Patents

Literature

35results about How to "Eliminate dissatisfaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

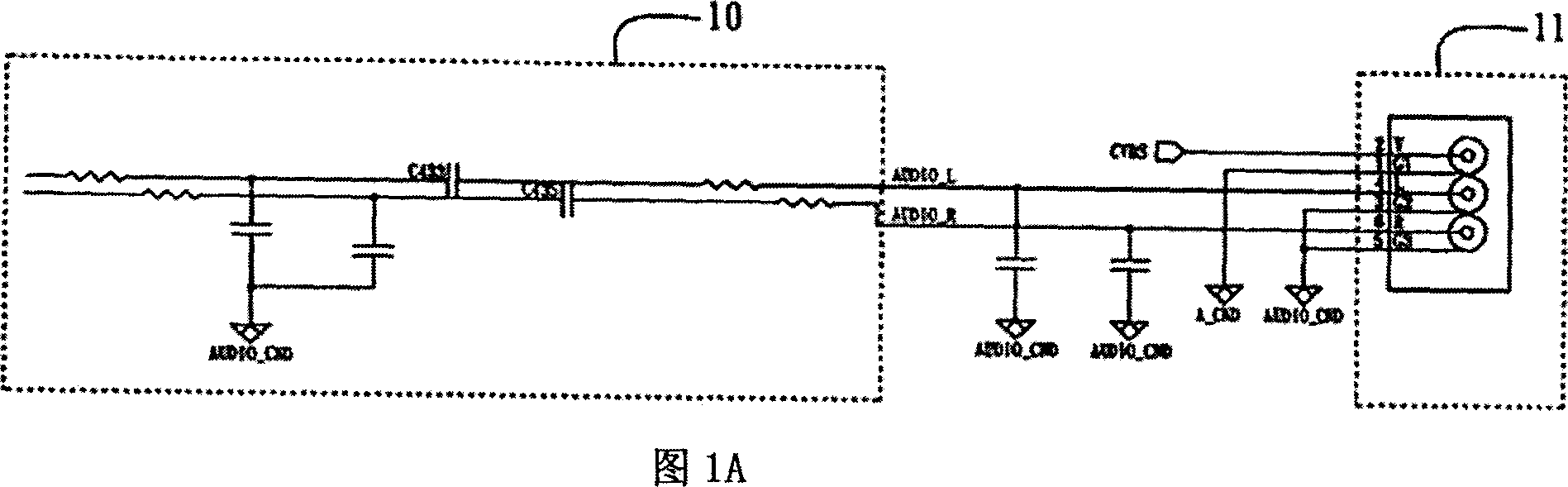

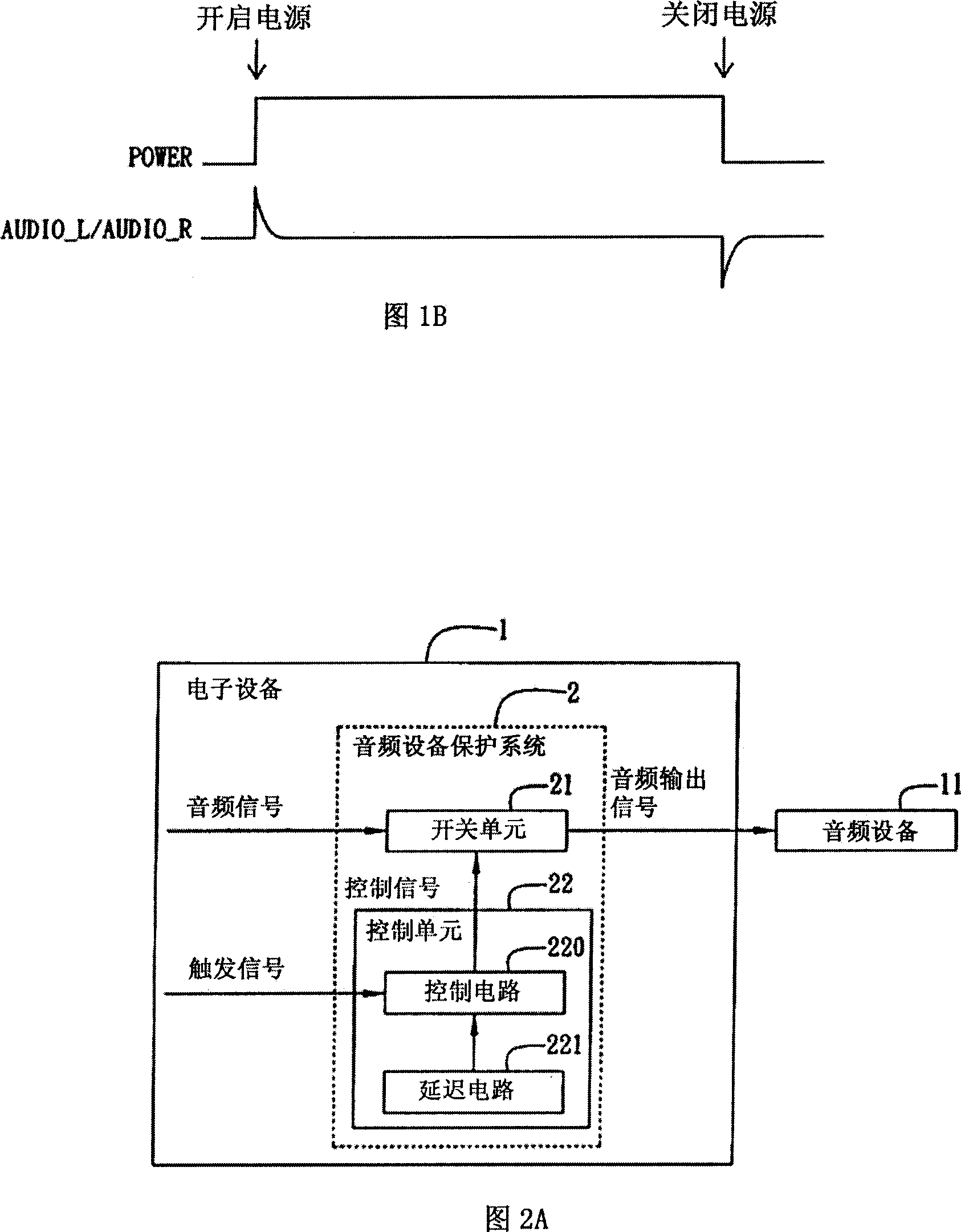

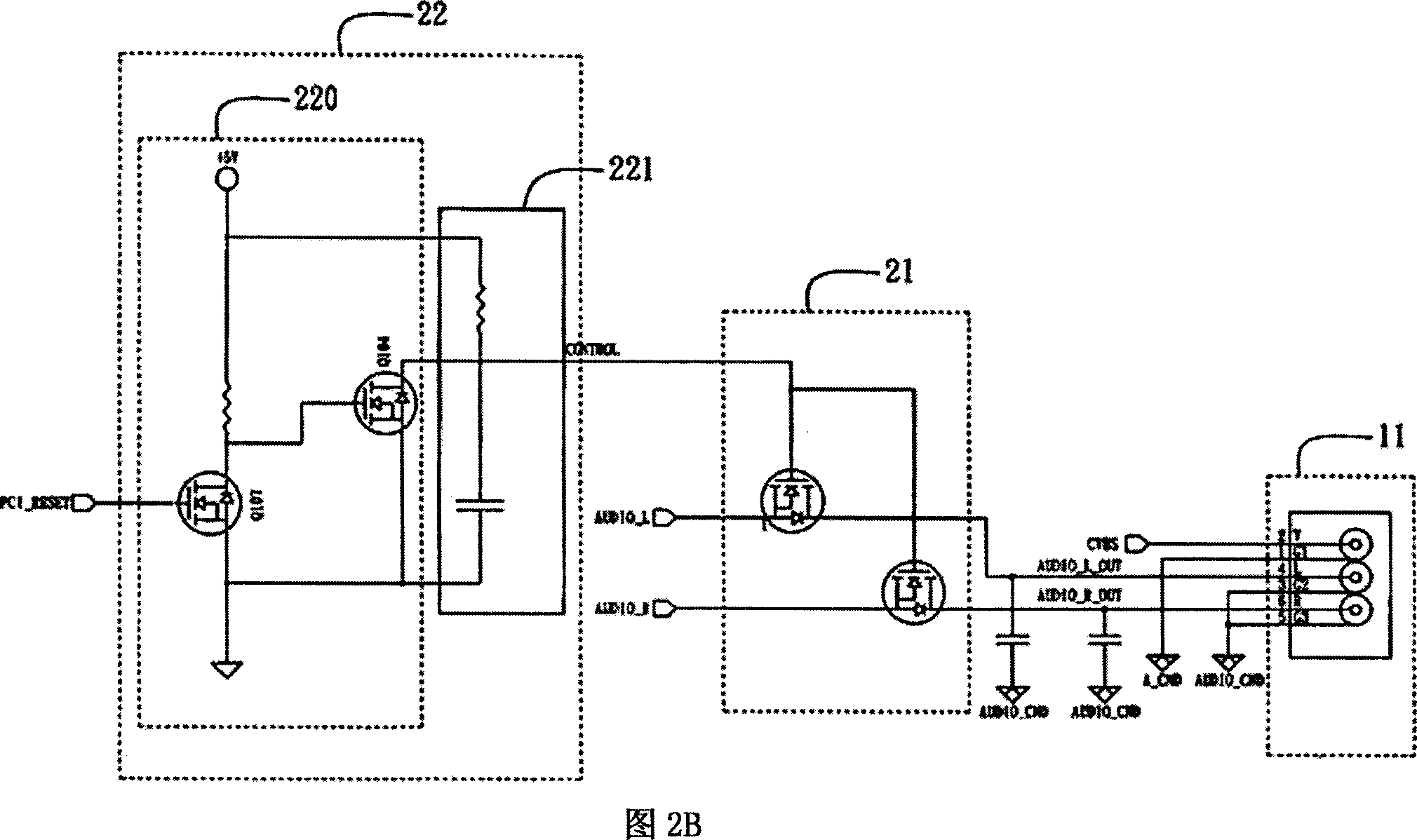

Audio device protection system

InactiveCN101087130ADisadvantages of Avoiding InjuryEliminate troublePulse manipulationEngineeringProtection system

The invention discloses an audio equipment protecting system, the audio equipment protecting system is applied in electronic equipment which is electric connected with audio equipment, the electronic equipment at least output audio signal, power on / off signal and trigger signal, the audio equipment protecting system includes: switching unit; and control unit; the audio equipment protecting system in the invention can eliminate audio noise output by electronic equipment on / off, so damnification of audio equipment induced by instant trigger and closing of noise can be avoided, so the audio equipment can not send audio noise of 'POP', obsession and inconvenience of user by audio noise can be eliminated.

Owner:INVENTEC CORP

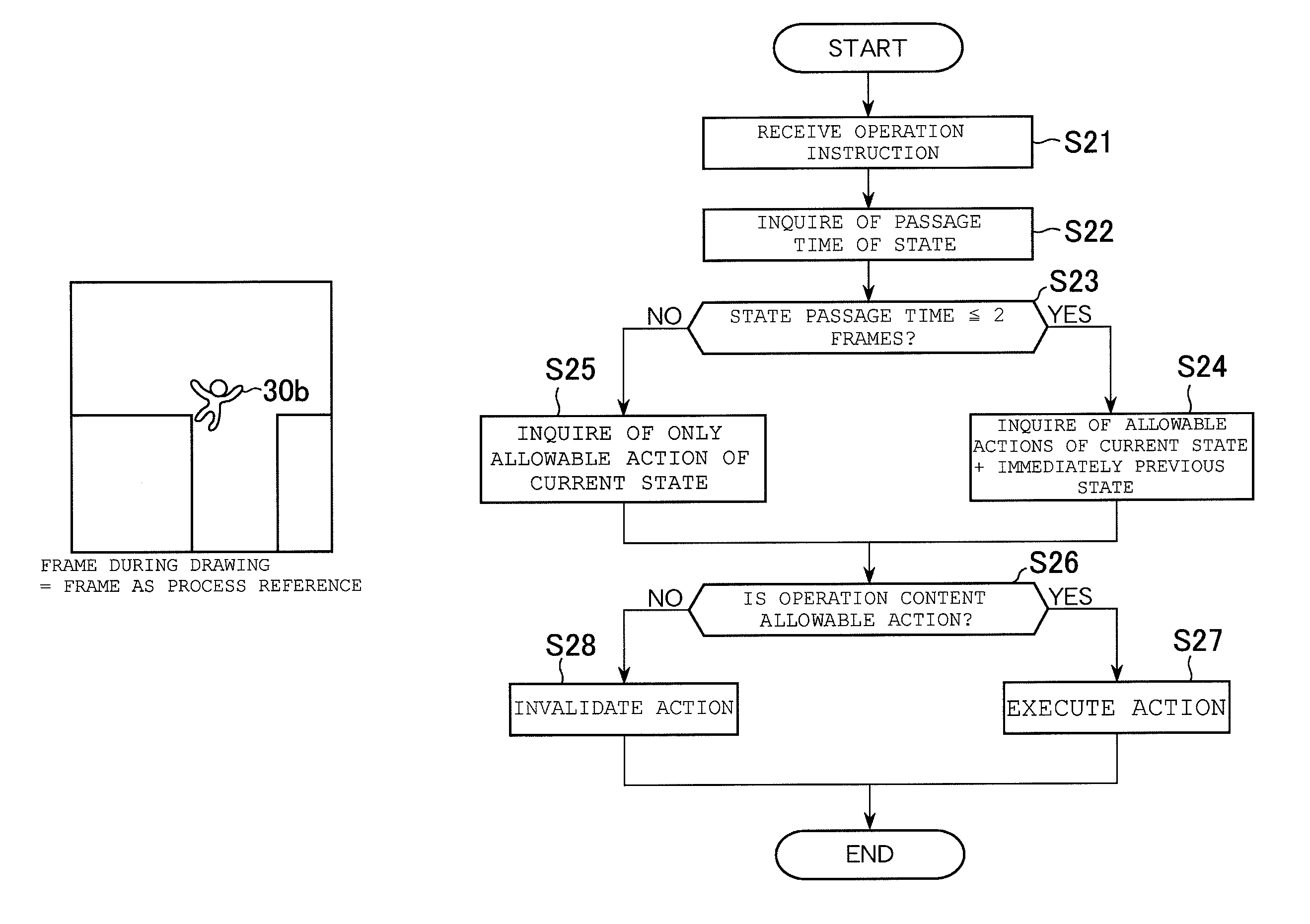

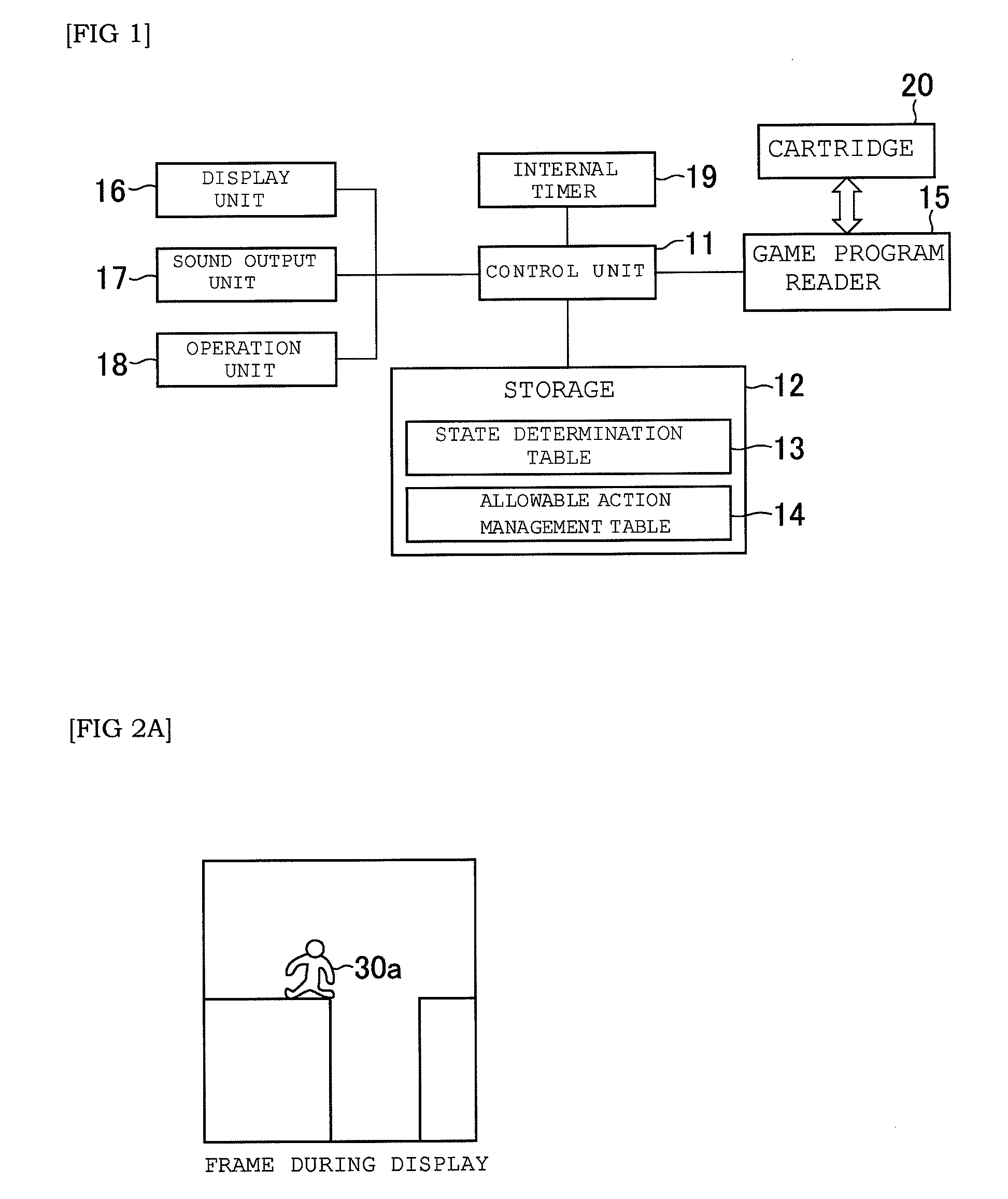

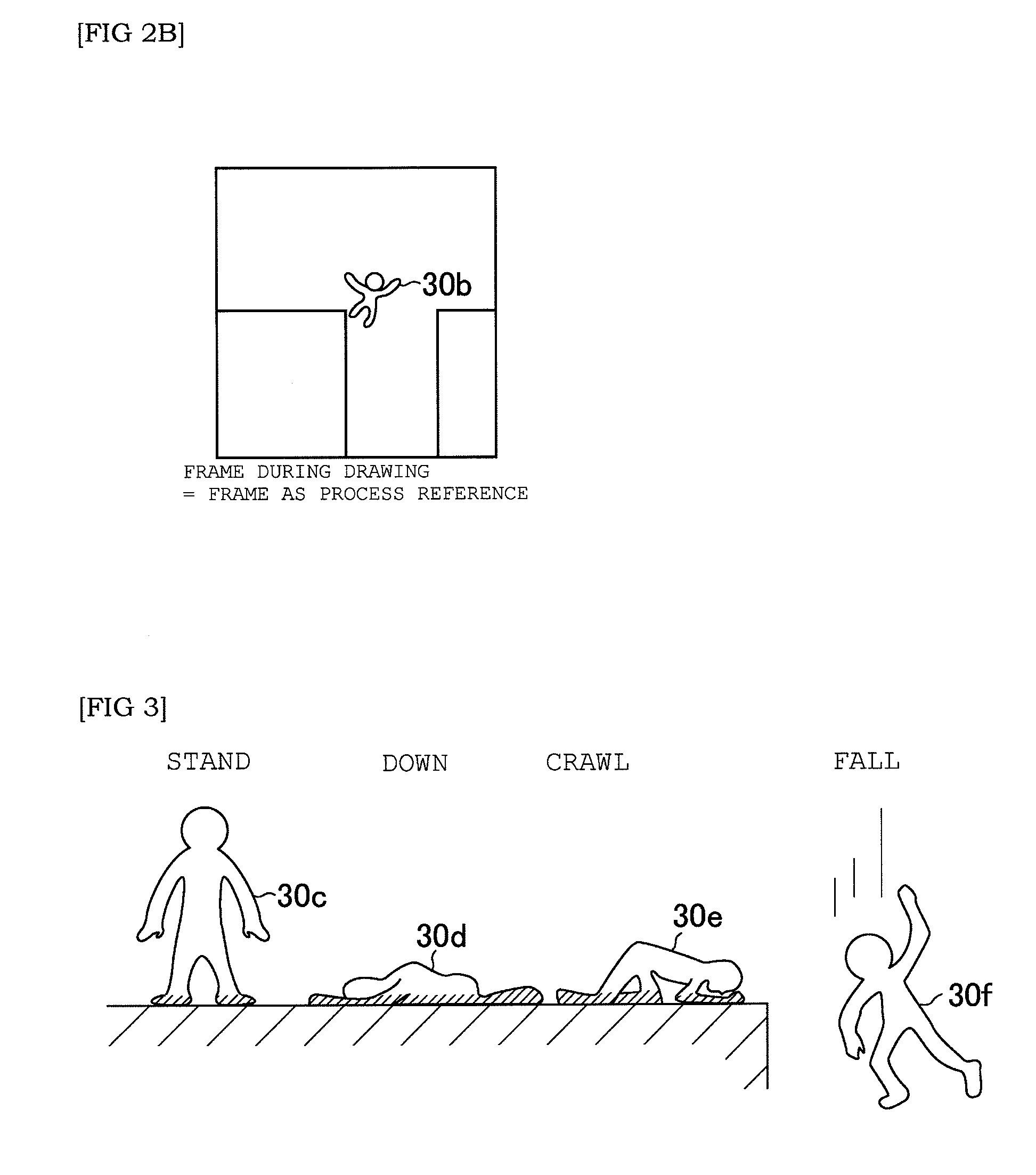

Video game with latency compensation for delay caused by frame buffering

ActiveUS8317580B2Eliminate dissatisfactionRaise the potentialVideo gamesSpecial data processing applicationsComputer scienceRecording media

The present invention provides a game apparatus, a game progressing method, and a recording medium that remove dissatisfaction of a player generated when an operation is not reflected on a progressing result of a game in spite of the operation being made at an appropriate timing and enhance entertaining potentialities. If an operation instruction on a player character is received from a player, a time period that has elapsed since a previous state has changed to a current state is measured. When the elapsed time is within a predetermined time, allowable actions in the current state and the previous state are inquired. When the elapsed time is not within the predetermined time, allowable actions in the current state are inquire. Based on an inquiry result, it is determined whether the operation instruction from the player is an allowable action.

