Patents

Literature

49results about How to "Avoid mechanical load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

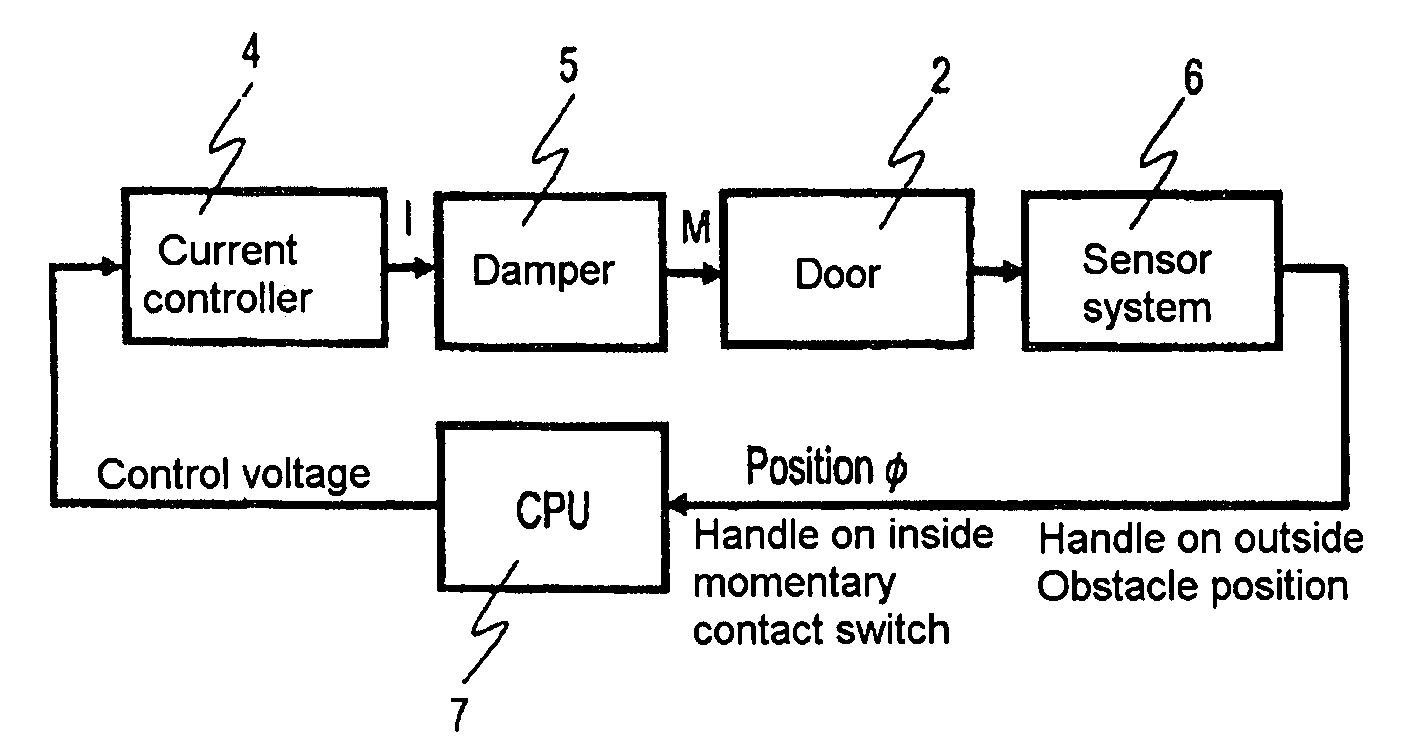

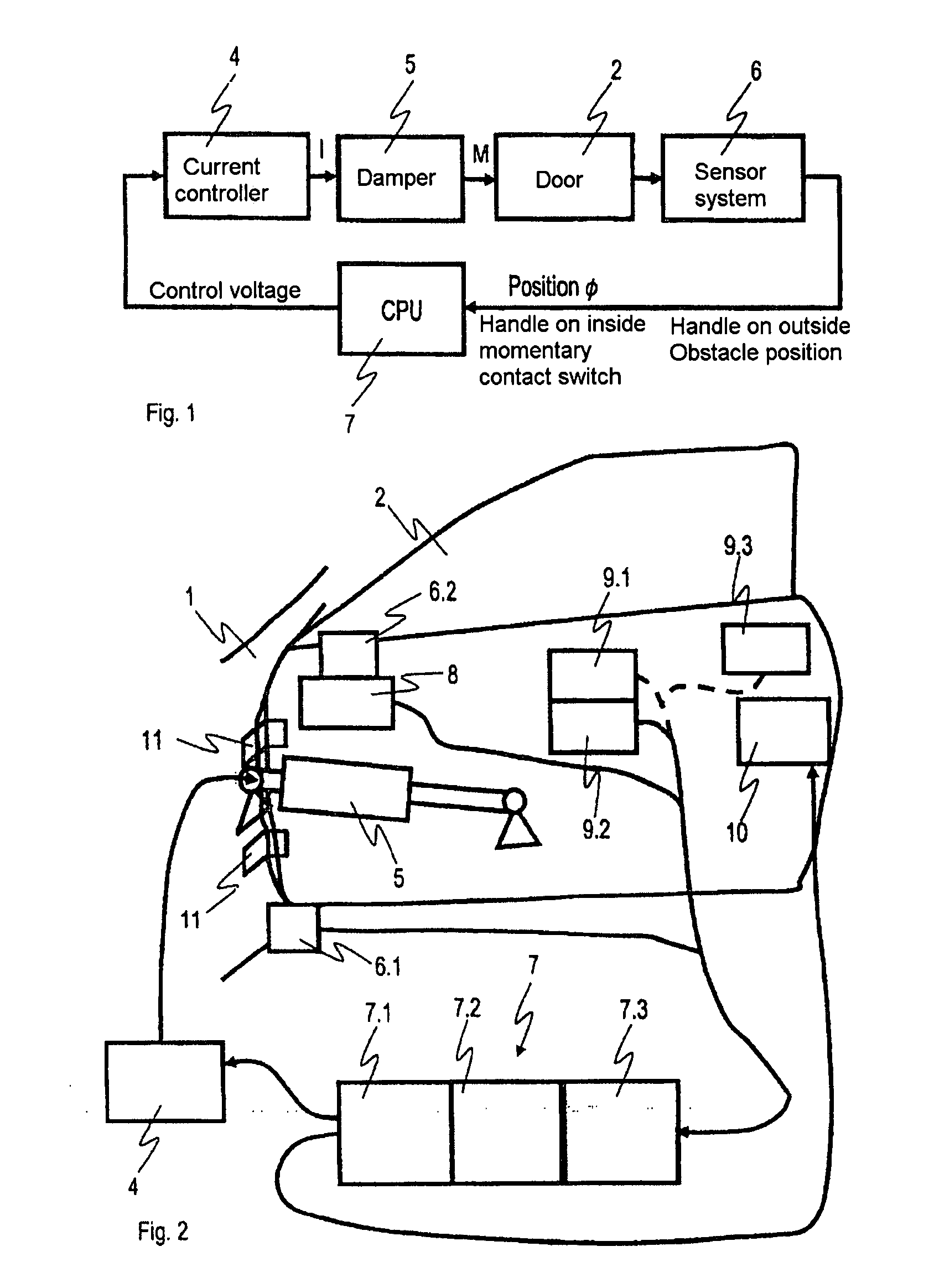

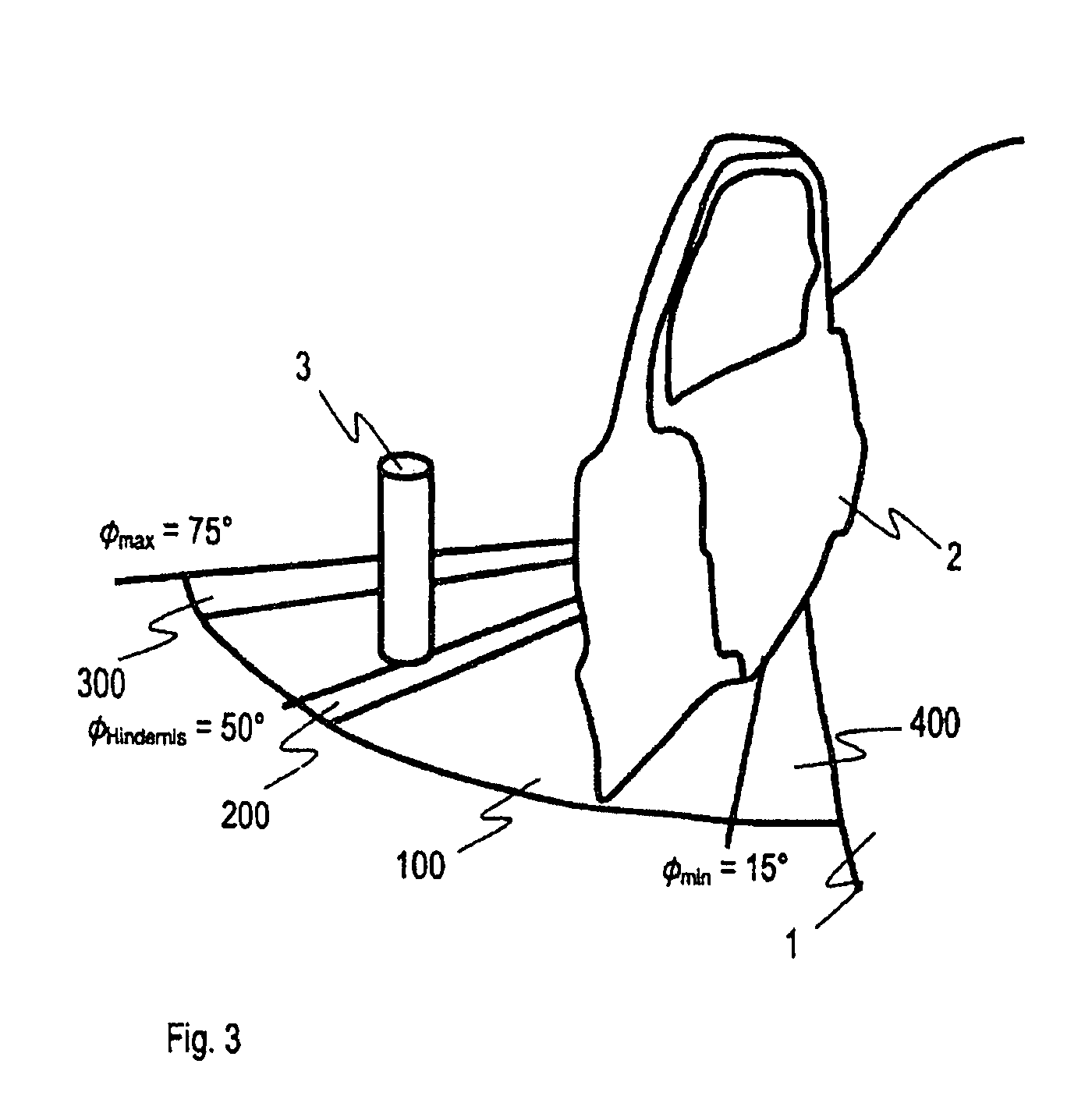

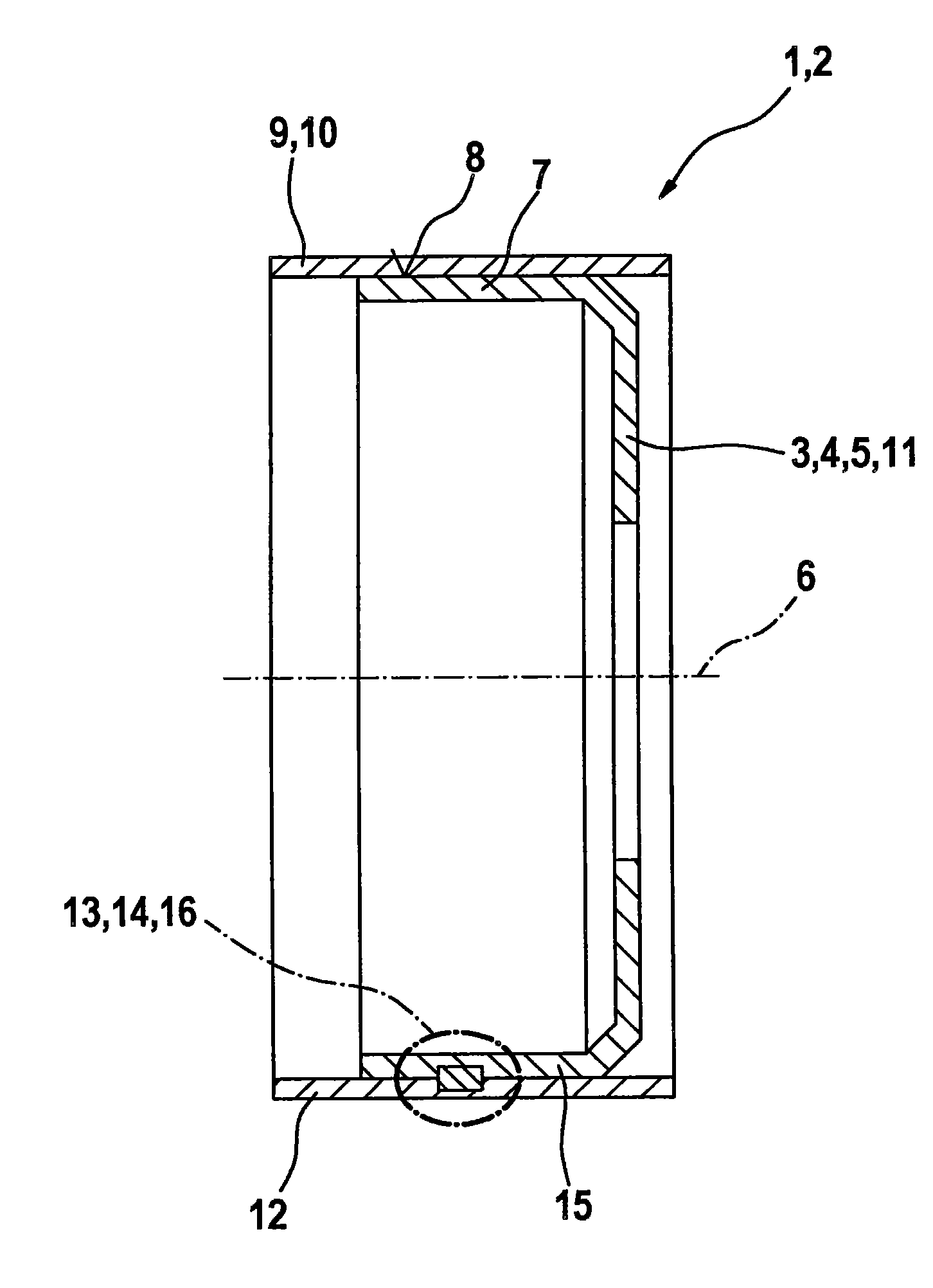

Vehicle Door Comprising a Deceleration Function

InactiveUS20090007489A1Avoid collisionAvoid mechanical loadBuilding braking devicesNon-mechanical controlsBrake torqueEngineering

The invention relates to a vehicle door comprising a braking function before a detected obstacle (3) and for damping the final position, which decelerates the movement of the vehicle door (2) by applying a braking torque, wherein an evaluation and control unit (7) determines the braking torque by evaluating an instantaneous door movement, which is sensed by a sensor system (6), or a sensed obstacle and actuates the damper (5) correspondingly. According to the invention, the braking function decelerates the vehicle door (2) aperiodically taking into account interference torques, wherein the evaluation and control unit (7) determines the braking torque for the braking function, in that during an opening process the vehicle door (2) reaches a target position with a speed with the value zero, and during a closing process reaches an end position (φ0) with a predefined target speed, wherein the target position corresponds to a predefined maximum opening angle (φmax) or a virtual stop which is determined by an obstacle (3) which is detected by the sensor system.

Owner:DAIMLER AG

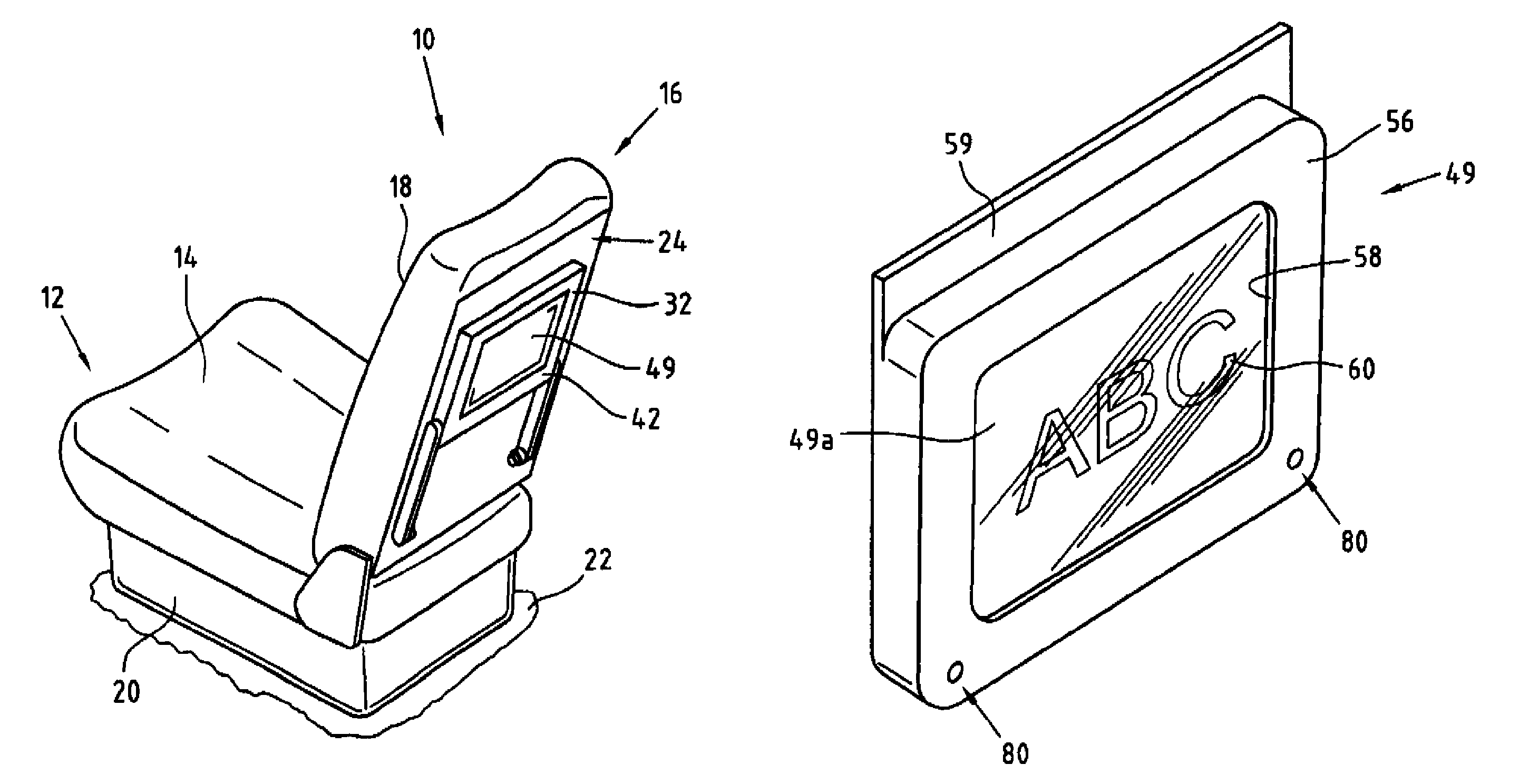

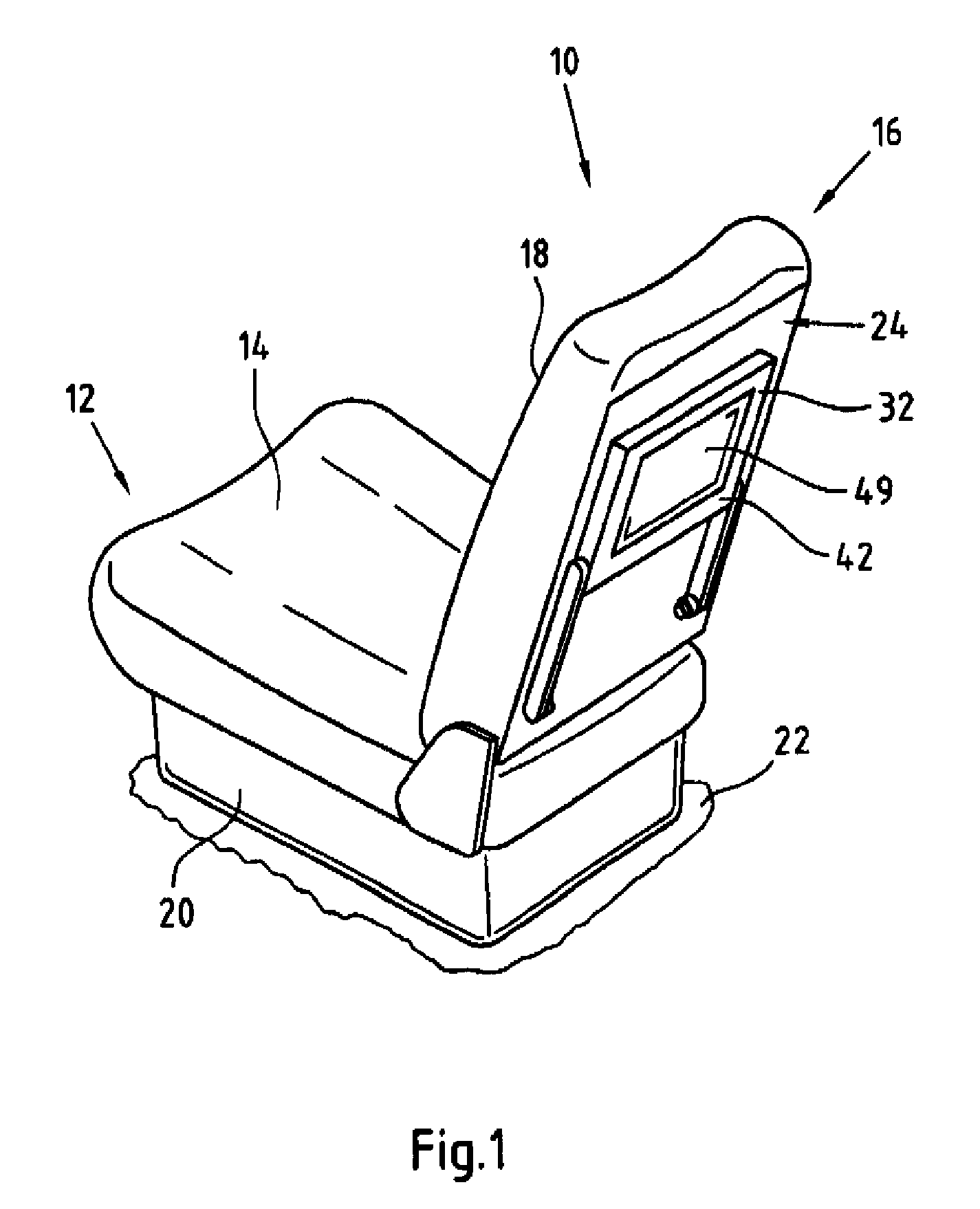

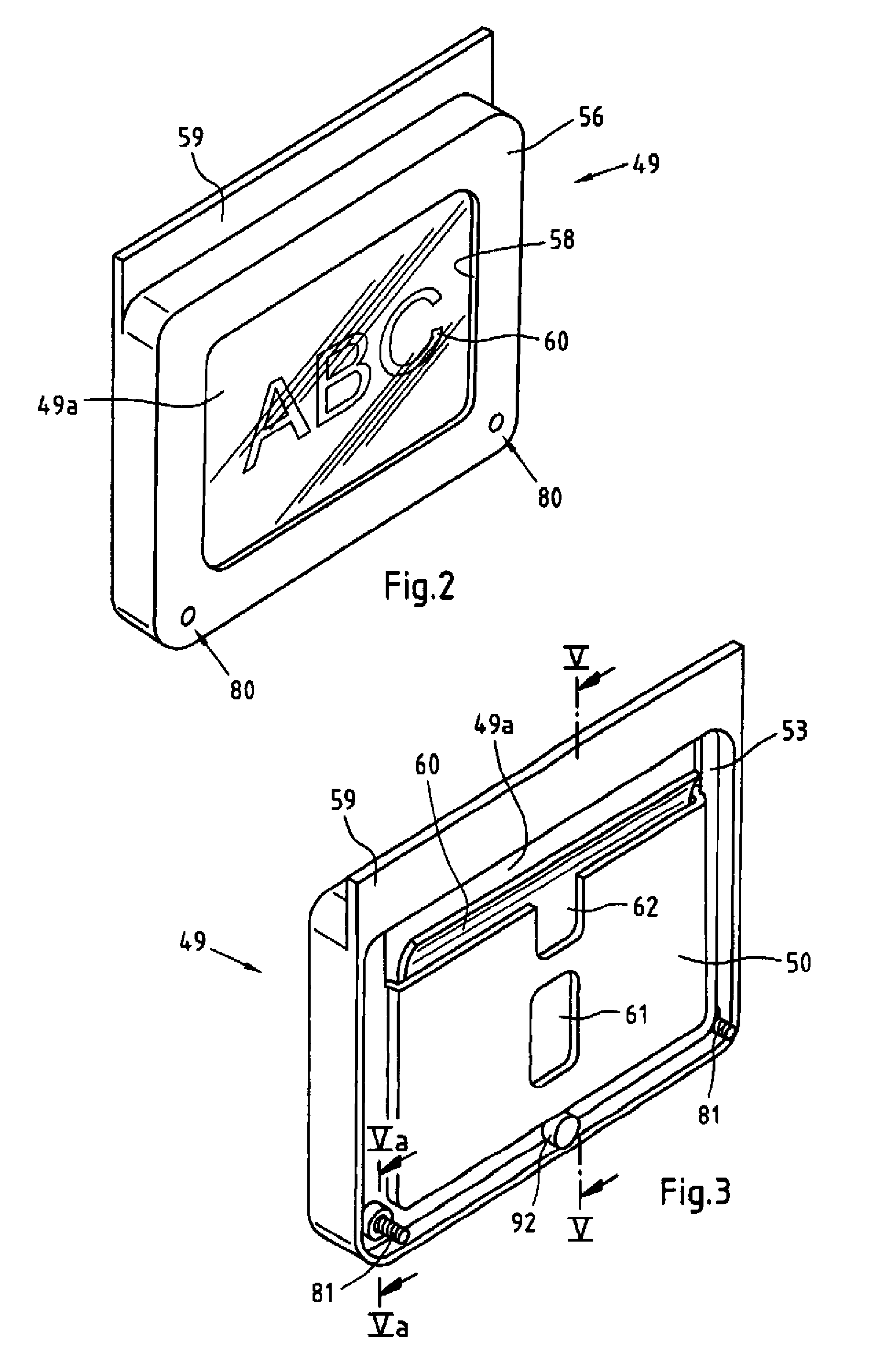

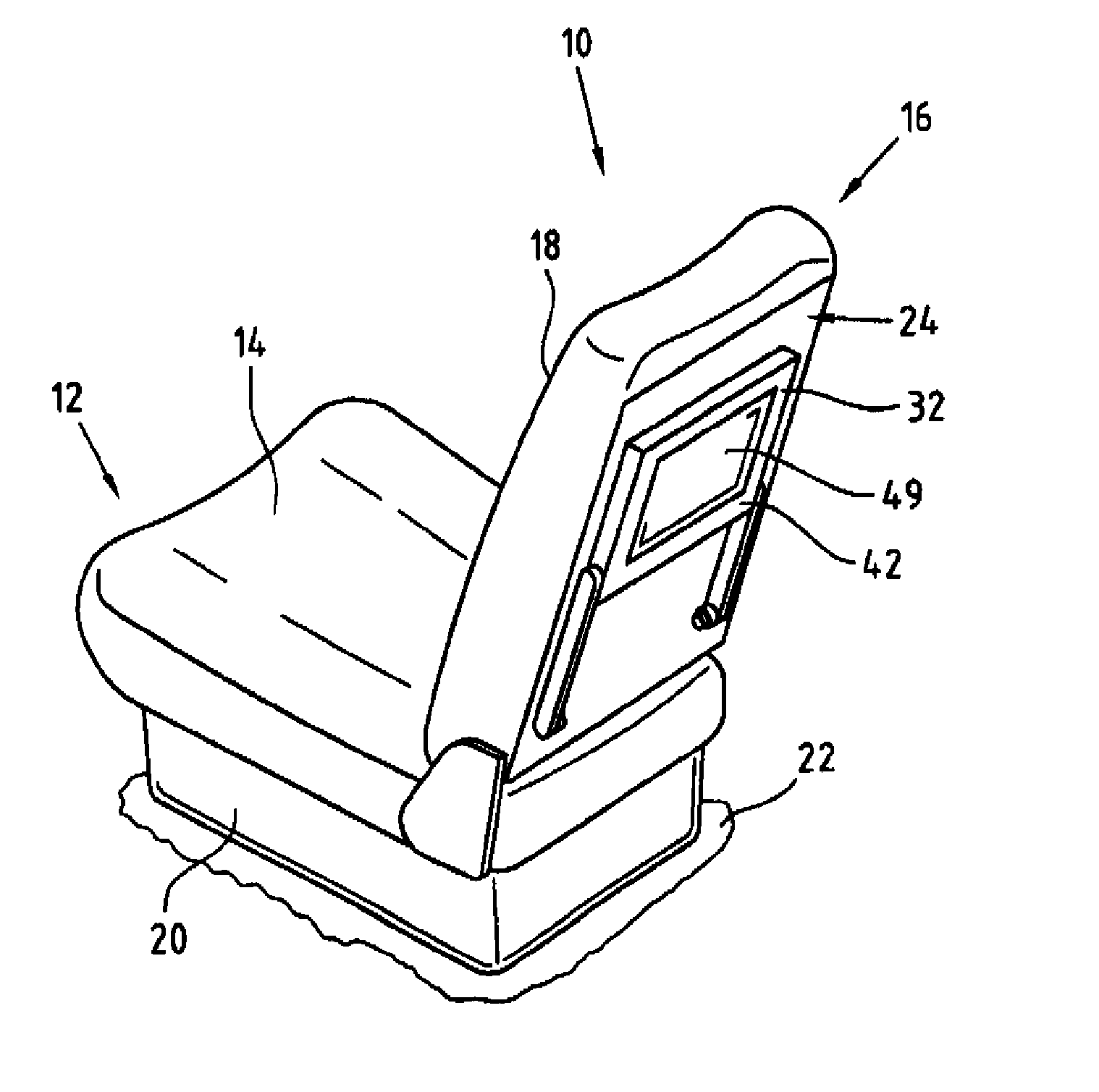

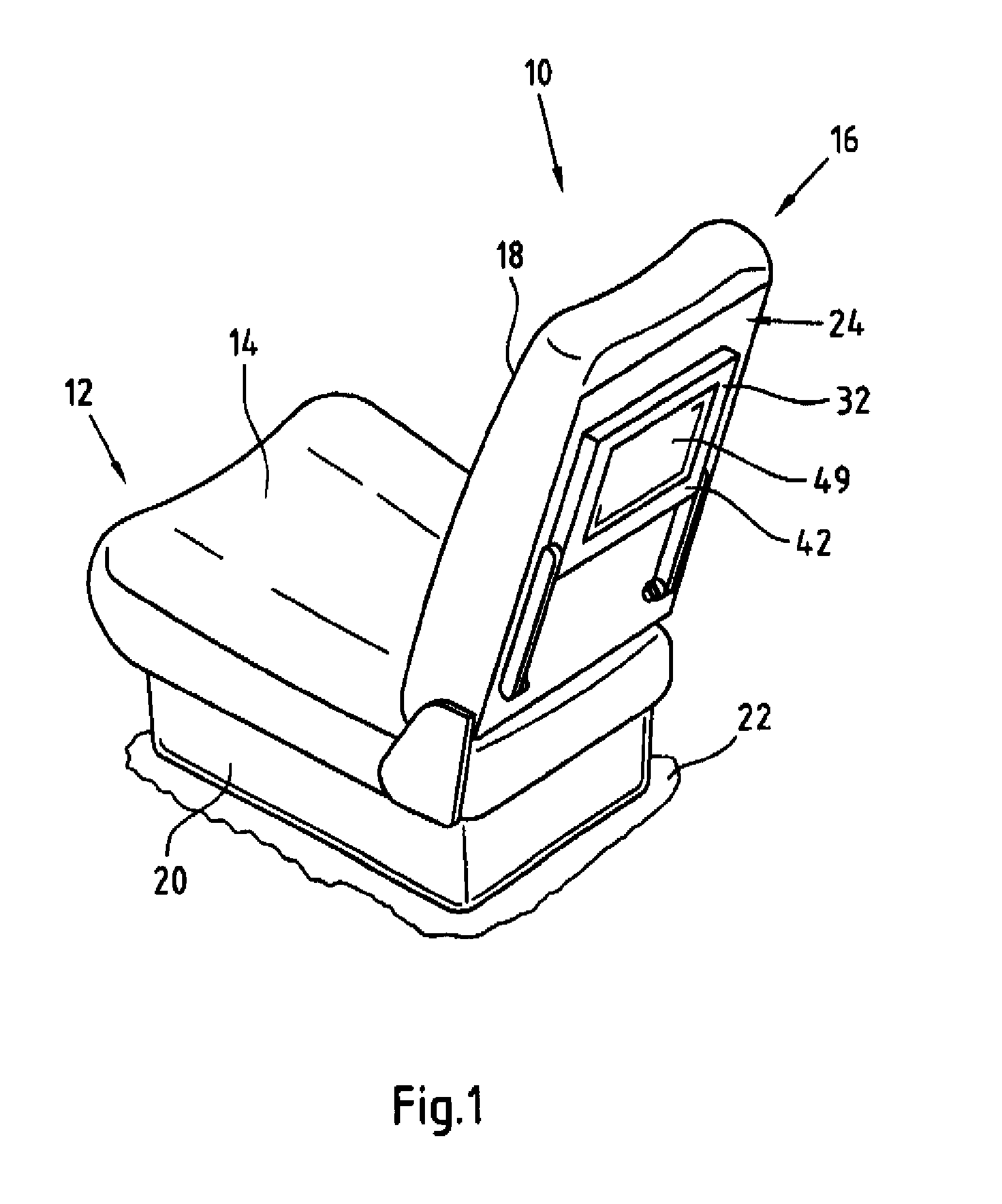

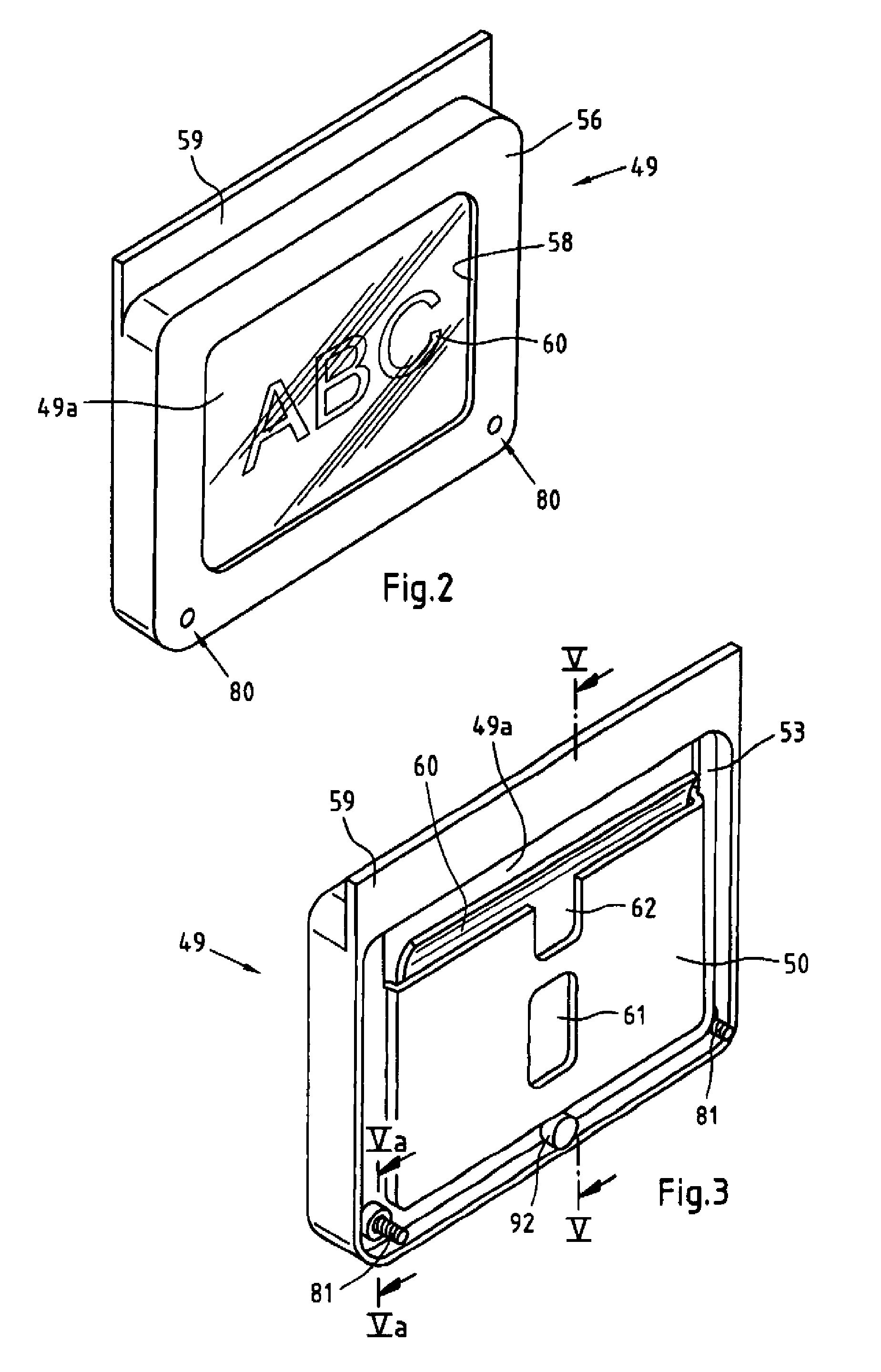

Apparatus for receiving an information medium

Owner:MAXPOSURE MEDIA GRP INDIA PVT LTD

Apparatus for Receiving an Information Medium

ActiveUS20120212012A1Simple and robust apparatusAvoid mechanical loadVehicle seatsStampsEngineeringInformation media

