Furniture hinge comprising a damper and a spring

A buffer and furniture technology, applied in the field of furniture hinges, can solve the problems of increasing the manufacturing cost of furniture hinges, increasing component costs, and high installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

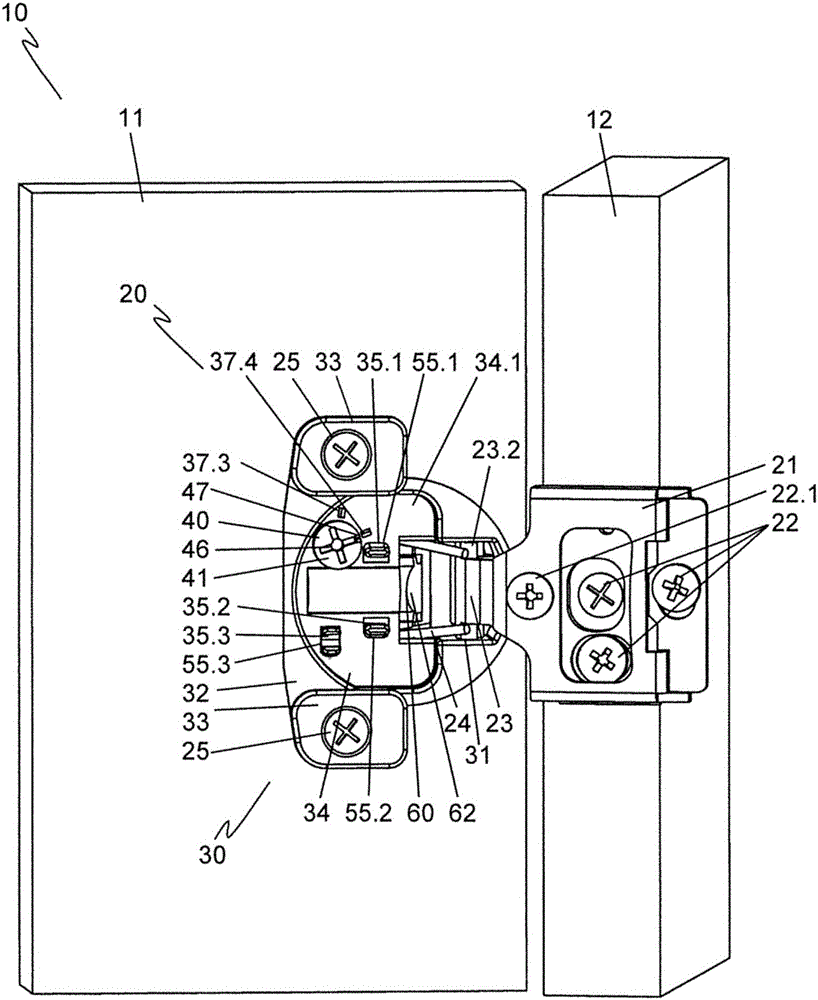

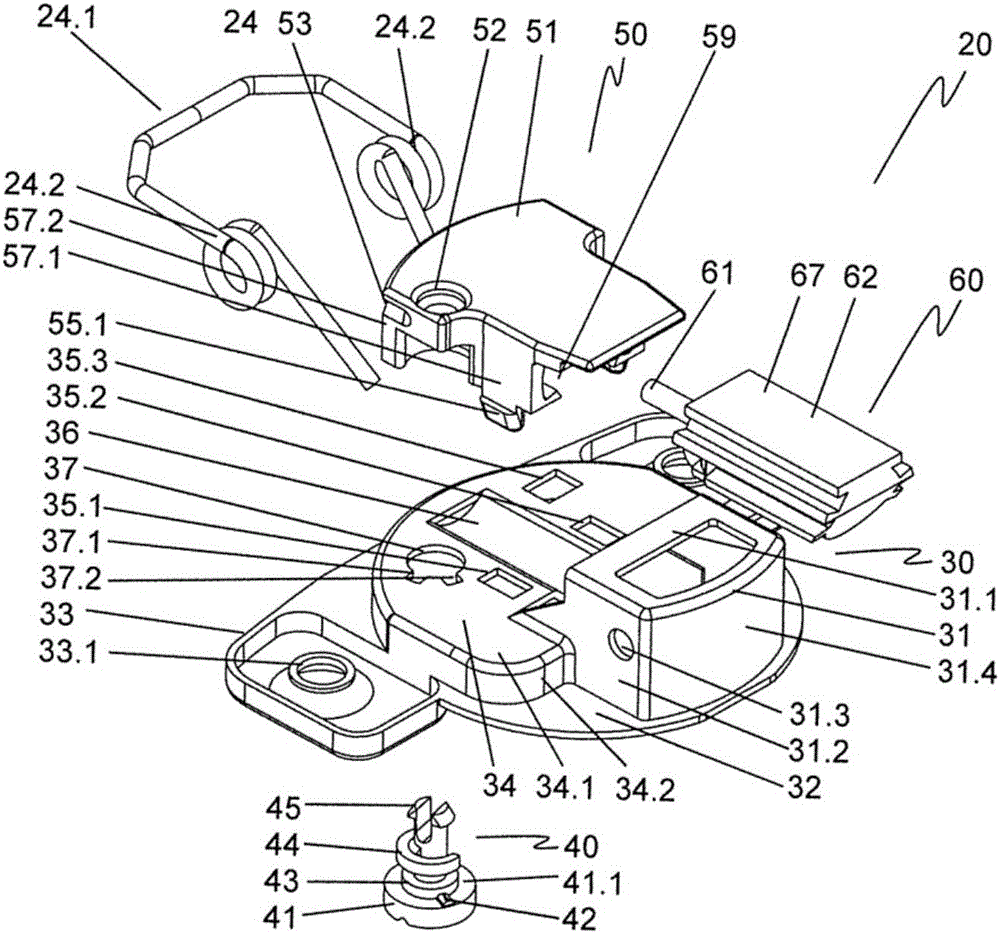

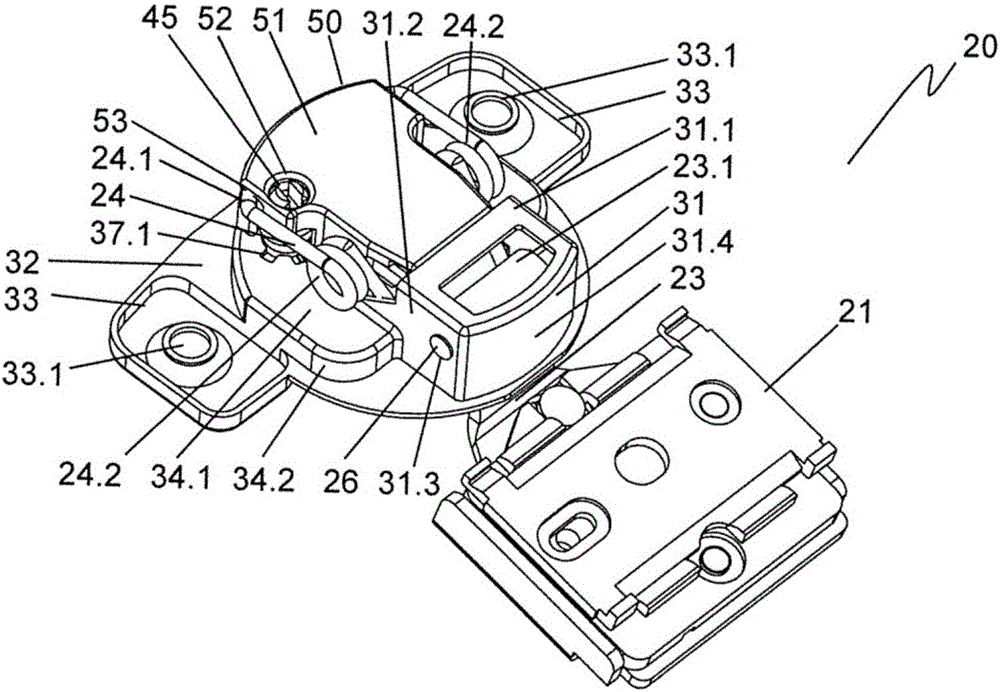

[0030] figure 1A detail of a piece of furniture 10 with a furniture hinge 20 is shown. The furniture hinge 20 connects the door 11 pivotably to the frame 12 of the furniture 10 . For this purpose, the stop element 21 is connected to the frame 12 and the hinge cup 30 is connected to the door 11 . The stop element 21 is fastened and aligned on the frame 22 via the mounting and adjustment element 22 . The hinge cup 30 is inserted into a hole in the door 11 and is screwed to the door 11 by means of screws 25 which are guided by side flanges 33 molded onto the hinge cup 30 at the side. The articulation lever 23 articulated on the hinge cup 30 within the centering region 31 connects the hinge cup 30 to the stop element 21 . The articulating lever 23 is screwed onto the stop element 21 by means of a fastening screw 22.1. The centering region 31 forms, starting from the outer support surface 32 , a depression which transitions into a mounting region 34 , which is likewise designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com