Resonance preventing structure of washing machine

A washing machine, drum type washing machine technology, applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of increased vibration, increased noise, etc., to achieve the effects of preventing resonance, eliminating dissatisfaction with noise, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

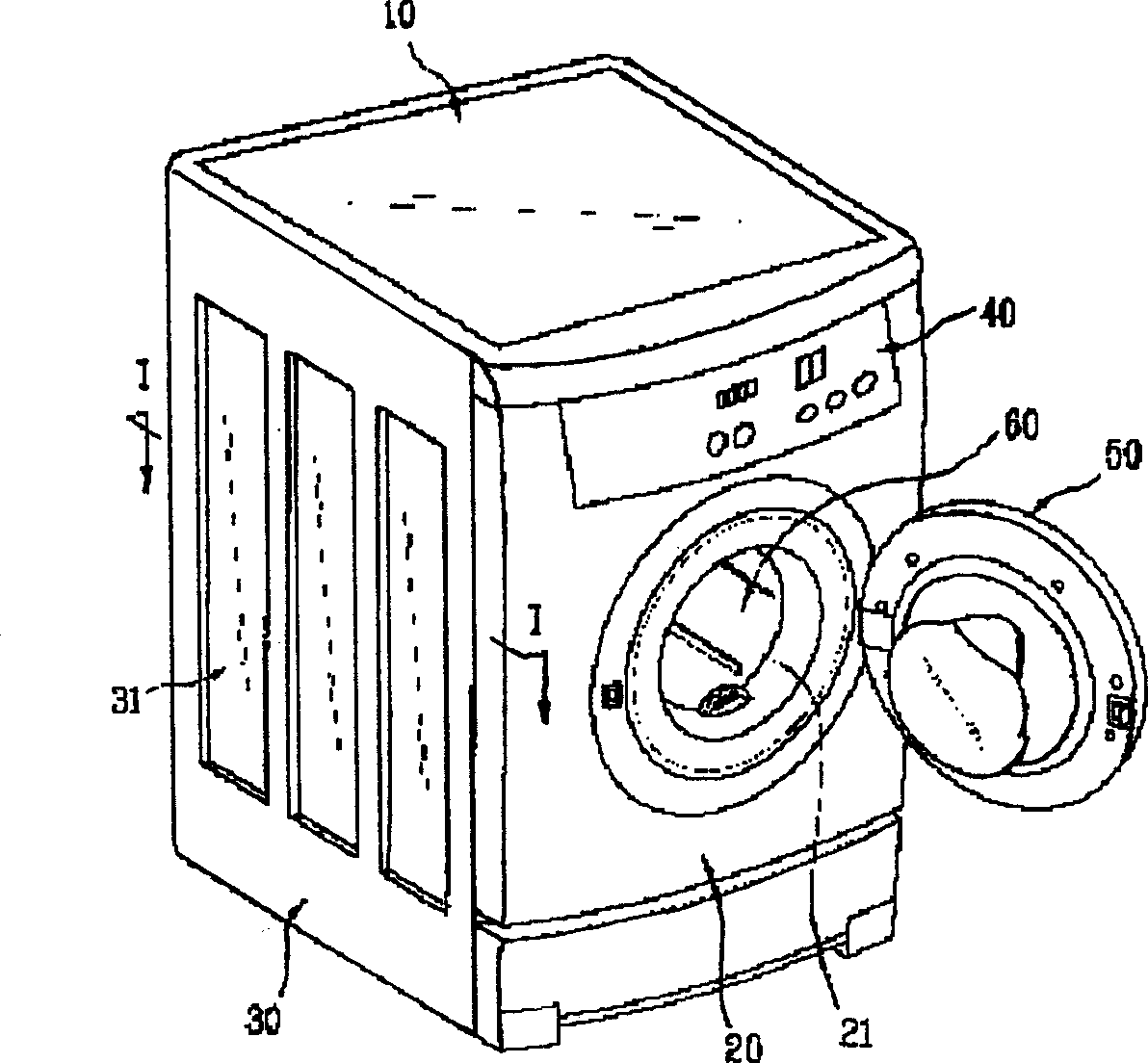

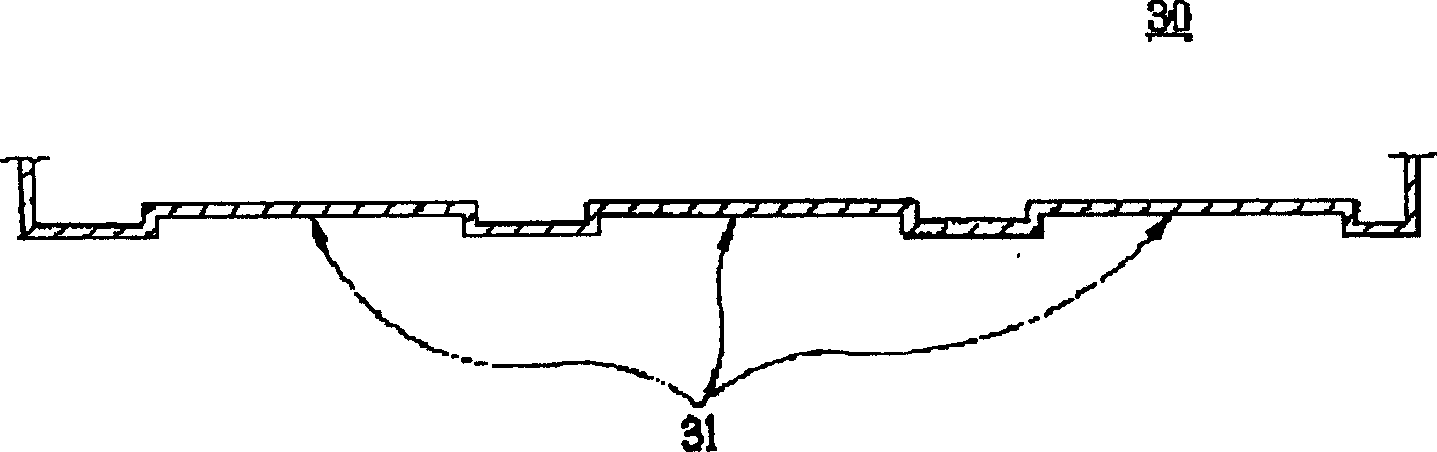

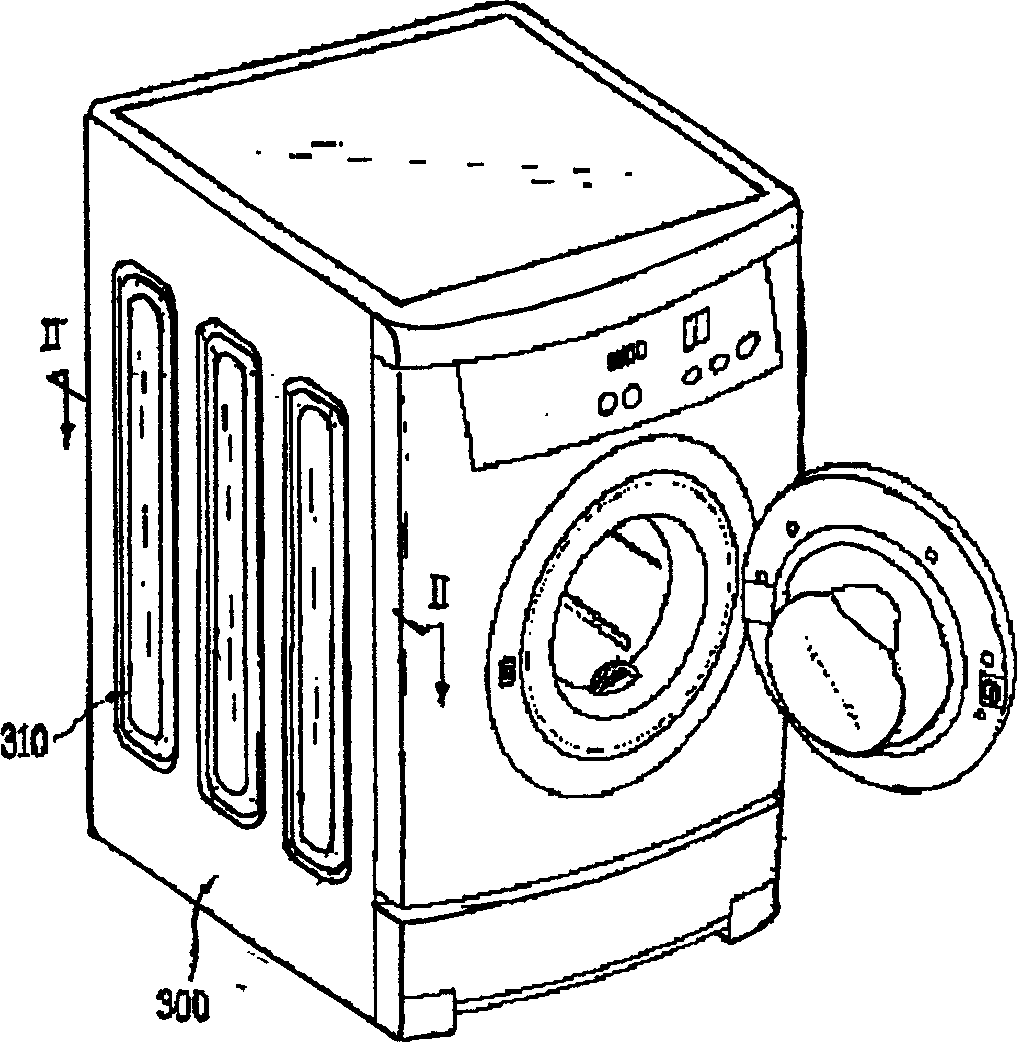

[0025] Below, combine Figure 3 to Figure 7 The resonance preventing structure of the washing machine of the present invention will be described in detail.

[0026] The anti-resonance structure of the washing machine of the present invention includes a top metal plate on the top of the washing machine, a front metal plate forming the front, metal plates forming the two sides, an operation panel for controlling various operations of the drum type washing machine, and selective opening and closing. The door inside the washing machine, wherein: at least one strip-shaped groove 310 is provided on the metal plate on the side of the washing machine. The strip-shaped groove 310 is recessed in a rectangular shape, and the recessed rectangular interior is further Convex in the direction opposite to the concave direction.

[0027] The recessed depth D of the elongated groove 310 is set to be greater than 2.5 mm.

[0028] The recessed depth D of the elongated groove 310 is set between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com