Owner:MAXPOSURE MEDIA GRP INDIA PVT LTD

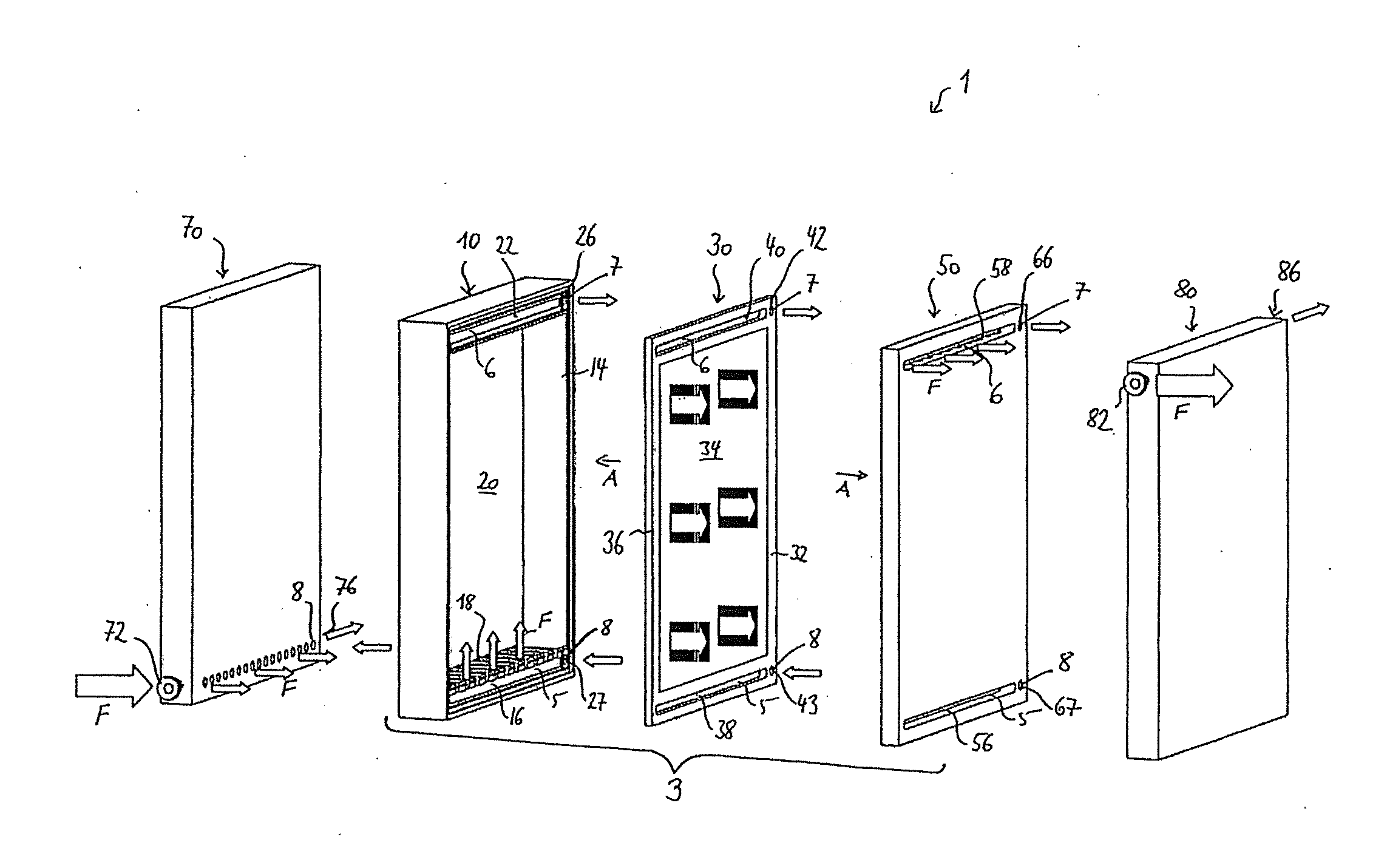

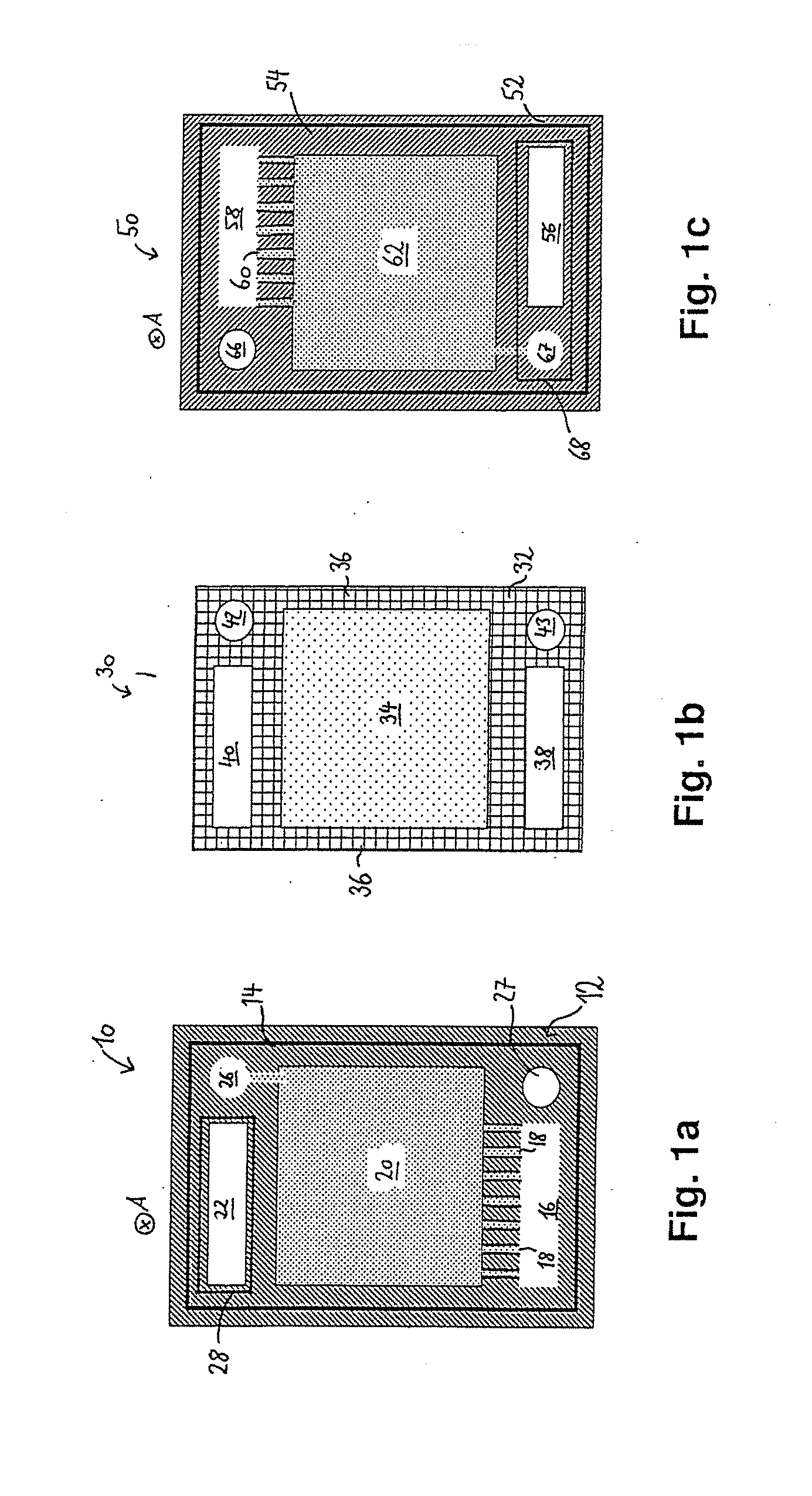

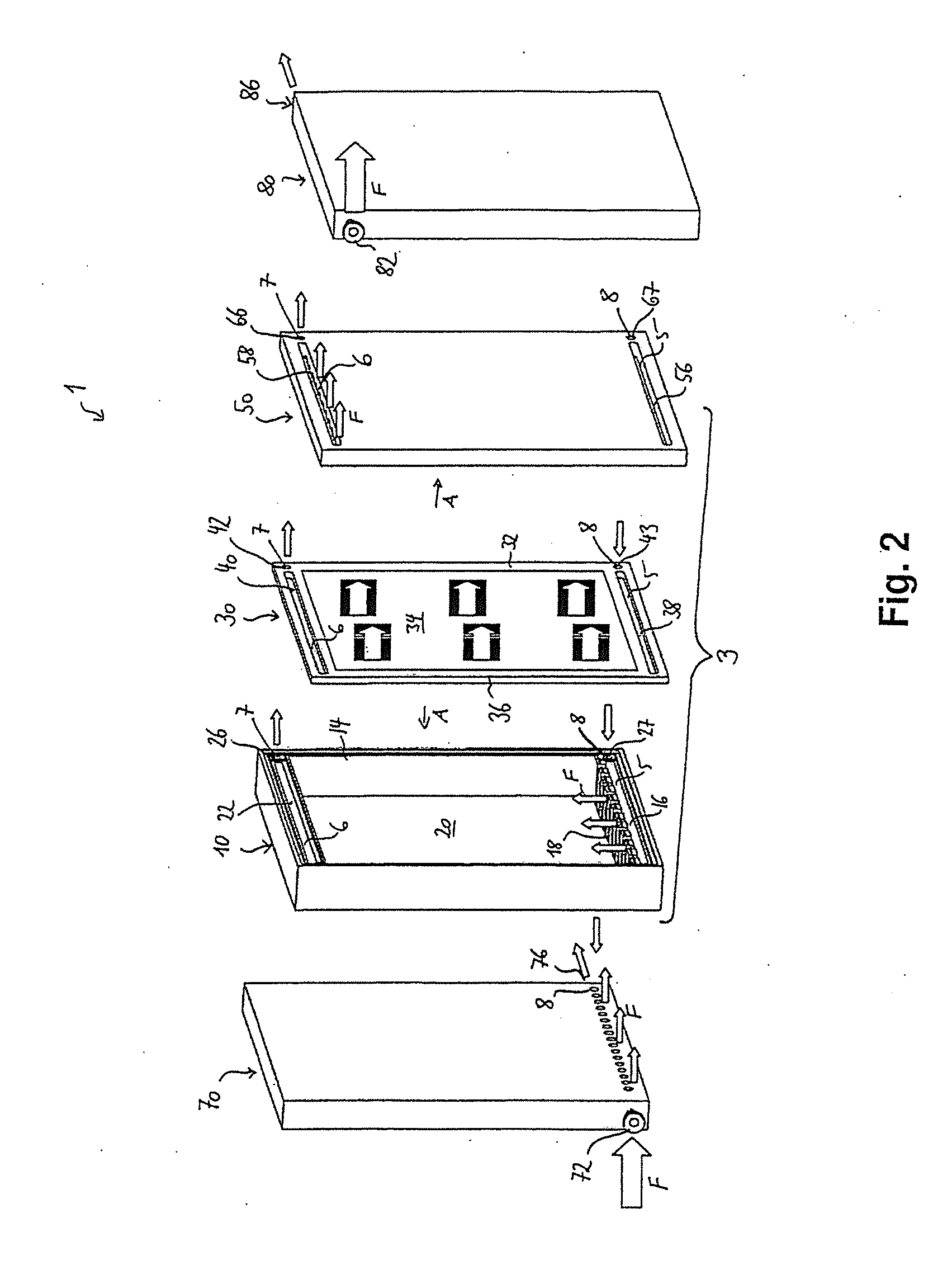

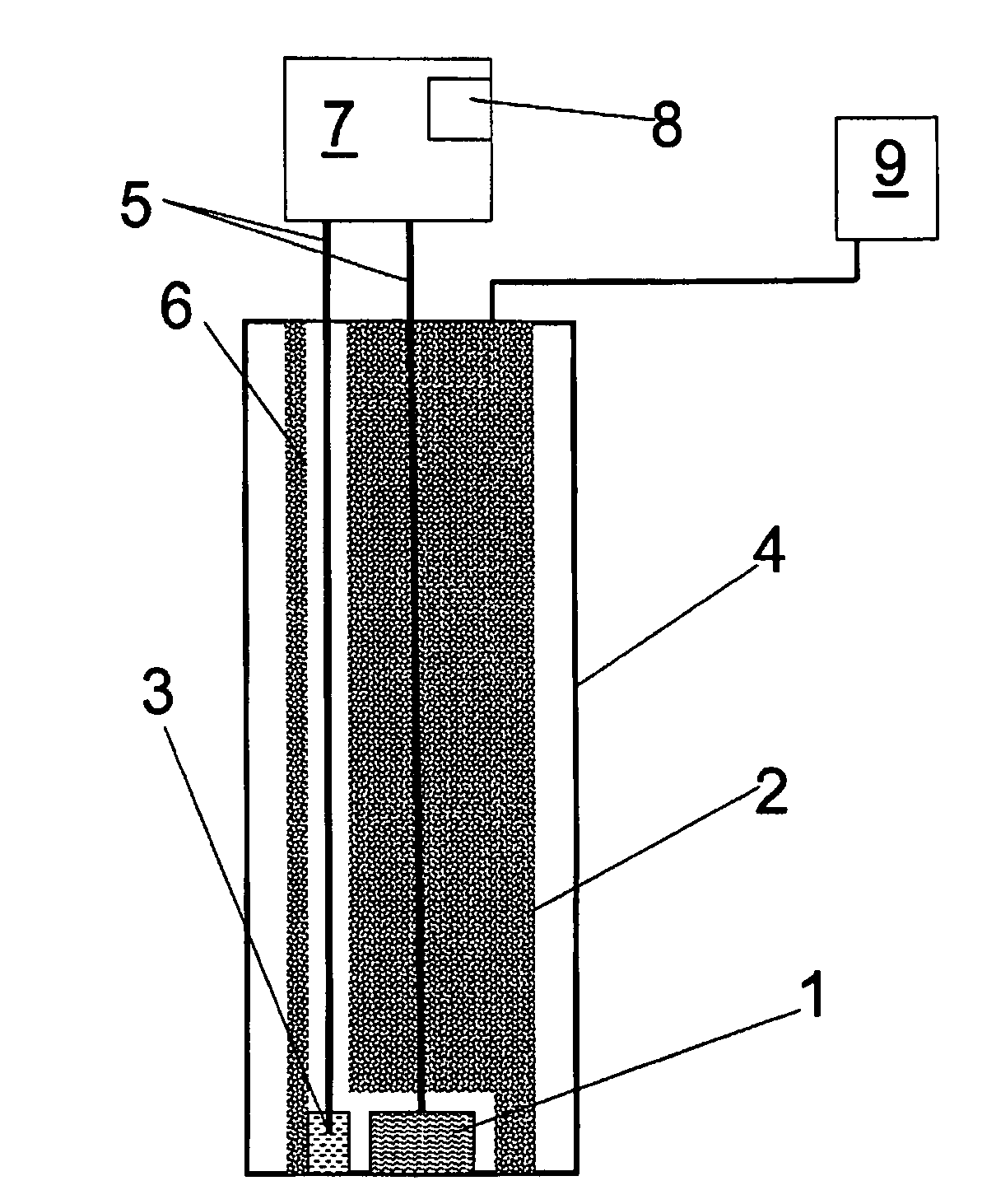

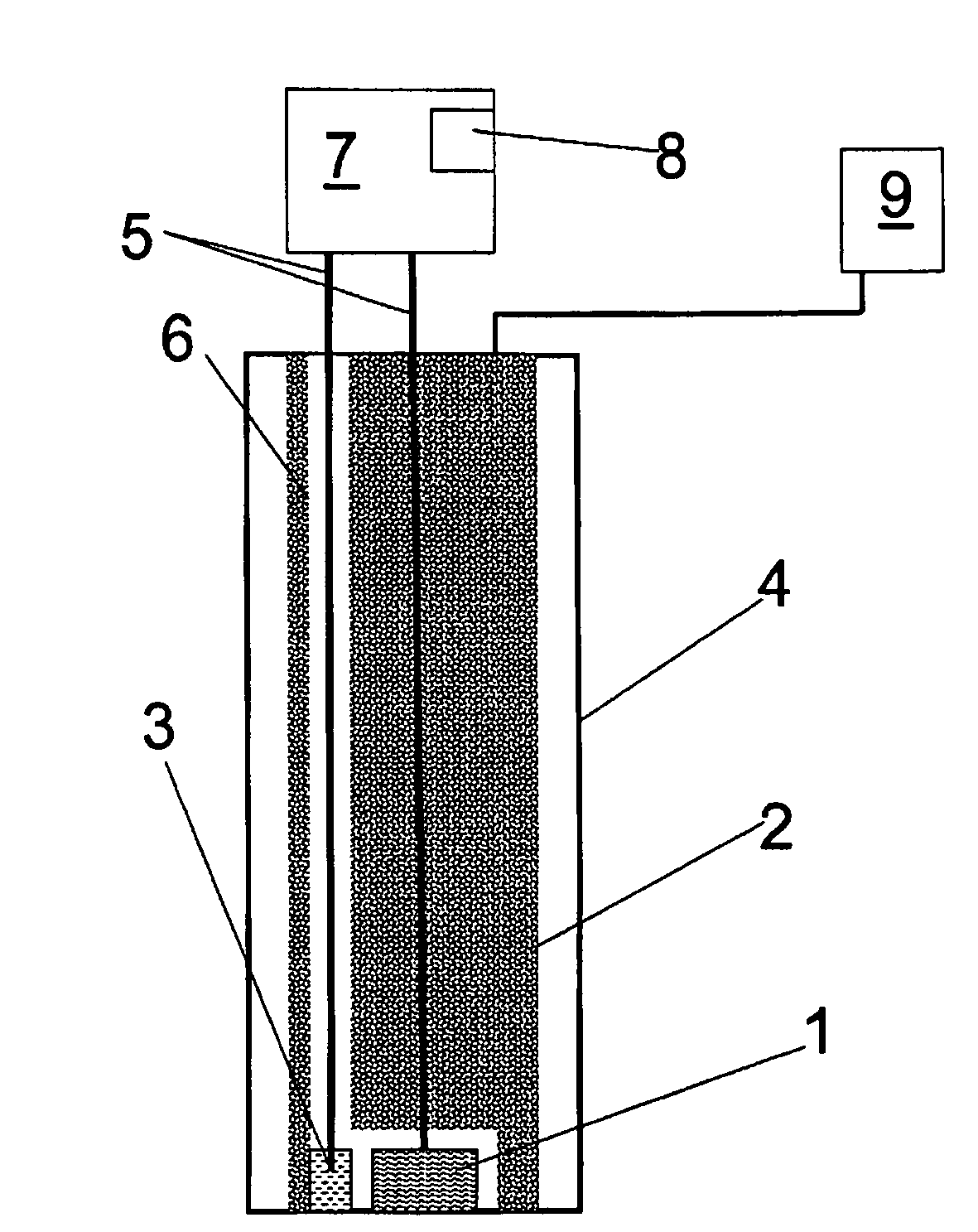

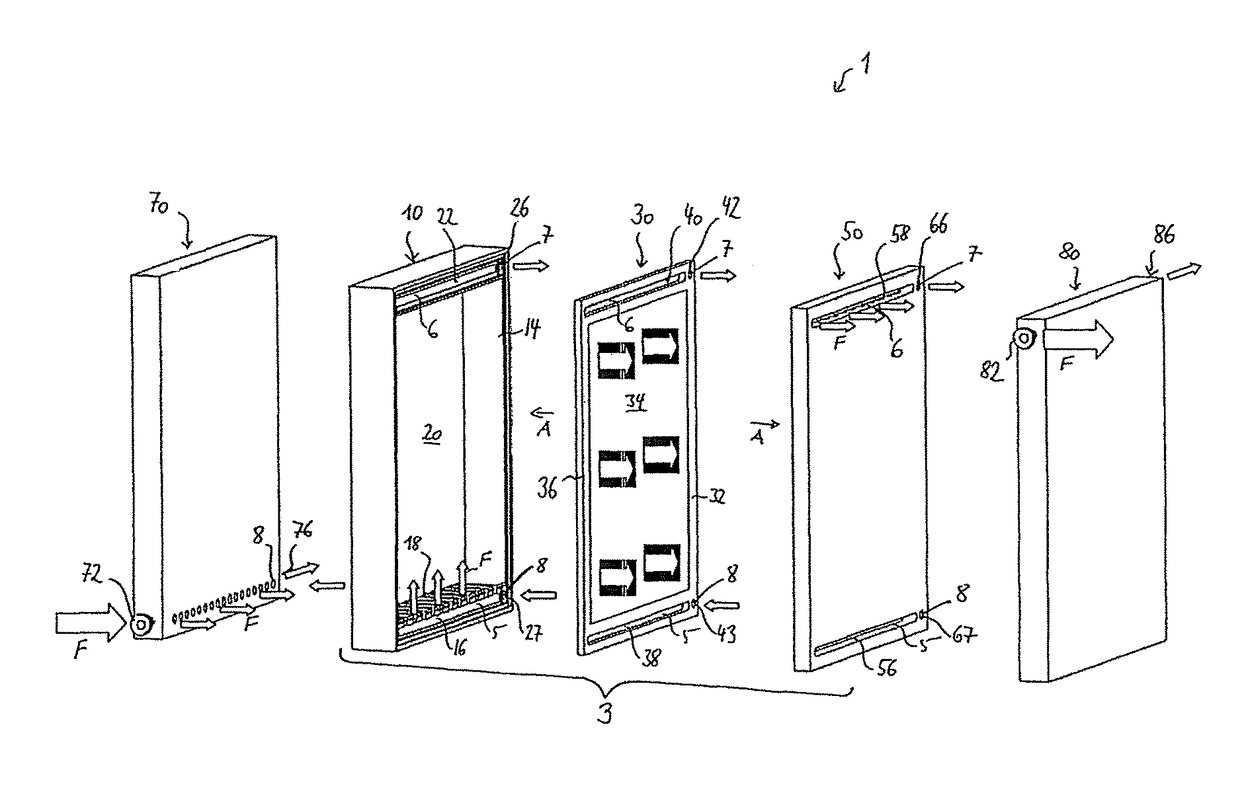

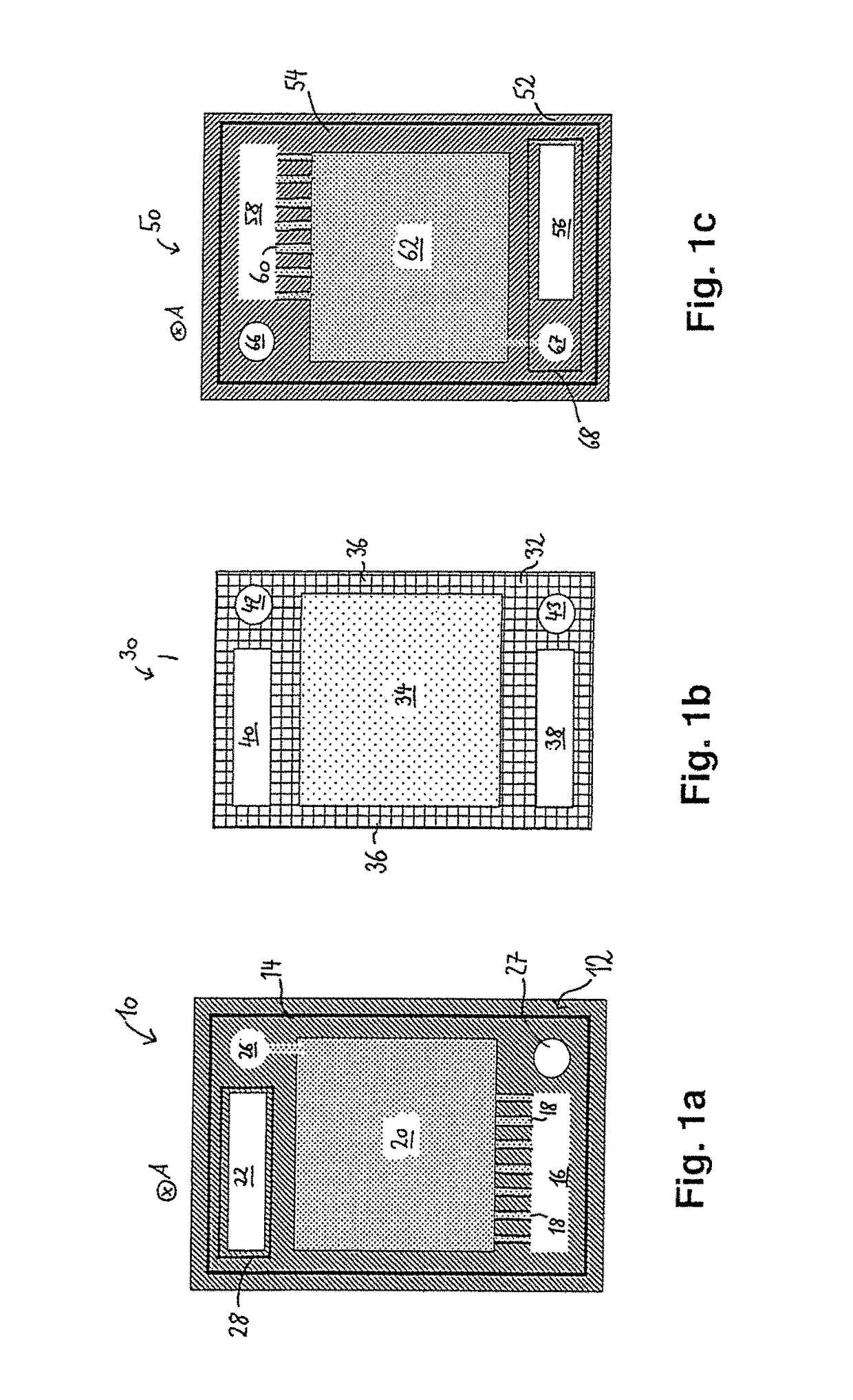

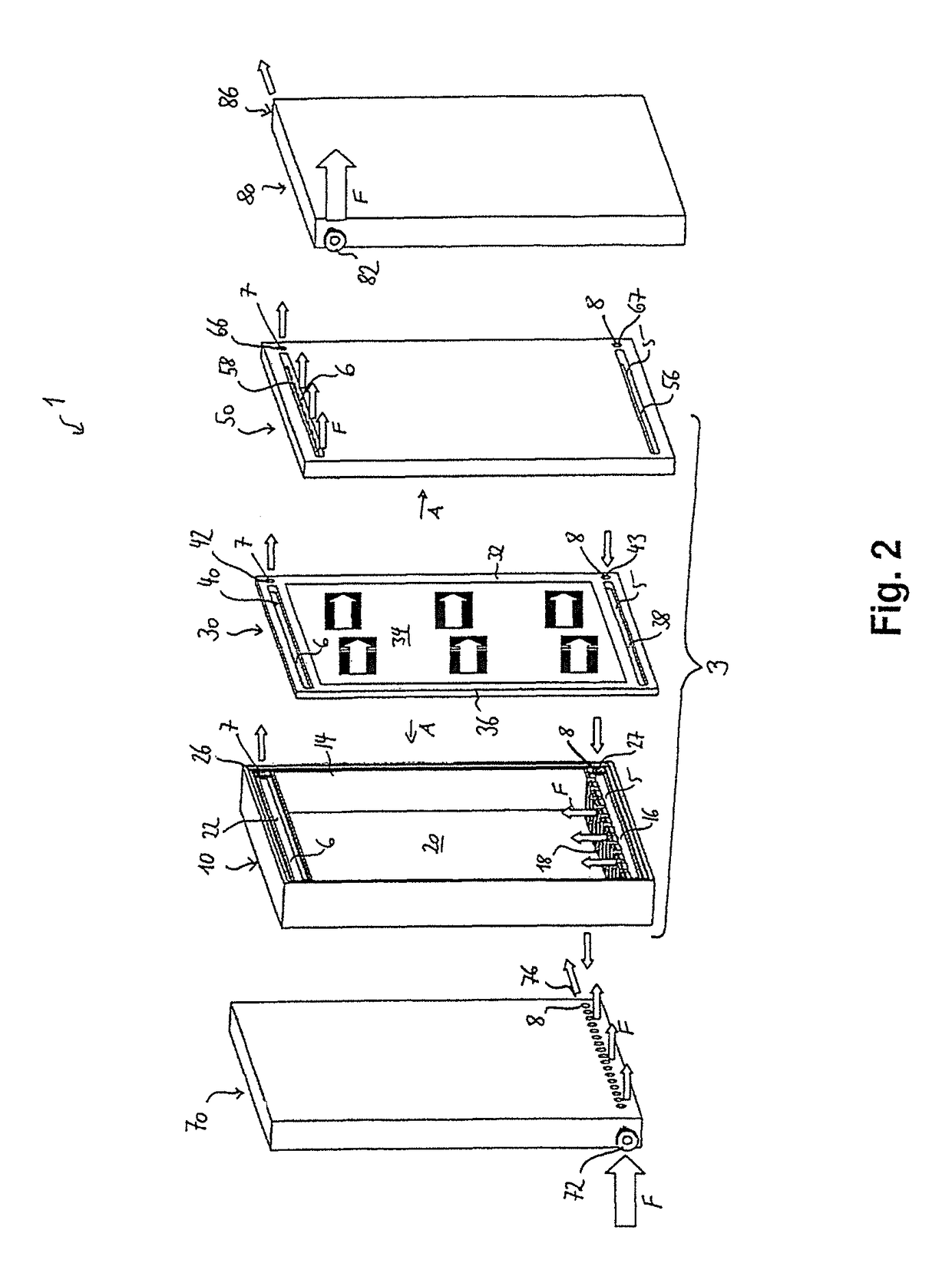

Filter module and modular filter system

ActiveUS20150001147A1Avoid contaminationAvoid damageSemi-permeable membranesMembranesFilter mediaFilter system

One aspect of the invention relates to a filter module comprising: —a filter element having at least one filter medium which separates a filtrate side and a retentate side of the filter element from one another, and having a filter medium holder to which the filter medium is attached and which has at least one holder intake channel and at least one holder discharge channel, —a first filter cartridge part having at least one first cartridge intake channel and at least one first cartridge discharge channel, —a second filter cartridge channel having at least one second cartridge intake channel and at least one second cartridge discharge channel, wherein the filter medium holder is arranged in an arrangement position between the first filter cartridge part and the second filter cartridge part in a fluid-tight manner, wherein the at least one holder intake channel has a fluid connection with the at least one first cartridge intake channel and the at least one second cartridge intake channel, in order to form a module intake channel, wherein the at least one holder discharge channel has a fluid connection with the at least one first cartridge discharge channel and the at least one second cartridge discharge channel, in order to form a module discharge channel, wherein the module intake channel has a fluid connection with the retentate side of the filter medium and wherein the module discharge channel has a fluid connection with the filtrate side of the filter medium, and a modular filter system.

