silicate. The ceramic preparation method applying the glaze used for the medium-temperature ceramic product comprises the following steps: (1) preparing a ceramic body, and drying for later use; (2) smearing a glaze avoiding agent; (3) preparing glaze slip; (4) glazing, and drying; (5) putting the dried ceramic body into a kiln, and firing; and (6) uniformly smearing ink or waste engine oil on the surface of a ceramic product, and standing for 1-2 days. The invention aims at providing the glaze with scientific formula and good using effect for the medium-temperature ceramic product and a ceramic preparation method applying the glaze provided by the invention, and the glaze and ceramic preparation method are applied to ceramic preparation.

Owner:GUANGDONG JIYU PORCELAIN CORP

Method for planting rivier giantarum rhizome through ditching, film laying and ridging

InactiveCN105493821ADisease resistanceEasy to digPlant cultivationCultivating equipmentsDiseasePlastic mulch

The invention discloses a method for planting rivier giantarum rhizomes through ditching, film laying and ridging. The method achieves fertilizer conservation, heat preservation, disease resistance, high yield and convenient digging. The method comprises the specific steps that 50-300 g of rivier giantarum rhizomes are selected as seed rivier giantarum rhizomes; ditches with the width of 0.8-1.2 m and the depth of 20-30 cm are dug, and black microhole mulching films are laid on the bottoms of the ditches; farmyard manure is laid on the black microhole mulching films and covered with soil with the thickness of 2-5 cm; the seed rivier giantarum rhizomes are placed on the soil layer according to the certain row spacing and line spacing, and then earthing and ridging are carried out, wherein the height of ridges is 20-40 cm; the ridge faces are covered with grass with the thickness of 2-5 cm; 1000-1500 jin of farmyard manure is applied to each mu of land. A row of corn can be planted on the sides of the ridges. The fertilizer efficiency can be sufficiently utilized, the production cost is reduced, it is ensured that the rivier giantarum rhizomes are dug conveniently and rapidly, and the digging cost can be saved by 400-500 yuan for per mu.

Owner:竹溪县泉溪益群魔芋专业合作社

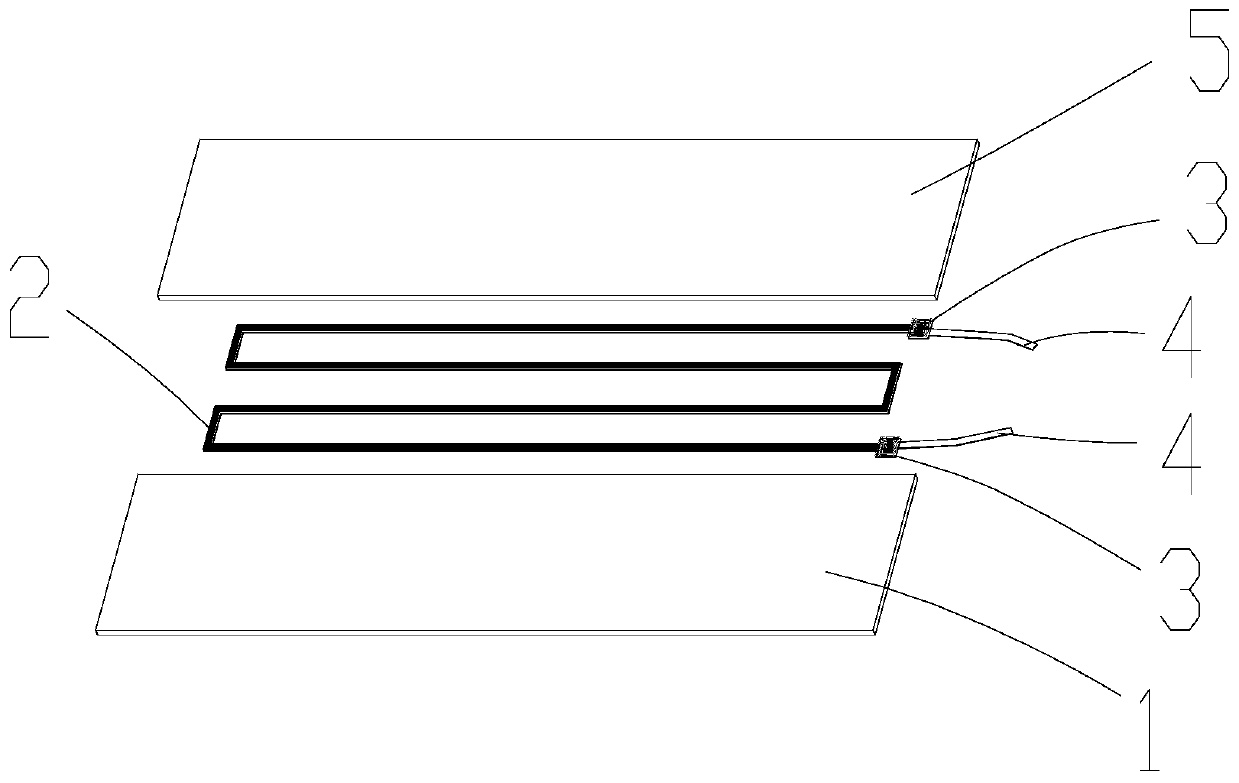

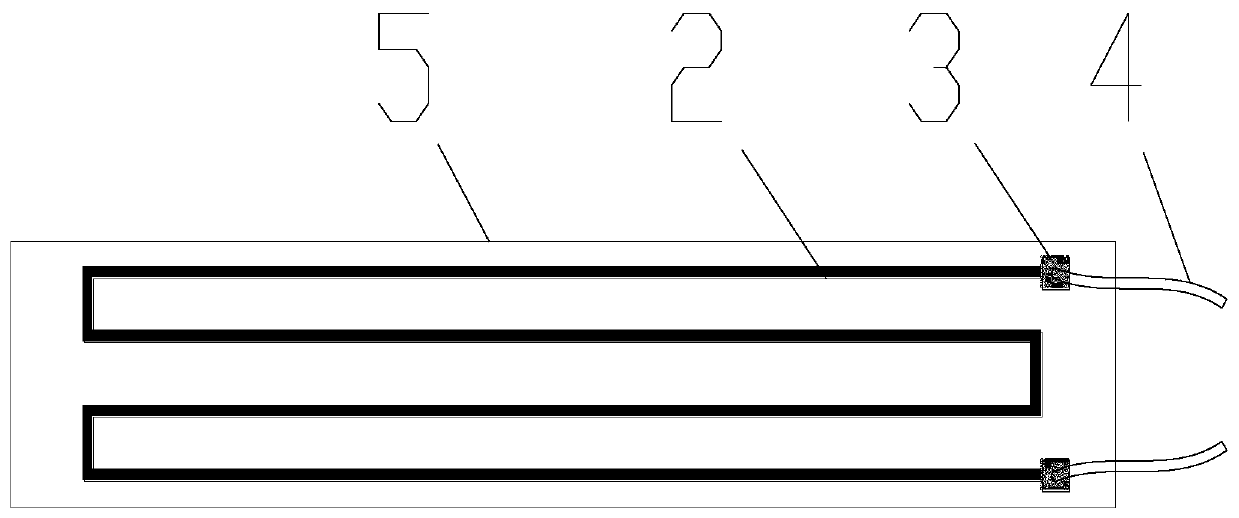

Thermoelectric sensor based on graphene material, and preparation method thereof

ActiveCN110702248APromote recoveryHeat dissipation fastThermometers using electric/magnetic elementsUsing electrical meansThermal dilatationHemt circuits

The invention belongs to the technical field of sensors, and particularly relates to a thermoelectric sensor based on a graphene material. The thermoelectric sensor comprises a first flexible layer, agraphene thermoelectric layer and a second flexible layer in sequence, wherein the graphene thermoelectric layer is attached to the first flexible layer, the graphene thermoelectric layer is of a grid-shaped structure, leading-out terminals are arranged at both ends of the graphene thermoelectric layer, the leading-out terminals are connected with an external circuit through conducting wires, andthe second flexible layer is attached to the first flexible layer and the graphene thermoelectric layer; and the coefficient of thermal expansion of the first flexible layer is 10 to 50 times greaterthan the coefficient of thermal expansion of the second flexible layer. At the same time, the invention further provides a preparation method of the thermoelectric sensor. The thermoelectric sensor provided by the invention has the advantages of excellent recovery performance, fast heat dissipation, fast response, simple structure and the like.