Owner:SQUARE ENIX HLDG CO LTD

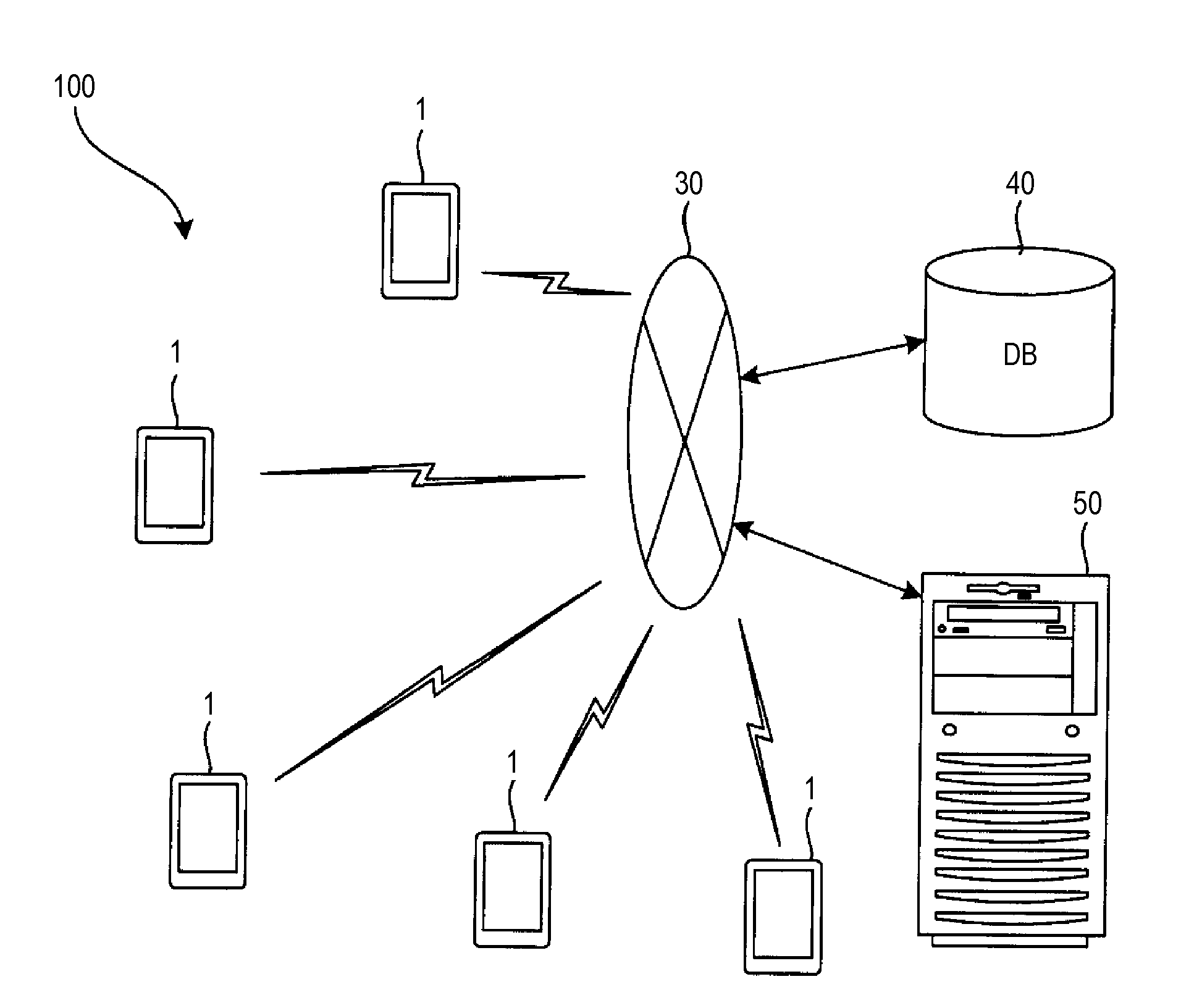

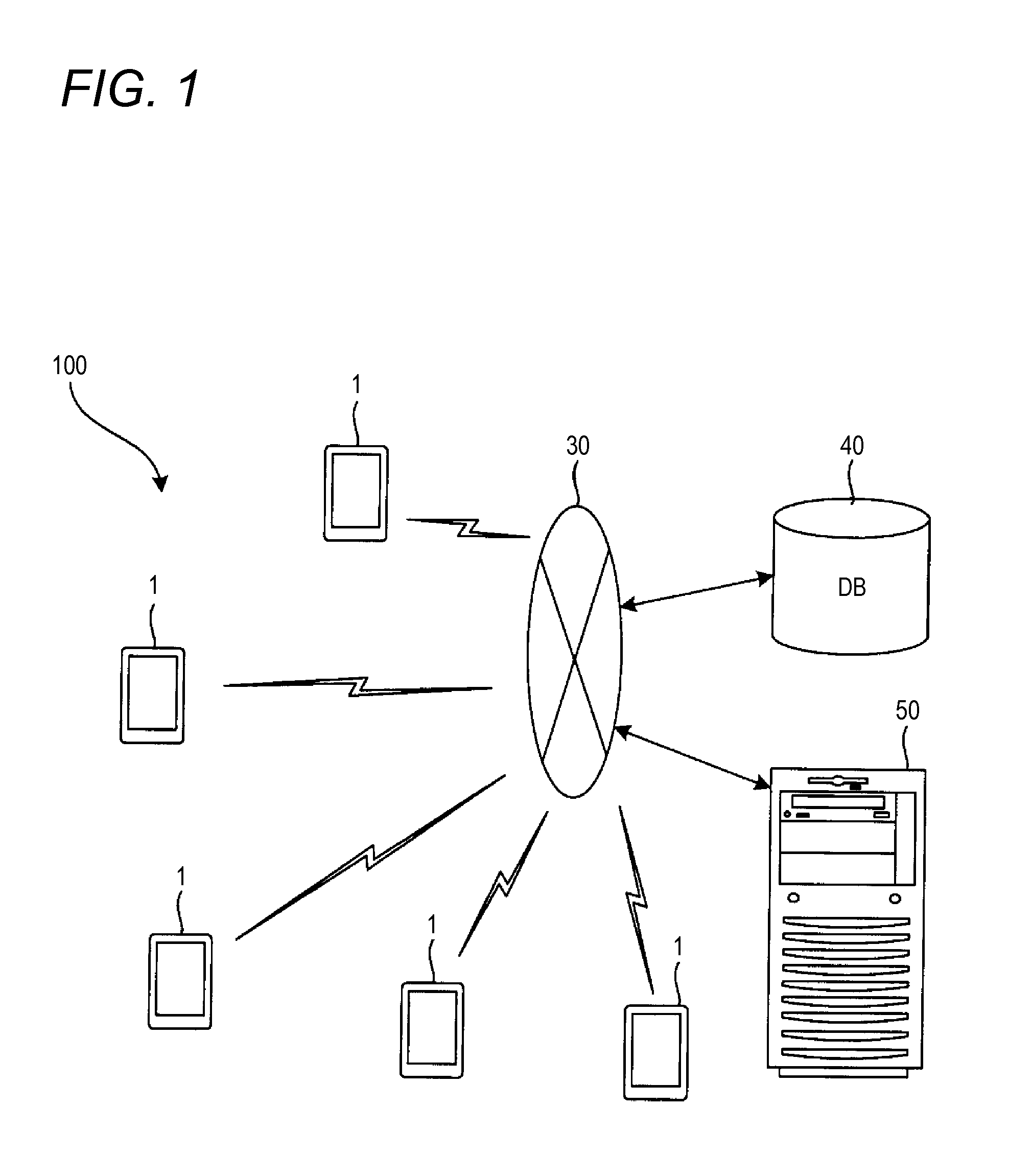

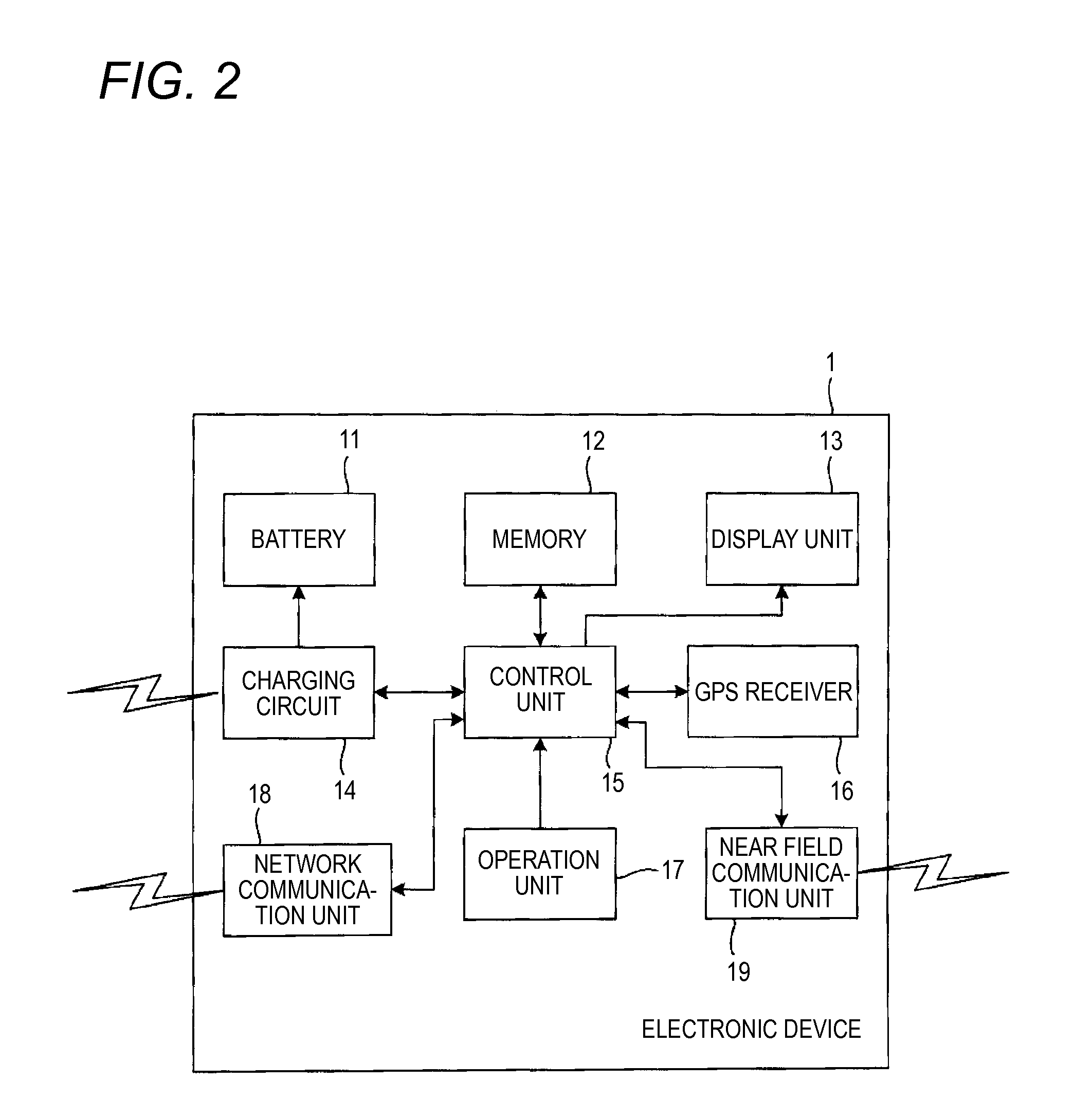

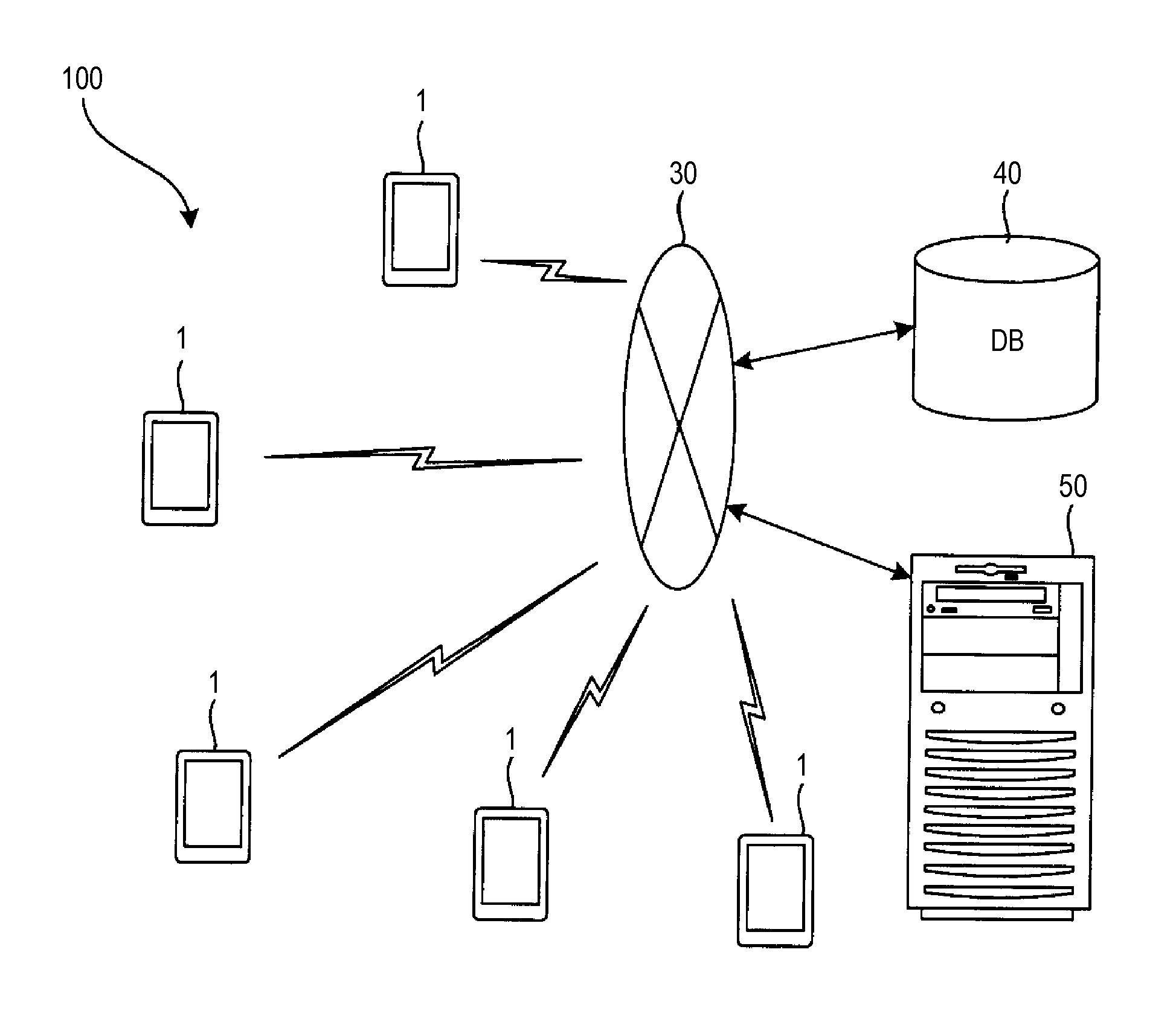

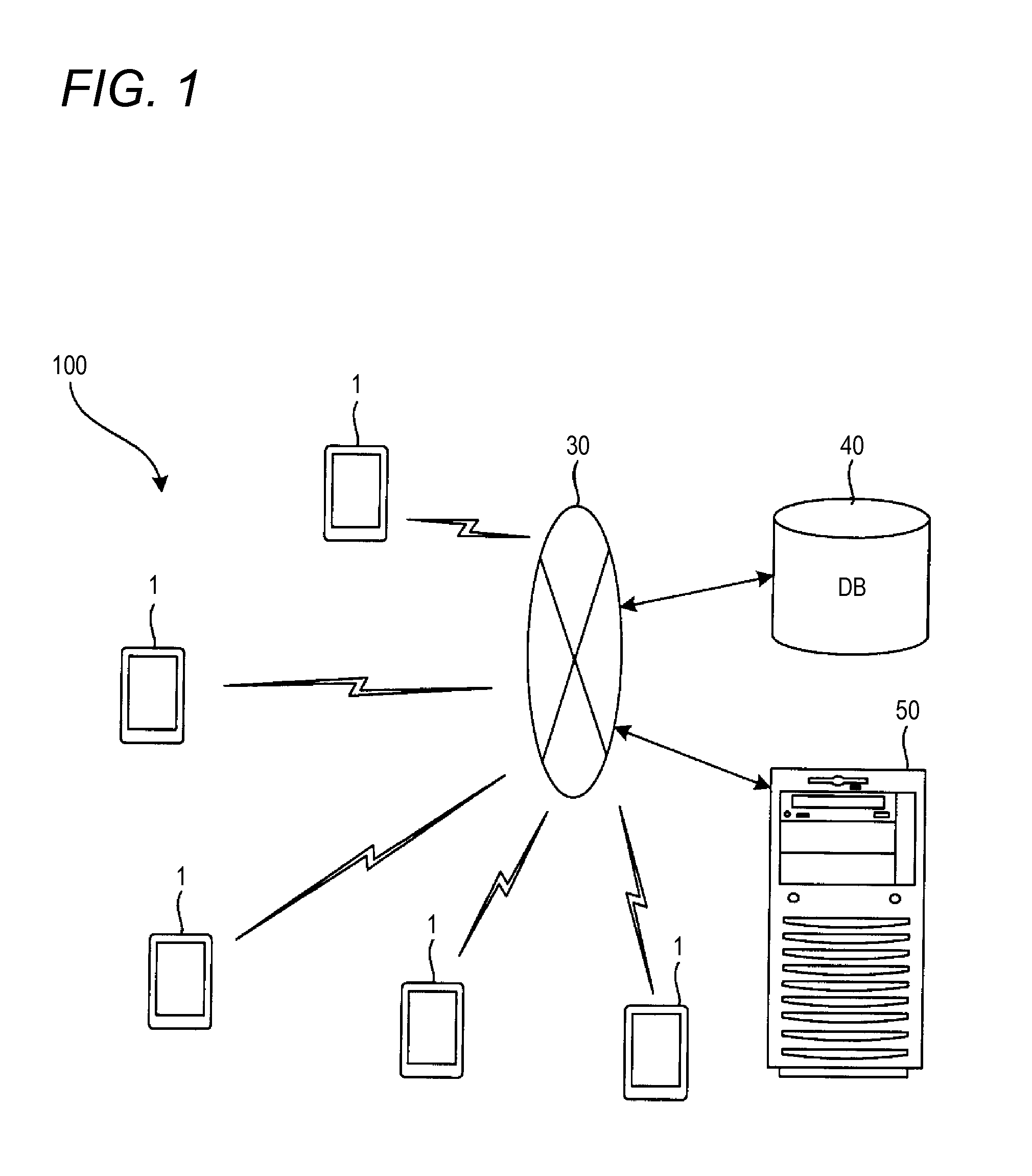

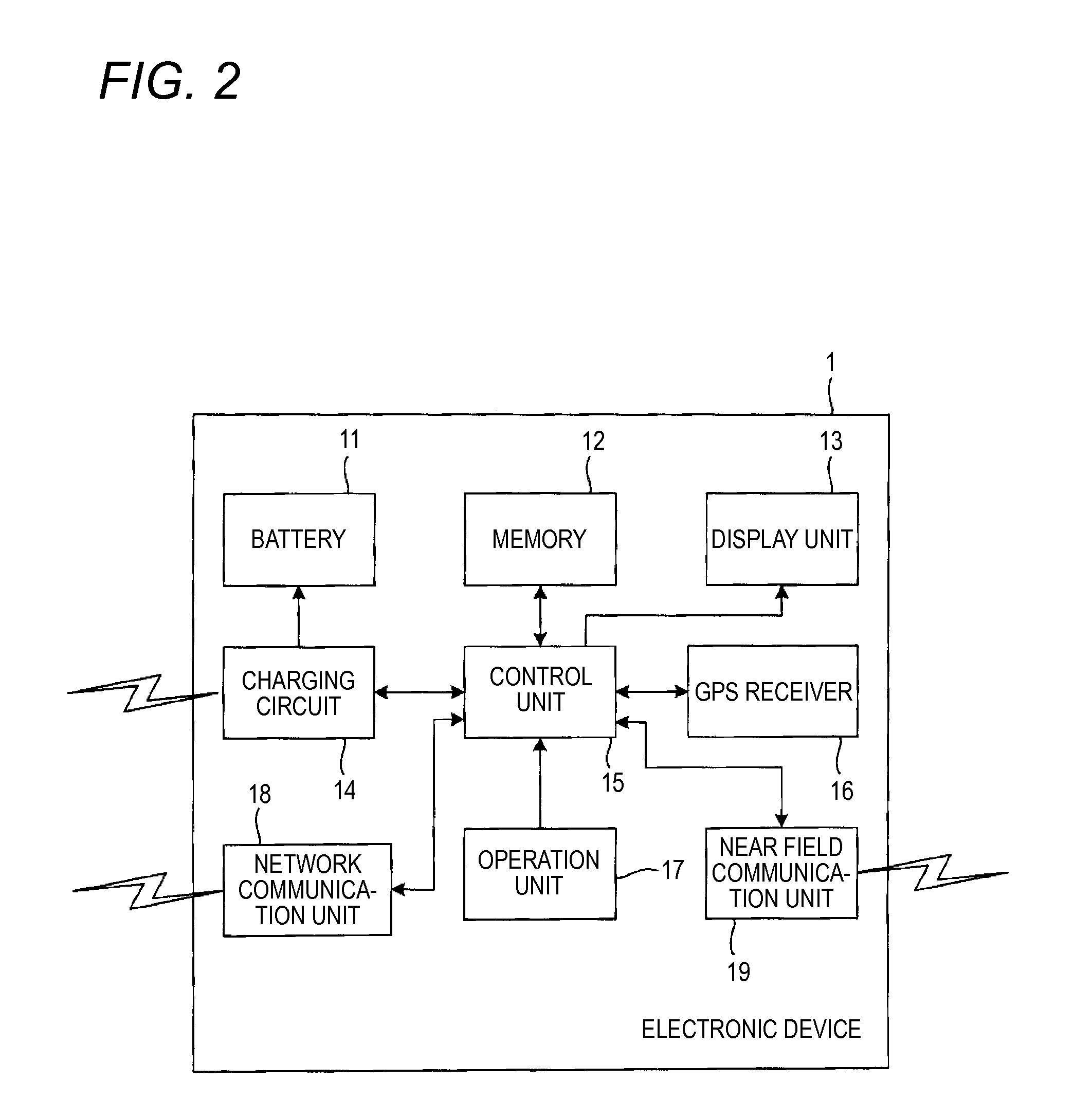

Charging support method, charging support management device, and charging support system

ActiveUS20150123607A1Stable chargingEliminate dissatisfactionNear-field transmissionCircuit monitoring/indicationSupporting systemEngineering

A system 100 includes a plurality of electronic apparatuses 1 which have a function of feeding power of a battery 11 to other electronic apparatuses and a function of receiving power from other electronic apparatuses and charging the battery 11, a management server 50, and a database 40. The management server 50 records, in the database 40, positional information of power feedable electronic apparatuses 1 which permit a power feed to other electronic apparatuses, acquires positional information of a power feed-desiring electronic apparatus 1 which desires a power feed from other electronic apparatuses, specifies a power feedable electronic apparatus 1 in the periphery of the power feed-desiring electronic apparatus 1 using the acquired positional information and the positional information of the power feedable electronic apparatuses 1 in the database 40, and transmits the positional information of the specified electronic apparatus 1 to the power feed-desiring electronic apparatus 1.

Owner:FUJIFILM CORP

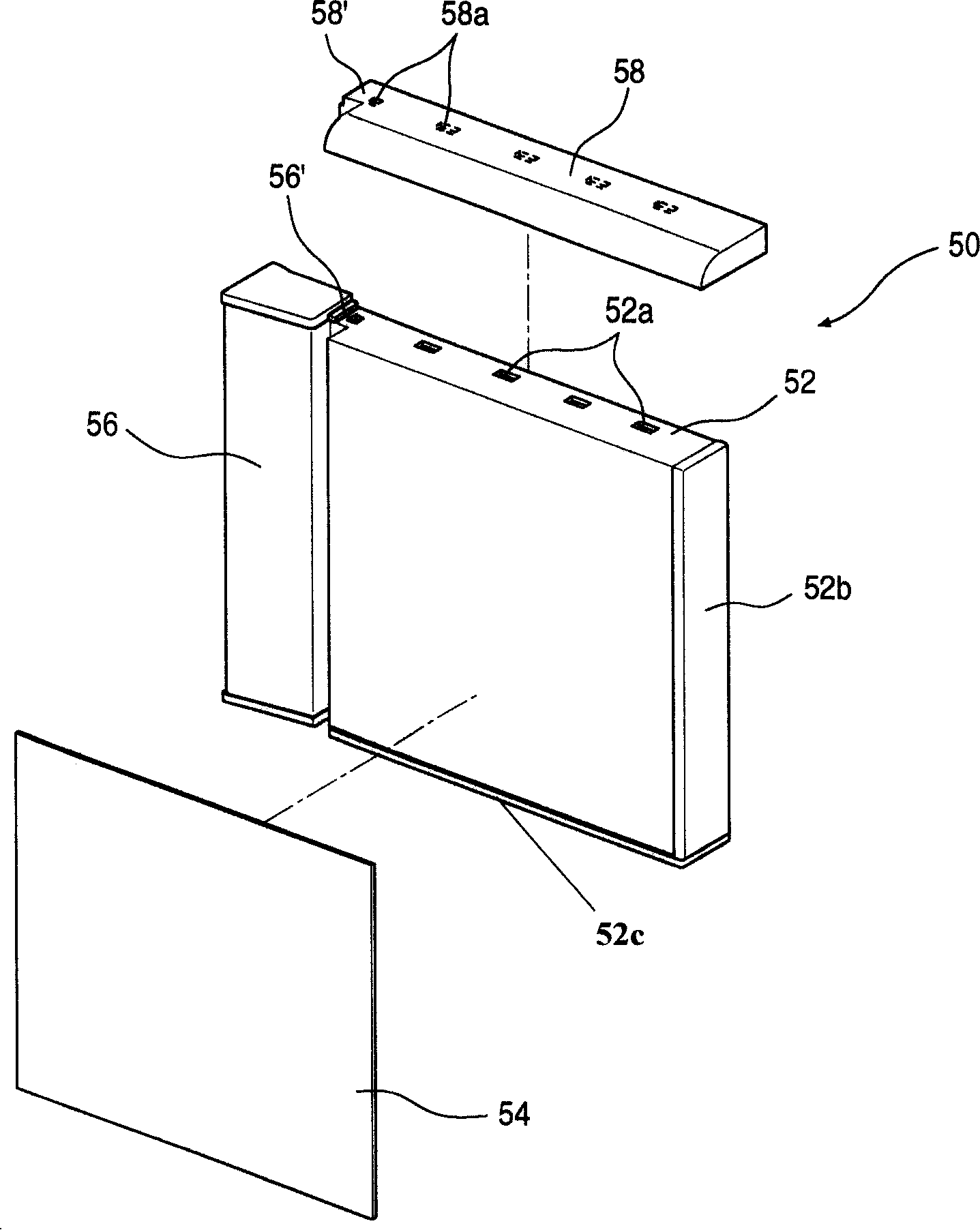

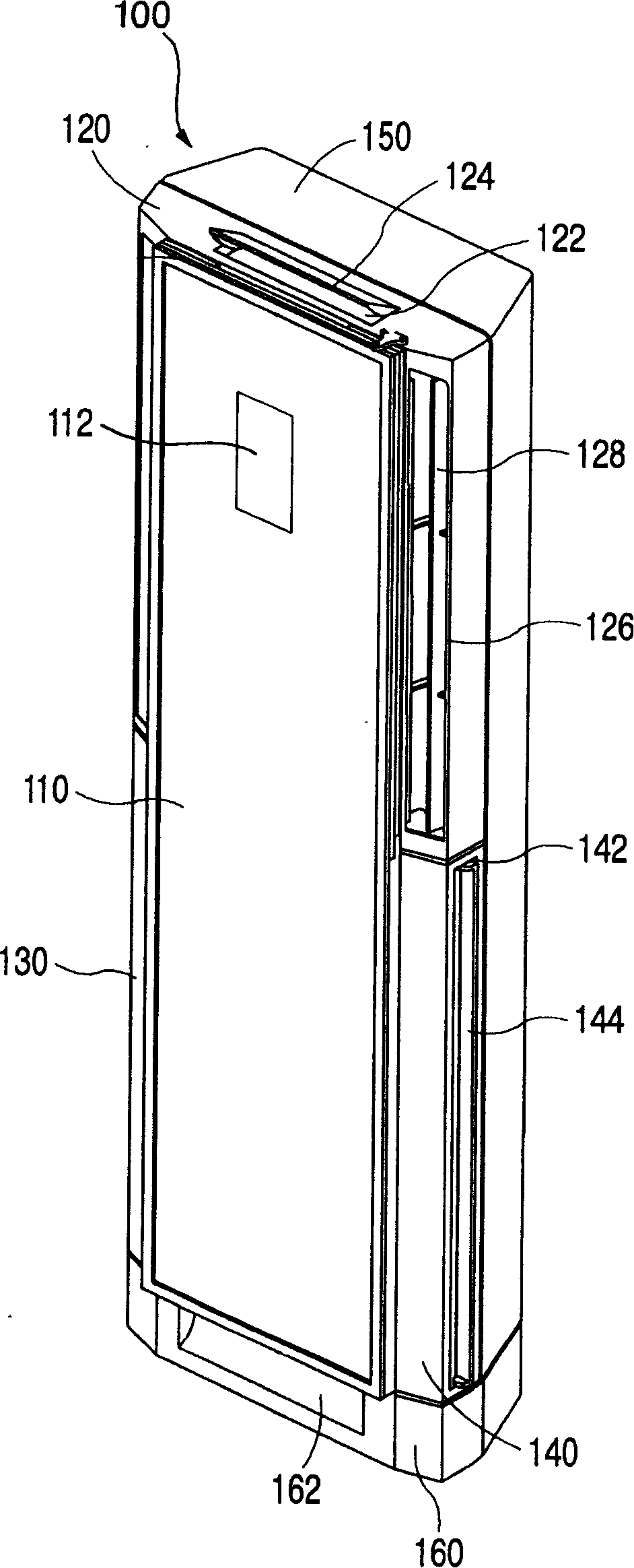

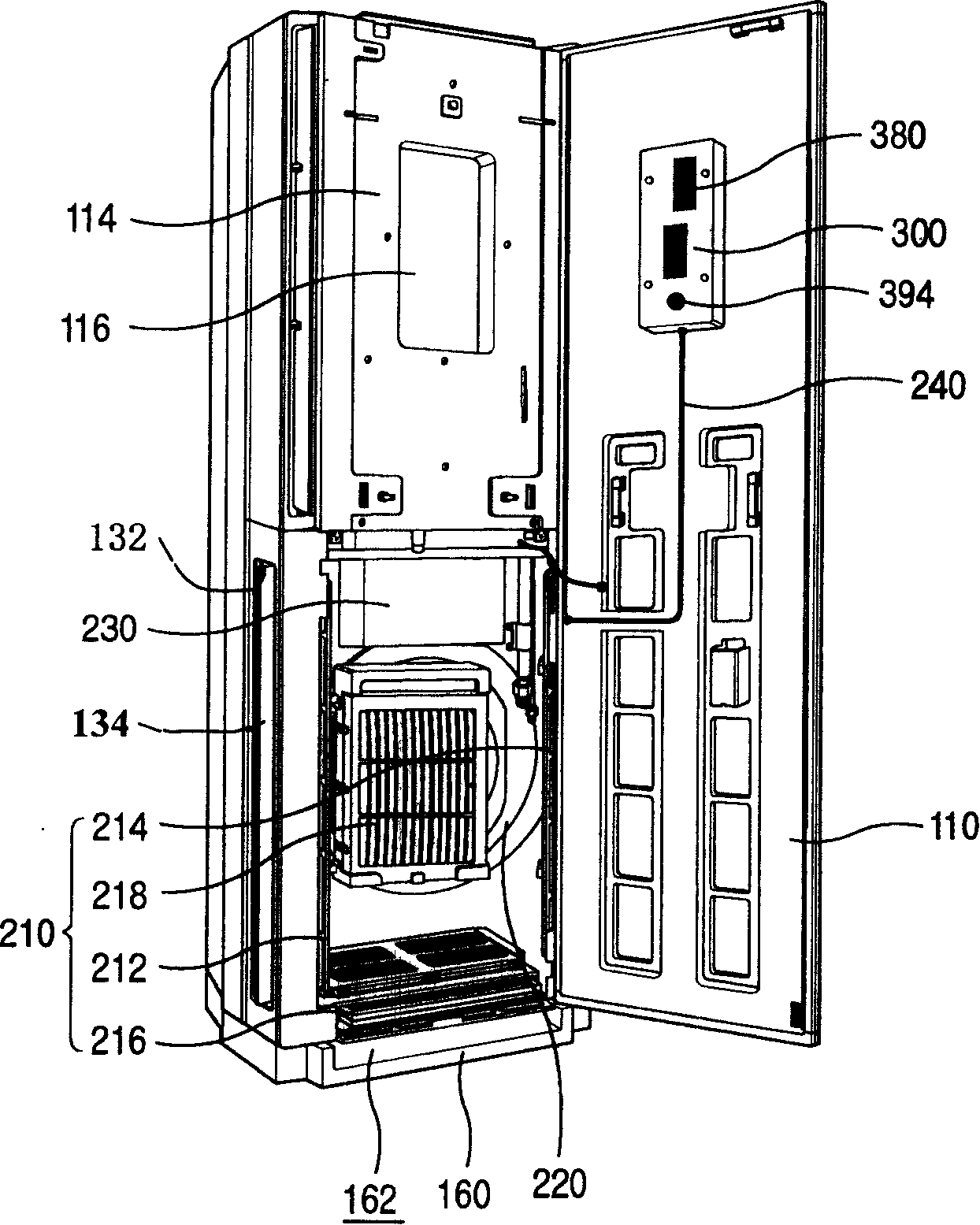

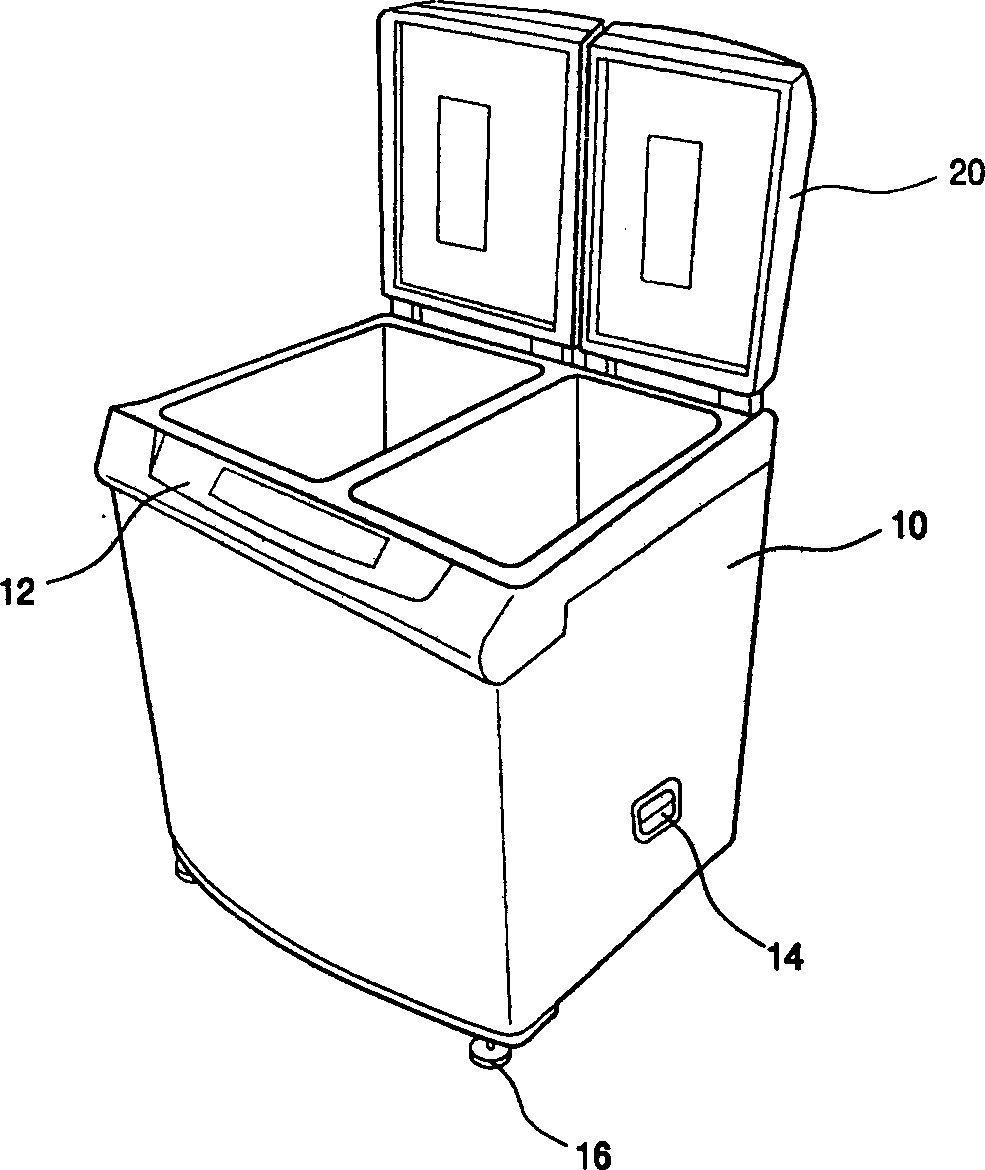

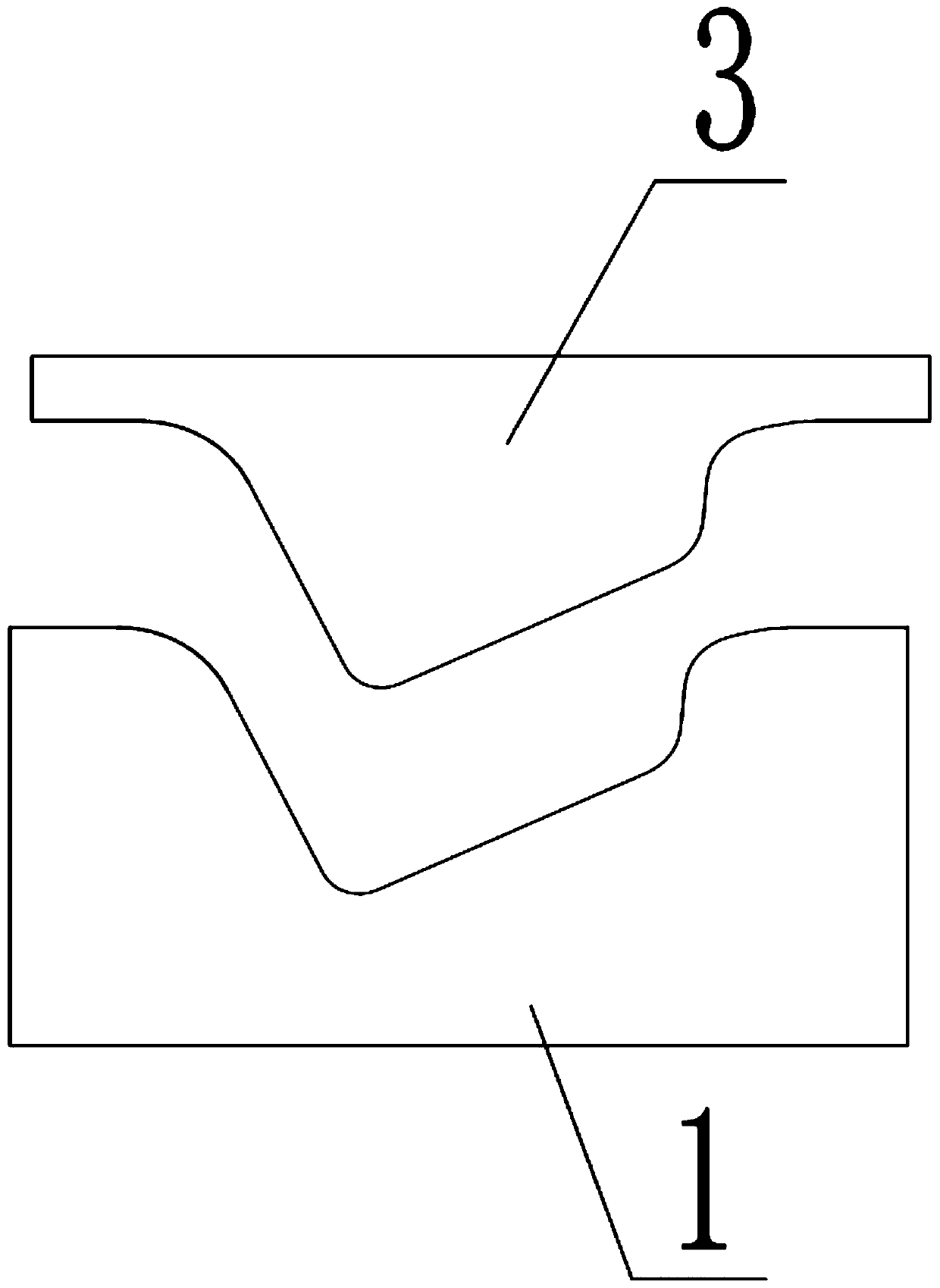

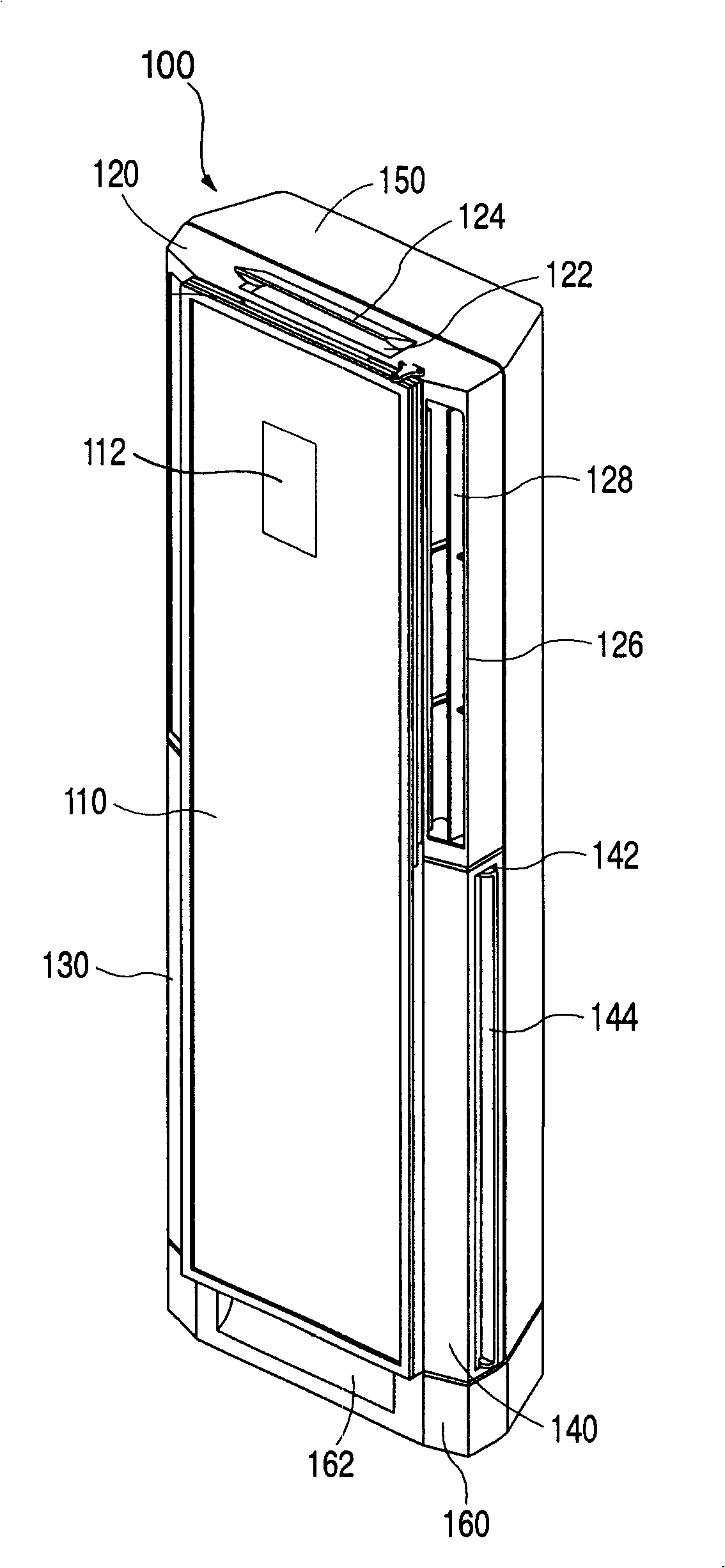

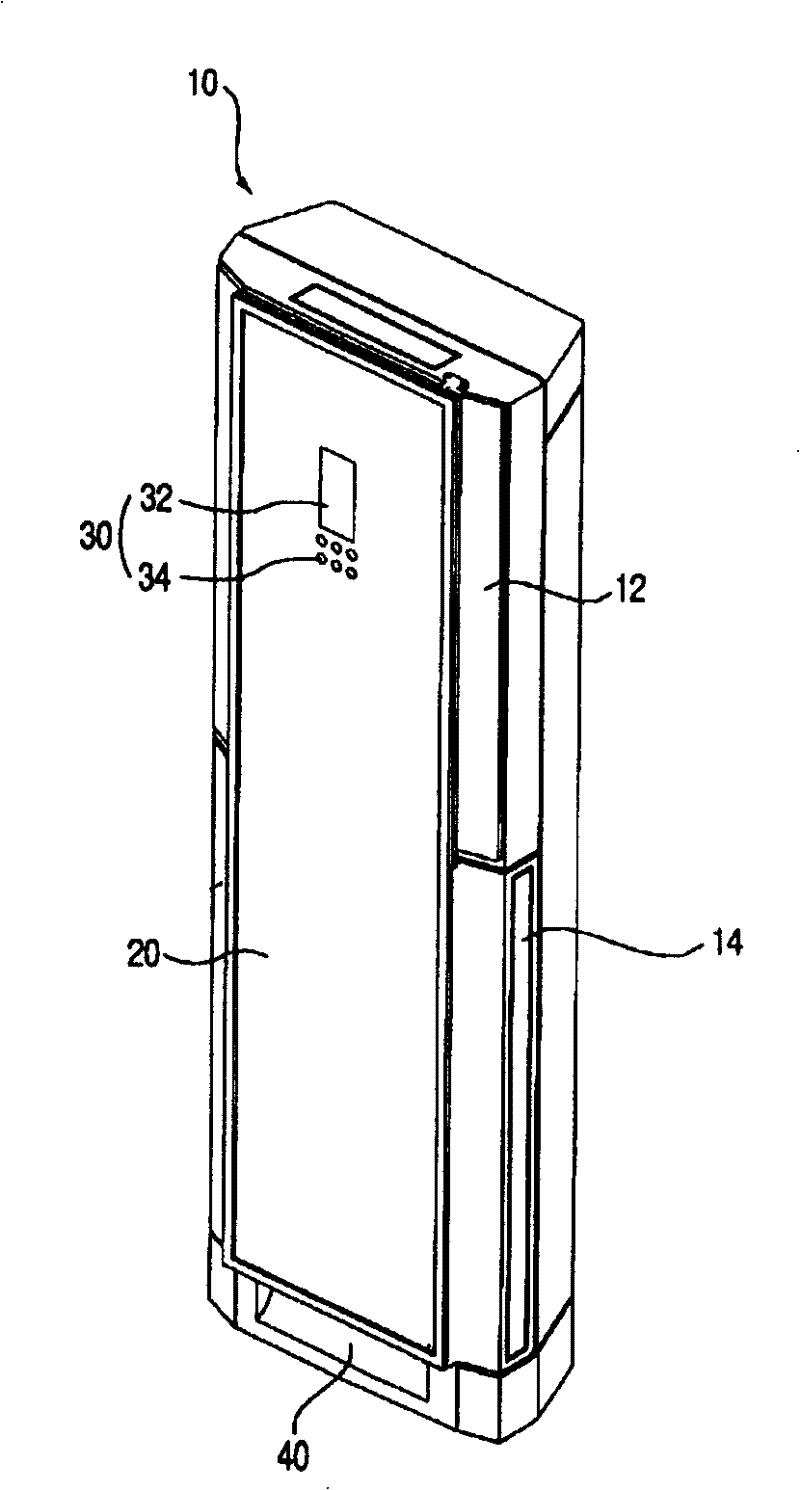

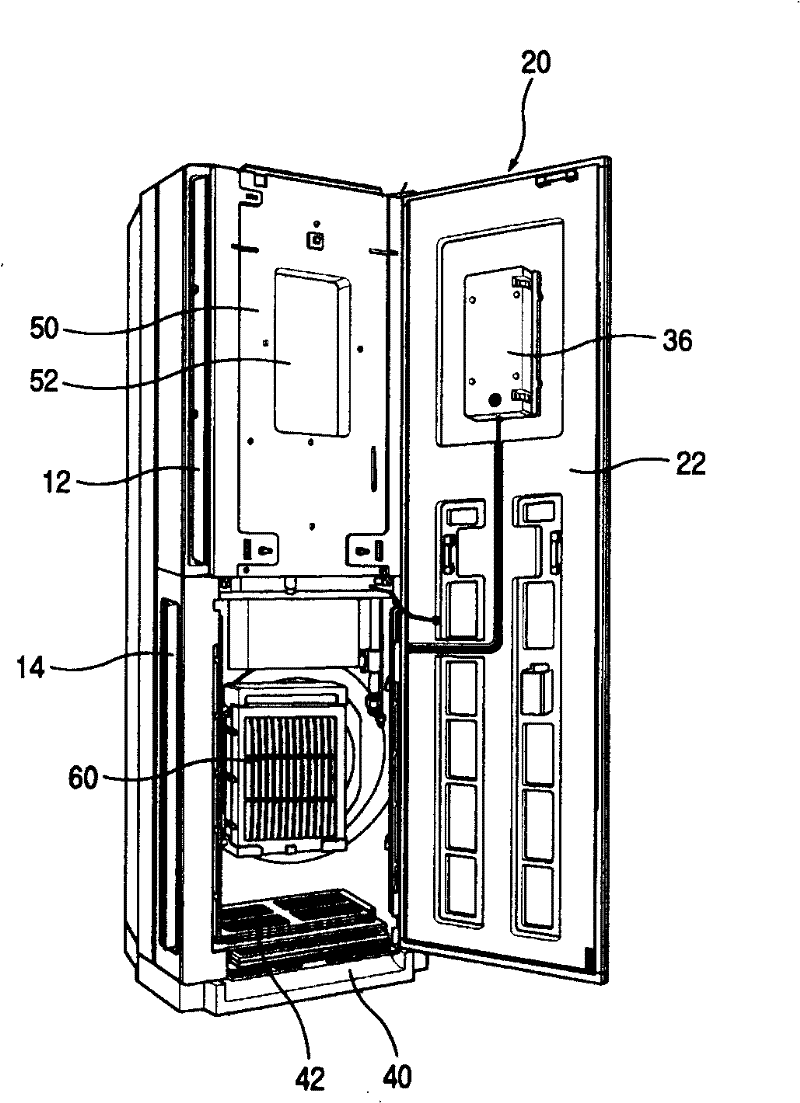

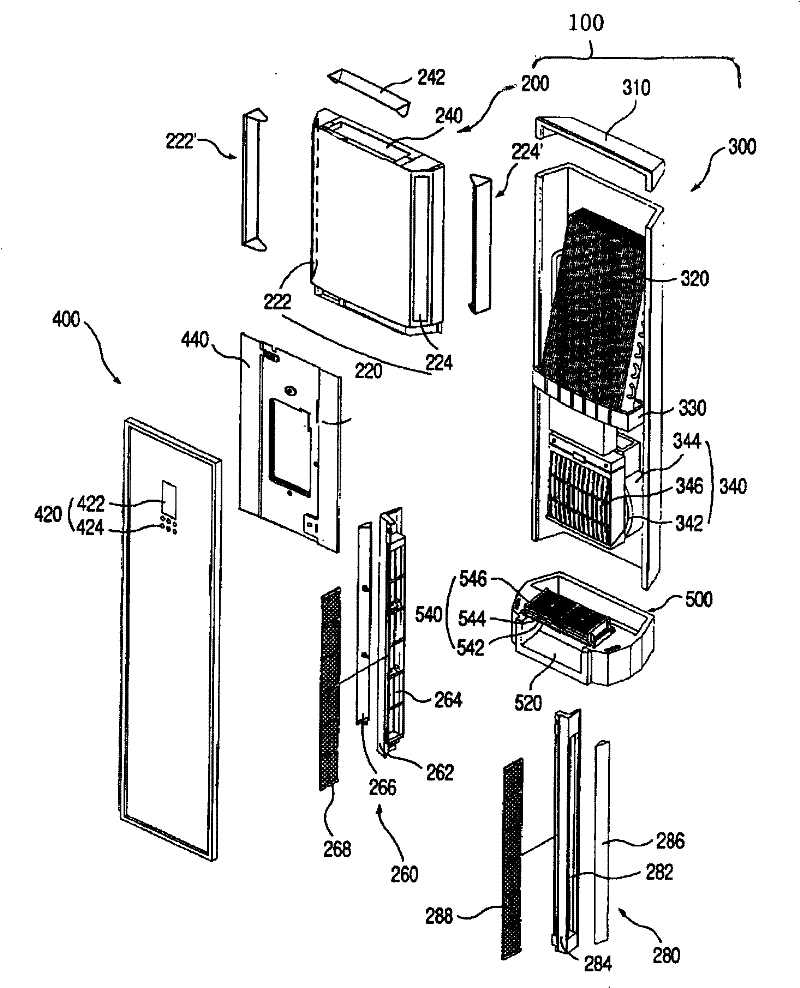

Decorative suite refrigerator door for kraut refrigerator

InactiveCN101231100AQuality improvementEliminate dissatisfactionDomestic cooling apparatusLighting and heating apparatusSize differenceRefrigerator car