Owner:SARTORIUS STEDIM BIOTECH GMBH

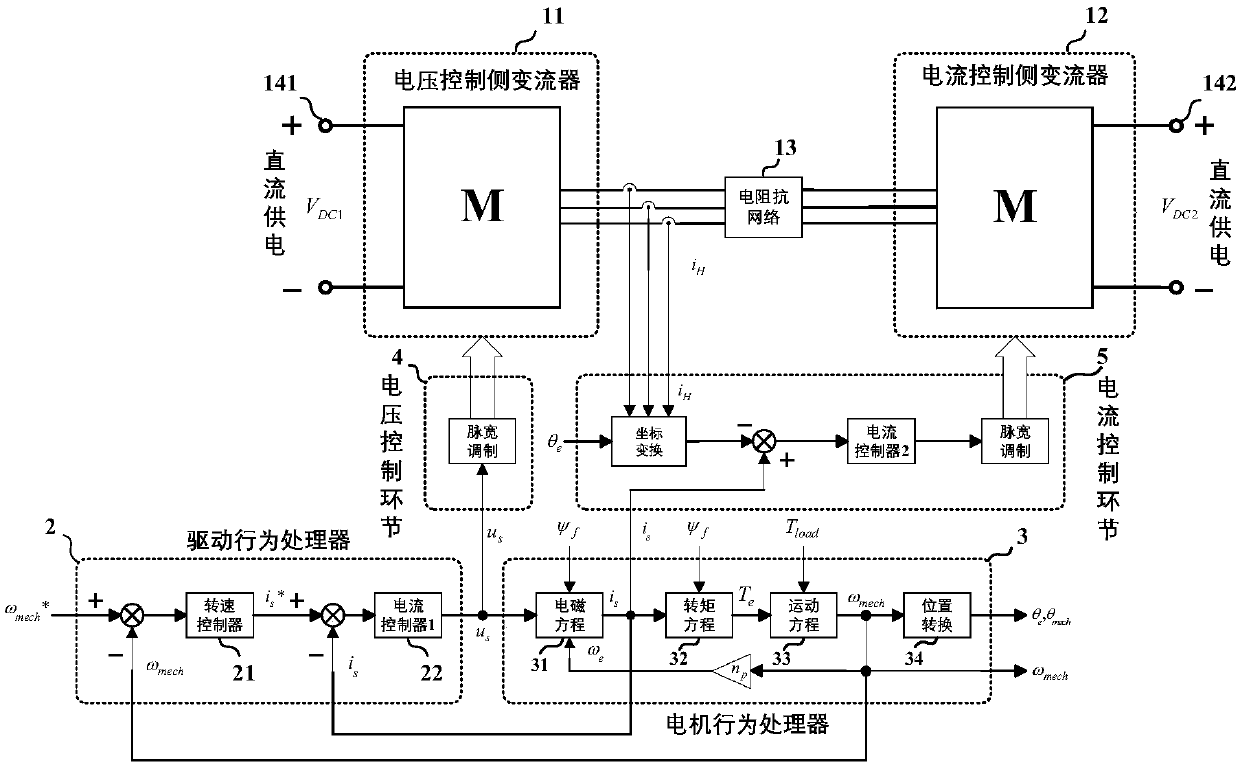

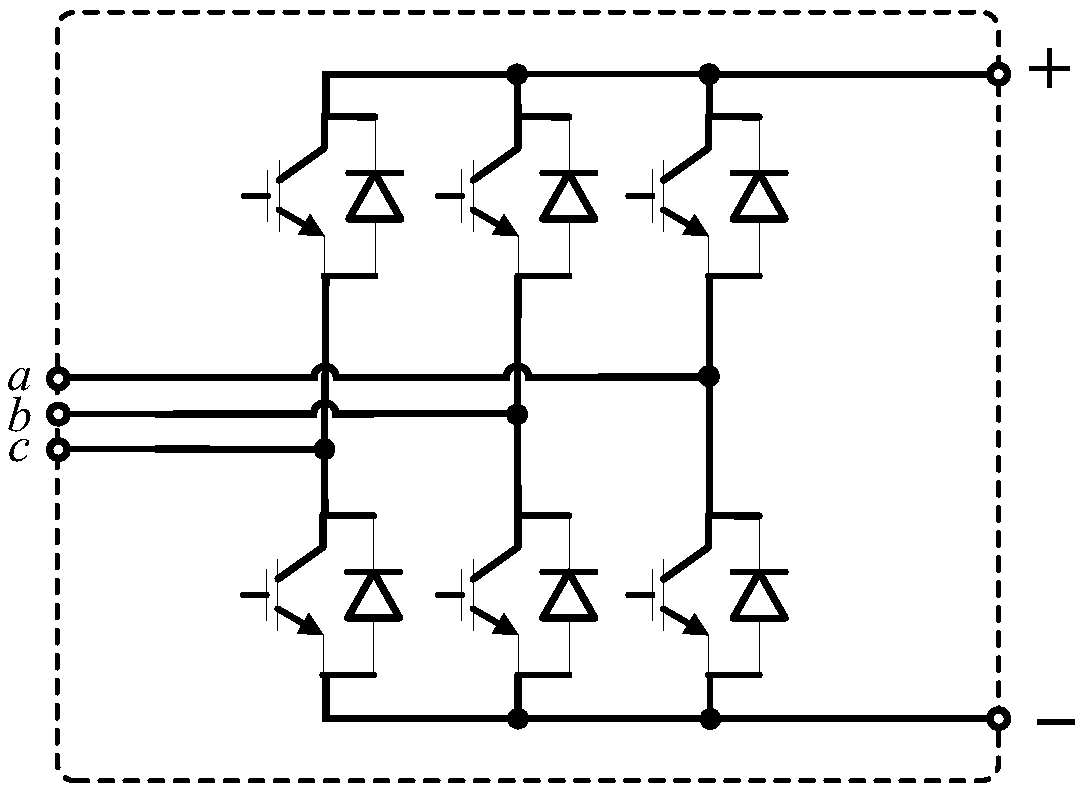

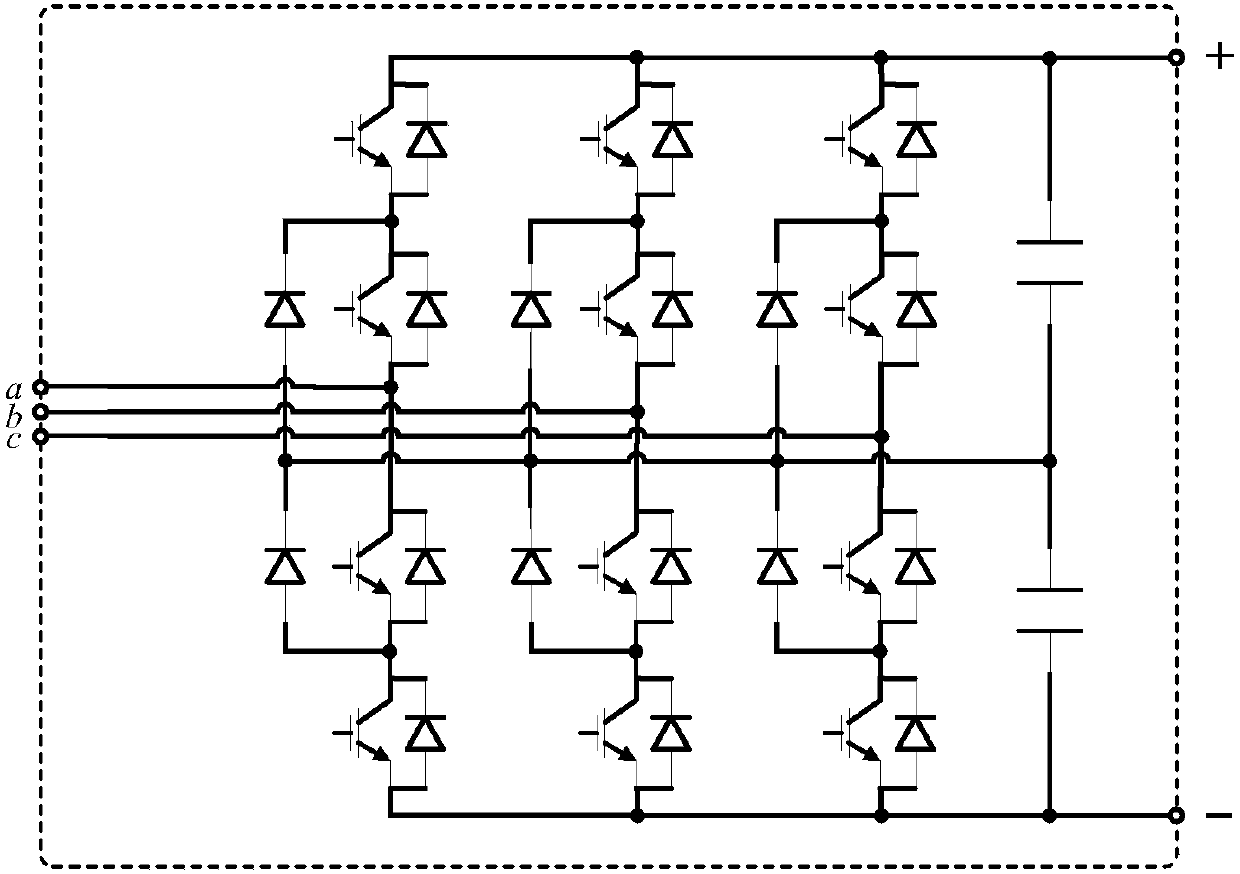

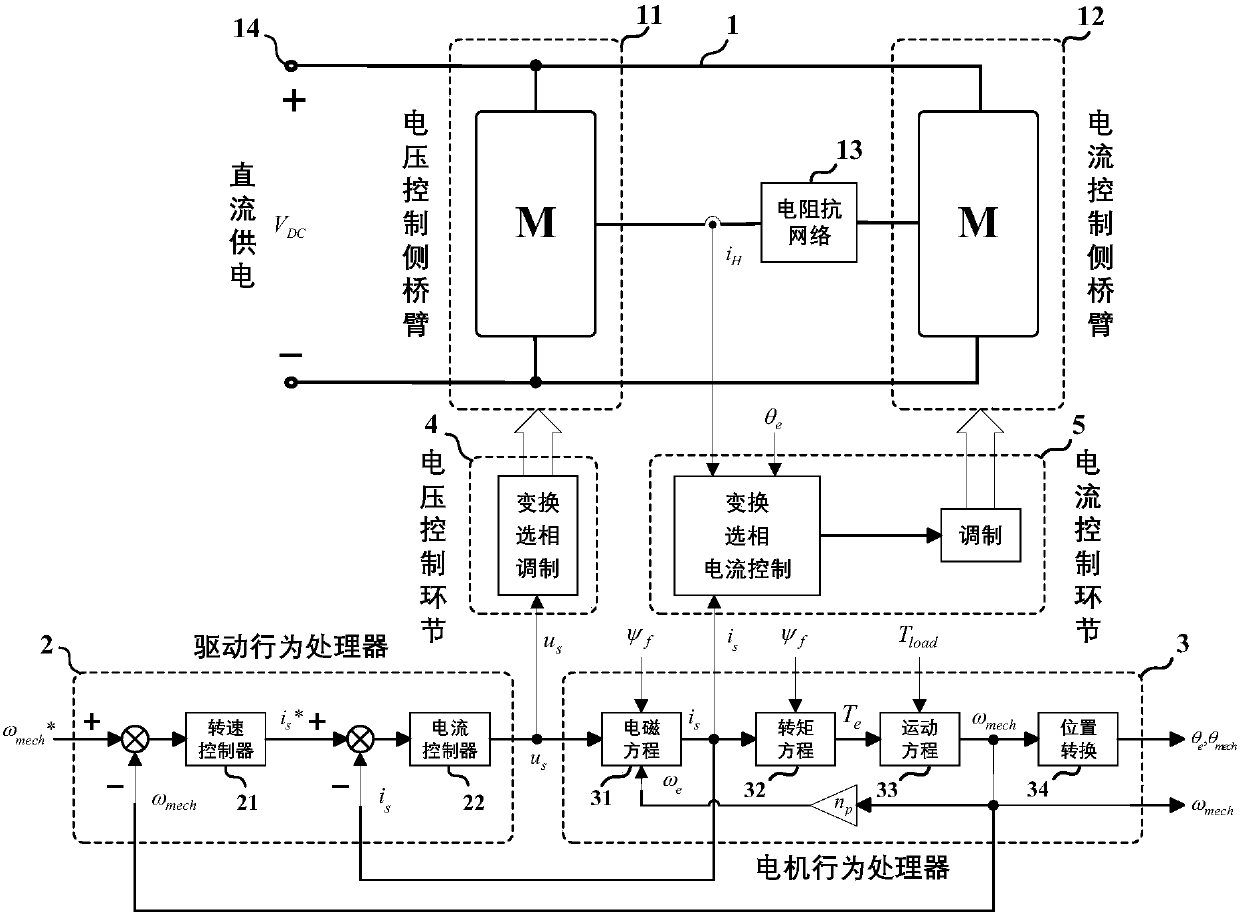

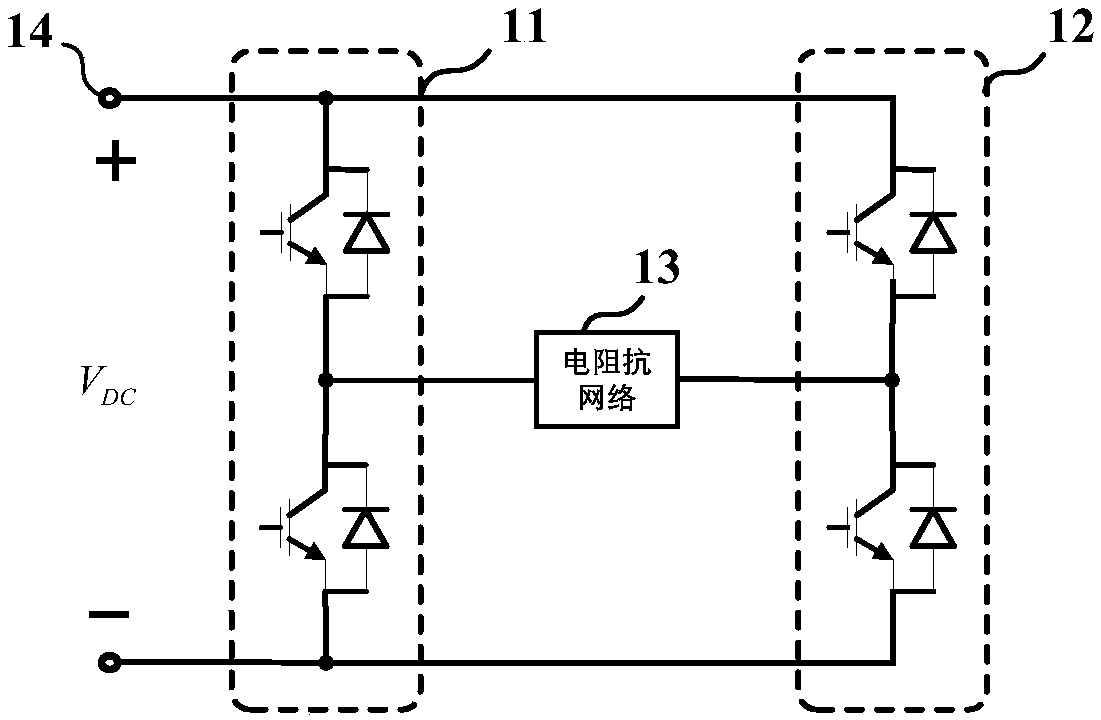

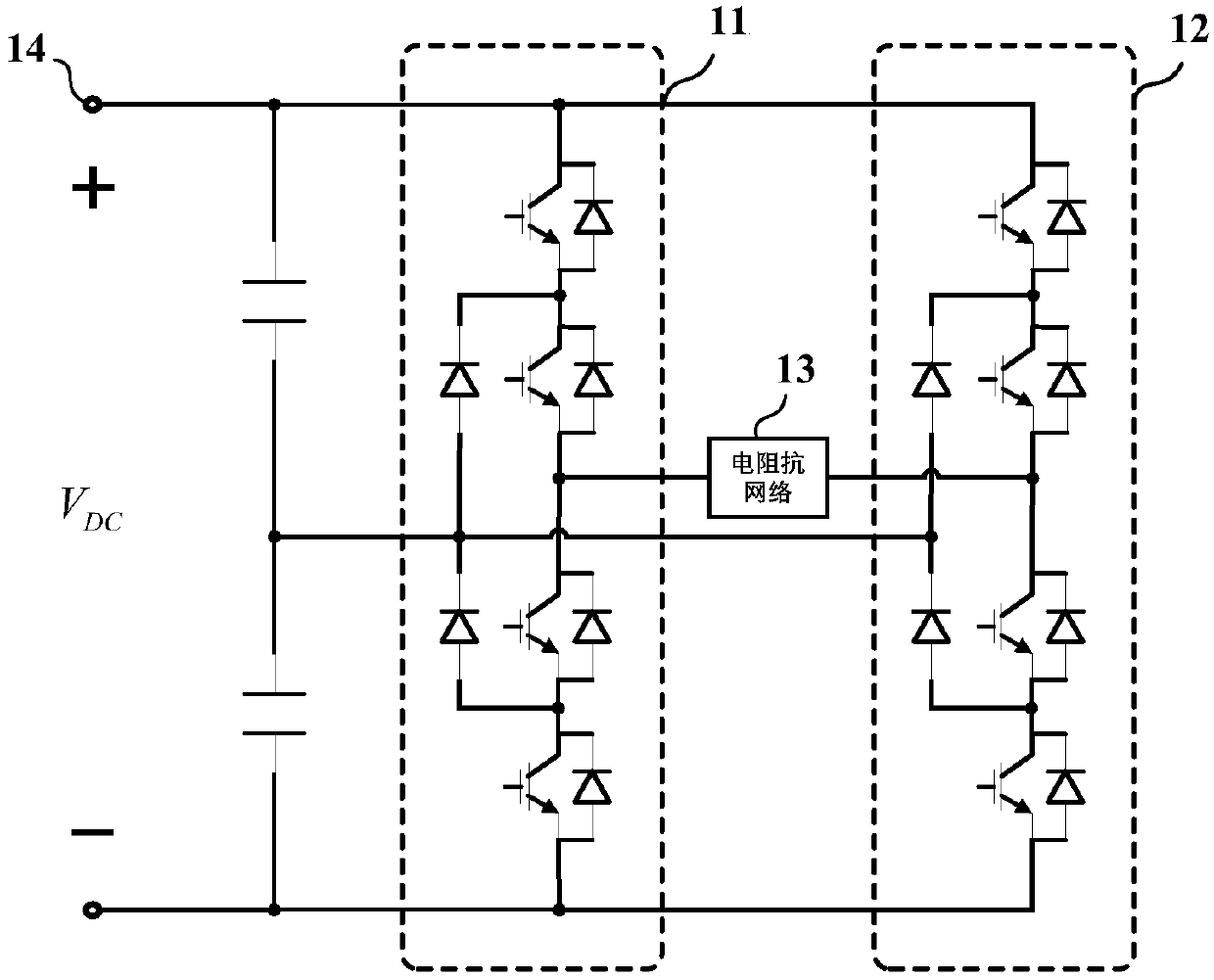

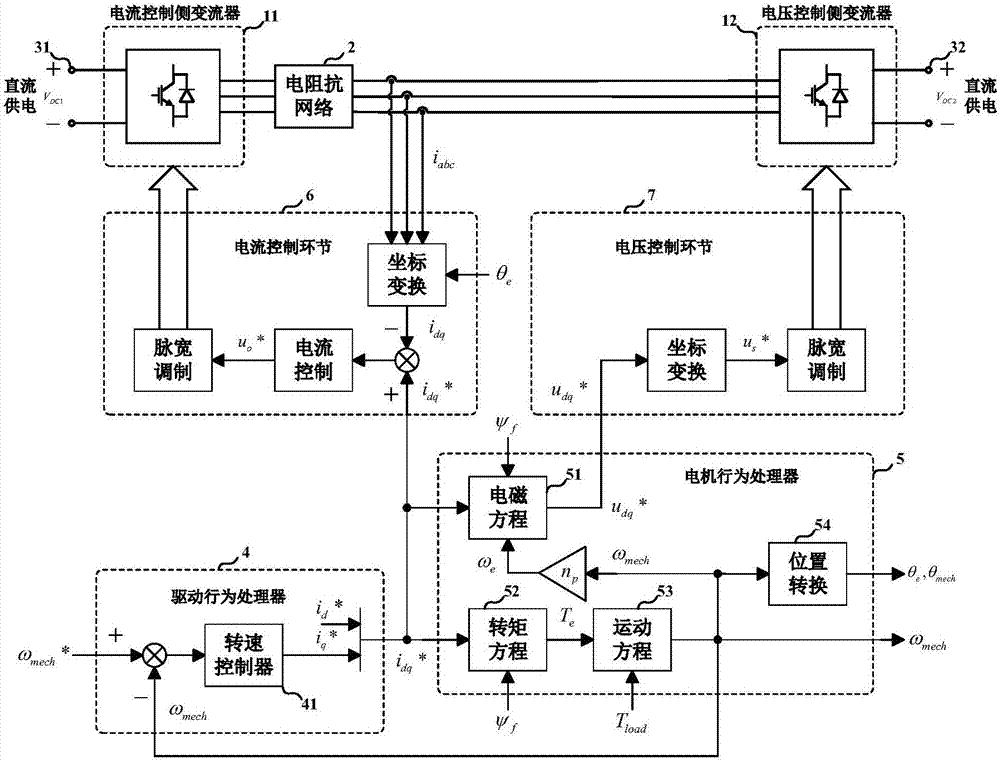

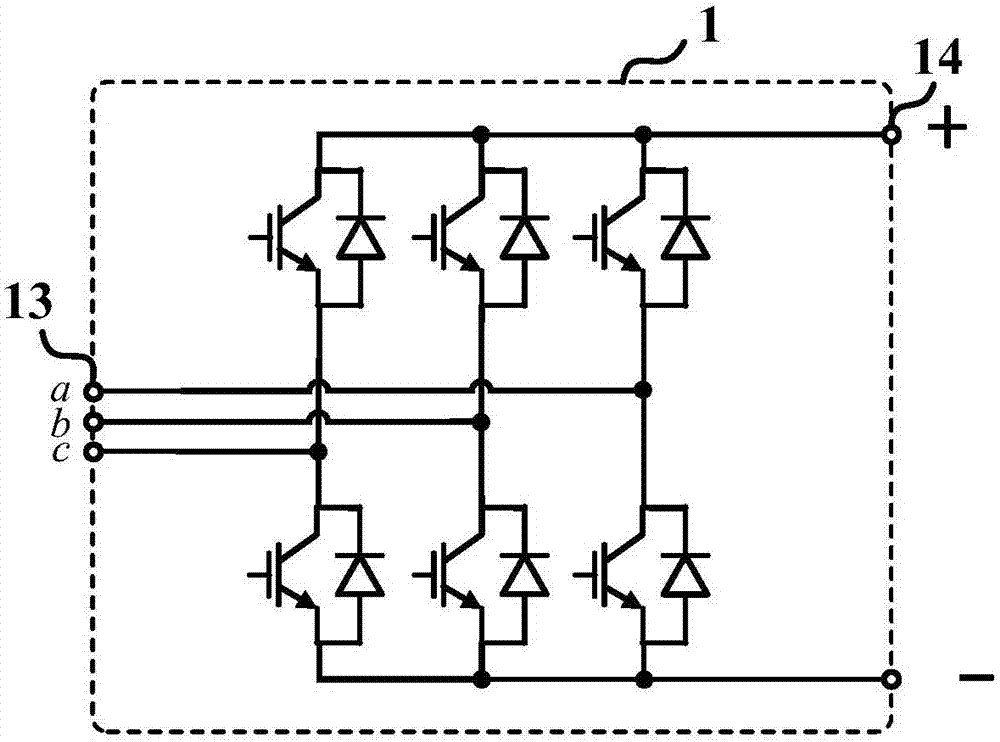

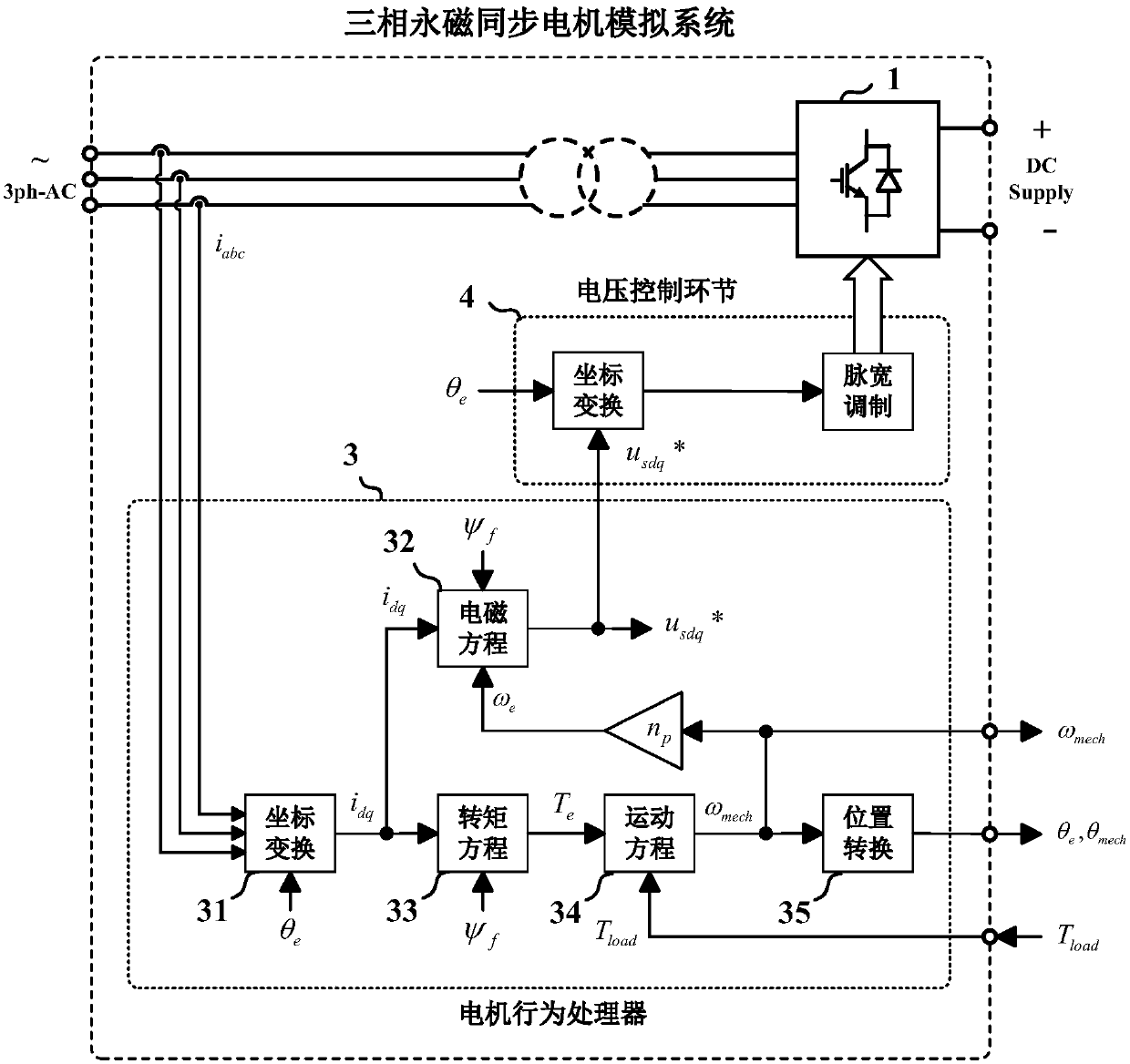

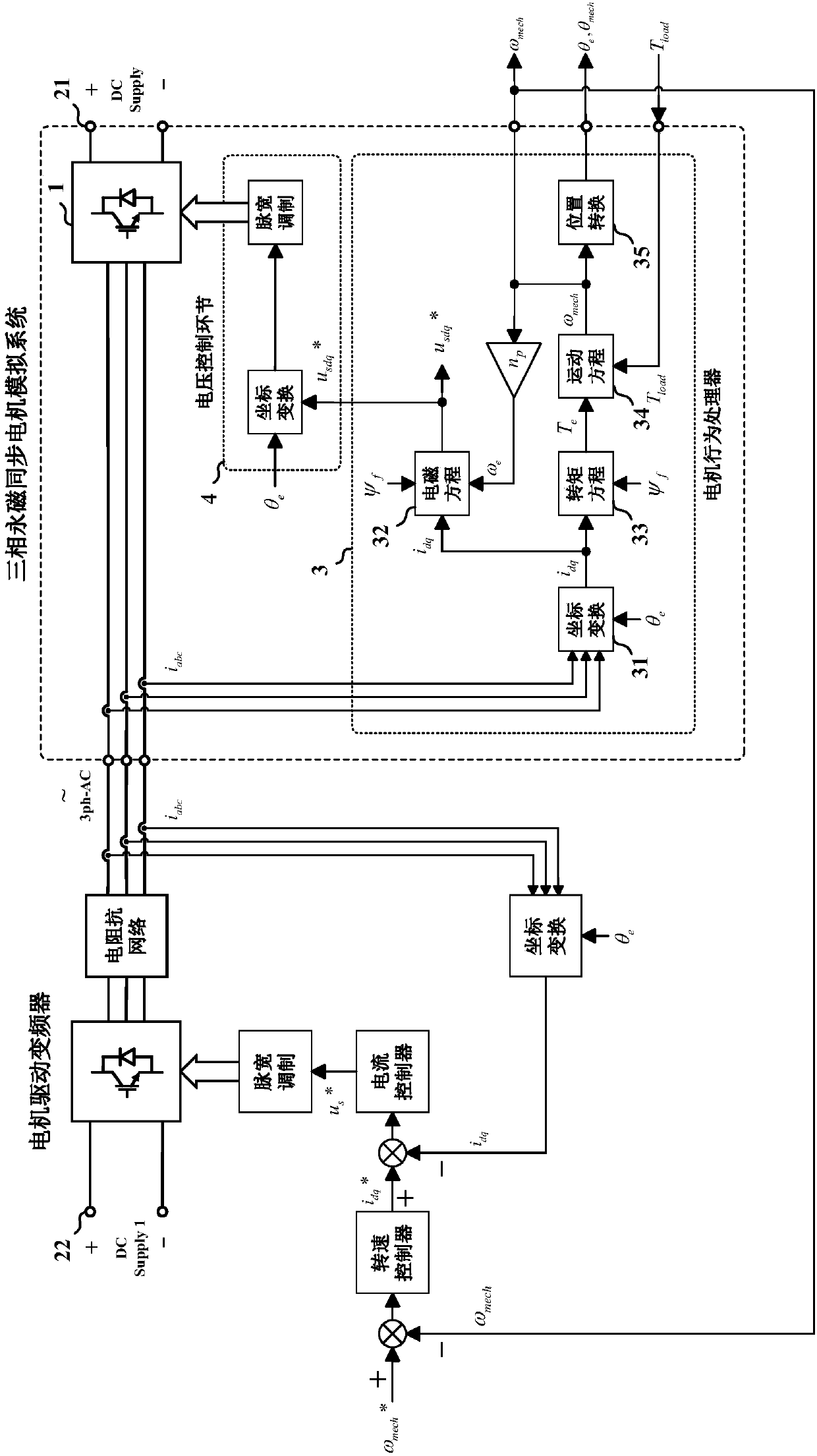

Three-phase simulator of current-response permanent magnet synchronous motor and drive system thereof

InactiveCN107645253ARealize simulationImprove reliabilitySingle motor speed/torque controlModelling/simulations for controlTest efficiencyElectric machine

The invention provides a three-phase simulator of a current-response permanent magnet synchronous motor and a drive system thereof. The three-phase simulator comprises at least two three-phase DC / AC converters, an electrical impedance network, a direct current power supply, a drive behavior processor, a motor behavior processor, a voltage control link and a current control link. Each three-phase DC / AC converter is used to simulate the working status of the permanent magnet synchronous motor and the drive system thereof at the circuit level. The drive behavior processor is used to simulate theelectrical characteristics of the drive system. The motor behavior processor is used to simulate the electrical and mechanical behavior characteristics of the permanent magnet synchronous motor. According to the invention, the simulator can simulate voltage applied to the three-phase permanent magnet synchronous motor port by the drive system and the current response of the permanent magnet synchronous motor to the voltage, so as to simulate the dynamic and static electrical and mechanical behaviors of the permanent magnet synchronous motor and the drive system thereof; the simulator can realize all-electric experiment and test of the motor and the drive system thereof; the test cost is saved; and the test efficiency and safety are improved.

