Patents

Literature

135results about How to "High yield stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

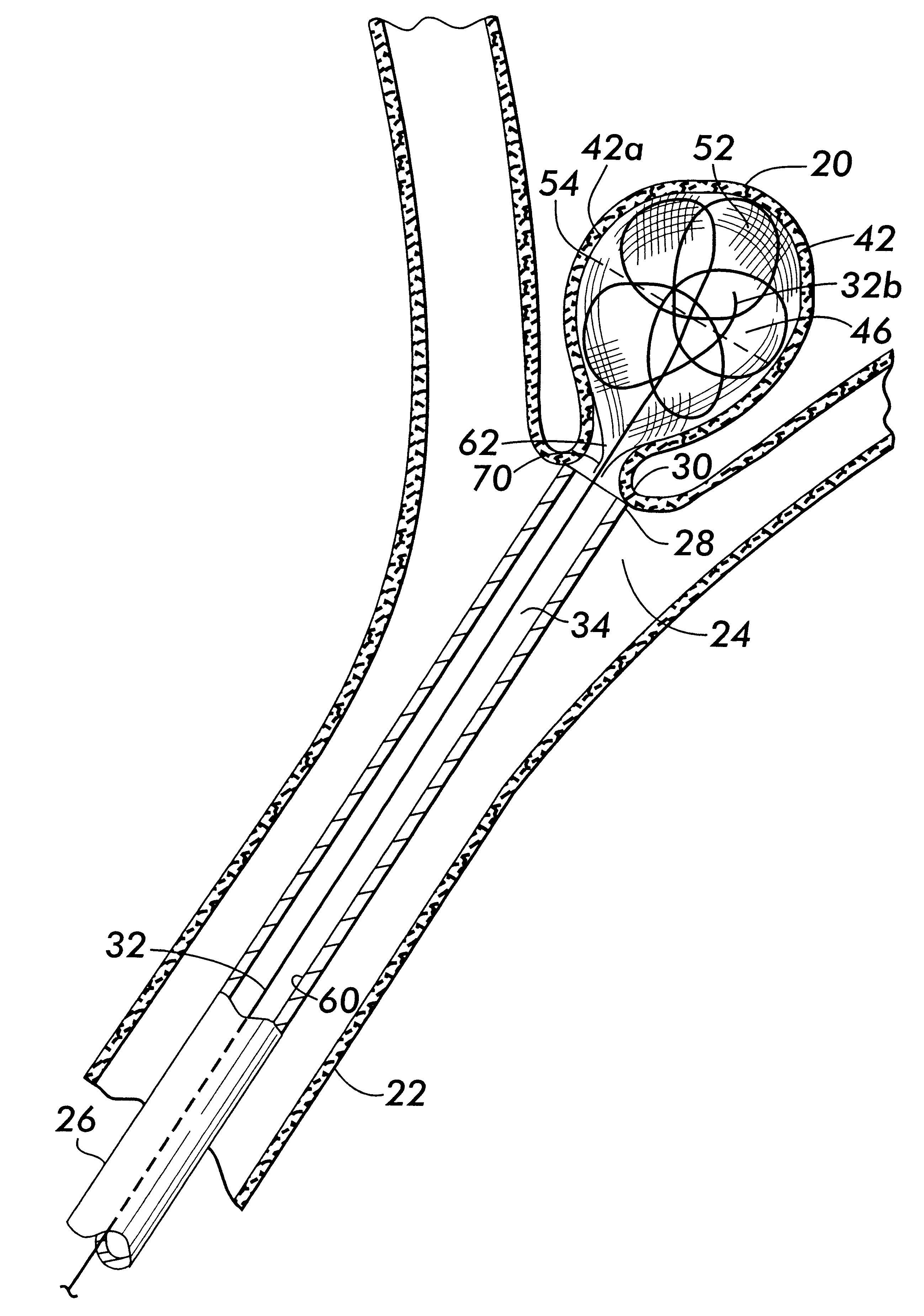

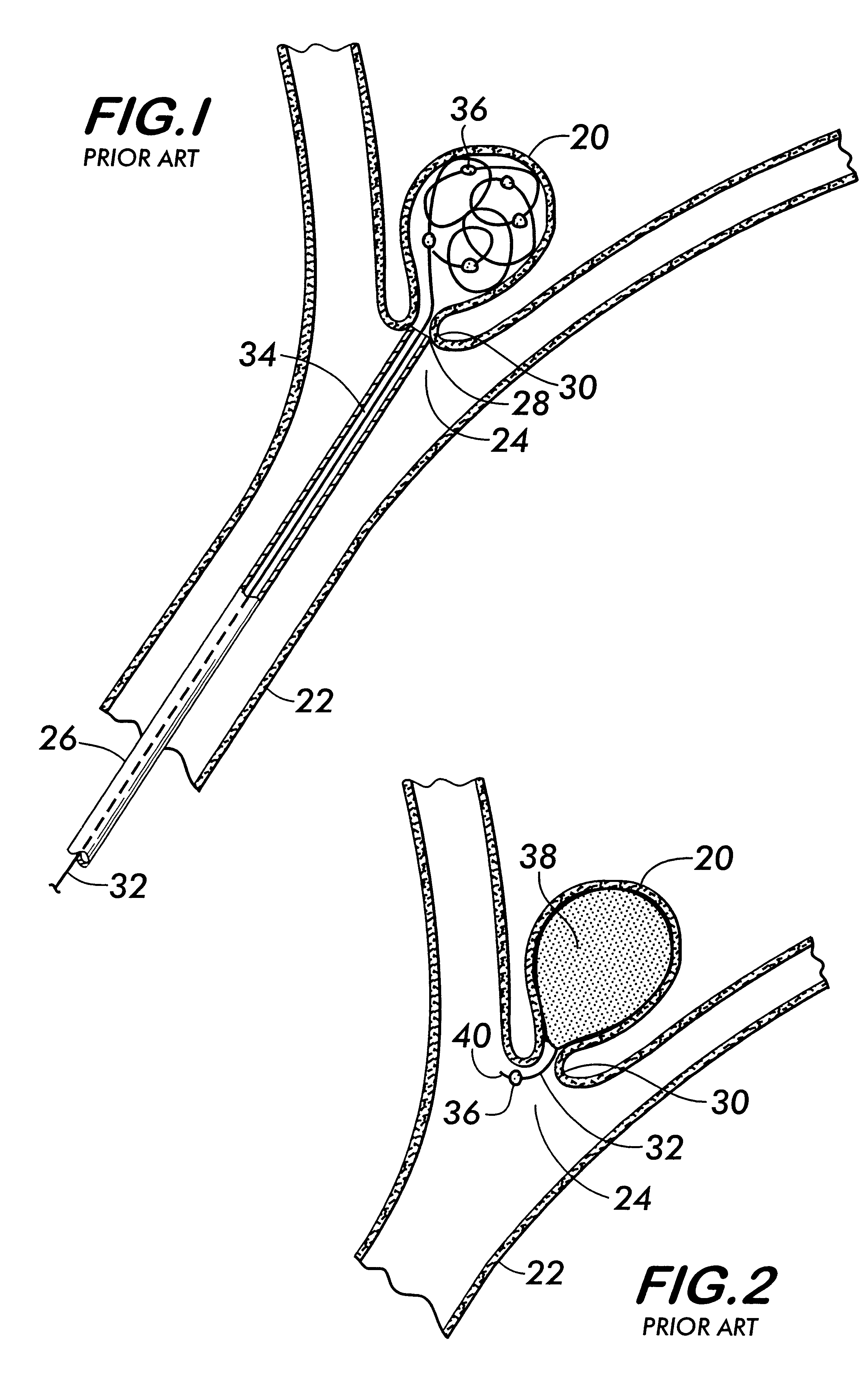

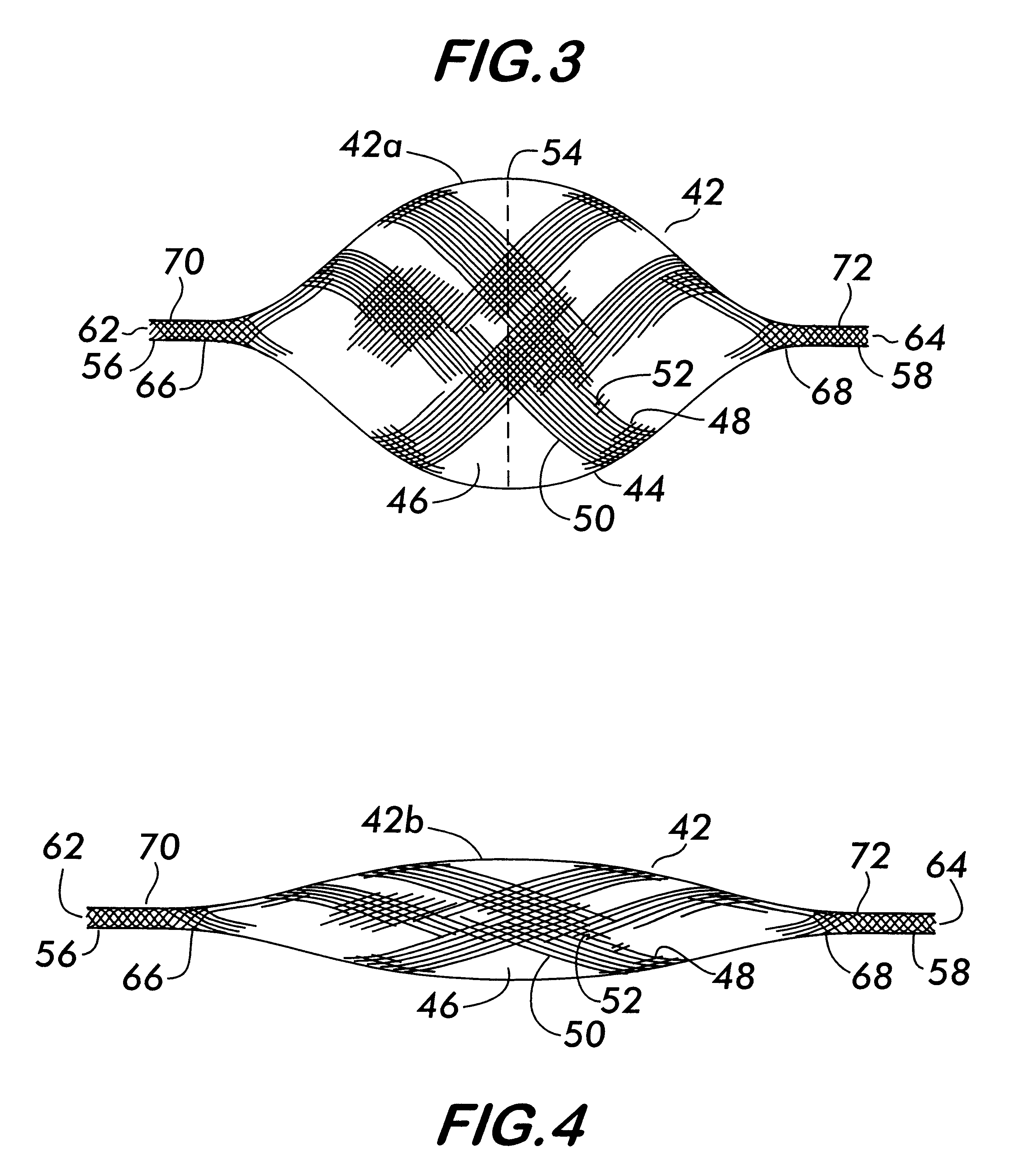

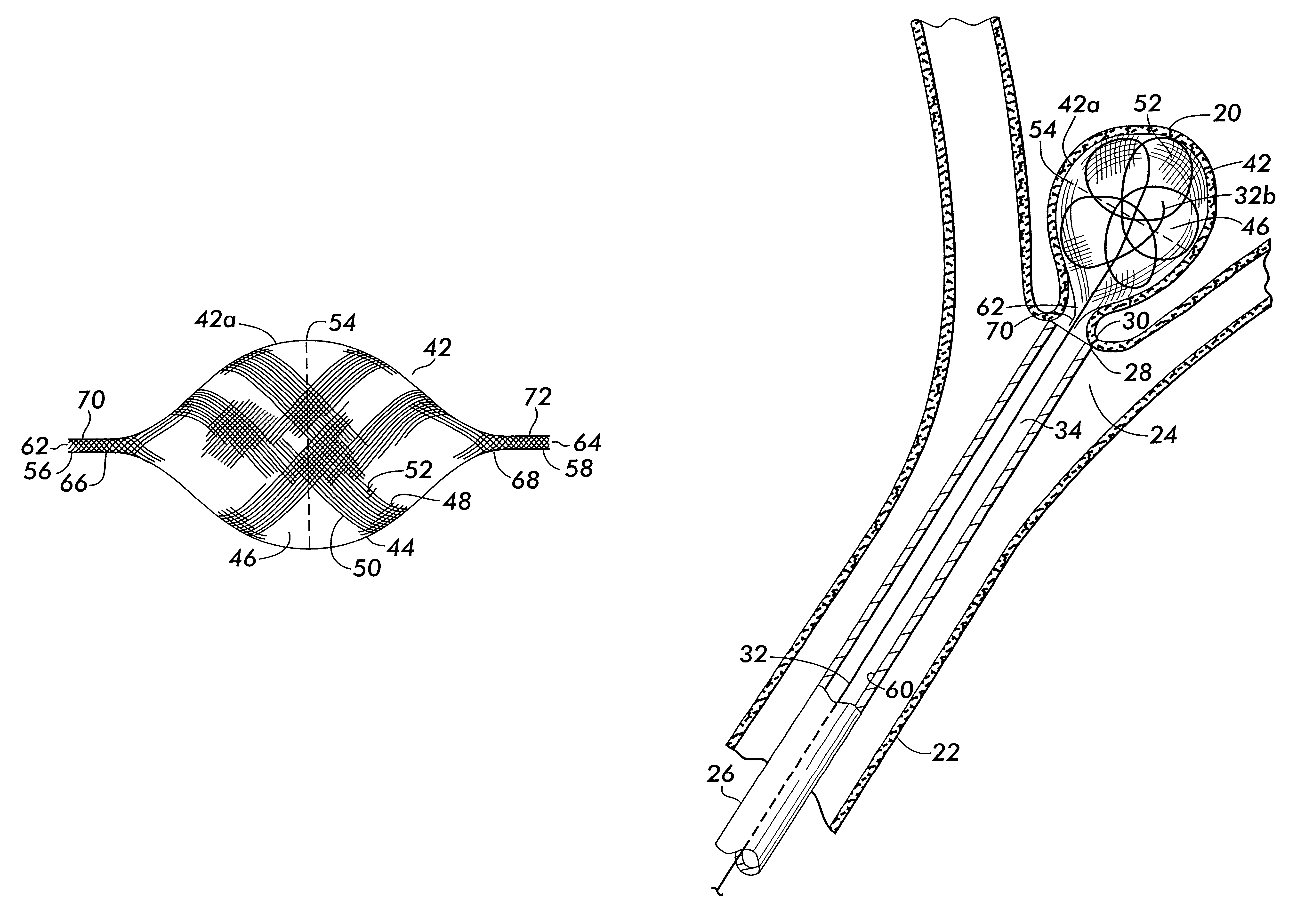

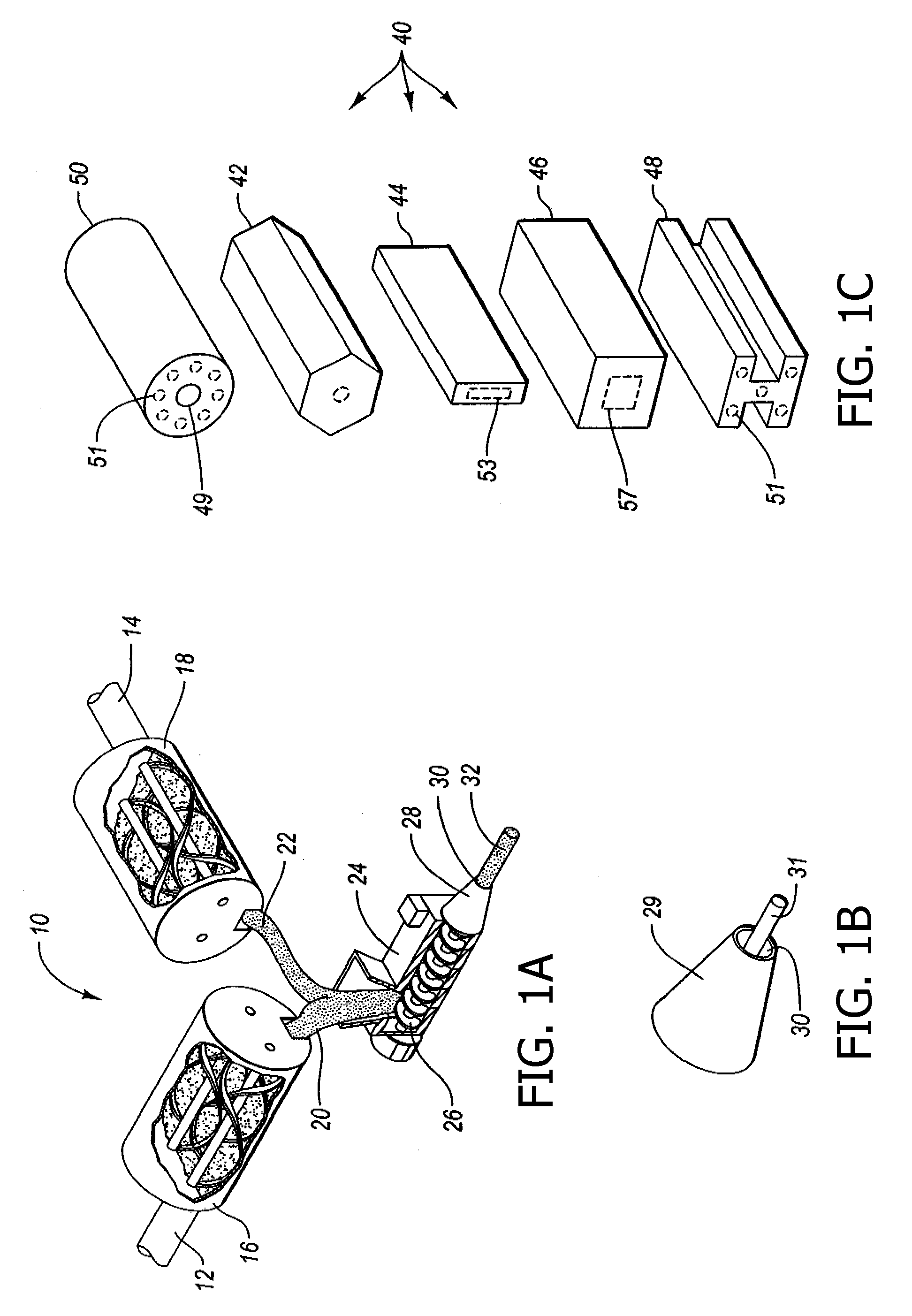

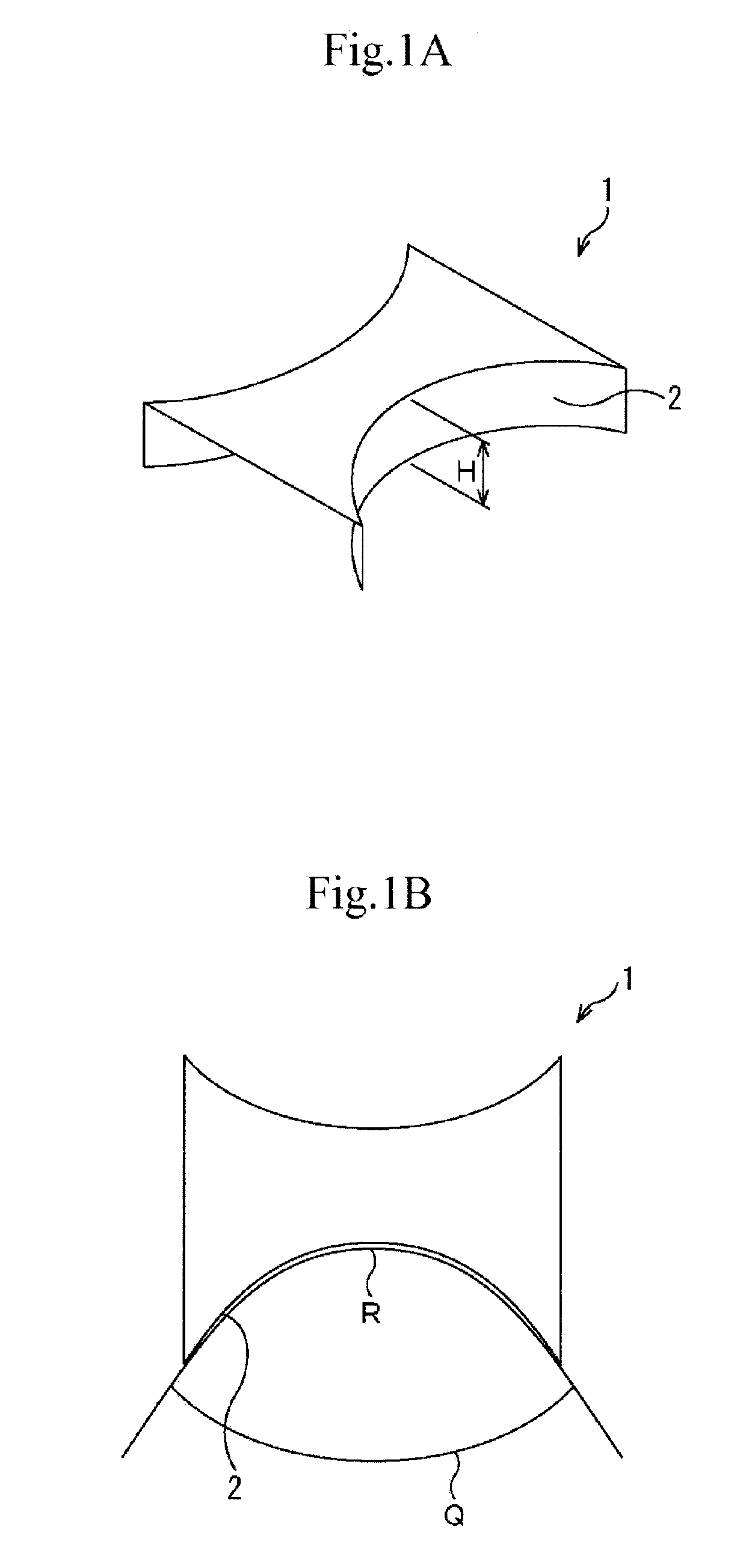

Bag for use in the intravascular treatment of saccular aneurysms

InactiveUS6346117B1Easy to controlHigh yield stressDilatorsOcculdersSaccular aneurysmsIliac Aneurysm