The invention discloses a decorative external member refrigerator door of a pickle refrigerator, which mainly comprises a door frame forming the major structure of the refrigerator door, a decorative front panel arranged at the front of the door frame, an upper plate which is arranged at the upper part of the door frame so as to form the exterior structure of the upper part of the refrigerator door, and a lateral plate which is arranged at one side of the door frame and forms part exterior structure of the refrigerator door, wherein, the lateral plate can limit the adjacent door frame and one side of the upper plate so as to be clipped on the door frame and the upper plate, thereby eliminating the size difference of the lateral plate with the upper plate and the door frame. The decorative external member refrigerator door of a pickle refrigerator provided by the invention can combine the door frame, the lateral plate and the upper plate only through combing the lateral plate, and can limit looseness of the lateral plate in the front-to-rear, the up-and-down and the left-right directions by means of pressing the upper plate provided with the lateral plate from the front to the rear and from the top down; thus, when the refrigerator door is assembled, the size difference of the lateral plate can be eliminated in the front-to-rear, the up-and-down and the left-right directions, thereby improving the quality of the refrigerator, but also eliminating the user dissatisfaction due to the size difference.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

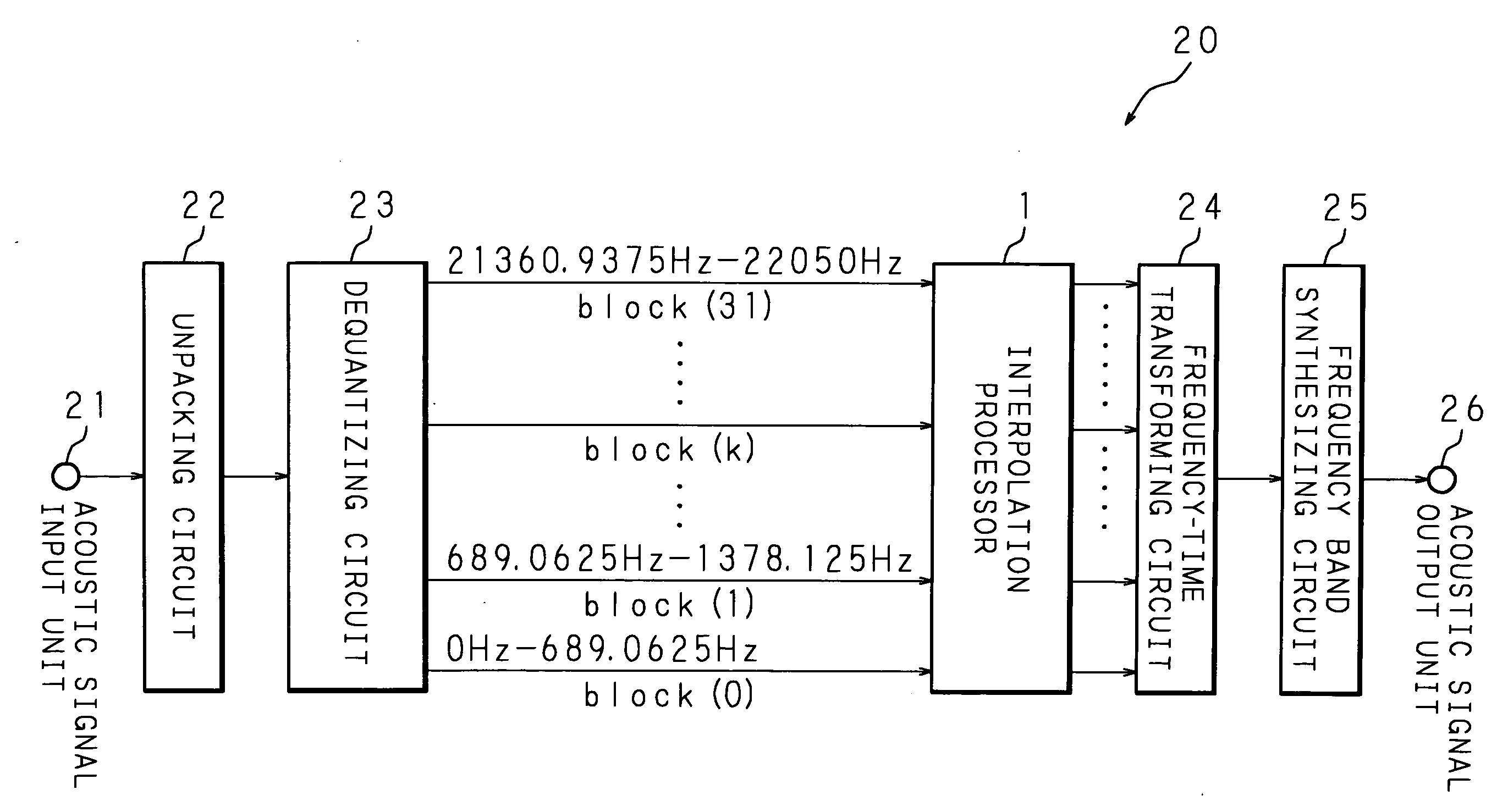

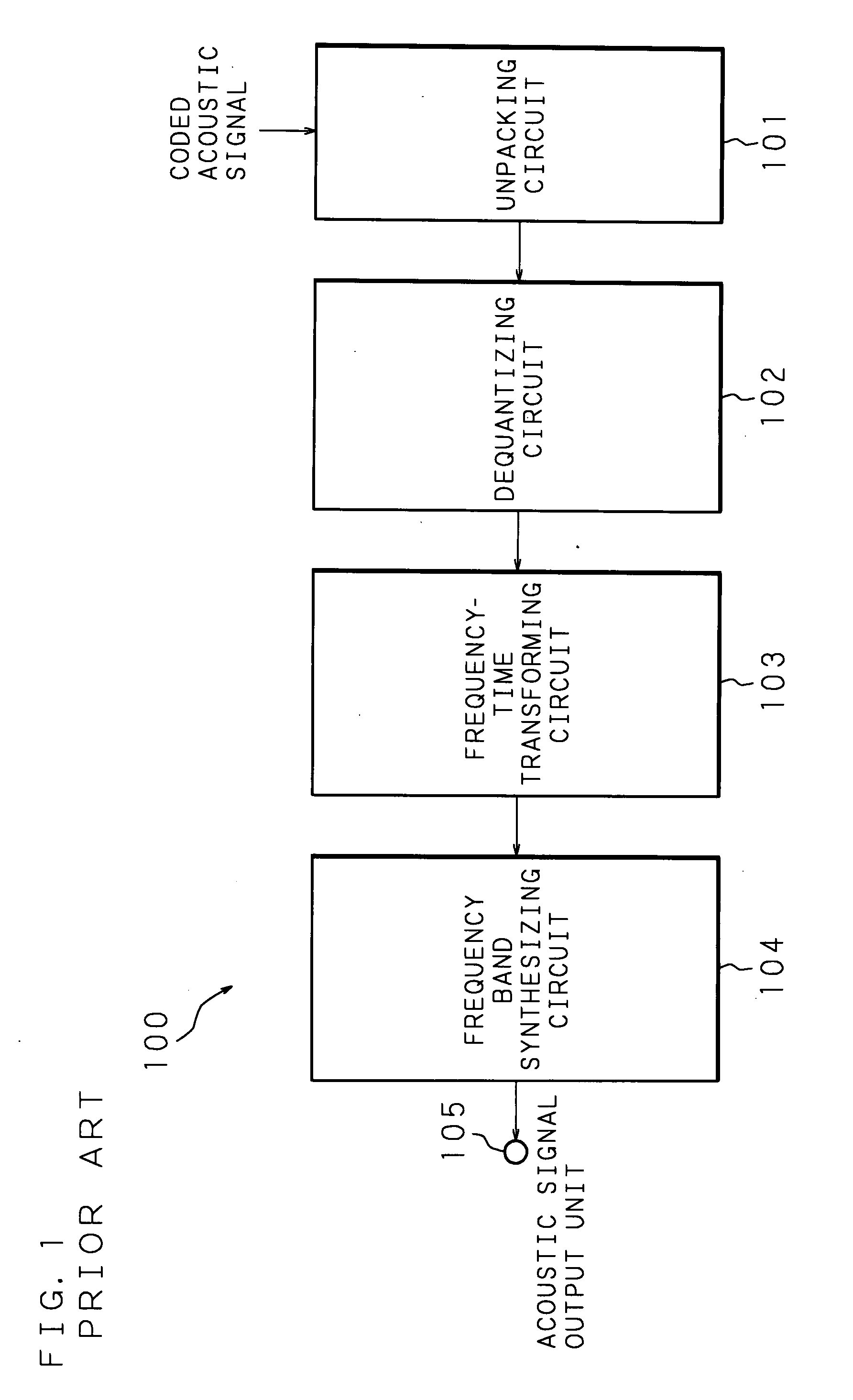

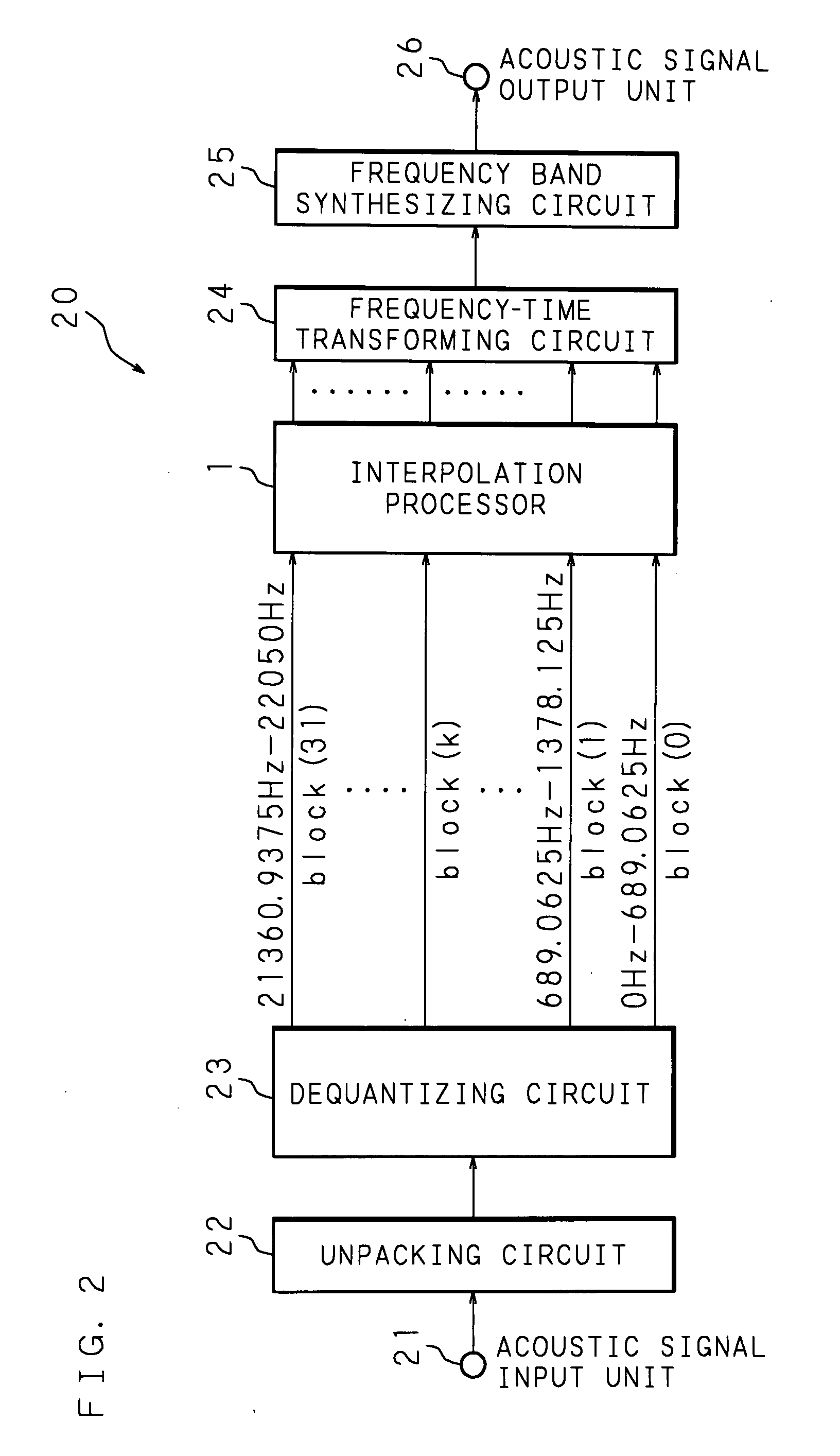

Signal processing method, signal processing apparatus and recording medium

InactiveUS20070270987A1Eliminate dissatisfactionVarious methodsSpeech analysisSpecial data processing applicationsComputer scienceWhite noise

The minimum value detecting circuit detects a minimum value, excluding zero, of a coefficient according to a dequantized acoustic signal. The correction coefficient computing circuit computes a correction coefficient based on the minimum value and white noise outputted from the white noise storage which stores white noise. In this process, a correction coefficient is computed by, for example, dividing the minimum value obtained by the minimum value detecting circuit by a value which is twice the maximum value or the mean value of white noise stored in the white noise storage. The correction value computing circuit computes a correction value by multiplying the correction coefficient computed by the correction coefficient computing circuit by white noise stored in the white noise storage. A corrected coefficient is computed by adding the correction value obtained as described above to a frequency band having a null coefficient according to a dequantized acoustic signal.

Owner:SHARP KK

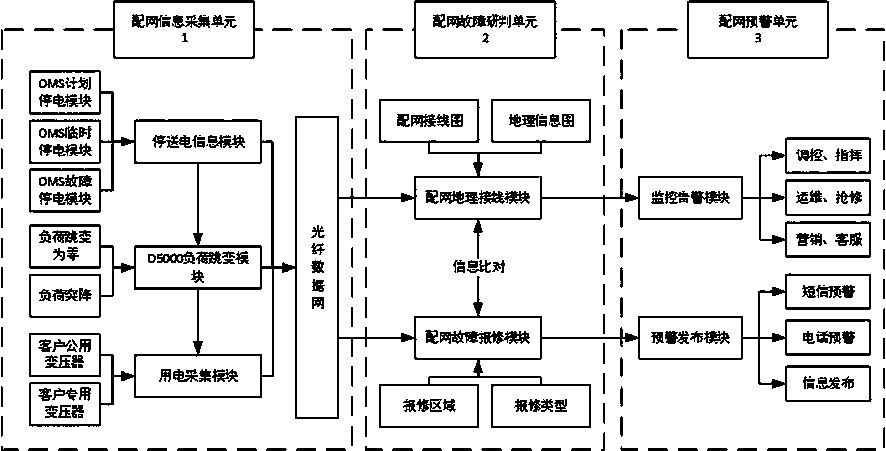

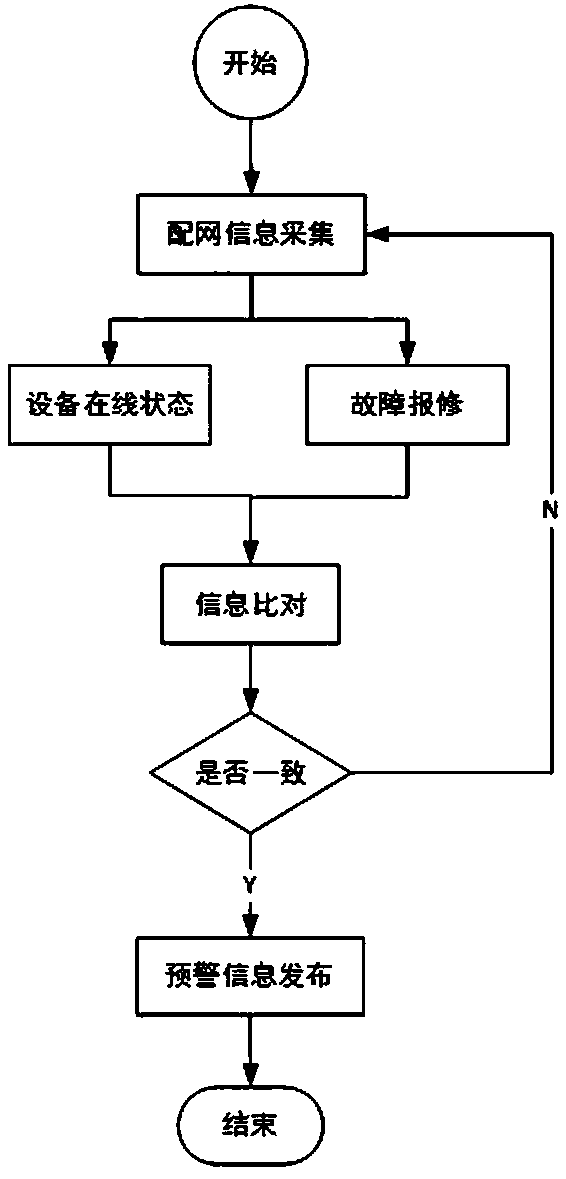

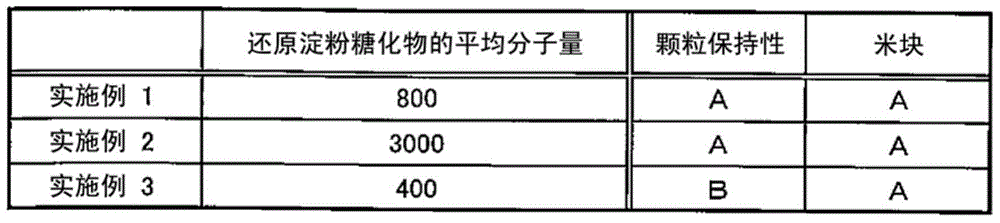

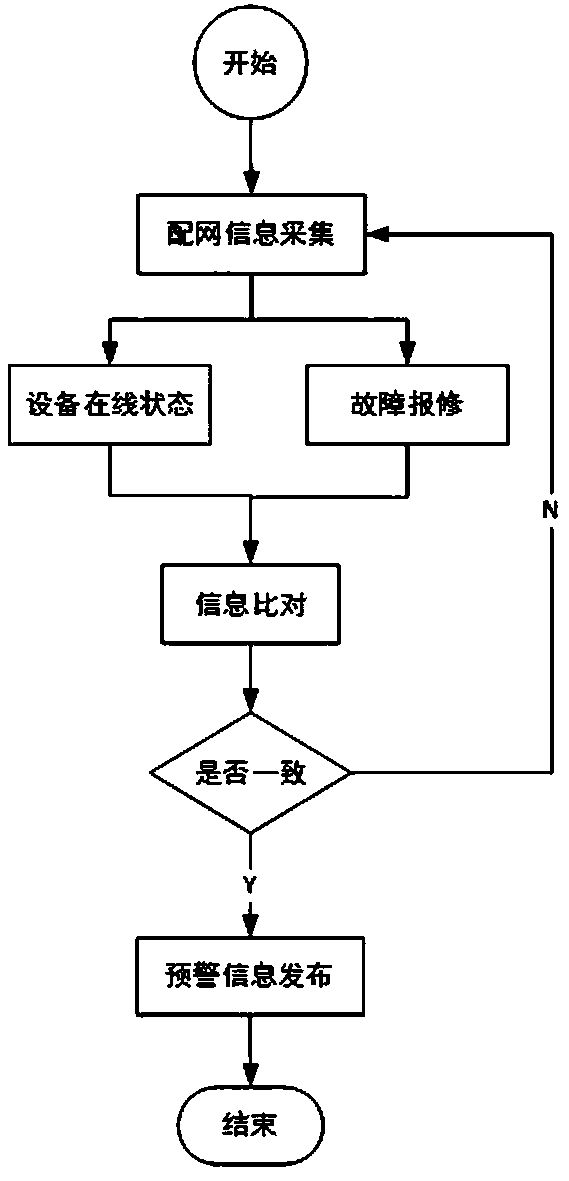

Distribution network fault research and judgment early warning system and implementation method thereof

ActiveCN108267670APrecise positioningEasy to determineFault location by conductor typesElectricityEarly warning system

The invention discloses a distribution network fault research and judgment early warning system and an implementation method thereof. The distribution network fault research and judgment early warningsystem includes a distribution network information acquisition unit, a distribution network fault research and judgment unit and a distribution network early warning unit, wherein the distribution network information acquisition unit includes a power off / on information module, a D5000 load jumping module and a power utilization acquisition module; the distribution network fault research and judgment unit includes a distribution network geographical wiring module and a distribution network fault repair module; the distribution network early warning unit includes a monitoring warning module andan early warning publishing module; and by means of coordination of the distribution network information acquisition unit, the distribution network fault research and judgment unit and the distribution network early warning unit, the system can greatly improve the efficiency of fault repairing and the service level, can perform visual displaying and accurate research and judgment through the distribution network fault research and judgment unit, can warn timely through the research and judgment comparison result, and at the same time can timely perform accurate positioning on the fault area through the distribution network wiring graph and the geographic information graph in the distribution network geographical wiring module, so as to be convenient for a repair person to determine the fault area and reduce the repair time.