Owner:SHANGHAI JIAO TONG UNIV

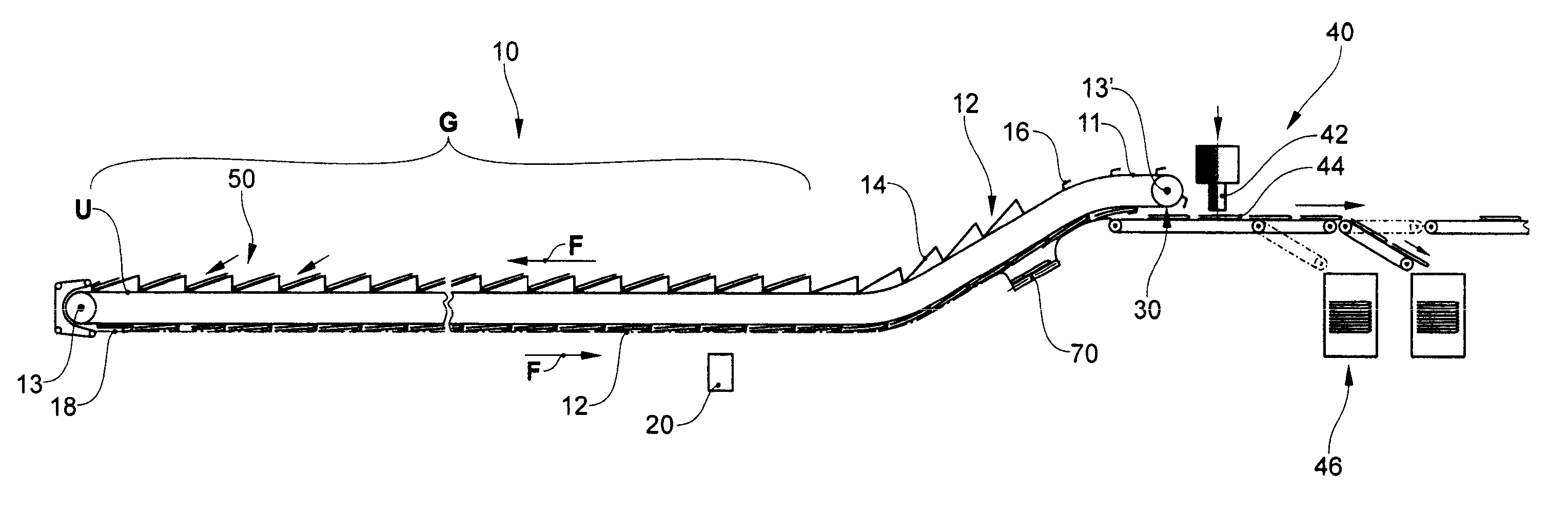

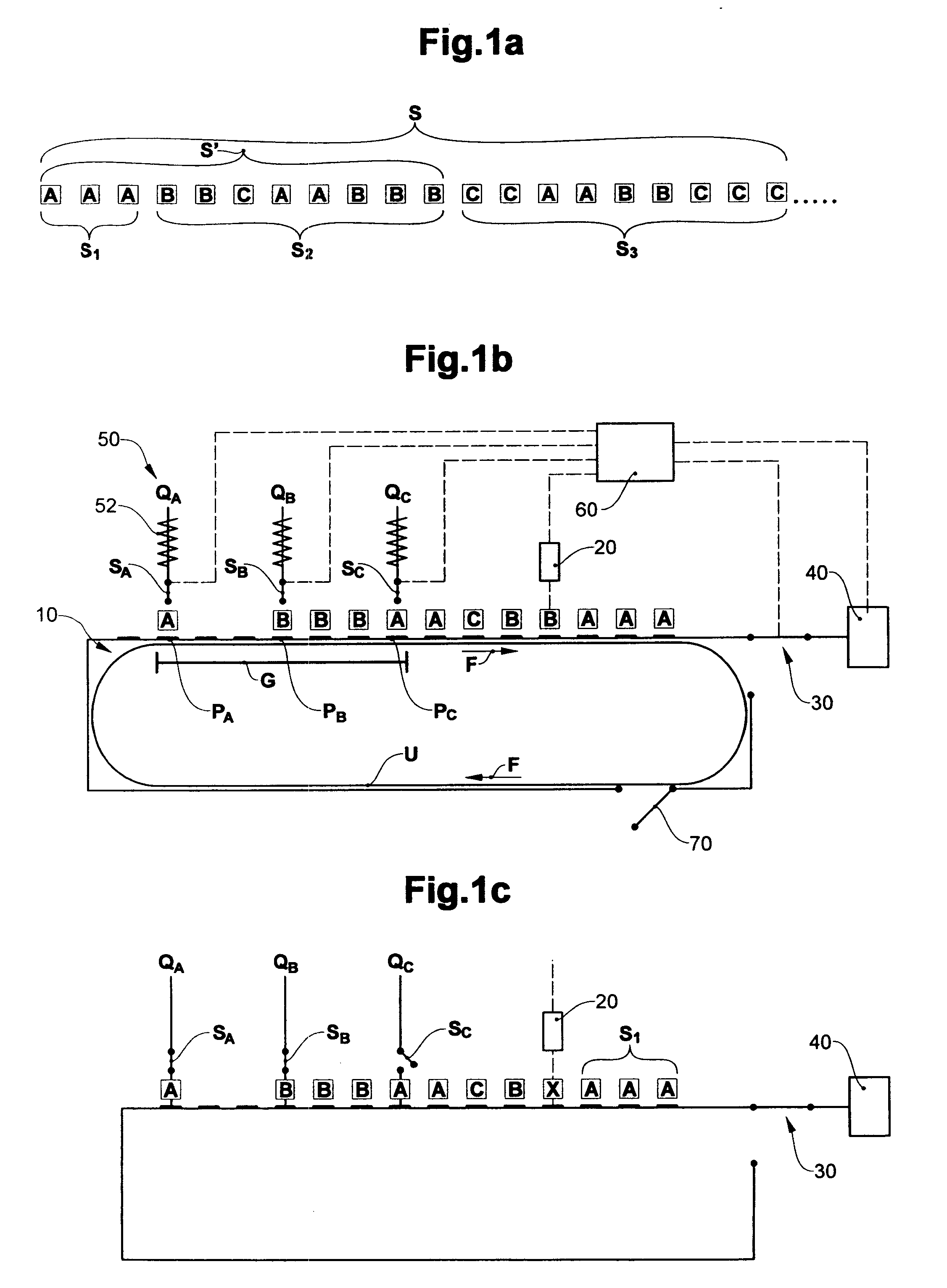

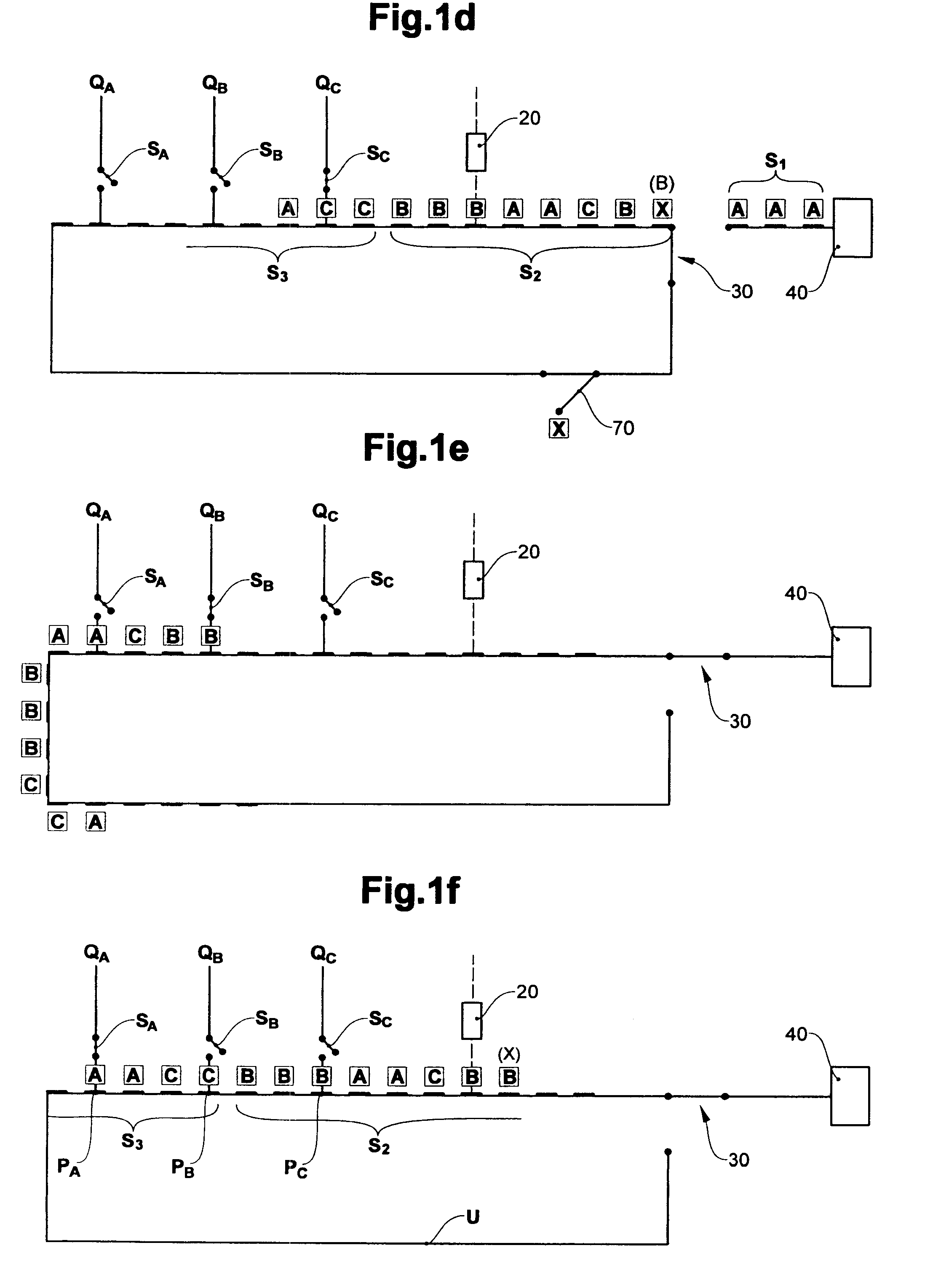

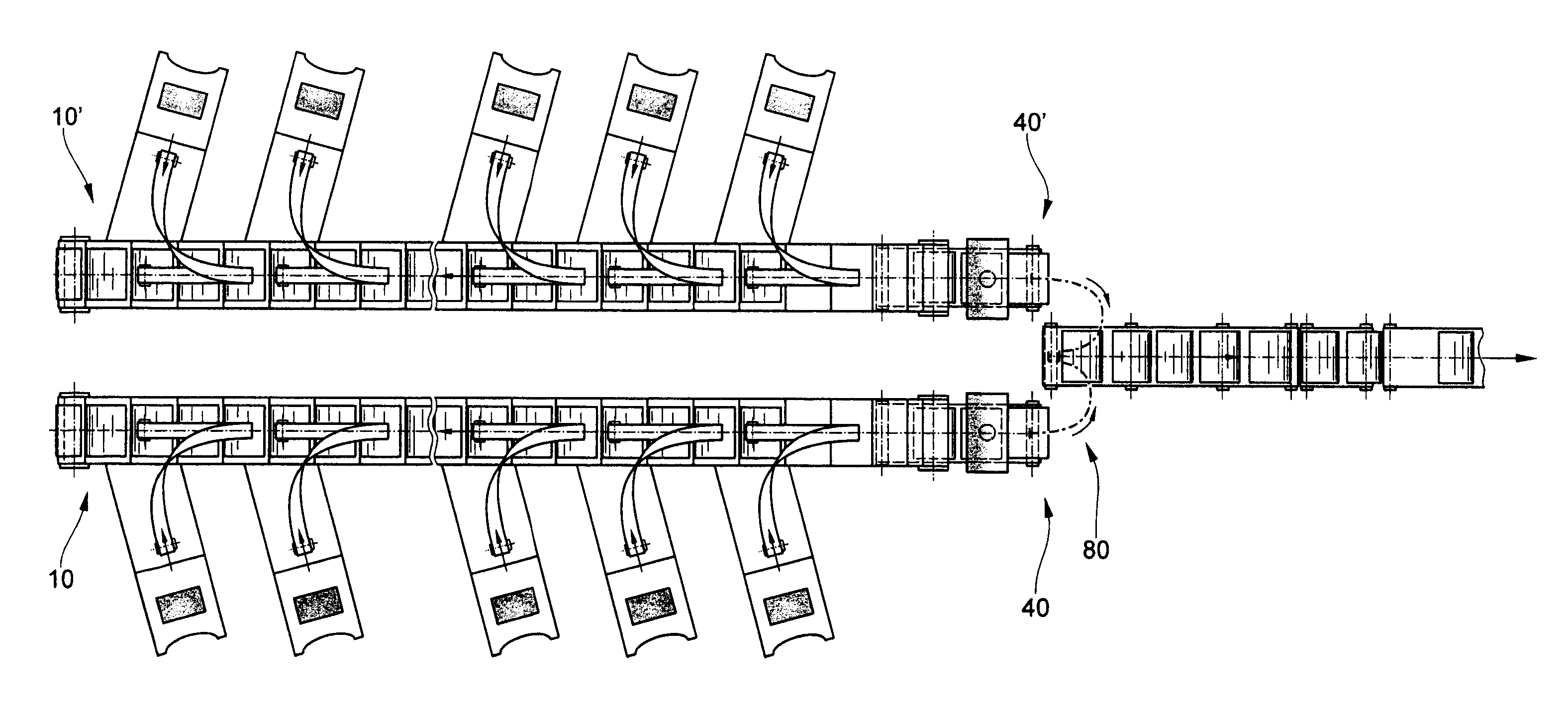

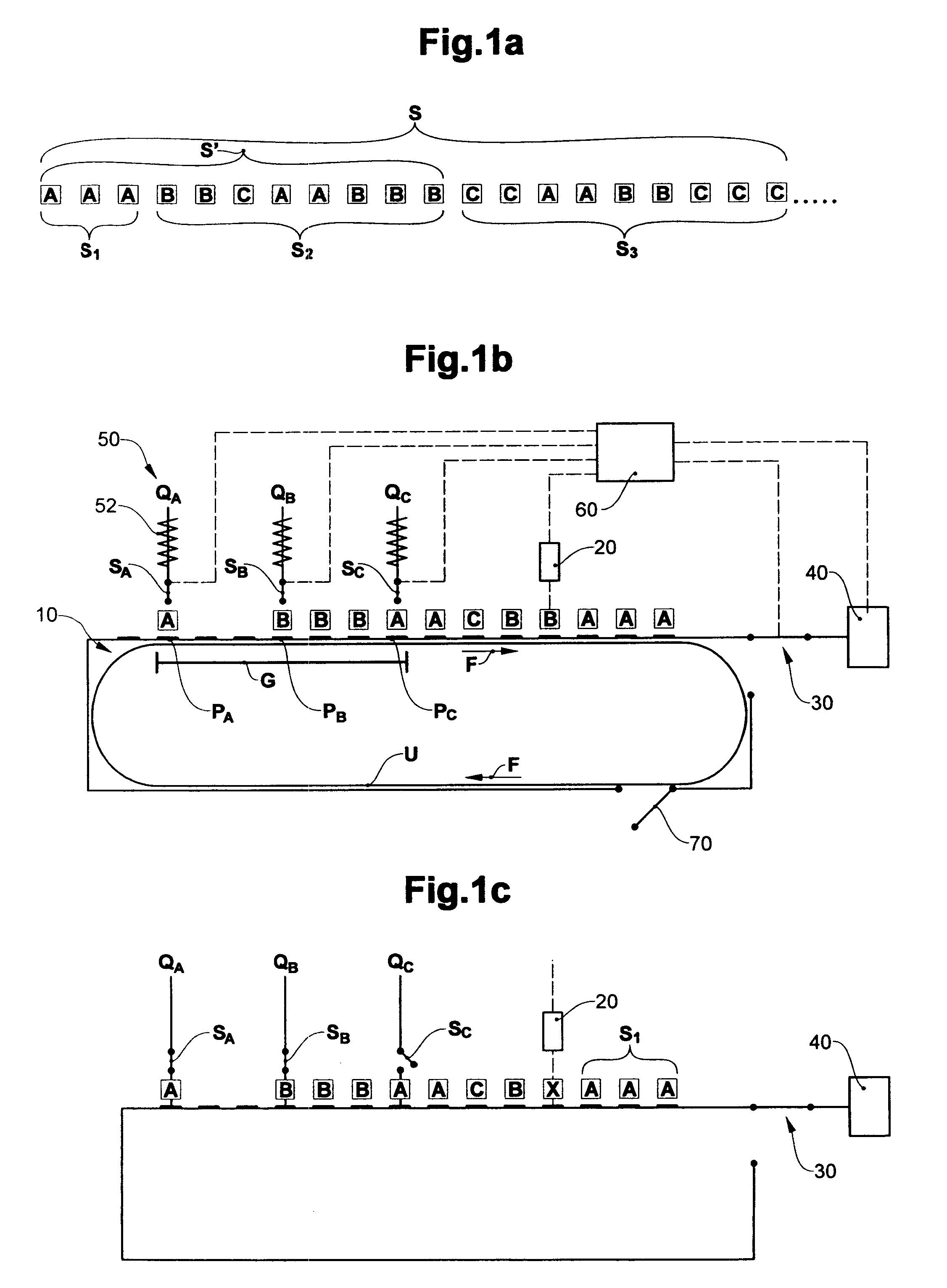

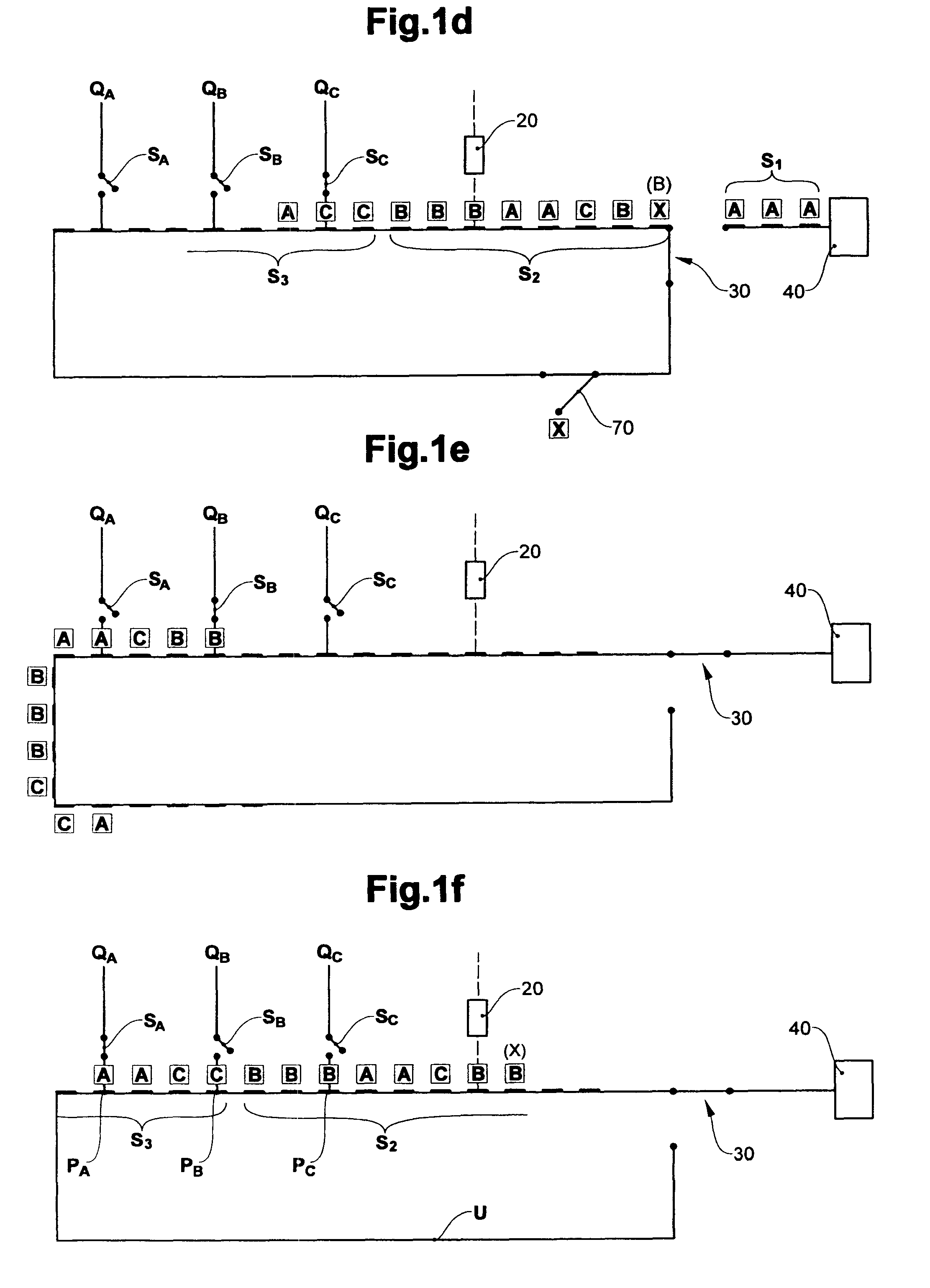

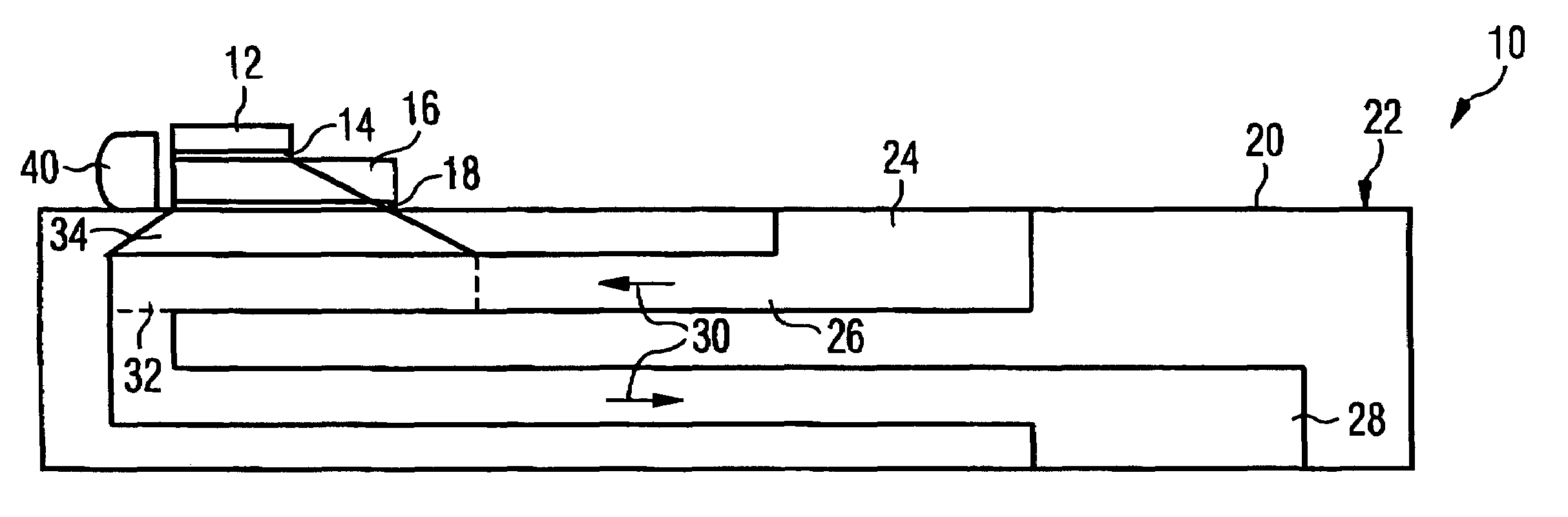

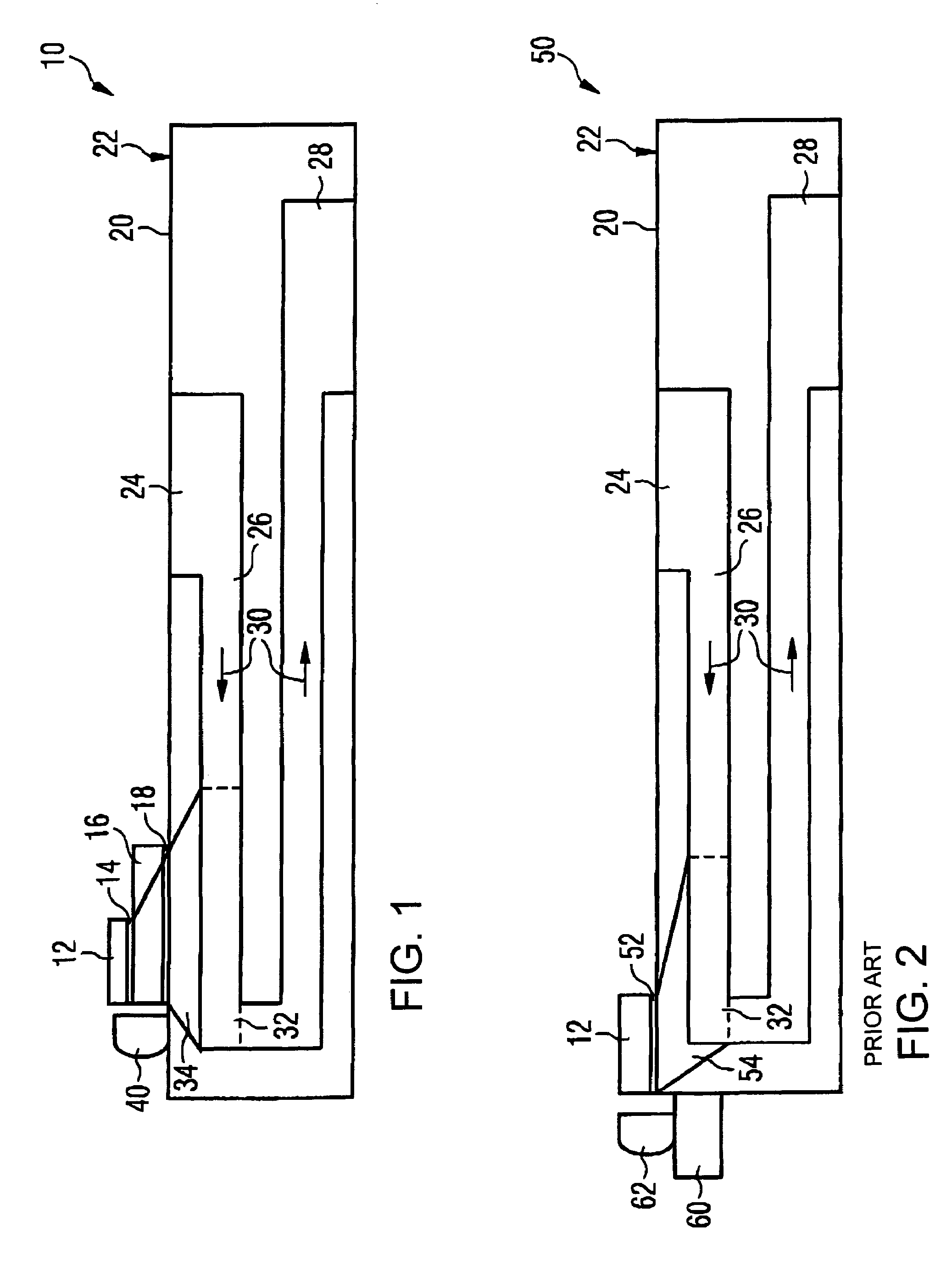

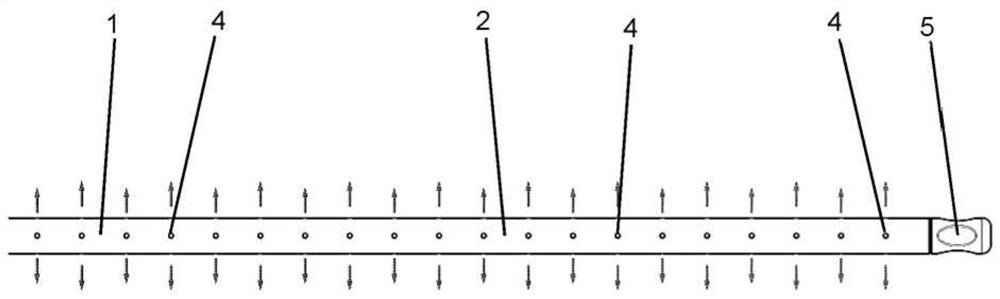

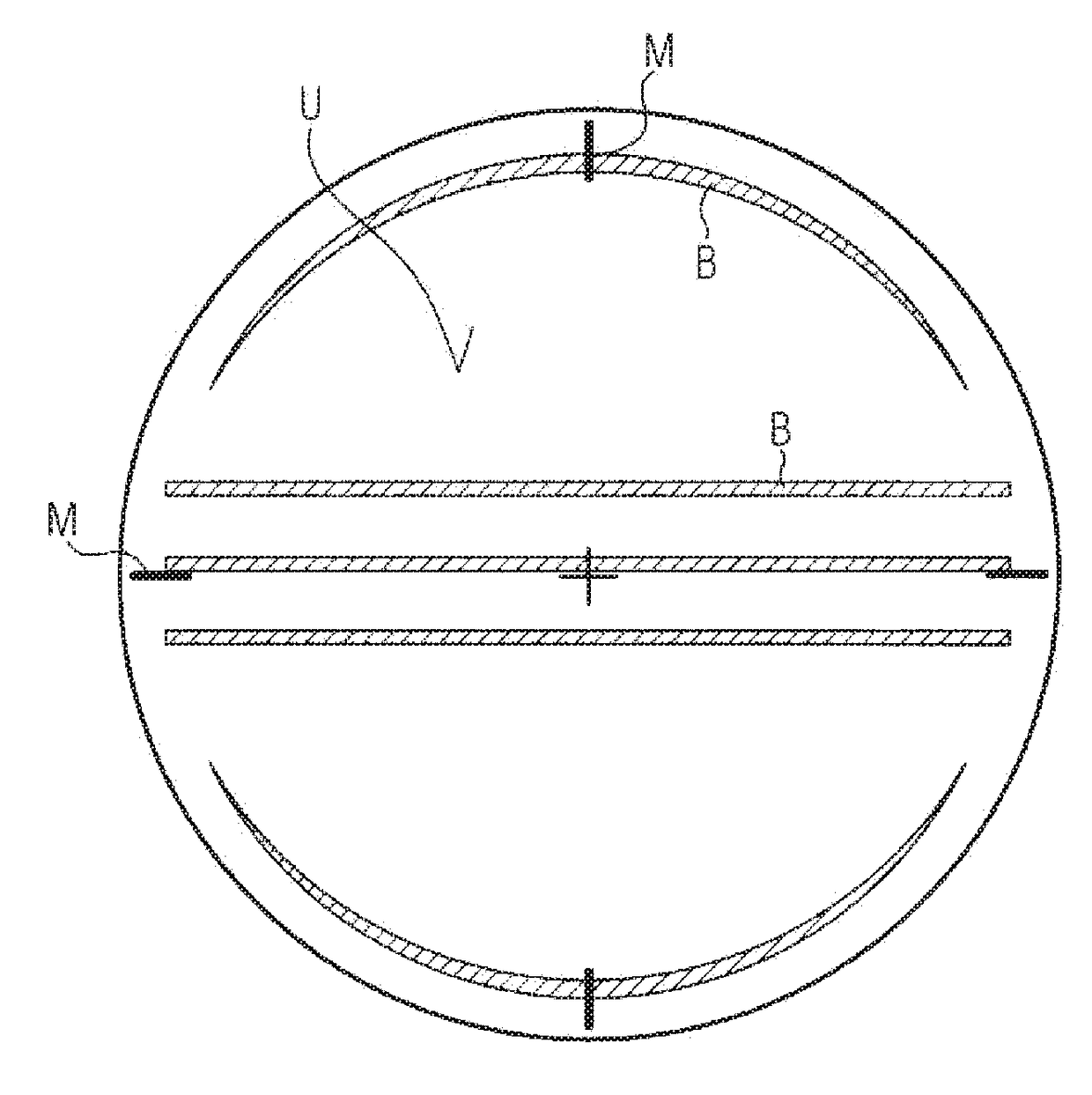

Method and device for creating a flow of flat products in a predefined sequence

InactiveUS20090250311A1Avoid disadvantagesAccurate sortingDigital data processing detailsFunction indicatorsEngineeringMechanical engineering

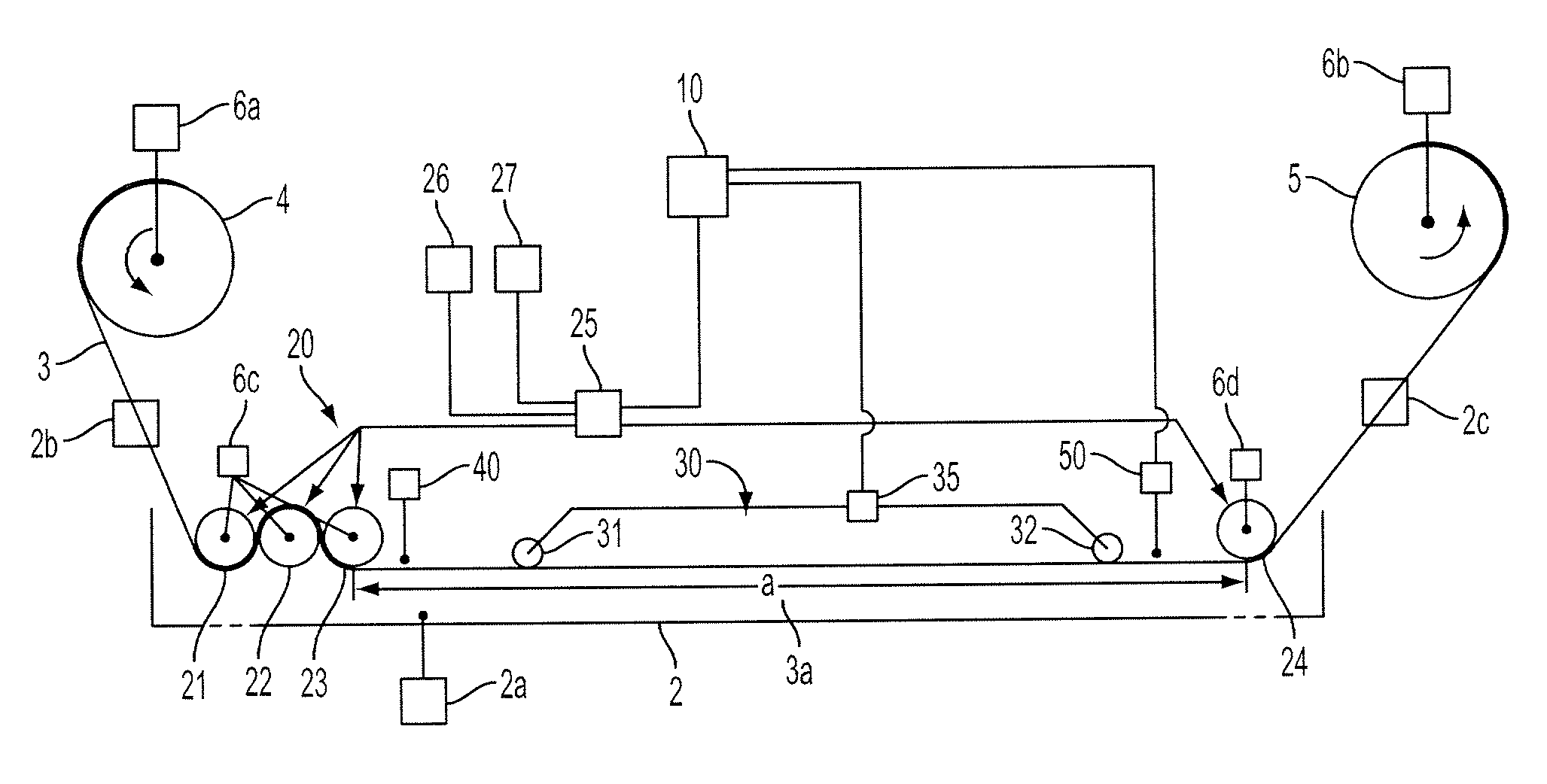

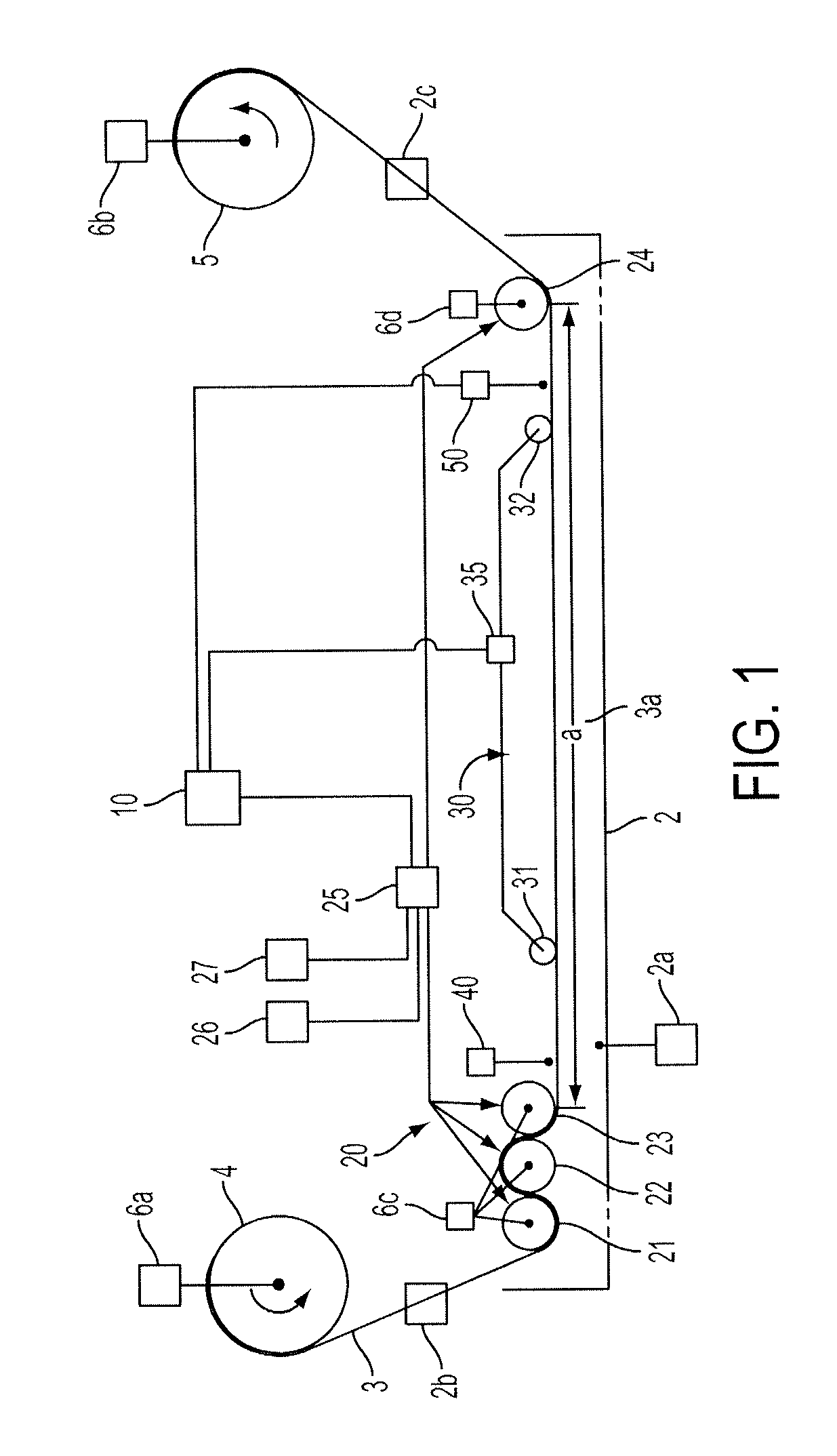

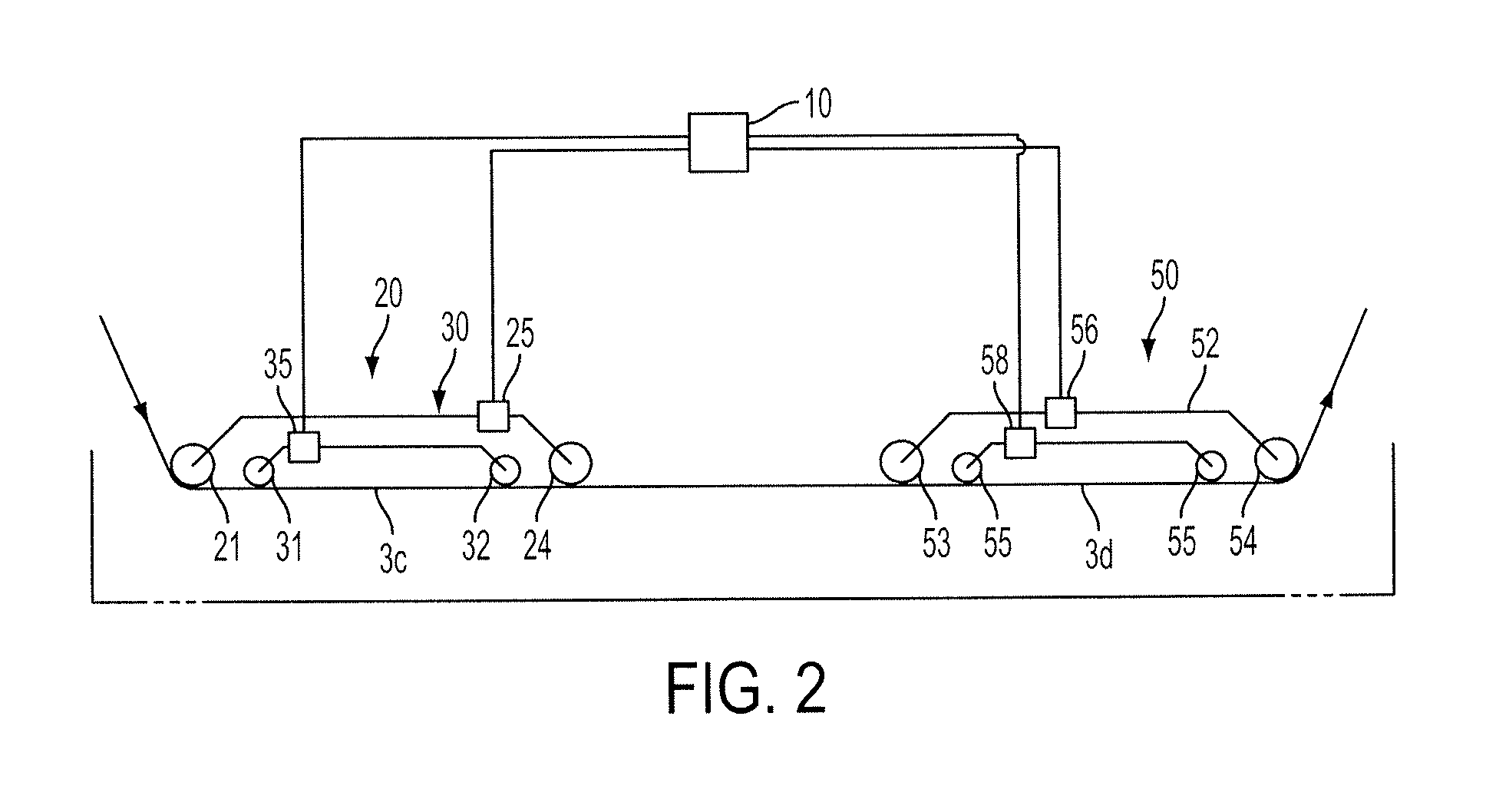

The invention relates to a method and to a device for creating a product flow according to a predefined sequence (S). The products (A, B, C) are fed from different feed flows of a grouping path (G) and there, according to the sequence (S), are deposited onto a conveyor (10,10) with a closed revolving path (U). According to the invention a repair function is realised in which the products (A, B, C) are then only transferred from the conveyor to a further-processing station if the sequence (S) is correct and all products (A, B, C) are present with the desired quality. Otherwise, the products (A, B, C) are led by the continuously operated conveyors (A, B, C) back to the grouping path (G). Here, the error is corrected by way of the deposition of the missing product (A, B, C), whilst the deposition of new products (A, B, C) is interrupted. For error correction, one may previously provide a discharge of a defect or wrong product (A, B, C). After the error correction, the creation of the product flow is continued by way of the sequentially correct deposition of further products (A, B, C). The method permits the error-free and sequentially correct creation of infinitely long and infinitely assembled sequences (S).

Owner:FERAG AG

Method and device for creating a flow of flat products in a predefined sequence

InactiveUS7845485B2Accurate sortingCorrection errorDigital data processing detailsFunction indicatorsEngineeringMechanical engineering

The invention relates to a method and to a device for creating a product flow according to a predefined sequence (S). The products (A, B, C) are fed from different feed flows of a grouping path (G) and there, according to the sequence (S), are deposited onto a conveyor (10, 10) with a closed revolving path (U). According to the invention a repair function is realised in which the products (A, B, C) are then only transferred from the conveyor to a further-processing station if the sequence (S) is correct and all products (A, B, C) are present with the desired quality. Otherwise, the products (A, B, C) are led by the continuously operated conveyors (A, B, C) back to the grouping path (G). Here, the error is corrected by way of the deposition of the missing product (A, B, C), whilst the deposition of new products (A, B, C) is interrupted. For error correction, one may previously provide a discharge of a defect or wrong product (A, B, C). After the error correction, the creation of the product flow is continued by way of the sequentially correct deposition of further products (A, B, C). The method permits the error-free and sequentially correct creation of infinitely long and infinitely assembled sequences (S).

Owner:FERAG AG

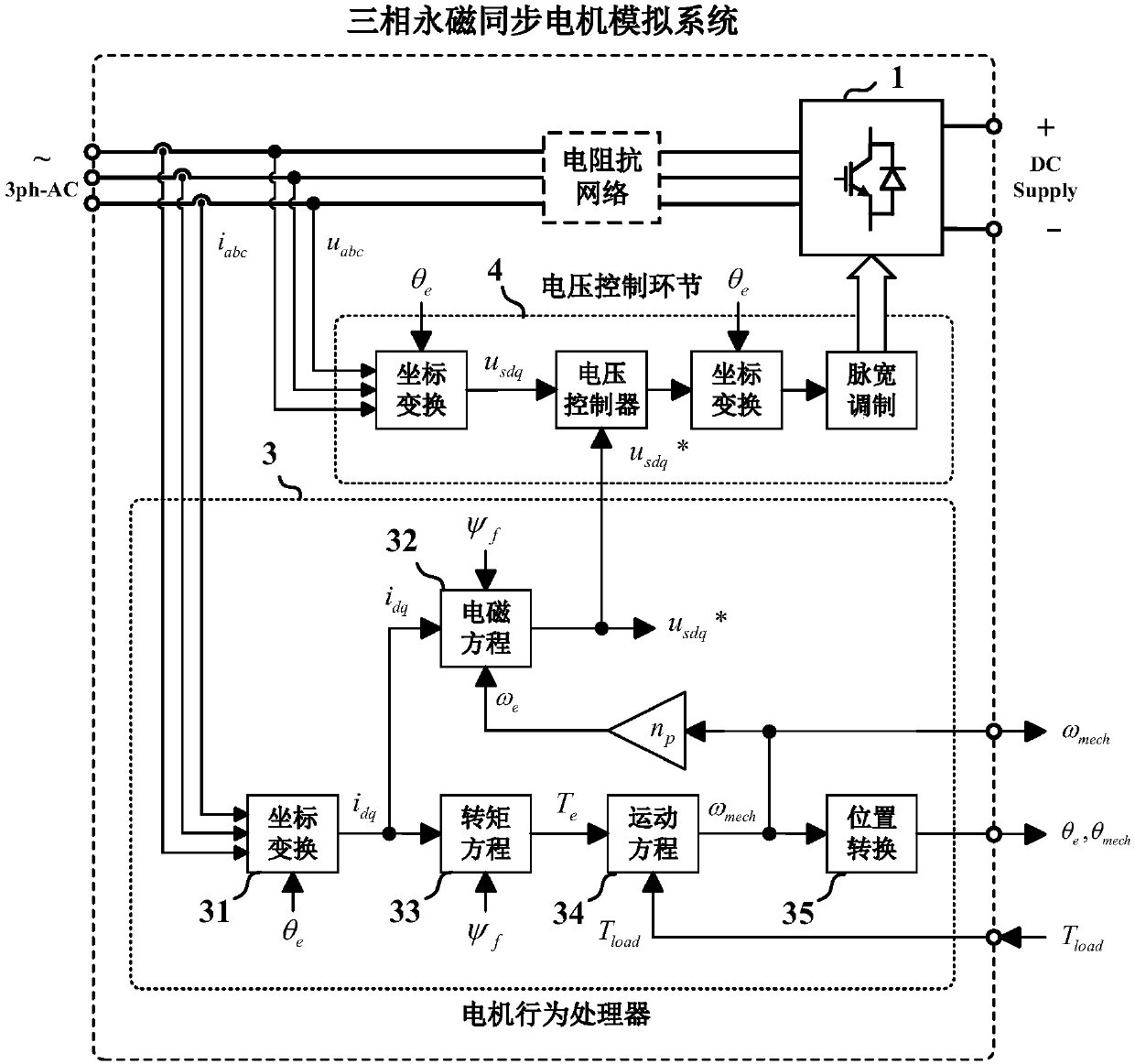

Single-phase simulator of current-responsive permanent magnet synchronous motor and driving system thereof

ActiveCN107834919ASimplify complexityRealize simulationVector control systemsSingle motor speed/torque controlTest efficiencyElectricity

The invention provides a single-phase simulator of a current-responsive permanent magnet synchronous motor and a driving system thereof. The main components of the single-phase simulator comprise a single-phase H-bridge circuit, a driving behavior processor, a motor behavior processor, a voltage control link and a current control link. The single-phase H-bridge circuit is used for simulating operating states of a permanent magnet synchronous motor and the driving system at a circuit level. The driving behavior processor is used for simulating electrical characteristics of the driving system. The motor behavior processor is used for simulating electrical and mechanical behavior characteristics of the permanent magnet synchronous motor. The single-phase simulator can simulate voltage added to a port of any phase of a three-phase or multi-phase permanent magnet synchronous motor by the driving system in the single-phase circuit and current response of the permanent magnet synchronous motor to the voltage, the simulation of dynamic and static electrical and mechanical behaviors of the permanent magnet synchronous motor and the driving system is realized, the full-electricity experiments and tests of the motor and the driving system can be realized by the simulator, the test cost is saved, and the test efficiency and safety are improved.

Owner:SHANGHAI JIAO TONG UNIV

Apparatus for measuring temperature

ActiveUS8231266B2Possible simplyAvoid mechanical loadThermometer detailsThermometers using material expansion/contactionTransmitterCooling Units

An apparatus for ascertaining and / or monitoring at least one temperature. The apparatus includes, according to a first variable, at least one temperature sensor, at least one reference temperature sensor and at least one heating / cooling unit, which is thermally coupled with the temperature sensor and with the reference temperature sensor. According to a second variant, the invention includes that at least one reference temperature sensor and the temperature sensor and the reference temperature sensor are embodied and placed in such a manner that they measure essentially the same temperature. At least one head transmitter is provided, which connects the temperature sensor and the reference temperature sensor with the head transmitter in such a manner that the head transmitter receives the data measured by the temperature sensor and the reference temperature sensor. At least one memory unit is provided, in which the measured data of the temperature sensor and the reference temperature sensor are storable.