Owner:JIANGSU UNIV

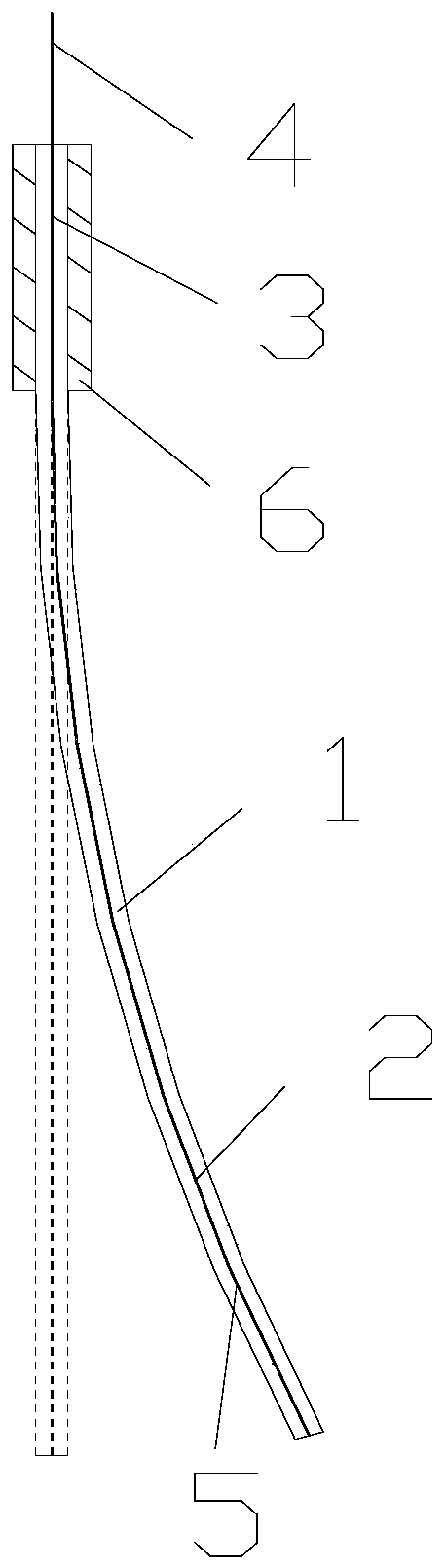

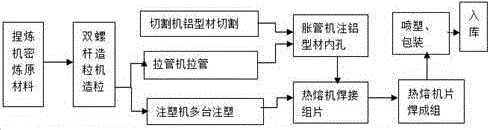

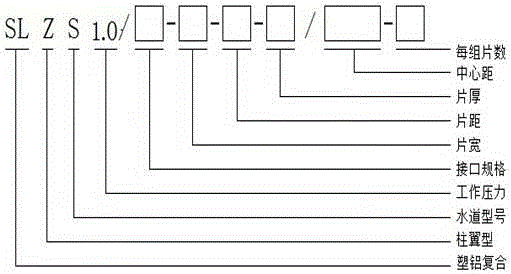

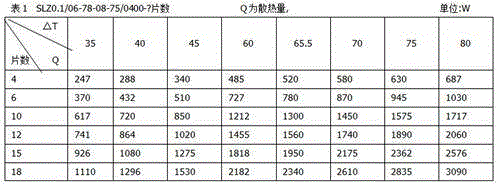

Thermal conductive plastic alloy, radiator based on alloy and preparation method

InactiveCN105175907AGood frost and heat resistanceStable molecular structureHeat exchange apparatusFiberAlloy

The invention discloses a thermal conductive plastic alloy used for a radiator, a radiator and a preparation method. The thermal conductive plastic alloy comprises polybutene or polyisobutene, polyethylene, graphite powder, carbon fiber, thermal conductive carbon black, a thermal conductive reinforcing agent, a titanate coupling agent and stearic acid. The thermal conductive plastic alloy is subjected to granulation, then pipe drawing and injection molding are carried out, an inner water channel pipe and a connecting piece of an radiator are prepared, the inner water channel pipe is expanded into an inner hole of an aluminum wing pipe of the radiator to obtain a radiator column material or sheet material, the column material or the sheet material and the connecting piece are subjected to sweat soldering to prepare a radiator single sheet, and finally the radiator single sheets are subjected to sweat soldering to compose a radiator. The thermal conductive plastic alloy and the radiator are advantaged by good environmental protection and excellent heat radiation performance, are stable and durable, and have protruding characteristics of no fouling, no rusting, no corrosion, no cracking, no pollution, no deformation, no abnormal sound and no aging.

Owner:徐继煌

Method for killing wood moth larvae and repairing wormhole

InactiveCN104472281APlay a role in repairing boreholesLarge expansion coefficientBiocideAnimal repellantsBacillus thuringiensisFungus

The invention relates to a method for killing wood moth larvae and repairing a wormhole. According to the method, bentonite, green muscardine fungi and bacillus thuringiensis are blended into unguent, the blended unguent is filled into a defecation hole for the wood moth larvae by the aid of a grease gun until the unguent overflows from a filling position, the bentonite is solidified to fill the whole wormhole, so that the wood moth larvae die due to asphyxia and mechanical injury, the wormhole is repaired, and the wood moth larvae are killed.