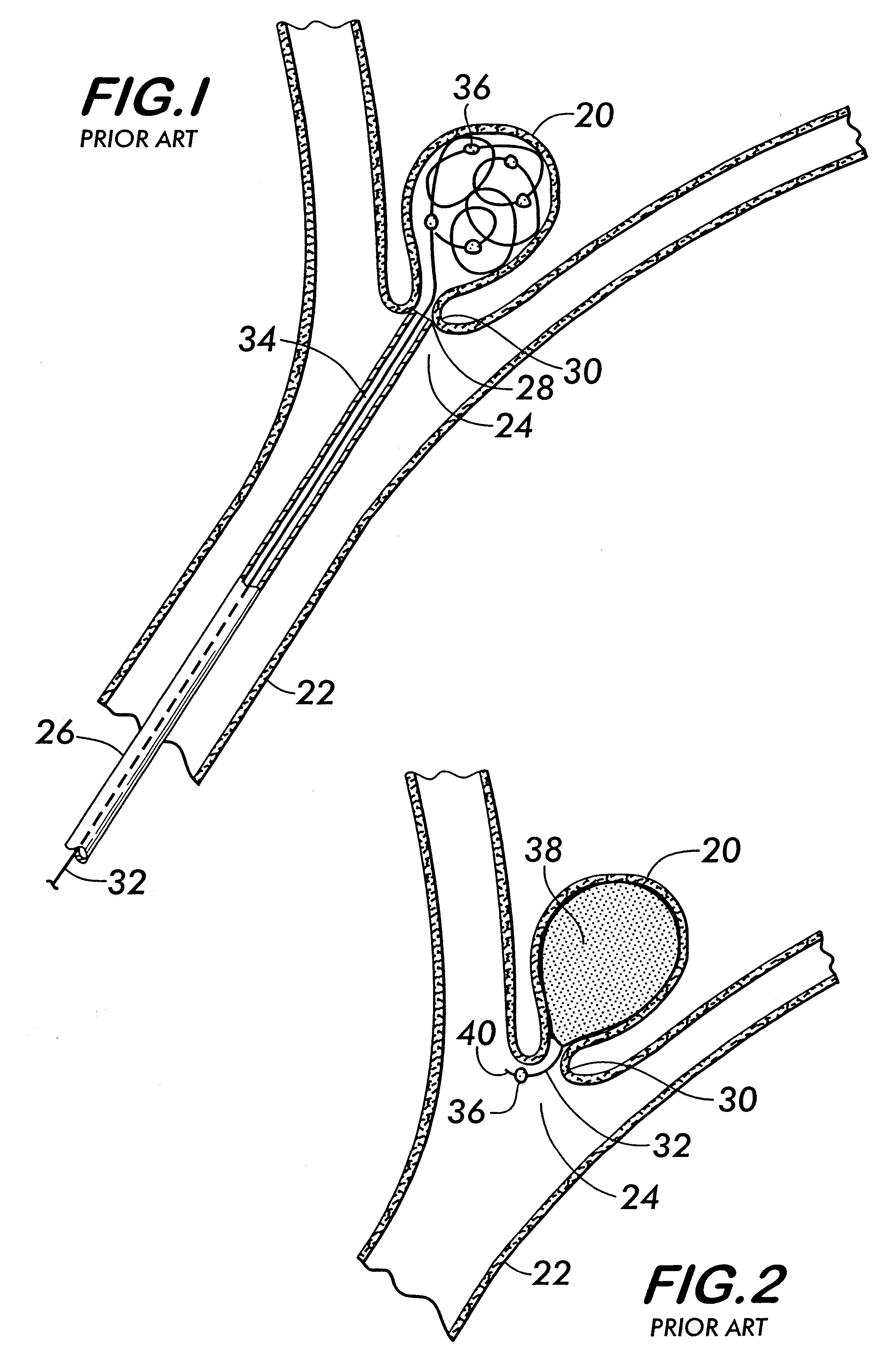

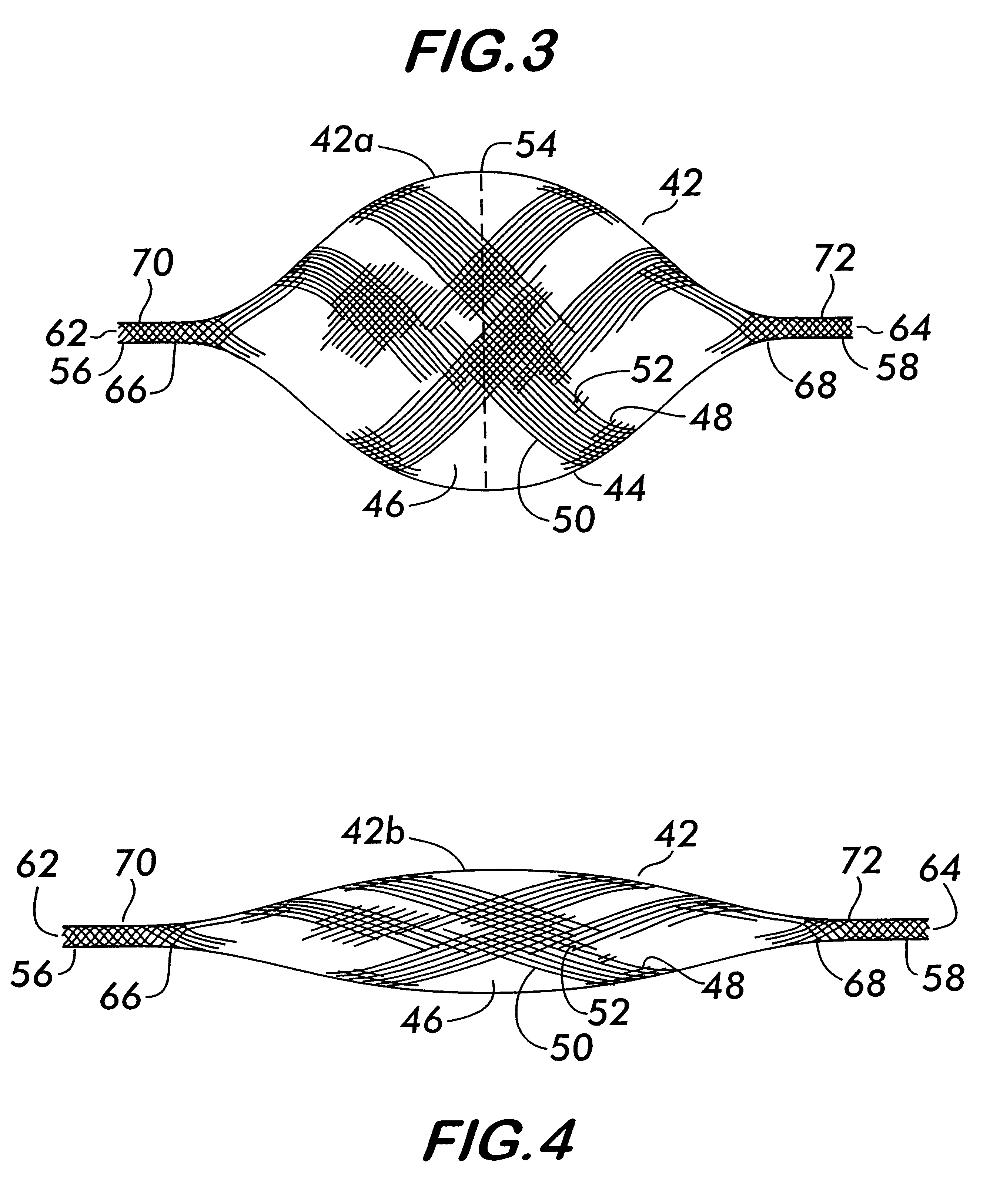

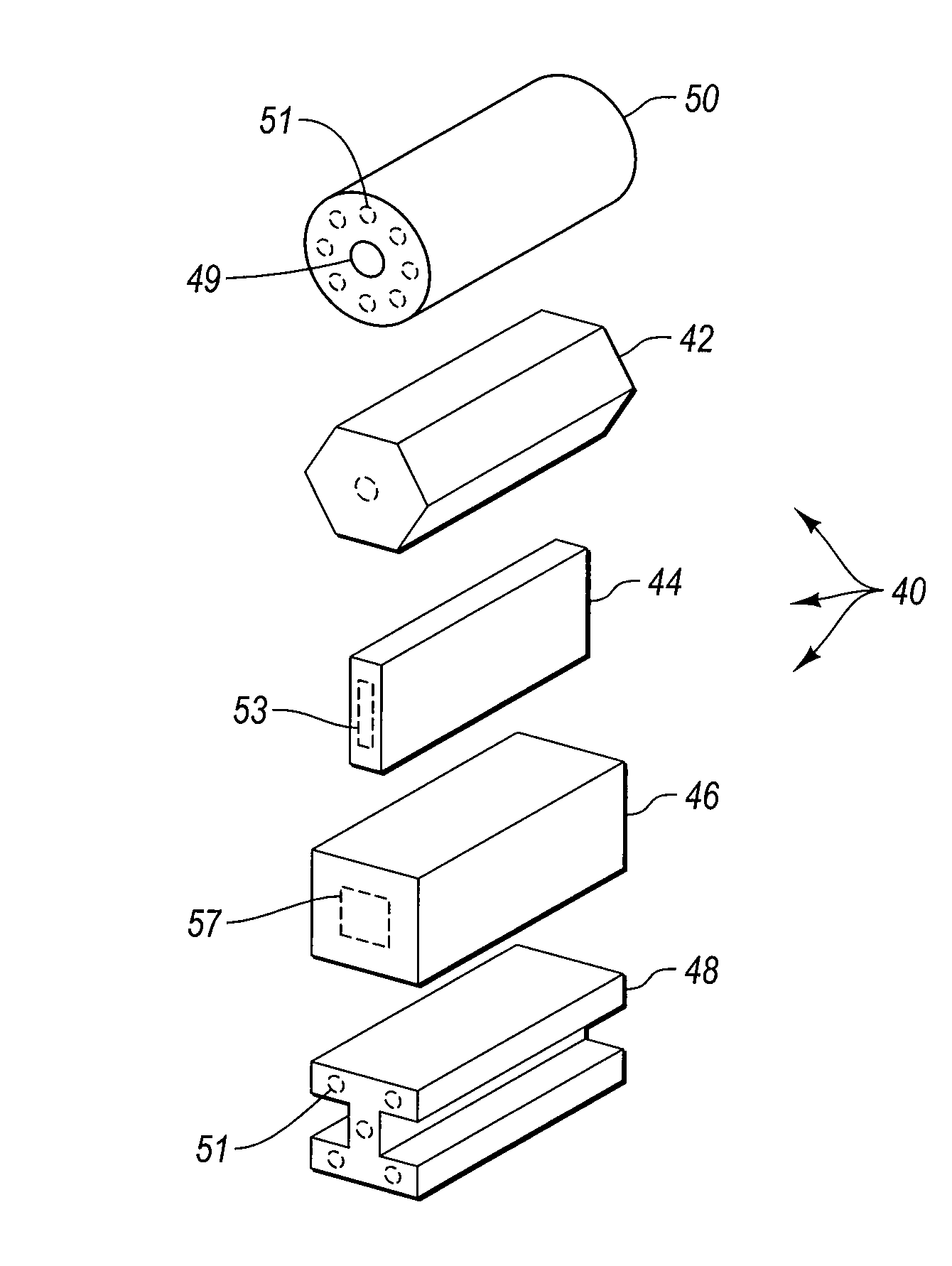

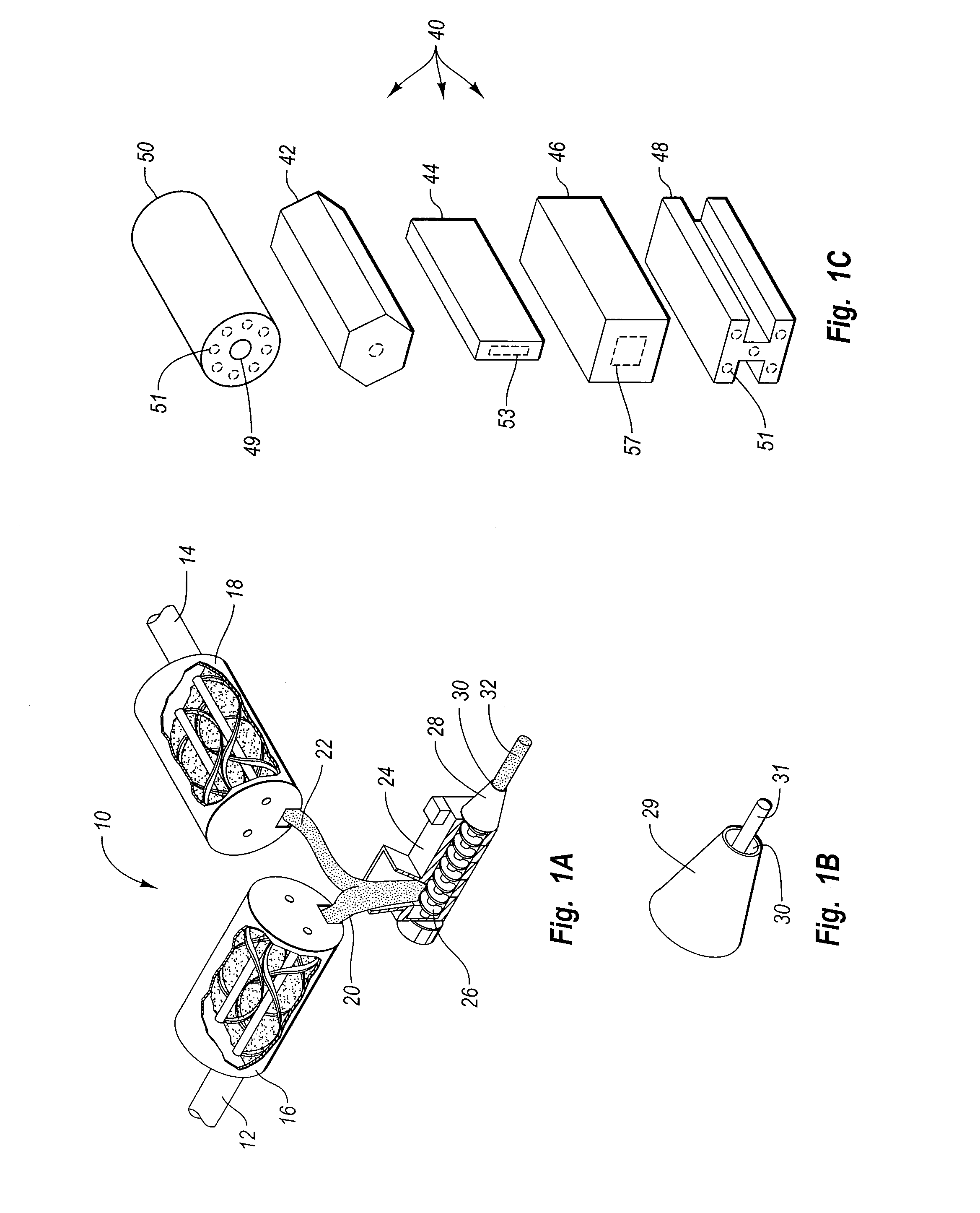

A bag for use in the intravascular treatment of saccular aneurysms and a method of forming the bag are disclosed. The bag is formed from a plurality of flexible, resilient filamentary members braided into a tubular sleeve and biased into a first shape having an expanded first diameter sized to substantially fill the aneurysm. The bag is resiliently deformable into a second shape having a diameter smaller than the first and sized to slidingly interfit within the lumen of a catheter. An opening is provided in the bag to receive a clotting medium, such as a platinum wire, on which blood clots can be induced to form by mechanical or electrolytic means. A closure is provided by biasing the filamentary members to form a constriction around the opening. In use the, bag is inserted into a saccular aneurysm via the catheter and expands to its first diameter upon release therefrom. Interstices between the interbraided filamentary members provide pores allowing blood from the aneurysm to enter the bag when the bag is positioned within the aneurysm. The clotting medium wire is packed into the bag, blood clots on the wire and occludes the aneurysm, sealing it off from the blood stream and preventing rupture. The wire is released from the catheter and is contained within the bag in the aneurysm.

Owner:PRODESCO

Bag for use in the intravascular treatment of saccular aneurysms

InactiveUS6391037B1Easy to controlHigh yield stressOcculdersWound clampsBlood streamAnterior Cerebral Artery Aneurysm

A bag for use in the intravascular treatment of saccular aneurysms and a method of forming the bag are disclosed. The bag is formed from a plurality of flexible, resilient filamentary members braided into a tubular sleeve and biased into a first shape having an expanded first diameter sized to substantially fill the aneurysm. The bag is resiliently deformable into a second shape having a diameter smaller than the first and sized to slidingly interfit within the lumen of a catheter. An opening is provided in the bag to receive a clotting medium, such as a platinum wire, on which blood clots can be induced to form by mechanical or electrolytic means. The opening is urged to a closed position by resiliently biasing the filamentary members. In use the, bag is inserted into a saccular aneurysm via the catheter and expands to its first diameter upon release therefrom. Interstices between the interbraided filamentary members provide pores allowing blood from the aneurysm to enter the bag when the bag is positioned within the aneurysm. The clotting medium wire is packed into the bag, blood clots on the wire and occludes the aneurysm, sealing it off from the blood stream and preventing rupture. The wire is released from the catheter and is contained within the bag in the aneurysm.

