Method for switching off a multi-phase electric machine in a motor vehicle

A technology of polyphase motors, motor vehicles, applied in the field of computer programs to solve problems such as undesired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

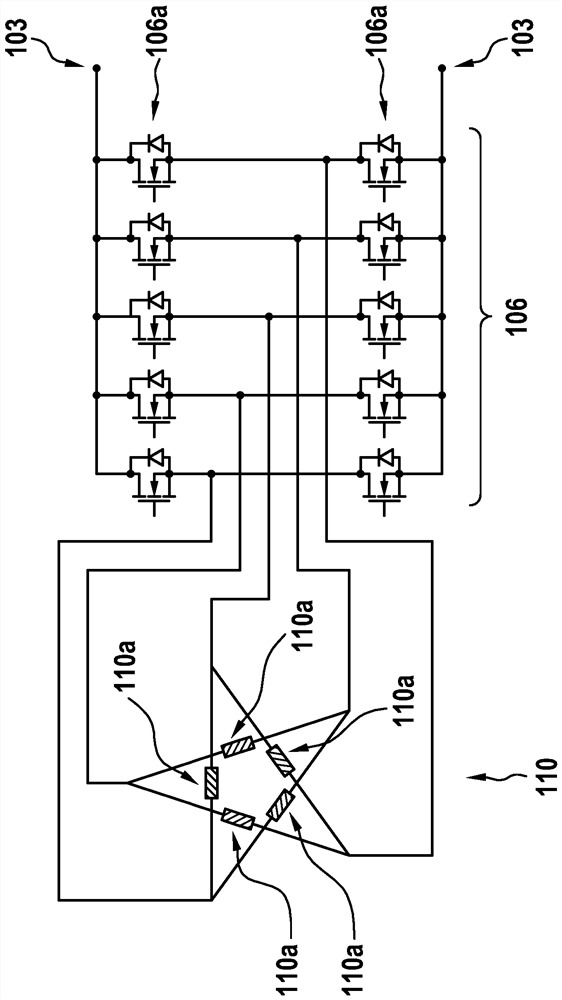

[0029] figure 1 Components of a motor vehicle are schematically shown. The motor vehicle has an electric machine 110 , an externally excited synchronous generator being the starting point below without limiting the generality. Electric machine 110 can be operated, for example, as a generator by internal combustion engine 109 of the motor vehicle. The electric machine 110 is connected in a torque-locked manner to the internal combustion engine 109 via a corresponding coupling means, for example a mechanical connection 108 in the form of a belt or a shaft. Alternatively, electric machine 110 can also be operated as a motor and can support internal combustion engine 109 here.

[0030] The electric machine 110 is electrically connected to the current converter 106 , wherein a plurality of phase connections 107 are provided. The current converter 106 can operate as a rectifier or as an inverter. The plurality of phase connections 107 are the phase connections of the multiphase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com