Owner:罗翼

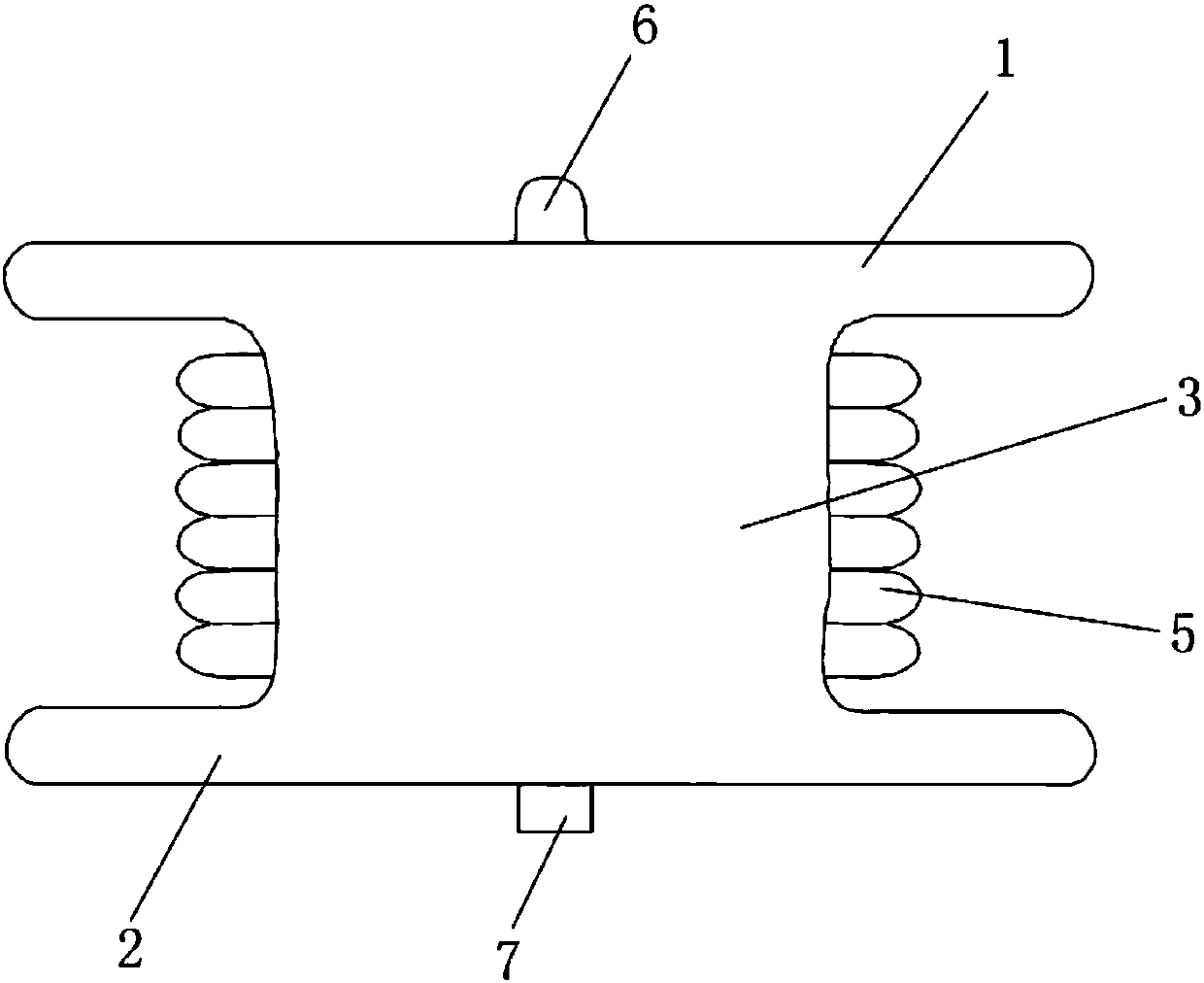

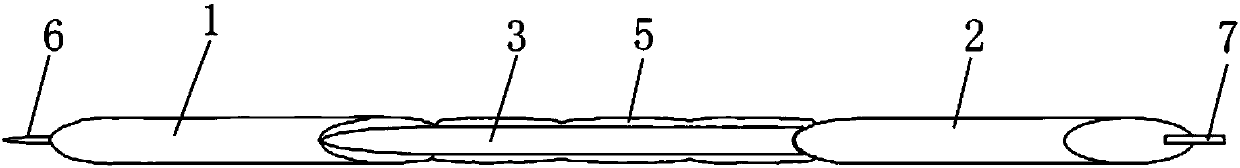

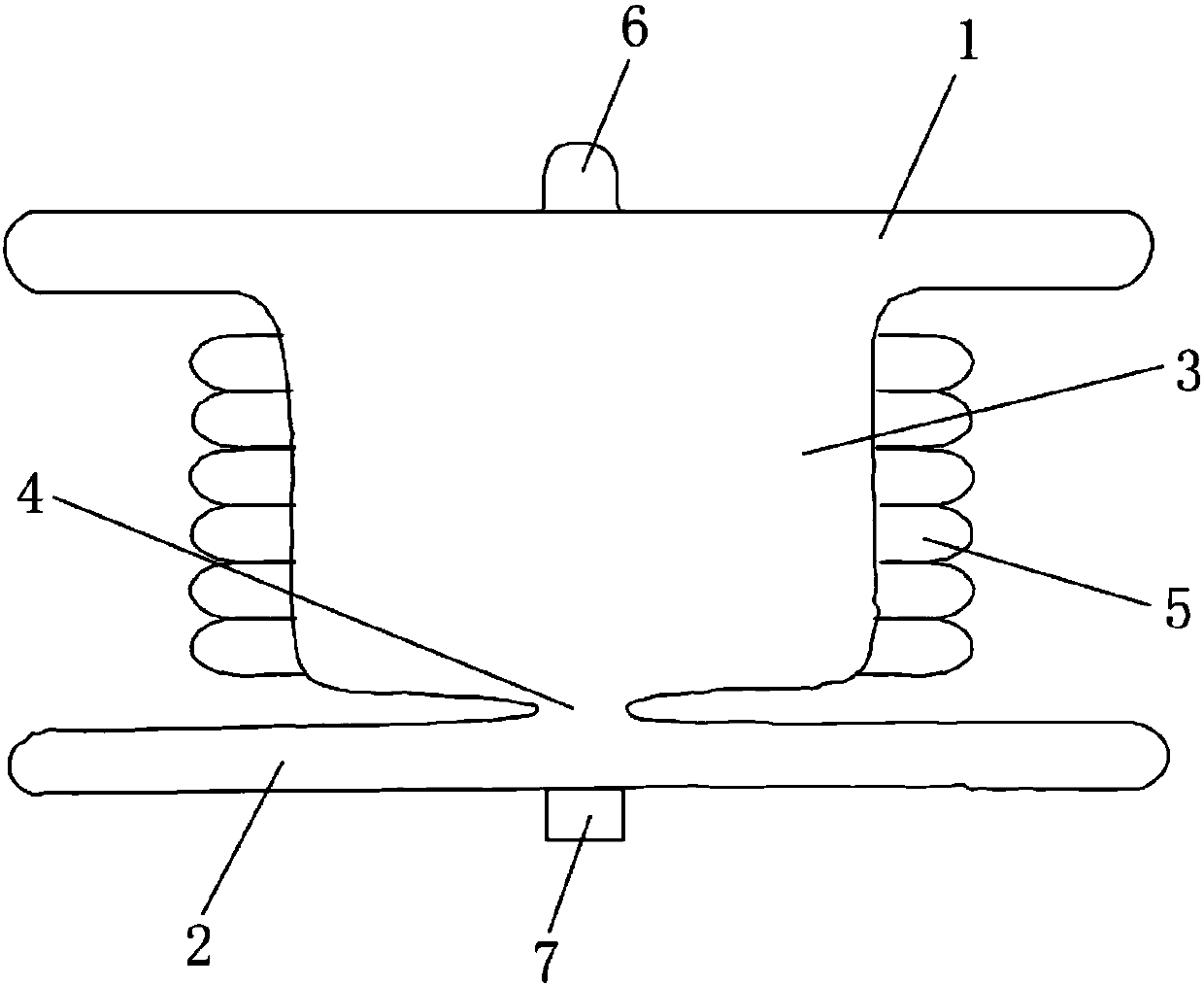

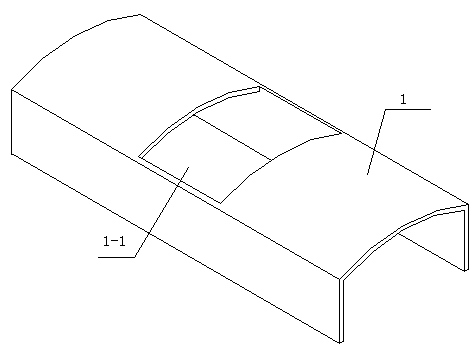

Perivalvular leakage plugging device

PendingCN107890357AShrinkage of the outer filmLarge expansion coefficientHeart valvesSurgeryTectorial membraneMedical equipment

The invention relates to the technical field of medical equipment, and particularly relates to a perivalvular leakage plugging device comprising a front-end parachute tray, a rear-end parachute tray and a waist connector for connecting the front-end parachute tray with the rear-end parachute tray, wherein an outer tectorial membrane is sewn on the waist connector and is made from polytetrafluoroethylene. Because polytetrafluoroethylene has great expansion coefficients, after the plugging device provided by the invention releases at the perivalvular leakage position, the outer tectorial membrane can quickly shrink, and irregular notches can be filled up according to the inherent structure form of perivalvular leakage; compared with conventional plugging devices, the plugging device disclosed by the invention can better conform to the irregular form of perivalvular leakage, and can effectively prevent postoperative residual diffluence.