Owner:EHNDRESS KHAUZER GMBKH KO KG

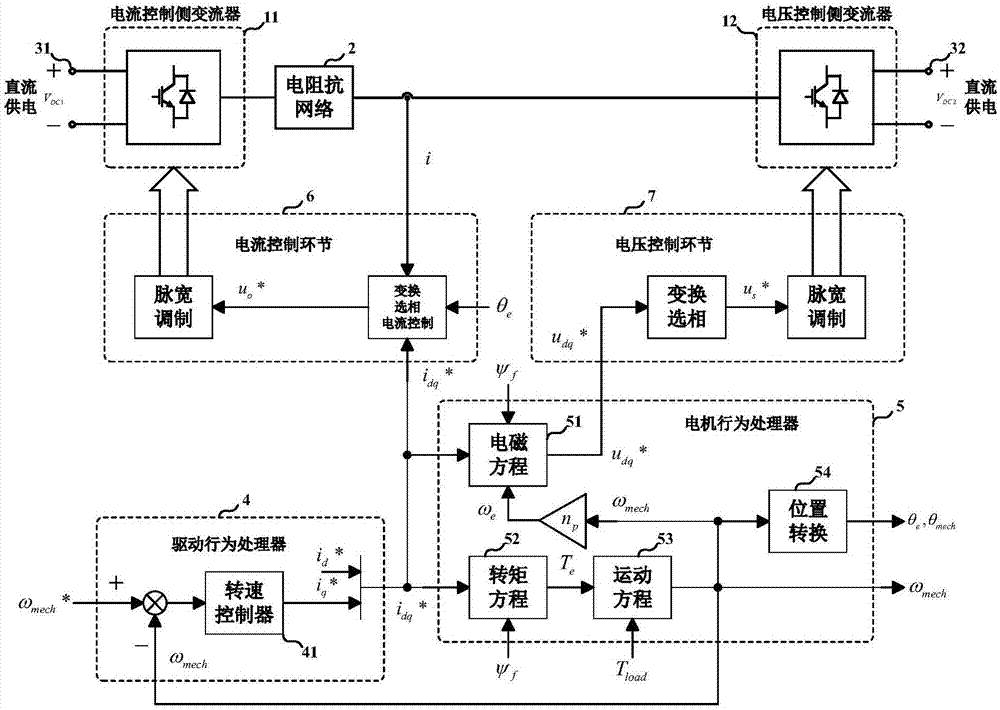

Voltage responding-type permanent magnet synchronous machine and simulator of driving system of voltage responding-type permanent magnet synchronous machine

ActiveCN107994820ARealize simulationConvenient reliability analysisAC motor controlElectric motor controlPermanent magnet synchronous machinePermanent magnet synchronous motor

The invention provides a voltage responding-type permanent magnet synchronous machine and a simulator of a driving system of the voltage responding-type permanent magnet synchronous machine. The voltage responding-type permanent magnet synchronous machine comprises at least two DC / AC power electronic converters, an electric impedance network, a direct current supply, a driving behavior processor,a motor behavior processor, a current control link and a voltage control link; the DC / AC power electronic converters are used for simulating the response of the driving system to incoming current of stator windings of the permanent magnet synchronous machine and the response of the permanent magnet synchronous machine to port voltage of stator current on a circuit layer separately; the driving behavior processor is used for describing electrical behavior characteristics of the driving system; the motor behavior processor is used for describing electrical and mechanical behavior features of thepermanent magnet synchronous machine. By means of the voltage responding-type permanent magnet synchronous machine, the response of the driving system to the incoming current of the stator windings of the permanent magnet synchronous machine and the response of the permanent magnet synchronous machine to the port voltage of the incoming current can be effectively simulated when the driving systemdrives the permanent magnet synchronous machine, full-electrification motor driving testing is achieved, and the testing efficiency and safety are improved.

Owner:SHANGHAI JIAO TONG UNIV

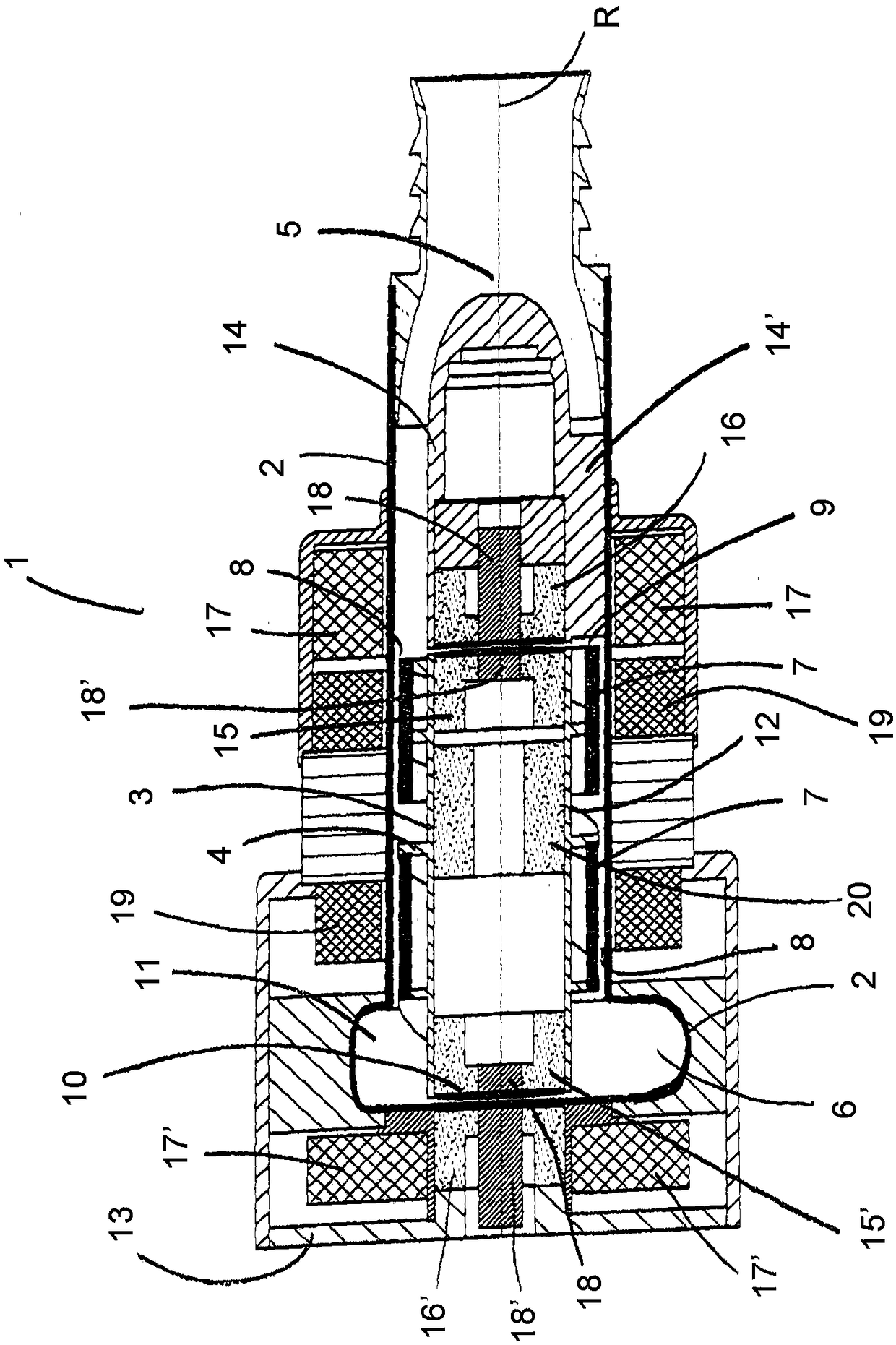

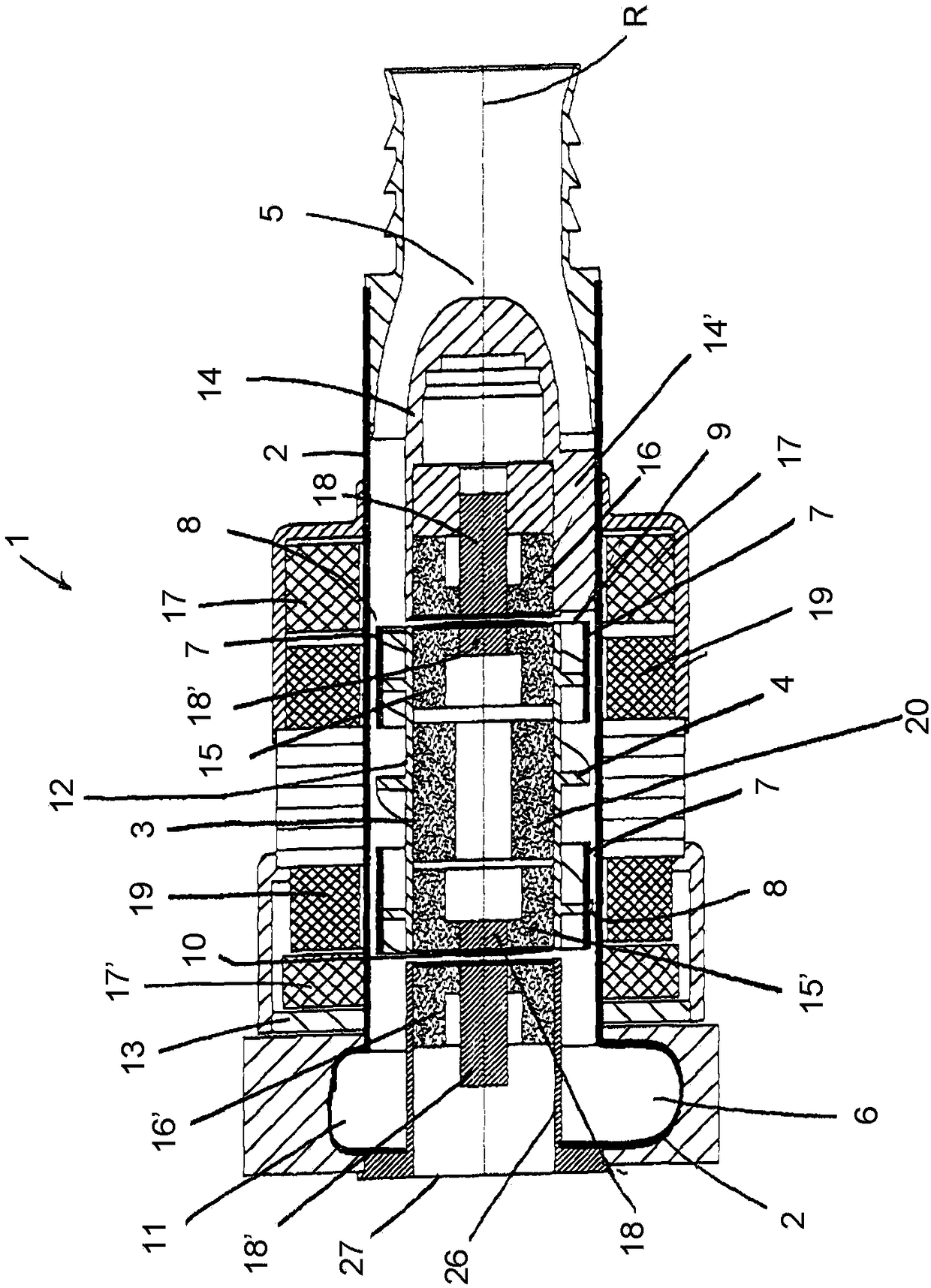

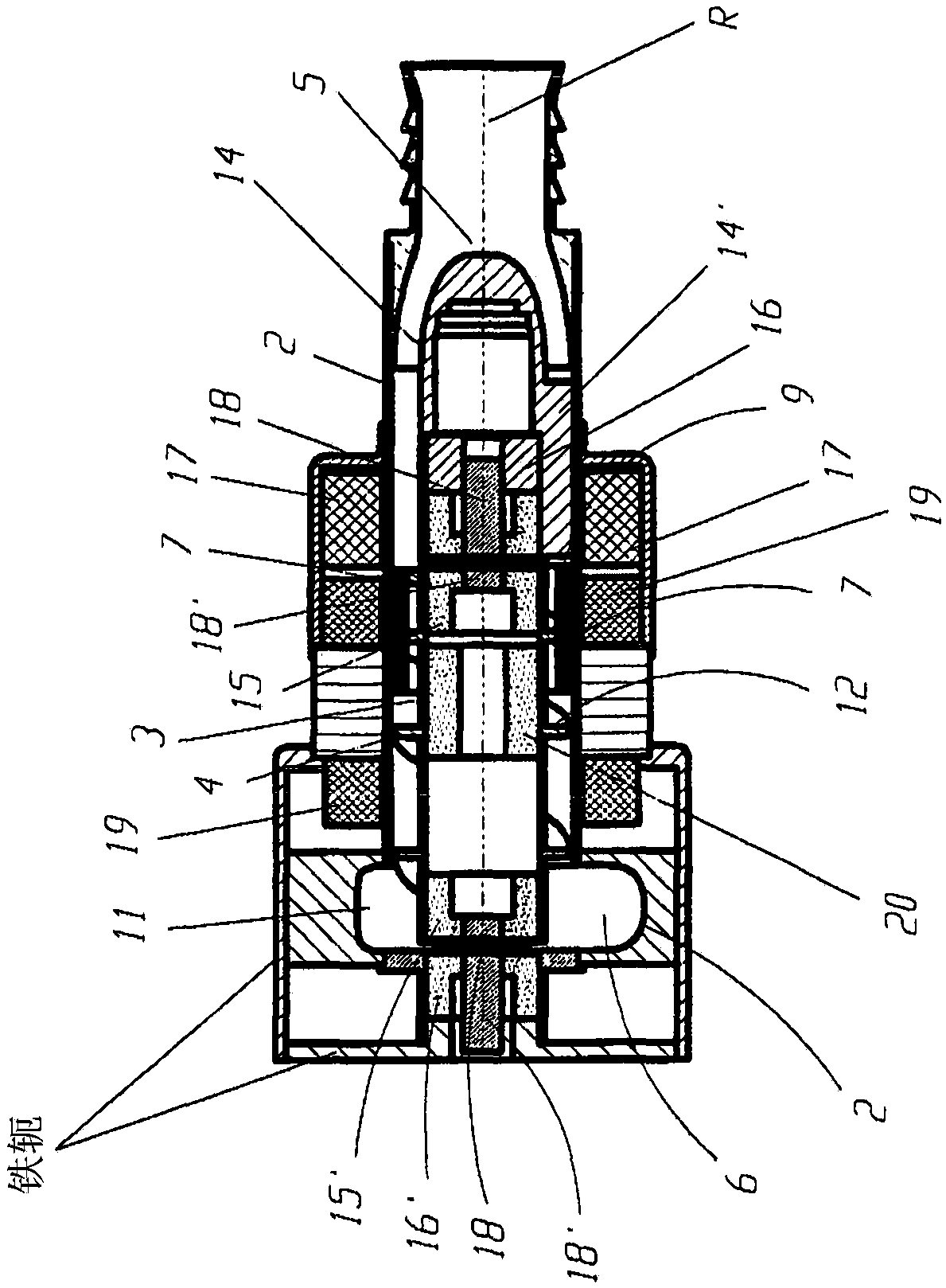

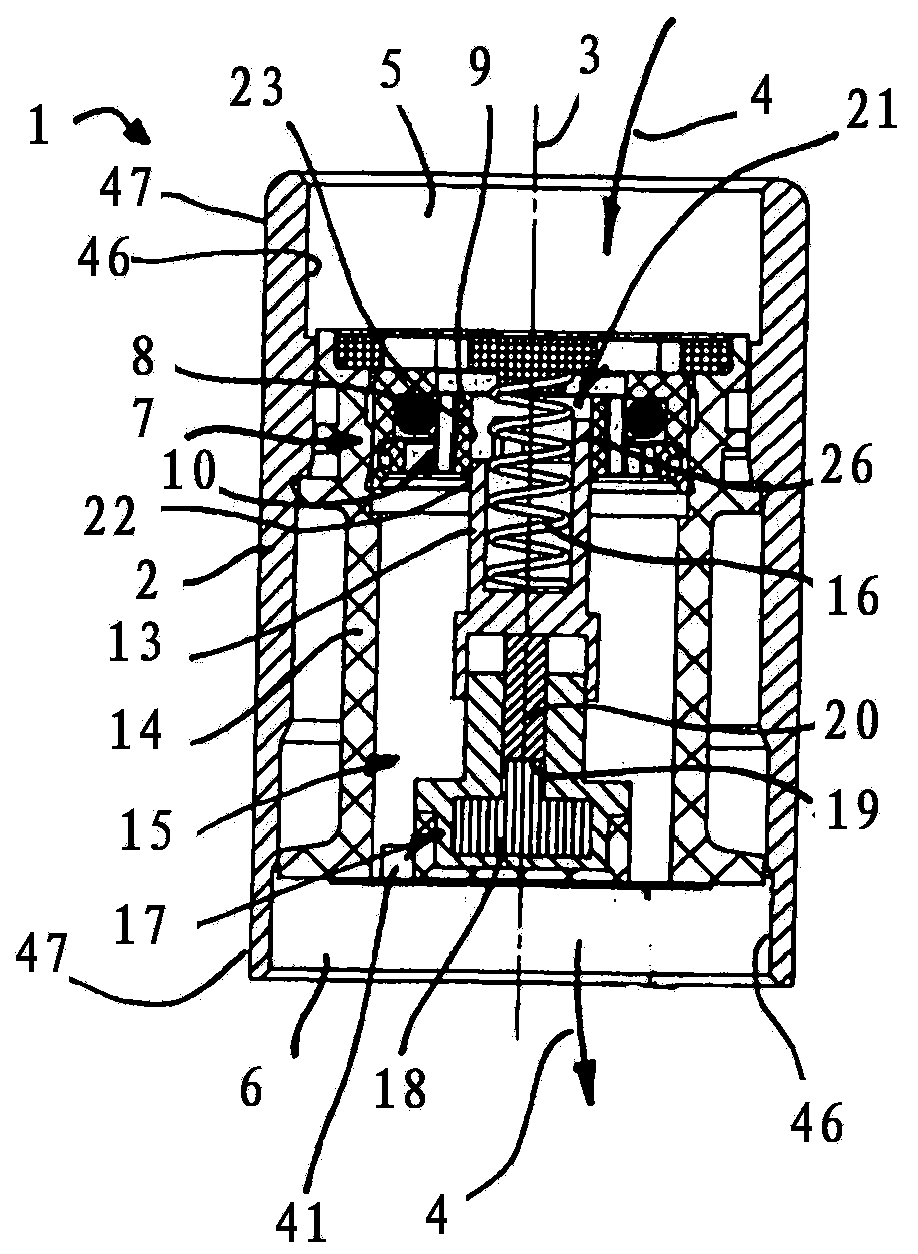

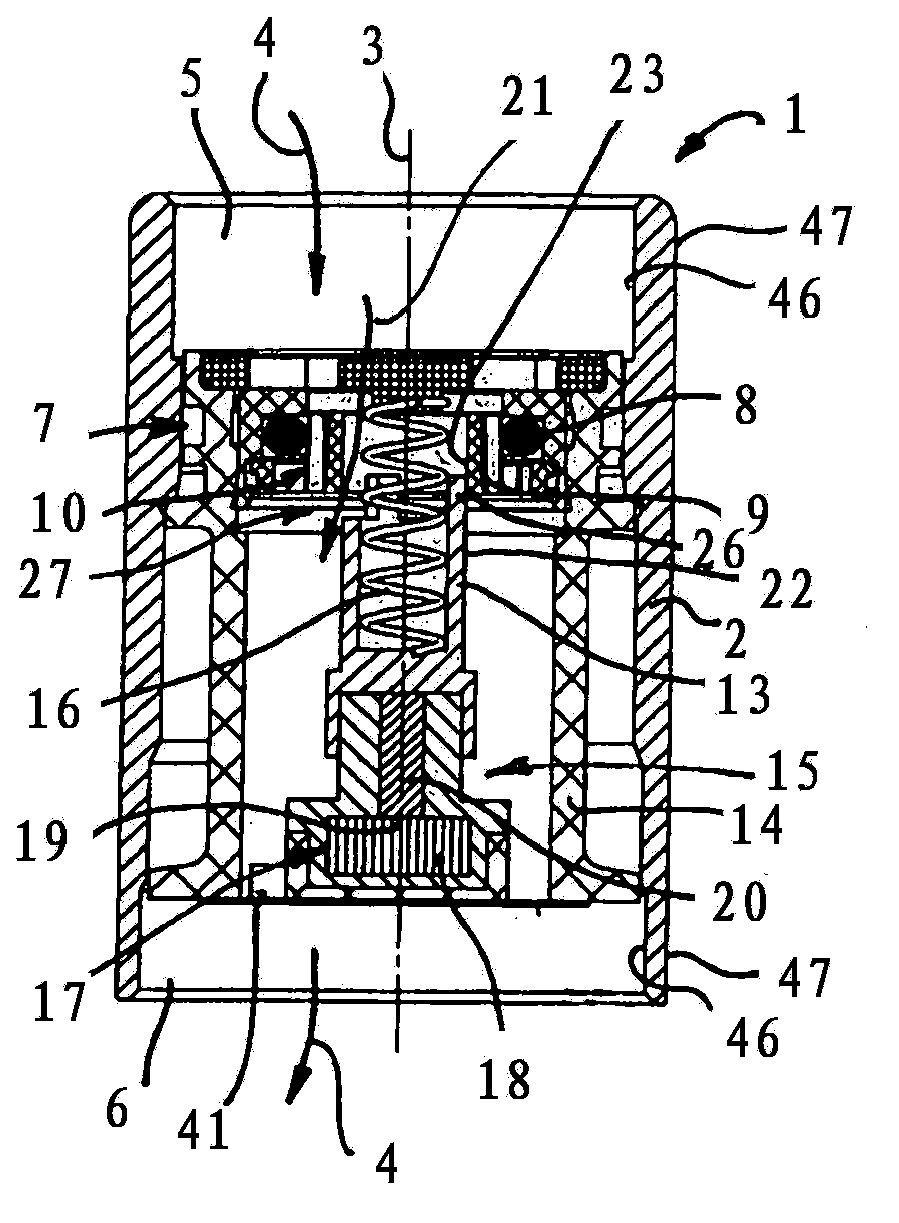

Blood pump

InactiveCN108514661AImproved kineticsAdjust the transmission effectControl devicesIntravenous devicesImpellerMagnetic bearing

The invention relates to a blood pump (1). The blood pump comprises a hollow body (2) and magnetic bearing devices (15, 15', 16, 16', 17, 17', 18, 18'), all of which at least partially and actively stabilize. The hollow body is equipped with an impeller (3) having a blade device (4), which is used for generating axial propulsion of blood along the impeller (3). The impeller is set to rotate arounda rotary axis (R) of the impeller (3) by means of a motor stator (10). The hollow body (2) comprises an inlet (5) and an outlet (6). The inlet enables blood to flow into the hollow body (2) in an inflow direction (E) basically parallel to the rotary axis (R). The outlet (6) enables blood to flow out of the hollow body (2) along an outflow direction (A).

Owner:BERLIN HEART GMBH

Semiconductor device with a cooling element

InactiveUS7567597B2High yield stressHigh temperature stabilitySemiconductor laser arrangementsSemiconductor/solid-state device detailsConduction coolingElastic modulus

A semiconductor device comprising a semiconductor component, particularly a power laser diode bar, disposed on a cooling element, wherein the cooling element contains in its interior a cooling channel for conducting a coolant. The coolant channel comprises in at least one region microstructures for effective heat transfer to the coolant. The semiconductor component substantially completely overlaps the region of the cooling channel comprising the microstructures. Disposed between the semiconductor component and the cooling element is an intermediate support so arranged and configured that it compensates for mechanical stresses between the semiconductor component and the cooling element occurring as a result of differing thermal expansions of the semiconductor component and the cooling element. The material of the cooling element particularly preferably has a high modulus of elasticity such that the compensation takes place substantially within the elastic strain regime.

Owner:OSRAM GMBH

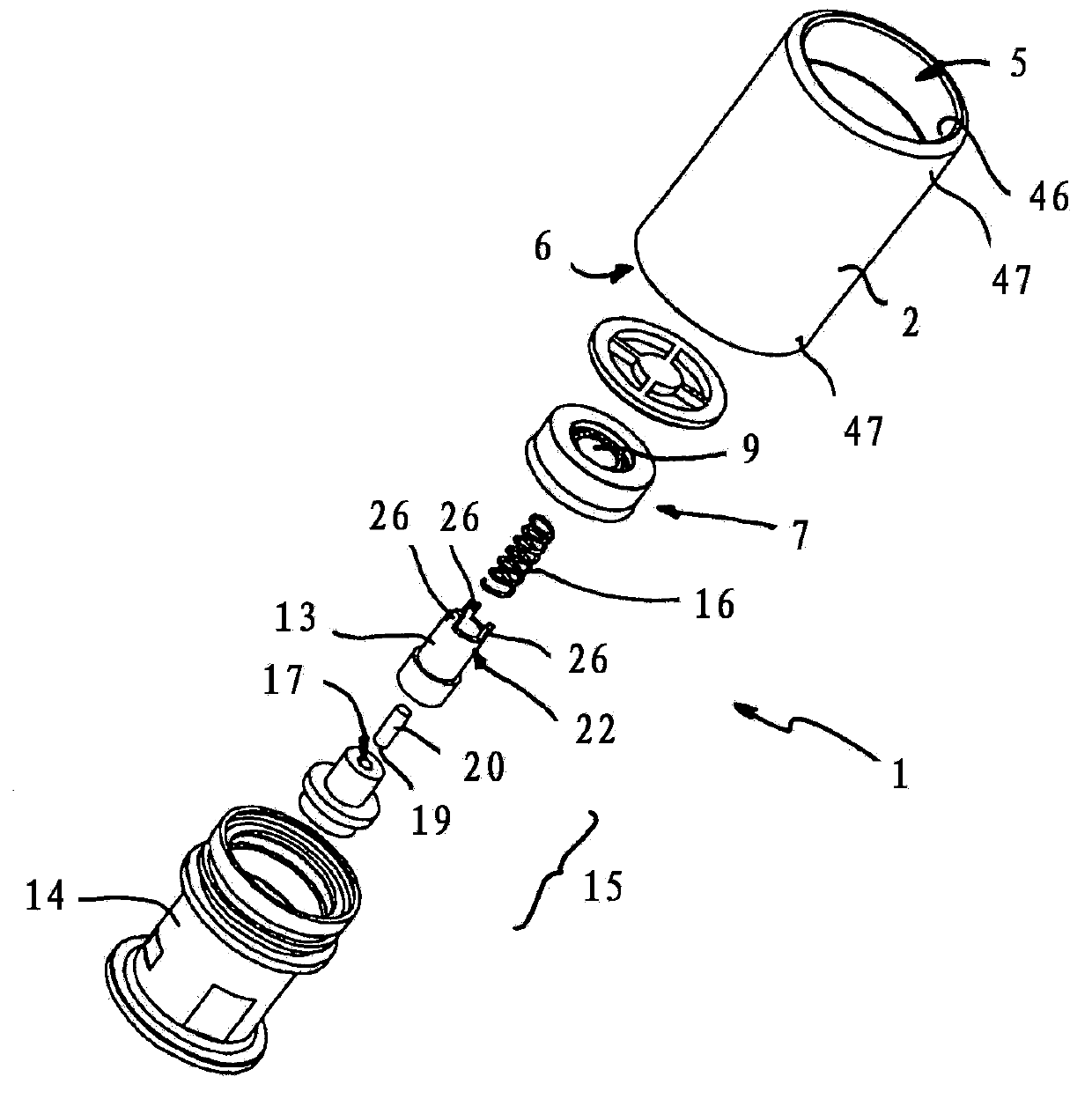

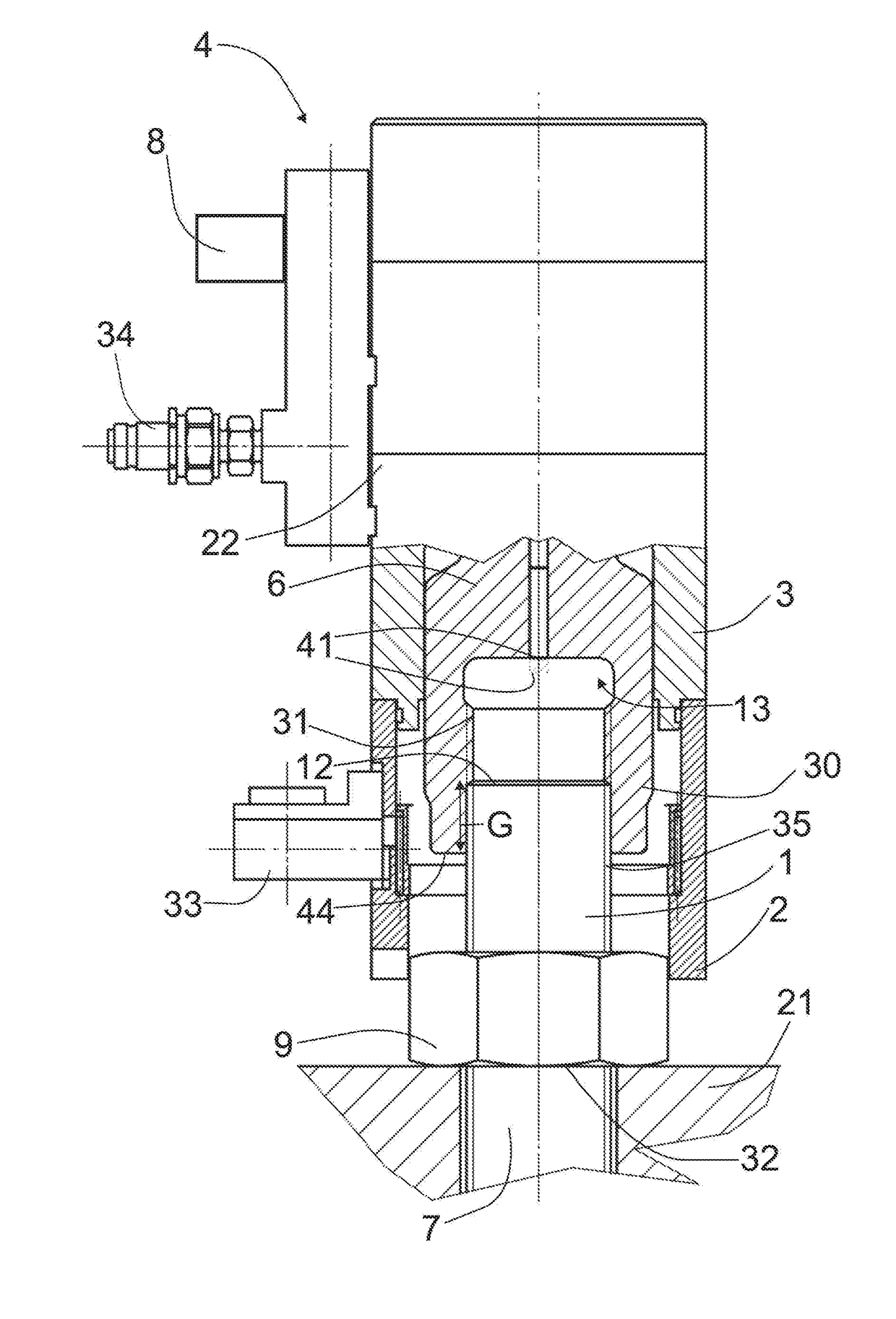

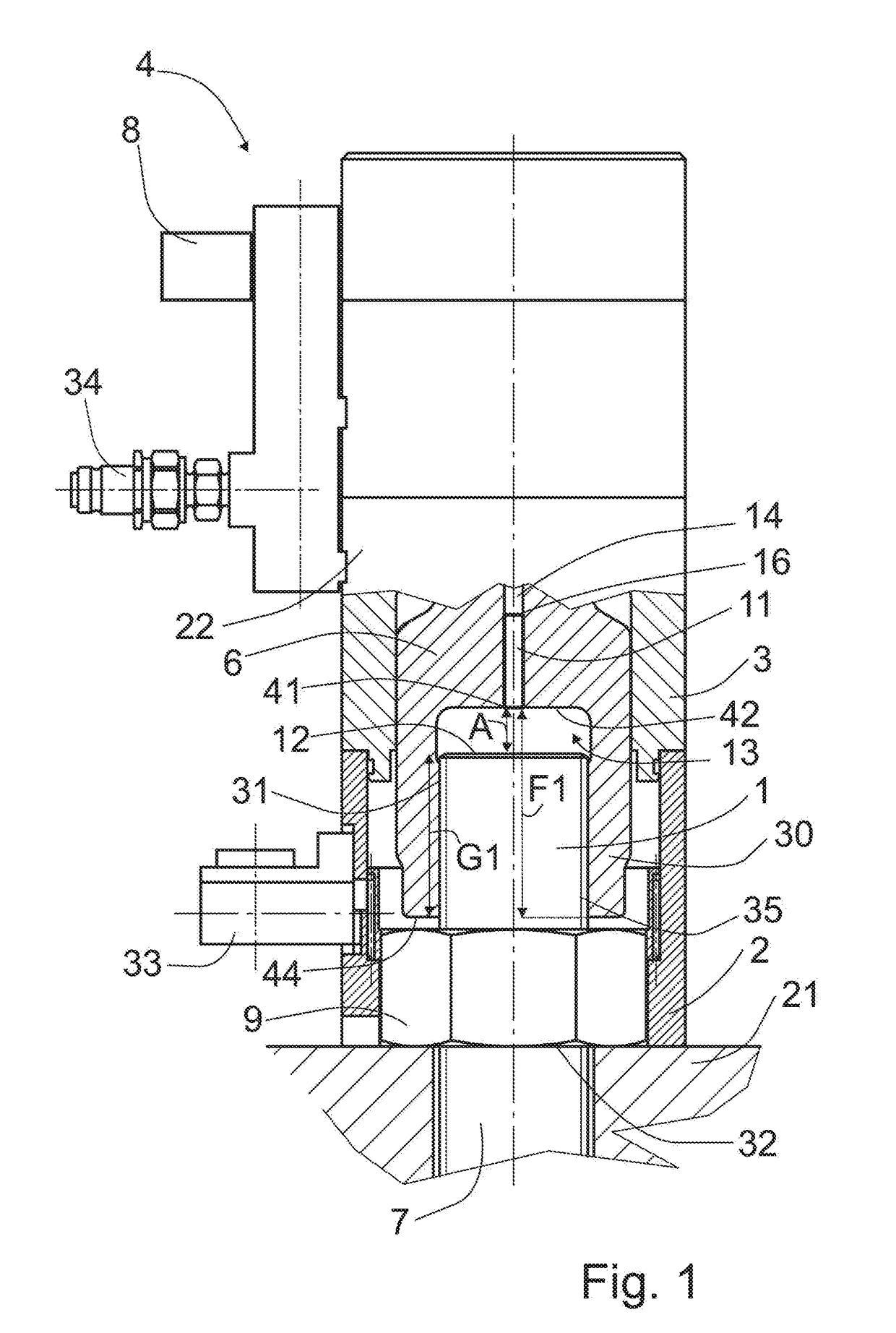

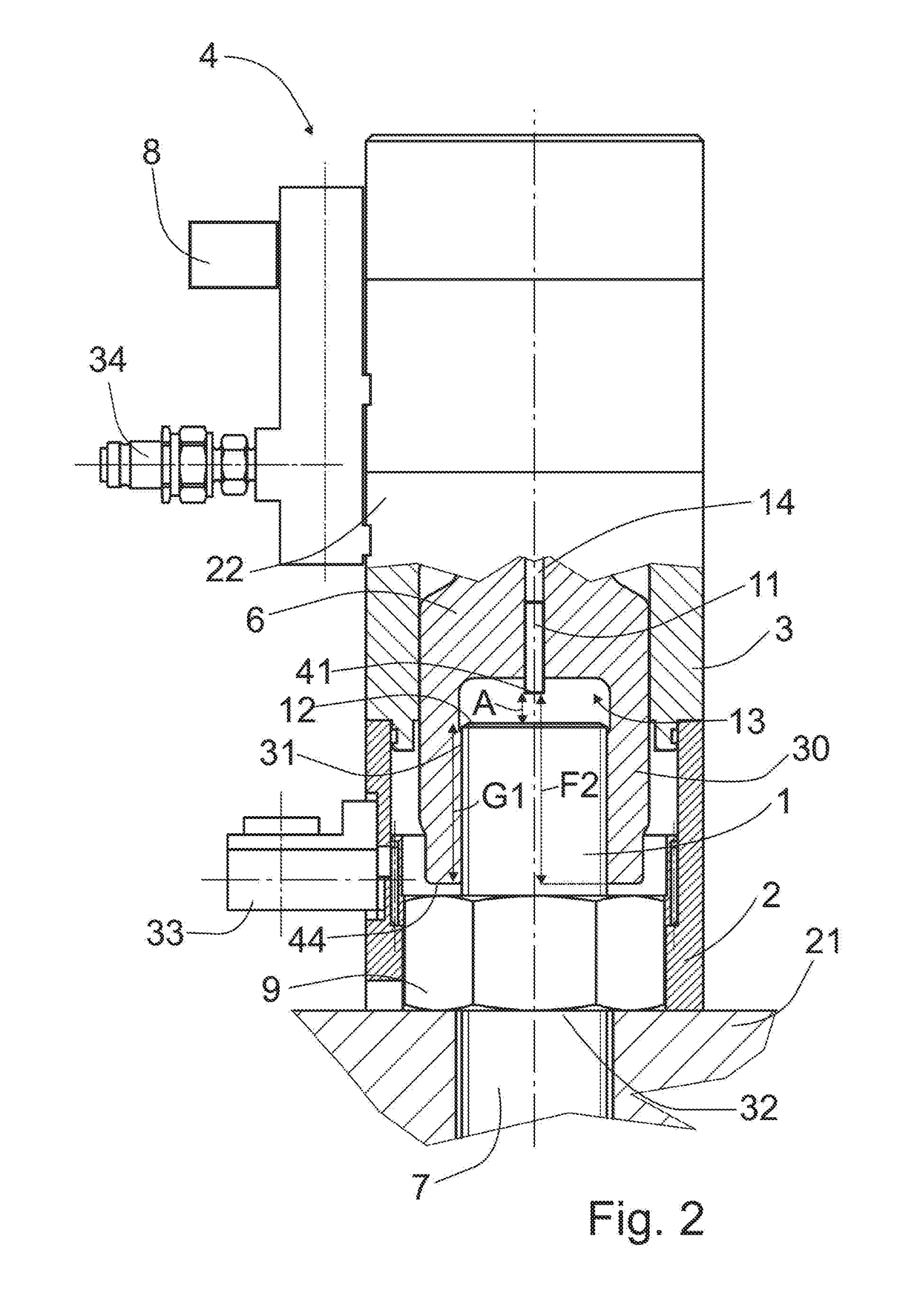

Sanitary installation part and component of a sanitary water faucet and method for controlling flow of flowing medium

ActiveCN103968143ALarge expansion coefficientAvoid mechanical loadTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringStreamflow

The invention relates to a sanitary installation part (1) which, along with a functional unit (7), forms a quantity regulator, it is proposed that a regulating element (13), which can be adjusted along an adjustment path, be coupled to a temperature-sensitive drive unit (15) such that different regulating positions of the regulating element (13) are set in dependence on the temperature of the medium flowing through the installation part (1), wherein the different regulating positions realize in each case different volume-flow dependencies (11, 12, 45, 48) and / or flow resistances (cf. figure 1).