Owner:STATE GRID CORP OF CHINA +1

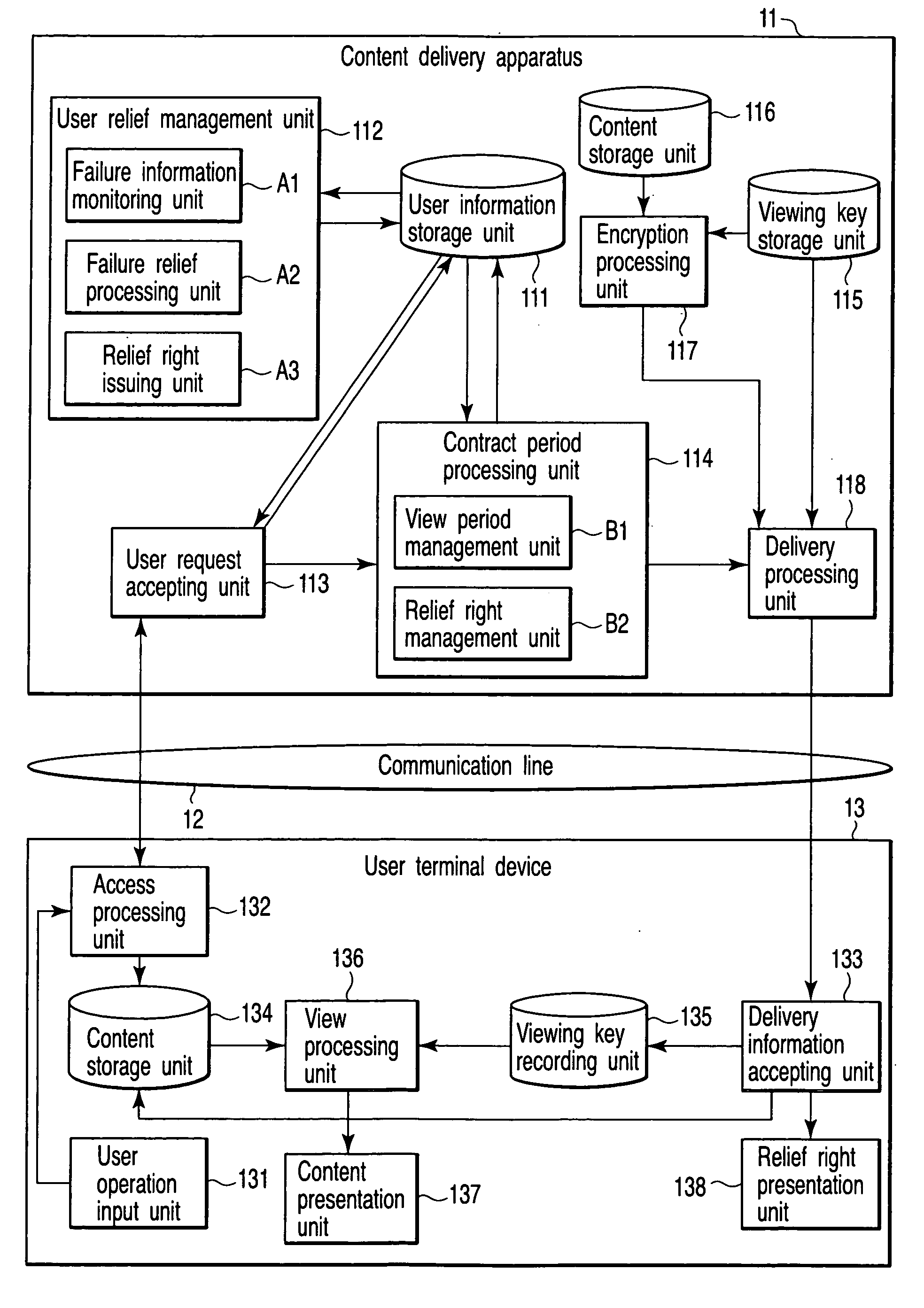

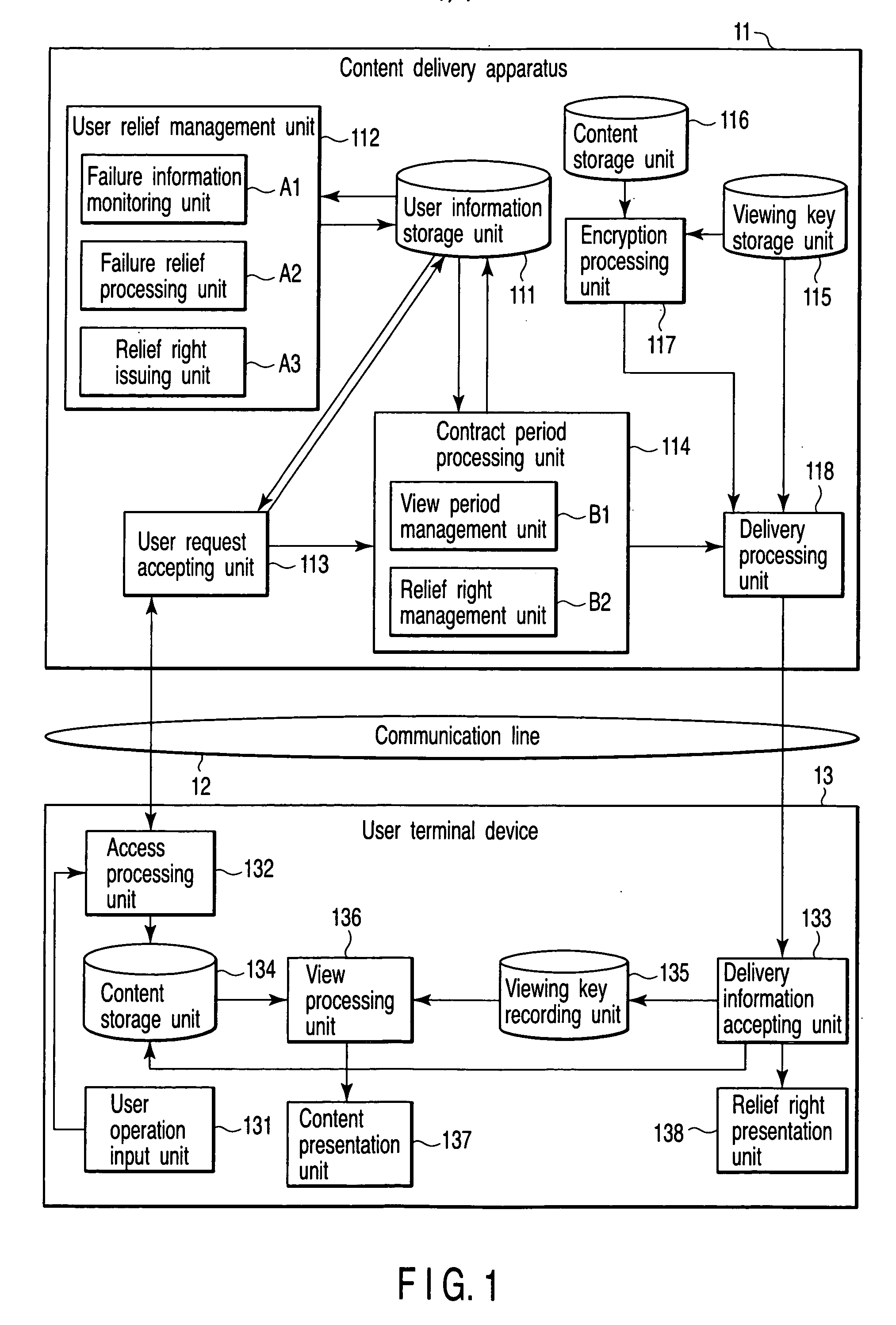

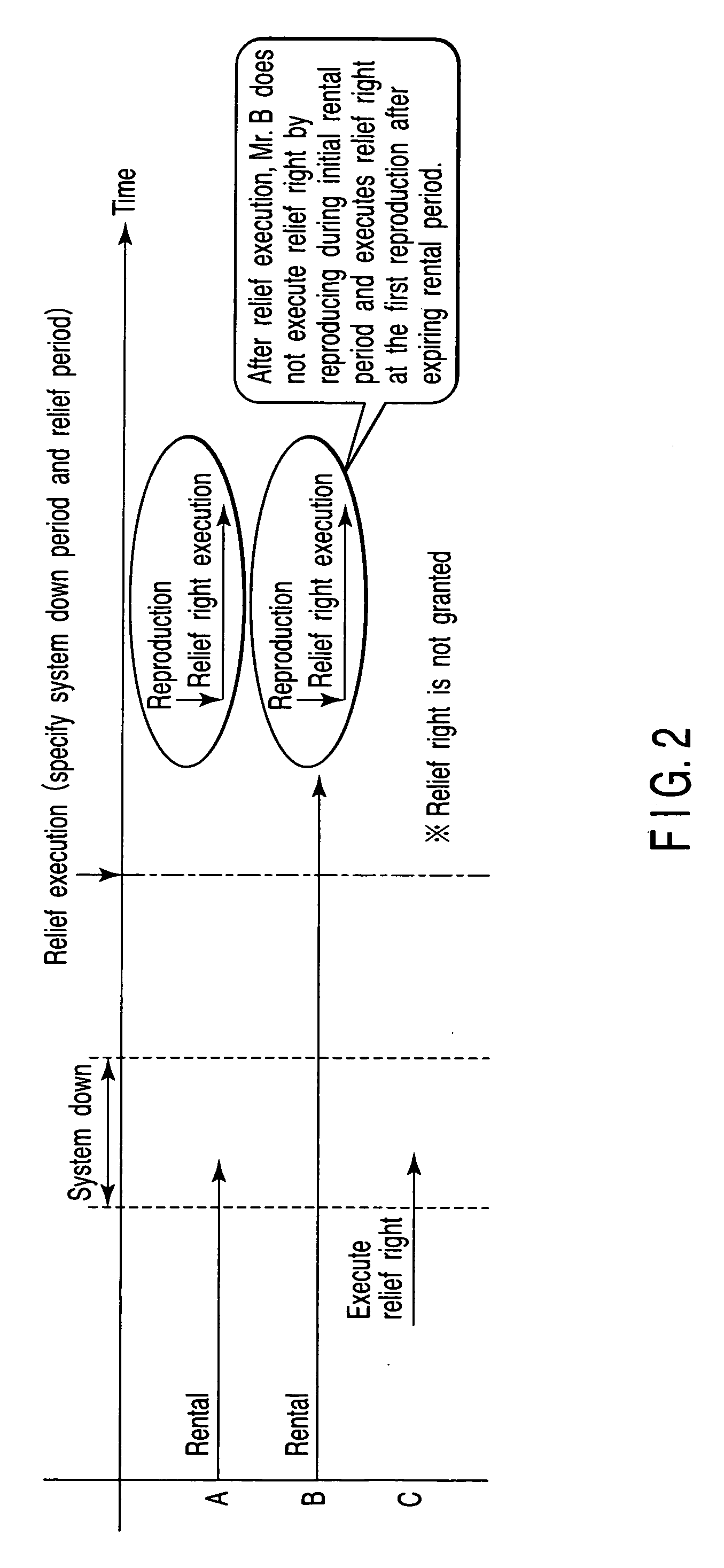

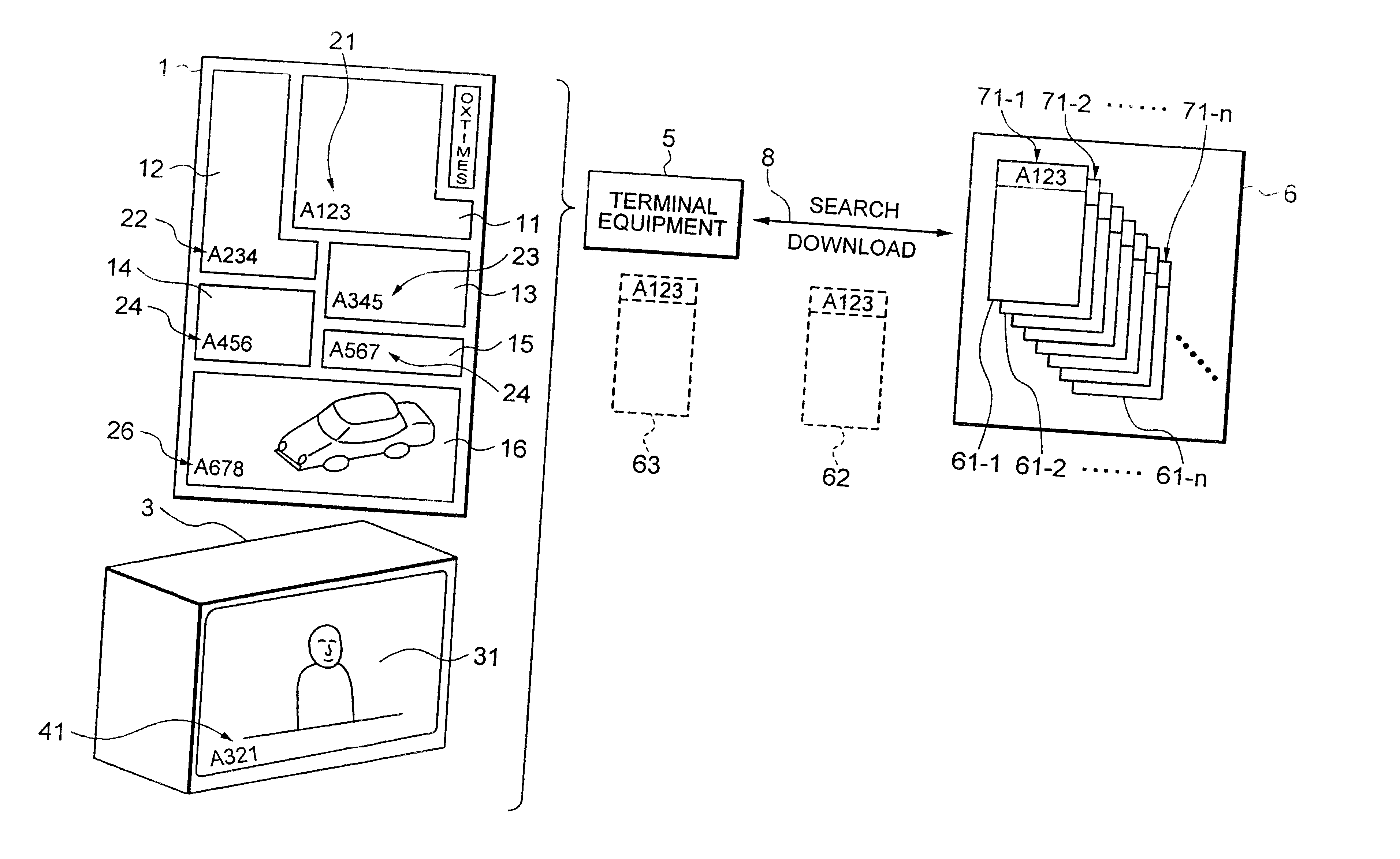

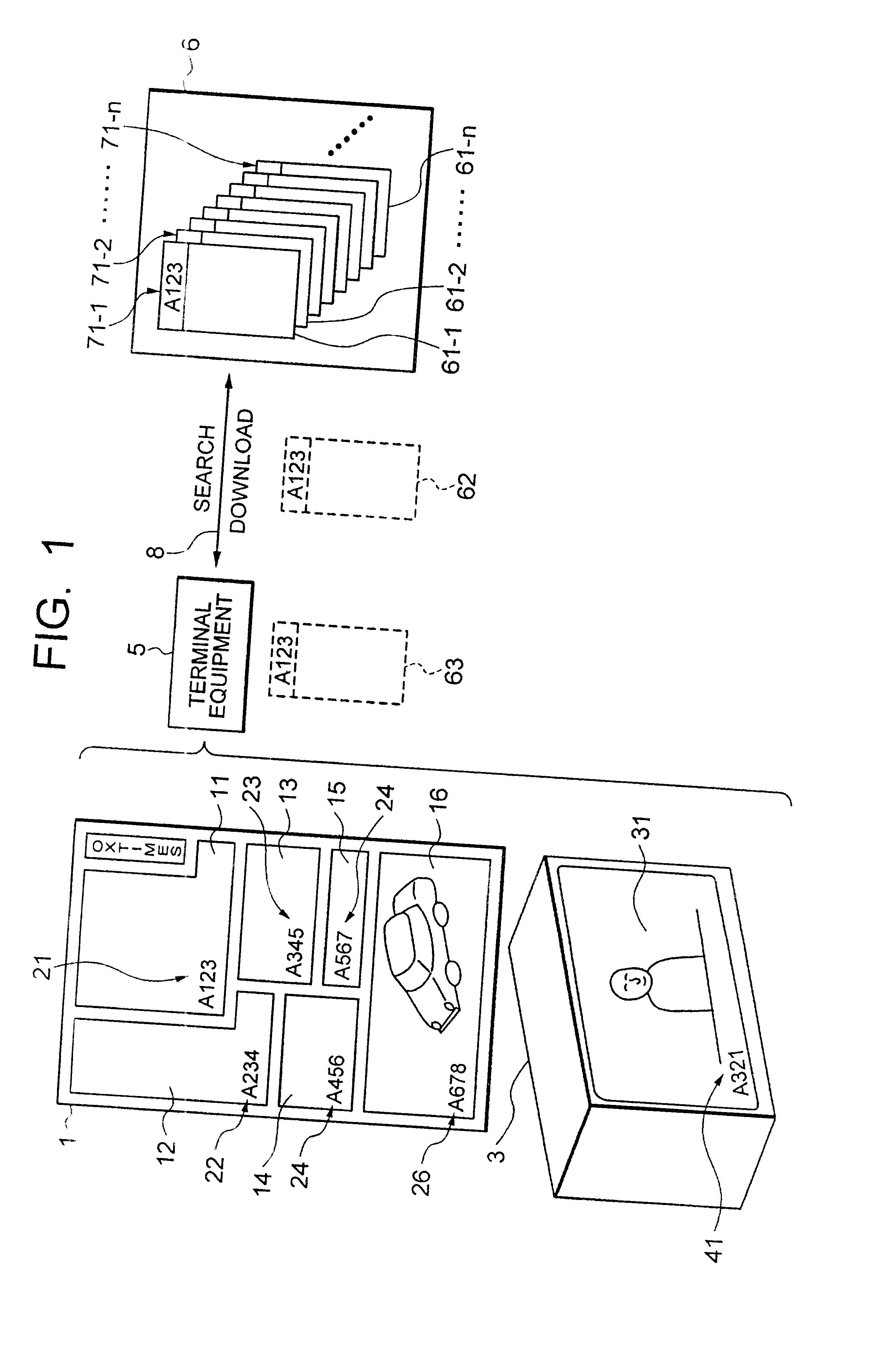

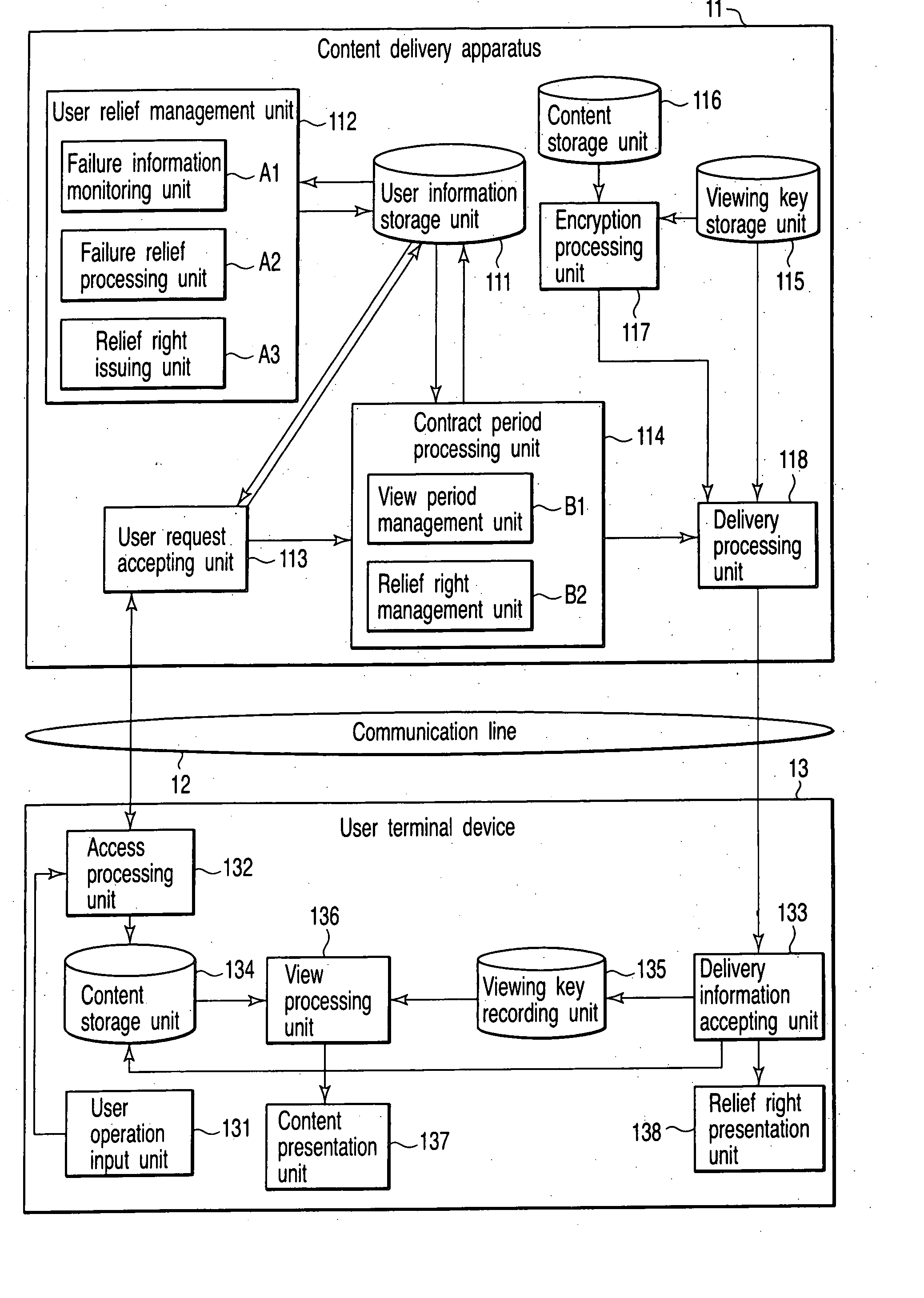

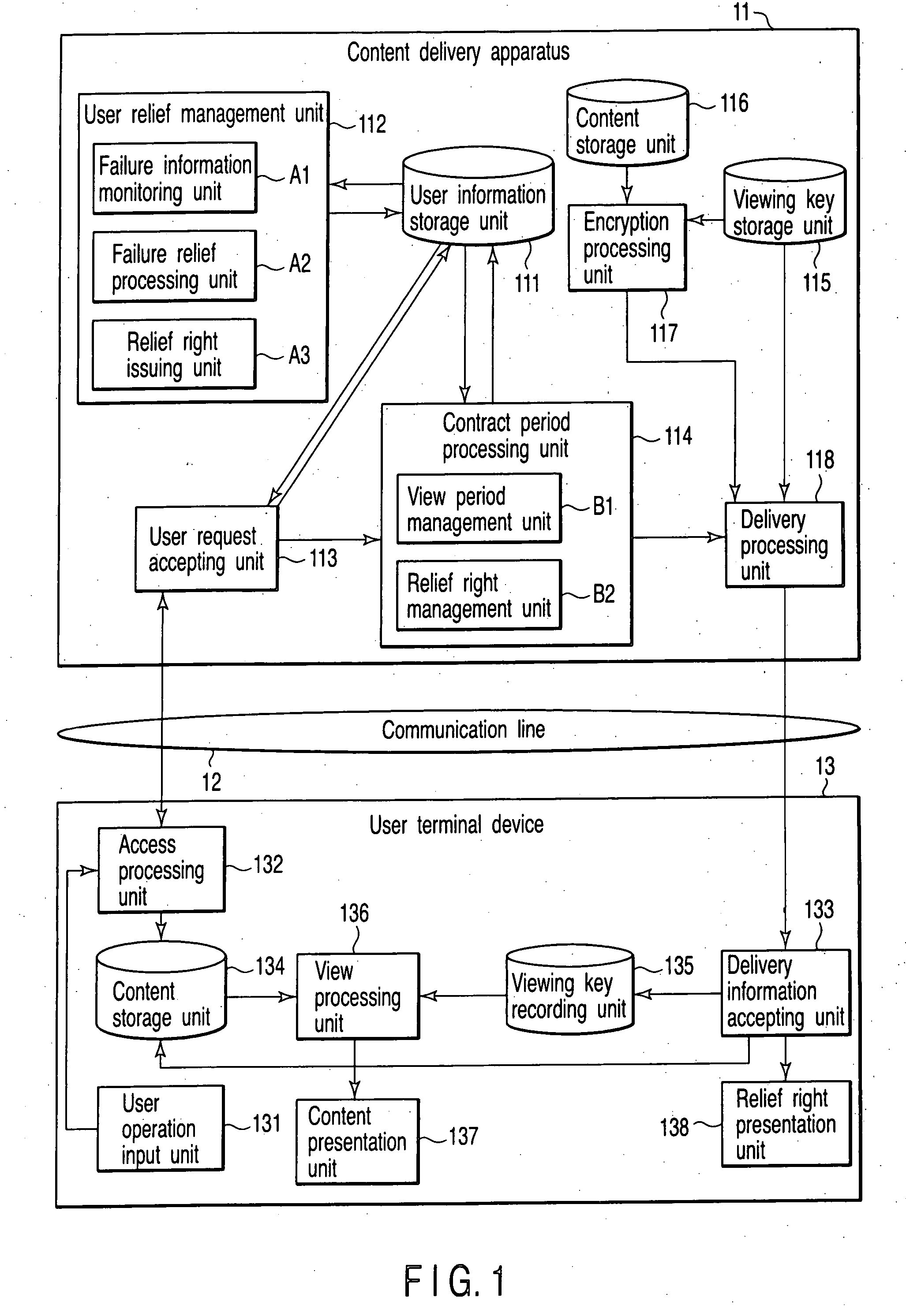

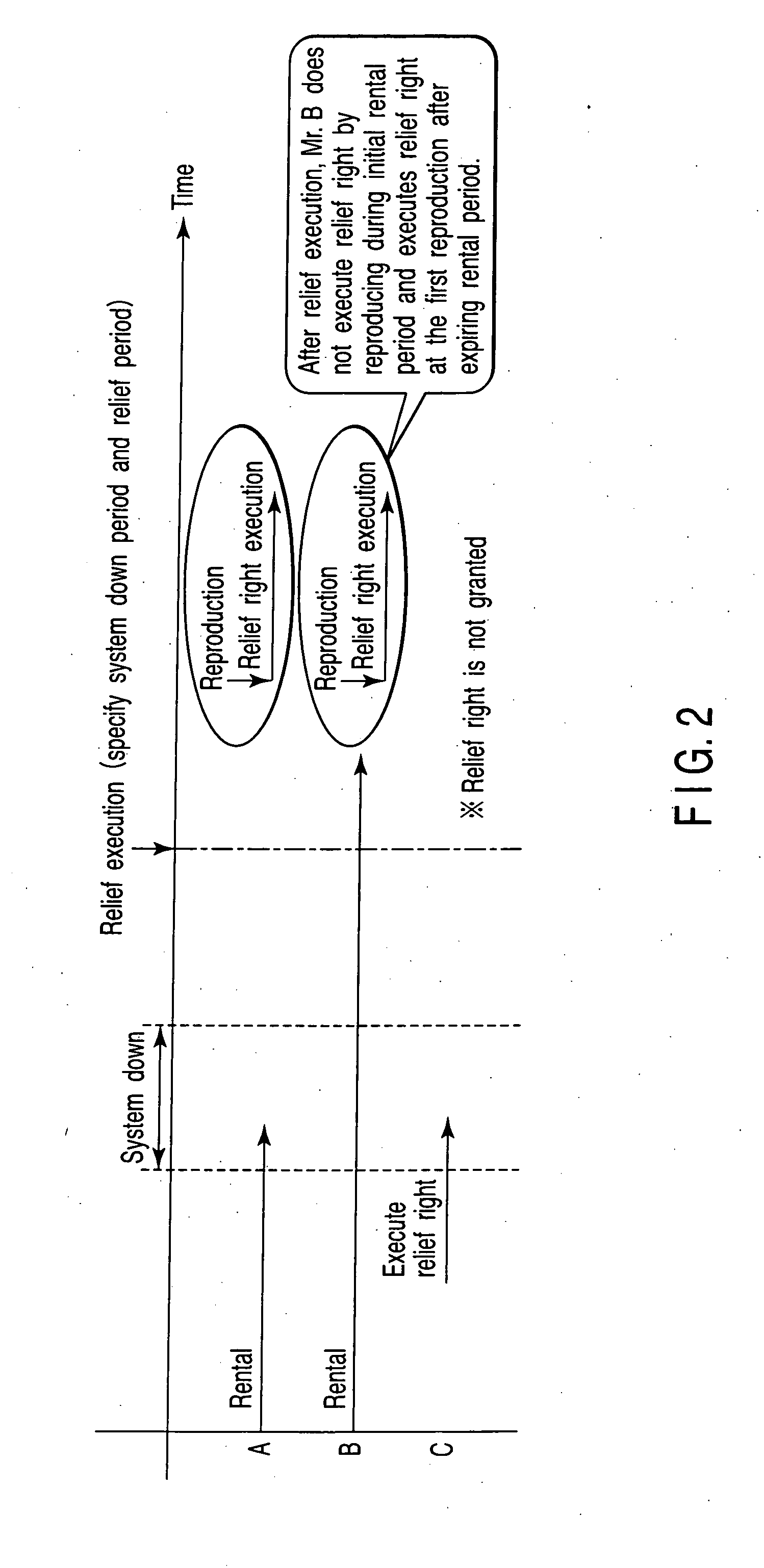

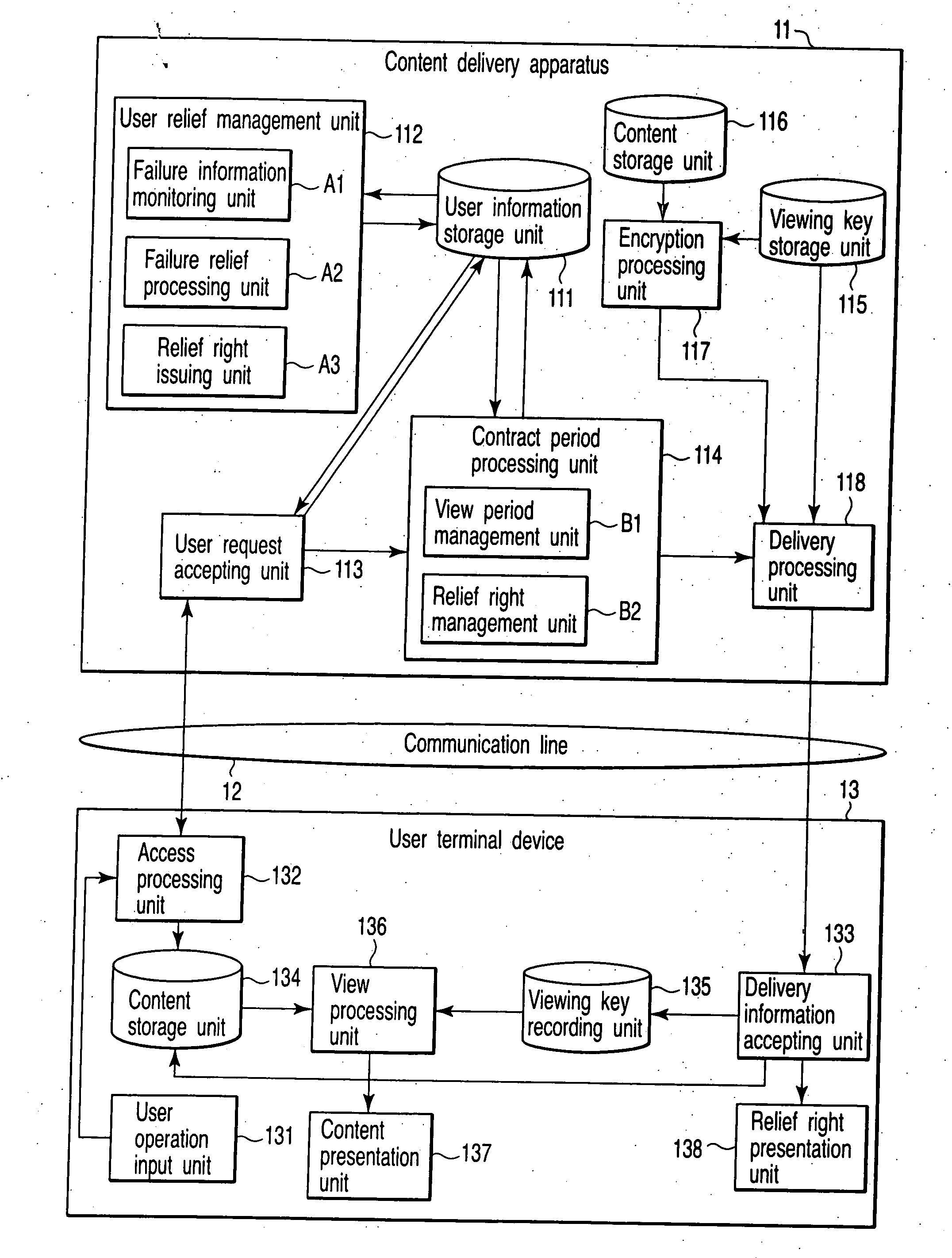

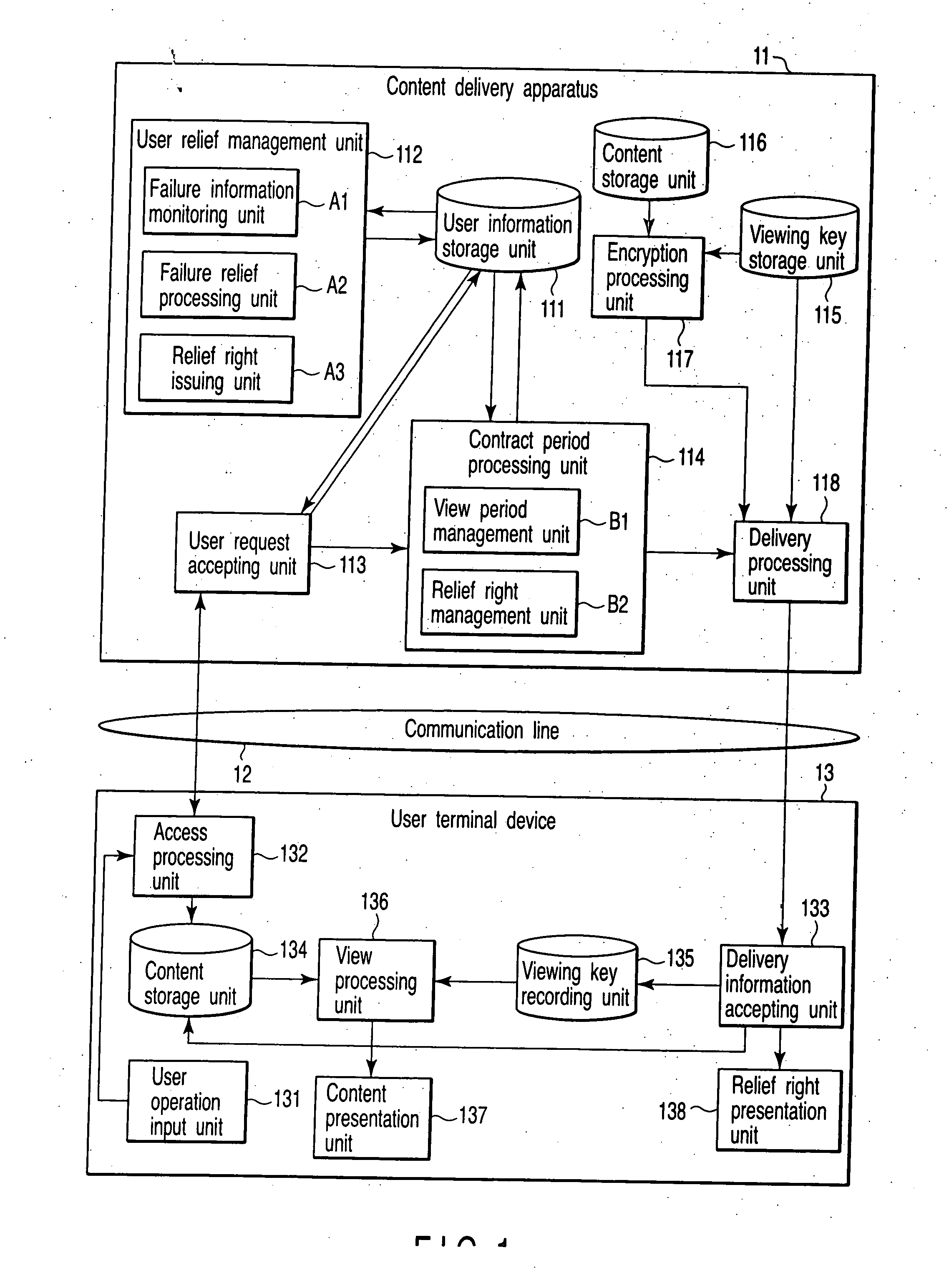

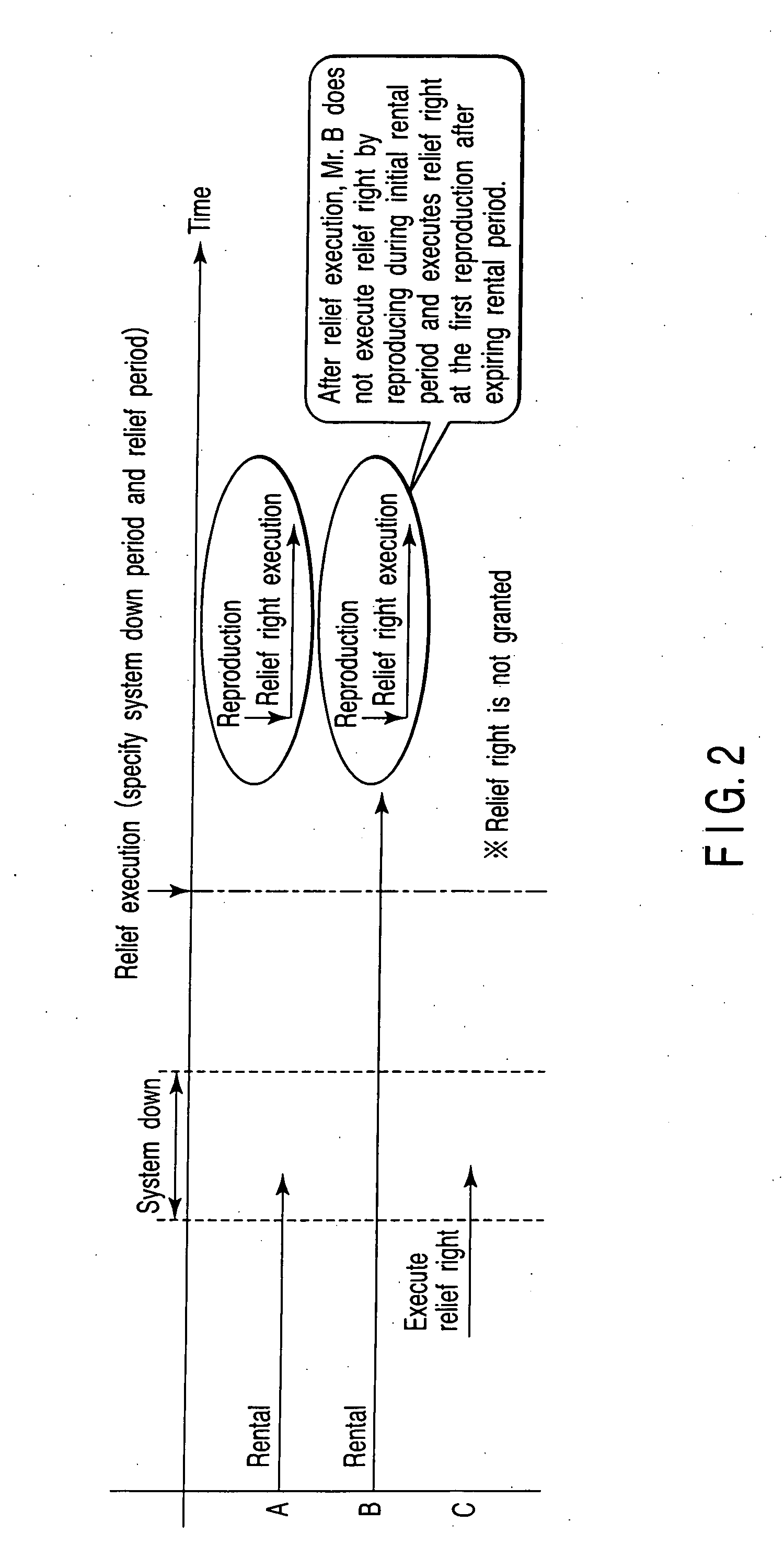

Content delivery apparatus, user terminal device, relief management method and computer program

InactiveUS20070061261A1Eliminate dissatisfactionSecure beliefAnalogue secracy/subscription systemsPayment architectureManagement unitTerminal equipment

A content delivery apparatus, when a content delivery request is outputted from a user terminal device, encrypts the requested content with an encryption key, adds a view period to it to deliver it to a request source and delivers a viewing key in response to a view request from the user terminal device within the view period. A user relief management unit monitors failure information notifying, grasps a delivery disabled period from the failure information, specifies a delivery destination user for a content of which the view period is overlapped with the delivery disabled period and issues a relief right with a relief period specified thereto to the specified user. A contract period processing unit manages the relief right and permits viewing within the relief period set by the relief right when a view right based on the relief right is output from the user terminal device.

