Method for connecting parts of multiple-part rotor carrier and rotor carrier of electric engine

A rotor bracket, multi-piece technology, applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., can solve problems such as laborious reprocessing, imbalance, quality damage, etc., to achieve reduction The effect of small extrusion force and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

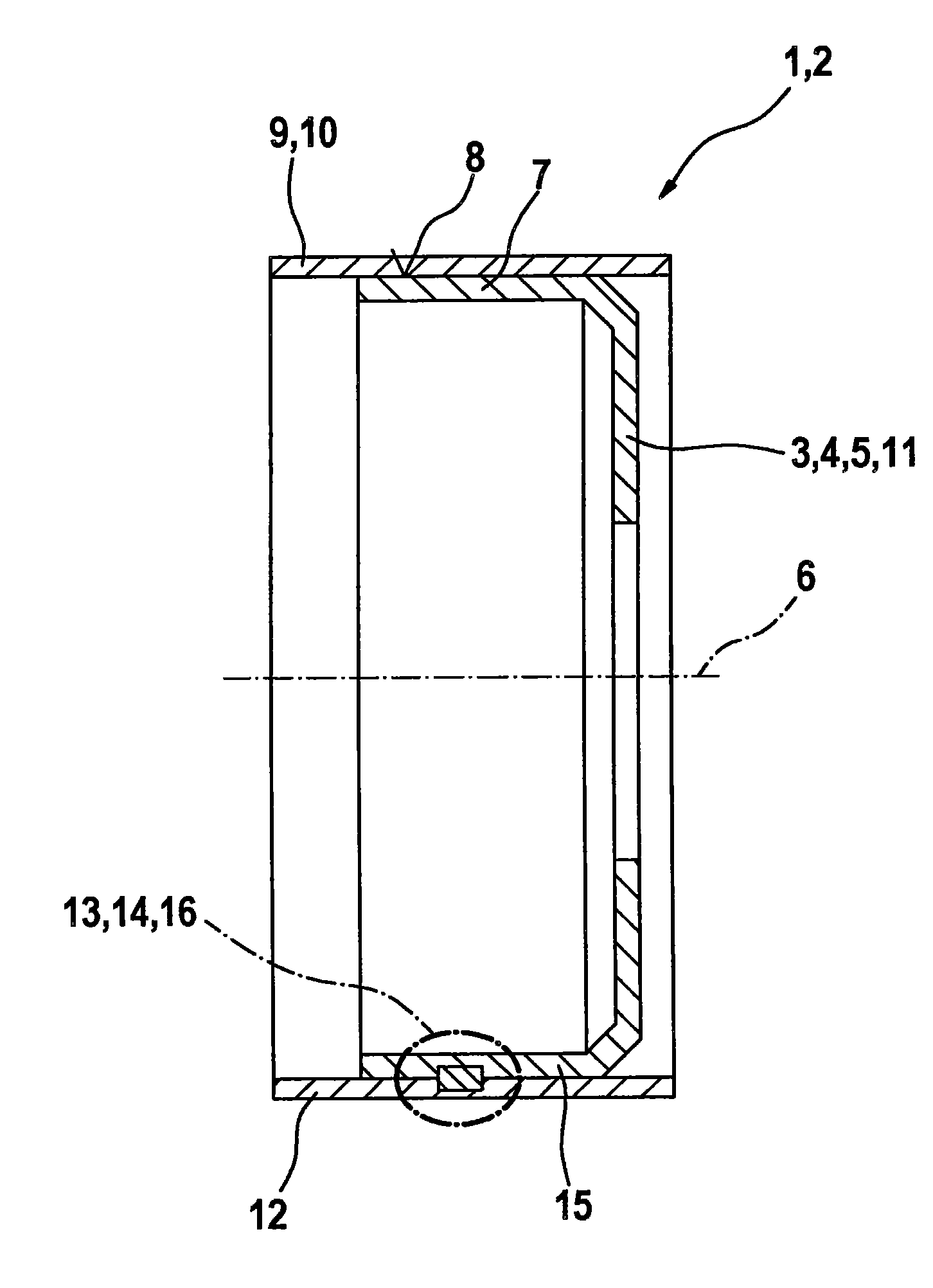

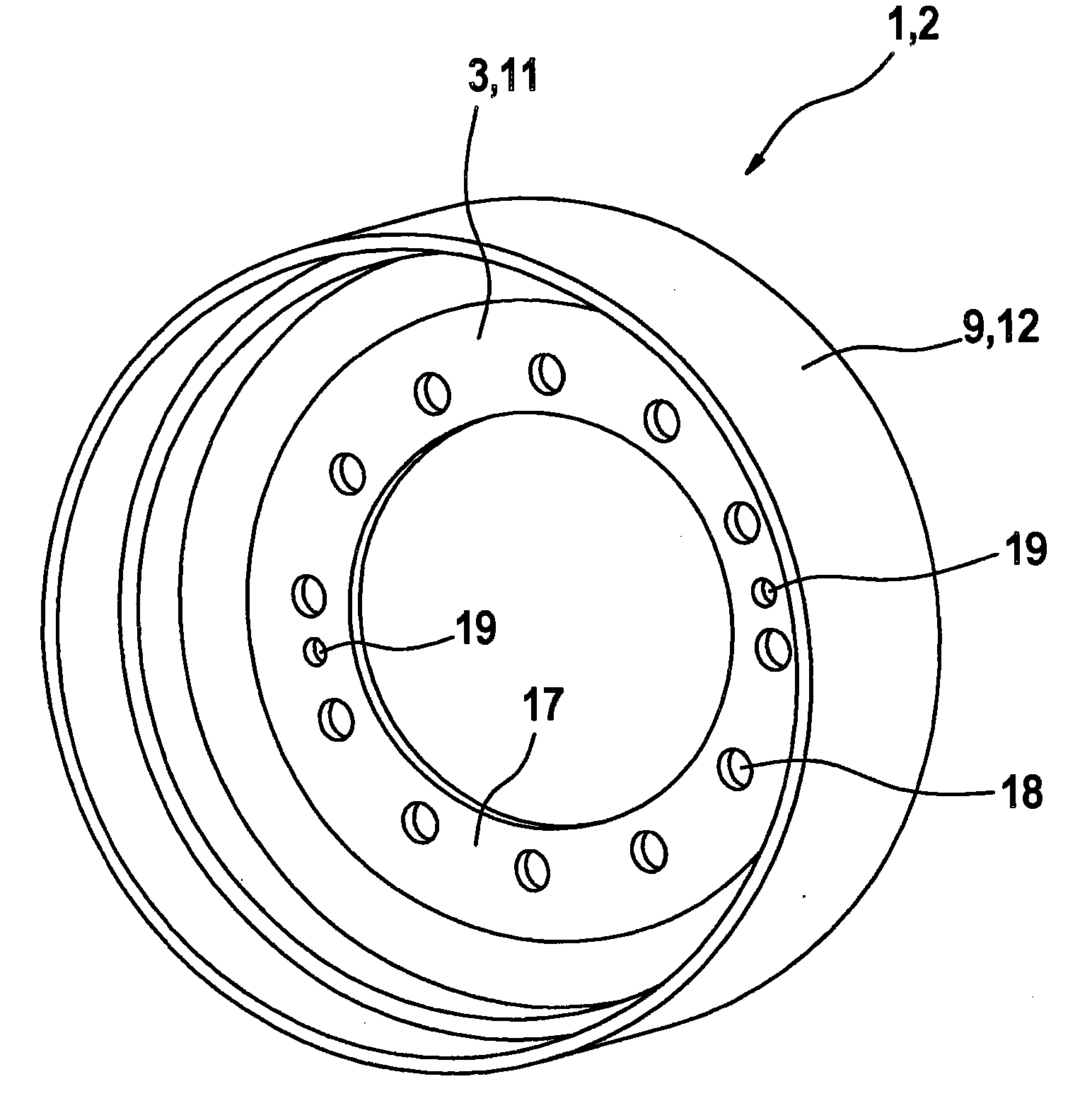

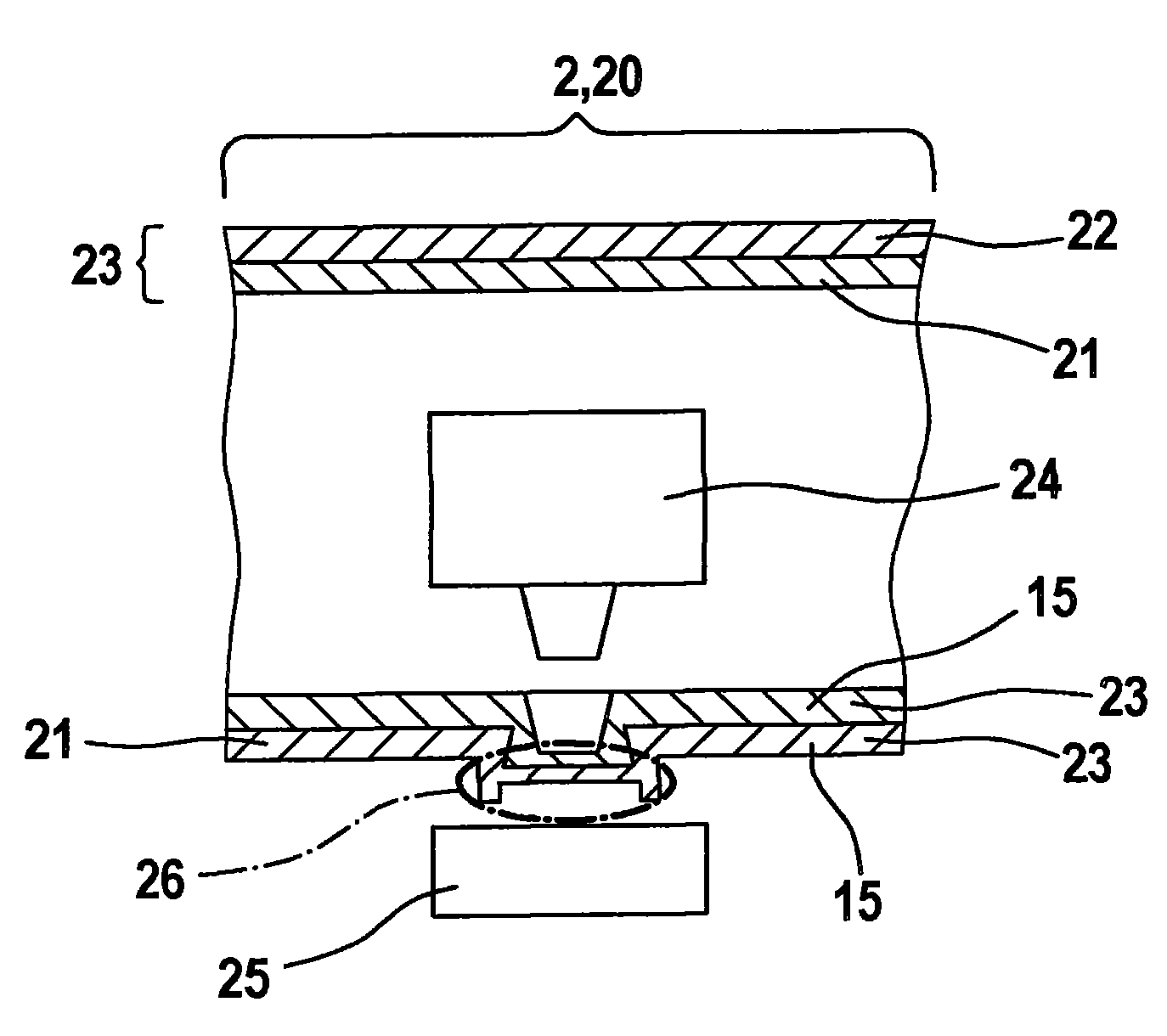

[0019] figure 1 A rotor carrier 1 is shown, ie a two-part rotor carrier 2 . The rotor carrier consists of a rotor hub 3 which is substantially designed in the form of a pot 4 , wherein the pot 4 has a rotating body 5 which is configured rotationally symmetrically with respect to the axis of rotation 6 of the rotor carrier 1 and has a A substantially parallel side wall section 7 of the axis of rotation 6, on the outer side 8 of which side wall section 7 is arranged a support part 9 of the rotor holder 1 in order to form the two-part rotor holder 2 and which forms is the pipe section 10 . In this case, the rotor hub 3 forms a part 11 of the rotor carrier 1 , and the support part 9 forms a further part 12 of the rotor carrier 1 . The one component 11 is connected to the other component 12 via at least one connecting point 13 , which is designed as a mixing joint 14 . In this case, the material 15 of the one component 11 penetrates into the other component 12 , so that the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com