Owner:PRODESCO

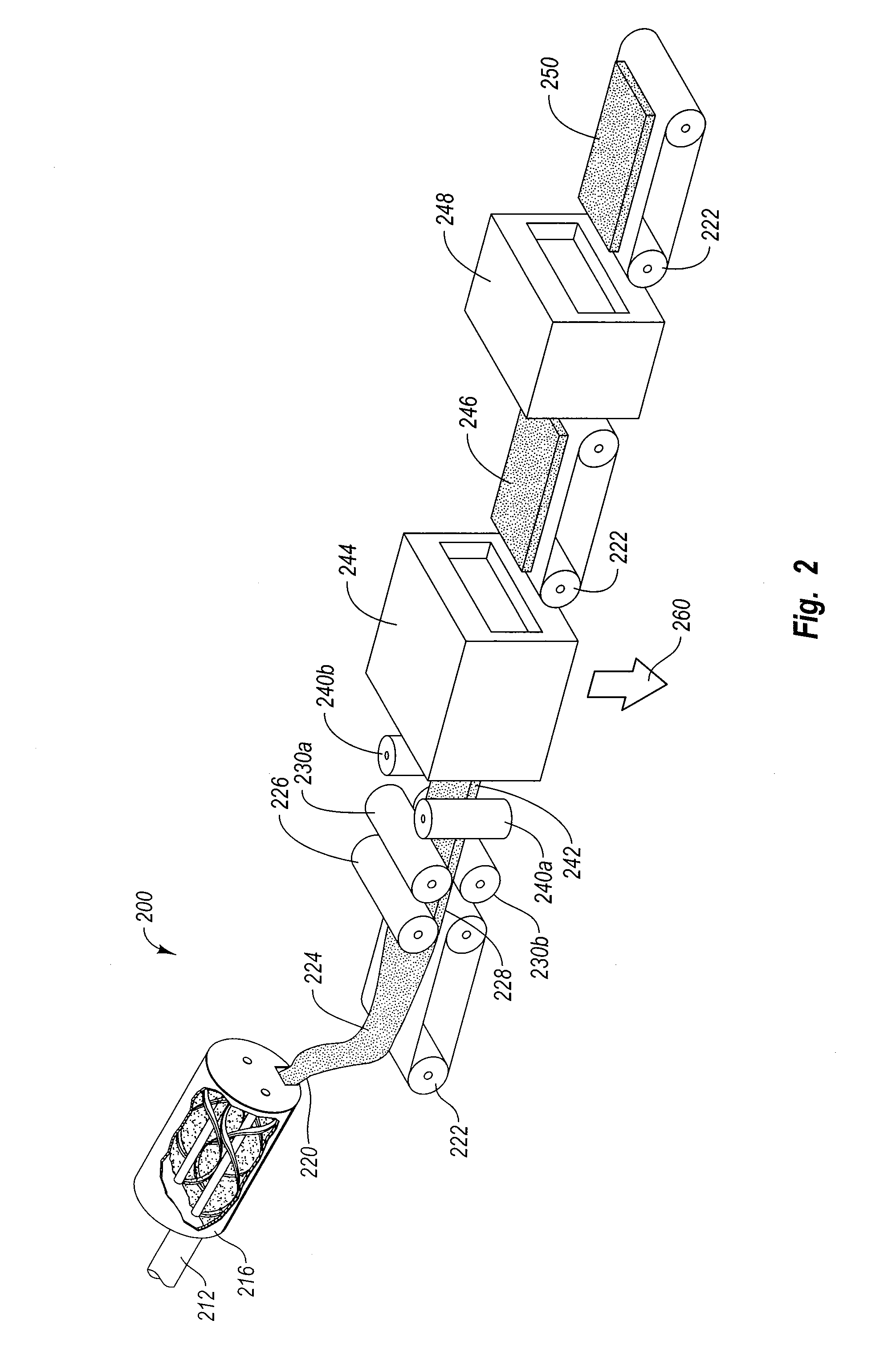

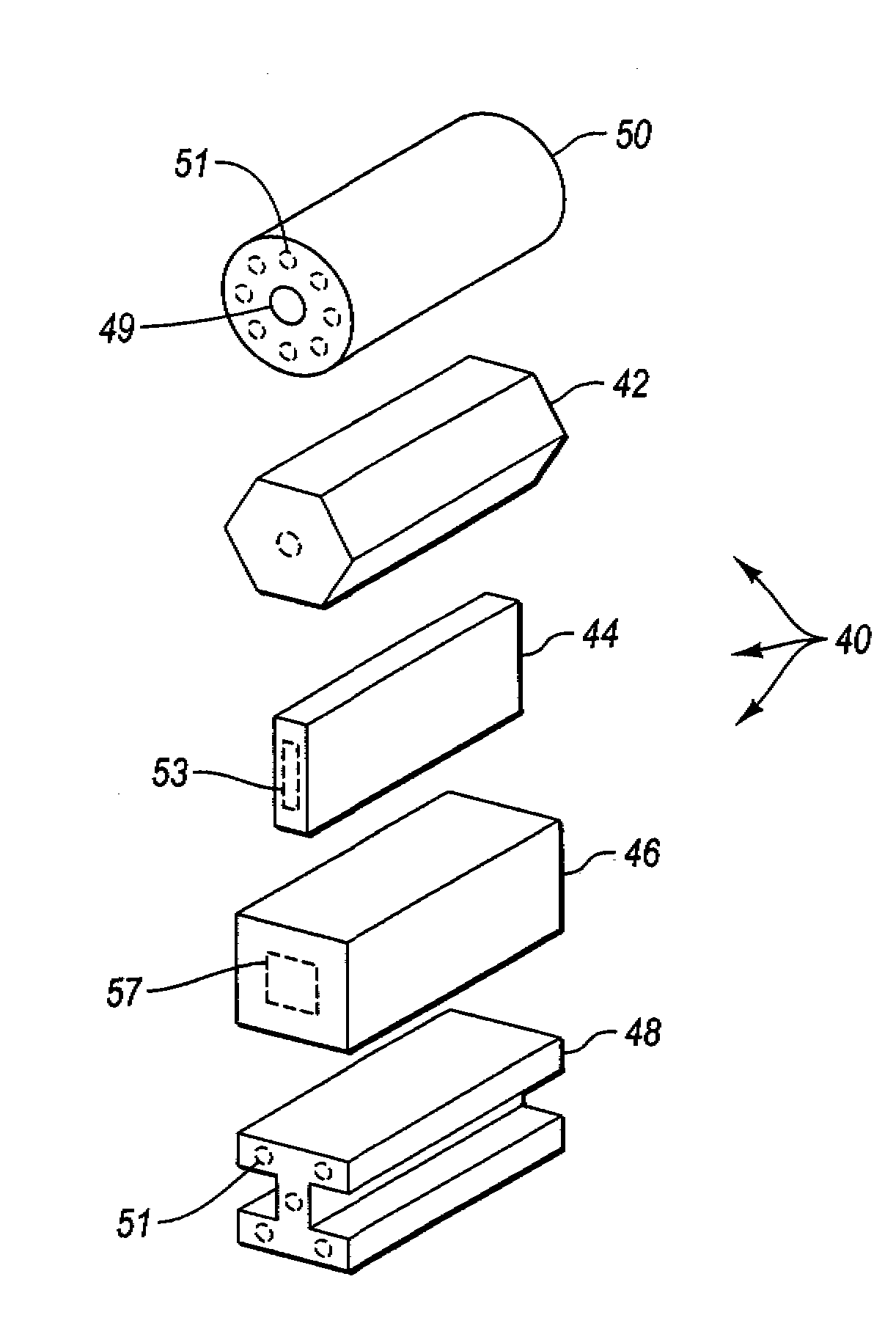

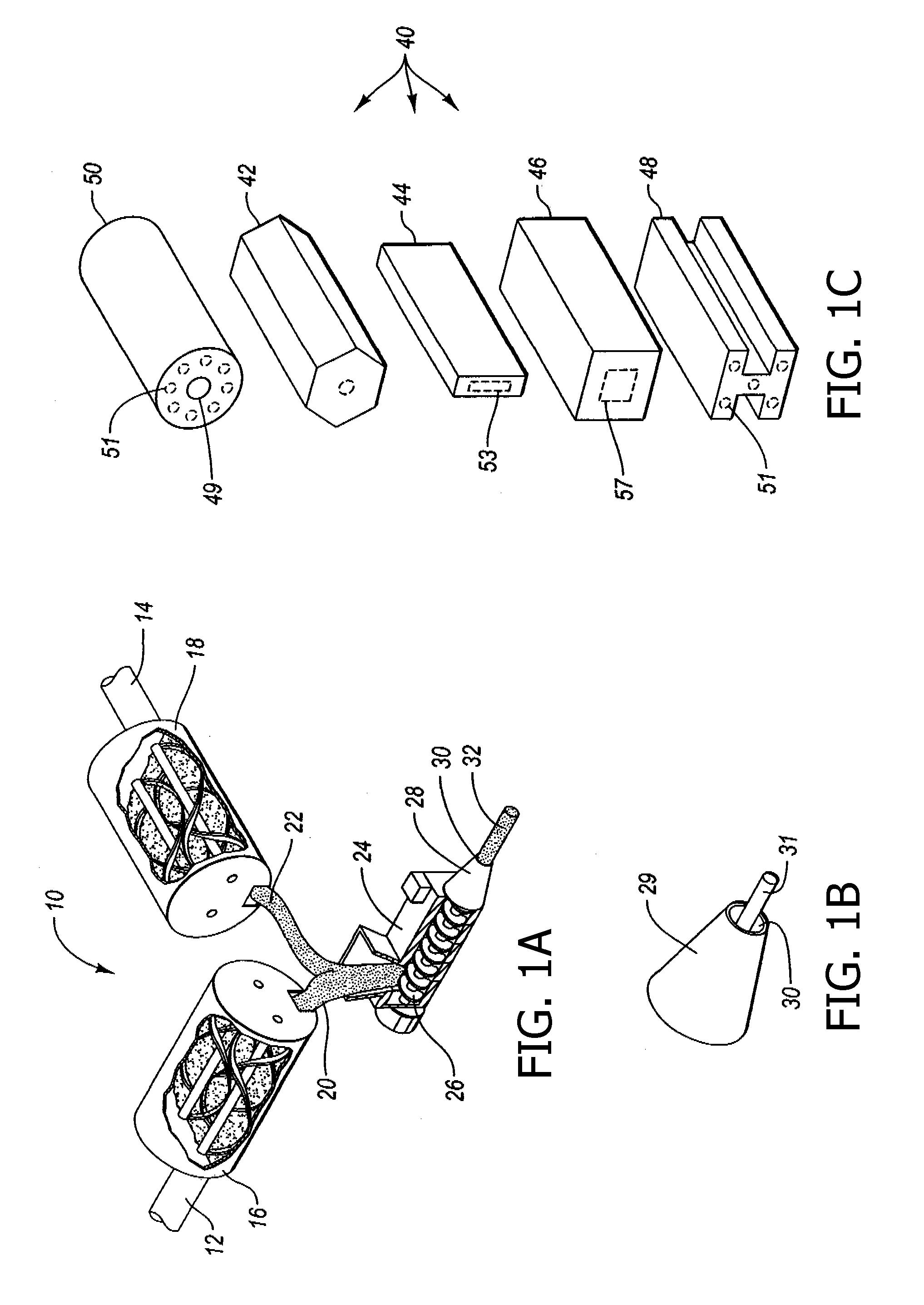

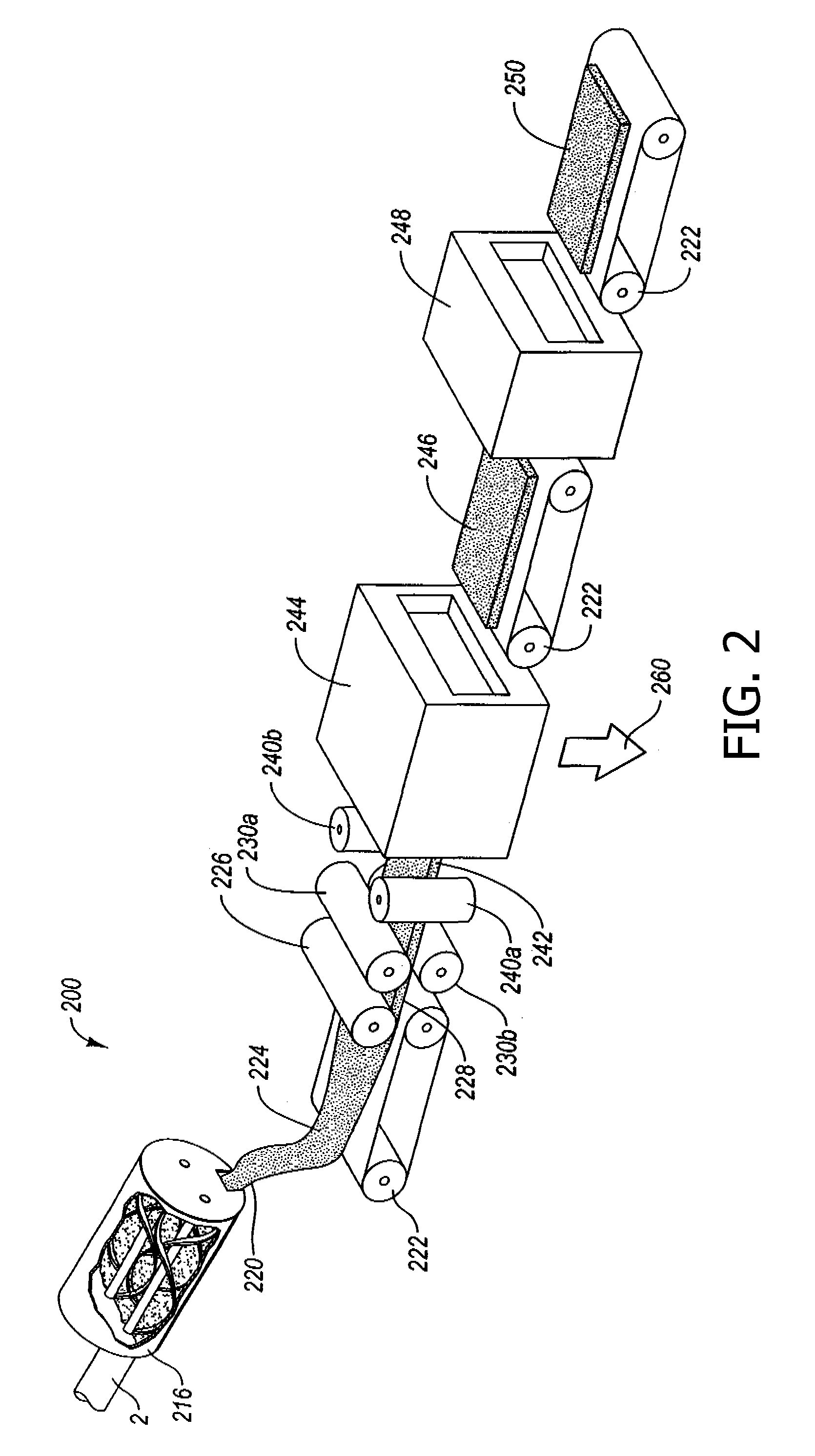

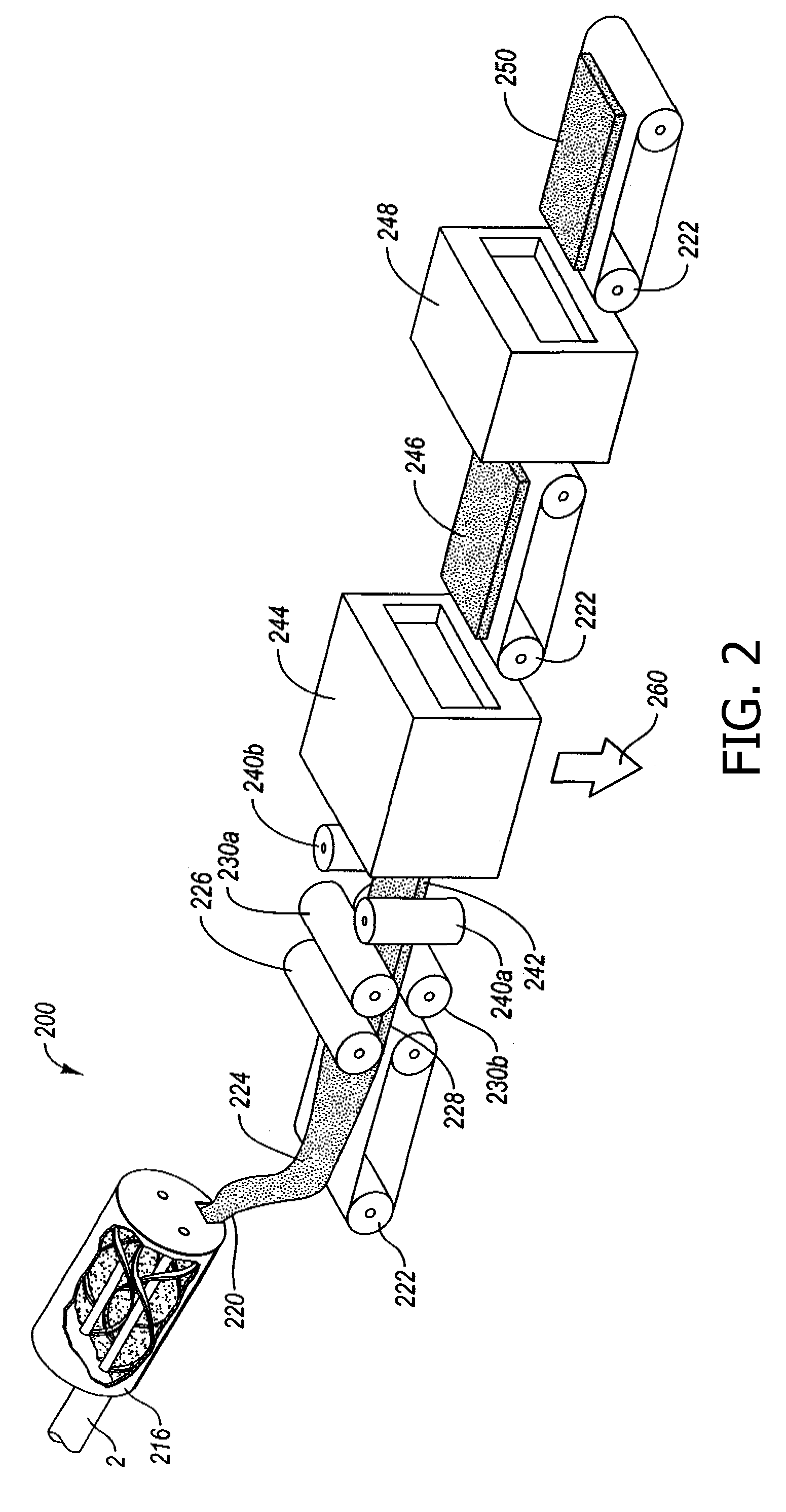

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

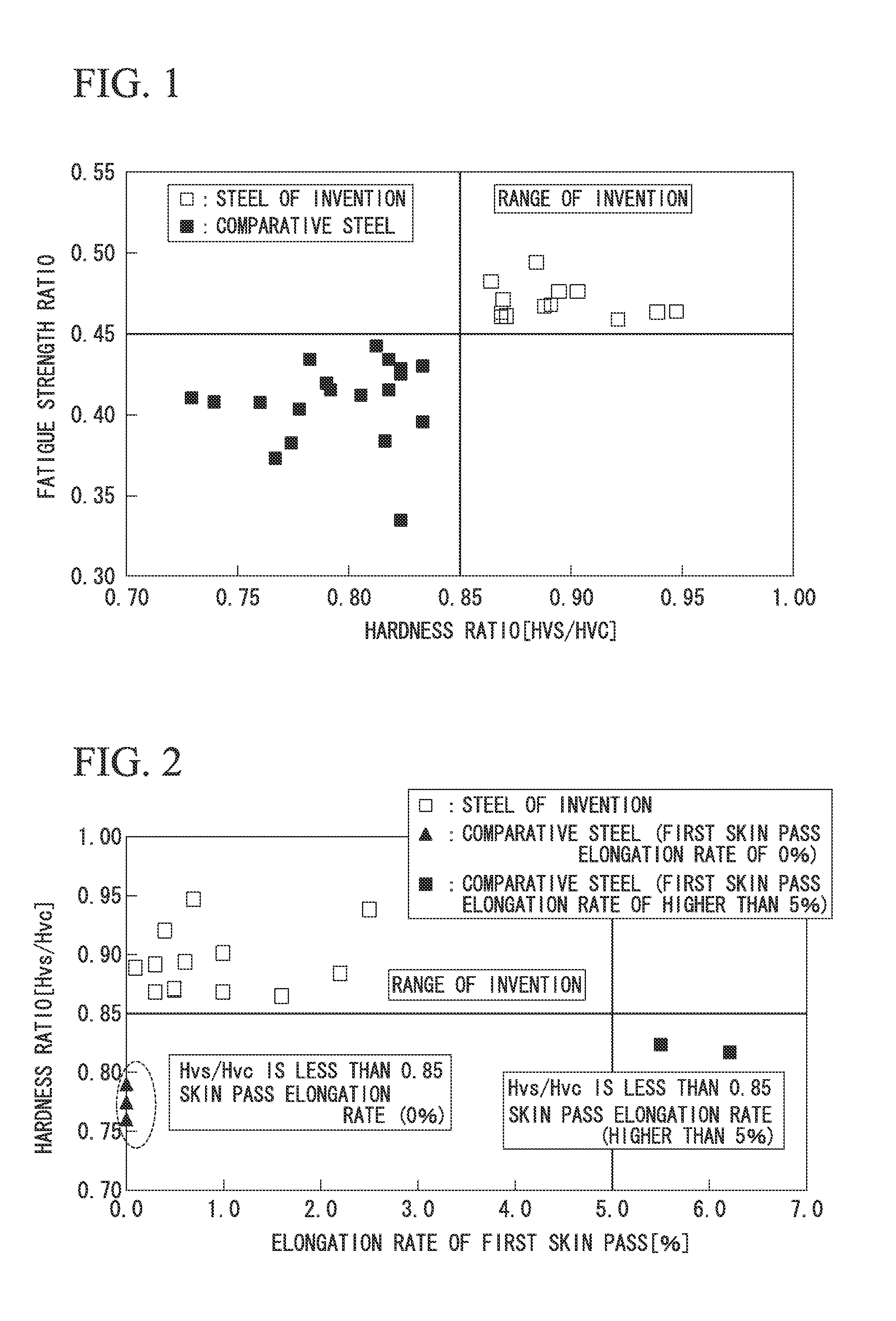

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

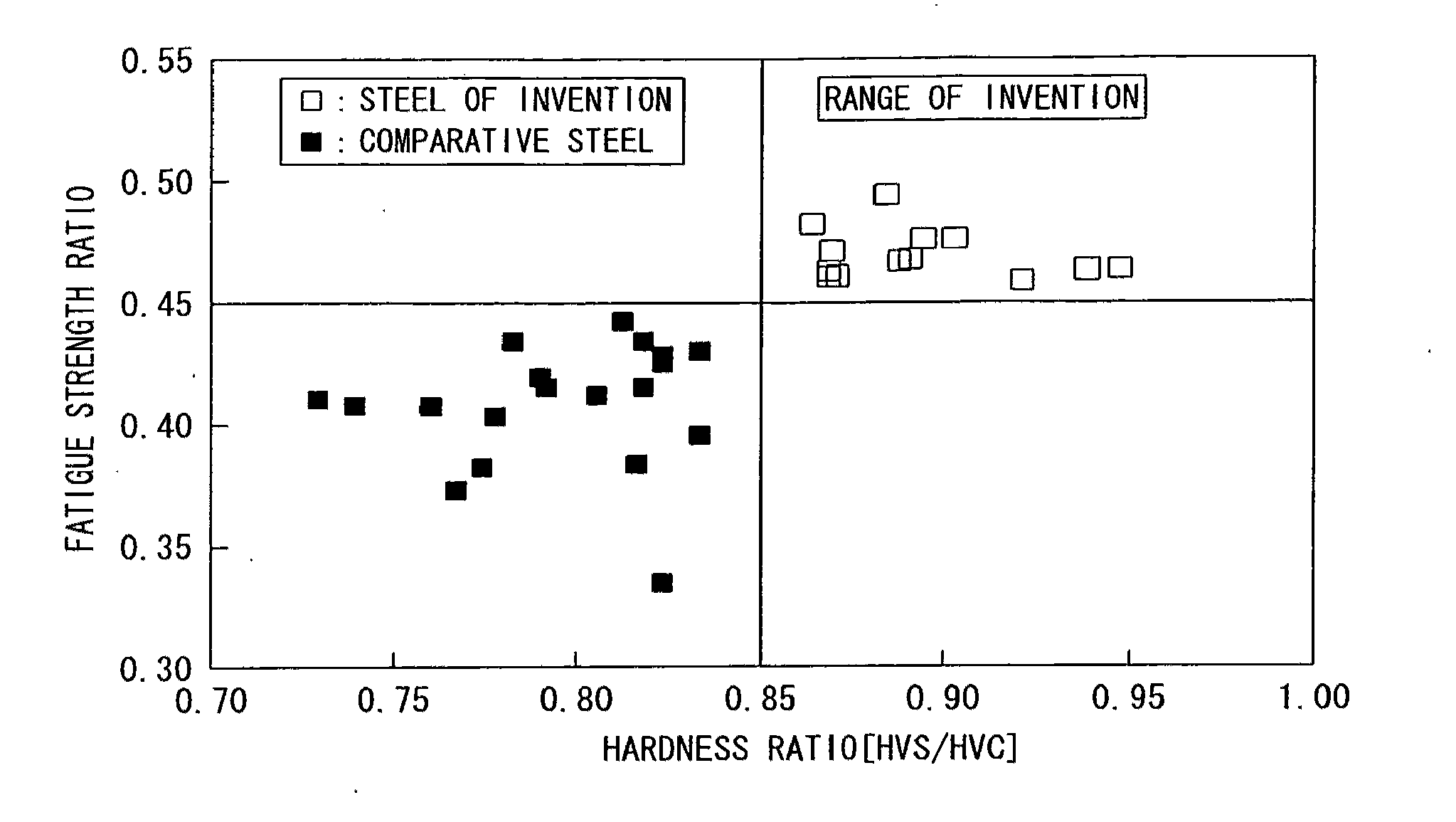

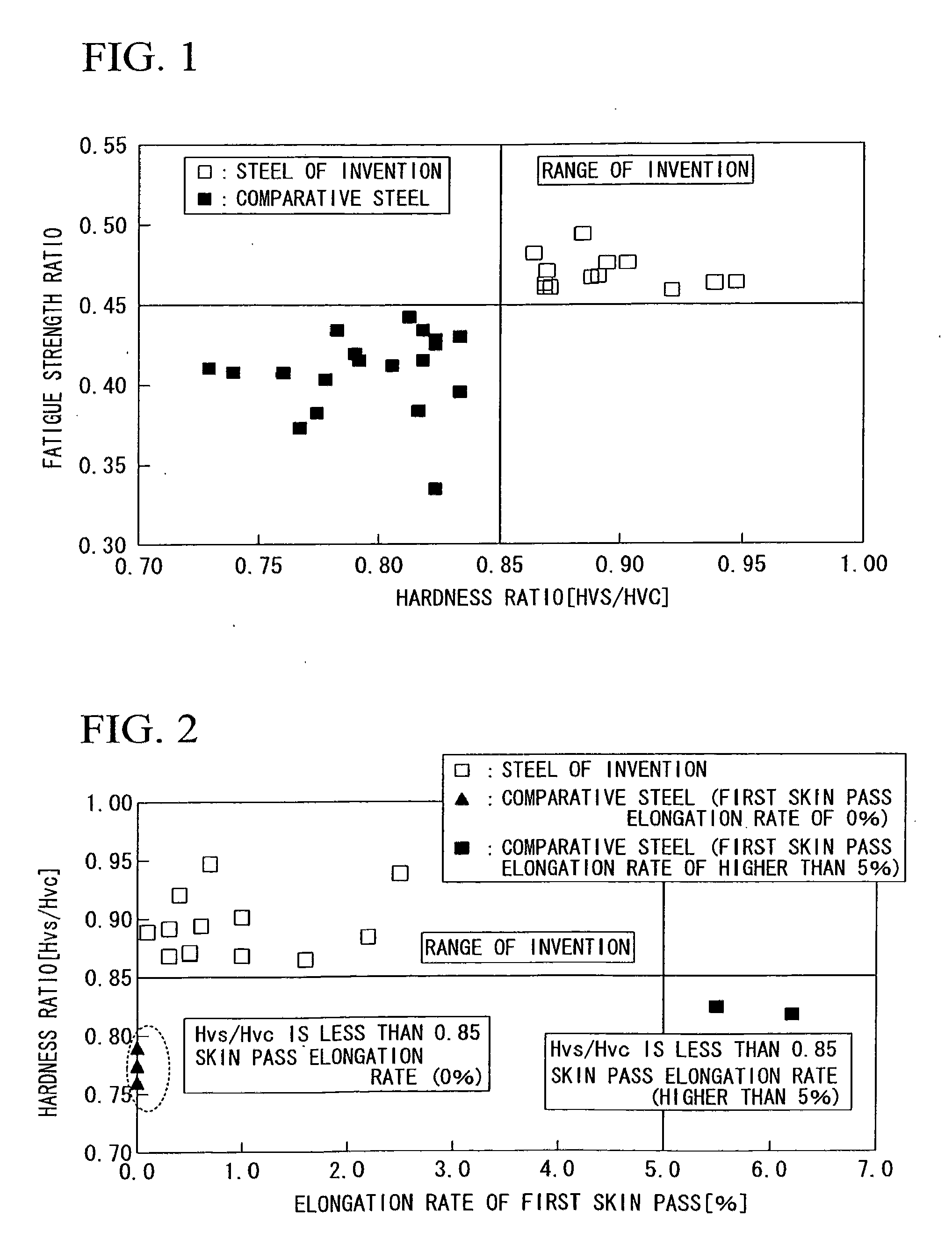

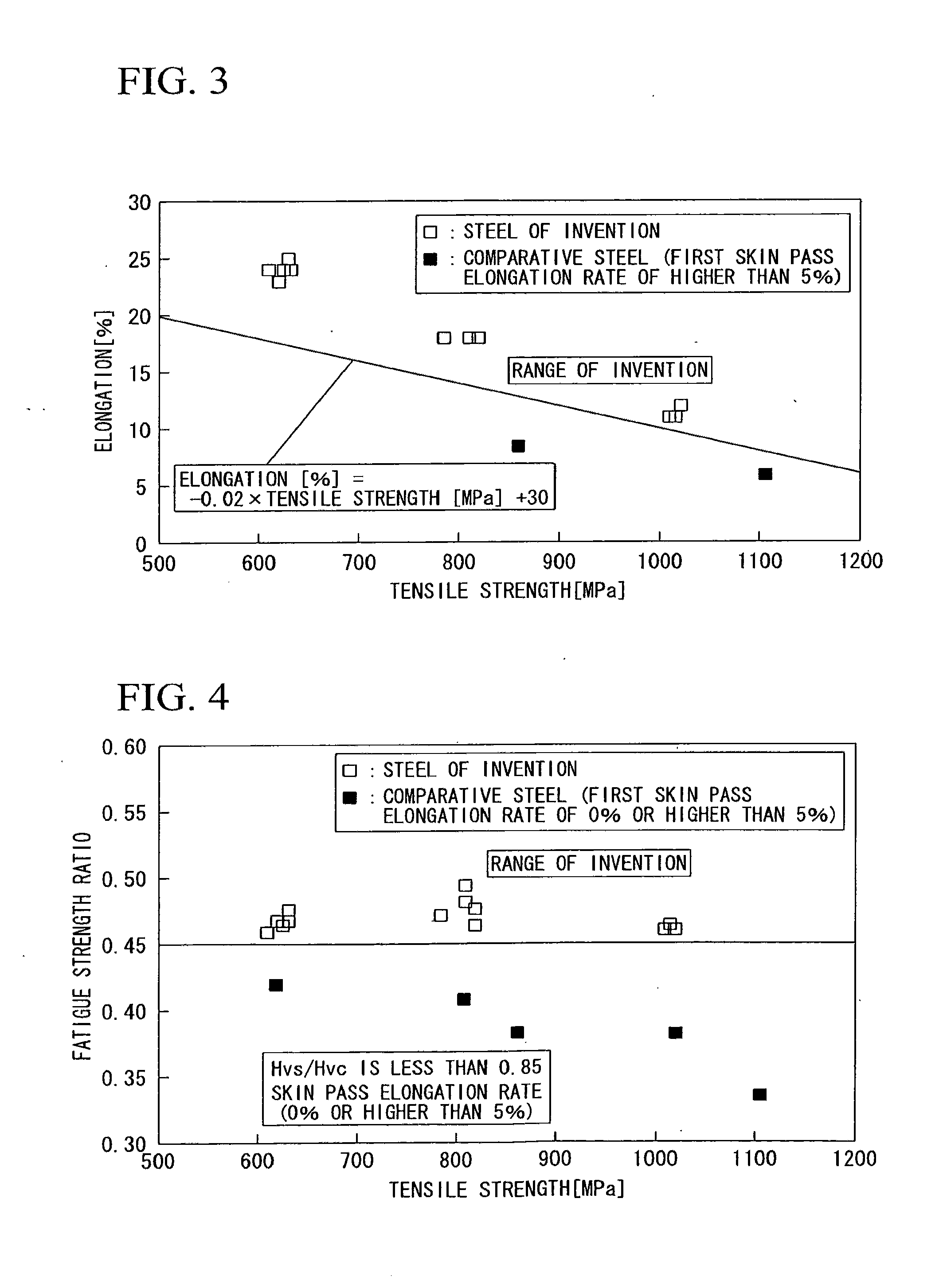