Owner:KK TOSHIBA

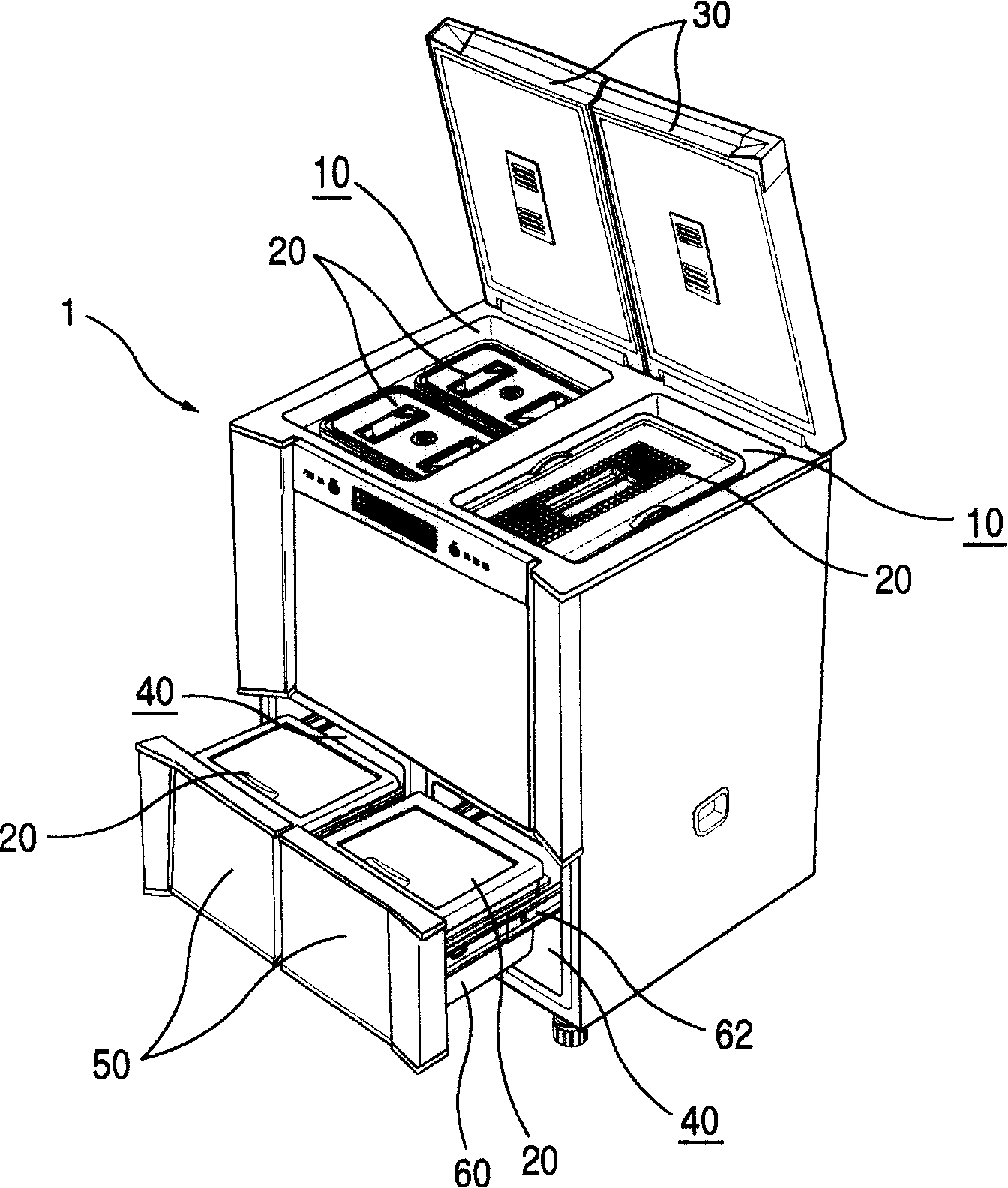

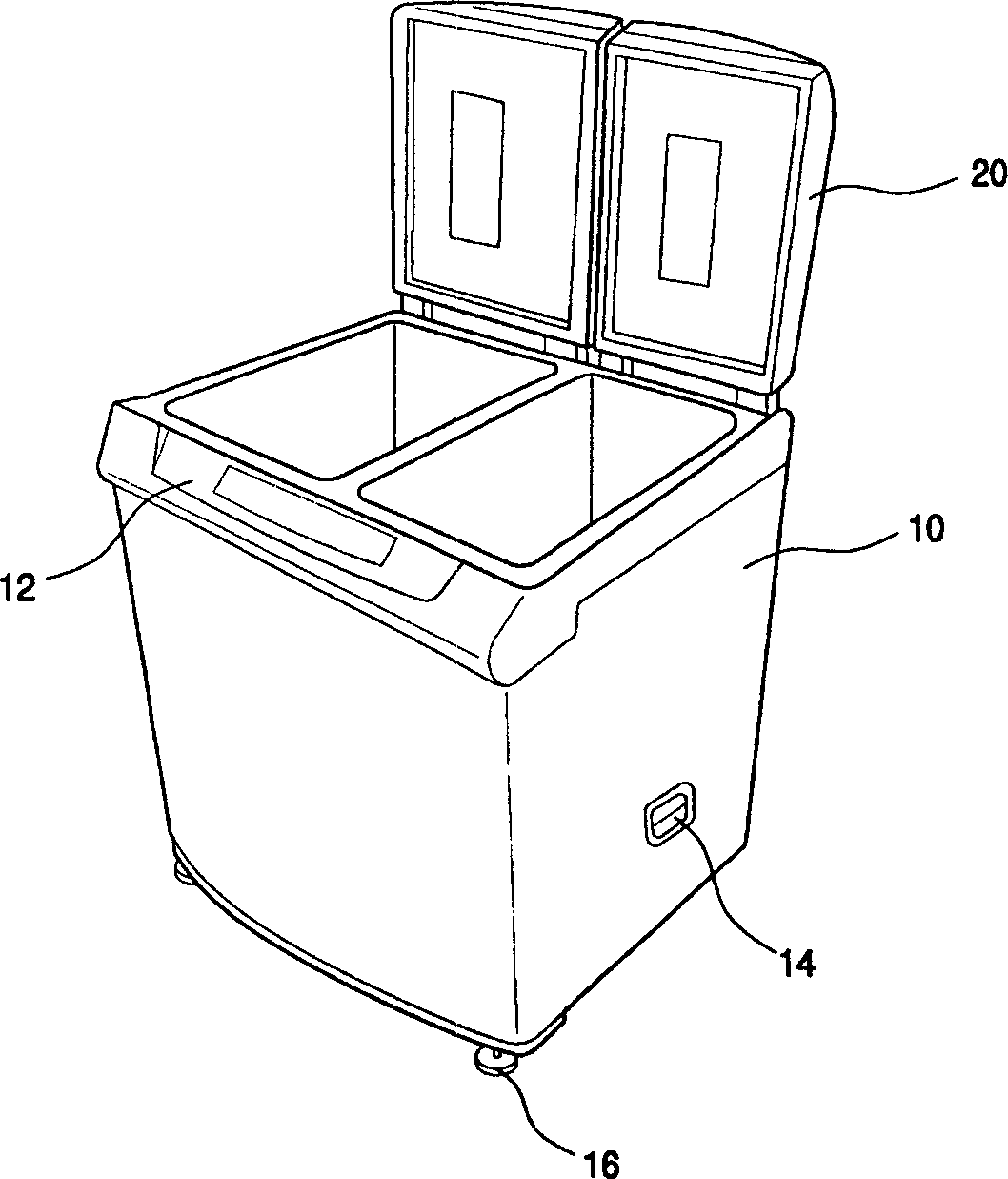

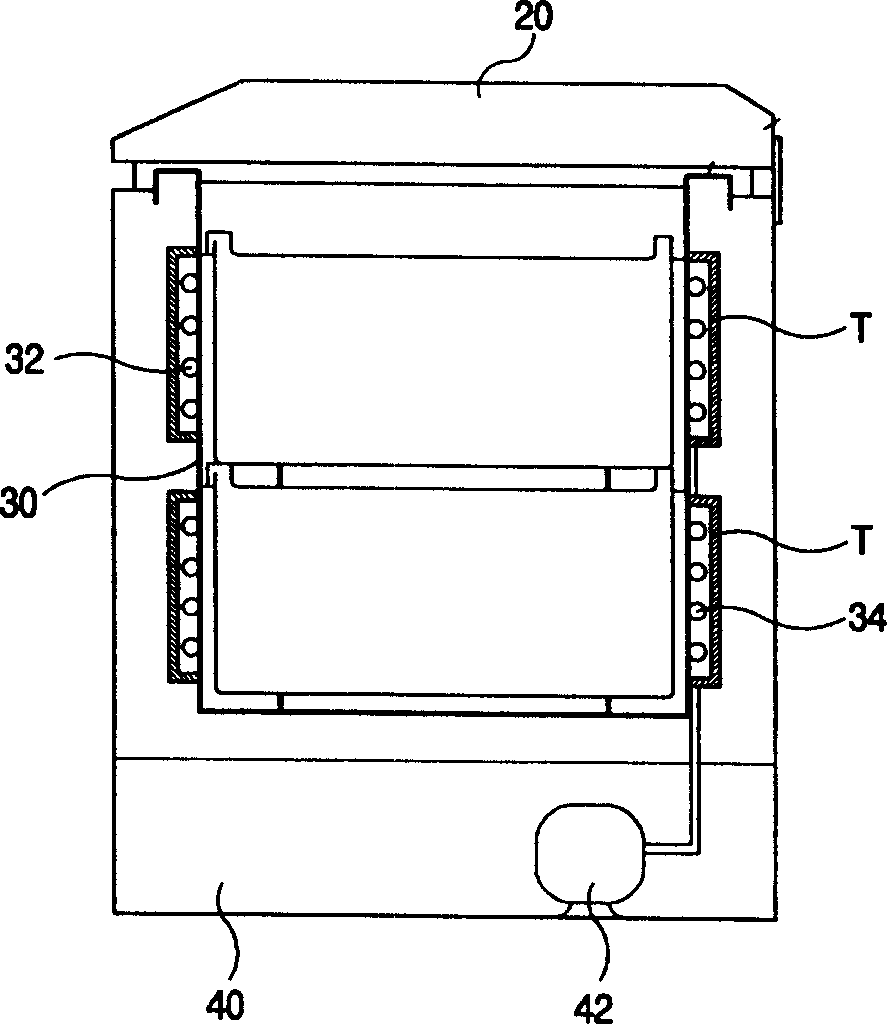

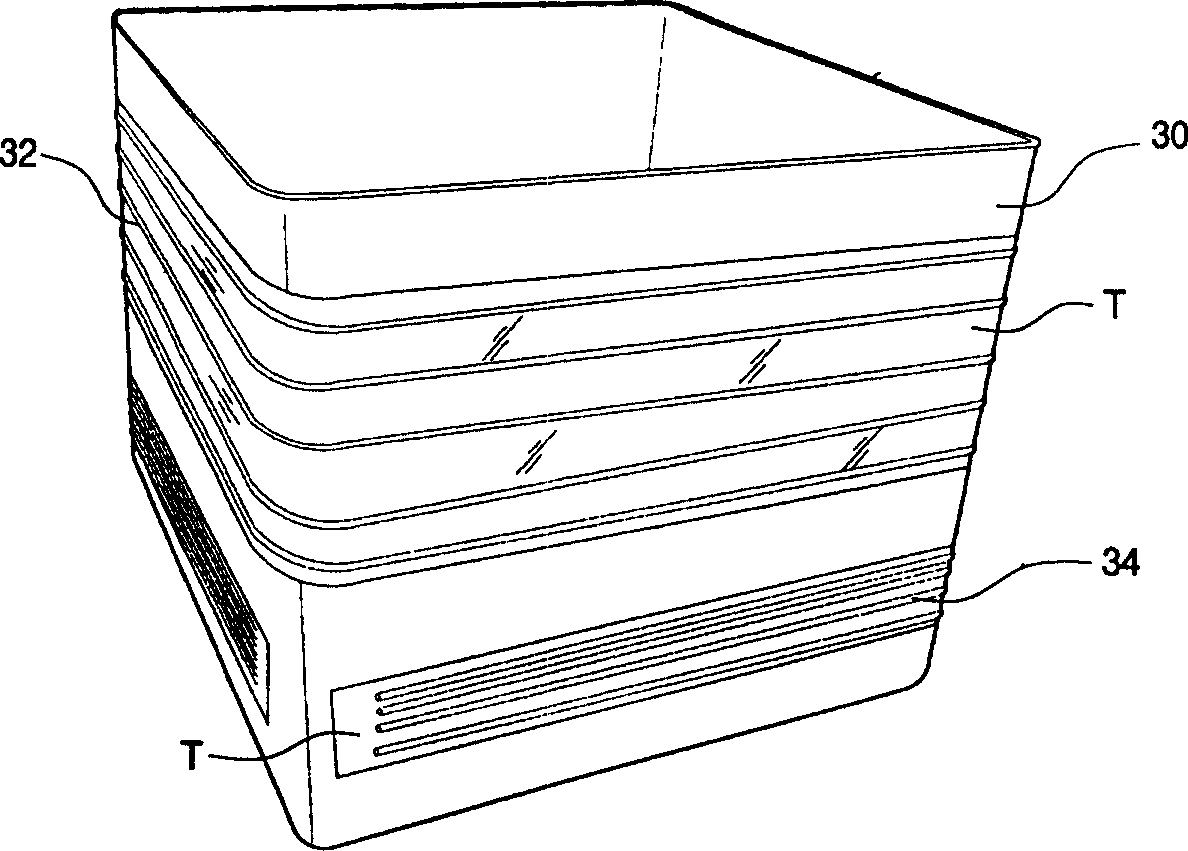

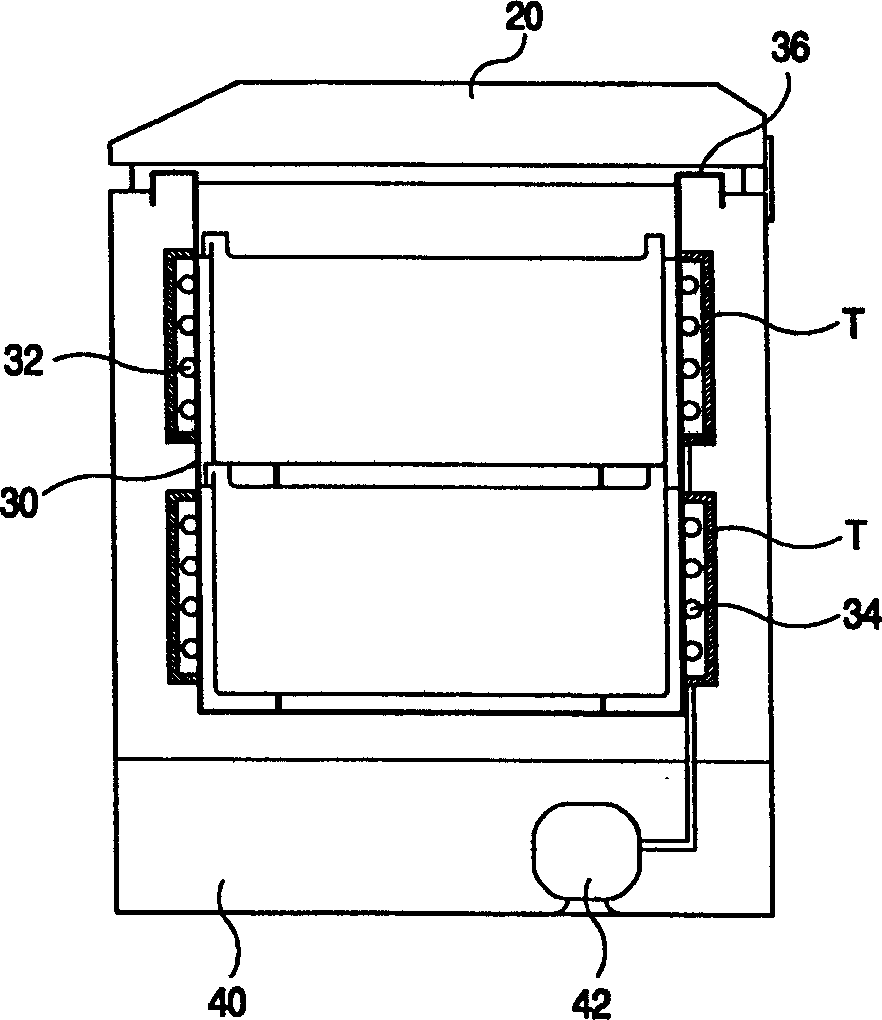

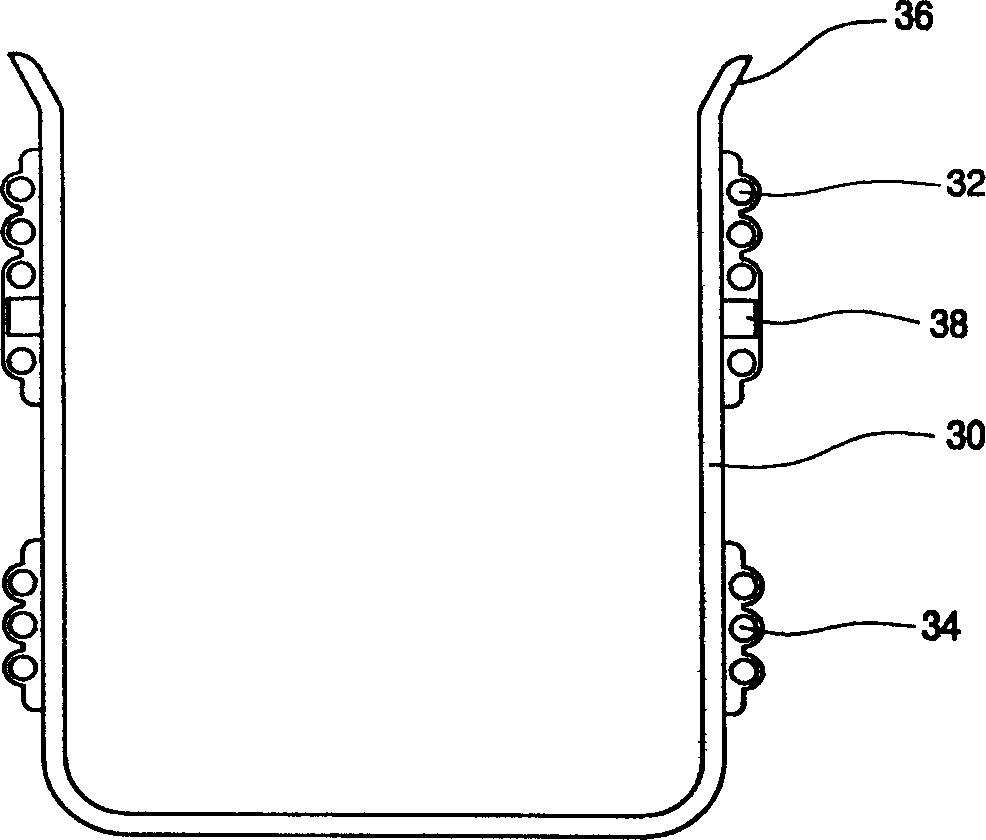

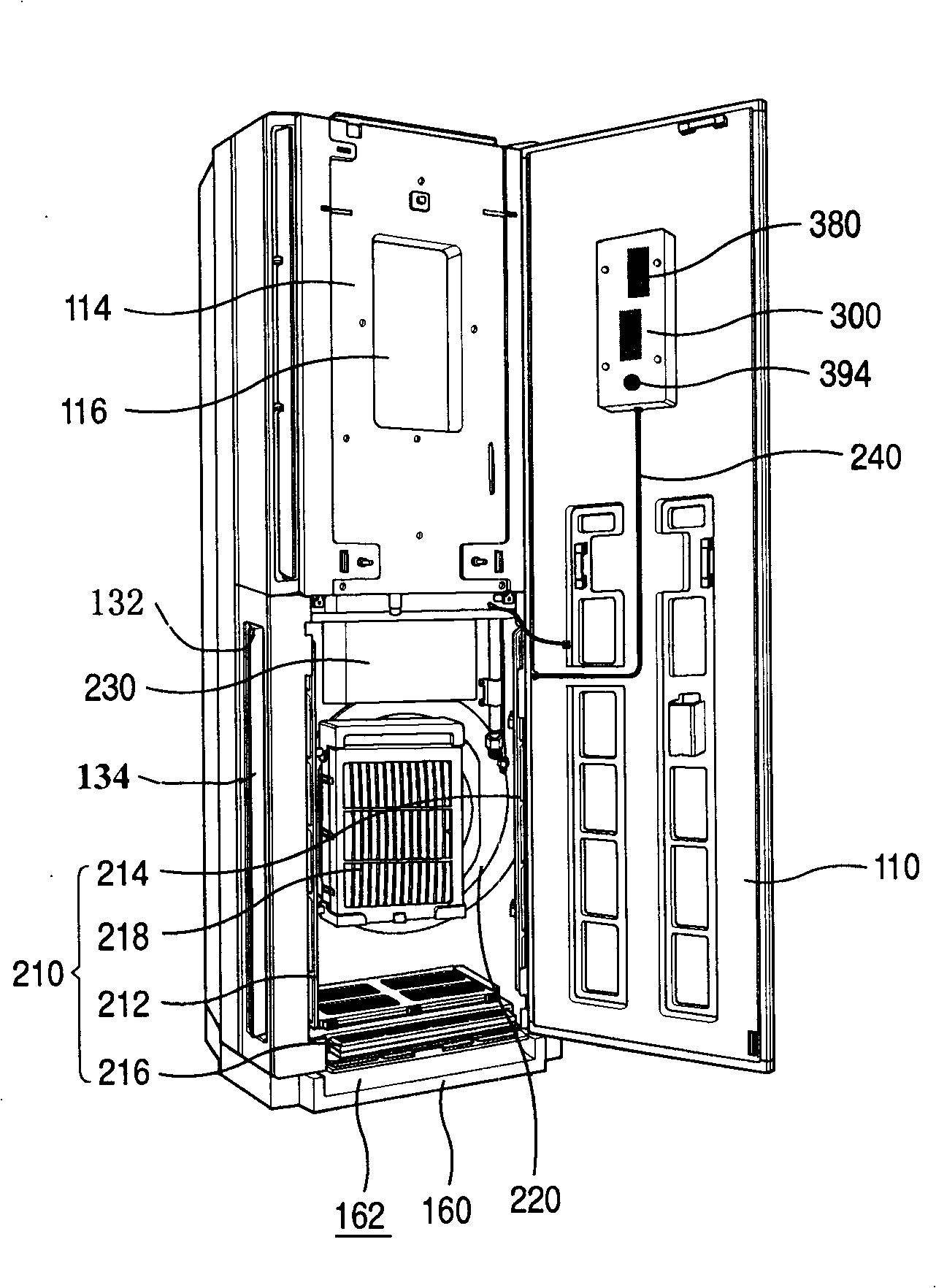

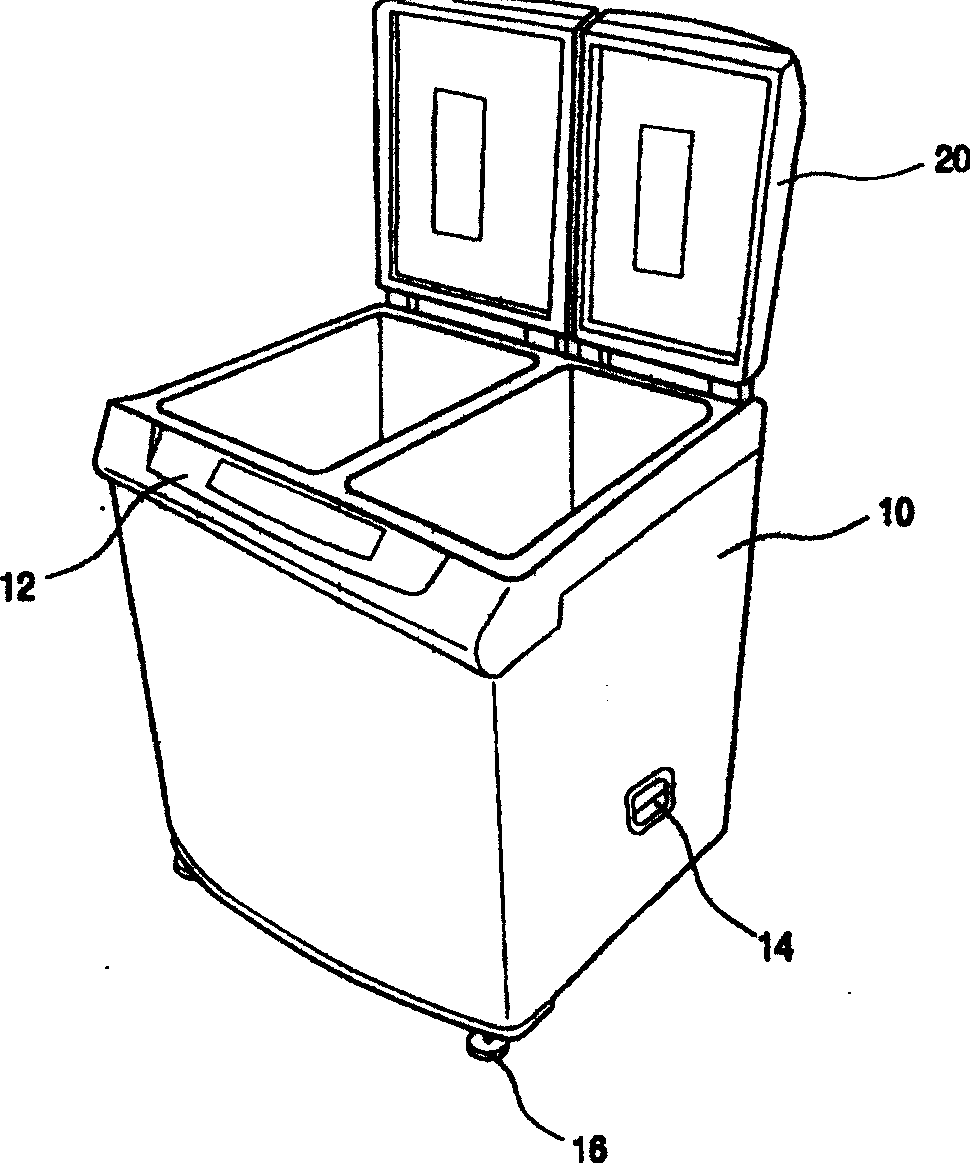

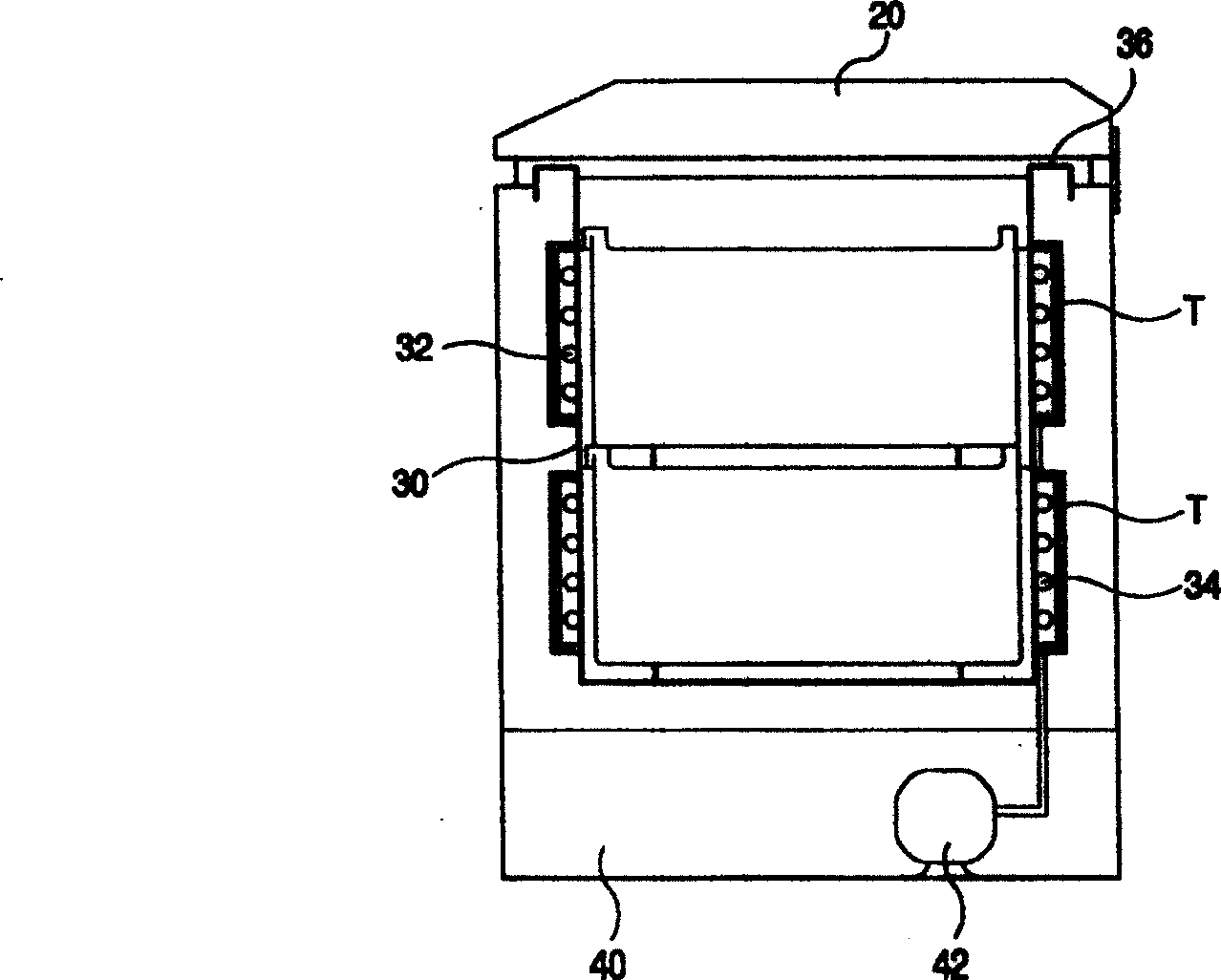

Pickles refrigerator

InactiveCN1862180AHigh strengthAvoid deformationDomestic refrigeratorsEvaporators/condensersRefrigerated temperatureBiomedical engineering

The present invention discloses a pickled vegetables refrigerator. It is characterized by that on the internal surface or internal surface and external surface of its internal box the impressed grains are formed or said internal surface or internal surface and external surface are undergone the process of etching treatment, so that the strength of internal box not only can be raised, but also the surface area of said internal box can be relatively increased.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