Owner:NEOPERL

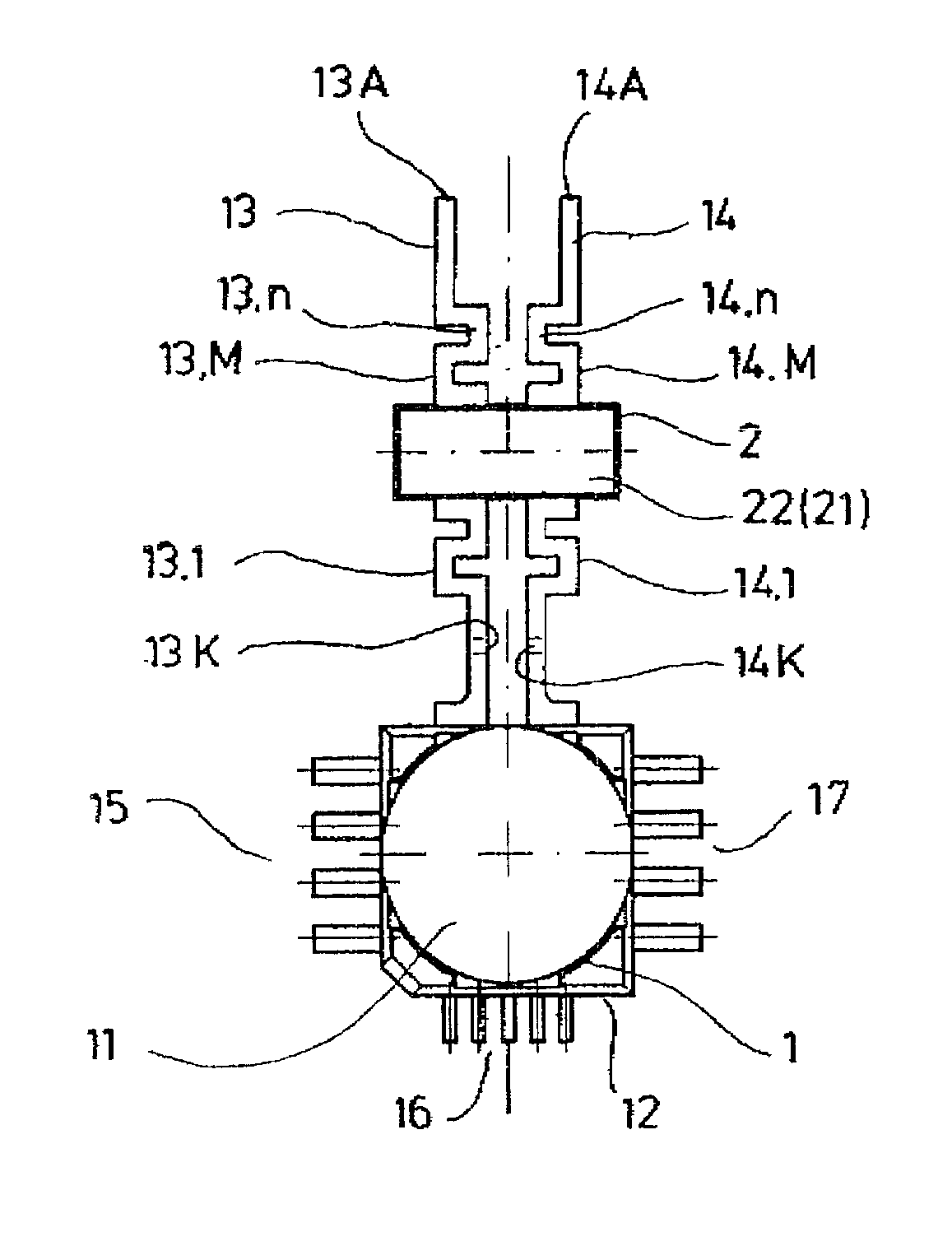

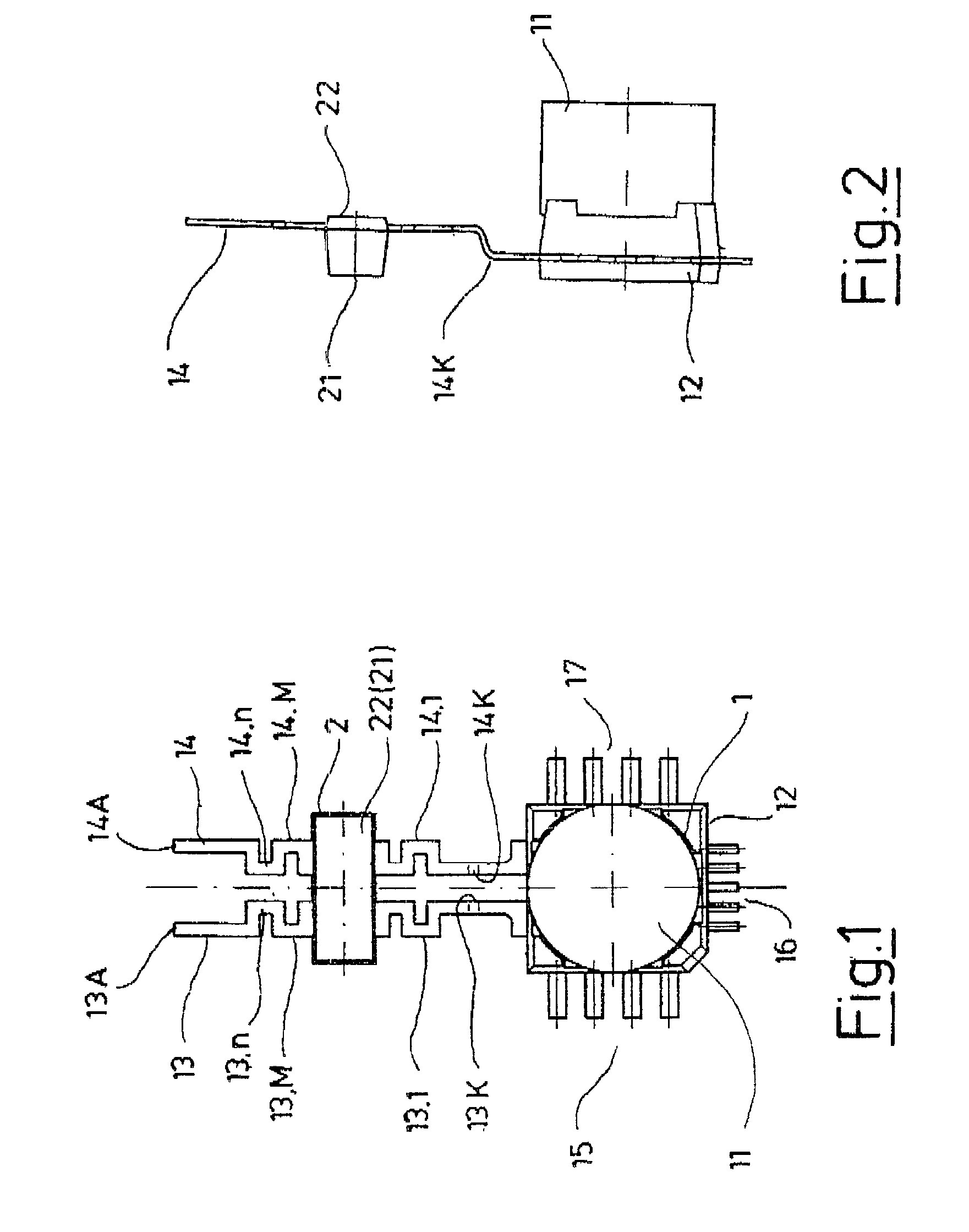

GMR module

InactiveUS7026910B2Avoid mechanical loadEffective and low-cost connectionNanomagnetismSolid-state devicesMeanderEngineering

So that the parts and connections of a component, particularly a Giant Magneto-Resistor, may withstand external forces, a meander group (13M, 14M) with at least one meander element (13.1, . . . , 13.n, 14.1, . . . , 14.n) is positioned in both connection elements (13, 14) between a component cell (1) and the straight functional connection element (13A, 14A). A capacitor unit (2) is mounted on the meander group (13M) of the first connection element (13) and on the meander group (14M; of the second connection element (14).

Owner:ELEKTRONIK

Simulation system of voltage response type three-phase permanent magnet synchronous motor

ActiveCN107807295AConvenient reliability analysisFunctional testing is convenientEnvironmental/reliability testsDynamo-electric machine testingPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention provides a simulation system of a voltage response type three-phase permanent-magnet synchronous motor. The simulation system comprises a three-phase DC / AC electric and electronic converter, a direct-current power supply port, a motor behavior processor and a voltage control link. The three-phase DC / AC electric and electronic converter is used for simulating port voltage response ofthe three-phase permanent-magnet synchronous motor during current inputting and performs electric energy exchange with an external motor driving system. The motor behavior processor is used for describing the electrical and mechanical behavior characteristics of the three-phase permanent-magnet synchronous motor. The voltage control link is used for using a permanent-magnet synchronous motor portvoltage signal calculated by the motor behavior processor as a reference and controlling alternating-current-end output voltage of the three-phase DC / AC converter. The simulation system can directly perform electric energy exchange with a real motor driving system and effectively simulate port voltage response of the three-phase permanent-magnet synchronous motor during current inputting of the motor driving system, achieves full-electrical motor driving testing, saves the testing cost and improves the testing efficiency and safety.

Owner:SHANGHAI JIAO TONG UNIV

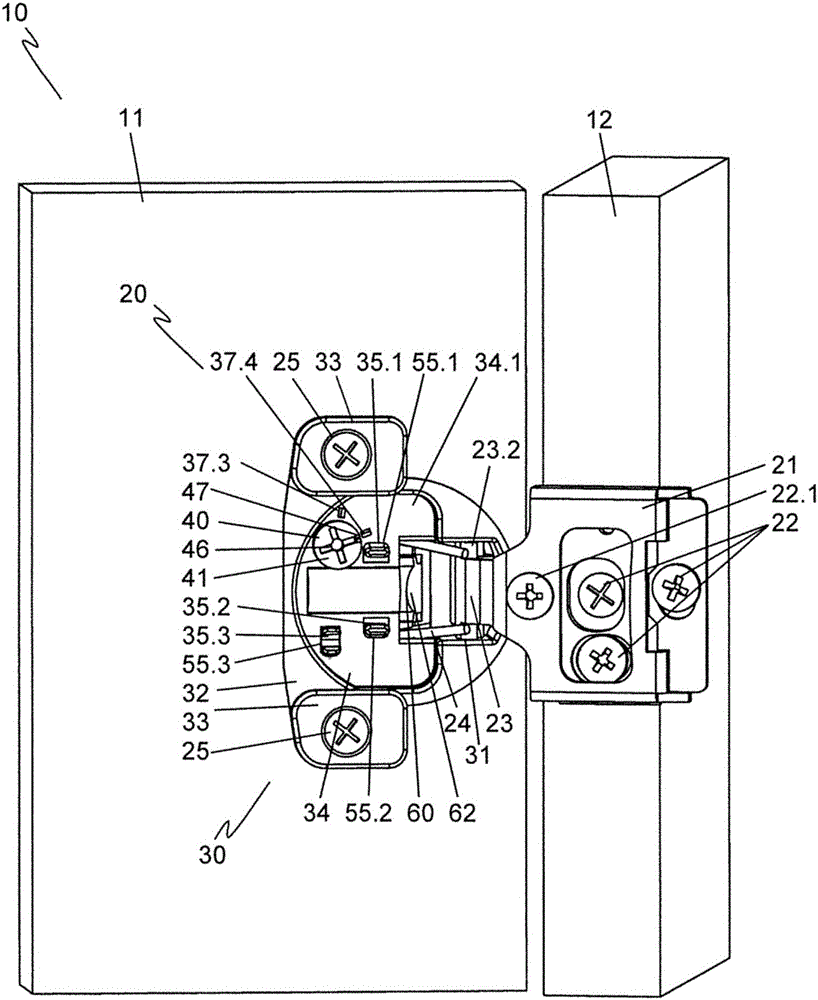

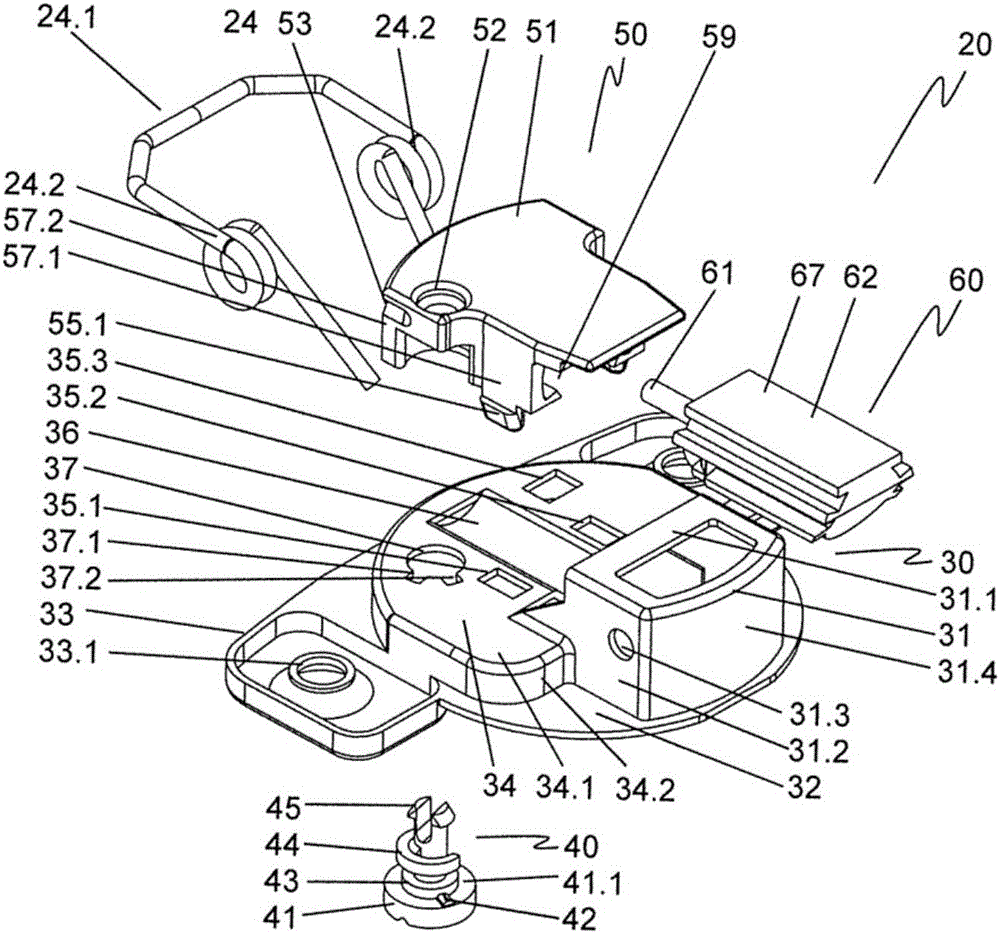

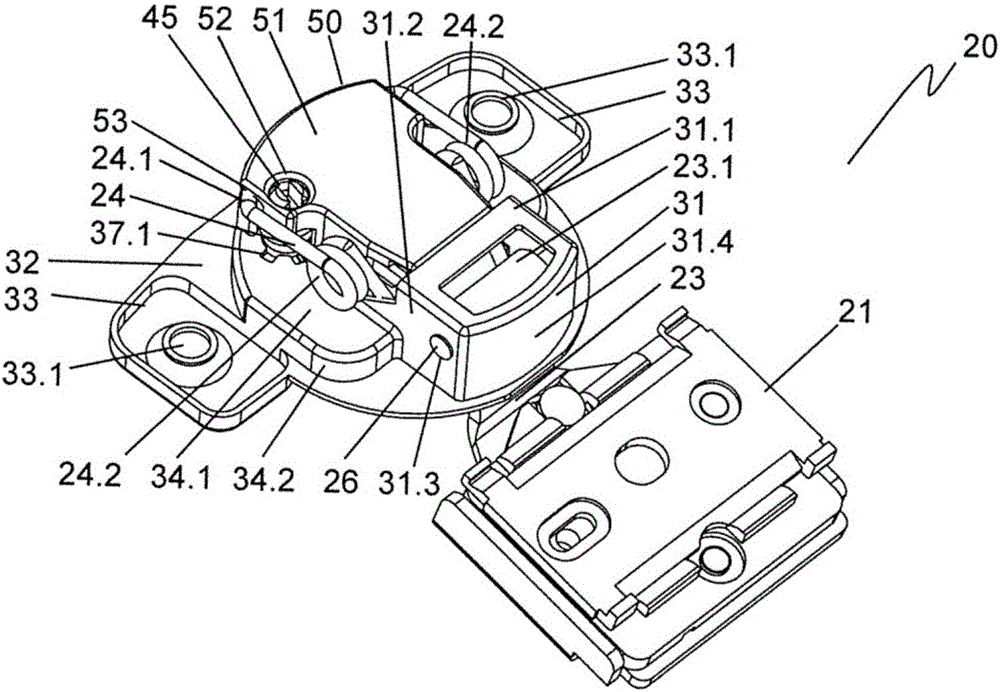

Furniture hinge comprising a damper and a spring

ActiveCN106121428AEasy to installRealization costBuilding braking devicesWing accessoriesMechanical engineering

Owner:SAMET KALIP VE MADENI ESYA SAN TIC AS

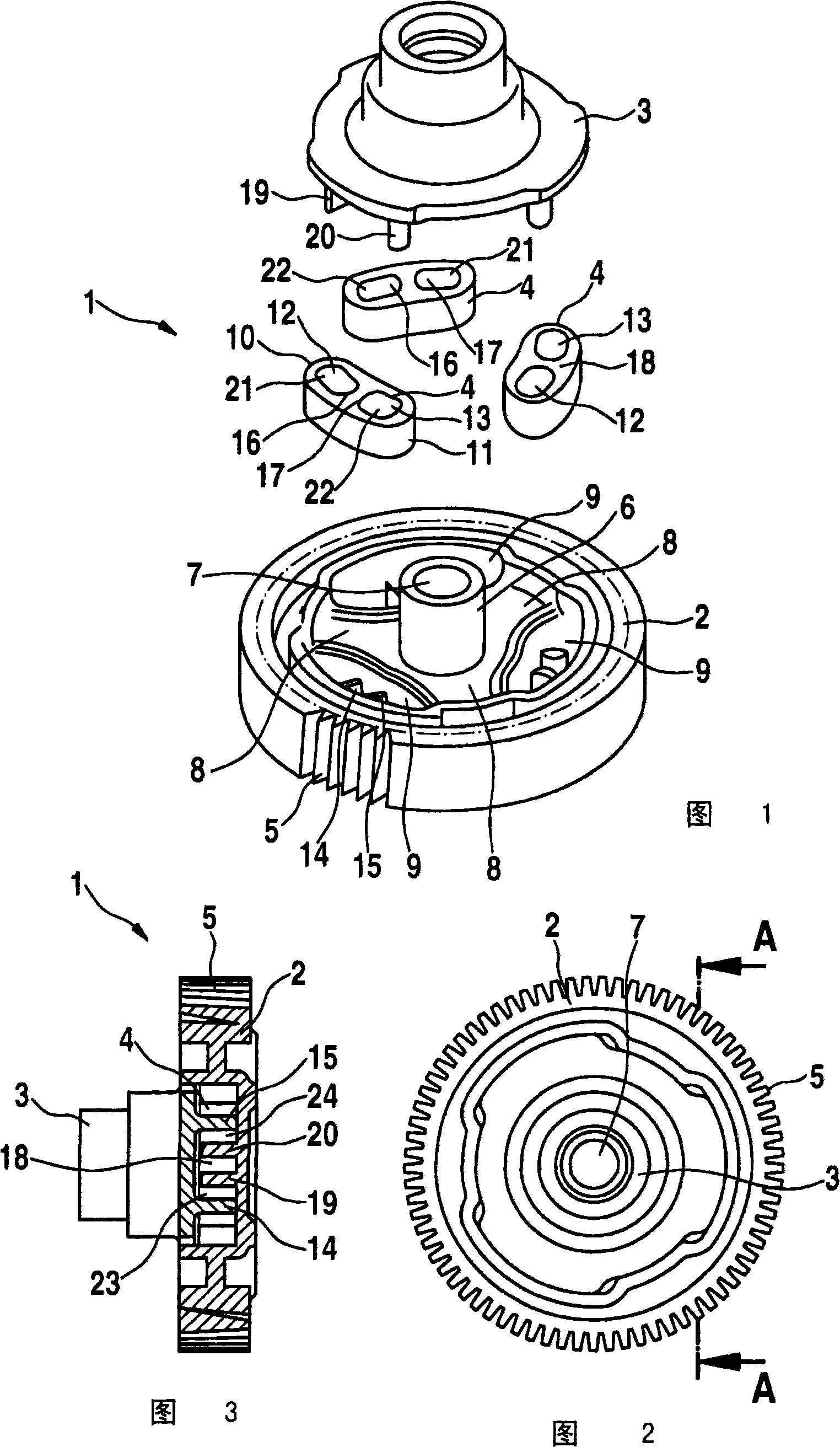

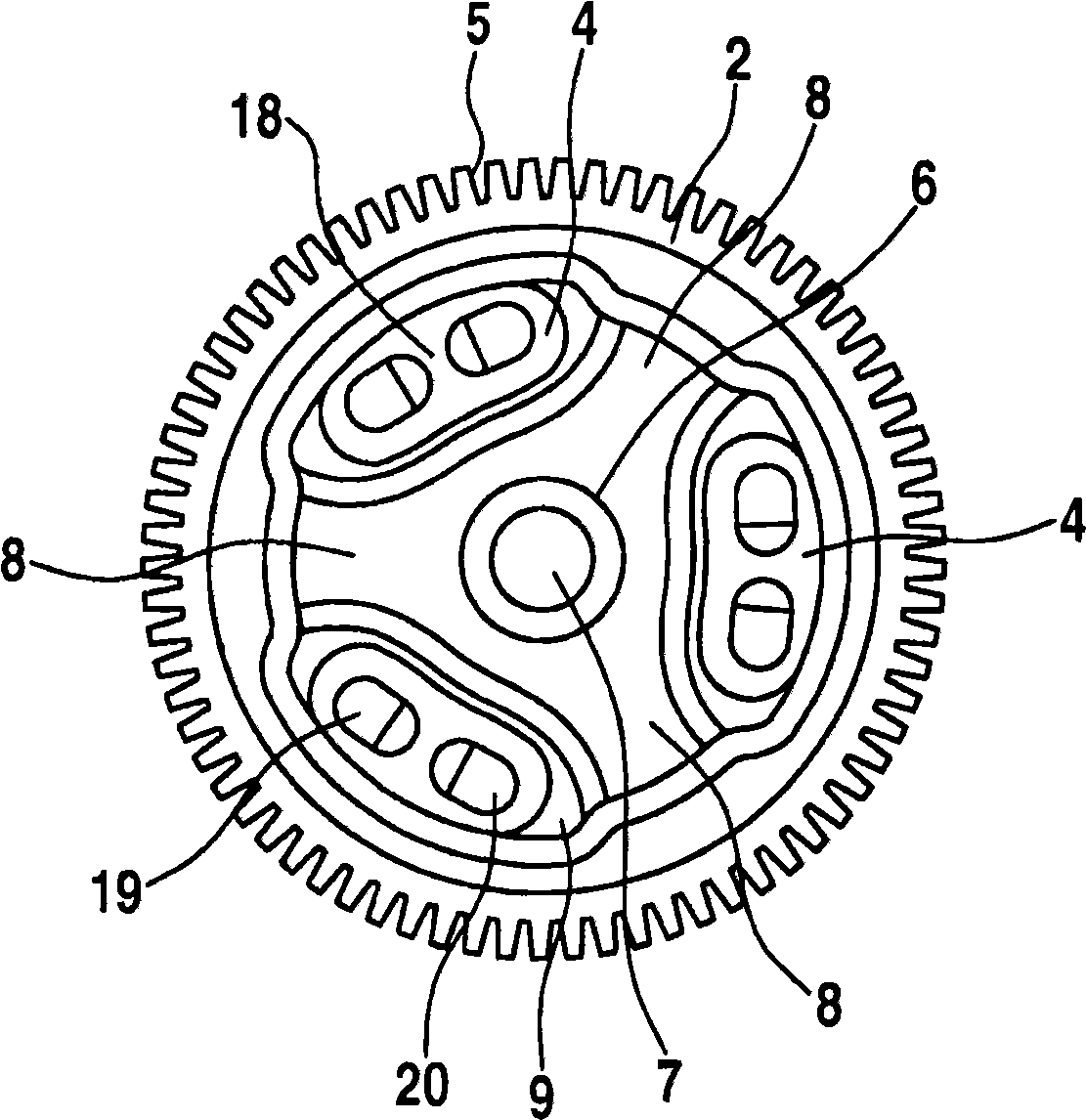

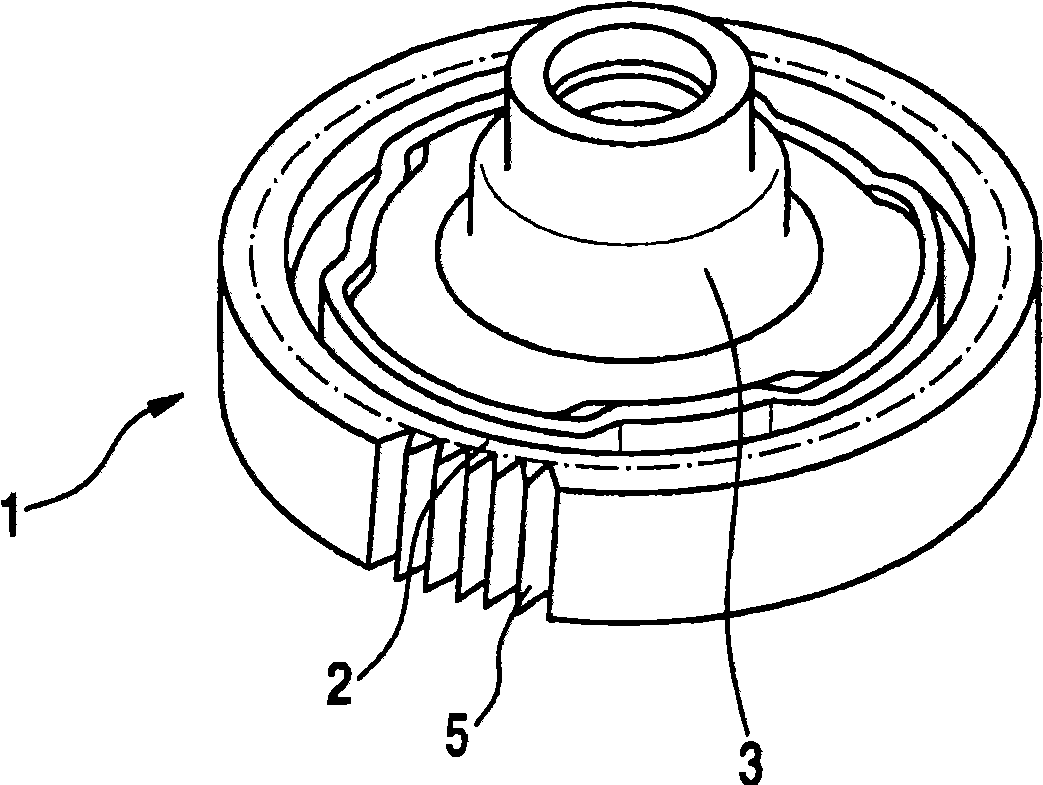

Transmission device

InactiveCN101512192AAvoid mechanical loadExtended service lifePortable liftingGearing elementsEngineeringGear wheel

The invention relates to a transmission device (1) comprising a first gear wheel (2) and a second gear wheel (3) that is rotatably coupled thereto, wherein a damping element (4) acting in the circumferential direction is provided axially between the gear wheels (2, 3). According to the invention it is provided that the damping element (4) can be tensioned by the gear wheels (2, 3) during the operation of the transmission device (1).

Owner:ROBERT BOSCH GMBH

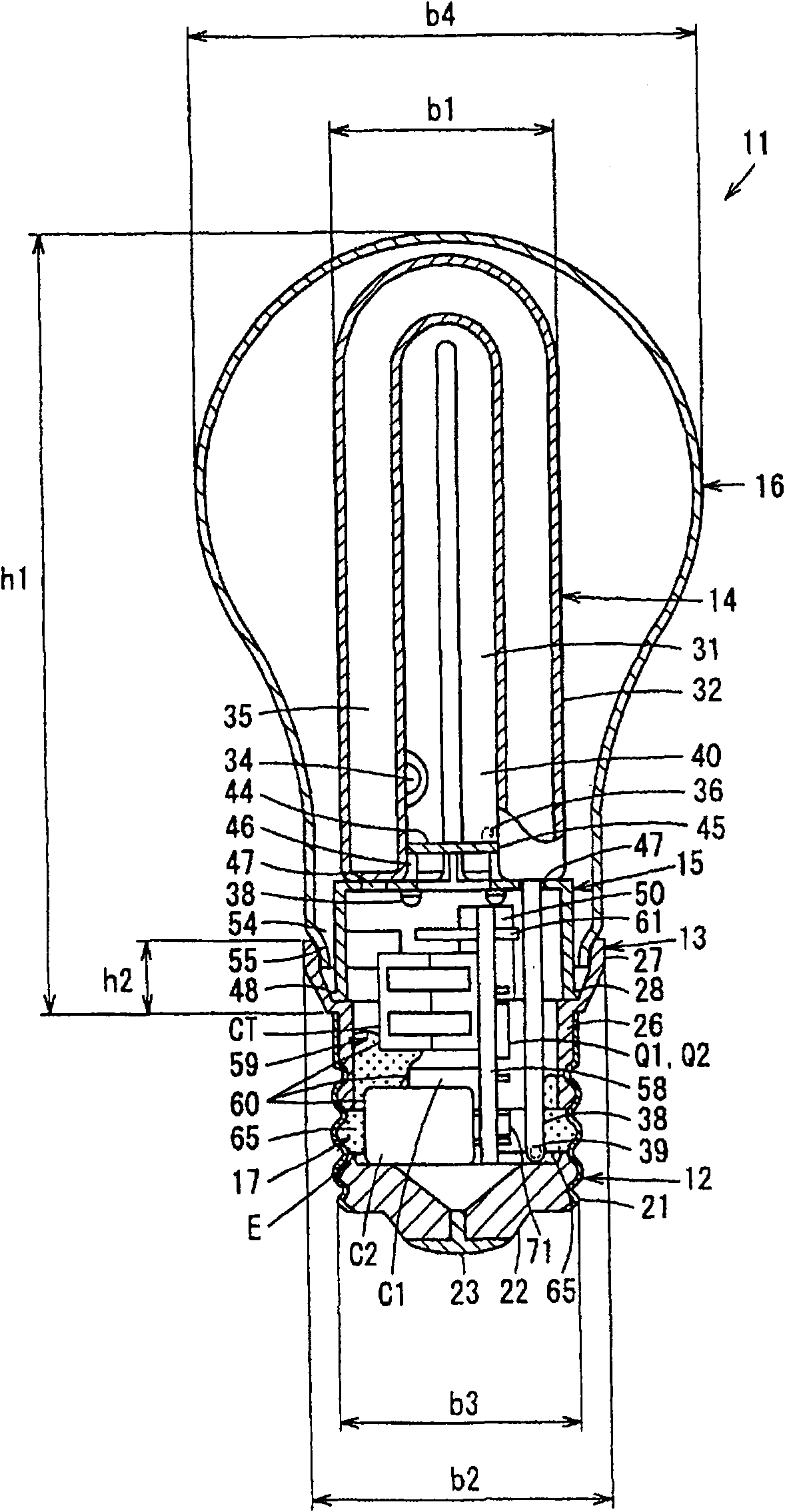

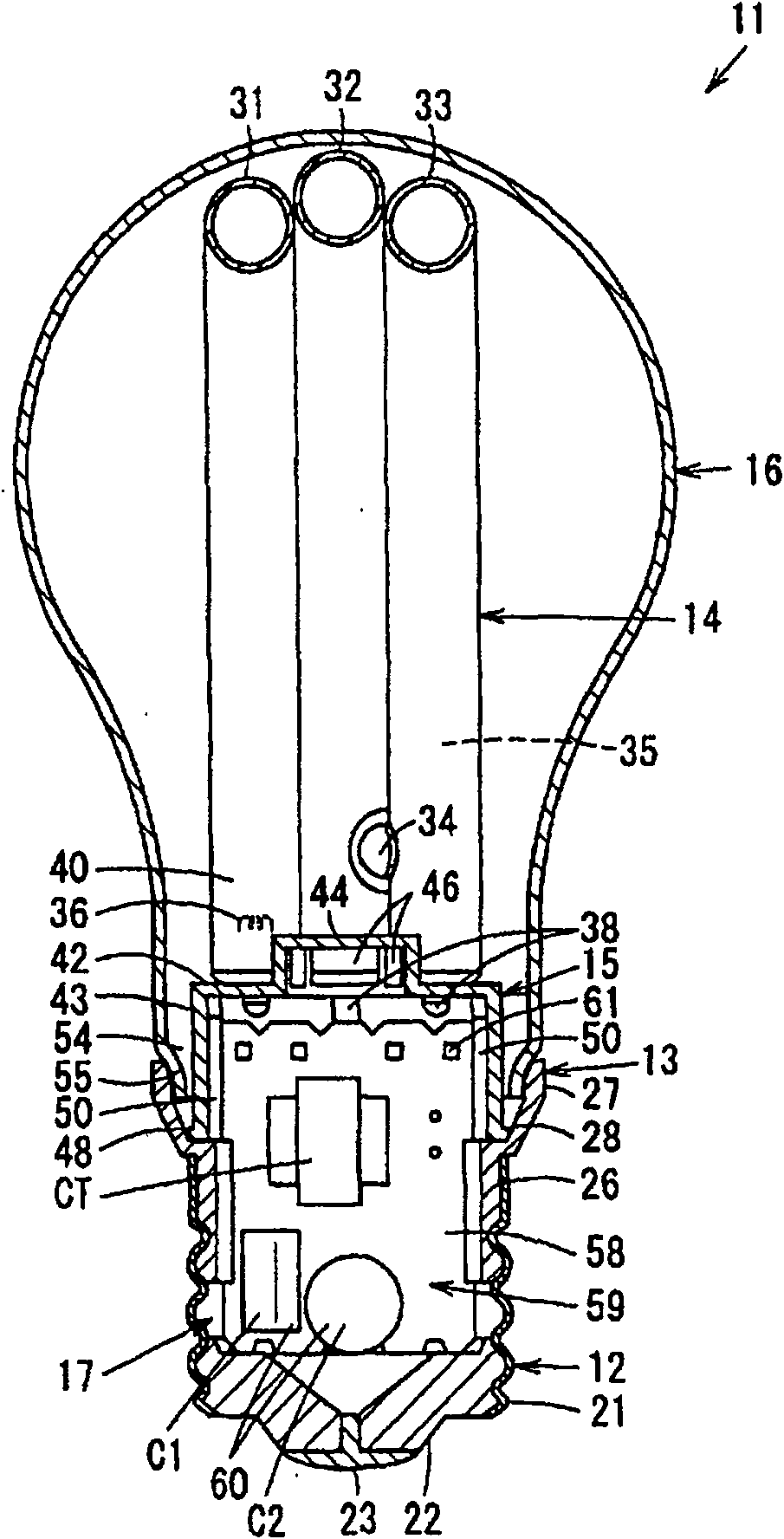

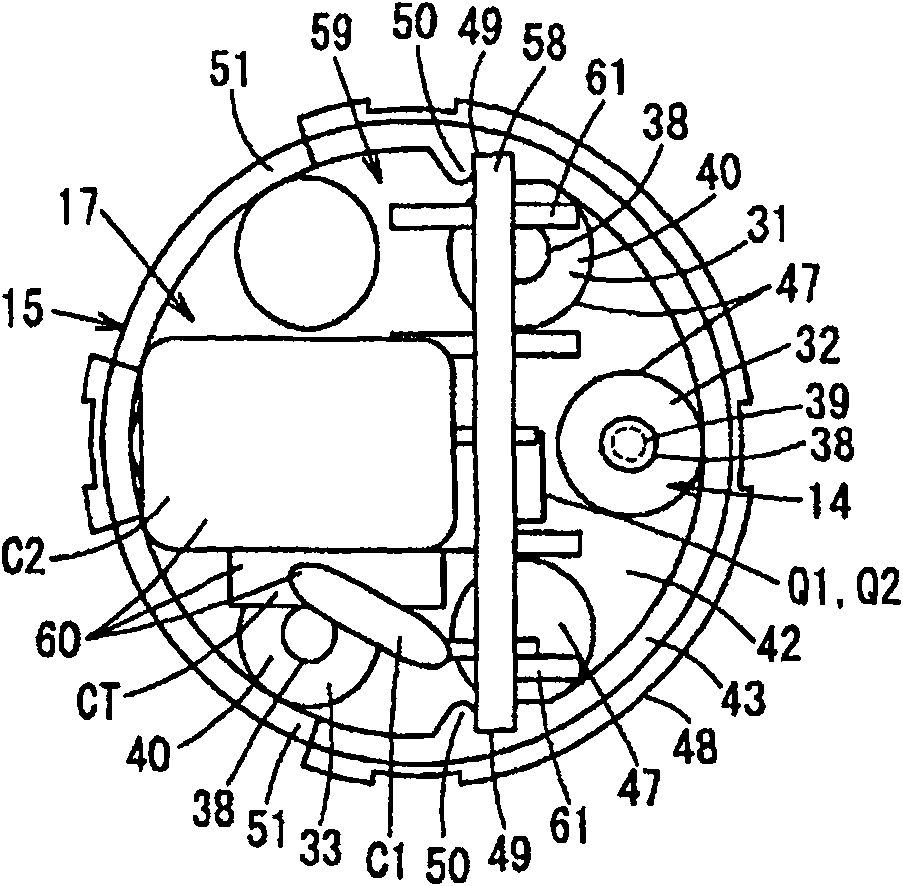

Compact self-ballasted fluorescent lamp and lighting apparatus

InactiveCN100580307CImprove thermal conductivityImprove insulation performanceElectrical apparatusElongate light sourcesMiniaturizationEffect light

A compact self-ballasted fluorescent lamp (11) capable of providing a roughly same appearance as that of general lighting bulbs by efficiently storing a lighting device (17) on the inside of a ferrule (12) to reduce the size of a cover (13) and a lighting apparatus. The ferrule (12) is fitted to one end of the cover (13) and a light emitting tube (14) is supported on the cover (13) at the other end. Electronic parts (60) forming a lighting circuit (59) lighting the light emitting tube (14) are mounted on the substrate (58) of the lighting device (17). The substrate (58) is formed to have such a width dimension that allows the substrate to be inserted into the ferrule (12) and vertically disposed along the direction of the centerline of the ferrule (12) at a position offset from the centerline of the ferrule (12). Large electronic parts (60) among the electronic parts (60) are disposed on the surface of the substrate (58) which is more apart from the ferrule (12) than the other. Since the lighting device (17) is efficiently stored on the inside of the ferrule (12), the size of the cover (13) can be reduced and roughly the same appearance as that of the general lighting bulbs can be provided to the fluorescent lamp.