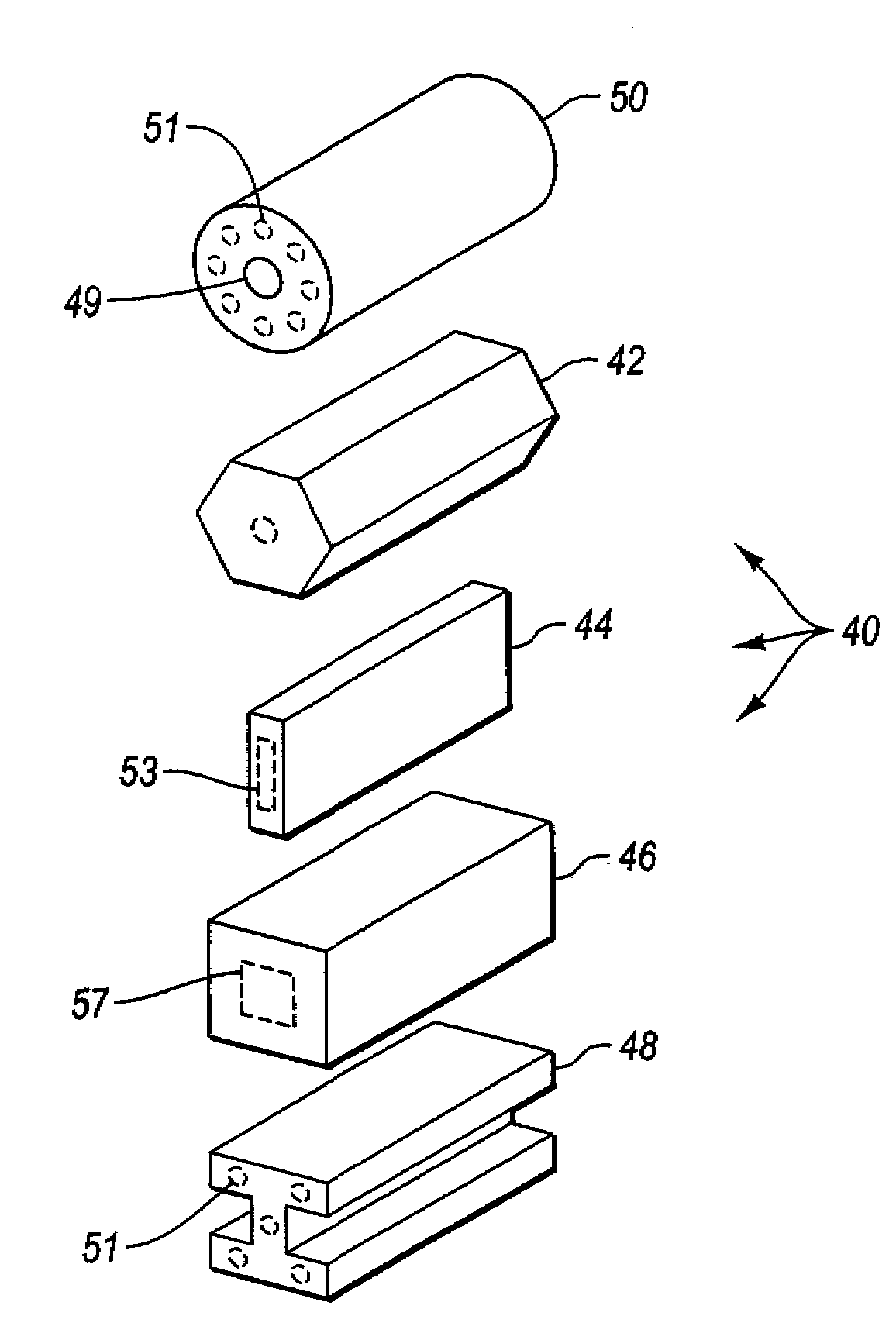

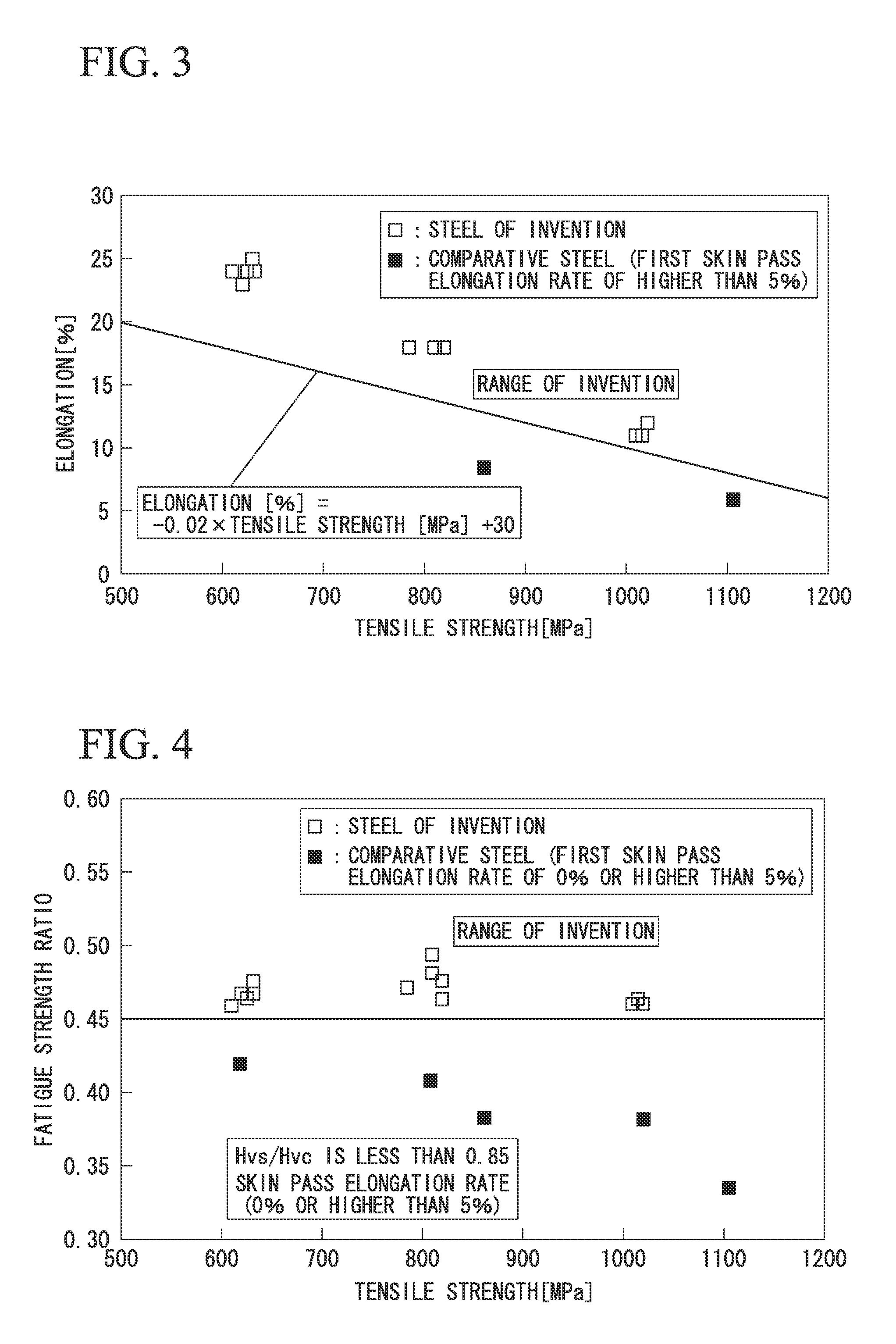

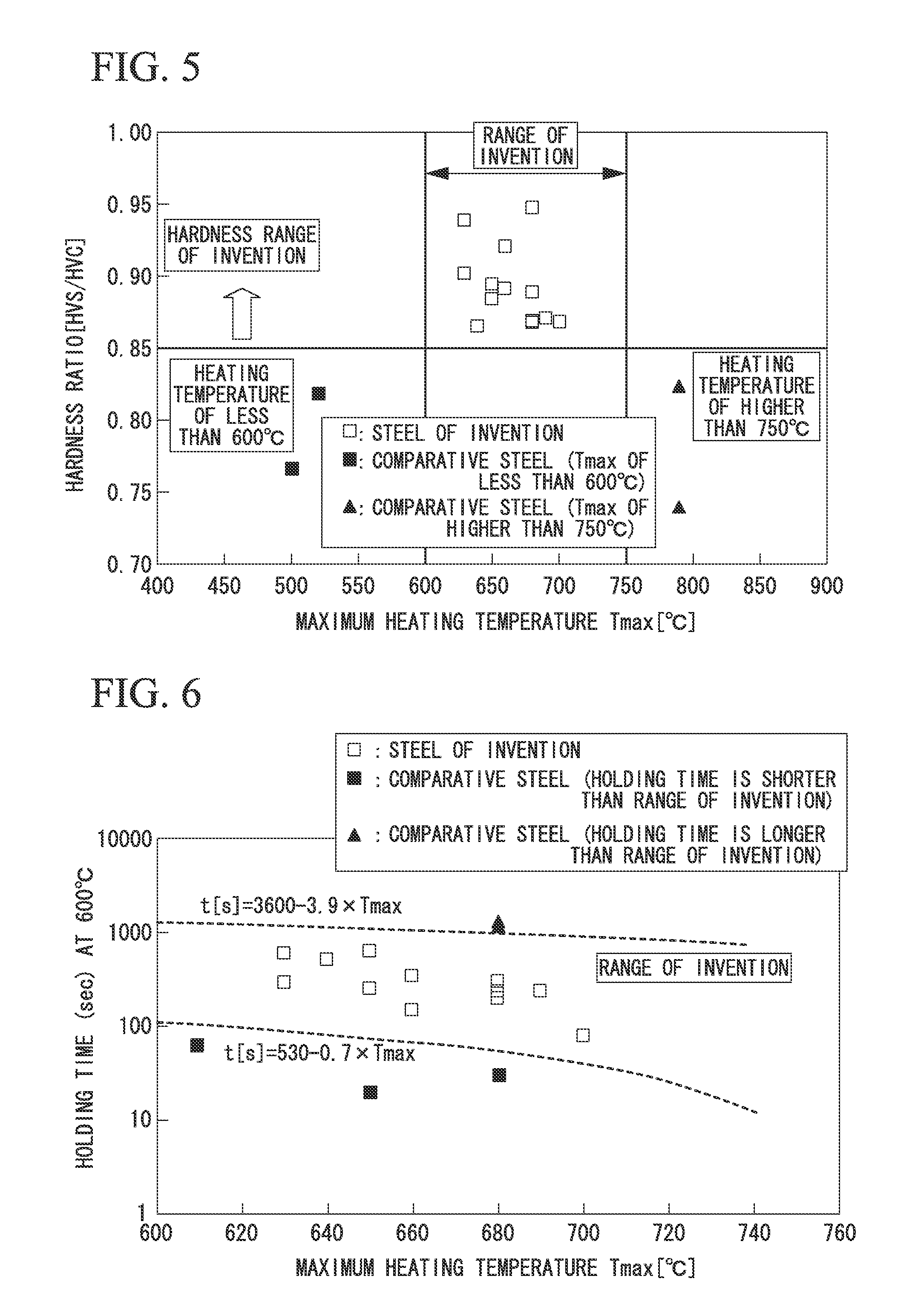

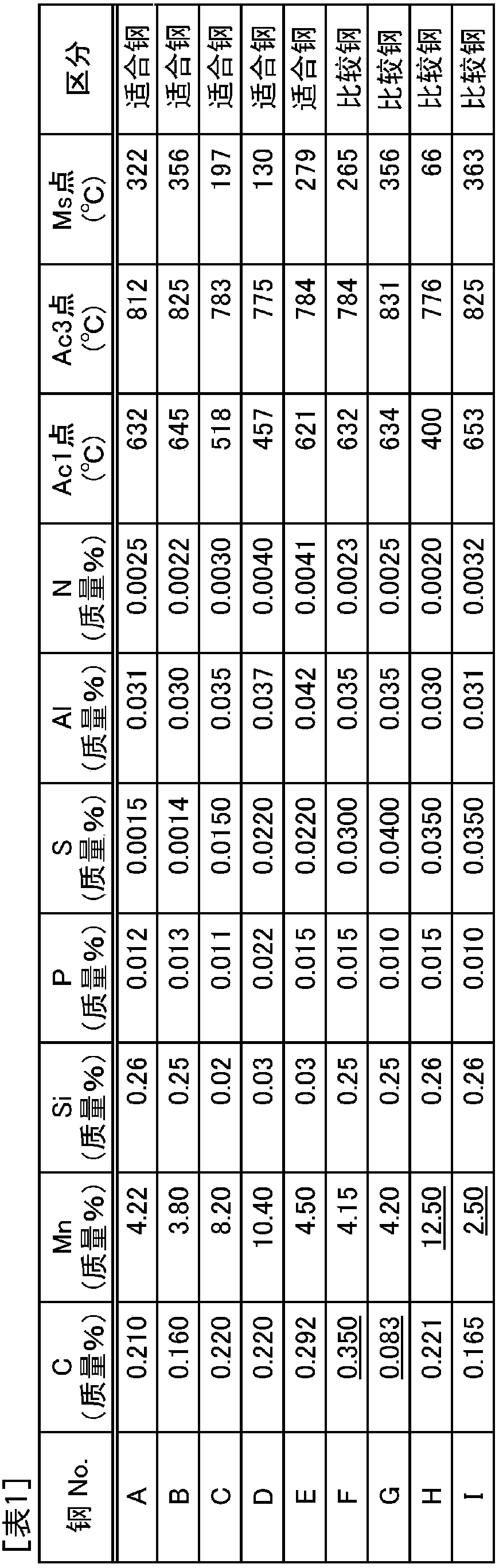

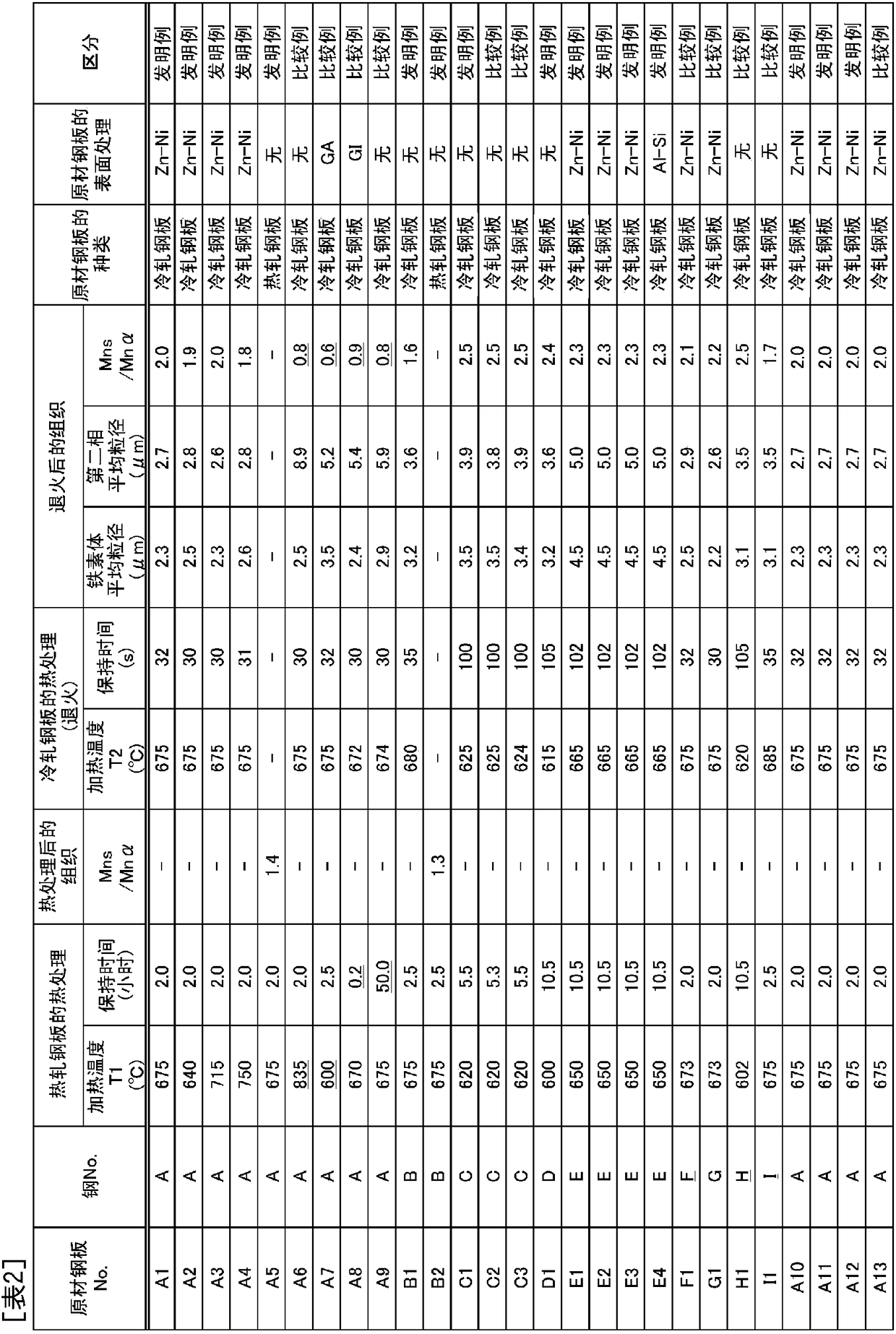

ActiveUS20120031528A1Improve crash performanceHigh yield stressHot-dipping/immersion processesFurnace typesUltimate tensile strengthImpurity

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20120276310A1Low densityReduce hardnessEnvelopes/bags making machineryCeramic extrusion diesPorosityBuilding product