Owner:SUZHOU INNOMED MEDICAL DEVICE +2

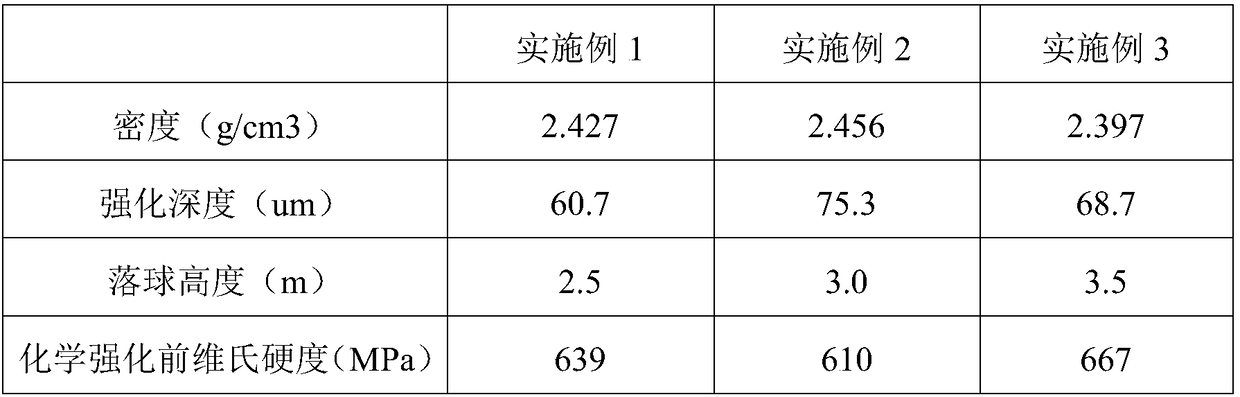

High temperature resistant tempered glass and preparation method thereof

ActiveCN108529876AIncrease high temperature viscosityGood chemical resistanceCoatingsGlass tempering apparatusStress relaxationTemperature resistance

The invention relates to the field of glass materials, and discloses high temperature resistant tempered glass and a preparation method thereof. The tempered glass comprises, by weight, 50-55 parts ofquartz sand, 10-20 parts of alumina, 10-13 parts of sodium carbonate, 4-6 parts of mirabilite, 10-15 parts of dolomite, 3-5 parts of feldspar, 1-2 parts of ceraphite, 3-5 parts of limestone, 1-3 parts of cosolvent, 0.2-0.5 part of cerium oxide composite clarifying agent, 1-2 parts of coloring agent, 10-15 parts of cullet, 1-3 parts of titanium oxide, 1-2 parts of antimony oxide, 0.5-1 part of yttrium oxide and 15-20 parts of high temperature resistant component. According to the tempered glass, components in the glass composition have a synergistic effect, so that the stress relaxation of theobtained glass is effectively improved, and the tempered glass has the advantages of enhanced compressive stress, deep strengthening depth, high impact strength, high temperature resistance and the like.

Owner:云南阳光利生玻璃科技有限公司

Coal ash thermal insulating material and preparation method thereof

The invention discloses a coal ash thermal insulating material and a preparation method of the coal ash thermal insulating material, belongs to the field of building material, and relates to a thermal insulating material and a preparation method of the thermal insulating material. The coal ash thermal insulating material is prepared by expanding and sintering coal ash and soda ash serving as raw material. The preparation method comprises the following steps of: mixing and stirring the coal ash and the soda ash in proportion; preheating the mixture to 600-1000 DEG C in a rotary kiln, and introducing the preheated mixture into a temperature resistant distributor; uniformly distributing a layer of material from the upper part of a tunnel kiln to a kiln car located inside the high-temperature area of the tunnel kiln by using the distributor, sintering and expanding the material at 1200-1250 DEG C so that the material is bonded together; when the material inside the tunnel kiln is sintered and formed to the prescribed thickness, sending the material and the kiln car out of the tunnel kiln, distributing, sintering, expanding and forming the material inside next kiln car, and repeatedly carrying out the operations; and introducing the material sent out of the kiln car into an insulating kiln, carrying out thermal insulation for 24 hours, then reducing the temperature to be below 300 DEG C, and cooling, cutting and forming. The preparation method disclosed by the invention has the advantages of controllable kiln temperature, low production cost, and good thermal insulation effect; moreover, place and equipment are saved.

Owner:哈尔滨琪裕新材料科技有限公司

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793BHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