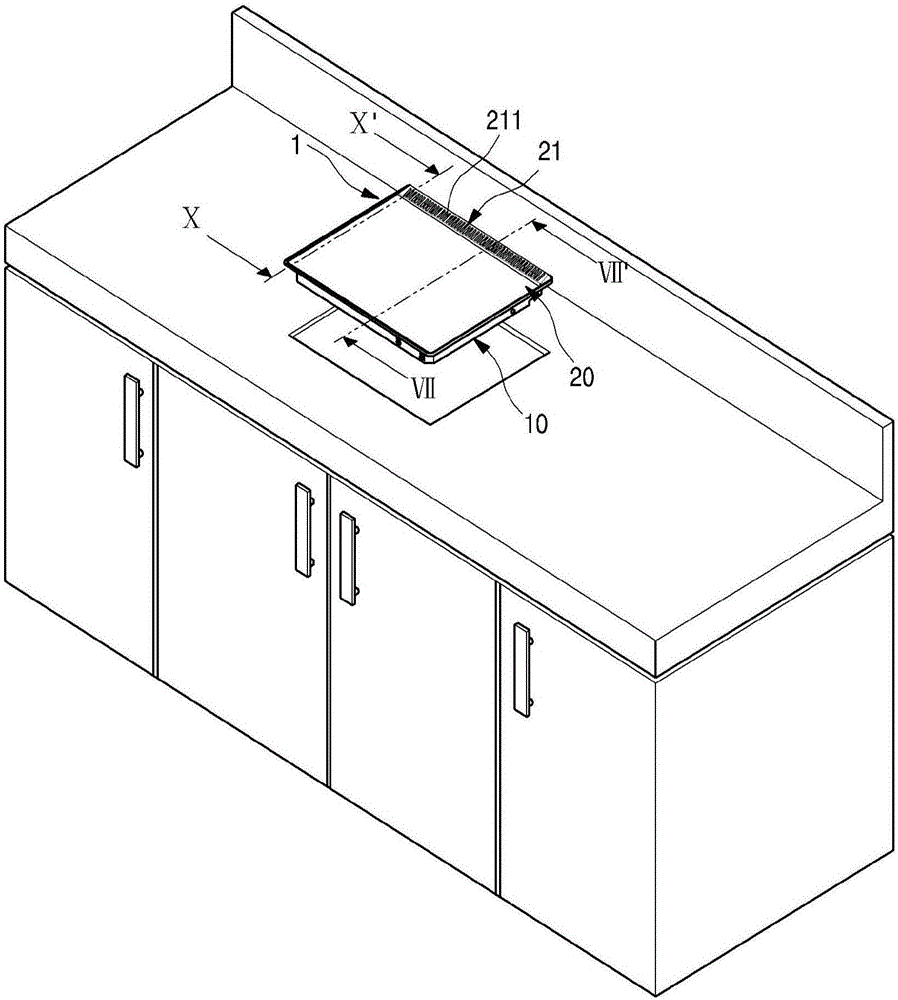

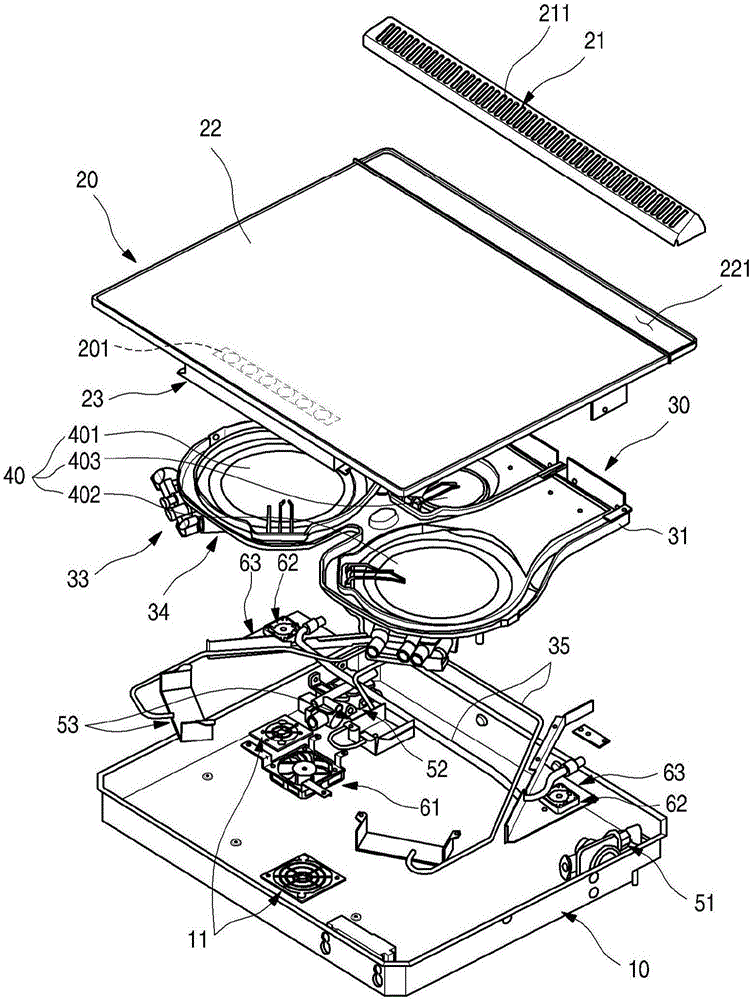

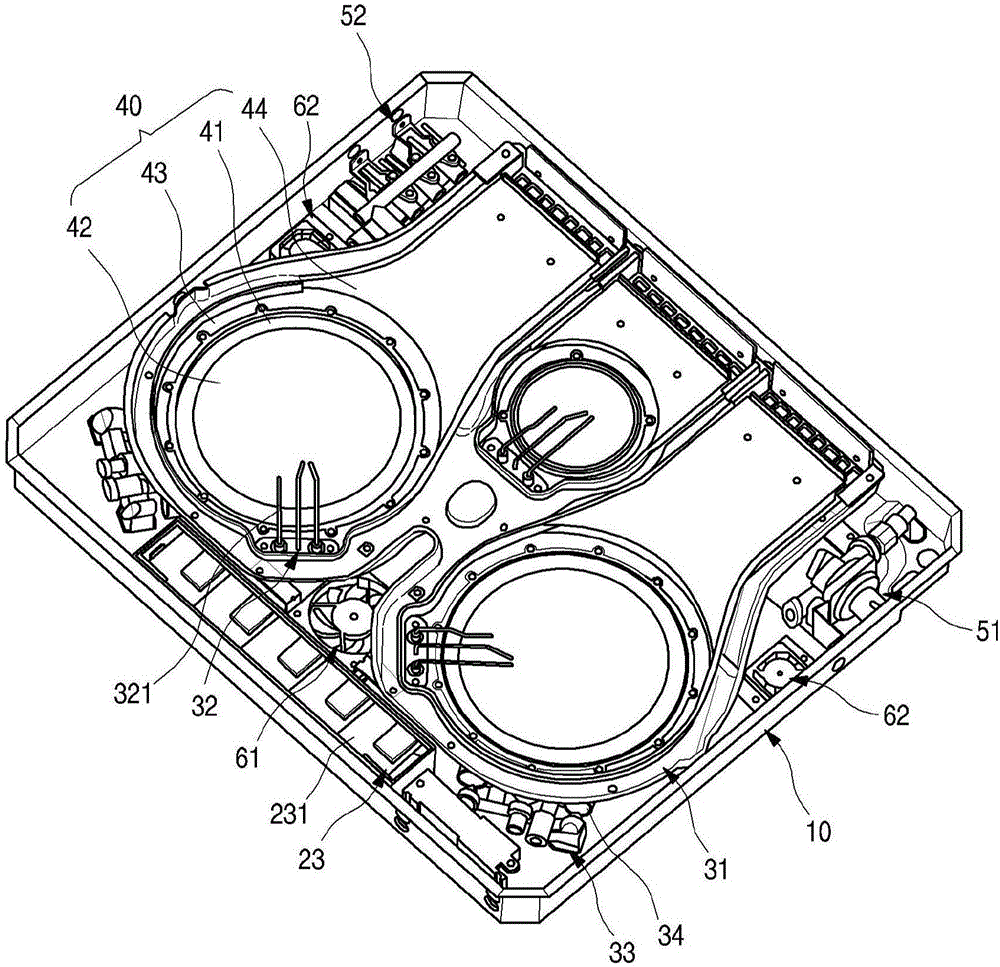

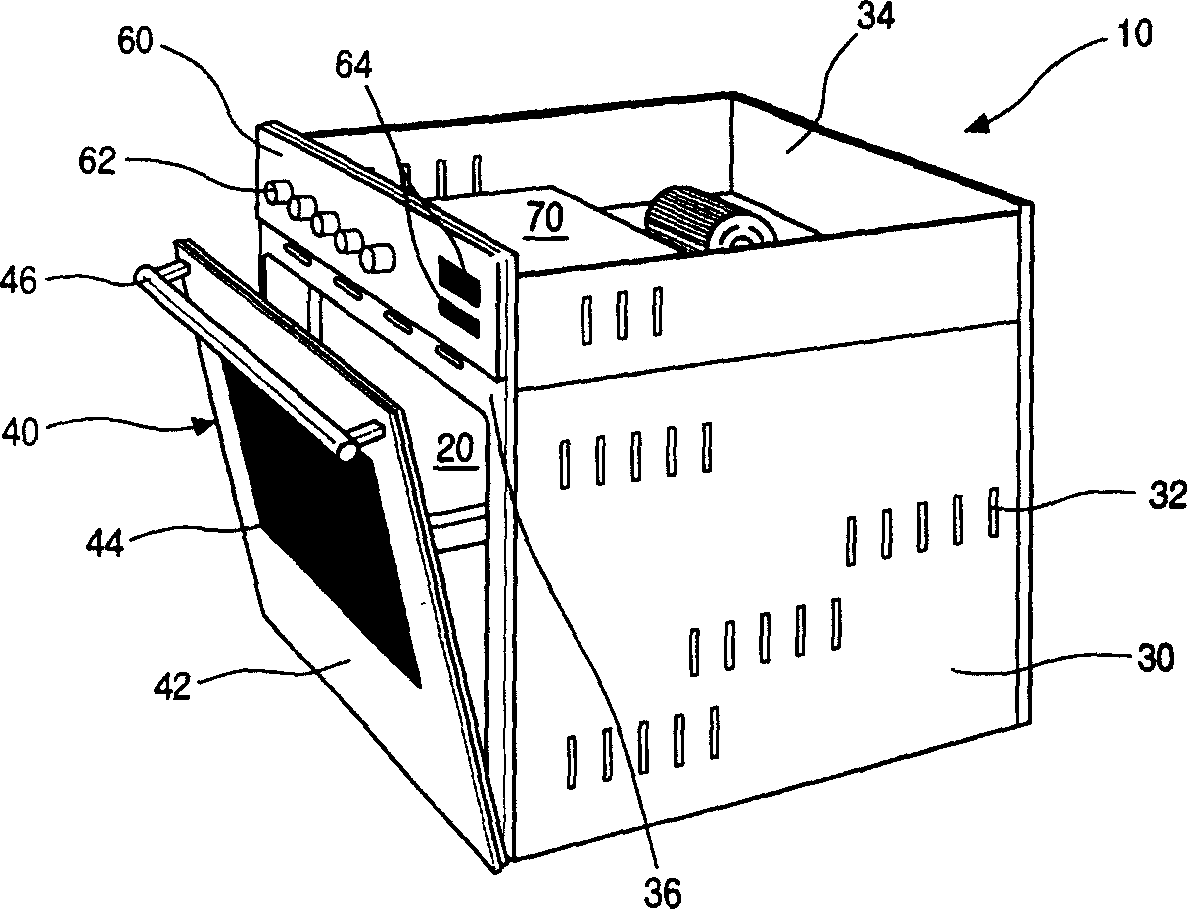

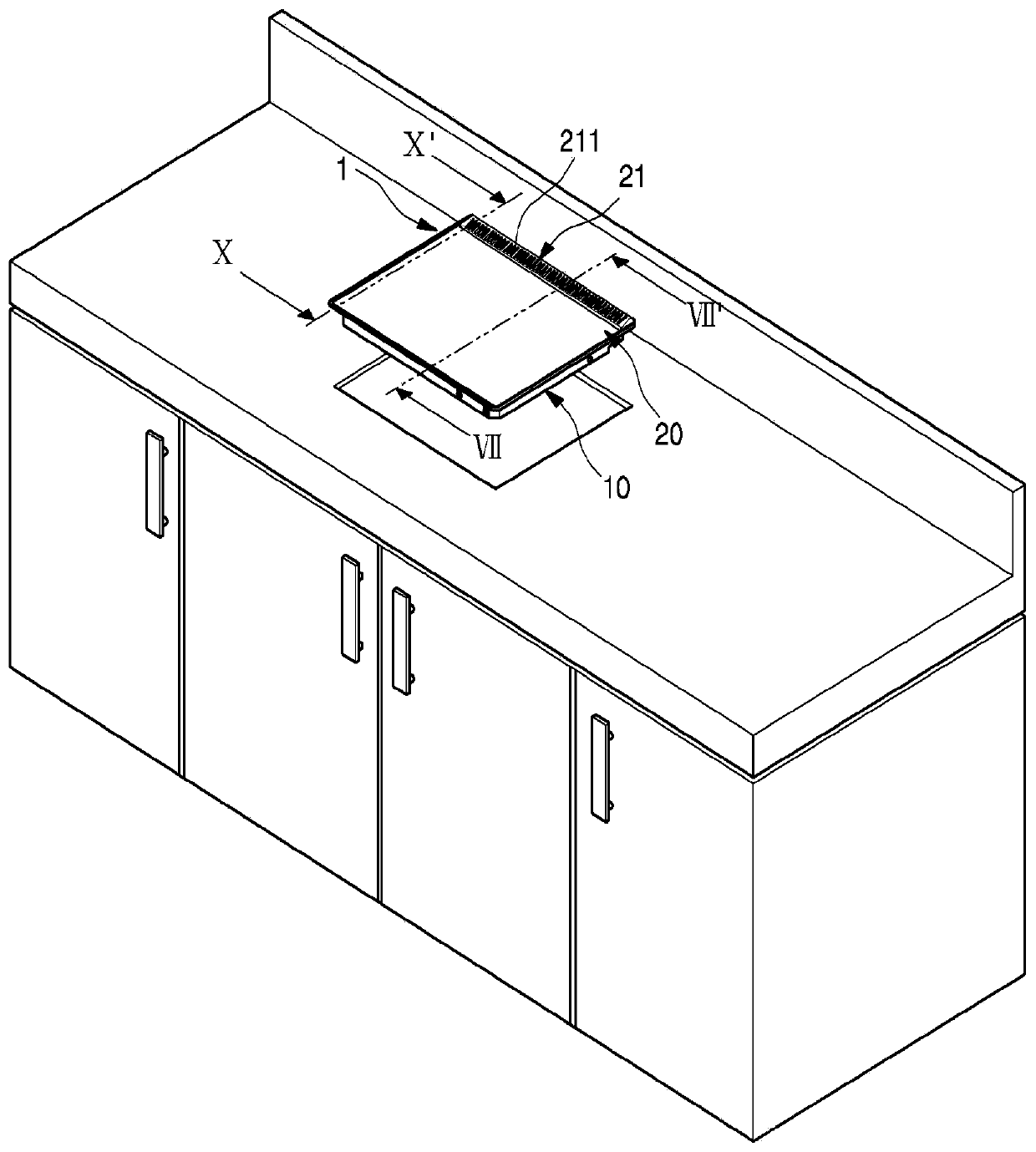

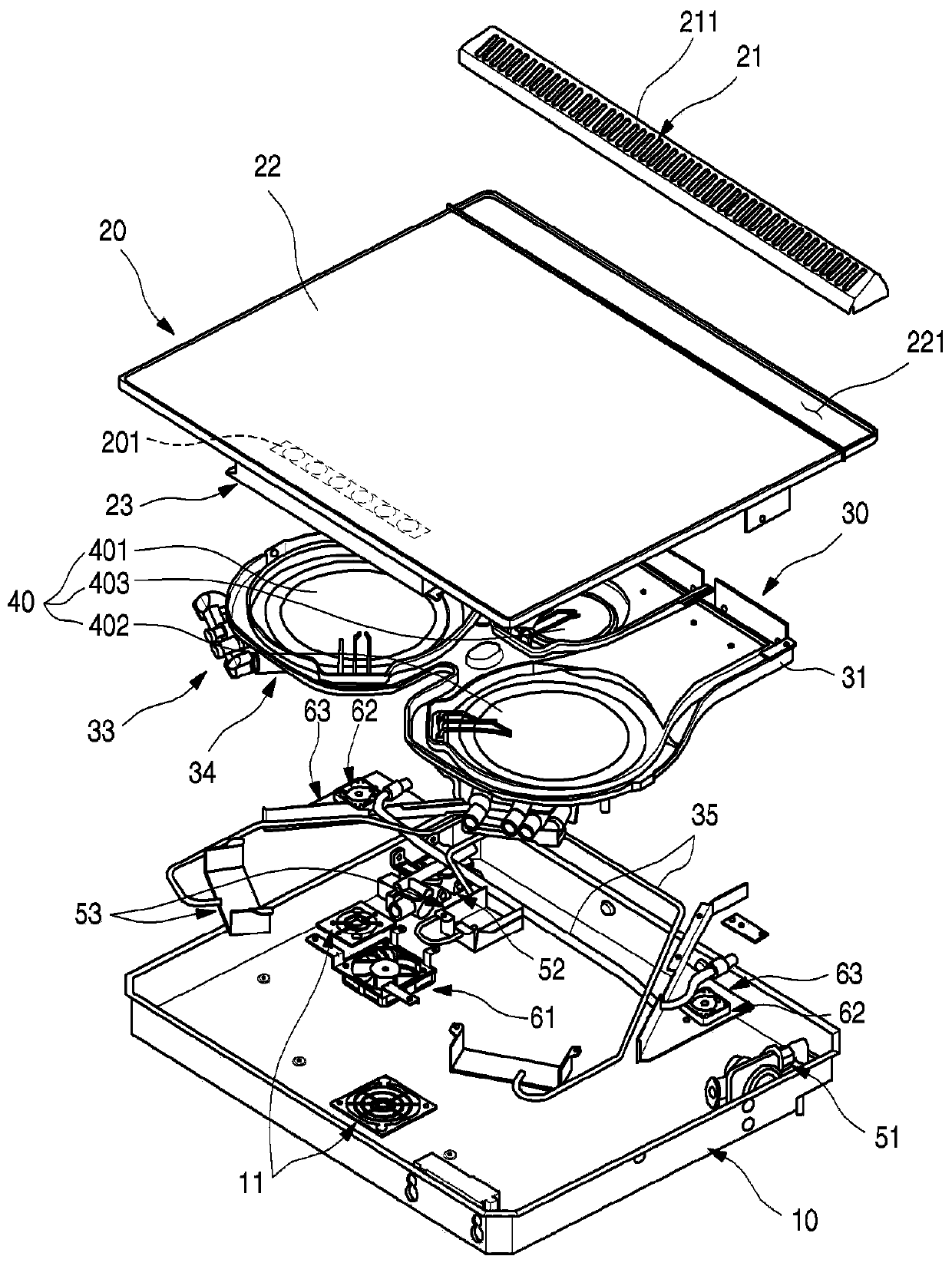

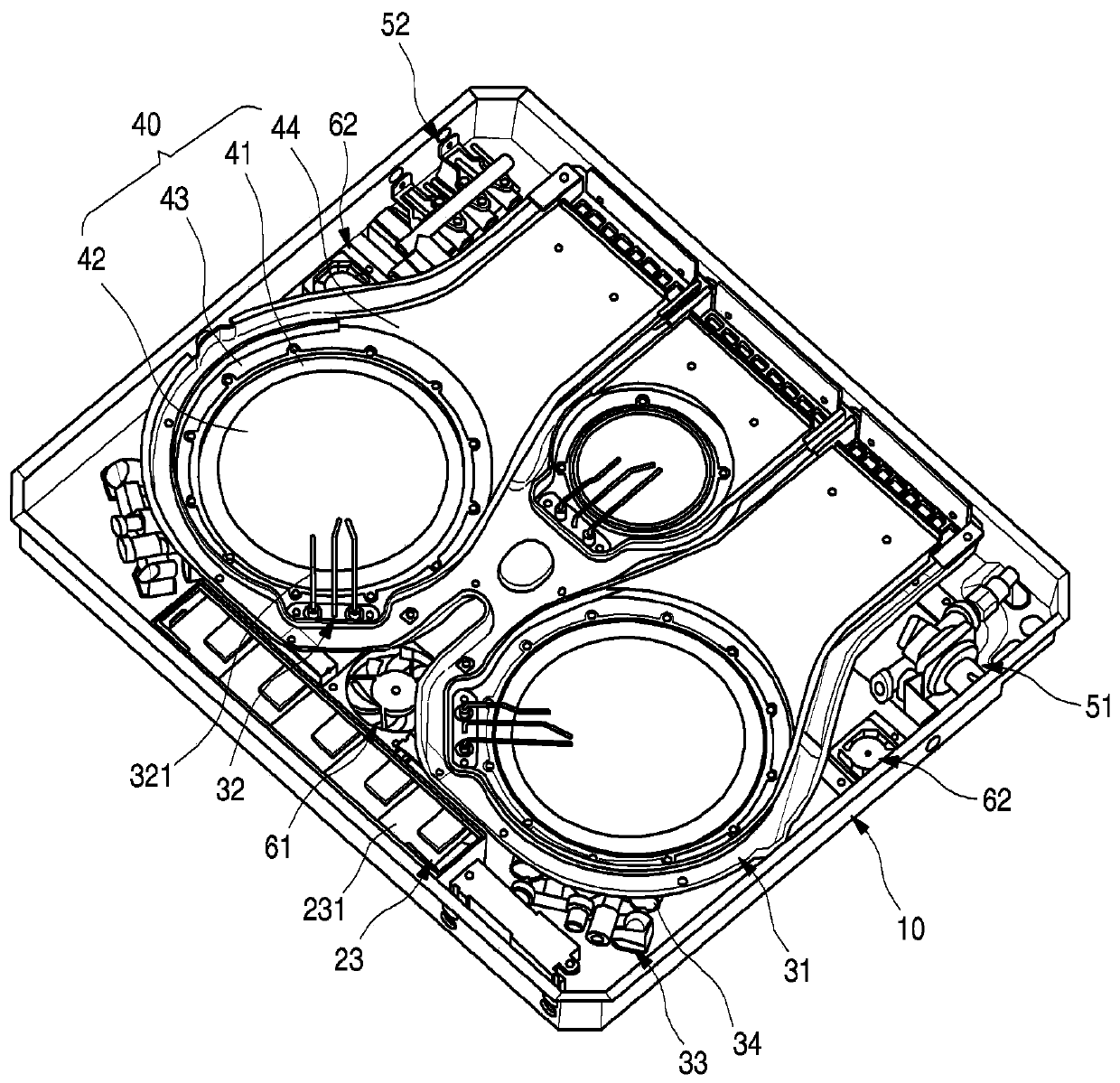

Gas cooker

ActiveCN106500135AEnsure job reliabilityImprove cooling effectDomestic stoves or rangesCooking fumes removalCombustorProcess engineering

The invention relates to a gas cooker which is characterized in that: the gas cooker includes a housing; a top plate which shields above side of an opening part of the housing; burner units which are accommodated inside the housing and includes a red heat plate which is heated by a hybrid gas; an operation unit which is arranged at the front end of the housing and operated by a user so as to enable the burner units to work; a main fan which is disposed between the burner units and the operation unit, and absorbs air outside the housing to cool the inside of the housing; and a gas exhaust part which is arranged at the rear end of the housing and is intended for exhaust the gas left after the combustion of the burner units and the cooled air inside the housing.

Owner:LG ELECTRONICS INC

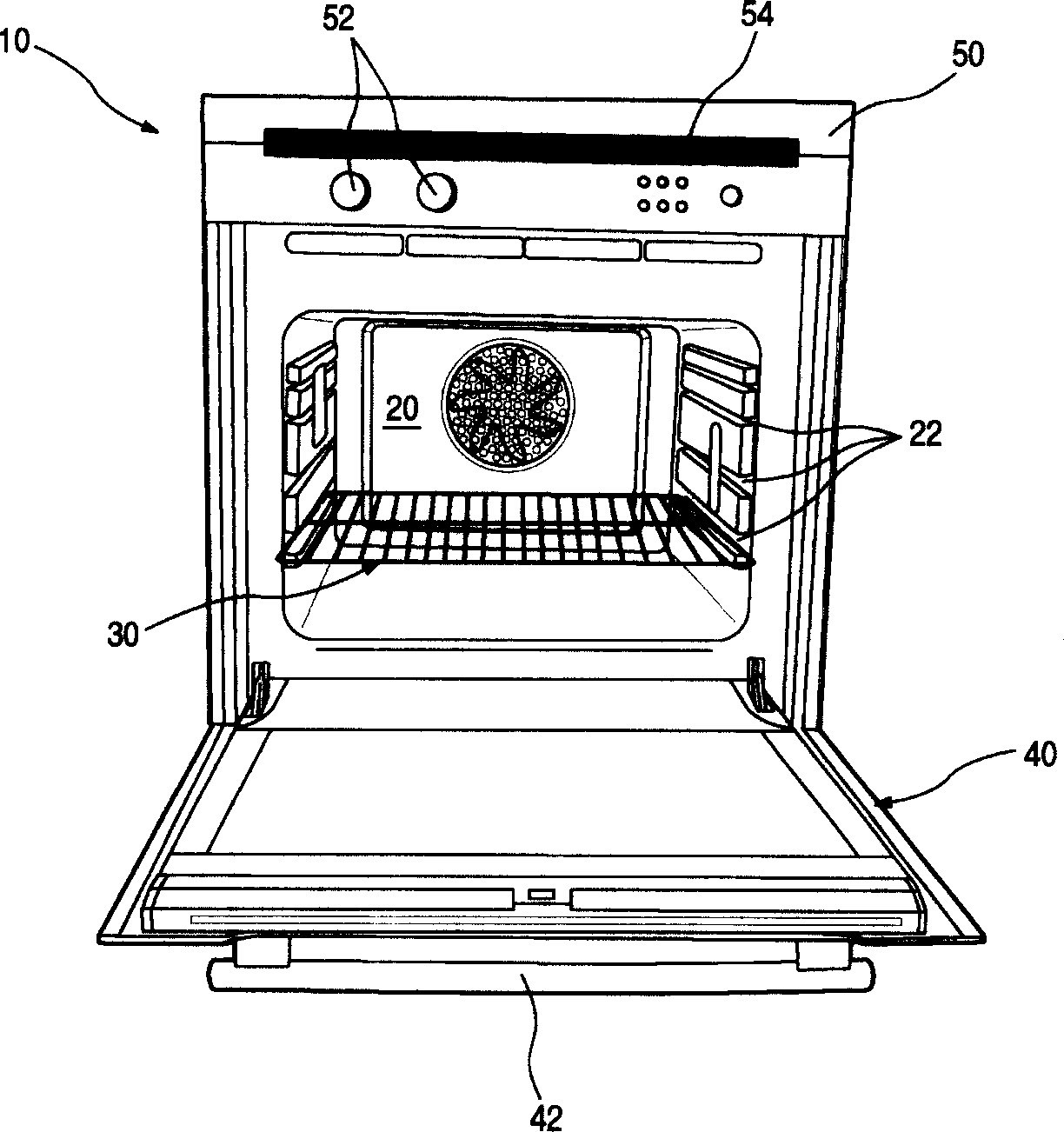

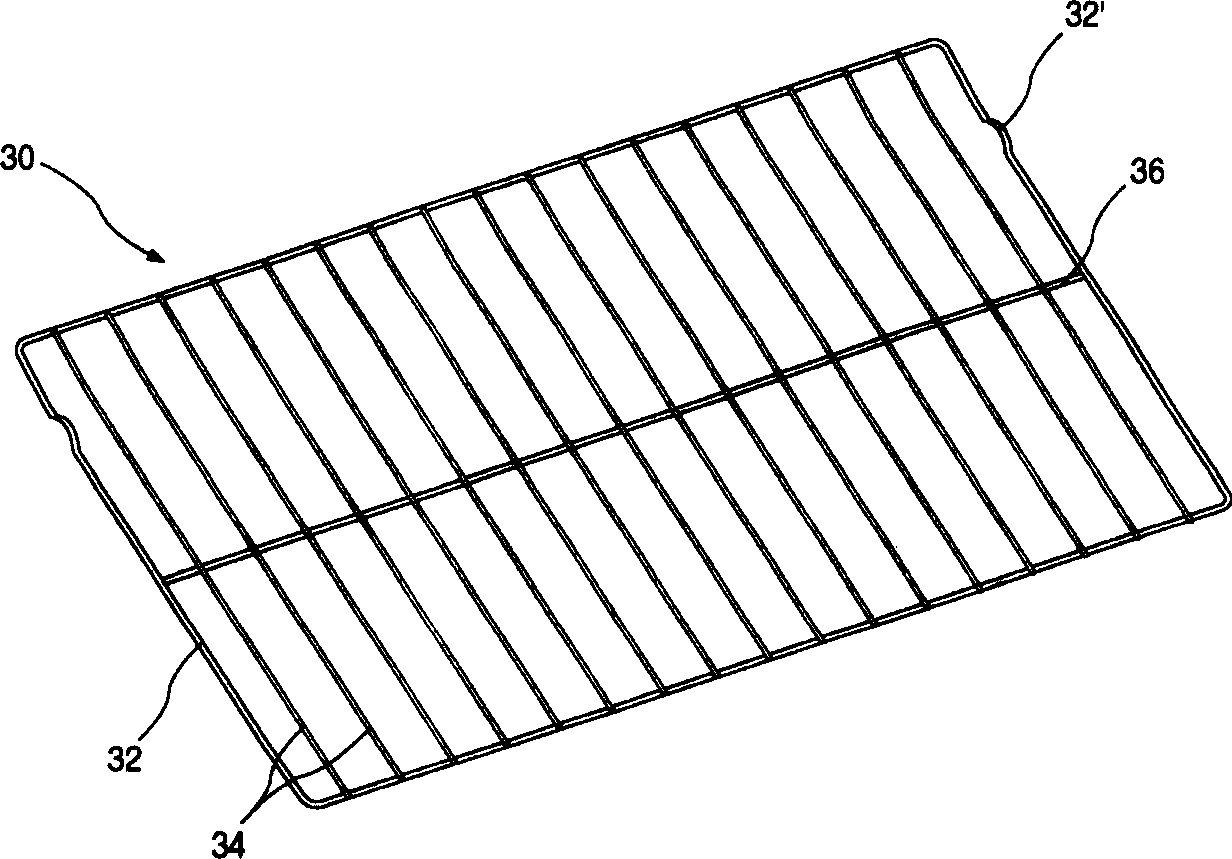

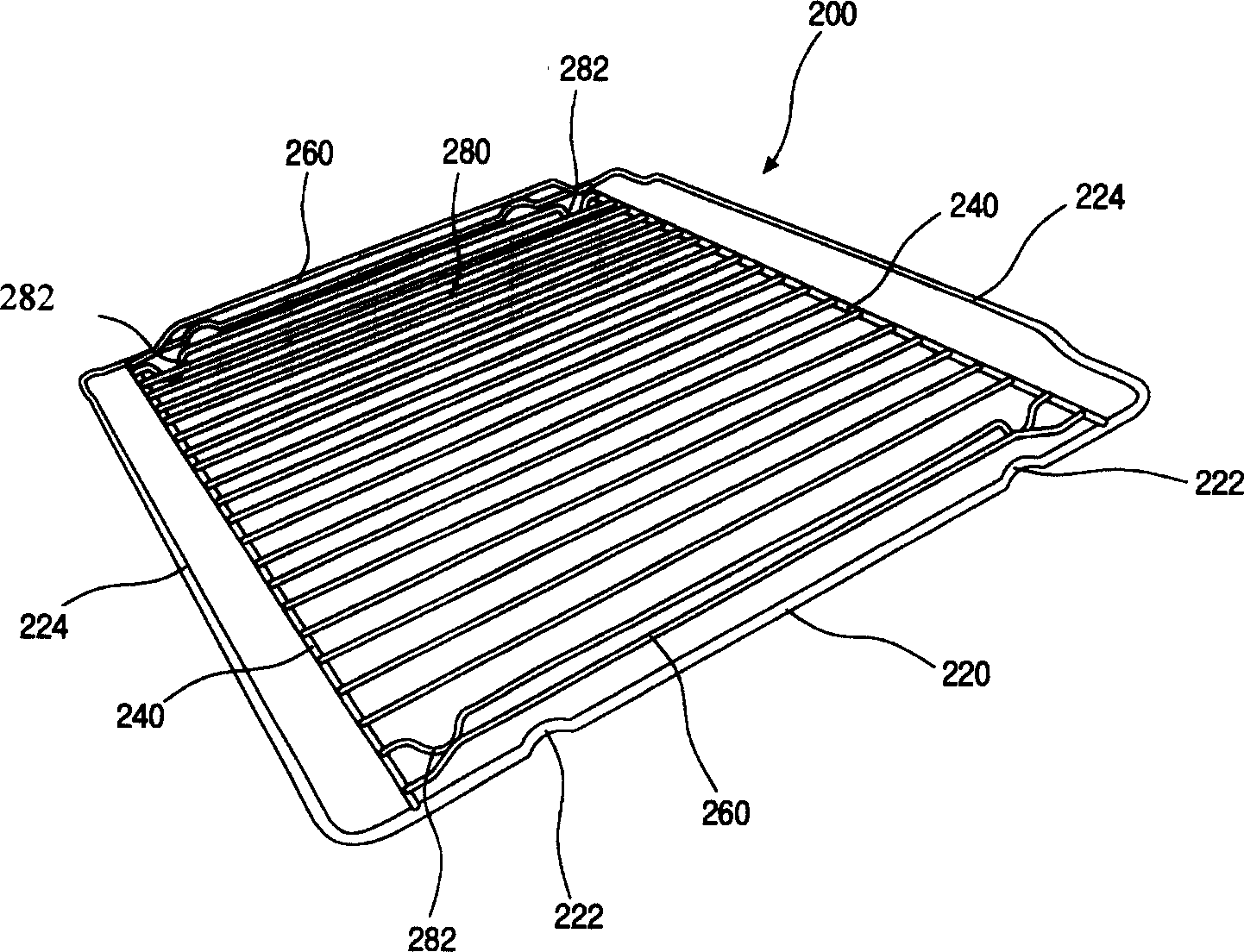

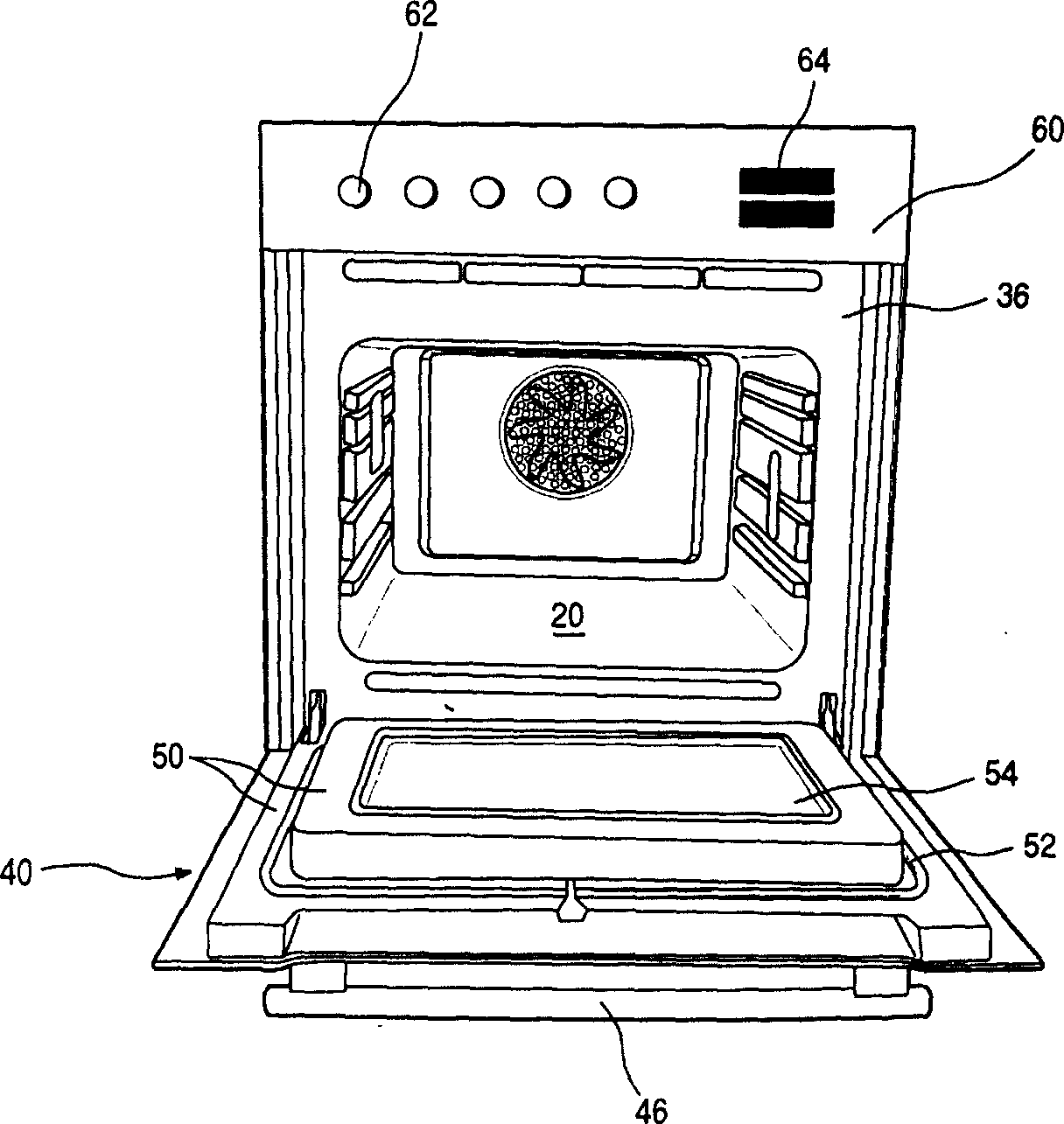

Rocking and sagging preventing frame of electric roaster

InactiveCN1899180AEasy to break awayEliminate dissatisfactionRoasters/grillsEngineeringMechanical engineering

The present invention relates to food roasting oven, and is especially one roasting box frame structure with side guide boards and back hanging slot and bending part and capable of preventing rocking and sagging. The food roasting oven includes roasting box frame inside the cooking room, leading slots on two side for leading the moving roasting box frame, connecting unit to divide the frame into one front part and one back part, side guide board on the sides, several food supporting units, hanging slot, and upwards bent unit. The food roasting oven can prevent the roasting box frame from rocking and sagging.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

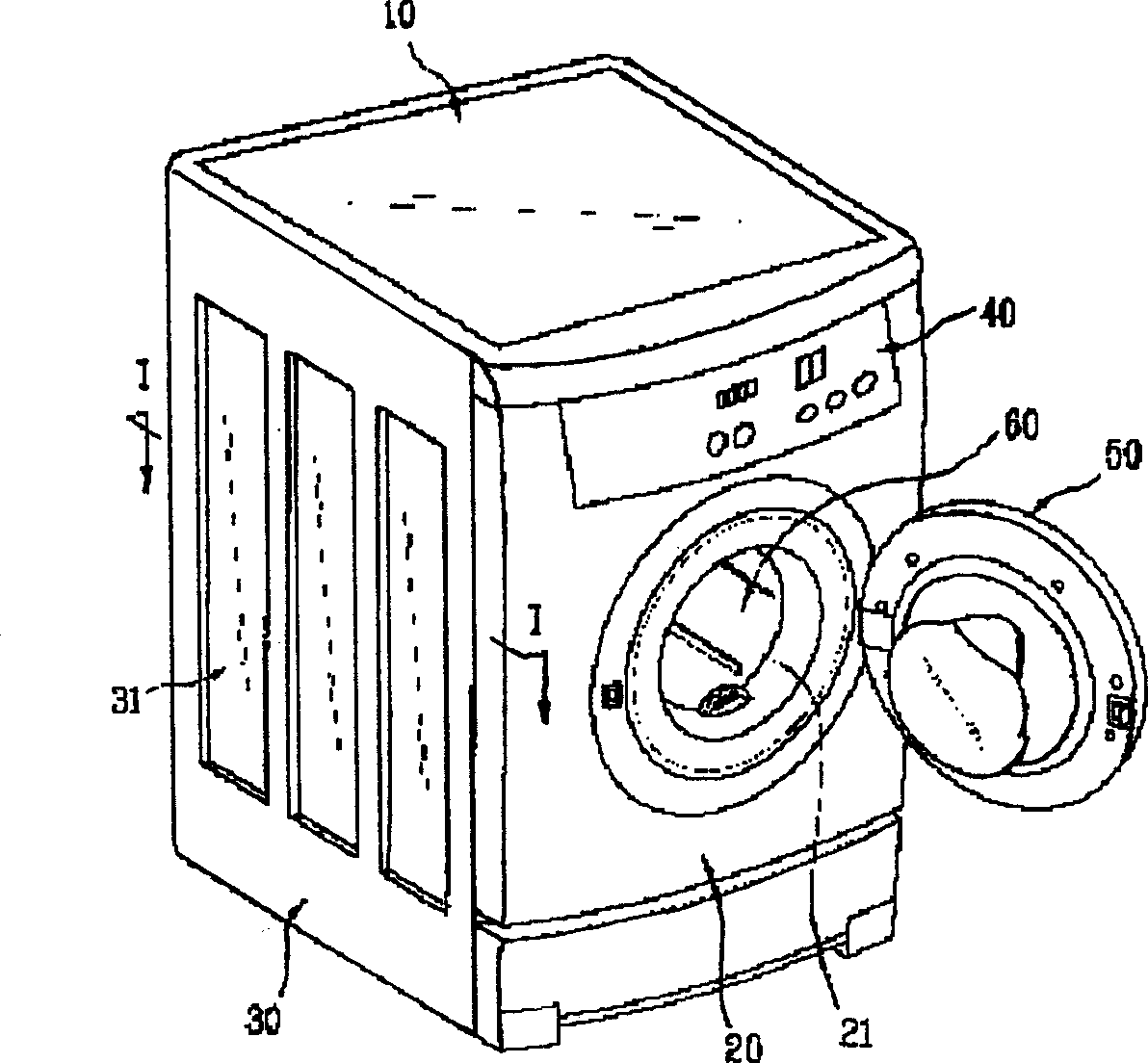

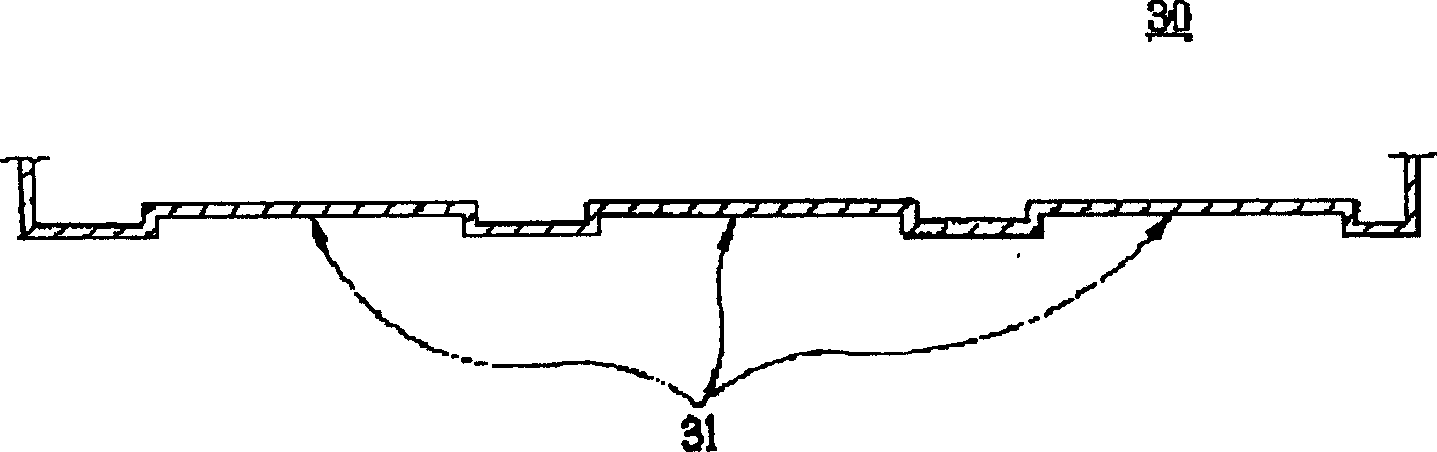

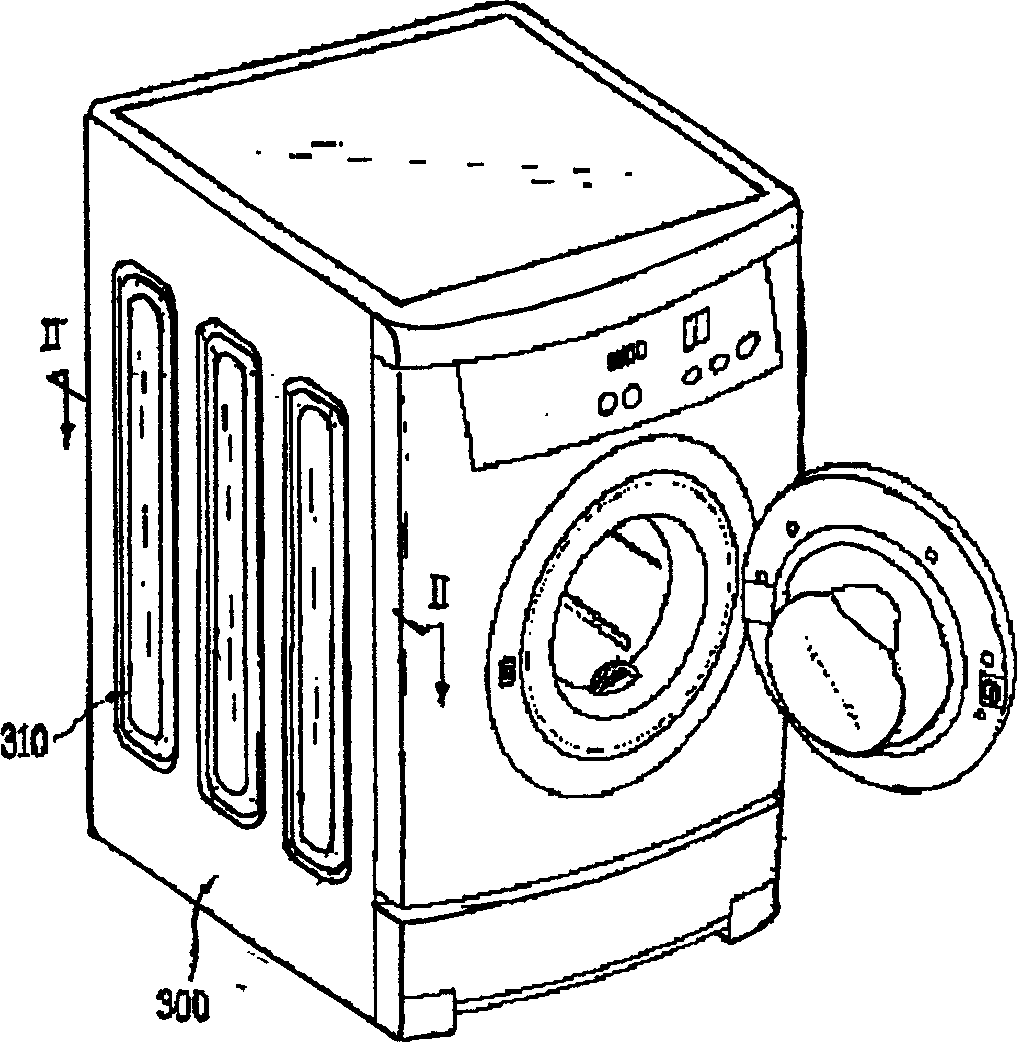

Resonance preventing structure of washing machine

InactiveCN1532325AAvoid resonanceReduce noiseOther washing machinesTextiles and paperResonanceEngineering

The resonance preventing structure for washing machine includes the top metal plate, front metal plate, side metal plates, the operation panel for the tumble washing machine and door for the opening and closing of inside of the washing machine. Each of the side plates has at least one long rectangular notch with opposite protrudent part. The present invention has the effect of preventing resonance during high speed rotation in various kinds of washing machine, preventing damage and destruction of parts caused by resonance and lowering noise of the washing machine during high speed rotation.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Information providing system and method

InactiveUS20020129117A1Eliminate dissatisfactionShort timeBroadcast with distributionBroadcast services for monitoring/identification/recognitionWeb siteWorld Wide Web

An information service comprising an identification code transmitted by mass media, together with primary information, and secondary information having a content relevant to the primary information that is published (i.e. made public) on a Web site, with the same identification code as that attached to the primary information; the secondary information published on the Web site being automatically acquired through auto-piloting, using the identification code transmitted together with the primary information as a clue is disclosed.