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

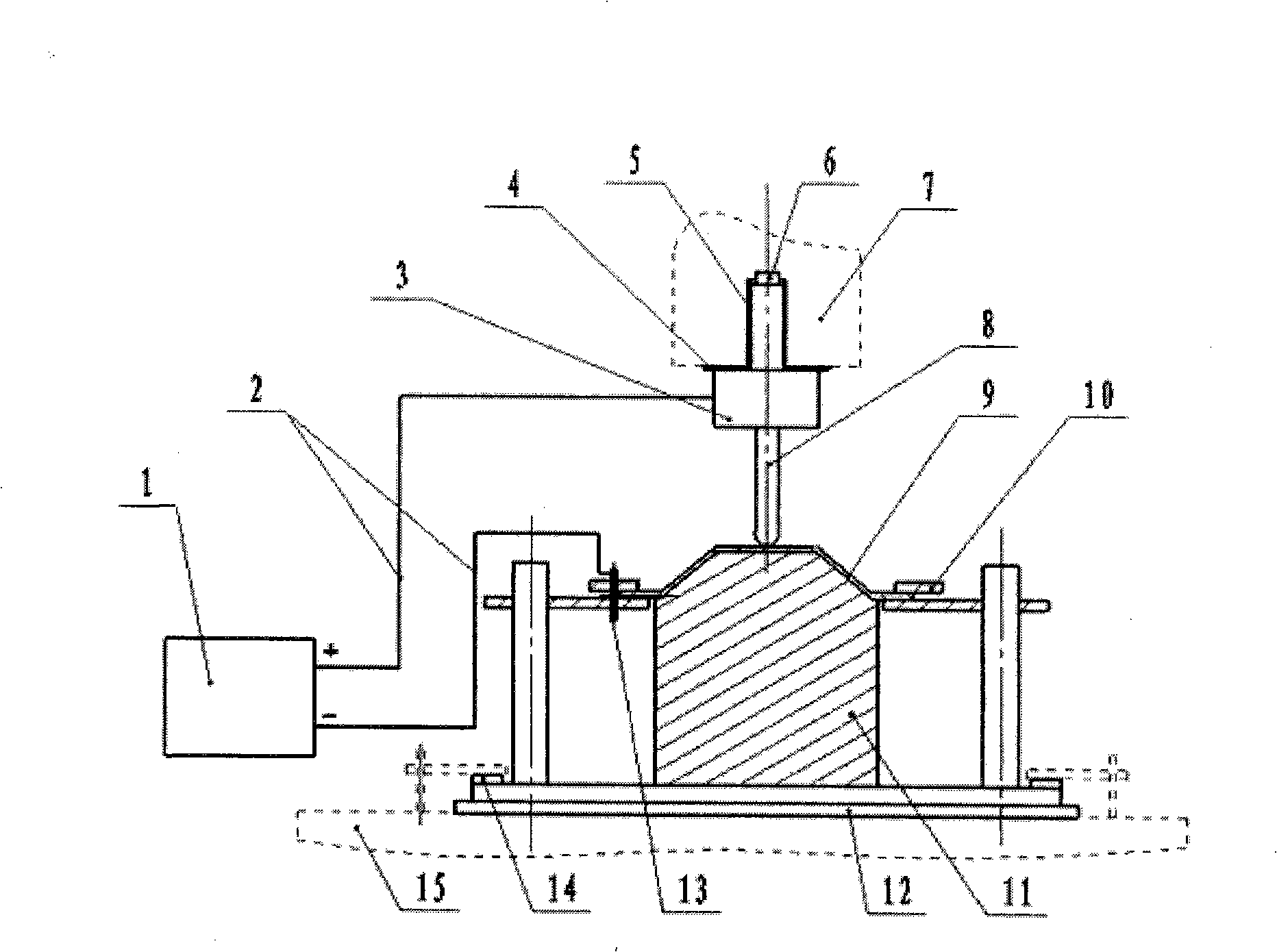

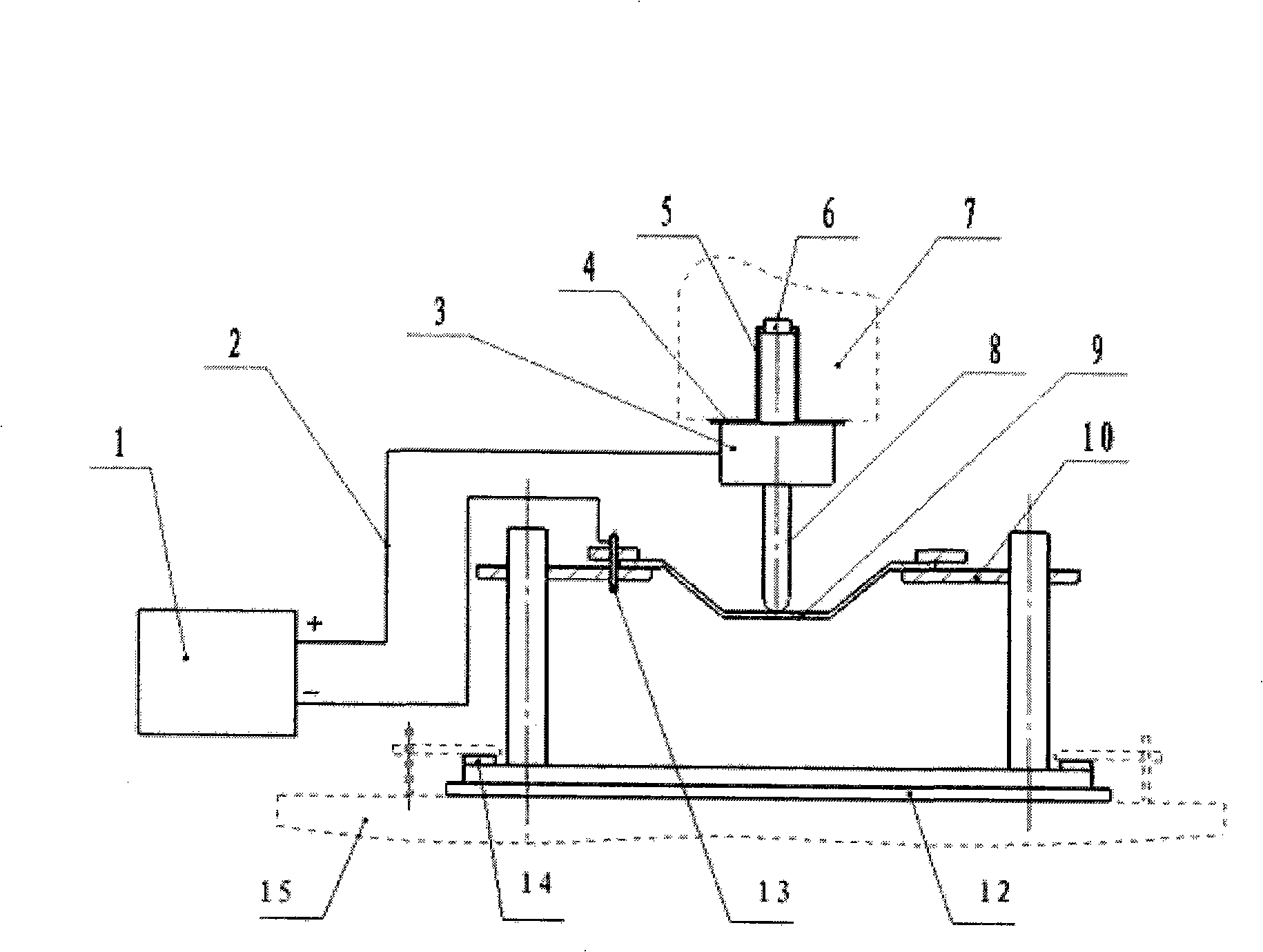

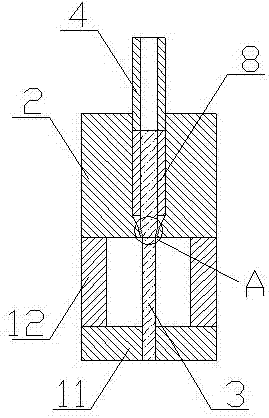

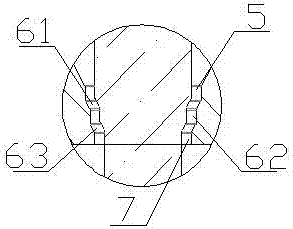

Electrical heating numerical control incremental forming processing method and device for plate

The invention relates to a device and a method of the electrical heating numerical control incremental forming processing of a sheet metal and belongs to the technical field of the sheet metal incremental forming processing. The key points of the device and the method lie in that a large current-carrying wire is used for forming an auxiliary power supply, a forming pressure head, a forming clamp and the sheet metal into a current loop; the power supply provides a low-voltage large current to cause the materials in a processing area to generate joule heat and to be softened in the sheet metal processing and forming so as to ensure the smooth implementation of the incremental forming processing. The heating method is fast in temperature rising, convenient in control and low in price, thus solving the problem that other heating methods are complex to control, improving the processing precision and being favorable for forming complex parts. At the same time, the method is suitable for the incremental processing of sheet metals such as the titanium magnesium sheet metal, and the like, which are hard to be plastically formed at normal temperature.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

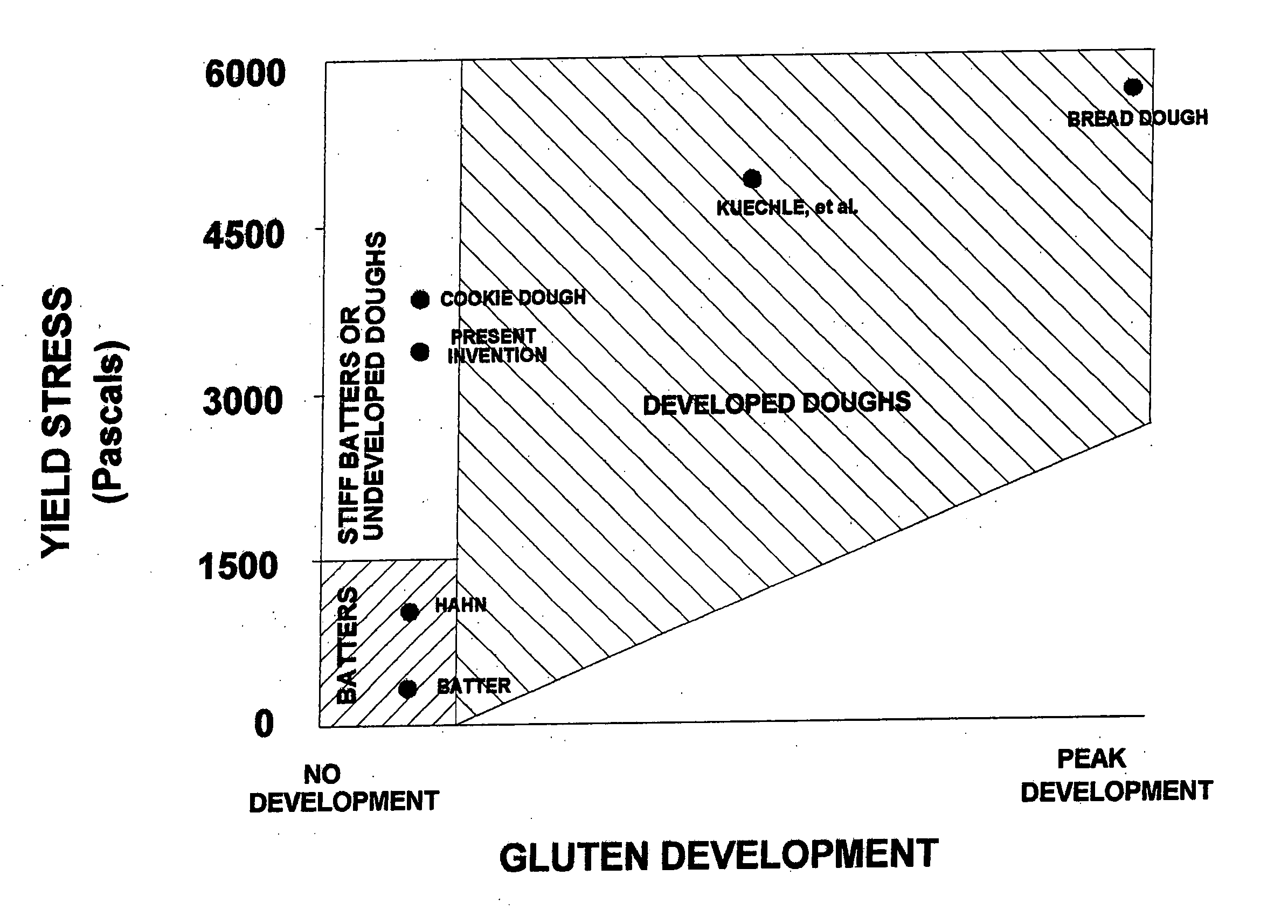

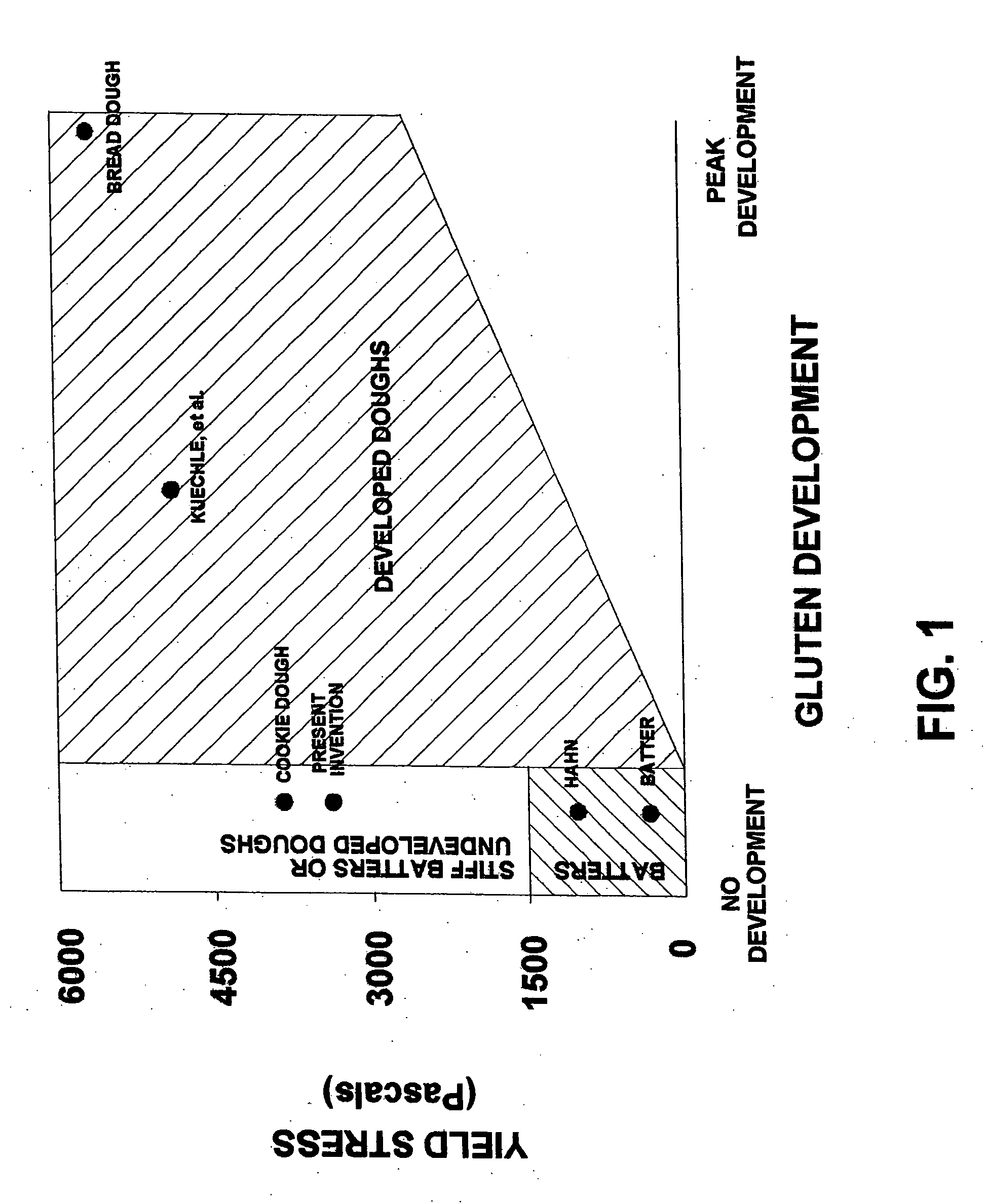

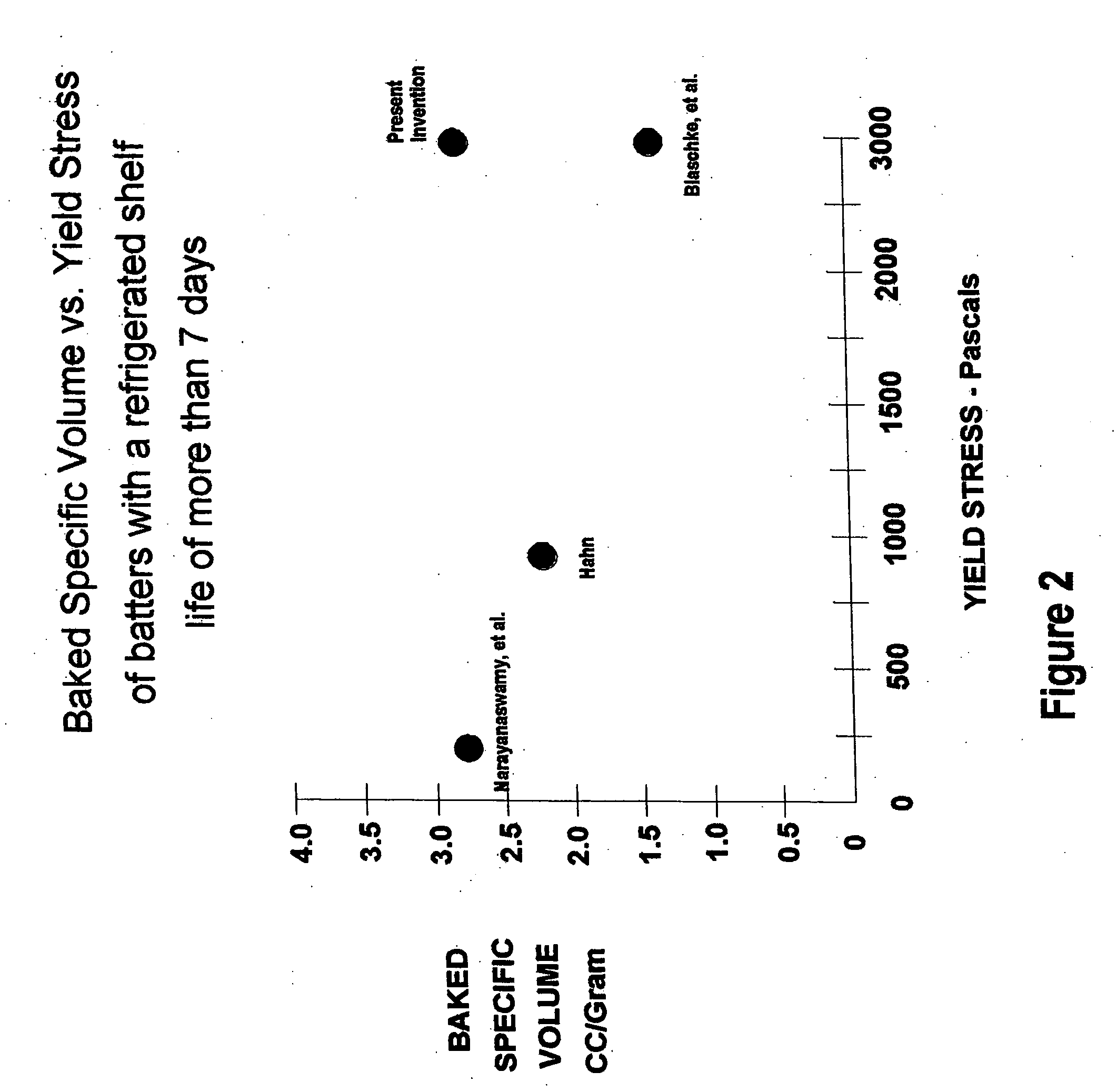

Ready to bake refrigerated batter

InactiveUS20070042099A1High yield stressSimple methodDough treatmentBaking mixturesFood gradeRefrigeration temperature

A ready to bake refrigerated batter containing one or more food grade edible hydrocolloids and having a high yield stress value at refrigeration temperature (>1500 Pa@ 4.5° C.). The batter bakes into products with specific volumes, textures, and overall product quality typical of bakery products made from conventional low yield stress batters. With a high yield stress value, the batter is stiff and sliceable; therefore, it can be formed into shapes convenient for the end user to bake. The stiff, sliceable batter can be used to make muffins, muffin tops, cakes, cupcakes, drop biscuits, scones, pancakes, cinnamon buns, donuts, waffles, brownies, and other bakery products made from batters. The batter can be pumped, extruded, or molded and subsequently sliced, scored, wire cut, stamped, or rolled into many different formats due to the fact that it retains its shape at refrigerated temperatures. Examples of such formats are: individual pieces of any shape (round pucks, hexagon pucks, cubes, etc.) cylinder shaped logs that can be sliced into individual pieces scored or unscored rectangular blocks that can be broken or cut into individual pieces flat sheets The refrigerated pieces can be placed directly onto a baking pan, muffin pan, aluminum muffin cup, cake pan, etc. and immediately baked in the oven to yield a product with a high specific volume. The batters of this application can be made to be stable for more than 75 days at refrigeration temperatures using conventional unmodified atmospheric packaging such as plastic films or plastic pails. Preferably, the packaging material have good moisture and oxygen barrier properties. The invention batter can also be stored frozen.