Owner:TOSHIBA LIGHTING & TECH CORP

Filter module and modular filter system

ActiveUS9669333B2Avoid contaminationAvoid damageMembranesSemi-permeable membranesFilter mediaFilter system

One aspect of the invention relates to a filter module comprising: —a filter element having at least one filter medium which separates a filtrate side and a retentate side of the filter element from one another, and having a filter medium holder to which the filter medium is attached and which has at least one holder intake channel and at least one holder discharge channel, —a first filter cartridge part having at least one first cartridge intake channel and at least one first cartridge discharge channel, —a second filter cartridge channel having at least one second cartridge intake channel and at least one second cartridge discharge channel, wherein the filter medium holder is arranged in an arrangement position between the first filter cartridge part and the second filter cartridge part in a fluid-tight manner, wherein the at least one holder intake channel has a fluid connection with the at least one first cartridge intake channel and the at least one second cartridge intake channel, in order to form a module intake channel, wherein the at least one holder discharge channel has a fluid connection with the at least one first cartridge discharge channel and the at least one second cartridge discharge channel, in order to form a module discharge channel, wherein the module intake channel has a fluid connection with the retentate side of the filter medium and wherein the module discharge channel has a fluid connection with the filtrate side of the filter medium, and a modular filter system.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Method for connecting parts of multiple-part rotor carrier and rotor carrier of electric engine

InactiveCN101821924AAvoid mechanical loadReduce extrusion pressureMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectrical and Electronics engineeringEngineering

Owner:ROBERT BOSCH GMBH

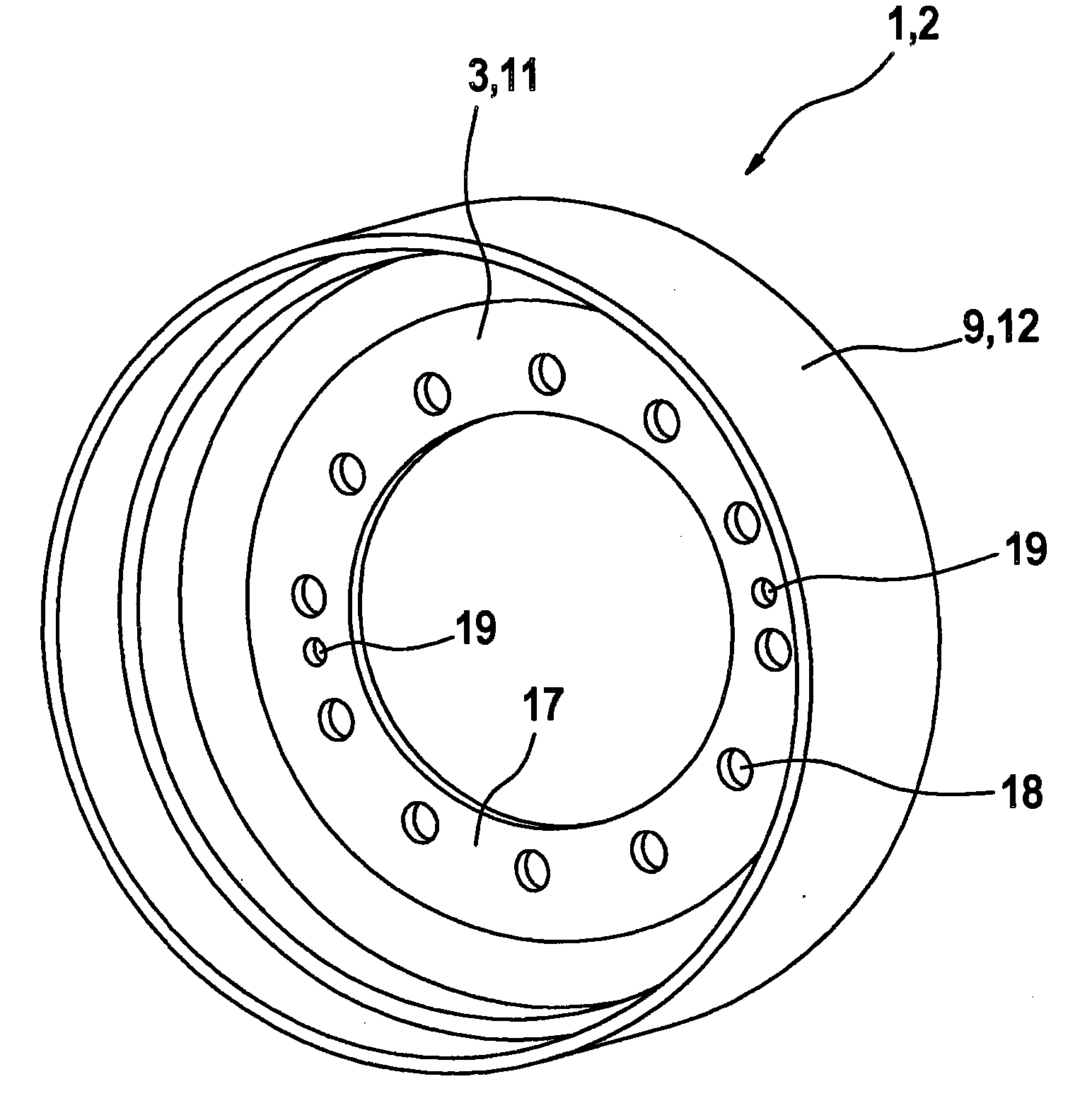

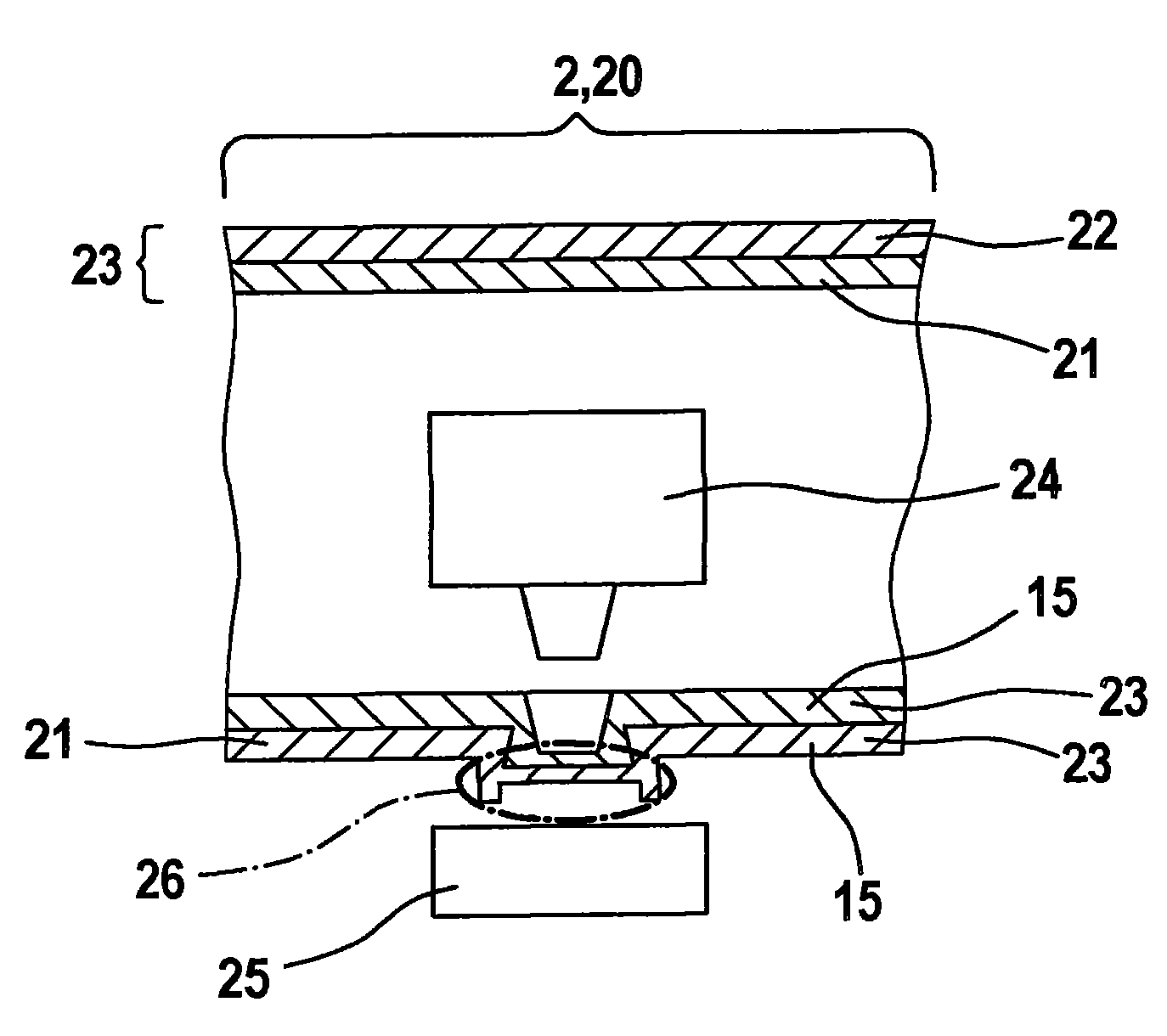

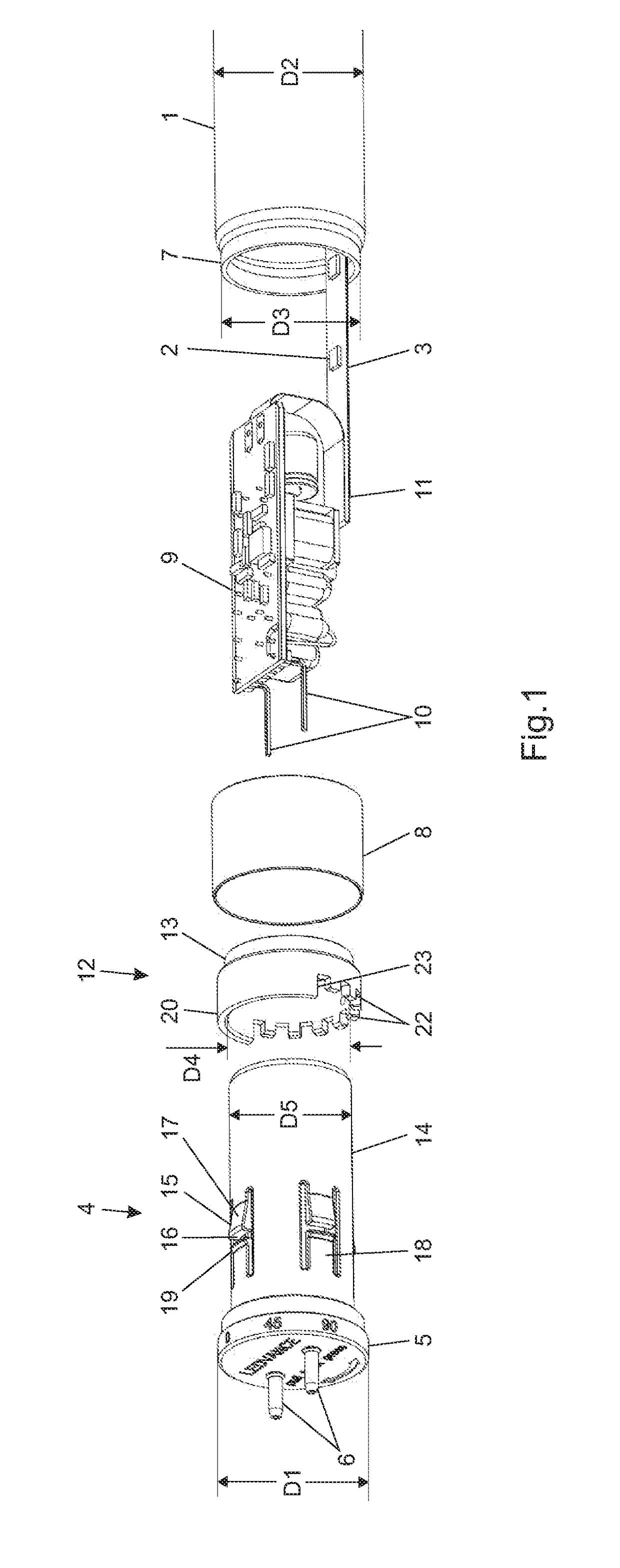

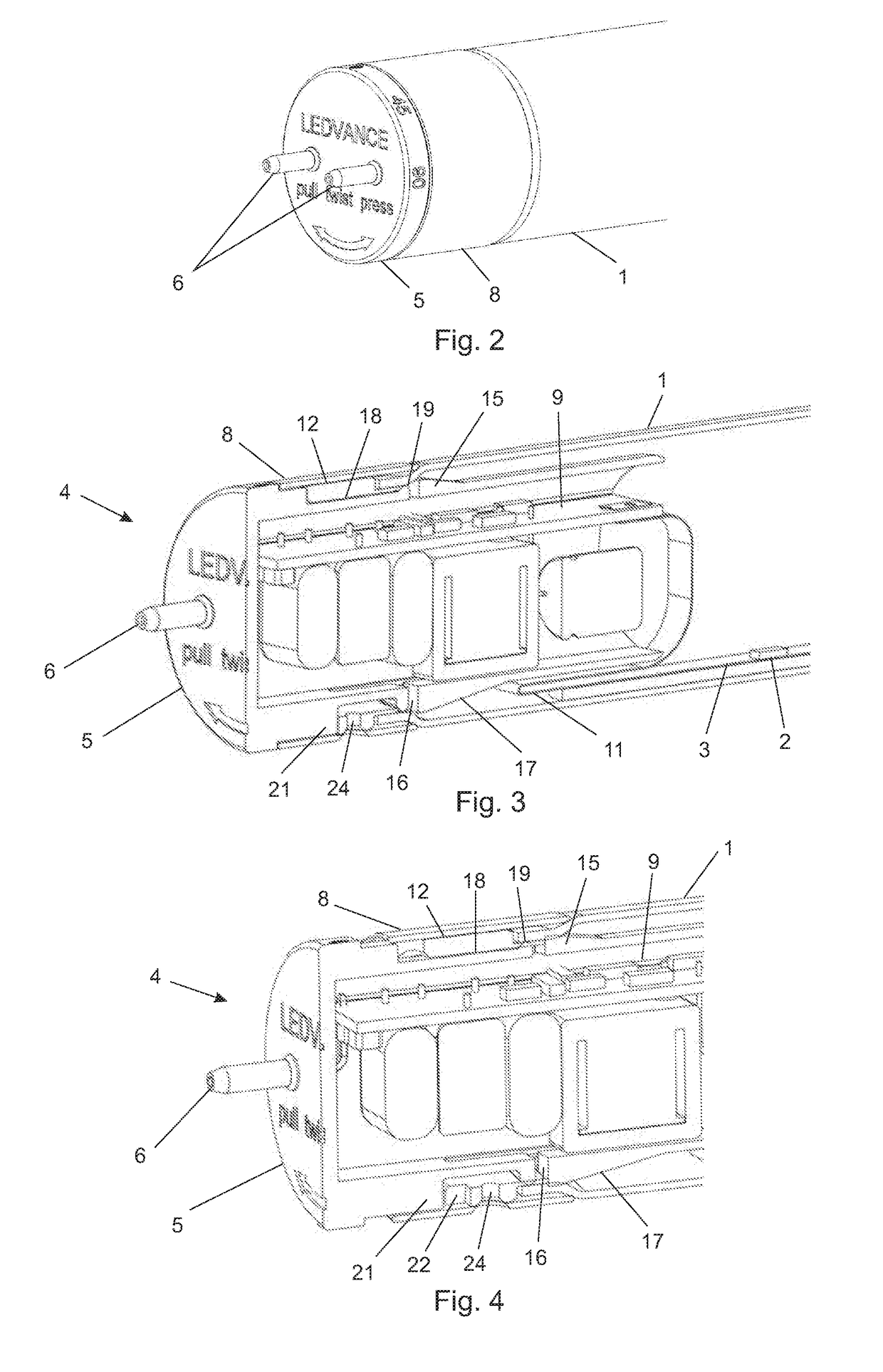

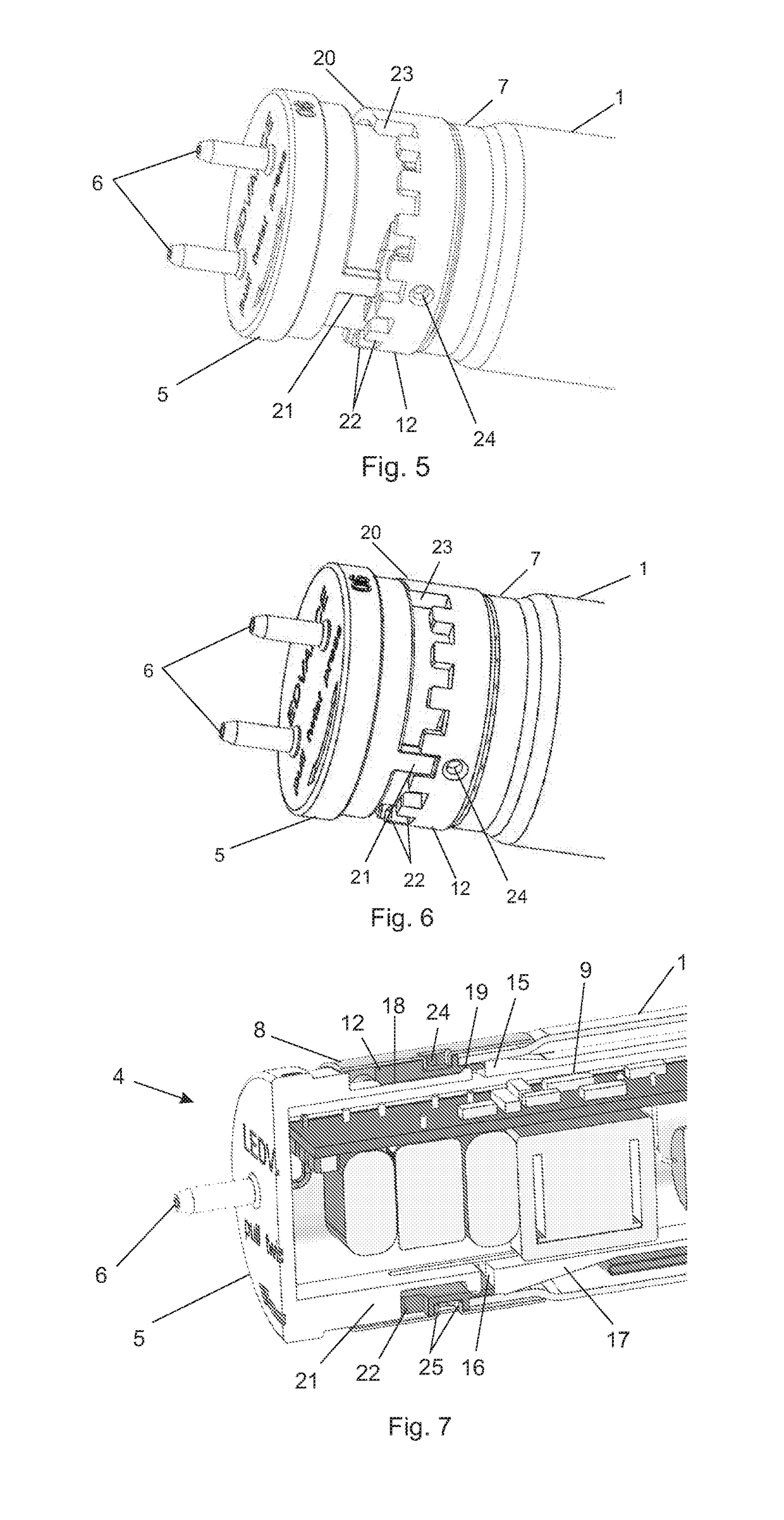

Rotateable endcap / base for tube lamps

ActiveUS20190063690A1Avoid mechanical loadLess spaceElectric circuit arrangementsLight fasteningsEngineeringBiological activation

A lamp includes a base with at least two electrical connecting elements. A bulb is rotatably mounted relative to the base. A light engine is arranged in the bulb with at least one light-emitting element and an electrically conductive substrate on which the light-emitting element is arranged. An electronic driver is connected to the electrically conductive substrate for activation of the light-emitting element. The base has a base sleeve in which the electronic driver is arranged. The electrically conductive substrate has a flexible connecting section between the electronic driver and the light-emitting element.

Owner:LEDVANCE GMBH

Clamping device for stretching a threaded bolt

ActiveUS20180015577A1Easy to operateOperational reliability is increasedMeasurement devicesMetal working apparatusScrew threadPhysics

A clamping device for stretching a threaded bolt by pulling on its threaded end section has a support tube surrounding the threaded end section, a cylinder disposed in extension of the support tube, a piston axially movable therein, a changeover bush to be screwed onto the threaded end section and carried along axially by the piston, a hydraulic device for the piston, and a signal link between hydraulic device and a device for detecting the extent of the thread engagement between the changeover bush and the threaded end section. A contactless measurement of the thread engagement between changeover bush and bolt to be clamped for measuring the thread engagement is provided in that the device for detecting the extent of the thread engagement includes a sensor element fastened on the changeover bush, which is positioned axially opposite the end face of the threaded bolt with axial separation.

Owner:HOHMANN JORG +1

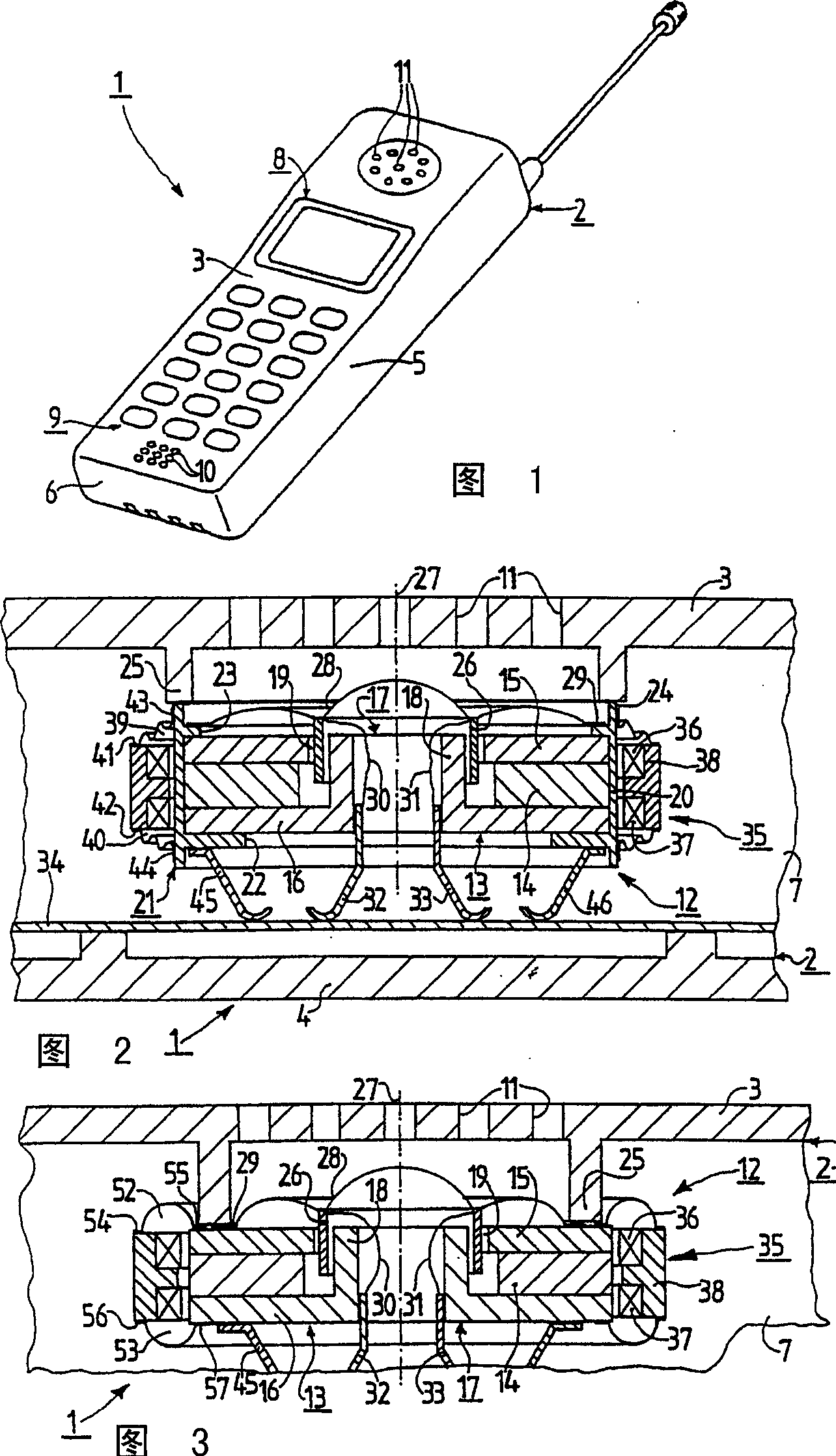

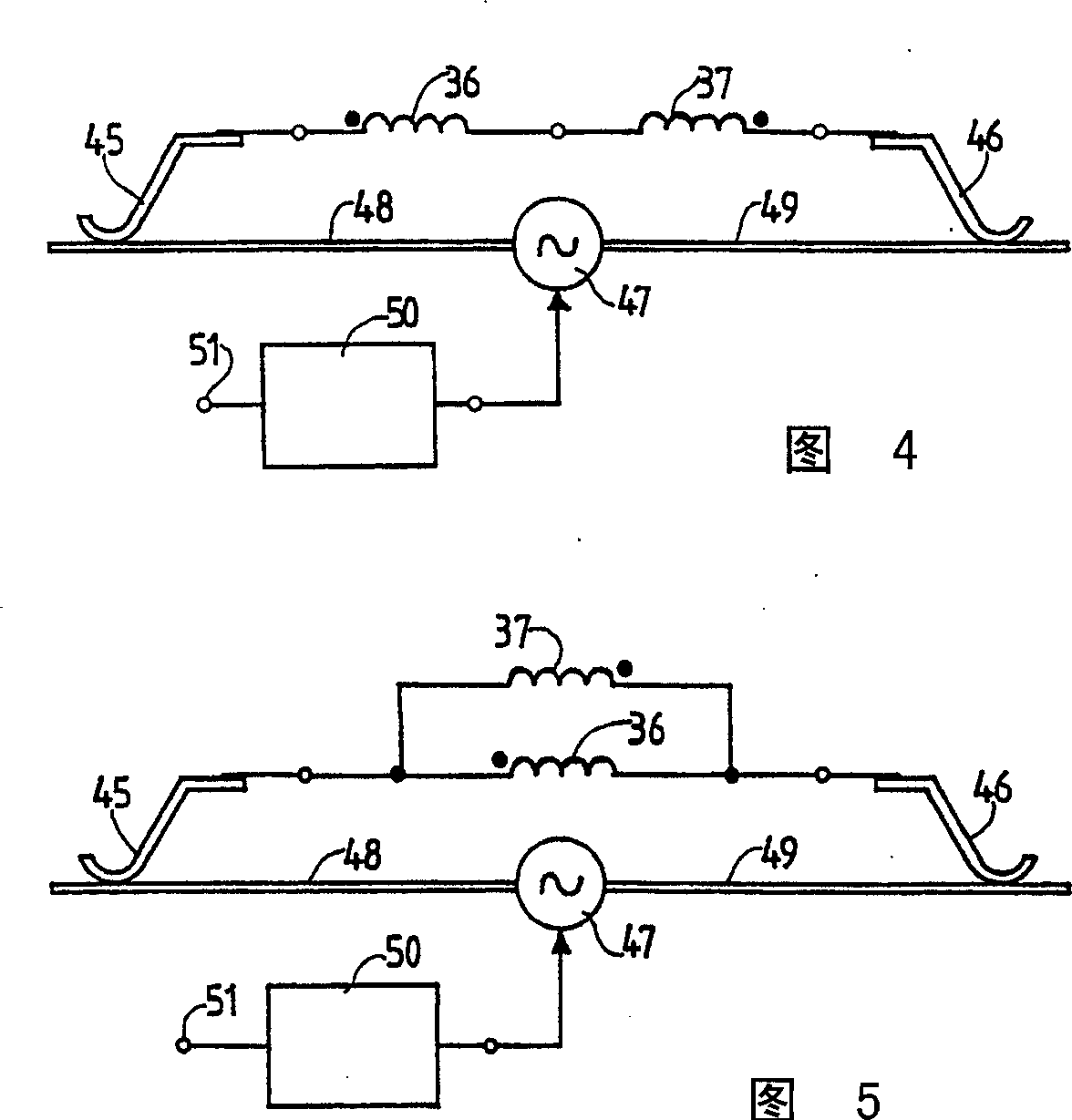

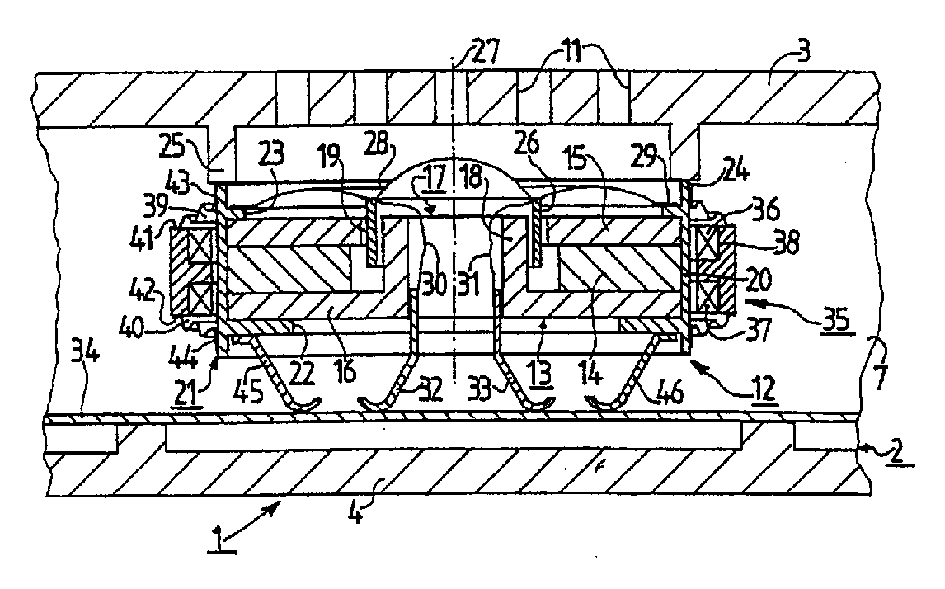

Apparatus having an electroacoustic transducer forming sound reproducing means and part of vibration generating means

InactiveCN1362895AAvoid mechanical loadGood vibration effectElectrical transducersMechanical vibrations separationTransducerMagnet

In an apparatus (1) having an electroacoustic transducer (12) which includes a magnet system (13) which is used to realize vibration generating means (35) the vibration generating means (35) include, in addition to the magnet system (13), at least one movably mounted vibration generating coil (36, 37) arranged in the stray field area of the magnet system (13), the vibration generating coil (36, 37) being preferably also connected to a metal part (38) which consists of a soft-magnetic material.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Device for temporary, local administration of fluids

ActiveCN112516441AAvoid external shape deformationExternal dimensionally stableMedical devicesCatheterManual insertionEngineering

The invention relates to a device and method for local administration of a medical fluid. The device having a hose which is flexibly deformable and has a hose wall. The hose wall has an outer wall ofa first material, which is arranged radially to the outside, and the an inner wall of a second material, which is arranged radially to the inside and which delimits an inner conduit of the hose. In adistal portion of the hose, the hose has multiple orifices in the hose wall. The multiple orifices connect the inner conduit with the surroundings of the hose. The distal portion of the hose is delimited by a distal end of the hose, the device further has a closing element, the hose is closed or closable in a liquid-tight manner at the distal end of the hose by means of a closure element. The closing element is manually insertable into the distal end of the hose. A proximal end of the hose is connectable with a container for the medical fluid such that the medical fluid is able to be forced out of the container through the proximal end of the hose into the inner conduit of the hose and forced through the multiple orifices to the surroundings of the hose.

Owner:HERAEUS MEDICAL

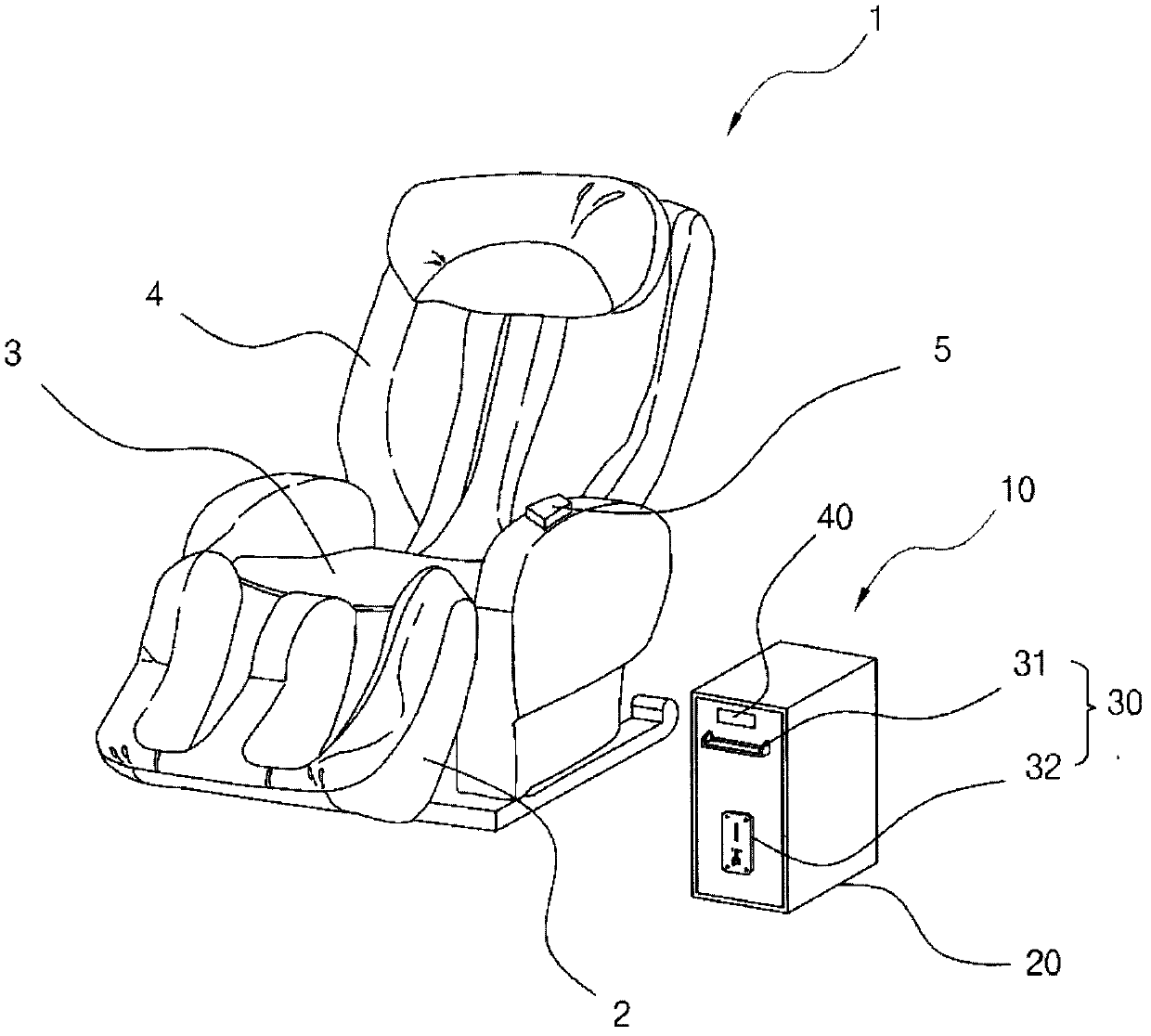

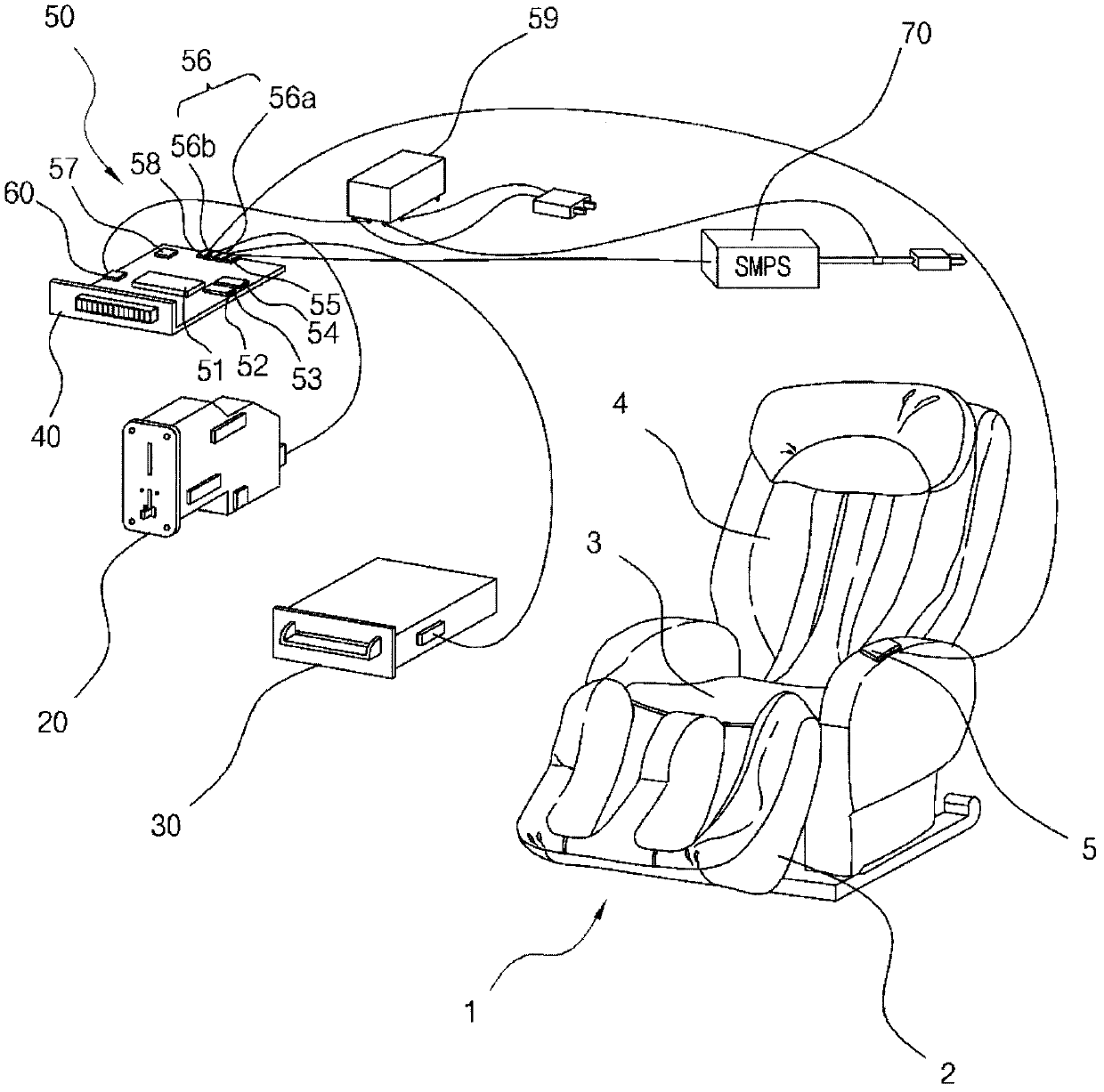

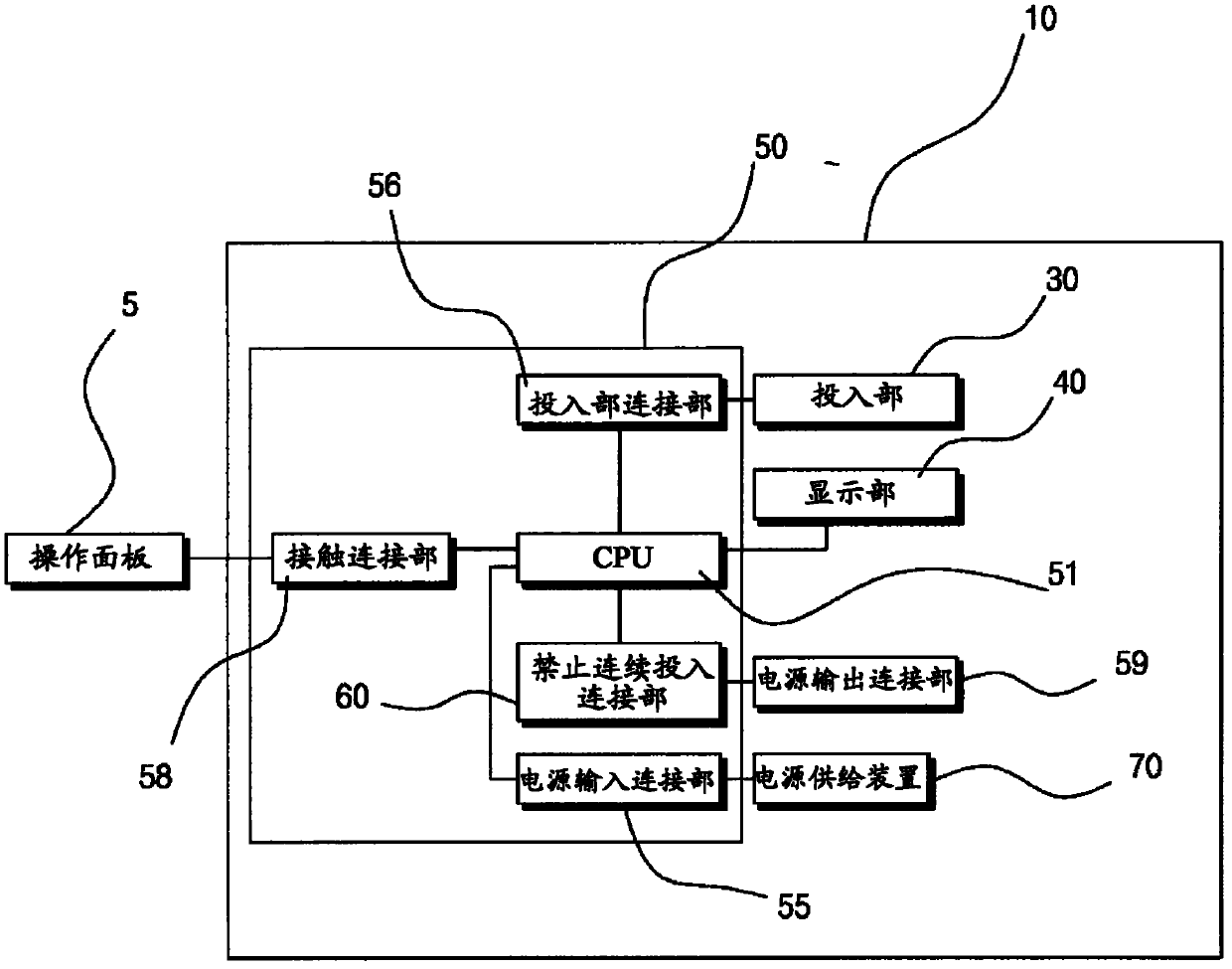

Device and method for controlling massage chair with reclining function

InactiveCN103379888AAvoid inconvenienceEliminate dissatisfactionApparatus for meter-controlled dispensingReclining chairsEngineeringMassage

The present invention relates to a device and a method for controlling a massage chair. According to one embodiment of the present invention, provided are a device and a method for controlling a massage chair with a reclining function, comprising: a case having a space portion inside; an insertion portion through which a coin or paper money is inserted, provided at one side of the space portion of the case; a display portion for displaying the sum of the inserted coin or paper money and time, provided at one side of the insertion portion; a control portion for transmitting an operation signal to an operation panel provided at one side of a massage chair to control the operation of the massage chair, provided at one side of the display portion; and a power supply device for supplying power to the control portion, provided at one side of the control portion.