Owner:TOKYO KIKAI SEISAKUCHI LTD

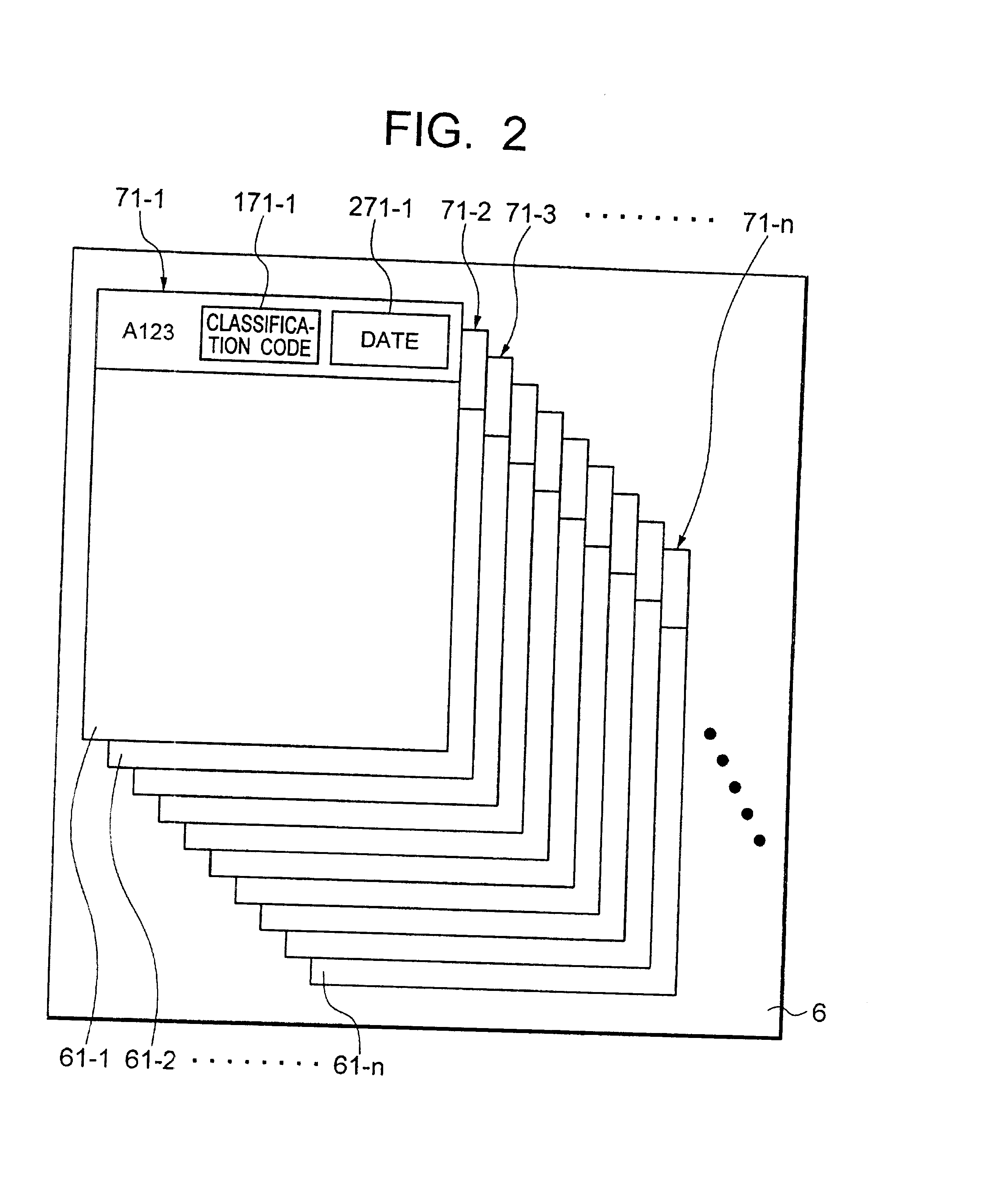

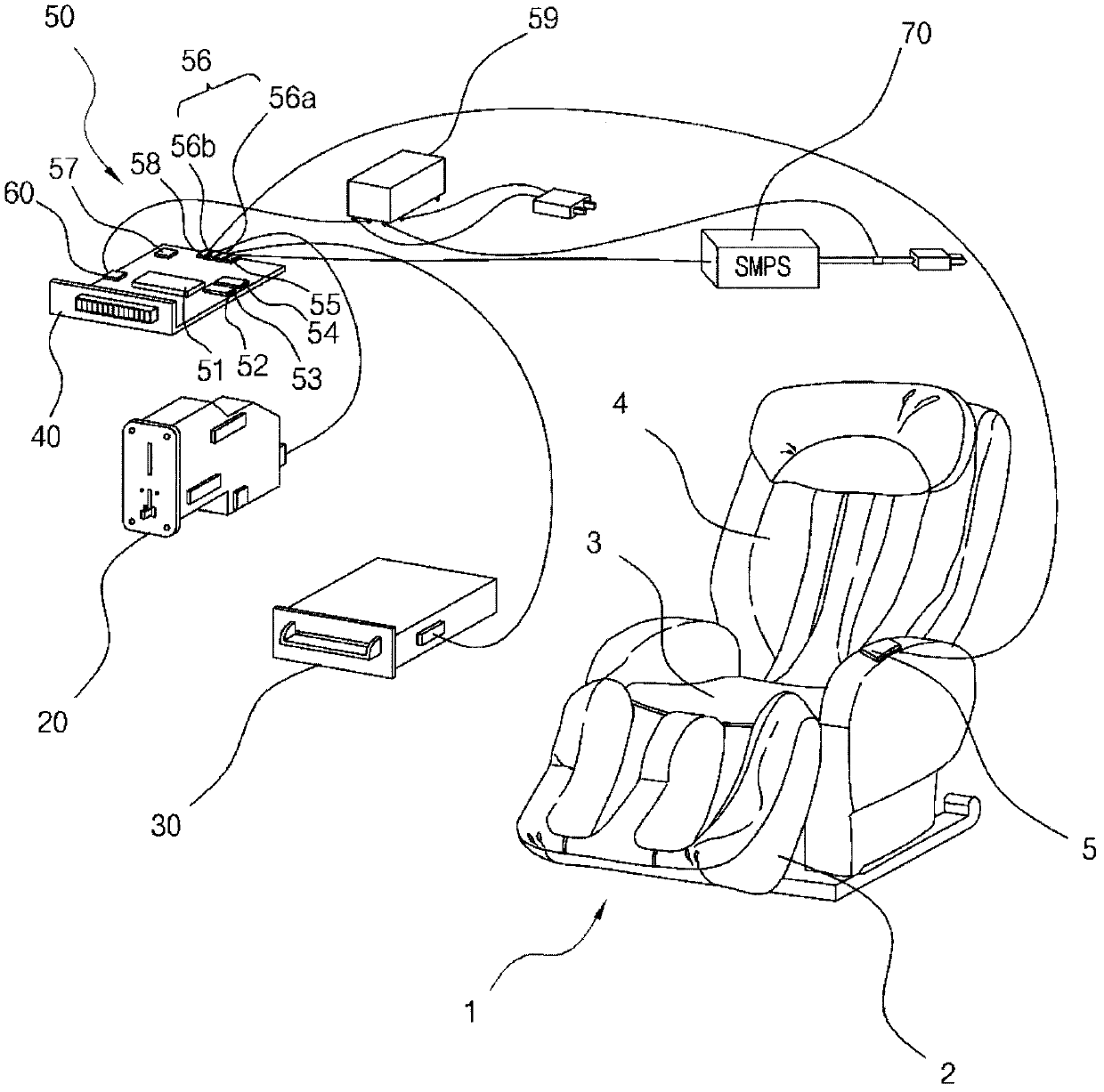

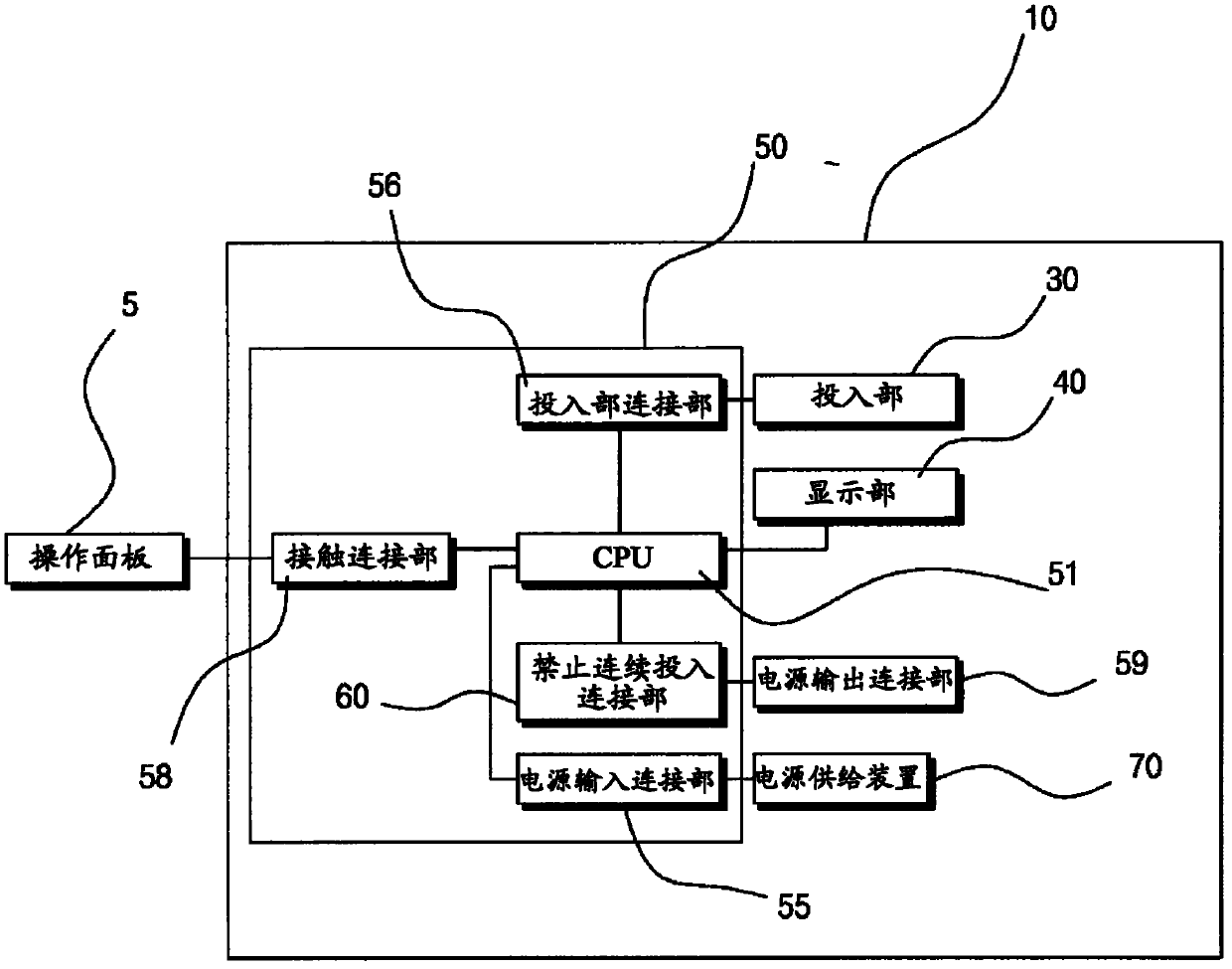

Device and method for controlling massage chair with reclining function

InactiveCN103379888AAvoid inconvenienceEliminate dissatisfactionApparatus for meter-controlled dispensingReclining chairsEngineeringMassage

The present invention relates to a device and a method for controlling a massage chair. According to one embodiment of the present invention, provided are a device and a method for controlling a massage chair with a reclining function, comprising: a case having a space portion inside; an insertion portion through which a coin or paper money is inserted, provided at one side of the space portion of the case; a display portion for displaying the sum of the inserted coin or paper money and time, provided at one side of the insertion portion; a control portion for transmitting an operation signal to an operation panel provided at one side of a massage chair to control the operation of the massage chair, provided at one side of the display portion; and a power supply device for supplying power to the control portion, provided at one side of the control portion.

Owner:INNO I

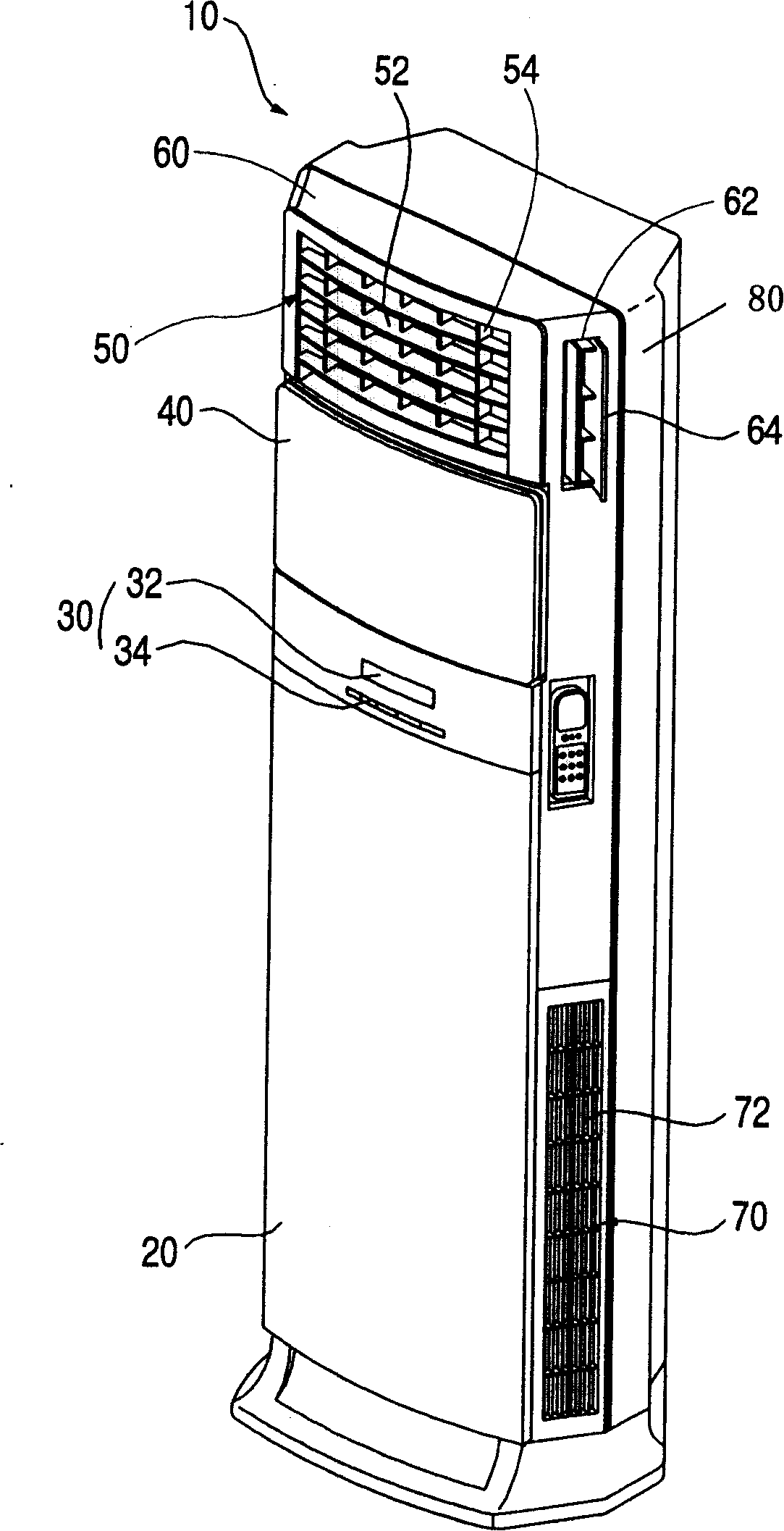

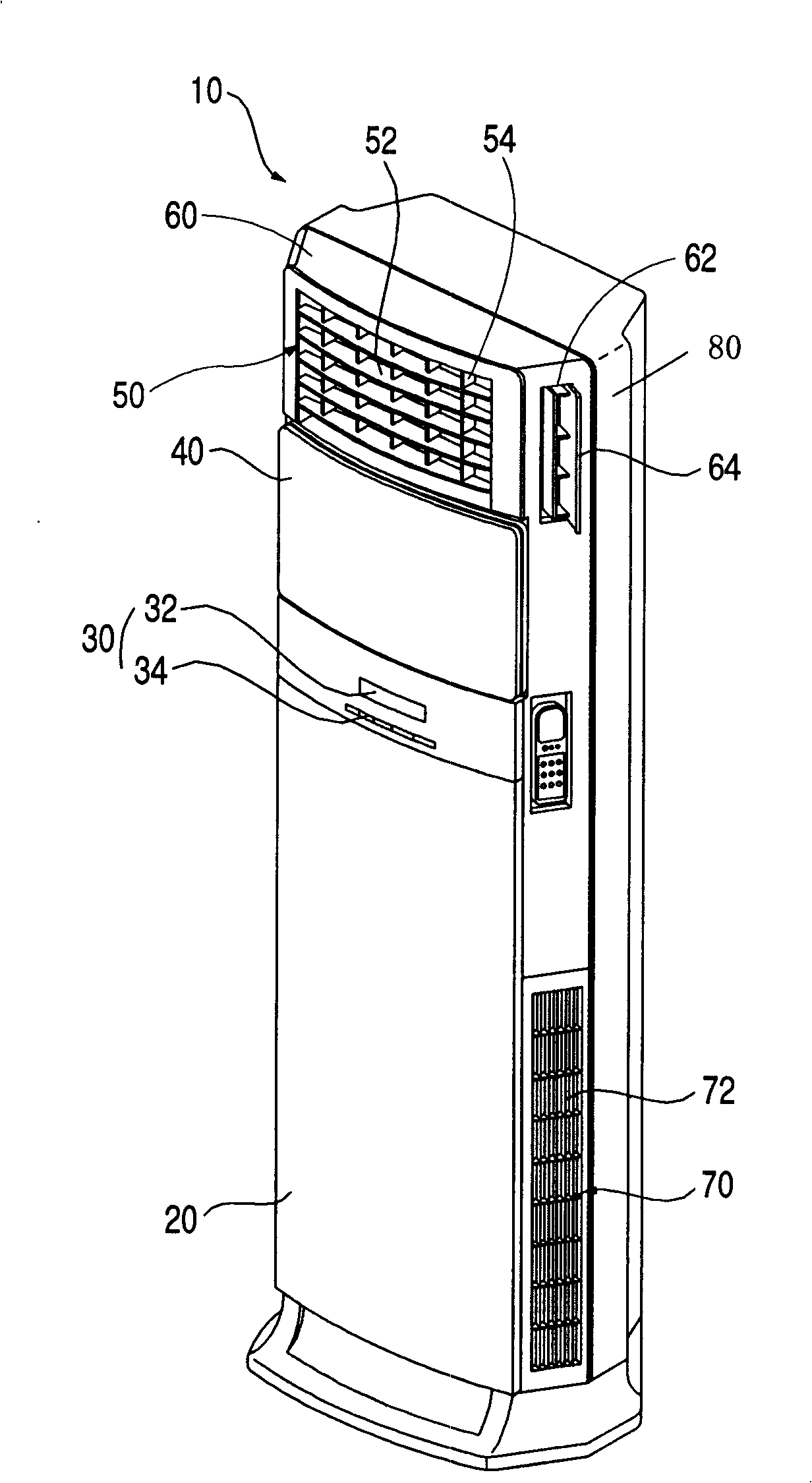

Indoor machine of air conditioner

InactiveCN101173784AFix damageSolve the problem that the temperature rises to tens of degreesLighting and heating apparatusHeating and ventilation casings/coversDisplay deviceEngineering

The invention relates to an indoor unit of an air conditioner, in particular to an indoor unit of air conditioner which is provided with a display cover with a plurality of through holes, which comprises a body, a front faceplate, a display cover and a display assembly. The body forms the indoor space and accommodates a plurality of air conditioner components. The front faceplate forms the front appearance of the body. The display cover is arranged behind the front faceplate and accommodates a plurality of electronic components. The display assembly, arranged in the display cover, displays and simultaneously controls the working state of the body. The display cover is provided with a plurality of through holes. Thus, the invention has an advantage that the heat produced by the display part fails to damage the electronic components which avoid misoperations to the maximum extent.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

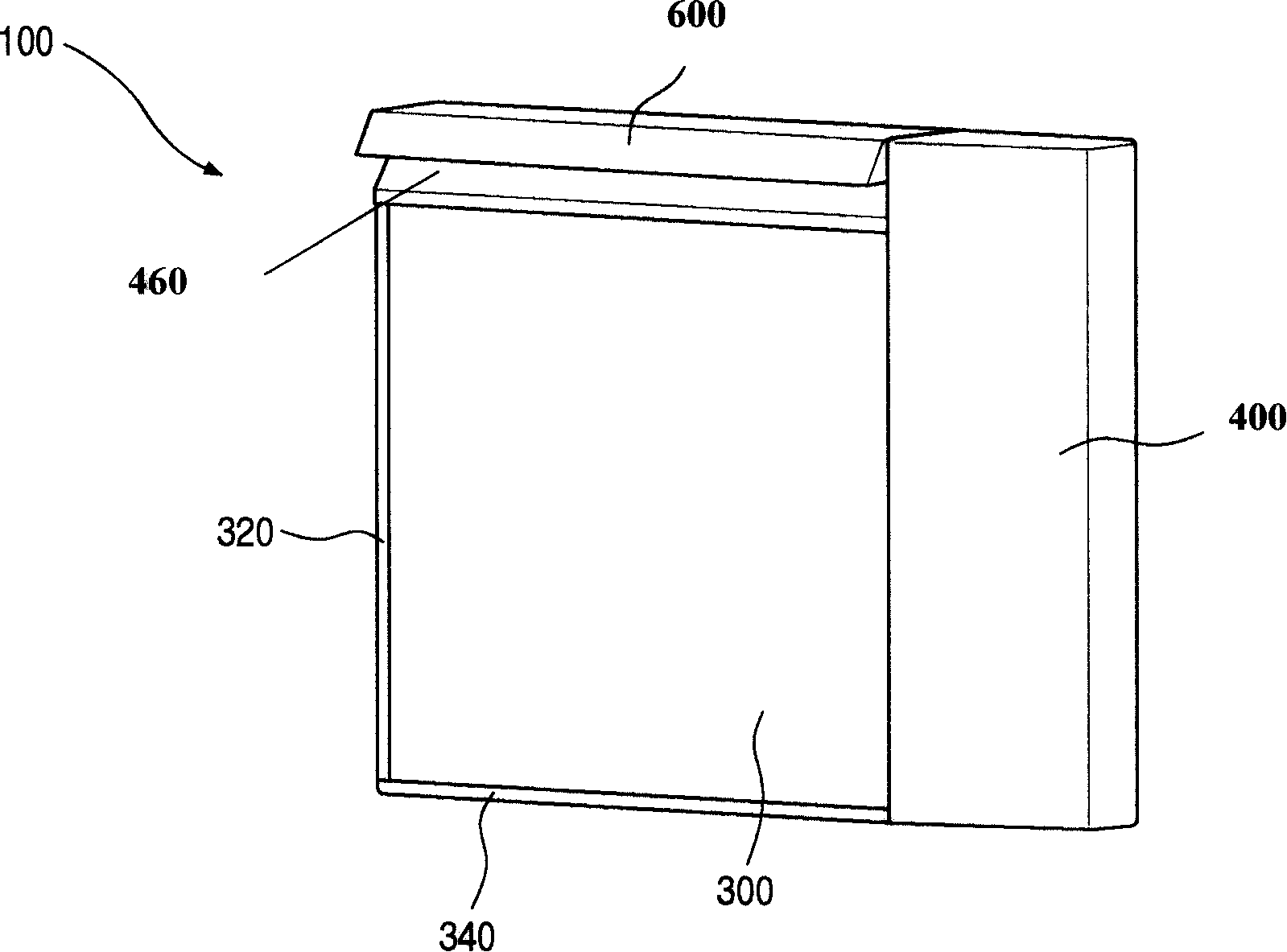

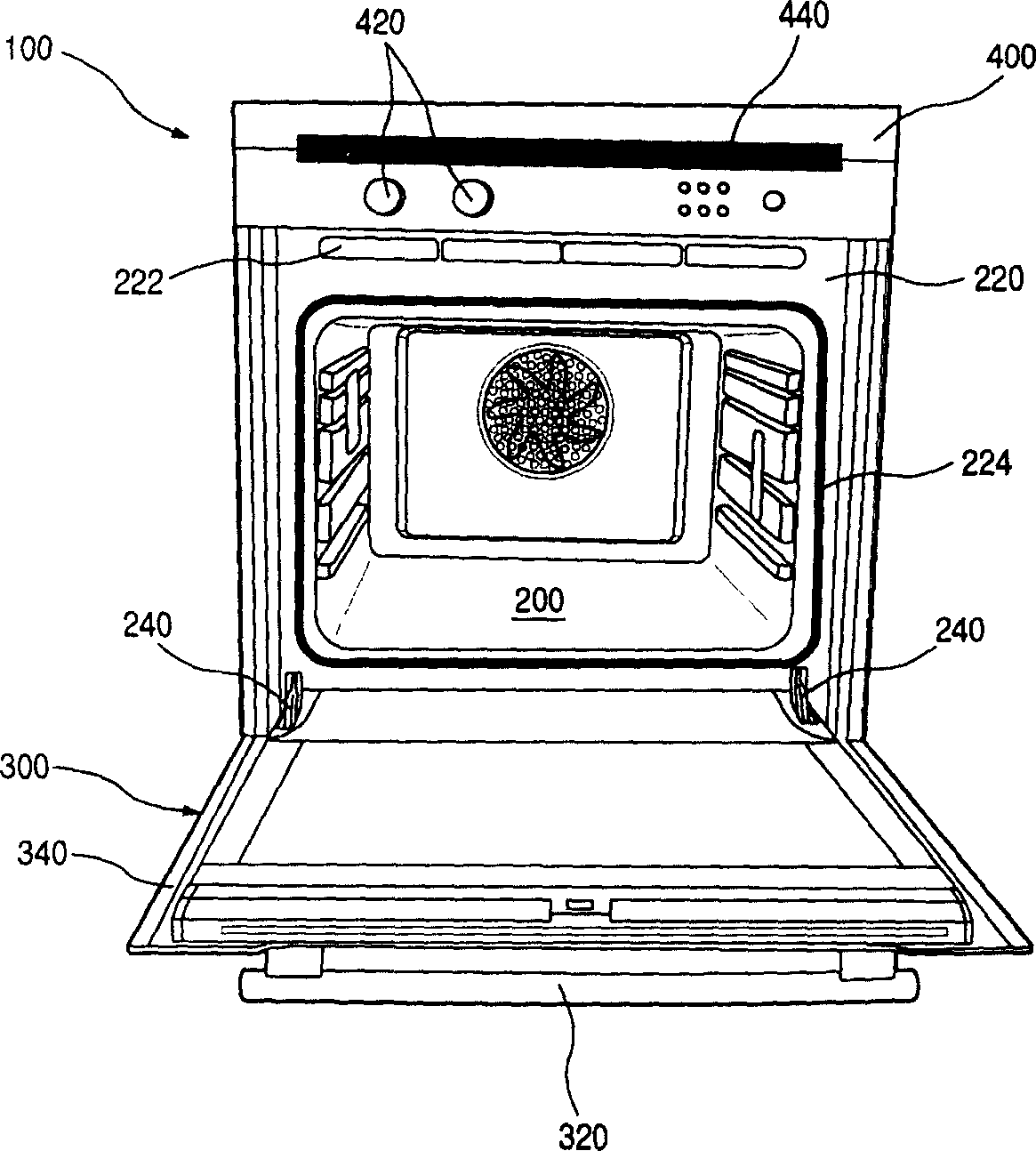

Full-glass oven door

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Pickles refrigerator

InactiveCN1862165AAvoid deformationEliminate deformationLighting and heating apparatusDomestic refrigeratorsRefrigerantRefrigerated temperature

The present invention discloses a pickled vegetables refrigerator. It includes the following several portions: external box formed into appearance of refrigerator; internal box placed in the interior of external box for storing various foods; refrigerant tube which is coiled on the external side surface of internal box and whose interior can allow the refrigerant to flow and make heat exchange; cooling unit formed from cooling sensor for detecting internal box coaling temperature; and heating unit which is coiled and set on lower side of cooling unit, in the heating unit interior are set a heater capable of releasing a certain heat quantity to raise internal box temperature and a heating sensor for detecting internal box temperature.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Content delivery apparatus, user terminal device, relief management method and computer program

InactiveUS20080052239A1DissatisfactionSecure beliefAnalogue secracy/subscription systemsPayment architectureManagement unitTerminal equipment

A content delivery apparatus, when a content delivery request is outputted from a user terminal device, encrypts the requested content with an encryption key, adds a view period to it to deliver it to a request source and delivers a viewing key in response to a view request from the user terminal device within the view period. A user relief management unit monitors failure information notifying, grasps a delivery disabled period from the failure information, specifies a delivery destination user for a content of which the view period is overlapped with the delivery disabled period and issues a relief right with a relief period specified thereto to the specified user. A contract period processing unit manages the relief right and permits viewing within the relief period set by the relief right when a view right based on the relief right is output from the user terminal device.

Owner:KK TOSHIBA

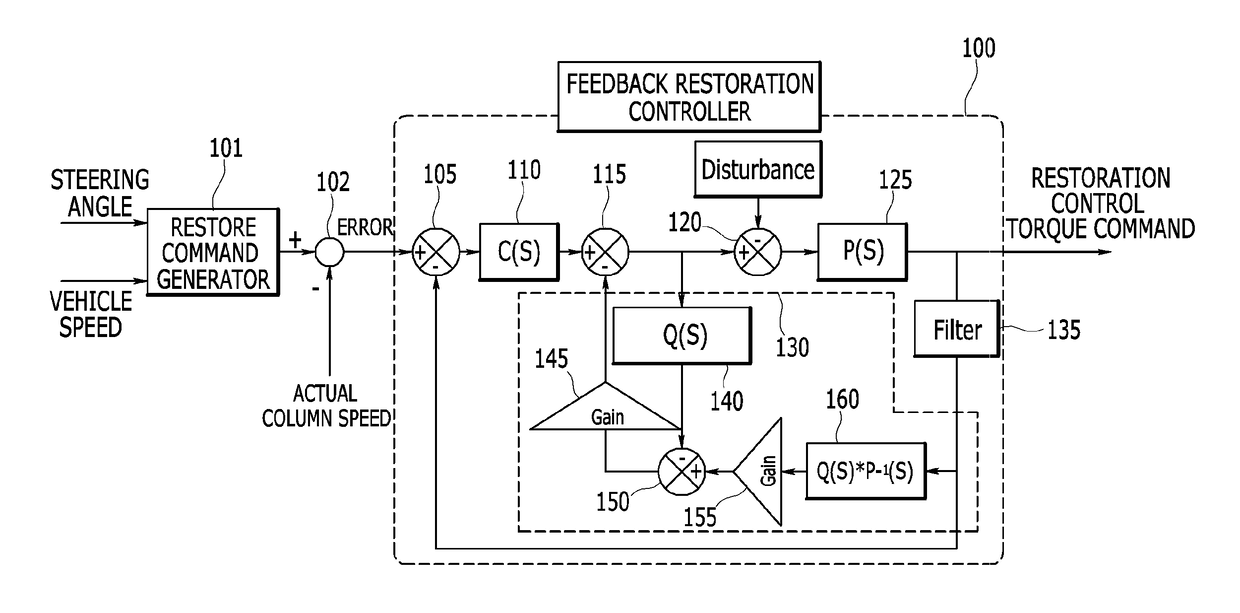

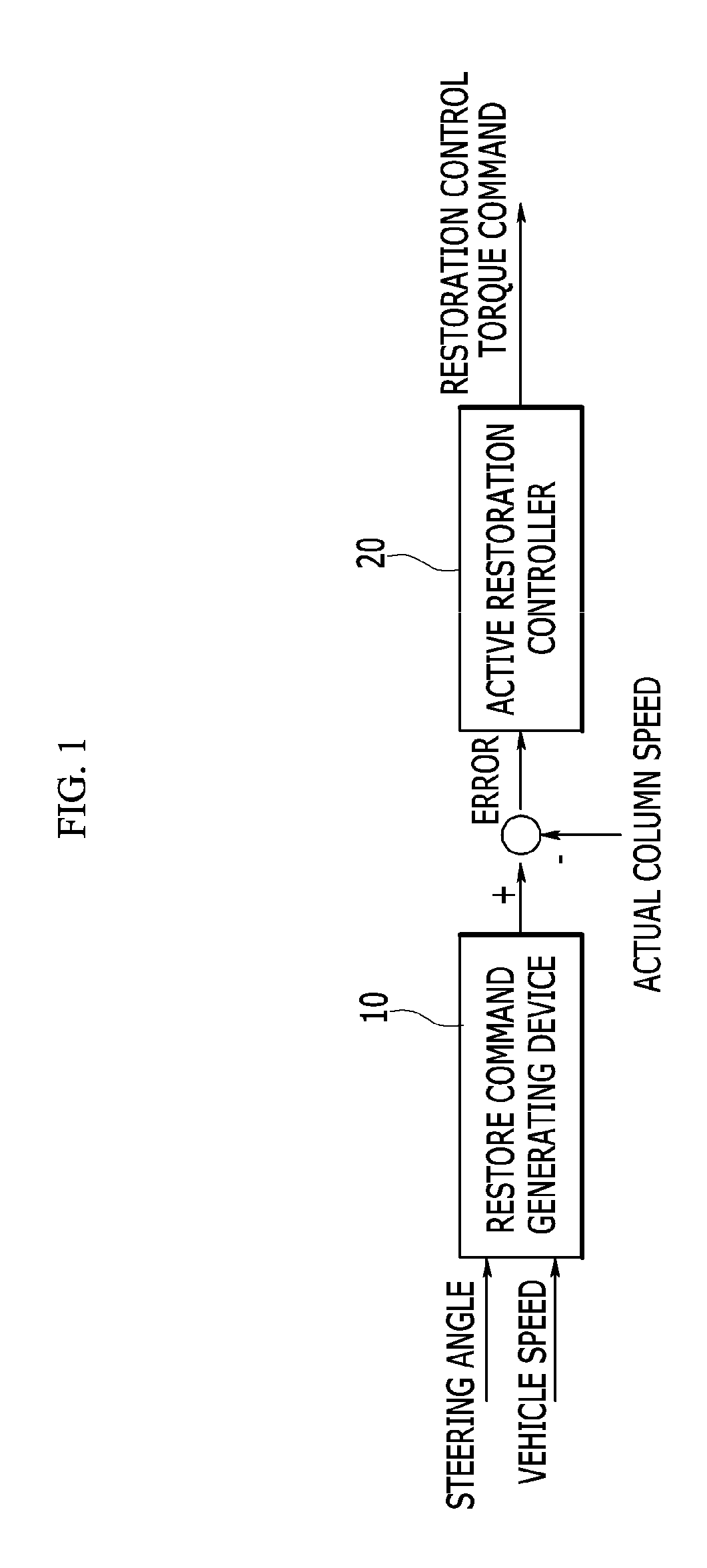

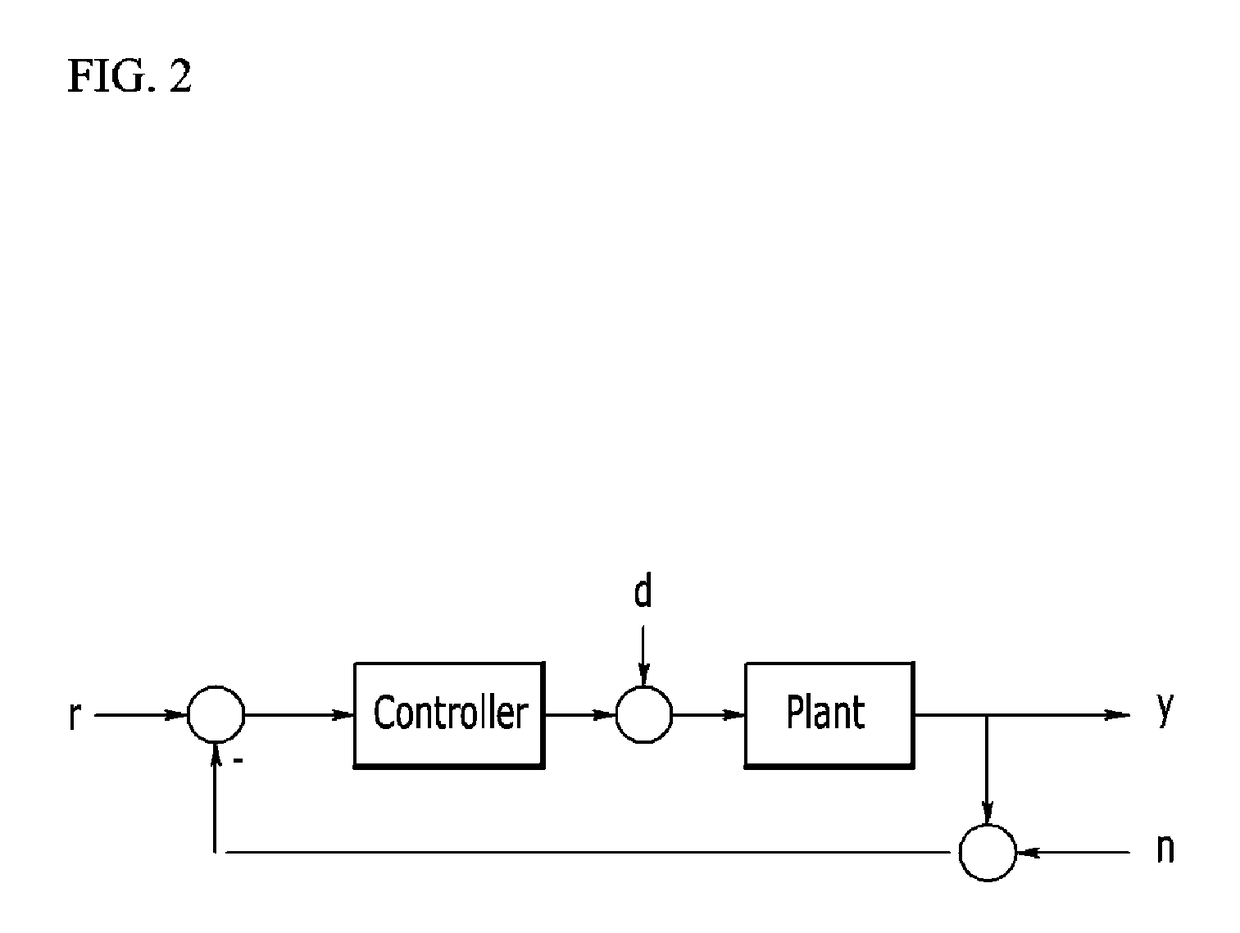

Device for controlling restoration of MDPS system

ActiveUS9981683B2Improve recovery effectEliminate dissatisfactionSteering linkagesAutomatic steering controlSteering columnMotor drive

A device for controlling restoration of a motor driven power steering (MDPS) system may include a controller configured to control an MDPS system model to output a target steering column speed command corresponding to a restoration control torque command based on a received error between a target steering column speed and an actual steering column speed, and a disturbance observer configured to compensate for a disturbance included in an output of the MDPS system model to provide the disturbance to an output of the controller, in which the output of the MDPS system model may be fed back to an input of the controller.

Owner:HYUNDAI MOTOR CO LTD

Charging support method, management device, and support system for performing wireless charging among plurality of devices

ActiveUS9496747B2Eliminate dissatisfactionStable chargingNear-field transmissionCircuit monitoring/indicationSupporting systemElectrical battery

A system includes a plurality of electronic apparatuses which have a function of feeding power of a battery to other electronic apparatuses and a function of receiving power from other electronic apparatuses and charging the battery, a management server, and a database. The management server records, in the database, positional information of power feedable electronic apparatuses which permit a power feed to other electronic apparatuses, acquires positional information of a power feed-desiring electronic apparatus which desires a power feed from other electronic apparatuses, specifies a power feedable electronic apparatus in the periphery of the power feed-desiring electronic apparatus using the acquired positional information and the positional information of the power feedable electronic apparatuses in the database, and transmits the positional information of the specified electronic apparatus to the power feed-desiring electronic apparatus.