Owner:OVEN LUVN

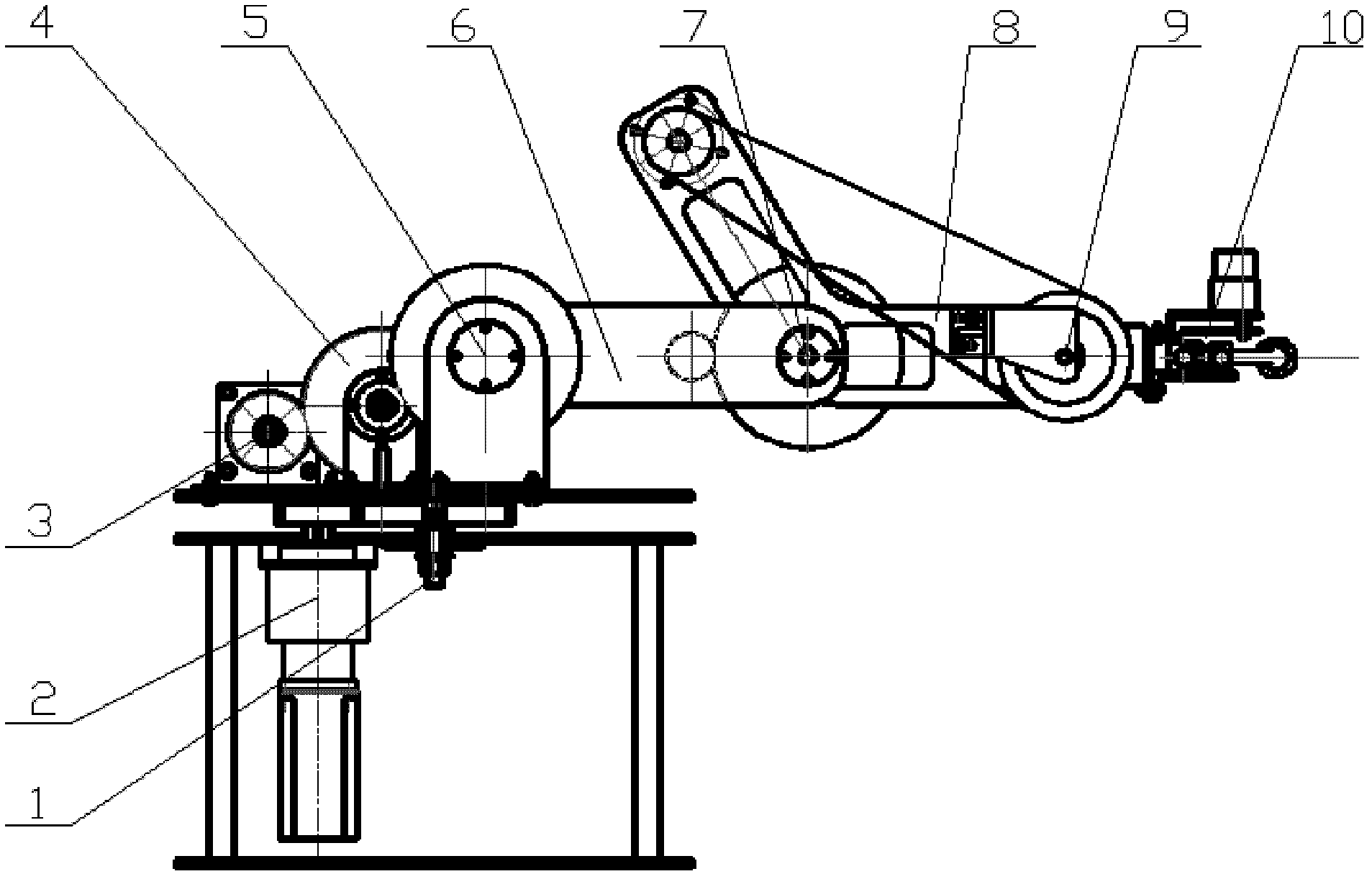

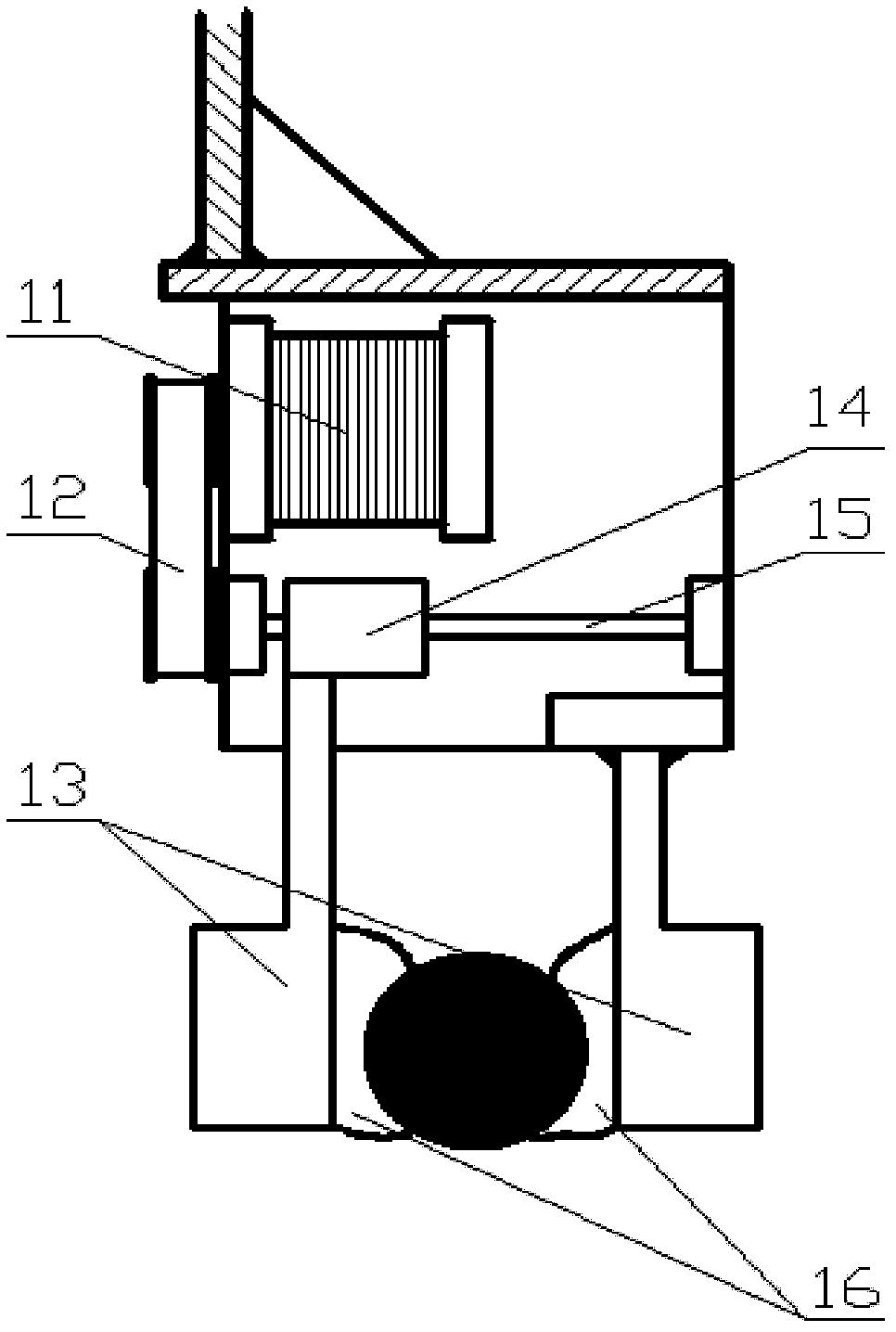

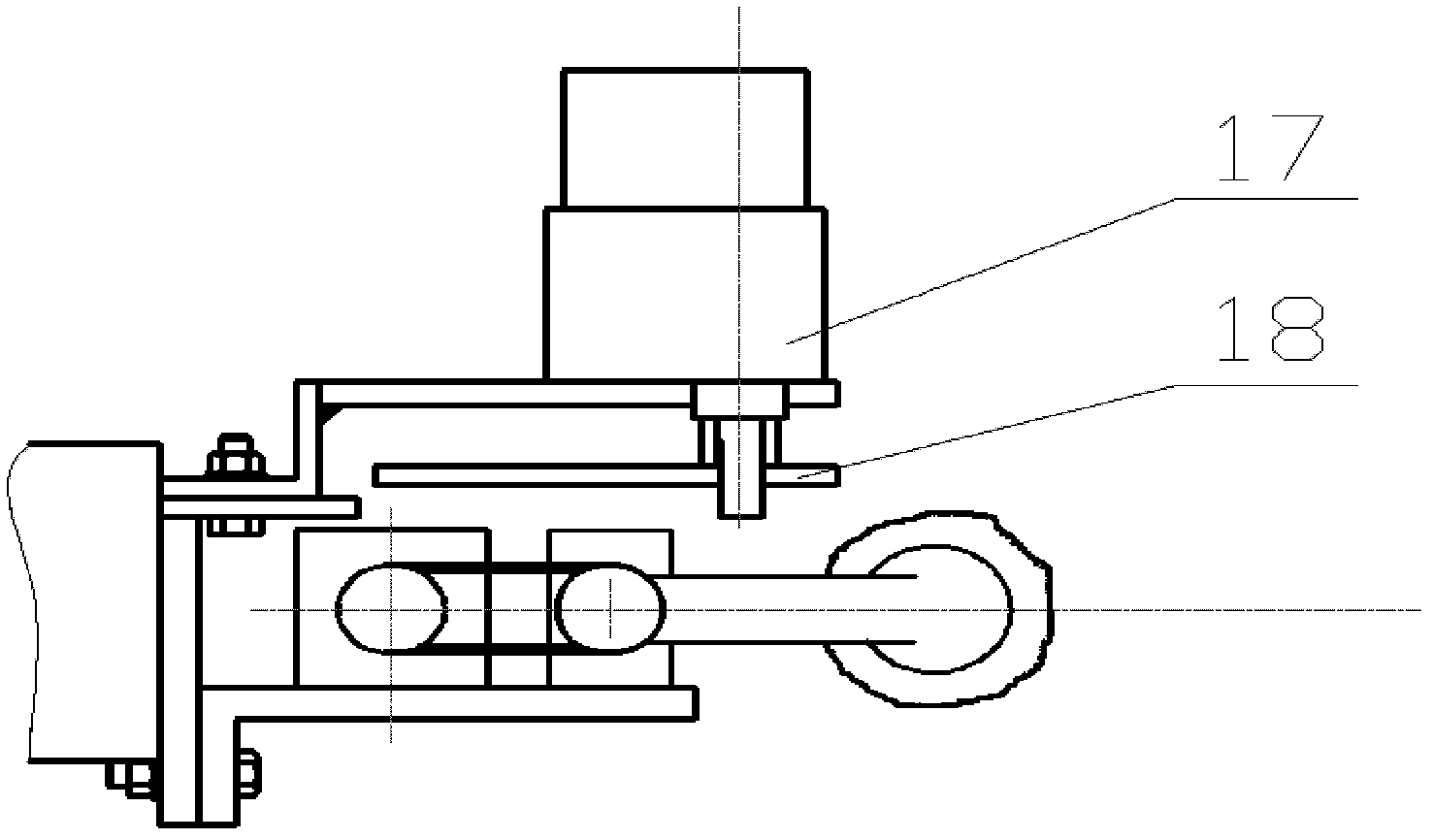

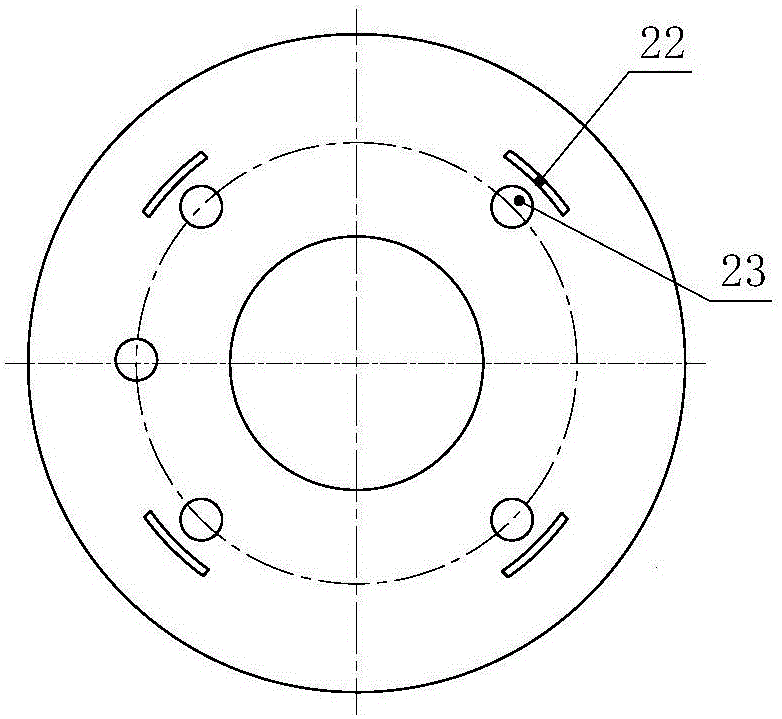

Magnetorheological conformable clamp holder and robot for picking multiple types of fruits and vegetables

The invention discloses a magnetorheological conformable clamp holder and a robot for picking various kinds of fruits and vegetables. The magnetorheological conformable clamp holder comprises a clamping handle, a magnetorheological liquid bag, a shell and a clamping handle translation mechanism; the magnetorheological liquid bag is arranged at the inner side of one end of the clamping handle, is filled with magnetorheological liquid, is connected with a control circuit, and fulfills the function of forming a shape most appropriate for clamping the fruits and vegetables by means of electric magnetization regulation. The robot for picking various kinds of fruits and vegetables comprises a working table, a manipulator and an end effector arranged at the tail end of the manipulator, and the end effector consists of the magnetorheological comformable clamp holder and a shearing mechanism. According to the magnetorheological conformable clamp holder and the robot, when the fruits and vegetables of different kinds are picked, the picking of the fruits can be well performed without replacing clamping devices, and the picking efficiency is high; the picking requirements on different positions within the space can be met, the movement is flexible, and compared with a stepping motor used by the traditional picking manipulator, servo motors can be used for controlling more accurately.

Owner:佛山市中科农业机器人与智慧农业创新研究院

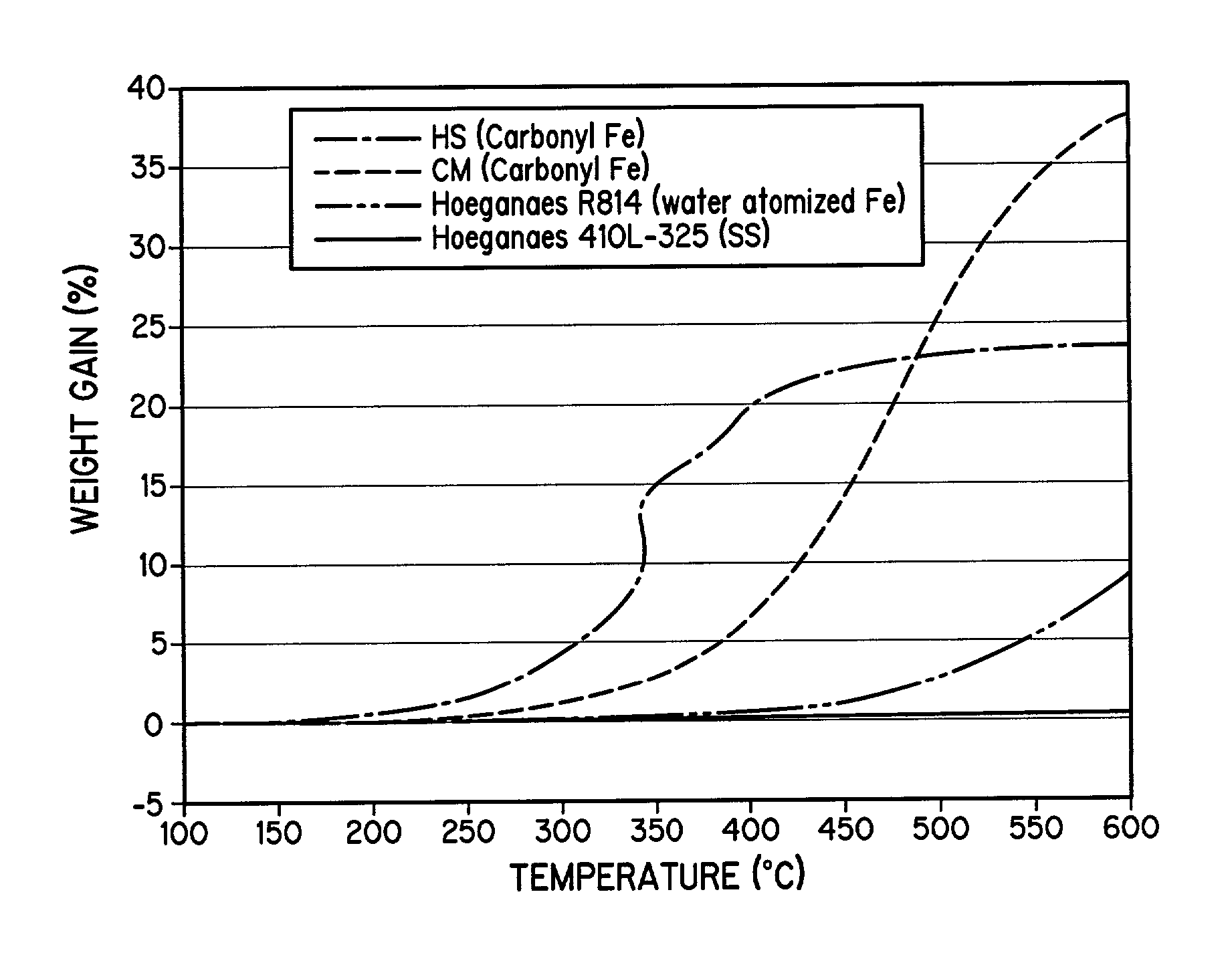

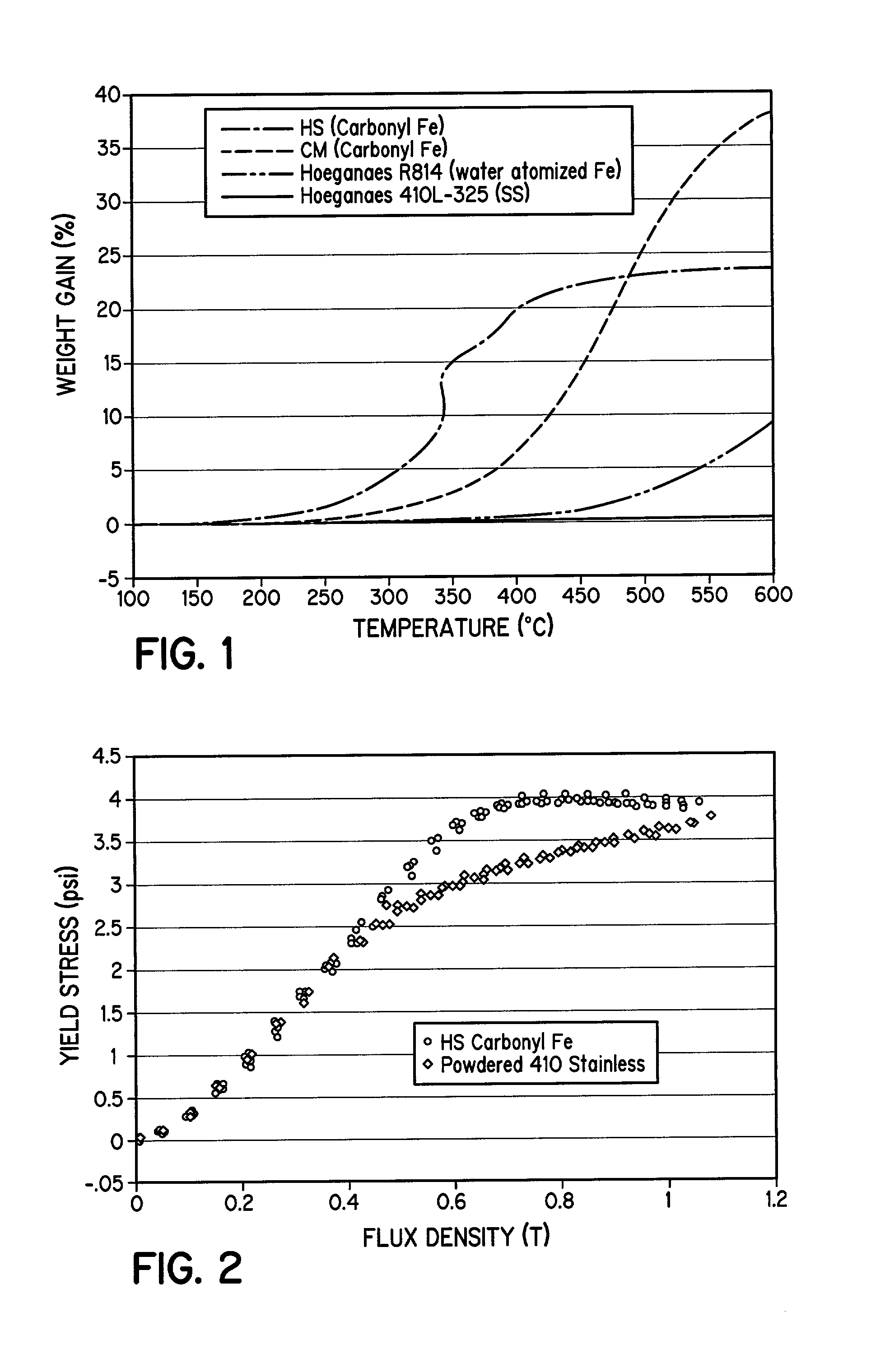

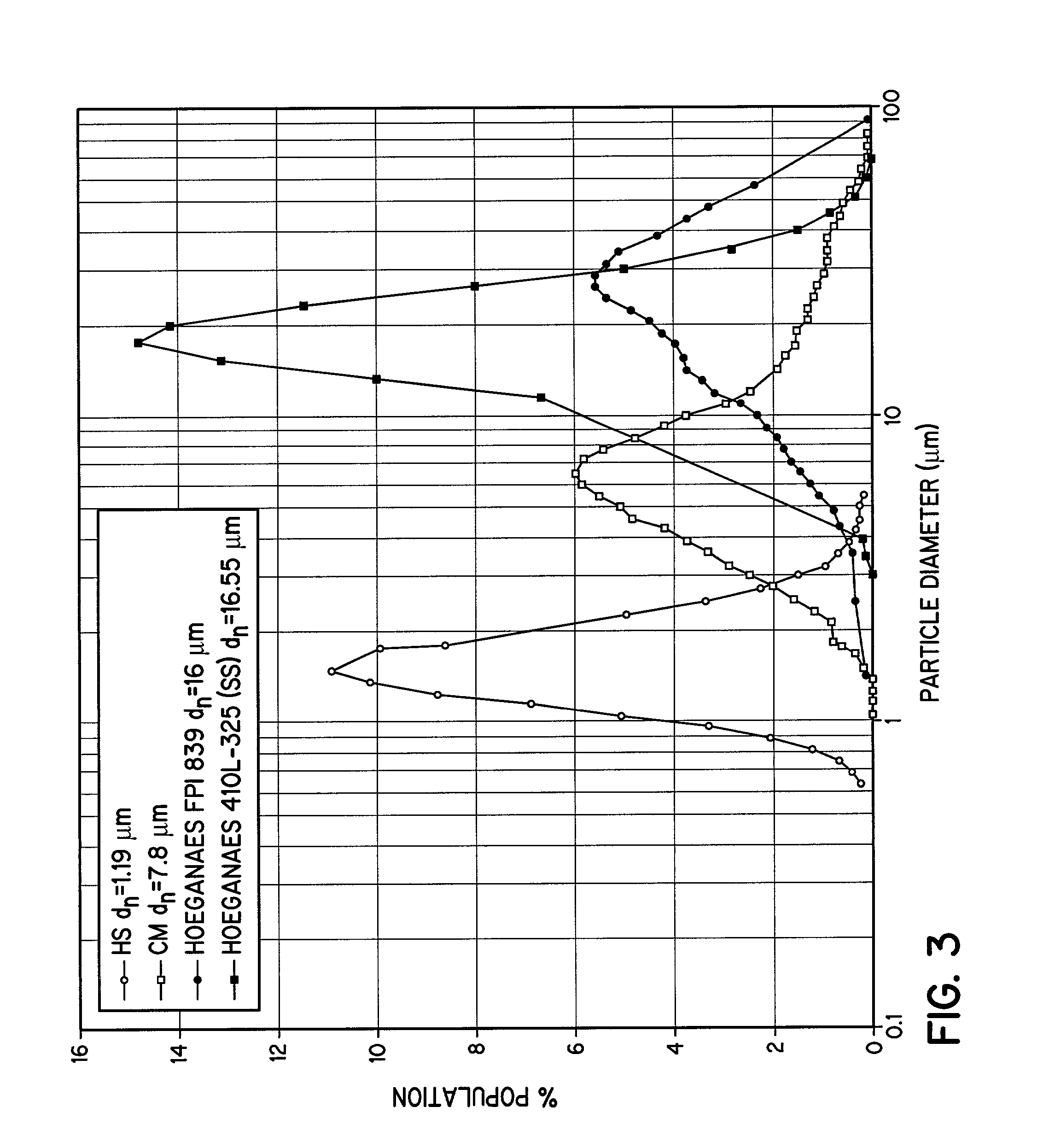

MR fluids containing magnetic stainless steel

InactiveUS20020130305A1High yield stressOther chemical processesLiquid organic insulatorsCorrosion resistantMagnetorheological fluid

A magnetorheological fluid formulation exhibiting consistently high yield stress during use. The MR fluid comprises martensitic or ferritic stainless steel particles prepared by a controlled water or inert gas atomization process. The stainless steel particles are resistant to corrosion and oxidation, are generally smooth and spherical, and maintain their shape and size distribution throughout their use under an applied magnetic field.

