Compact self-ballasted fluorescent lamp and lighting apparatus

A technology of self-ballasting and fluorescent lamps, which is applied in the direction of lighting devices, components of lighting devices, cooling/heating devices of lighting devices, etc. It can solve the problems of reducing electronic components, increasing the occupied area of electronic components, and making it difficult to form the appearance of light bulbs, etc. , to achieve the effect of improving installation efficiency and ensuring width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

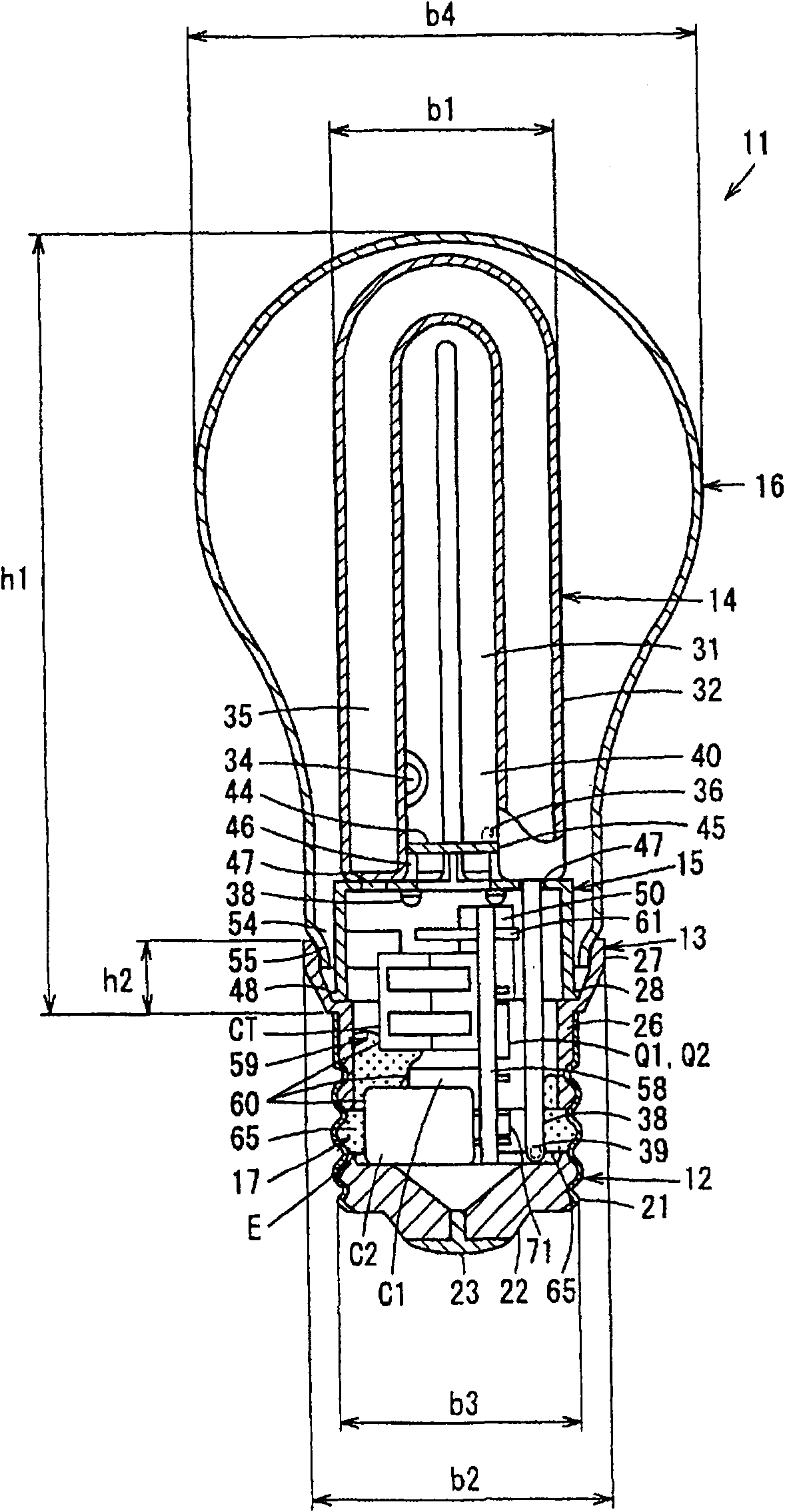

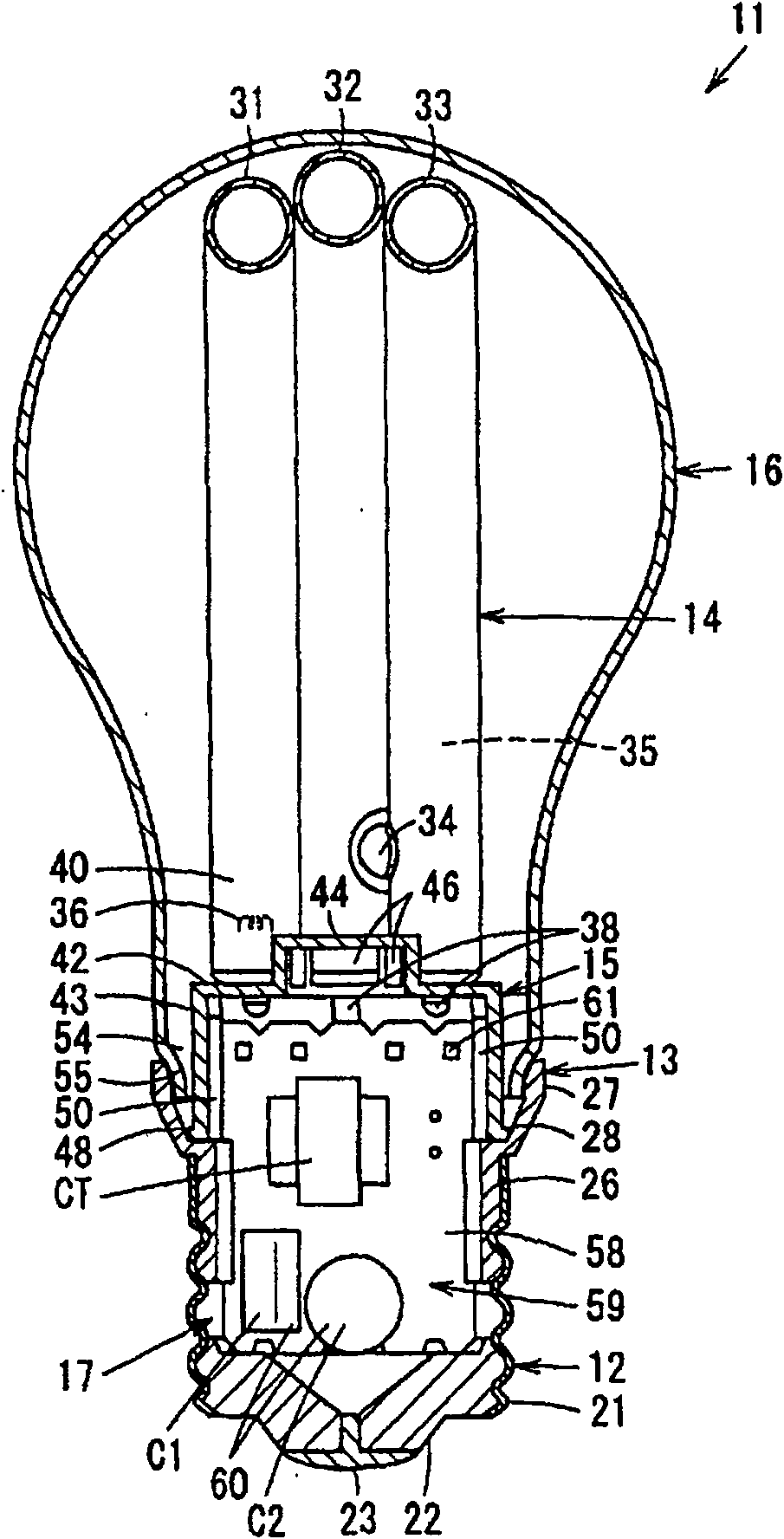

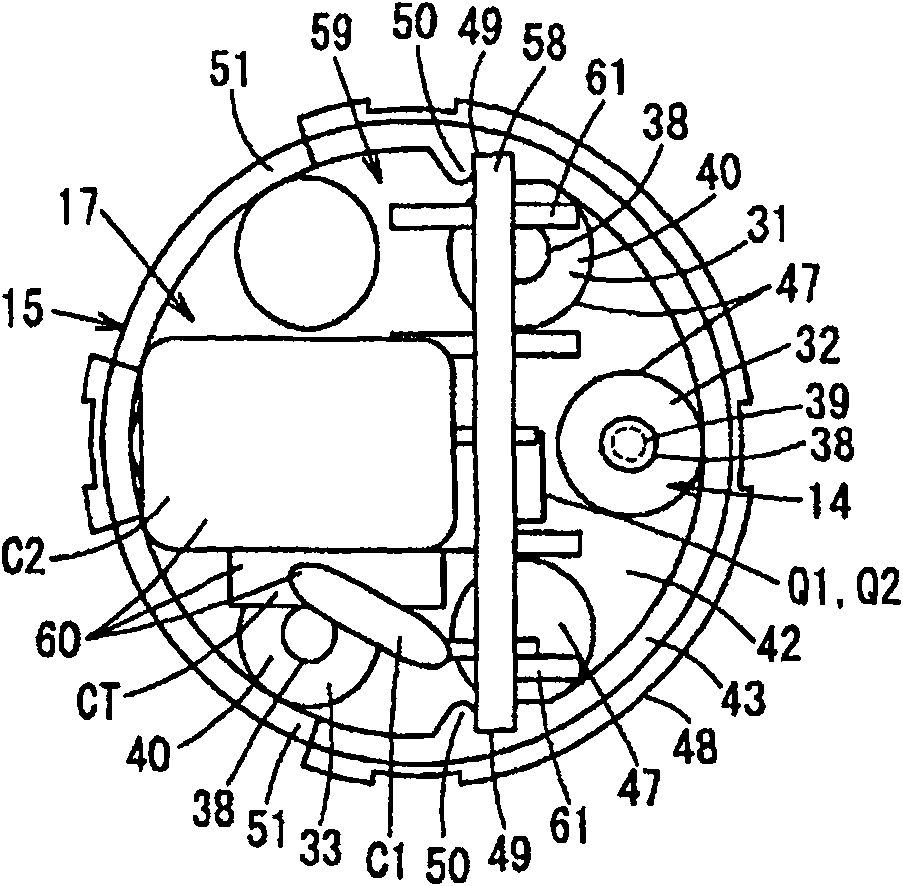

[0056] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0057] Figure 1 to Figure 8 1st Embodiment is shown. figure 1 This is a cross-sectional view of a compact self-ballasted fluorescent lamp viewed from the side where the vacuum tubes are arranged side by side. figure 2 It is a cross-sectional view when viewed from a direction intersecting the direction in which the vacuum tubes of the compact self-ballasted fluorescent lamp are arranged side by side. image 3 It is a bottom view when the cover and glass bulb of the small self-ballasted fluorescent lamp are removed and viewed from one end side of the bracket. Figure 4 It is a perspective view of a bracket for a compact self-ballasted fluorescent lamp. Figure 5 It is a perspective view of a small self-ballasted fluorescent lamp assembly, a light-emitting tube, and a base plate. Figure 6 It is a cross-sectional view showing the positional relationship between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com