Owner:FUJIFILM CORP

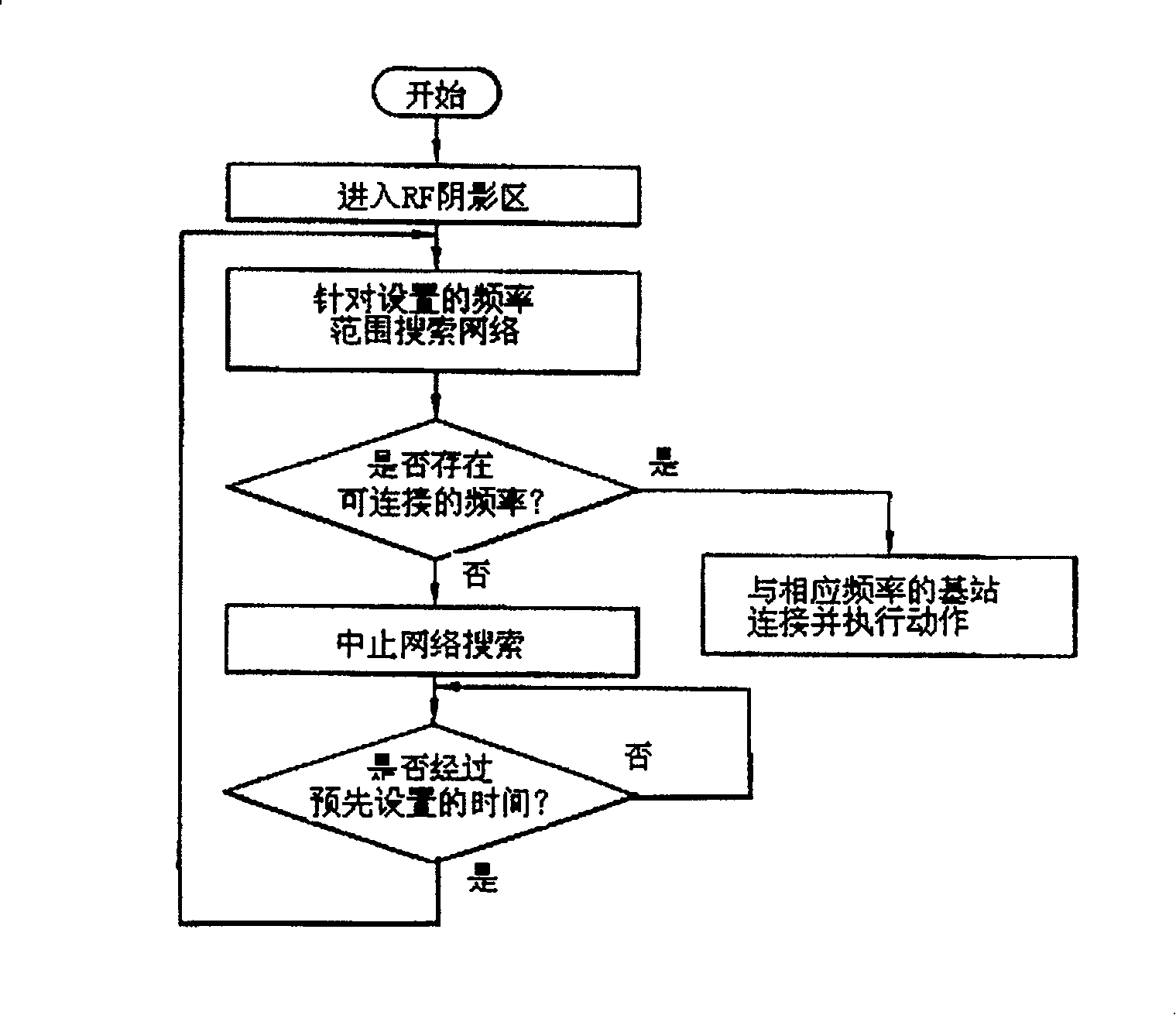

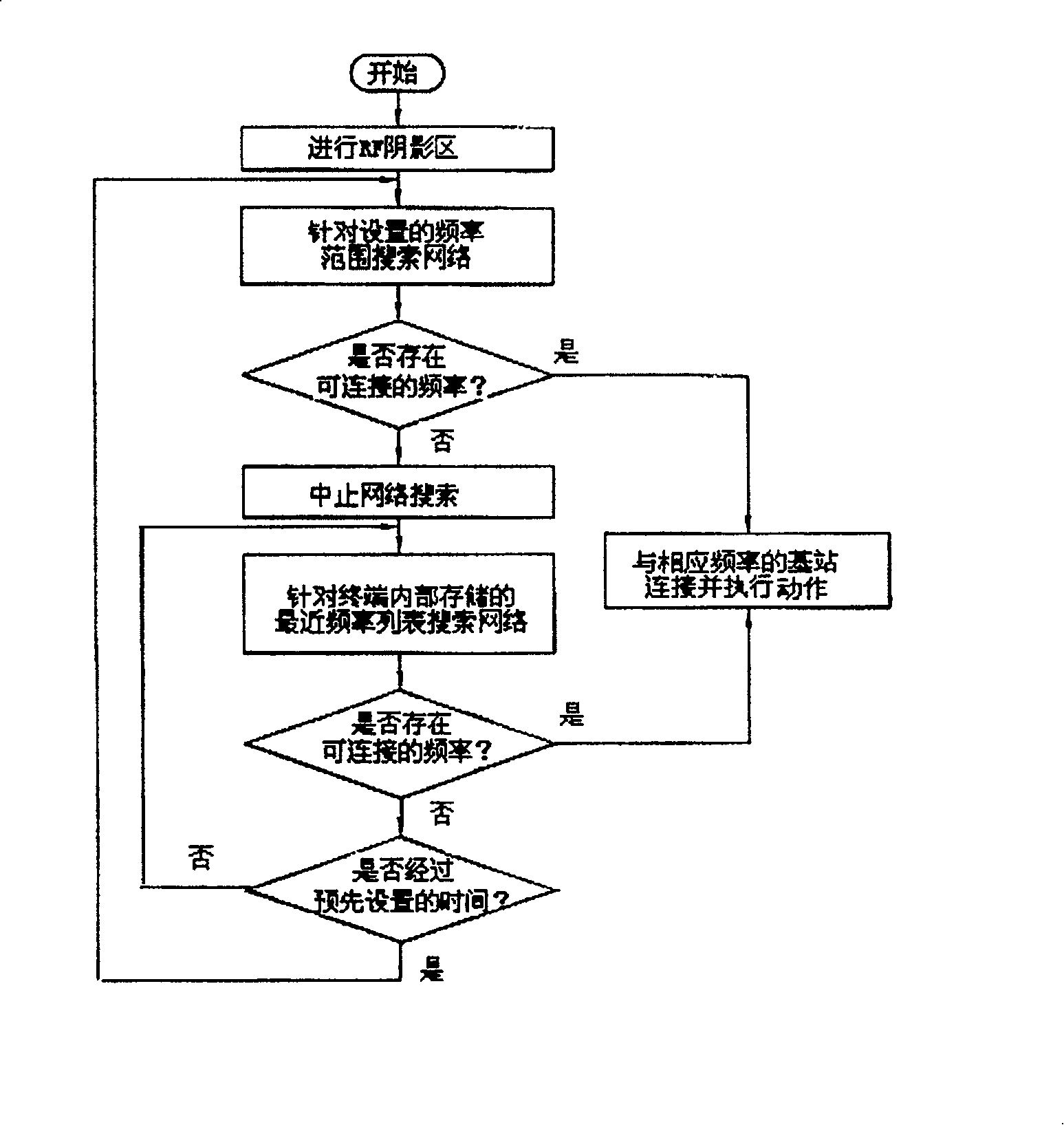

Network searching method for GSM terminal

InactiveCN100401830CEliminate dissatisfactionAssess restrictionConnection managementMobile Telephone ServiceGSM

A network searching process capable of rapidly searching network GSM (global digital mobile telephone system) terminal within RF (wireless frequency) shadow area comprises the following steps: step 1 that if a wireless frequency (RF) shadow area is entered, the network is search aiming at the frequency range set in advance; step 2 that if the mentioned above searching results show that a network with a frequency connected with the terminal does not exist, the network searching is stopped, the other network searching is executed aiming at the recent frequency listing stored in the terminal with the period set in advance; step 3 that if the results of the network searching aiming at the frequency listing mentioned above show that a network with a frequency connected with the terminal does not exist, a network searching aiming at the frequency range set in advance is executed again after the preset time set in advance. In accordance with the present invention, defects existing in known technology are conquered, base stations capable of being connected can be searched rapidly in the RF shadow area and dissatisfaction of user can be eliminated.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

gas cooking equipment

InactiveCN106500135BEnsure job reliabilityImprove cooling effectDomestic stoves or rangesCooking fumes removalThermodynamicsCombustor

The present invention relates to a gas cooking device, which is characterized by comprising a casing; a top plate that covers an upper face of an opening of the casing; a plurality of burner units accommodated inside the casing, and includes a red hot plate heated by mixed gas; an operation unit located at the front end of the housing and operated by the user to operate the burner unit; a main fan located at a plurality of the burner units and all of the burner units between the operation unit, and sucks the air outside the housing to cool the inside of the housing; and an exhaust part, which is located at the rear end of the housing, for discharging the burned gas of the burner unit gas and cooling air inside the housing.

Owner:LG ELECTRONICS INC

A kind of forging forming process of subway vehicle bearing seat

ActiveCN108015216BEliminate folding defectsEliminate dissatisfactionRailway componentsMetal-working apparatusFriction forceMaterials science

The invention provides a forging molding process for a bearing seat of a metro vehicle and belongs to the field of forging. The forging molding process comprises the following steps of 1, blanking, wherein raw materials are selected according to product requirements; 2, blank production, wherein the raw materials are heated through first flames, so that oxide skin is removed, and a blank is produced on a one-ton hammer through a blank production mold; 3, pre-bending, wherein the blank is heated through second flames, pre-bending is conducted in a preparing-for-bending mold cavity of a two-station mold on a 1600-ton friction force machine, so that the oxide skin is removed; 4, molding, wherein finish forging for molding is conducted in a finish forging mold cavity of the a two-station mold;and 5, flash cutting, wherein flashes on a forged piece obtained after the finish forging for molding are cut off through a flash cutting machine. By means of the forging molding process, the problems that according to traditional technological methods, free forging is adopted for blank production, a five-ton mold forging hammer is adopted for mold forging molding, so that blank production is notconducted precisely, the folding phenomenon is caused in the mold forging process, and corners are in short shot after mold forging is completed are solved; the scrap rate of the forged piece is greatly lowered; and the product production quality cost is saved.

Owner:ZHUZHOU TIANLI FORGING IND

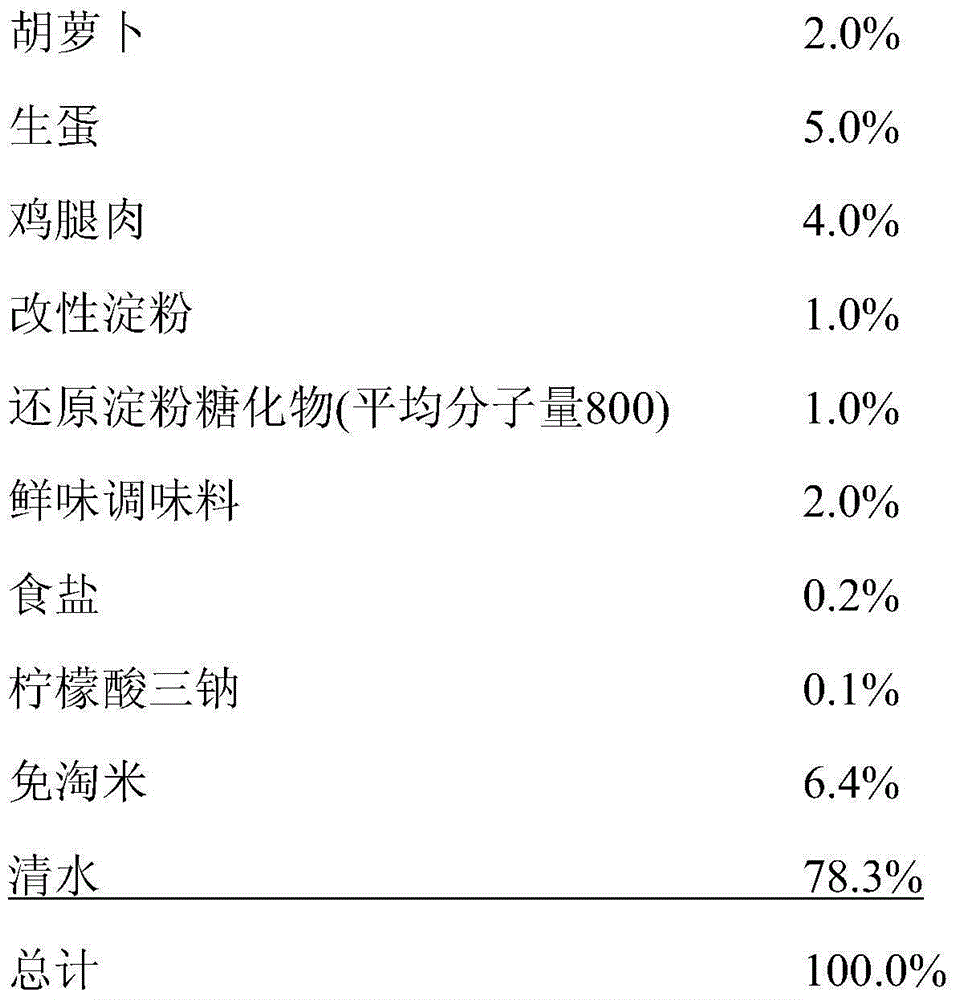

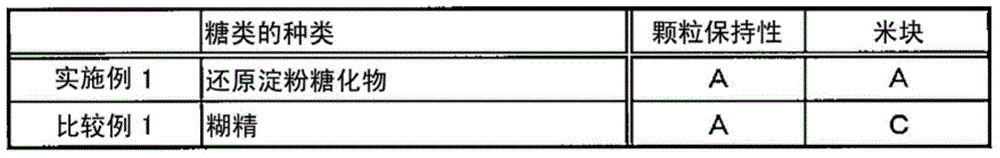

Food for colon endoscopy

Provided is a food product for colonoscopy, wherein by adding a reduced starch saccharification product and heated and solidified egg to Japanese rice soup in a sealed container that has been sterilized by heating under pressure, the residual rice grains impart a food that is filling and excellent as a colonoscopy food without being lumpy and interfering with the colonoscopy.

Owner:Q P CORP

A distribution network fault research and early warning system and its implementation method

ActiveCN108267670BPrecise positioningEasy to determineFault location by conductor typesEarly warning systemPower usage

The invention discloses a distribution network fault research and judgment early warning system and an implementation method thereof. The distribution network fault research and judgment early warningsystem includes a distribution network information acquisition unit, a distribution network fault research and judgment unit and a distribution network early warning unit, wherein the distribution network information acquisition unit includes a power off / on information module, a D5000 load jumping module and a power utilization acquisition module; the distribution network fault research and judgment unit includes a distribution network geographical wiring module and a distribution network fault repair module; the distribution network early warning unit includes a monitoring warning module andan early warning publishing module; and by means of coordination of the distribution network information acquisition unit, the distribution network fault research and judgment unit and the distribution network early warning unit, the system can greatly improve the efficiency of fault repairing and the service level, can perform visual displaying and accurate research and judgment through the distribution network fault research and judgment unit, can warn timely through the research and judgment comparison result, and at the same time can timely perform accurate positioning on the fault area through the distribution network wiring graph and the geographic information graph in the distribution network geographical wiring module, so as to be convenient for a repair person to determine the fault area and reduce the repair time.

Owner:STATE GRID CORP OF CHINA +1

Indoor machine of air conditioner

InactiveCN101173784BFix damageAvoid damageLighting and heating apparatusHeating and ventilation casings/coversInterior spaceDisplay device

The invention relates to an indoor unit of an air conditioner, in particular to an indoor unit of air conditioner which is provided with a display cover with a plurality of through holes, which comprises a body, a front faceplate, a display cover and a display assembly. The body forms the indoor space and accommodates a plurality of air conditioner components. The front faceplate forms the front appearance of the body. The display cover is arranged behind the front faceplate and accommodates a plurality of electronic components. The display assembly, arranged in the display cover, displays and simultaneously controls the working state of the body. The display cover is provided with a plurality of through holes. Thus, the invention has an advantage that the heat produced by the display part fails to damage the electronic components which avoid misoperations to the maximum extent.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Content delivery apparatus, user terminal device, relief management method and computer program

InactiveUS20080052240A1DissatisfactionSecure beliefAnalogue secracy/subscription systemsPayment architectureManagement unitTerminal equipment

A content delivery apparatus, when a content delivery request is outputted from a user terminal device, encrypts the requested content with an encryption key, adds a view period to it to deliver it to a request source and delivers a viewing key in response to a view request from the user terminal device within the view period. A user relief management unit monitors failure information notifying, grasps a delivery disabled period from the failure information, specifies a delivery destination user for a content of which the view period is overlapped with the delivery disabled period and issues a relief right with a relief period specified thereto to the specified user. A contract period processing unit manages the relief right and permits viewing within the relief period set by the relief right when a view right based on the relief right is output from the user terminal device.

Owner:KK TOSHIBA

Indoor machine of air conditioner

InactiveCN101173786BAdjustable lengthSuitable for air distributionLighting and heating apparatusAir conditioning systemsEngineeringAirflow

The invention relates to an indoor unit of air-conditioner, in particular to an indoor unit with selectively extended discharge blades. The indoor unit of air-conditioner comprises a housing with internal space, a front door, a front bracket, a plurality of discharge blades and a plurality of auxiliary blades, wherein, the housing forms the external appearance; the front door can be used to selectively open and close the front side of the housing; the front bracket is arranged at rear side of the front door and forms the front half part of the housing; the discharge blades are arranged at both sides of the front bracket and used to control discharge direction of the air adjusted inside the housing; the auxiliary blades are arranged on the discharge blades and can selectively do linear back-and-forth movement. The invention has the advantages that length of the discharge blades can be adjusted so that the optimal airflow distribution can be formed.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Pickles refrigerator

InactiveCN100498156CAvoid deformationEliminate deformationLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerant

The present invention discloses a pickled vegetables refrigerator. It includes the following several portions: external box formed into appearance of refrigerator; internal box placed in the interior of external box for storing various foods; refrigerant tube which is coiled on the external side surface of internal box and whose interior can allow the refrigerant to flow and make heat exchange; cooling unit formed from cooling sensor for detecting internal box coaling temperature; and heating unit which is coiled and set on lower side of cooling unit, in the heating unit interior are set a heater capable of releasing a certain heat quantity to raise internal box temperature and a heating sensor for detecting internal box temperature.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

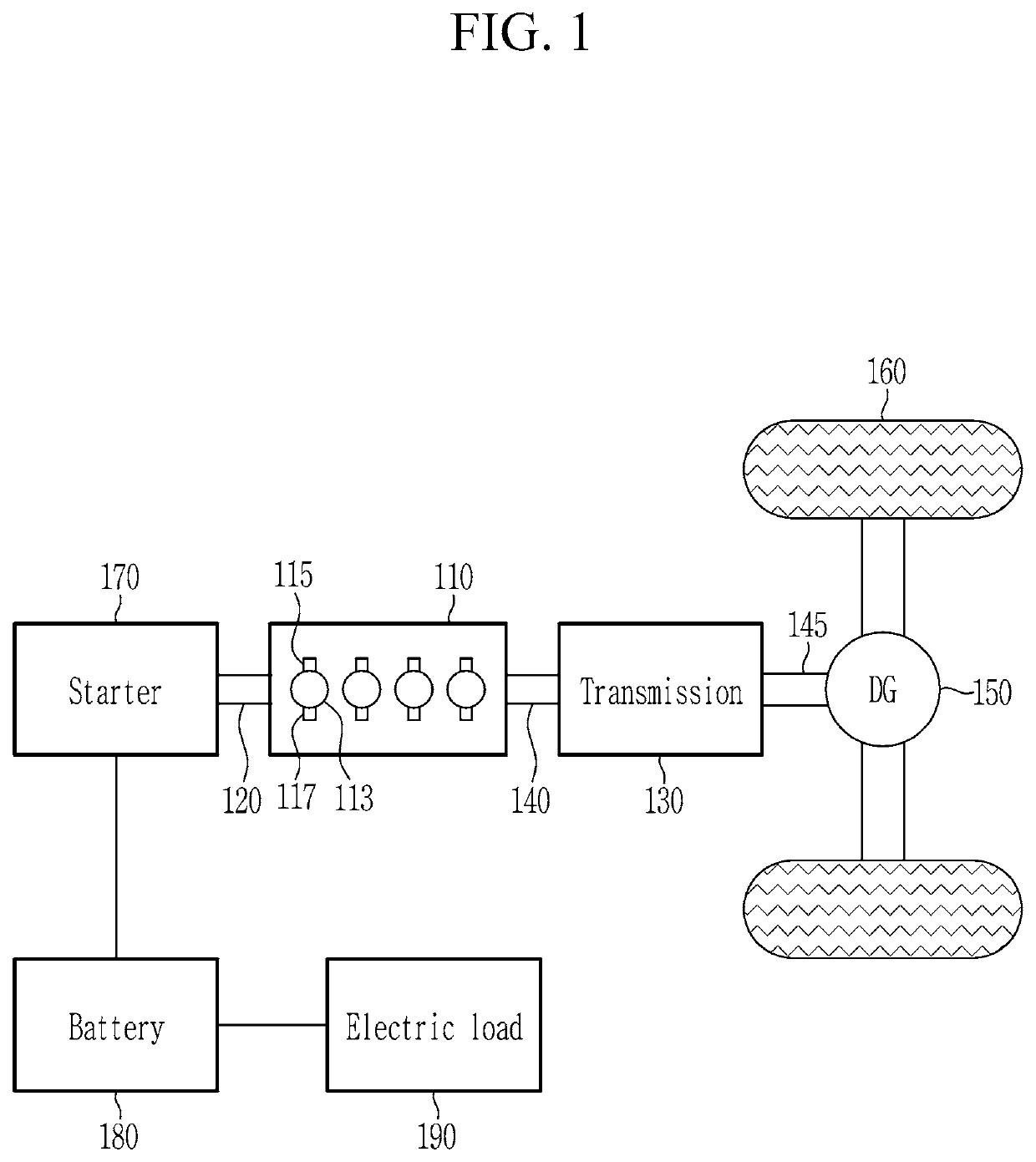

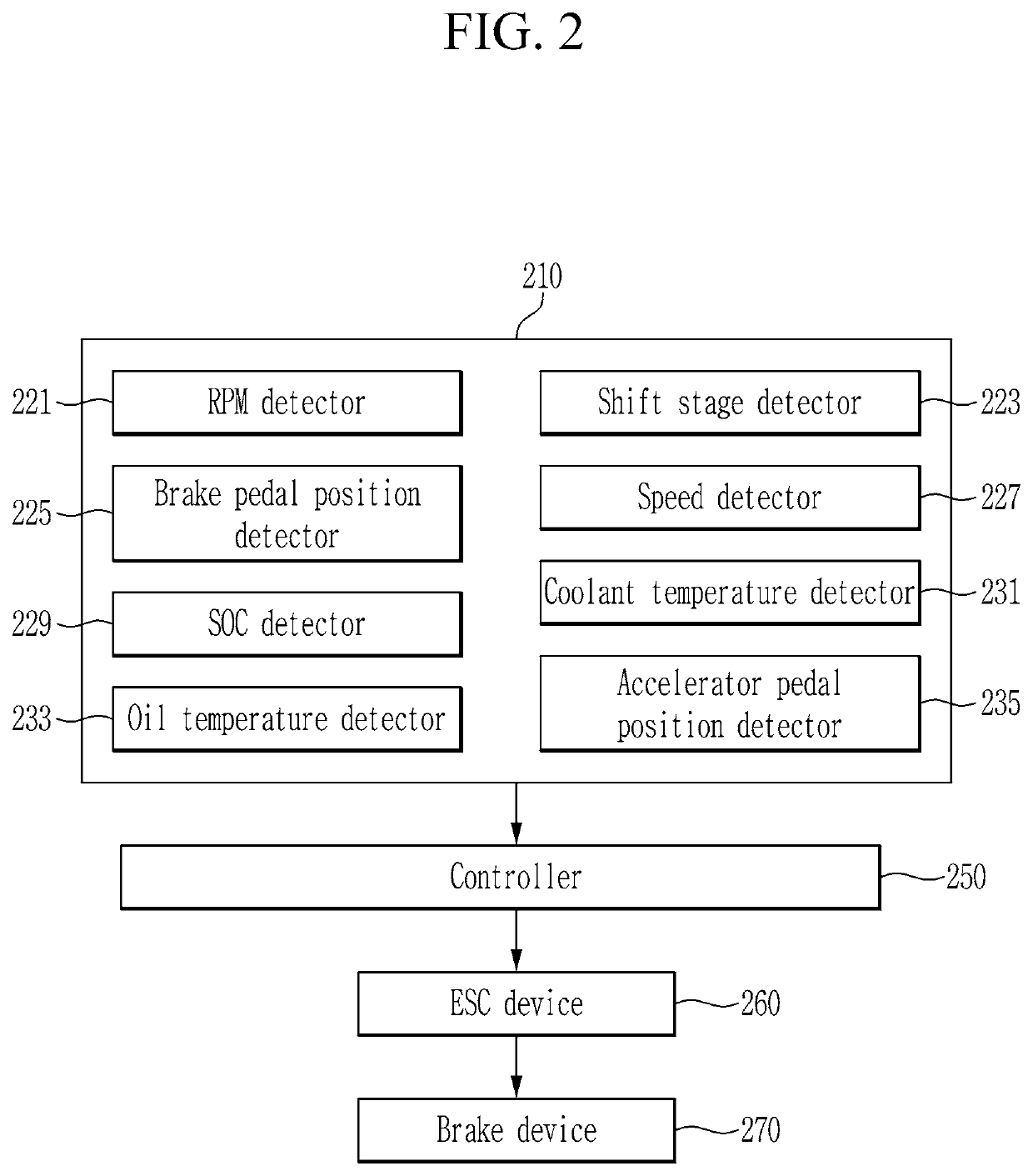

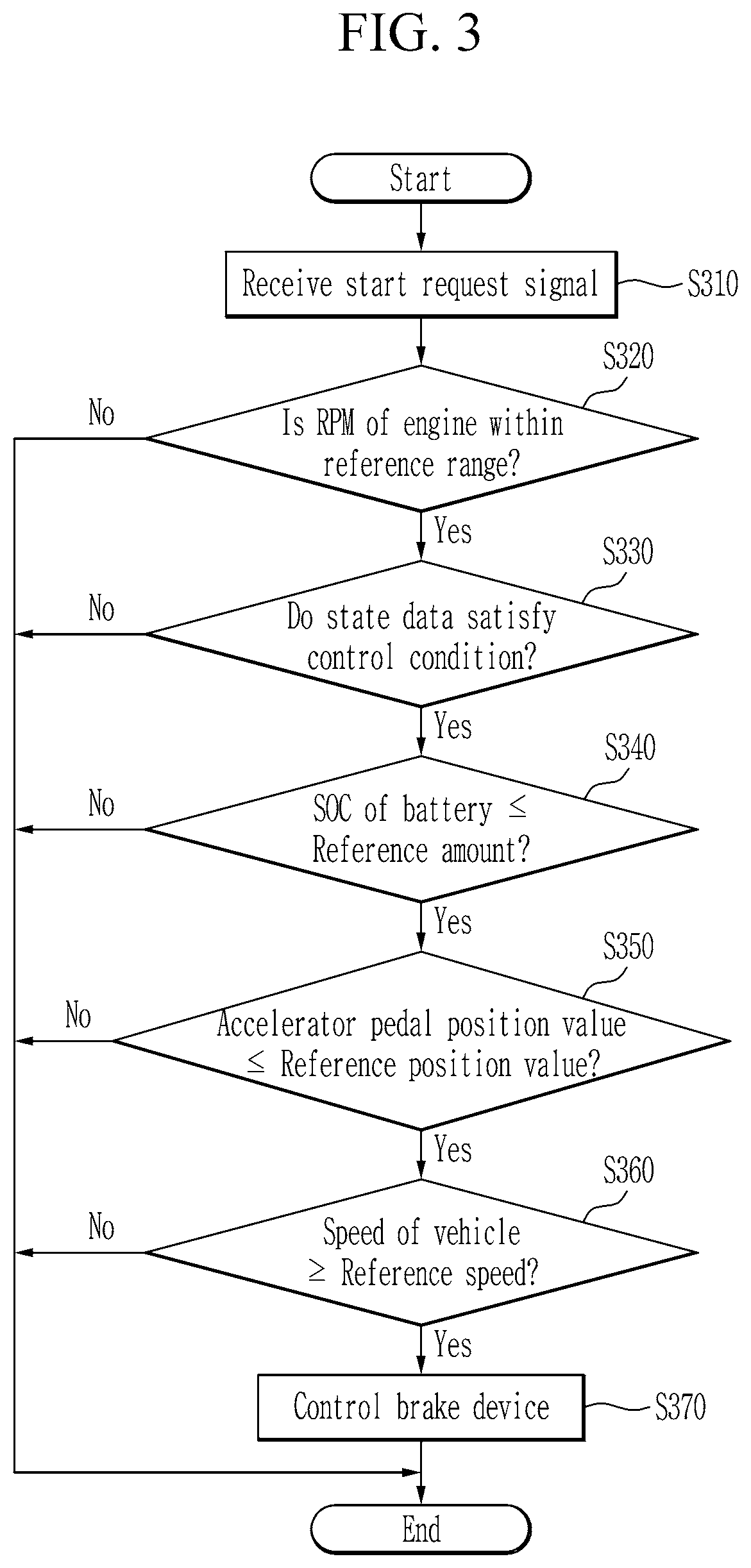

Method and device for controlling start of vehicle

ActiveUS11220990B2Eliminate dissatisfactionImprove drivabilityElectrical controlRegistering/indicating working of vehiclesControl engineeringControl theory

Owner:HYUNDAI MOTOR CO LTD +1

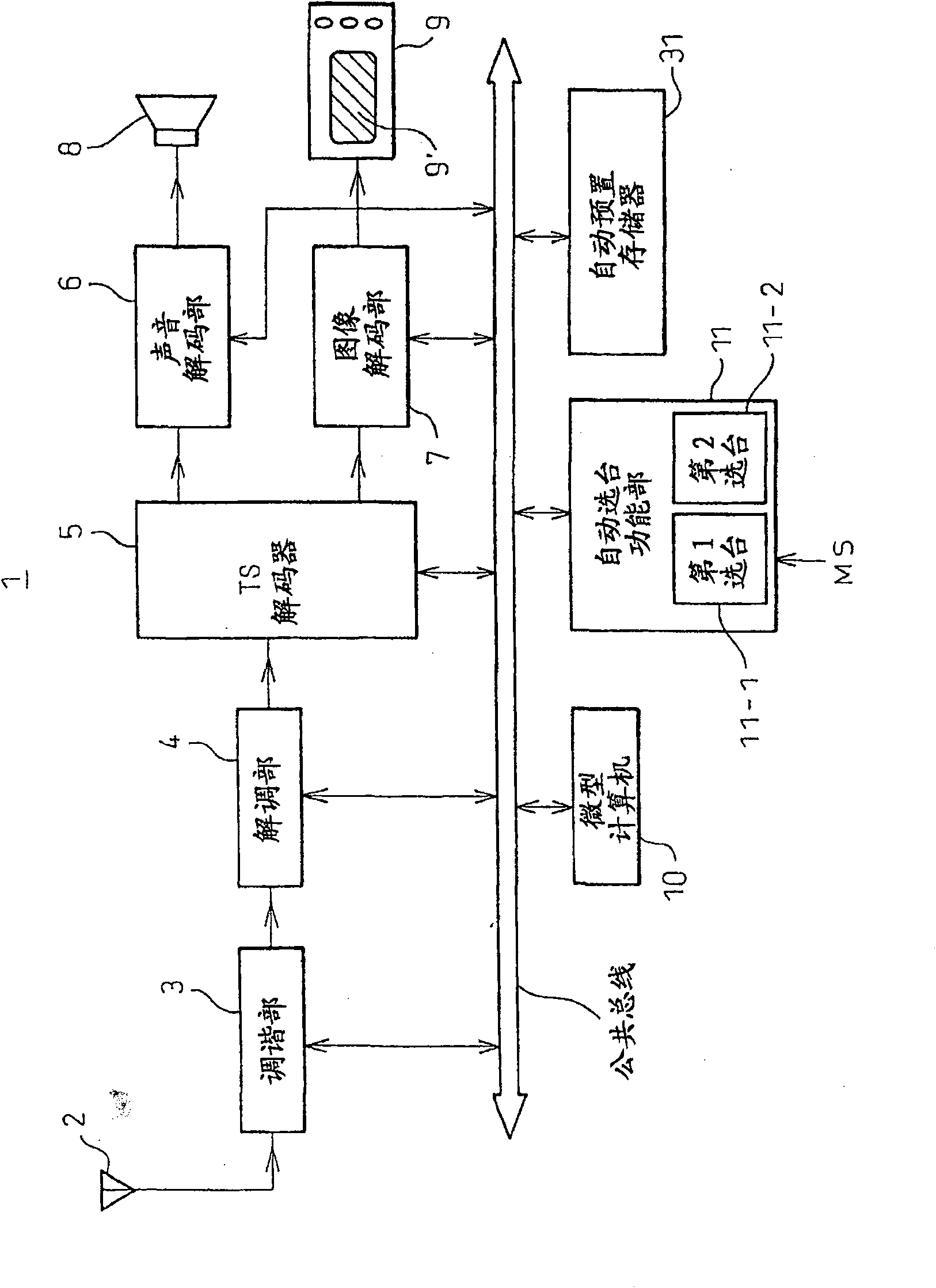

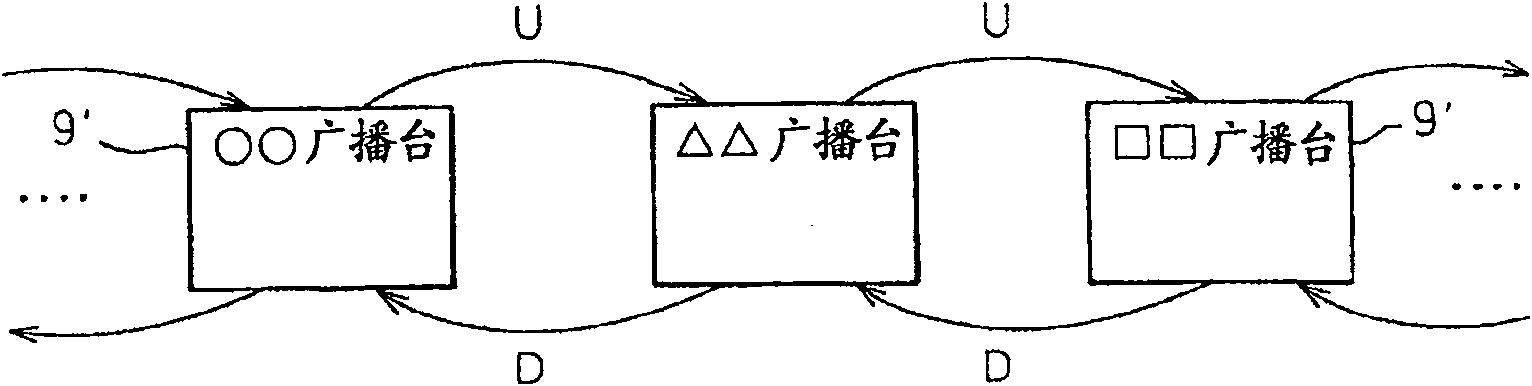

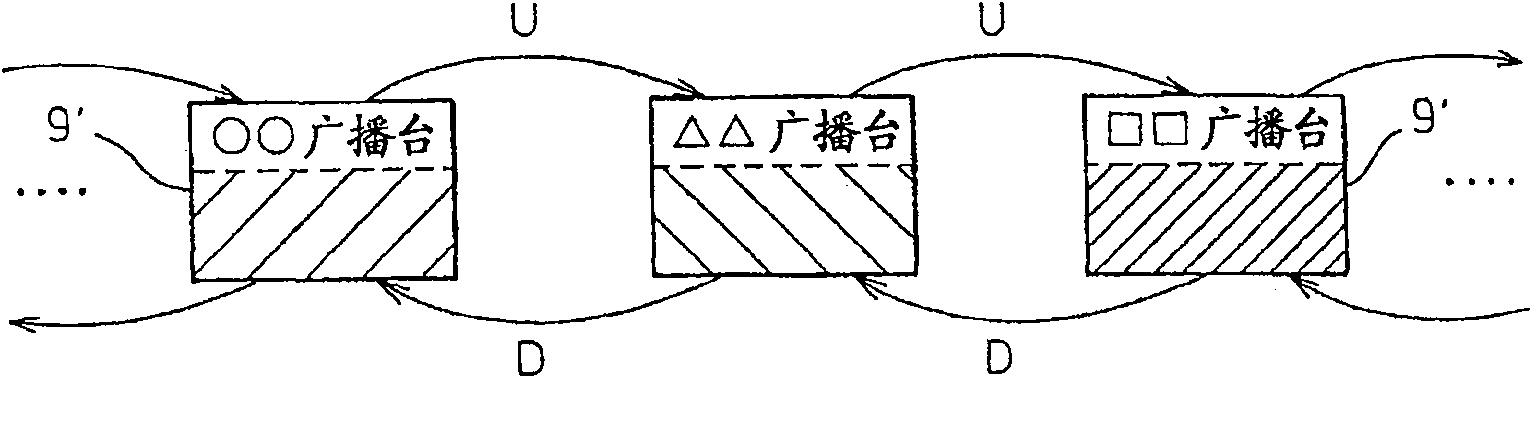

Broadcasting receiver

InactiveCN100555883CEliminate dissatisfactionTelevision system detailsColor television detailsBroadcast radiationDigital broadcasting

A digital broadcast receiving apparatus provided with a user friendly automatic channel selection function is provided. An automatic channel selection function unit 11 operating under a plurality of channel selection modes is provided. As this plurality of channel selection modes, a first channel selection mode (11-1) of searching only for broadcast stations and further a second channel selection mode (11-2) of additionally searching for service IDs provided by the broadcast station are included.

Owner:FUJITSU GENERAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com