Owner:DELPHI TECH INC

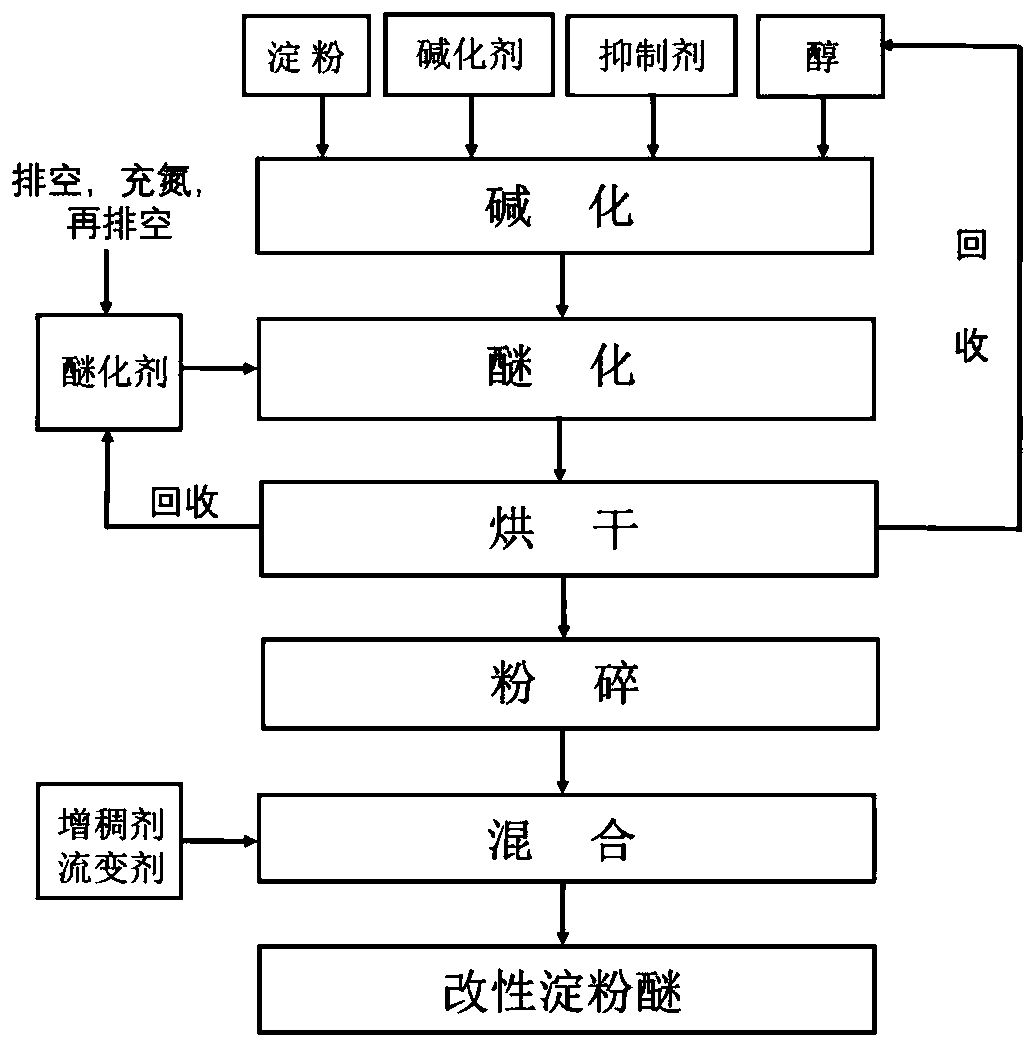

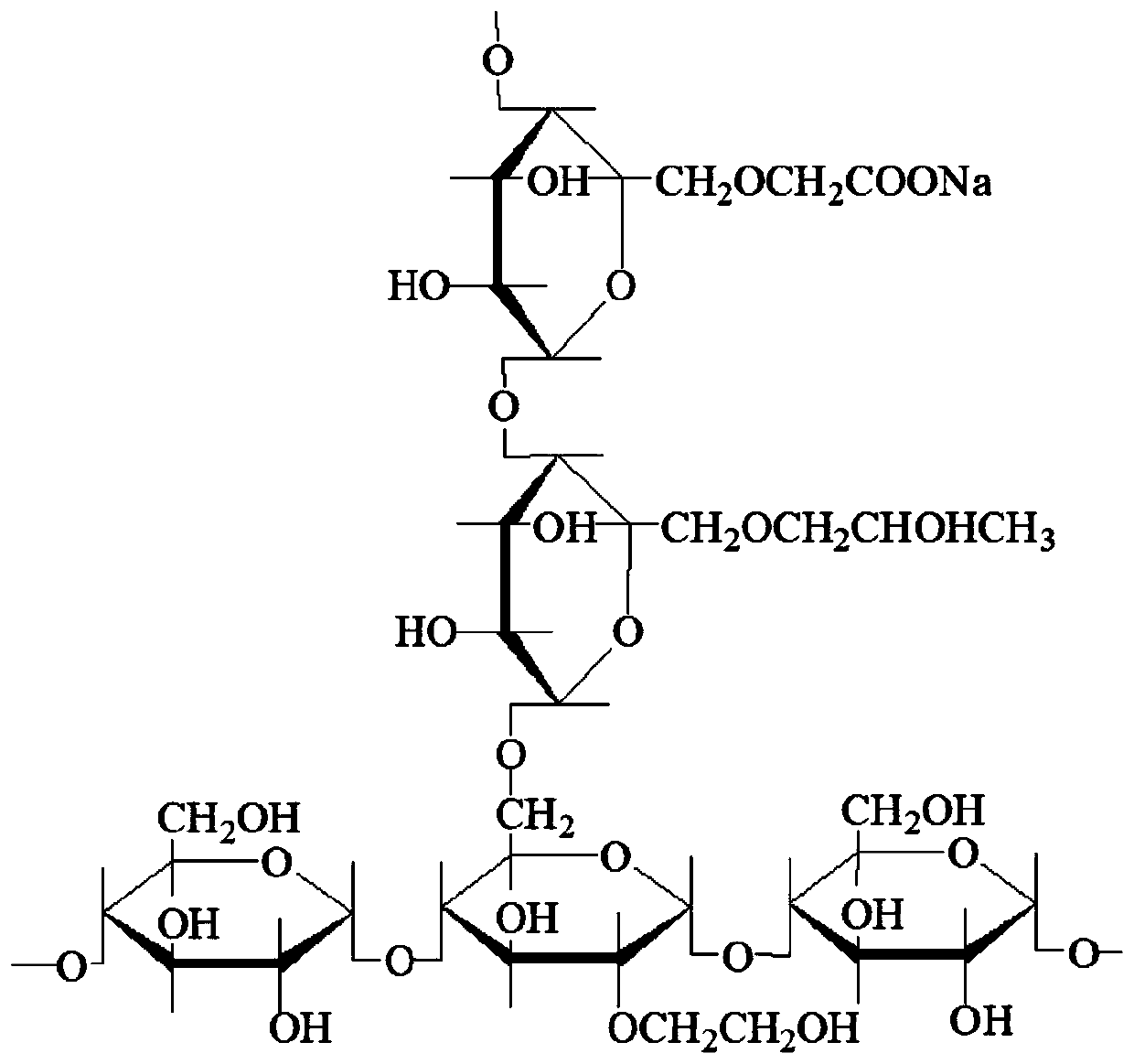

Preparation method of modified starch ether for improving slip performance of ceramic tile glue

ActiveCN110590966AImprove sliding performanceImprove slip resistanceStarch derivtive adhesivesMacromolecular adhesive additivesChemical treatmentEther

The invention relates to the technical field of building additives, in particular to a preparation method of a modified starch ether for improving slip performance of ceramic tile glue. The preparation method comprises the following steps: carrying out one-step etherification chemical treatment modification on starch to obtain starch ether, and carrying out physical modification treatment. According to the preparation method, the complex operation of multi-step etherification in existing modified starch ether preparation process is changed, a starch ether modified product with better performance can be obtained only by one-step simultaneous etherification, and when the obtained product is used for the ceramic tile glue, the slippage performance of ceramic tile glue can be remarkably improved because of adoption of the physical modification treatment; meanwhile, compared with the prior art, the operation conditions of one-step simultaneous etherification treatment are obviously different.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

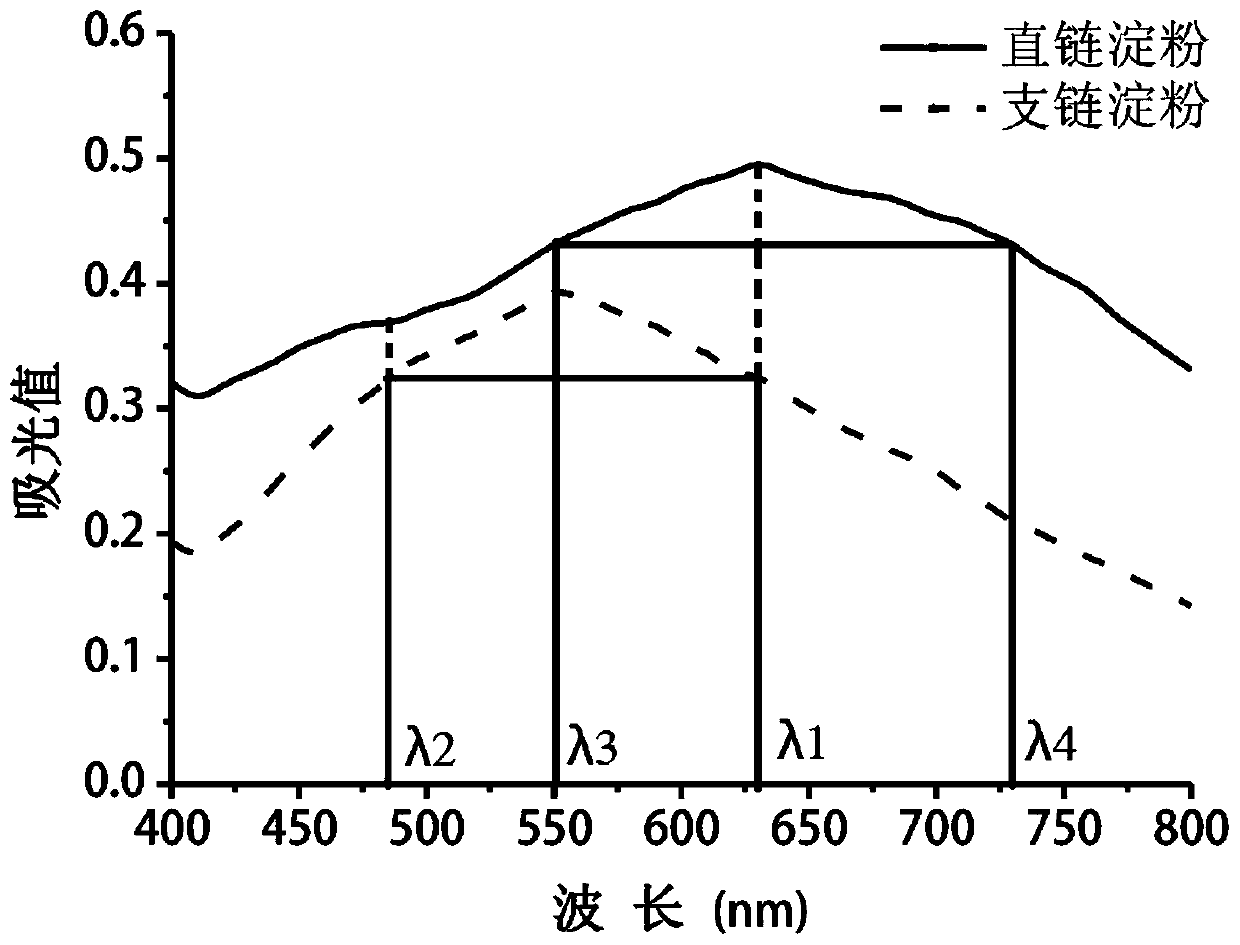

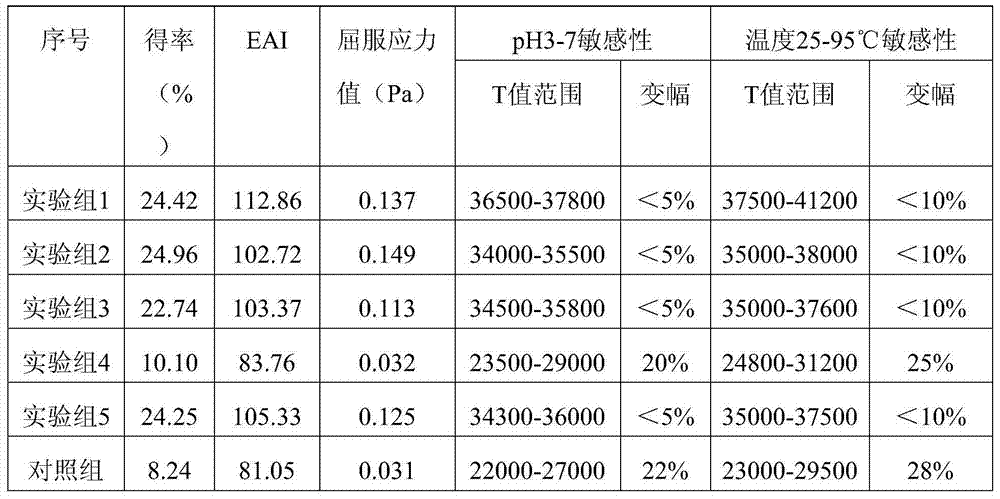

Beet pectin and extraction method thereof

The invention relates to a beet pectin and an extraction method thereof, and concretely relates to a beet pectin with good emulsibility, good emulsification stability and excellent yield stress, and an extraction method thereof. An acid extraction-cooling-pH adjustment-alcohol precipitation technology adopted by the extraction method further improves the emulsion turbidity, the purity and the yield stress of the obtained beet pectin. The beet pectin is especially suitable being used in stabilizers and emulsifiers in the food industry in order to improve the economic benefit of the sugar industry, and provides a good approach for further comprehensive utilization of wastes.

Owner:COFCO NUTRITION & HEALTH RES INST +2

Structuring agent for liquid detergent and personal care products

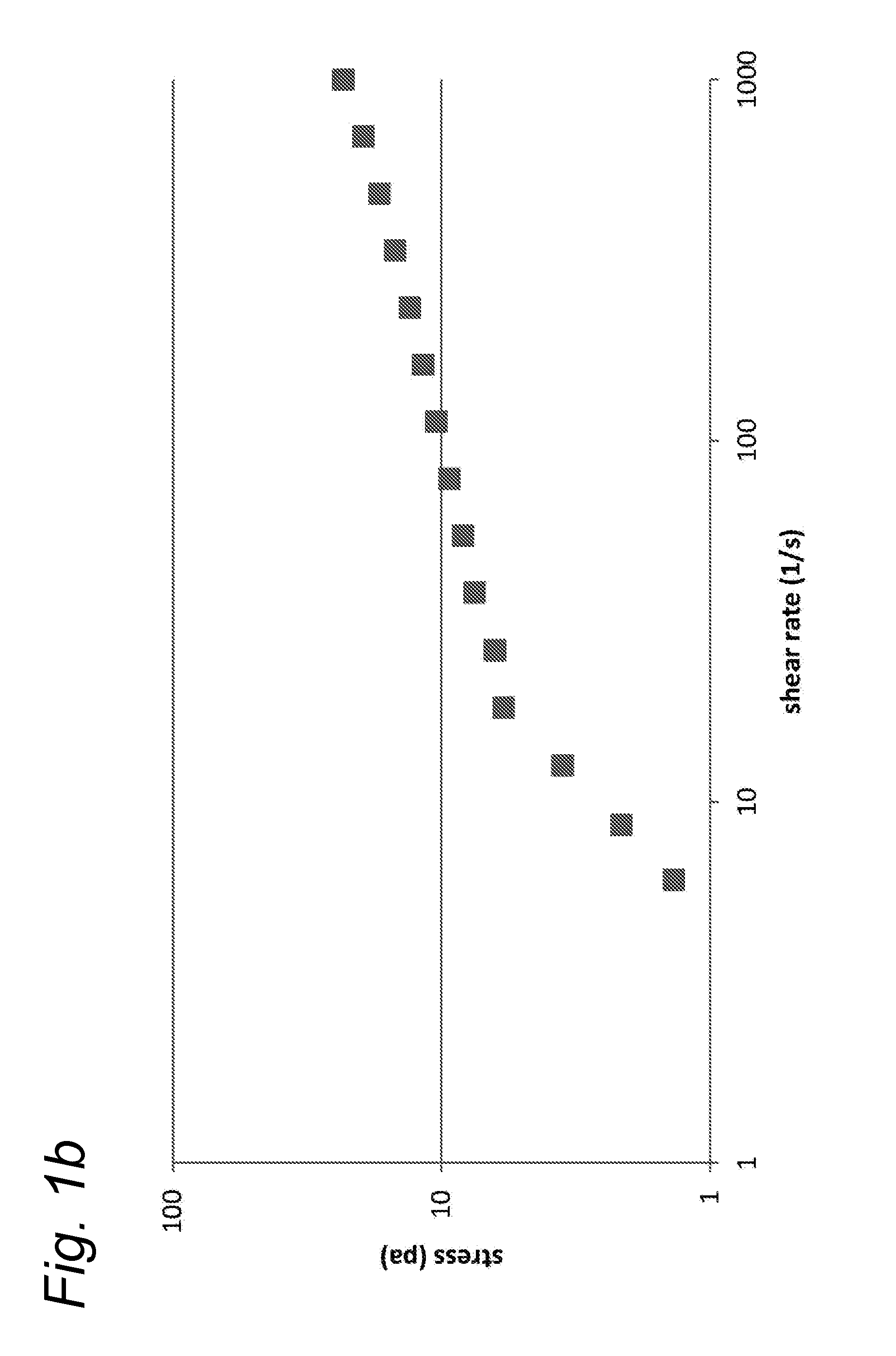

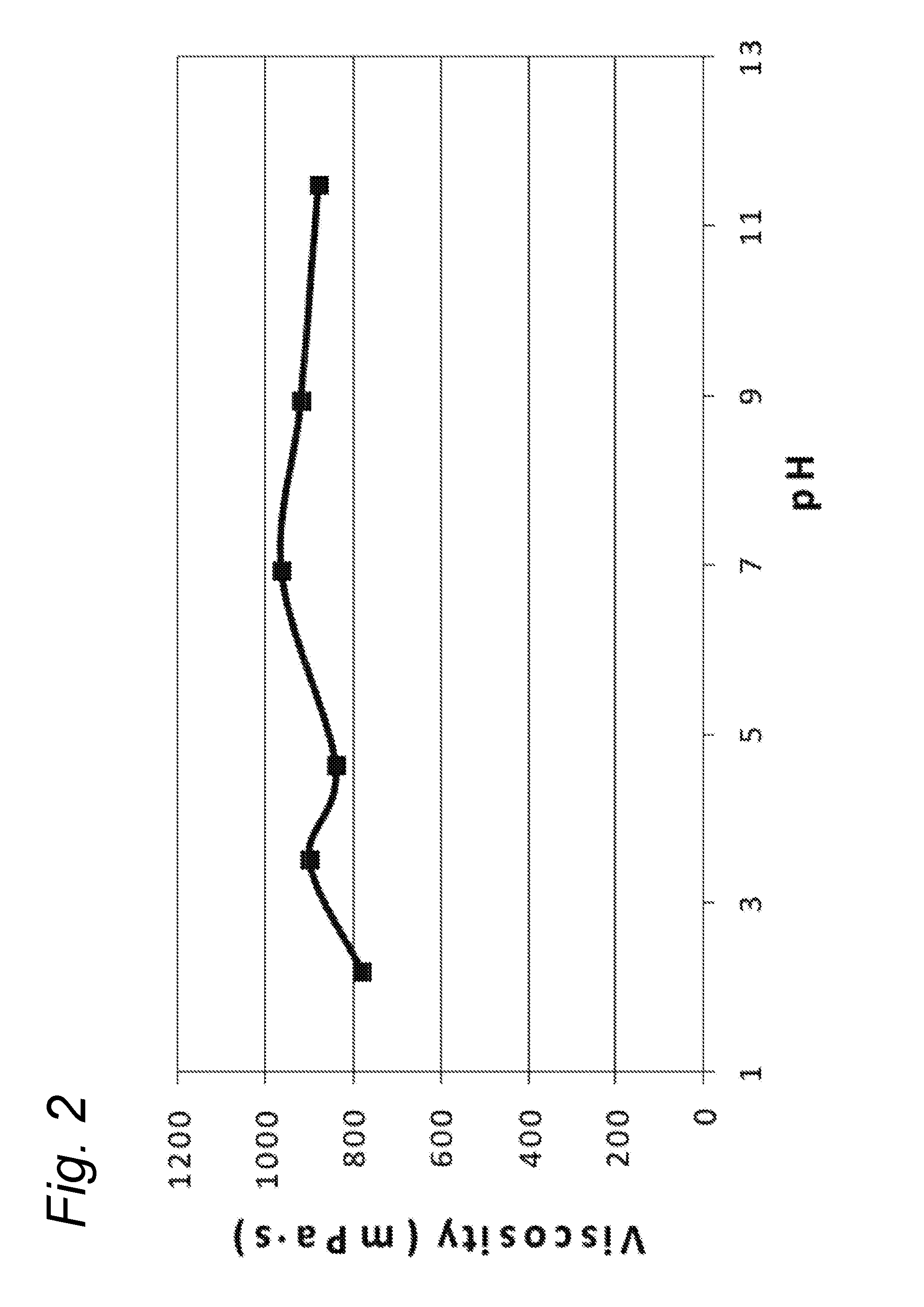

ActiveUS20150210967A1High viscosityStable Structural PropertiesCosmetic preparationsOrganic detergent compounding agentsFiberFibril

This invention relates to an external structuring agent for application in liquid detergent and personal care products. It has been found that cellulose based particles, which comprise cell wall material and their networks of cellulose based fibers and nanofibrils can advantageously be used to structure liquid detergent and personal care products, providing certain benefits that are much sought after in the design of such products. It is assumed that the organization of the cellulose fibrils, as it exists in the parenchymal cell walls, is at least partly retained in the cellulose based particles of the invention, even though part of the pectin and hemicellulose is removed there from. The process of making the structuring agent involves processing under relatively mild conditions, of a biological material that is currently considered a by-product.