Owner:INNO I

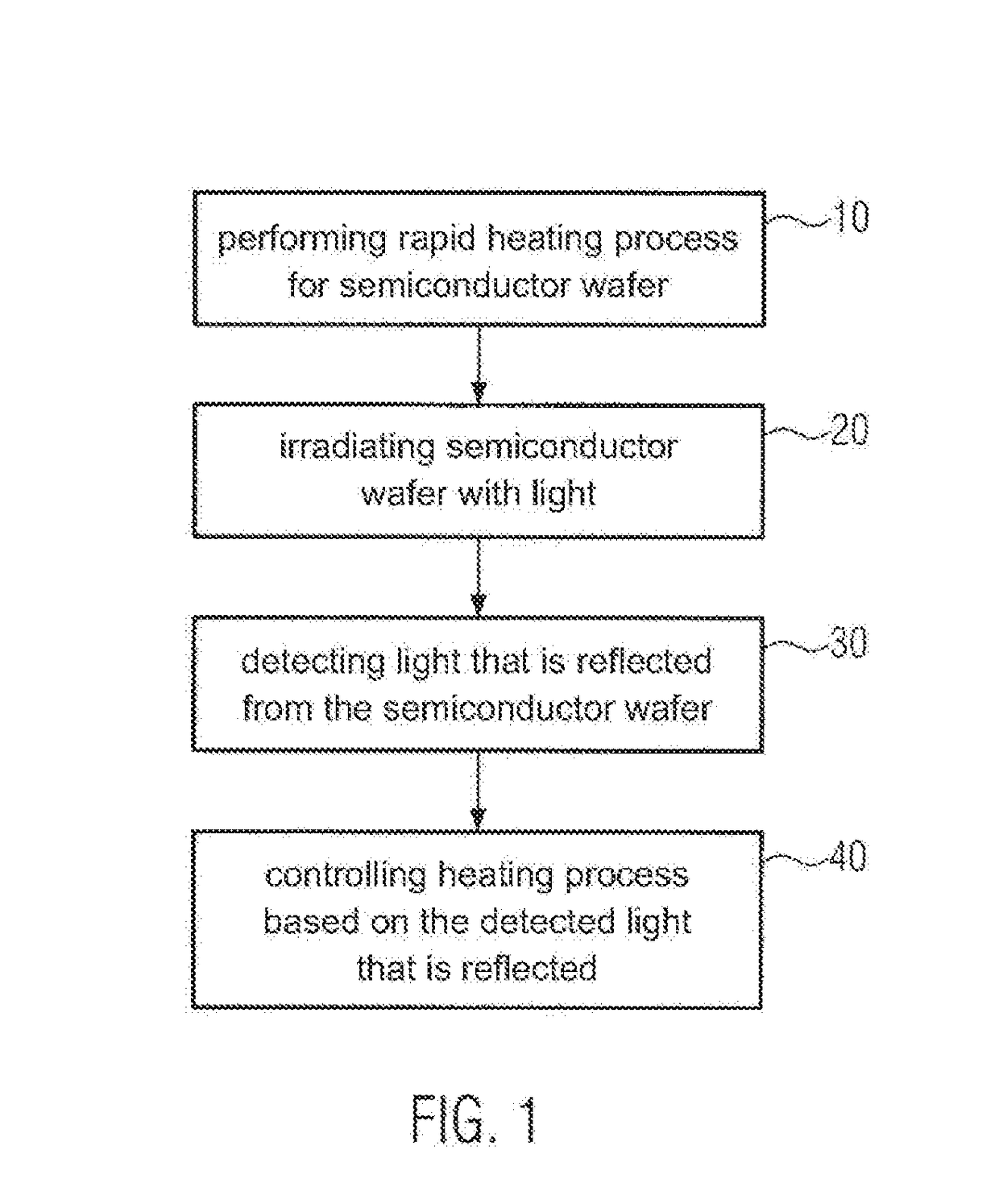

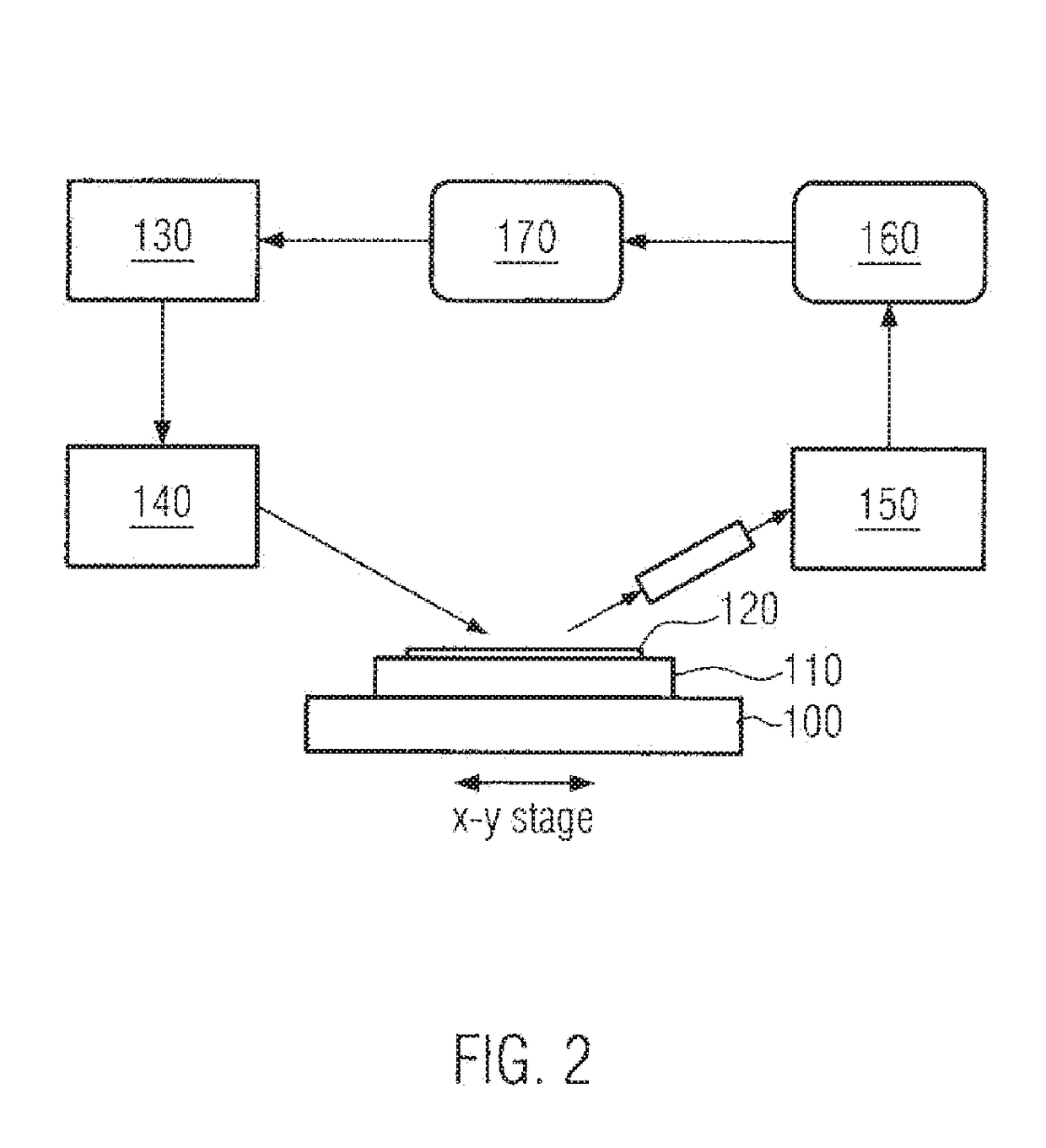

Rapid heating process in the production of semiconductor components

ActiveUS20170236721A1Increase spacingGood repeatabilityTransistorSemiconductor/solid-state device testing/measurementLaser beamsSemiconductor components

A method for monitoring a rapid heating process to which a semiconductor wafer is subjected includes performing the heating process for a region of the semiconductor wafer, irradiating the semiconductor wafer with a laser beam, detecting light of the laser beam that is reflected from the semiconductor wafer, creating haze data based on the detected light and determining heated regions and / or transition regions between heated and non-heated regions of the semiconductor wafer on the basis of the haze data.

Owner:GLOBALFOUNDRIES US INC

Devices for temporary topical application of fluids

ActiveCN112516441BAvoid external shape deformationExternal dimensionally stableMedical devicesCatheterEngineeringMechanical engineering

The present invention relates to an apparatus and method for topical administration of medical fluids. The device has a hose that is flexibly deformable and has a hose wall. The hose wall has an outer wall of a first material and an inner wall of a second material, the outer wall being arranged radially outside, and the inner wall being arranged radially inside and delimiting the inner conduit of the hose. The hose has a plurality of orifices in the hose wall in the distal portion of the hose. A plurality of orifices connect the inner conduit of the hose with the surrounding environment of the hose. The distal portion of the hose is bounded by the distal end of the hose. The device has a closing element by which the hose is closed or can be closed in a liquid-tight manner at the distal end of the hose. The closure element can be manually inserted into the distal end. The proximal end of the hose is connected or connectable in a liquid-permeable manner with a container for medical fluid, so that the medical fluid can be pressed from the container through the proximal end of the hose into the inner conduit of the hose and through Multiple orifices press out into the surroundings of the hose.

Owner:HERAEUS MEDICAL

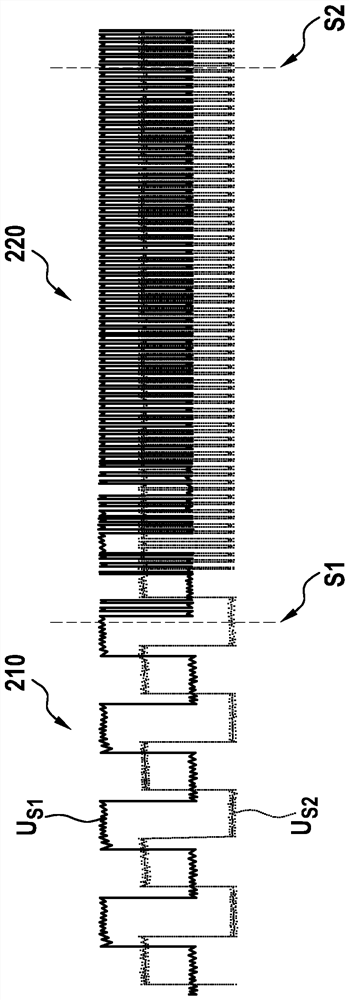

Method for switching off a multi-phase electric machine in a motor vehicle

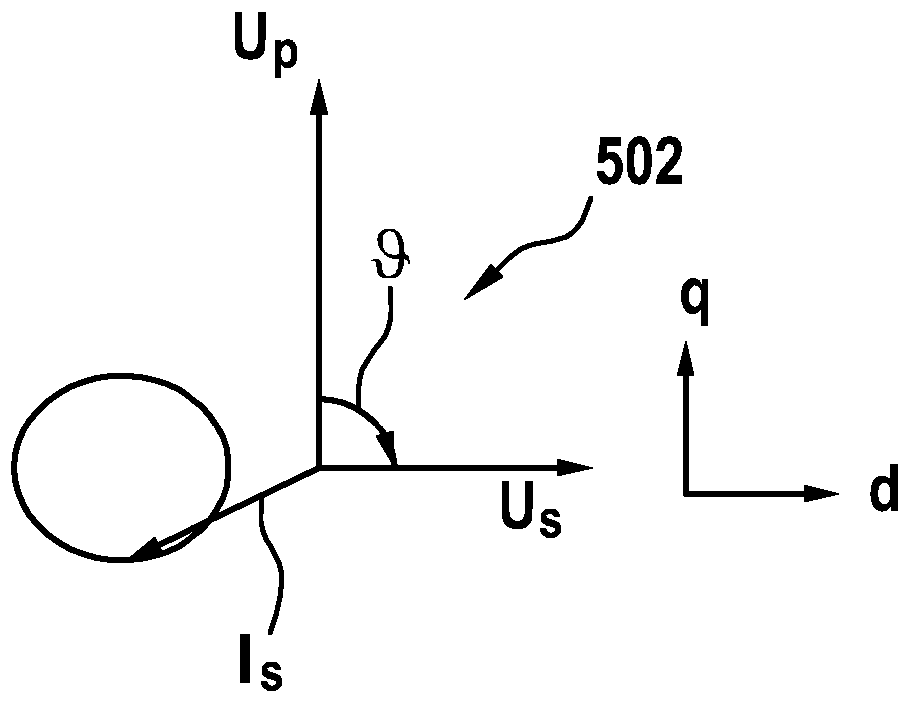

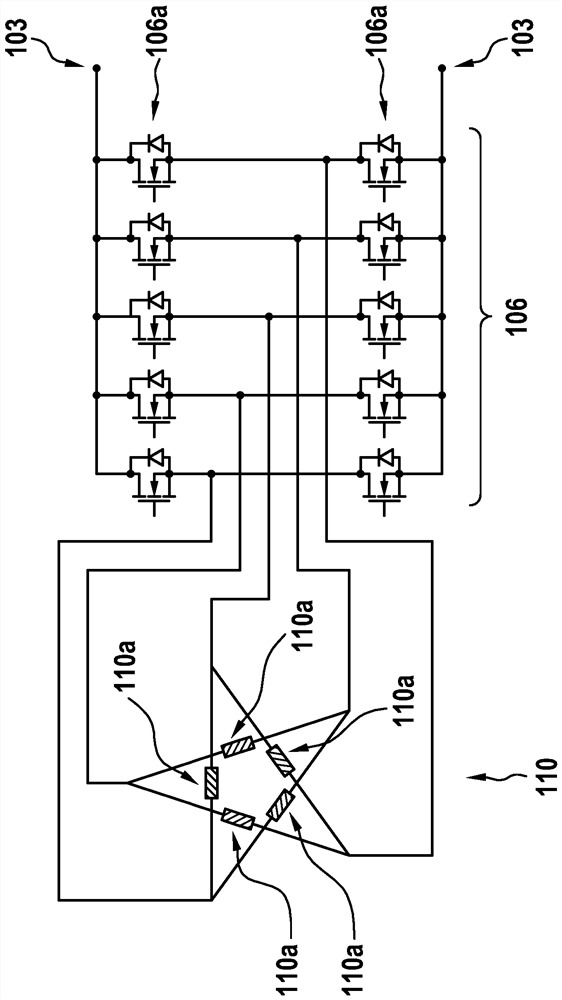

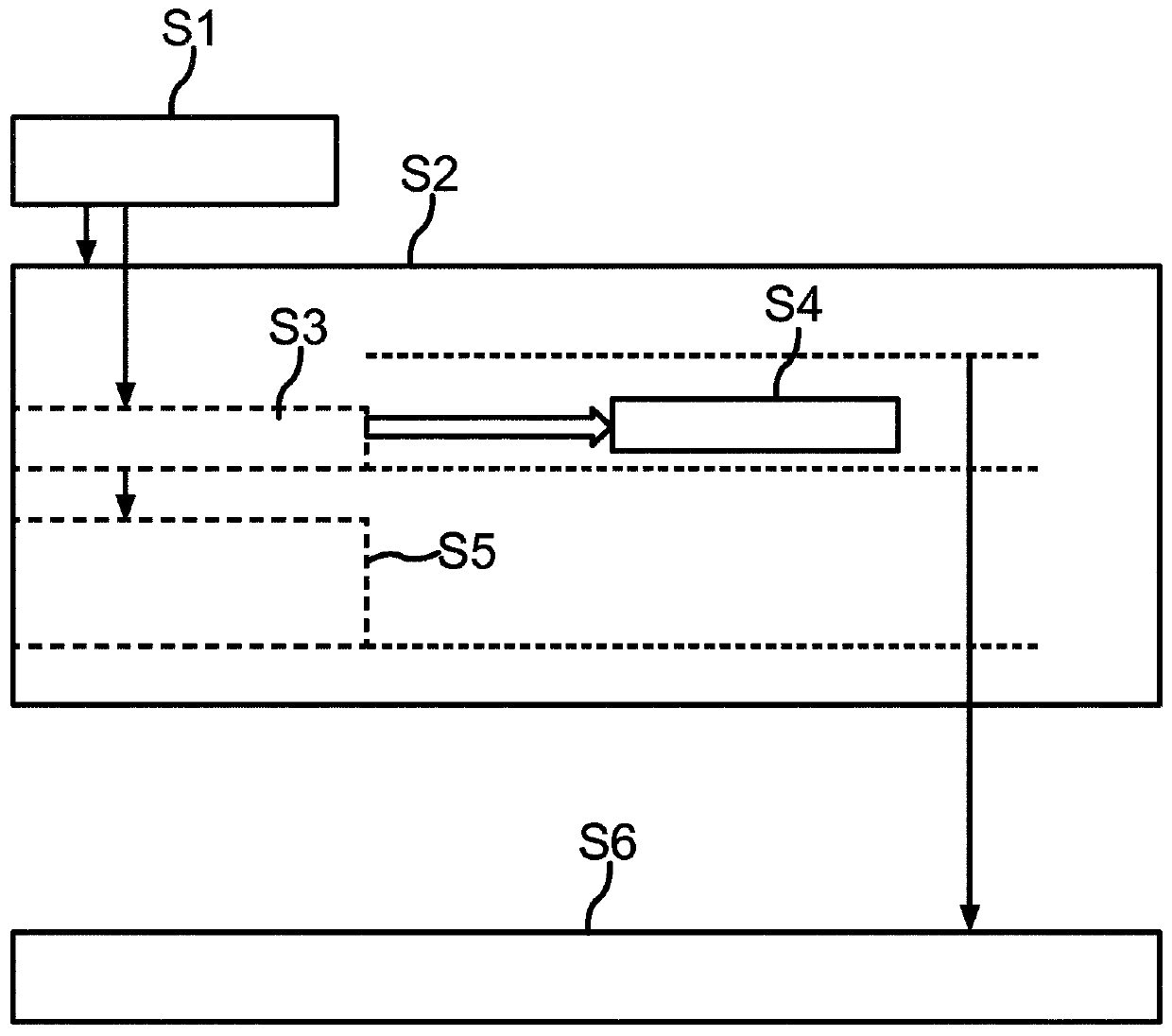

ActiveCN109247057BAvoid flowPrevent hot loadingSpeed controllerMotor/generator/converter stoppersAutomotive engineeringInductor

The invention relates to a method for switching off a polyphase electric machine (110) in a motor vehicle, wherein the polyphase electric machine (110) comprises a rotor with a rotor winding (101) and a stator winding with multiple phases (110a ) of the stator, where, in block operation (210) of the motor (110), the inductor voltage vector (U p ) parameters are changed such that the inductor voltage reaches the first threshold (S 1 ), where the block runs (210) upon reaching the first threshold (S 1 ) is deactivated, and is applied with a phase voltage vector (U s ) phase voltage PWM operation (220) is activated, where the phase voltage vector (U s ) and the inductor voltage vector (U p ) is changed during PWM operation (220) until the parameter affecting the inductor voltage reaches another threshold (S 2 ), where, when another threshold is reached (S 2 ), the phase voltage (U s ) is turned off. The invention also relates to a computing unit ( 112 ) configured to implement the method.

Owner:ROBERT BOSCH GMBH +1

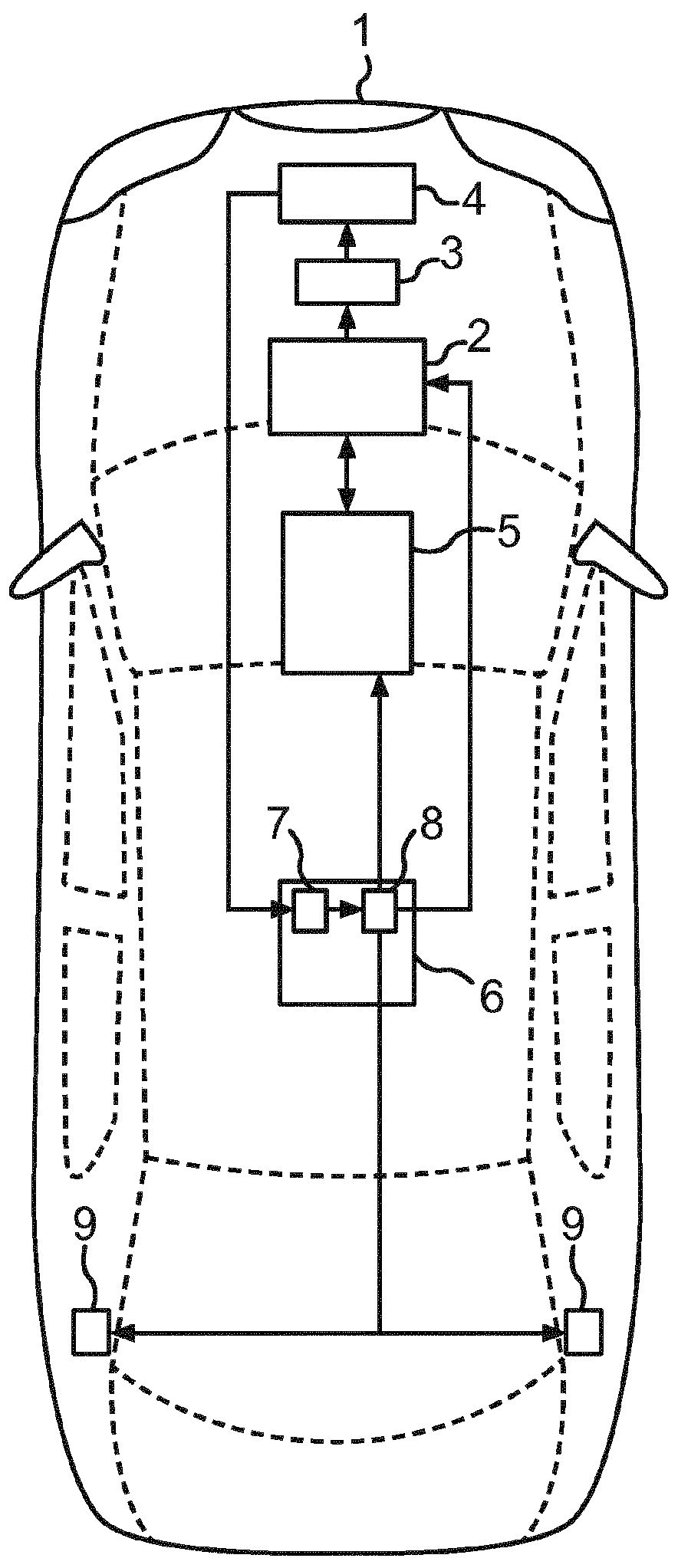

Method and device for setting an idling speed of an internal combustion engine of a motor vehicle and motor vehicle

ActiveCN110088452AIncreased idle speedImprove idle speedHybrid vehiclesElectrical controlIn vehicleInternal combustion engine

The invention relates to a method for setting an idling speed of an internal combustion engine (2) of a motor vehicle (1), in which the idling speed of the internal combustion engine (2) is increasedif a predetermined power request within an on-board power system (4) of the motor vehicle (1) is detected, wherein a generator (3) for electrically supplying the on-board power system (4) is driven bymeans of the internal combustion engine (2), and wherein the internal combustion engine (2) is connected to a transmission (5) of the motor vehicle (1), wherein the connection between the internal combustion engine (2) and the transmission (5) is disconnected, and / or a predetermined braking force is made available by means of at least one brake (9) of the motor vehicle (1) if the predetermined power request is detected.

Owner:AUDI AG

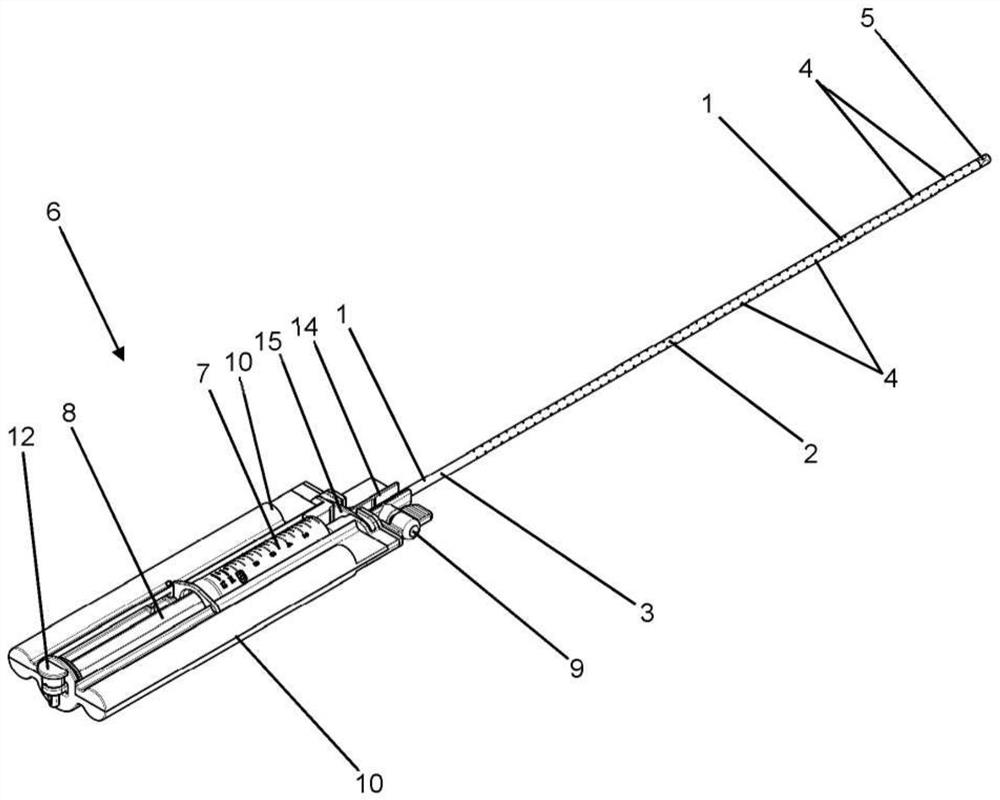

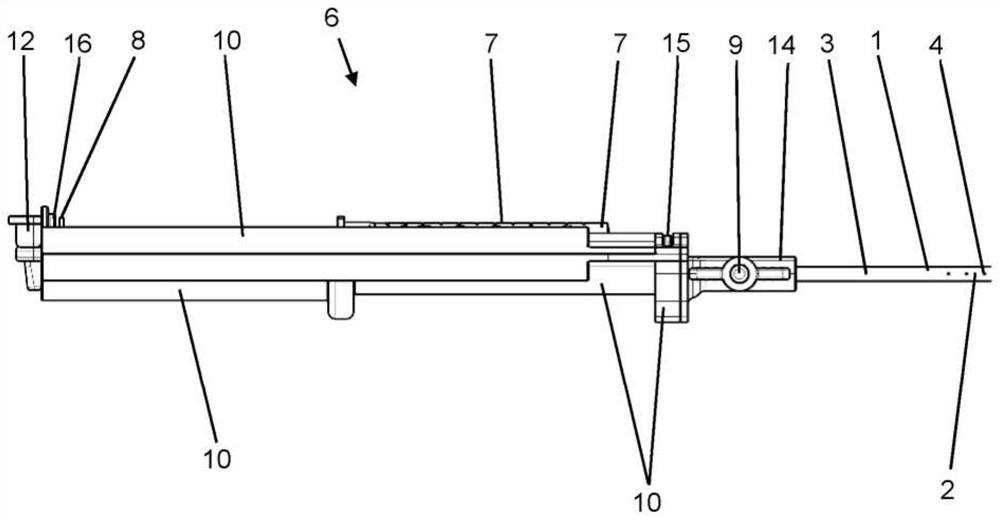

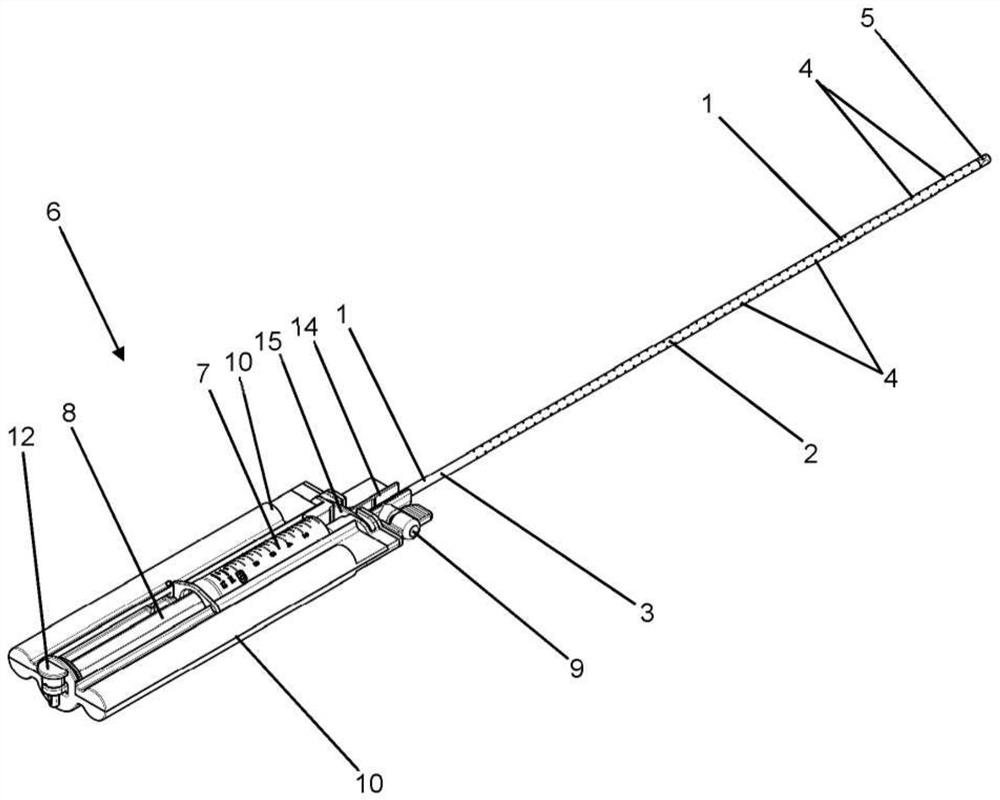

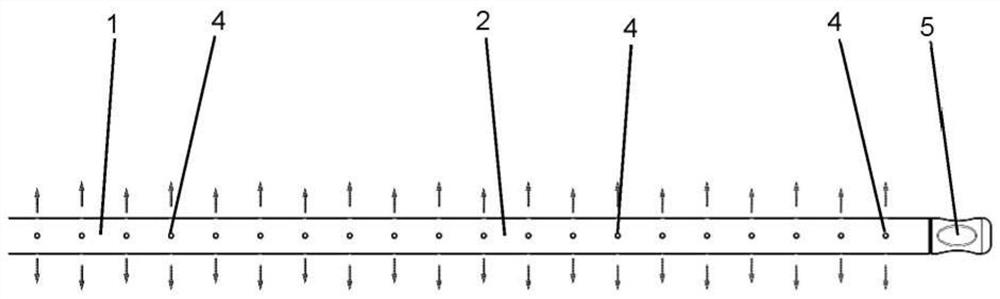

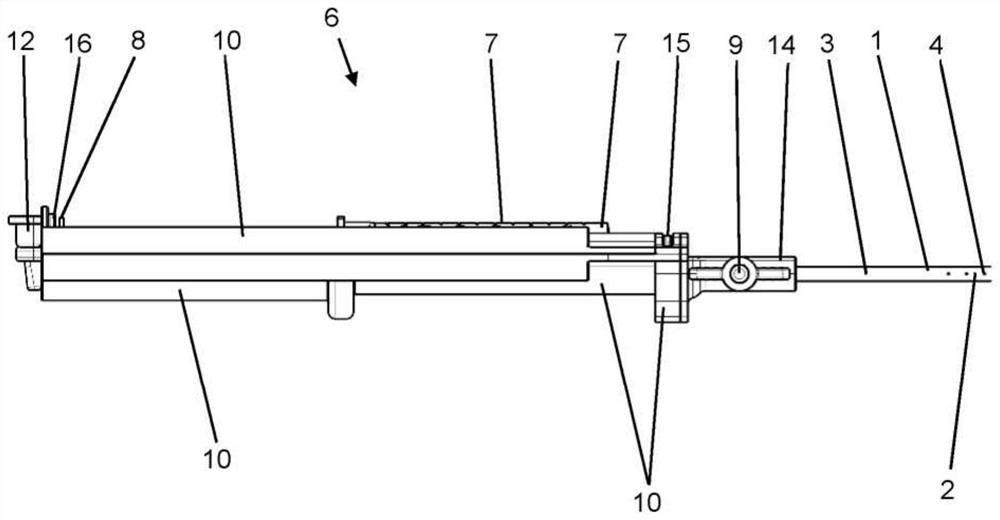

Method and device for the quality control of superconducting bands

ActiveUS9081048B2Carry-out quicklyAvoid mechanical loadSuperconductive properties measurementsFault location by increasing destruction at faultElectricityQuality control

A method and device for quality control of superconducting bands includes: cooling a section of the superconducting band to a temperature at which said band section becomes superconducting, generating an electrical transport current in the superconducting band section in the longitudinal direction of the band by contacting with a contact assembly, contacting the cooled band section with electrical contacts of the contact assembly, which are spaced apart in the longitudinal direction of the band, in order to form a measurement section over a partial length of the band section, continuously moving at least one part of the band through the contact section and / or measurement section to generate the transport current, detecting a physical measured variable using measurement contacts, wherein the physical measured variable is a measure of the superconducting electrical transport properties of the band section or a part of the band.

Owner:COMMONWEALTH FUSION SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com