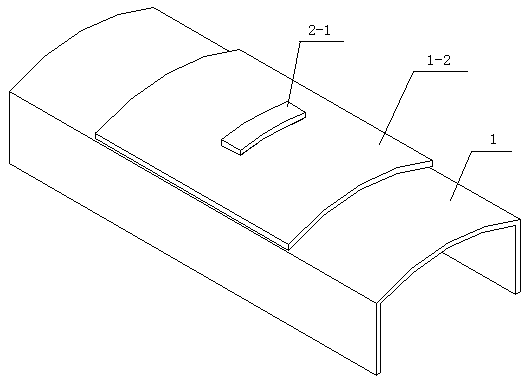

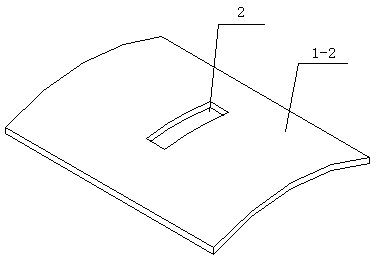

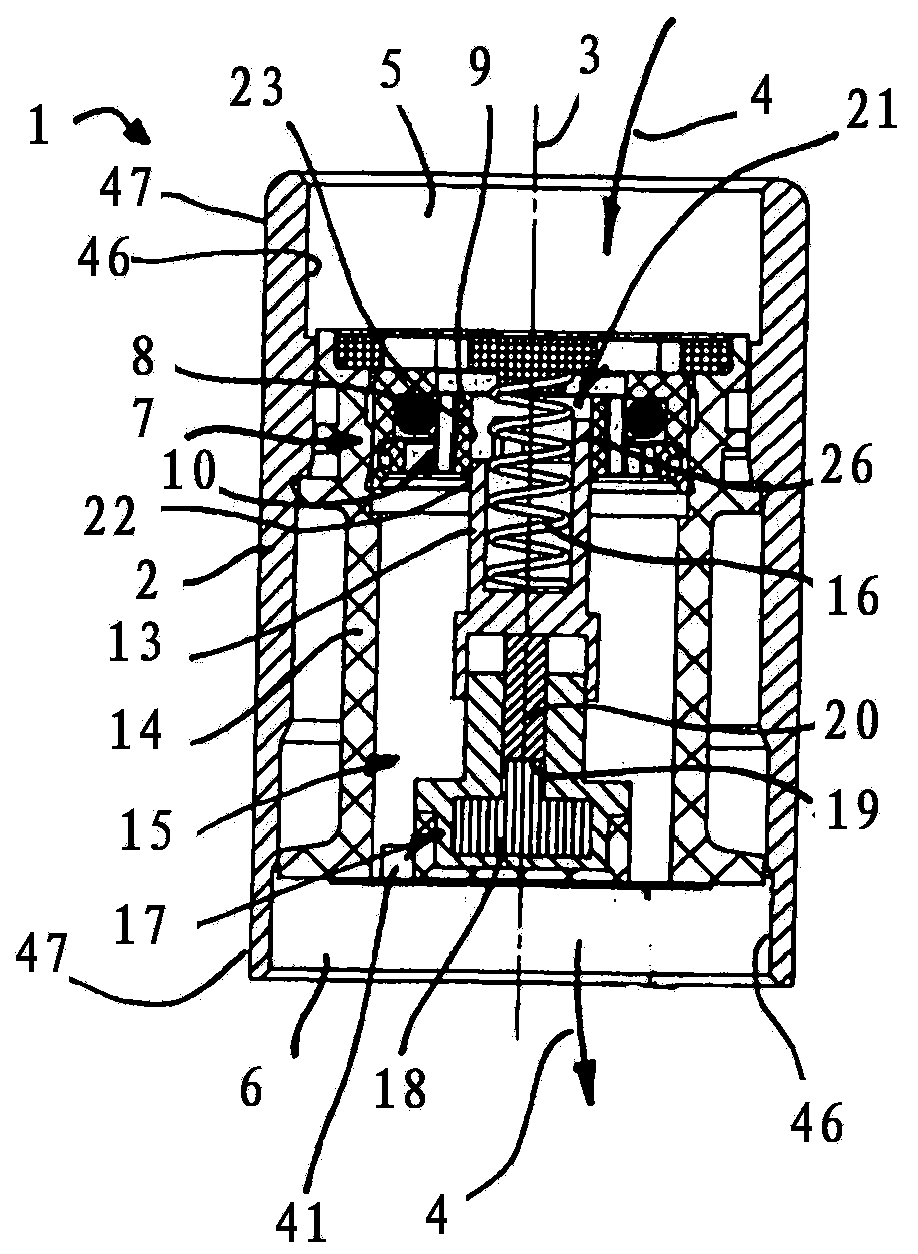

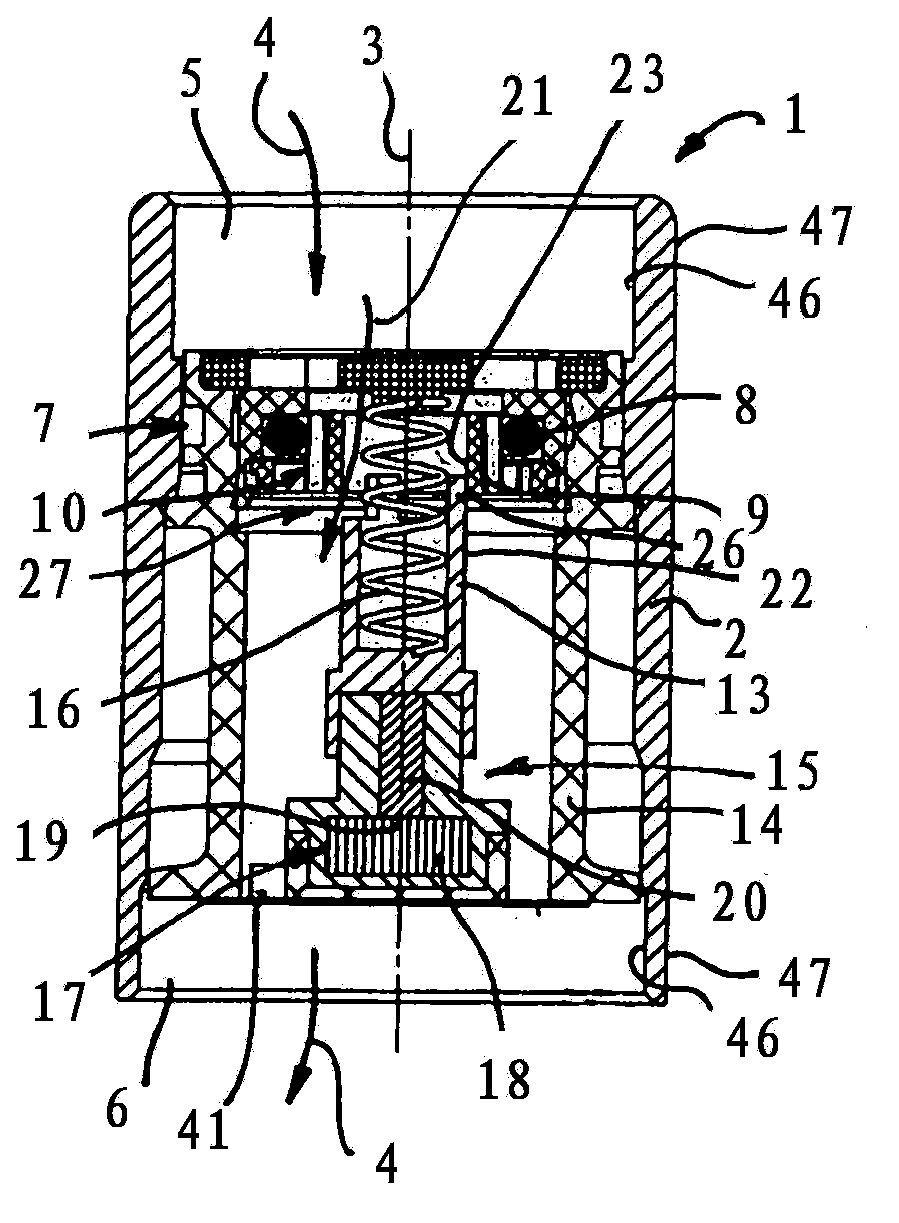

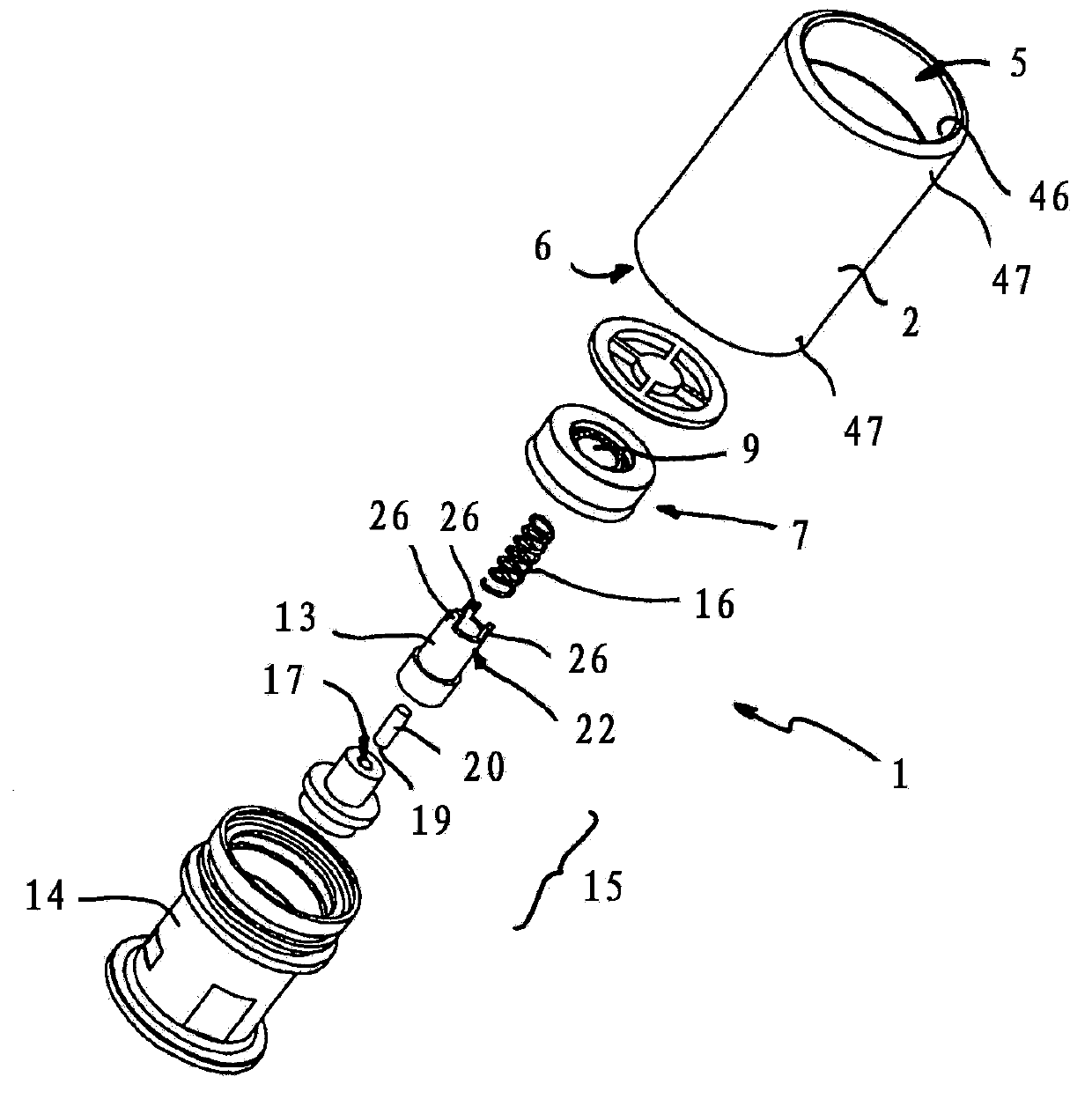

Sanitary installation part and component of a sanitary water faucet and method for controlling flow of flowing medium

ActiveCN103968143ALarge expansion coefficientAvoid mechanical loadTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringStreamflow

The invention relates to a sanitary installation part (1) which, along with a functional unit (7), forms a quantity regulator, it is proposed that a regulating element (13), which can be adjusted along an adjustment path, be coupled to a temperature-sensitive drive unit (15) such that different regulating positions of the regulating element (13) are set in dependence on the temperature of the medium flowing through the installation part (1), wherein the different regulating positions realize in each case different volume-flow dependencies (11, 12, 45, 48) and / or flow resistances (cf. figure 1).

Owner:NEOPERL

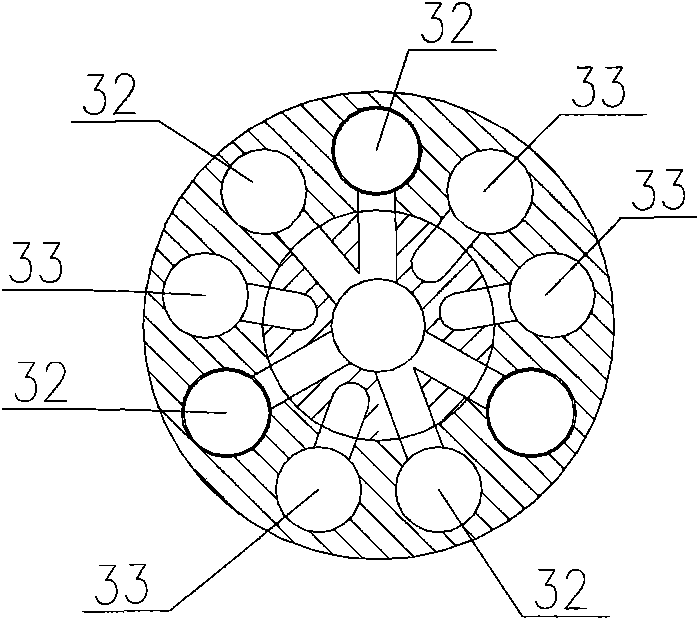

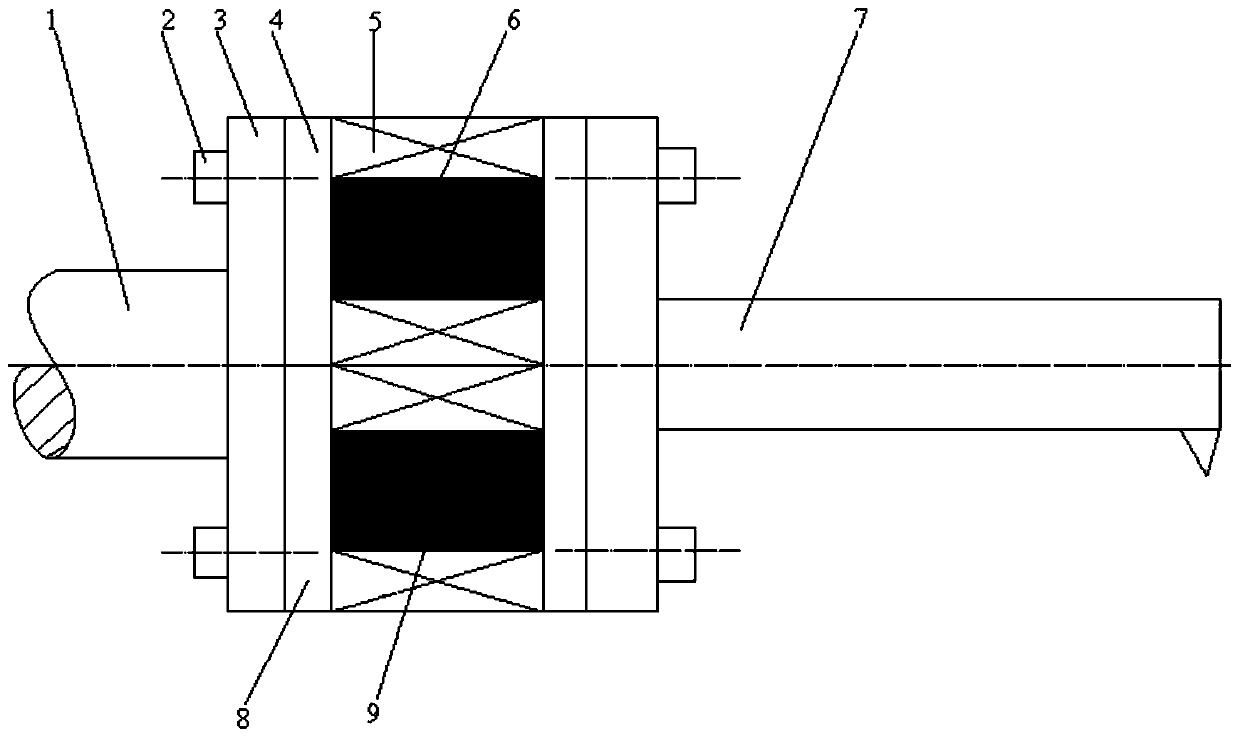

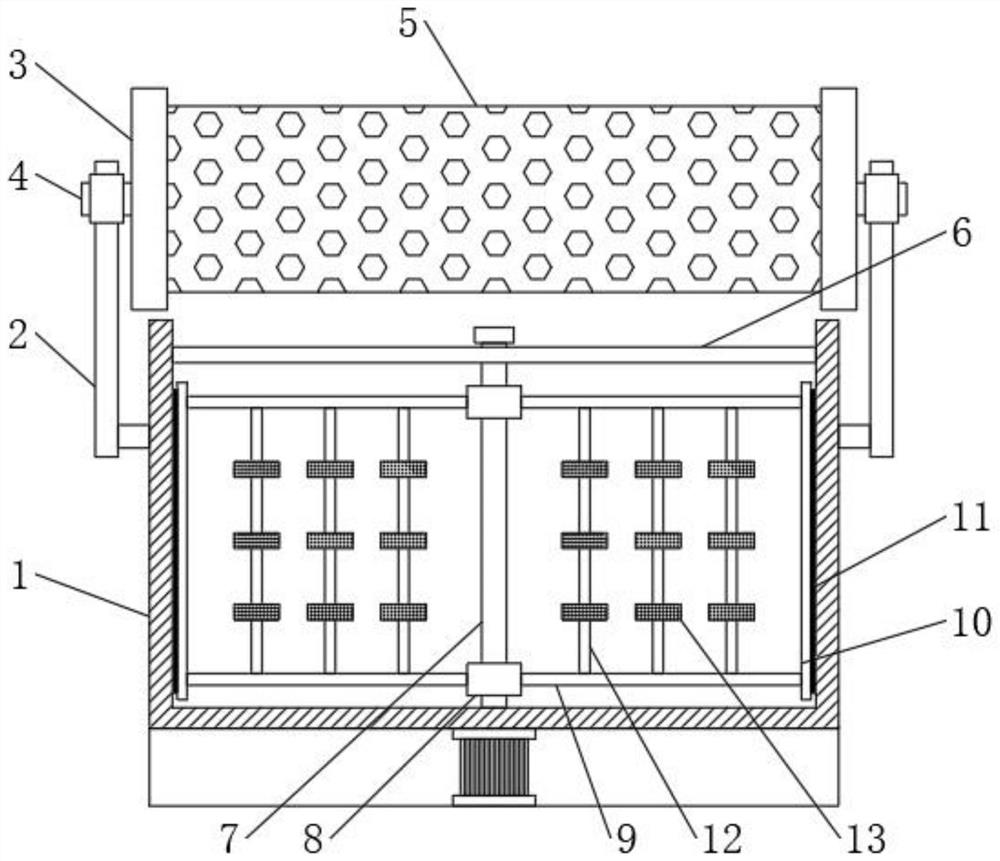

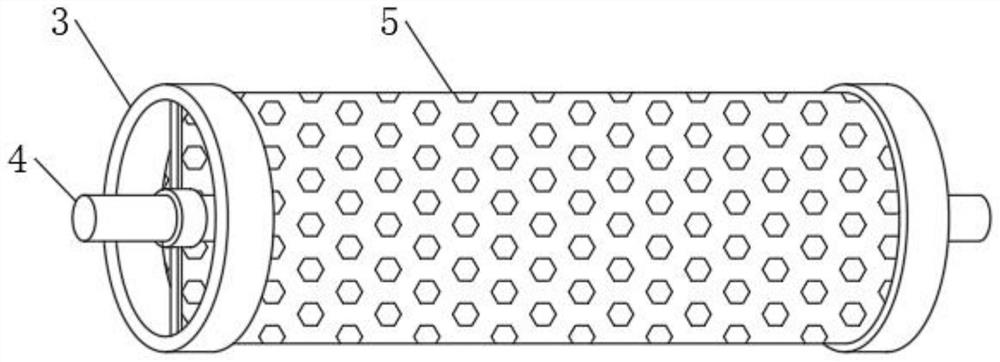

Giant magnetostrictive material-driven intelligent boring rod

InactiveCN104084624AGreat driving forceLarge expansion coefficientBoring barsFeeding apparatusEngineeringMachining

The invention discloses a giant magnetostrictive material-driven intelligent boring rod, which comprises a static pressure boring machine spindle, wherein a fixed seat is fixedly arranged on the static pressure boring machine spindle; an upper excitation coil bracket and a lower excitation coil bracket are fixedly arranged on the fixed seat respectively; an upper giant magnetostrictive rod and a lower giant magnetostrictive rod are fixedly arranged on the upper and lower excitation coil brackets respectively; excitation coils are correspondingly wound outside the upper and lower giant magnetostrictive rods on the upper and lower excitation coil brackets respectively; a boring rod is fixedly connected between the upper and lower giant magnetostrictive rods; a cutting tool is fixedly connected to the front end of the boring rod. The giant magnetostrictive material-driven intelligent boring rod is reasonable and reliable in structure; the giant magnetostrictive rods can extend and contract under the action of a magnetic field to drive the boring rod to be axially deflected to radially feed the cutting tool for the boring machining of an irregularly-shaped pinhole.

Owner:CHIZHOU UNIV

Construction method of existing railway tunnel overhaul polyurethane plugging agent high-pressure grouting

InactiveCN110030021AEasy constructionGood operabilityUnderground chambersTunnel liningHigh pressureStructural engineering

The invention relates to a construction method of existing railway tunnel overhaul polyurethane plugging agent high-pressure grouting. Existing railway cracks are plugged and grouted by cleaning the surface, drilling, embedding needle heads, grouting and removing a grouting pipe, and water stopping and plugging effects are performed.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD +1

Preparation method of recycled concrete based on house construction

InactiveCN112917671AEasy to GrindSlow down the speed of solidificationMixing operation control apparatusHollow article cleaningThermal dilatationElectric machine

The invention discloses a preparation method of recycled concrete based on house construction, and belongs to the field of concrete. According to the preparation method of the recycled concrete based on the house construction, in the scheme, lubricating oil expands in a storage cavity and flows into gaps of a screening cylinder through high temperature generated during friction between concrete waste residues and the screening cylinder, and the probability of screening cylinder blockage caused by concrete blocks is reduced. A main motor is started, a fixed shaft is driven to rotate, the concrete blocks are stirred through a stirring rod and a cleaning plate, when the main motor drives the stirring rod to rotate, the concrete is better ground through grinding beads at the outer end of a grinding ring, and when the concrete is slowly solidified, heat is generated, heat expansion air bags are heated and expand, and T-shaped sliding rods are ejected towards the outer side. Meanwhile, the grinding beads are softened by heat, and the grinding beads are punctured through ejector pins on the outer sides of ejector plates, so that a cement retarder flows out and is mixed into the concrete, and the solidification speed of the concrete is effectively slowed down.

Owner:广西安业建设集团有限公司

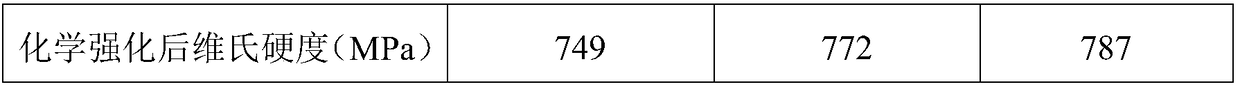

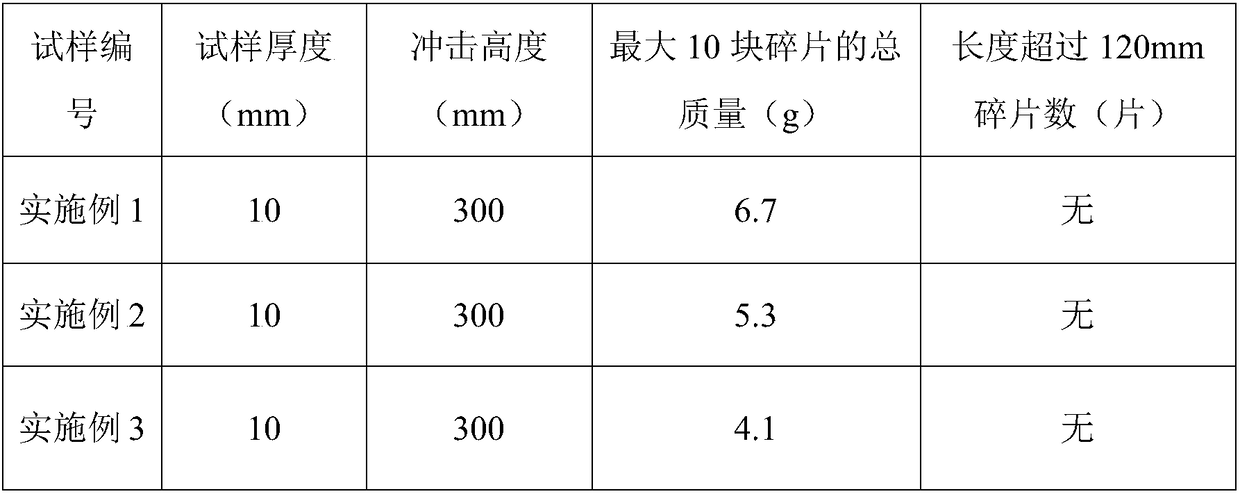

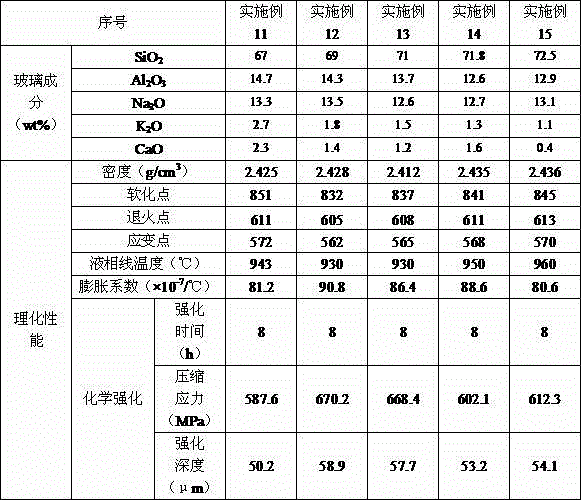

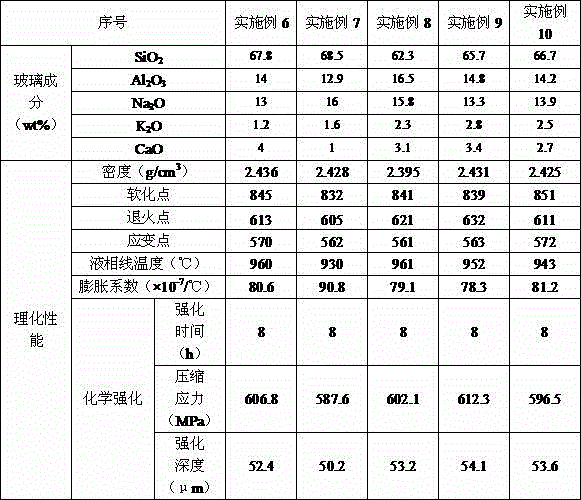

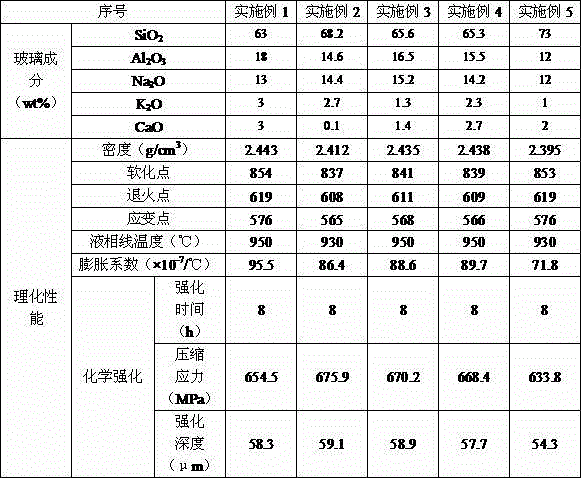

Prescription of cover plate glass for light touch screen

The invention discloses a prescription of a cover plate glass for a light touch screen. Experiments show that the major ingredients of the cover plate glass contain SiO2, Al2O3, Na2O, K2O and CaO, for the glass prepared according to the prescription provided by the invention, the aim of improving the coefficient of thermal expansion is realized by regulating the contents of the ingredients in the prescription, and simultaneously, improving the coefficient of thermal expansion of the glass by using the large proportion of metals containing Ba and Sr is avoided; in the prescription provided by the invention, CaO is selected instead of MgO, the MgO is not added, devitrification tendency of the glass can be lowered, the high-temperature viscosity can be lowered, melting is facilitated, and after being enhanced chemically, the glass can effectively prevent the impact and the scratch damage to the protective screen surface of the touch products, and prolong the service life of the products with touch screens.

Owner:TUNGHSU GRP

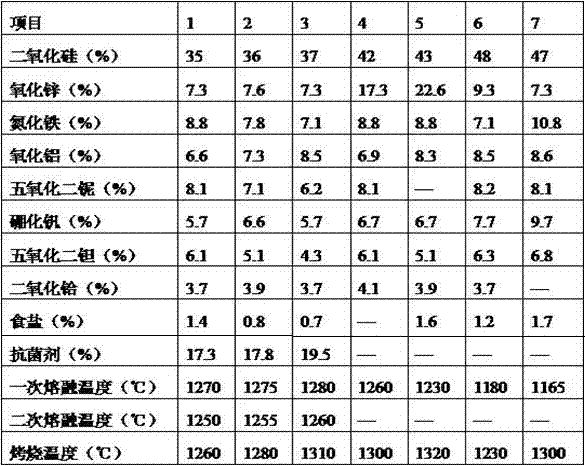

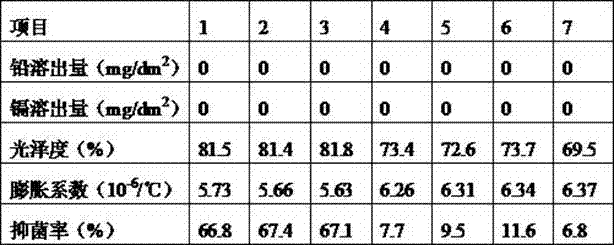

High-temperature environment-friendly antibacterial glaze

InactiveCN107021630AAbundant raw materialsReduce manufacturing costBiocideDead animal preservationIron nitrideCeramic glaze

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a high-temperature environment-friendly antibacterial glaze. The high-temperature environment-friendly antibacterial glaze is prepared from the following raw materials: silicon dioxide, zinc oxide, iron nitride, aluminum oxide, niobium pentoxide, vanadium boride, tantalum pentoxide, hafnium oxide, table salt and an antibacterial agent. A ceramic product keeps the original color and luster after being subjected to short-time high-temperature burning, the production cost is lowered by 13.1 percent, and the antibacterial rate is up to 67.4 percent; the ceramic product is safe, environment-friendly and healthy, and no lead or cadmium is dissolved out; the antibacterial agent is abundant in raw materials, has a high antibacterial rate, high heat resistance and high stability, and has antibacterial time being up to 9 years when being used normally; the raw materials are subjected to repeated melting, quenching and ball milling after being subjected to ball milling, the table salt is added after primary quenching, and the antibacterial agent is added after secondary melting, so that the fineness and fluidity of the glaze are improved, an expansion coefficient is matched, and the glaze is smooth; the antibacterial agent is added at a low temperature, and short-time high-temperature treatment is performed, so that the influence on the color and luster of the ceramic product can be avoided, and the antibacterial life can be prolonged.

Owner:界首市伟盛古窑彩陶制作发展有限公司

Production method of konjak and highland barley high-fiber slimming food

InactiveCN102907681AMeeting nutritional needsLarge expansion coefficientFood preparationFiberWhey protein powder

The invention discloses a production method of konjak and highland barley high-fiber slimming food, and relates to food and a preparation methods of the food. The production method belongs to the technical field of food processing. The konjak and highland barley high-fiber slimming food comprises the raw materials in parts by weight: 80-120 parts of konjaku powder, 180-240 parts of highland barley germ swelled powder, 90-140 parts of lactalbumin powder, 50-80 parts of white fungus grains and 0.1-0.4 parts of folic acid. The production method has the benefits that the content of a main component, namely glucomannan, in the konjac reaches as high as 50-65% in the konjak and highland barley high-fiber slimming food produced by the production method; a swelling coefficient of the glucomannan is large; the viscosity can reach above 100-300 times; the glucomannan can keep stable in a highly acidic stomach for a long time; therefore, the satiety is generated obviously after the konjak and highland barley high-fiber slimming food is eaten; the appetite can be controlled; the food intake is reduced; the daily nutritional requirements of fat persons or persons with abnormal weight on carbohydrate are met; and the purposes of losing weight and slimming are achieved.

Owner:SICHUAN YUEWANG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com