Owner:KONINK COOPERATIE COSUN U A

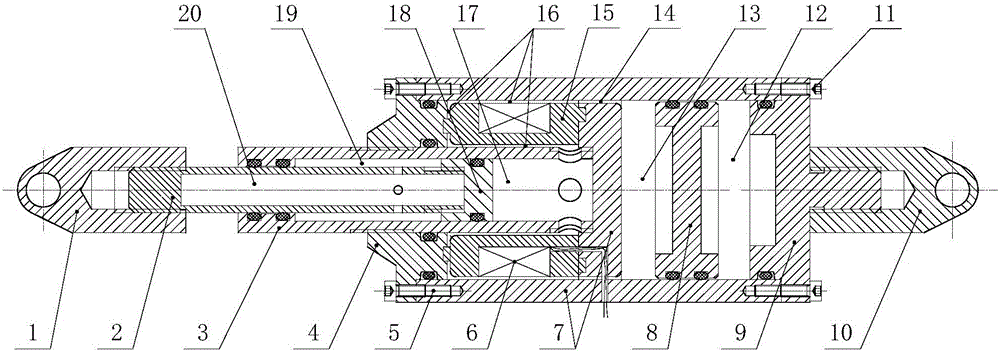

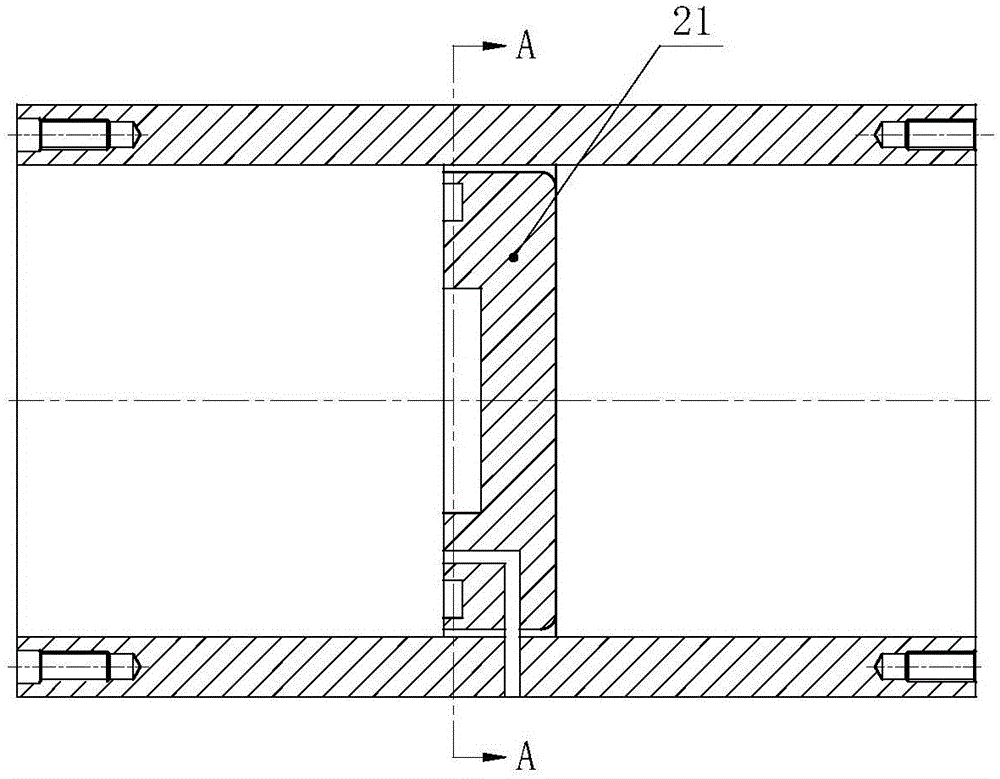

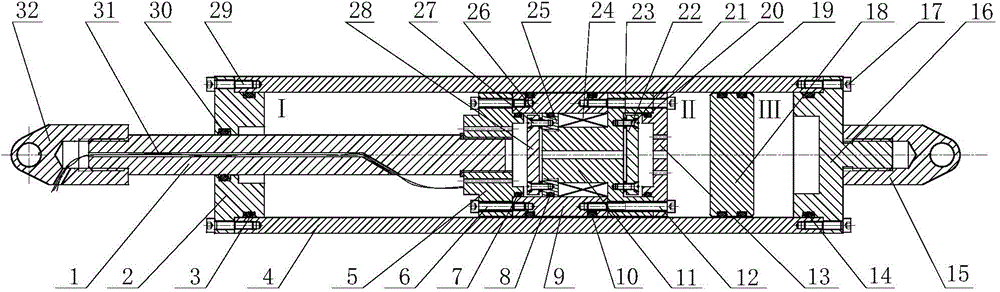

Magnetorheological damper with built-in magnetorheological valve for damping performance control

ActiveCN105003589ALarge damping forceHigh viscositySpringsNon-rotating vibration suppressionEngineeringBody fluid

The invention discloses a magnetorheological damper with a built-in magnetorheological valve for damping performance control, which mainly comprises a piston rod, a piston cylinder, a damper cylinder body, a valve core, a floating piston, end covers, lifting lugs and the like. The piston rod, the damper cylinder body, the valve core, an excitation coil, cylinder liquid flow passages, and U-type liquid flow passages form the built-in magnetorheological valve. When the excitation coil is conductive, flowability of magnetorheological liquid inside effective damping gaps of the cylinder liquid flow passages and the U-type liquid flow passages is reduced due to electromagnetic effects, a pressure difference is formed between a first magnetorheological liquid accommodating cavity and a second magnetorheological liquid accommodating cavity, a damping force applied to the right end surface of the piston head changes, and the purpose that the magnetorheological valve controls the damping performance of the magnetorheological damper is realized. Due to the U-type liquid flow passages, the damping length is effectively increased, and the damping force adjustable range is increased. The magnetorheological damper is particularly suitable for being applied to a shock absorption system for a railway, a train, a bridge and the like, and has the advantages of large adjustment range, compact structure and small size.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Steel sheet and plated steel sheet

ActiveUS20190233926A1High strengthImprove ductilityHot-dipping/immersion processesFurnace typesMaximum diameterMetallurgy

A steel sheet has a specific chemical composition and has a structure represented by, by area ratio, ferrite: 5 to 95%, and bainite: 5 to 95%. When a region that is surrounded by a grain boundary having a misorientation of 15° or more and has a circle-equivalent diameter of 0.3 μm or more is defined as a crystal grain, the proportion of crystal grains each having an intragranular misorientation of 5 to 14° to all crystal grains is 20 to 100% by area ratio. Hard crystal grains A in which precipitates or clusters with a maximum diameter of 8 nm or less are dispersed in the crystal grains with a number density of 1×1016 to 1×1019 pieces / cm3 and soft crystal grains B in which precipitates or clusters with a maximum diameter of 8 nm or less are dispersed in the crystal grains with a number density of 1×1015 pieces / cm3 or less are contained, and the volume % of the hard crystal grains A / (the volume % of the hard crystal grains A +the volume % of the soft crystal grains B) is 0.1 to 0.9.

Owner:NIPPON STEEL CORP

High strength and high magnetic permeability steel sheet for cathode ray tube band and method for production thereof

InactiveUS20060134452A1Steady increase in intensityRealize blockingHot-dipping/immersion processesInorganic material magnetismChemical compositionReduction ratio

A high-strength, high-permeability steel sheet for picture tube band comprises, in mass percent, C: 0.003-0.010%, Si: 0.5-1.0%, Mn: 1.0-2.0%, P: 0.04-0.15%, S: not more than 0.02%, Al: not more than 0.030%, N: not more than 0.004% and the balance of Fe and unavoidable impurities, has a chemical composition satisfying C×Mn×P≧2.5×10−4, and has a ferrite crystal grain diameter of 10-100 μm and a yield stress of 300 N / mm2 or higher, and preferably has a specific permeability μ0.35 in a DC magnetic field of 0.35 Oe of 400 or higher. The steel sheet can be produced by regulating the hot-rolling coiling temperature to 600-700° C. and selecting an appropriate combination of the cold rolling reduction ratio and a final annealing temperature in the range of 750-900° C.

Owner:NISSHIN STEEL CO LTD

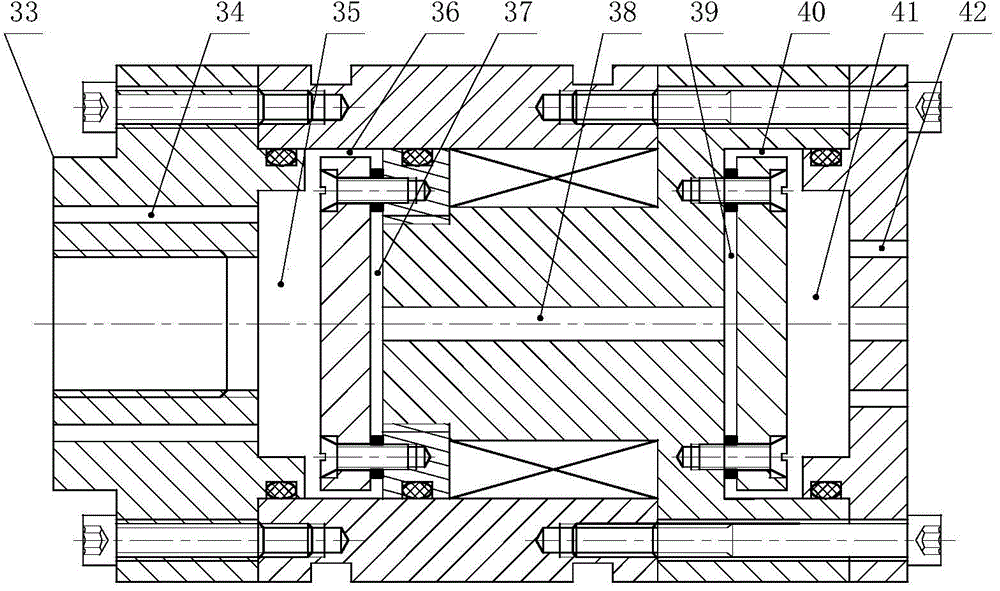

Magneto-rheological damper with mixed flow type fluid flowing channel

ActiveCN104963986AIncrease the lengthIncrease the areaSpringsNon-rotating vibration suppressionCircular discMixed flow

The invention discloses a magneto-rheological damper with a mixed flow type fluid flowing channel. The magneto-rheological damper is mainly composed of a piston rod, a damper end cover, a sleeve, a piston end cover, a valve bush, a valve element, a floating piston, a magnet exciting coil, a positioning disc, magnetic conductive discs, a lifting lug and the like. A fluid flowing channel among the left magnetic conductive disc, the valve bush and the valve element forms a first section of effective damping gap and a second section of effective damping gap. A fluid flowing channel between the right magnetic conductive disc and the valve element forms a third section of effective damping gap and a fourth section of effective damping gap. When electric conduction is carried out on the magnet exciting coil, the four sections of effective damping gaps generate a magnetic field with a certain size, the viscosity of magneto-rheological fluid flowing through the four sections of effective damping gaps is increased, the yield stress is improved, and therefore pressure difference is formed between a first cavity and a second cavity of the damper. The damping force can be effectively controlled by controlling the magnitude of applied current. The magneto-rheological damper is wide in damping force dynamic adjustment range, simple in structure, small in size and particularly applicable to vibration damping systems of railways, automobiles, bridges and the other structures.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Leakage-proof speed reducer lubricating grease composition and preparation method thereof

ActiveCN102433192AGood colloidal stability and thixotropyHigh yield stressLubricant compositionCooling temperatureAntiwear additive

The invention relates a speed reducer lubricating grease composition and a preparation method thereof. The composition comprises 69 to 80 percent of mineral base oil, 12 to 23 percent of ester base oil, 3.2 to 6 percent of thickening agent, 0.6 to 2 percent of dinonyl sulfonate or zinc naphthenate, and 1 to 2.8 percent of solid wear-resistance additive. The preparation method comprises: adding the mineral base oil into a reaction kettle, adding fatty acid, mixing, raising temperature to 80 to 85 DEG C, adding an aqueous solution of lithium hydroxide, heating to 90 to 100 DEG C, and performingsaponification for 1 to 2 hours; raising temperature to 210 DEG C, adding the mineral base oil into the reaction kettle, and quenching, wherein the quenching temperature is kept between 140 to 190 DEG C, and the quenching oil accounts for 14 to 43 percent of the total amount of the base oil; adding the ester base oil, and cooling; when the temperature is below 100 DEG C, adding the dinonyl sulfonate or zinc naphthenate, cooling to a temperature below 80 DEG C, and adding the solid wear-resistance additive; and cooling to a temperature below 60 DEG C, rolling oil by a three-roll machine for three times and filling to obtain finished speed reducer lubricating grease composition. In the invention, the lubricating grease is prepared by one-step direct reaction, the process and equipment are simple and energy-saving, and the quality of the product produced by the process is stable.

Owner:CHINA PETROLEUM & CHEM CORP

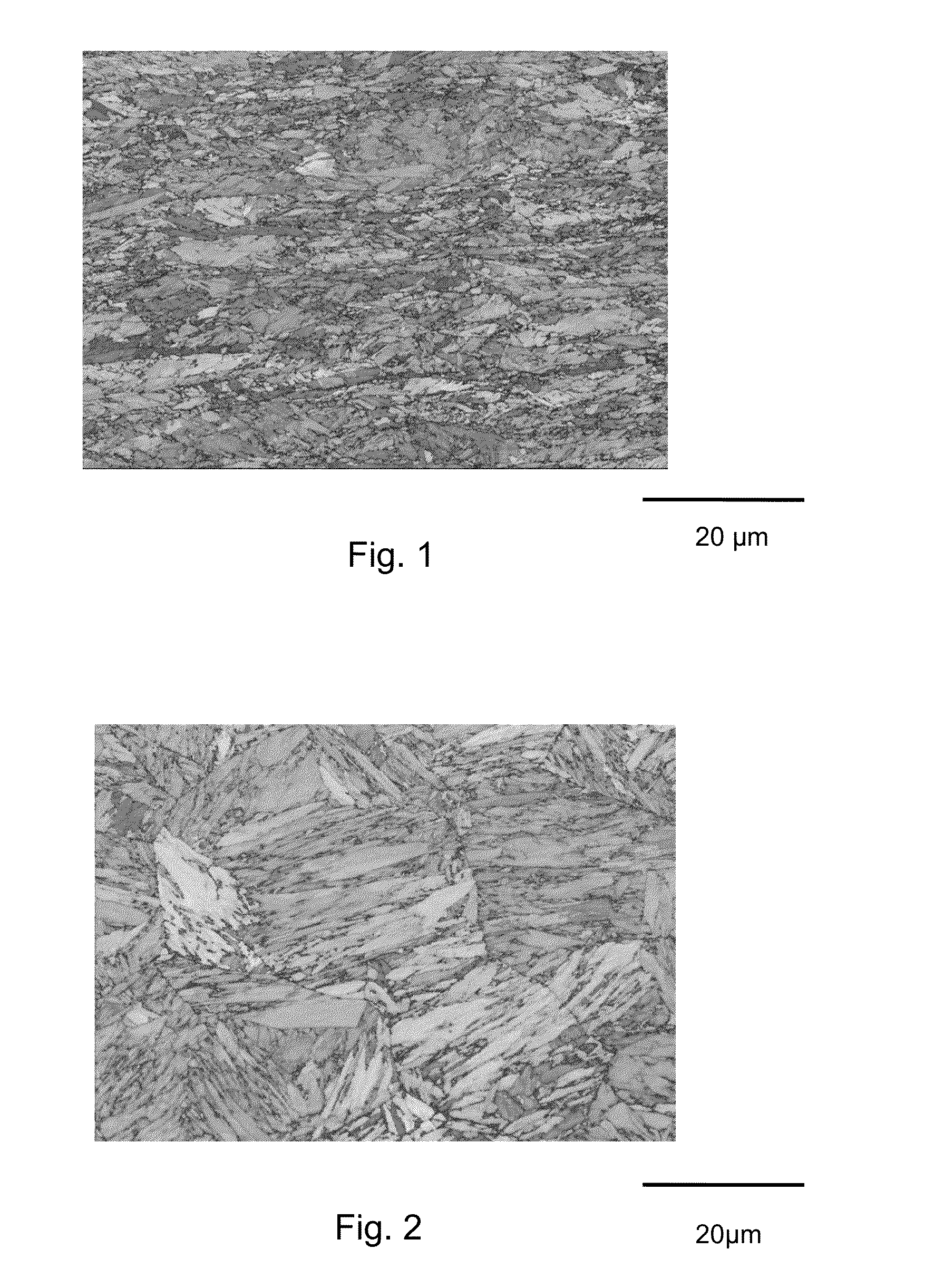

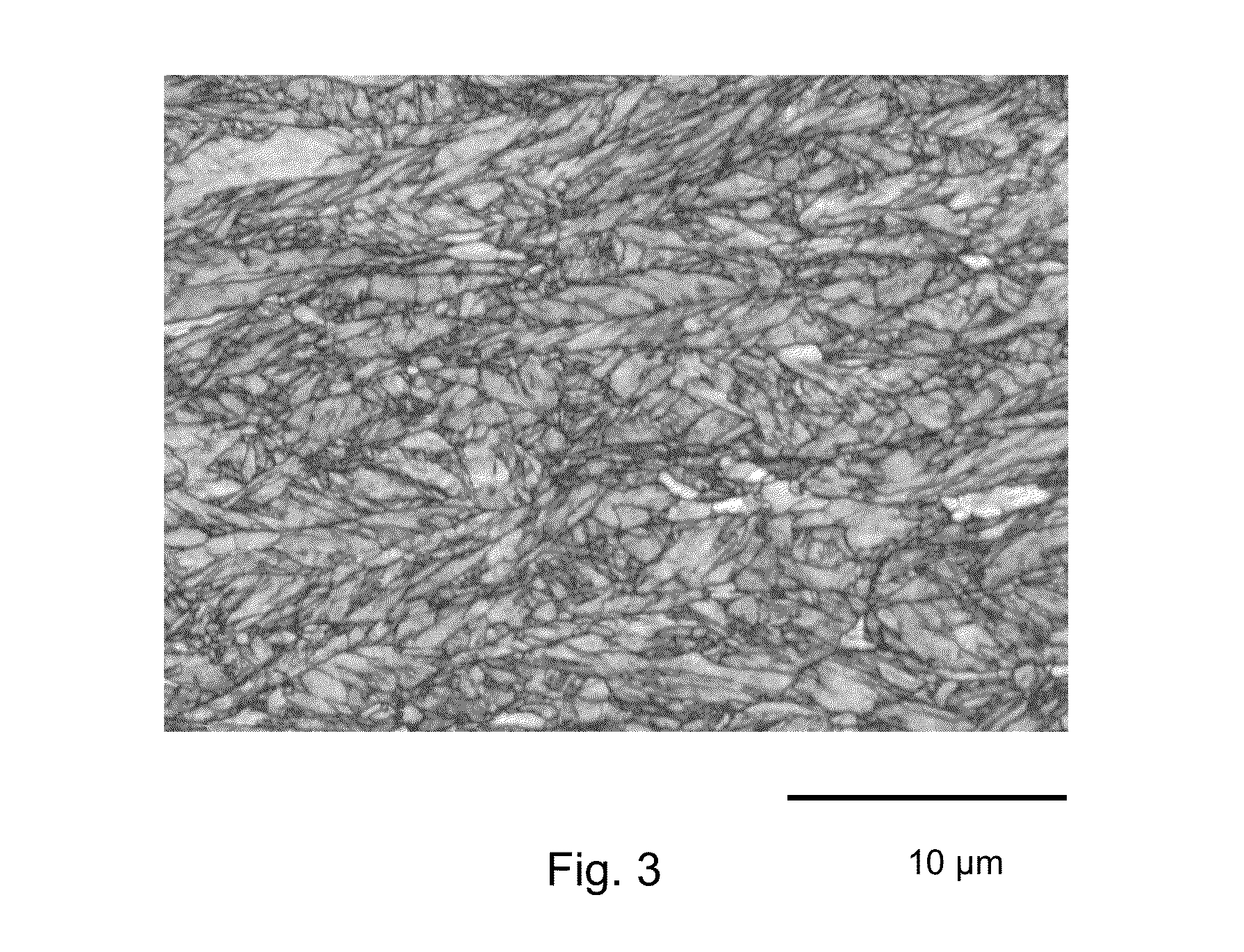

Method for the production of very high strength martensitic steel and sheet or part thus obtained

ActiveUS20140076470A1Great mechanical strengthCarbon content be reduceFurnace typesHeat treatment furnacesQuenching rateCrystallite

The present invention provides a method for the fabrication of a steel sheet with a completely martensitic structure which has an average lath size of less than 1 micrometer and an average elongation factor of the laths is between 2 and 5. The elongation factor of a lath is defined as a maximum dimension divided by and a minimum dimension 1max. The steel sheet has a yield stress greater than 1300 MPa and a mechanical strength greater than (3220(C)+958) megapascals. A composition of a semi-finished steel product includes, expressed in percent by weight, is, 0.15%≦C≦0.40%, 1.5%≦Mn≦3%, 0.005%≦Si≦2%, 0.005%≦Al≦0.1%, 1.8%≦Cr≦4%, 0%≦Mo≦2%, whereby: 2.7%≦0.5 (Mn)+(Cr)+3(Mo)≦5.7%, S≦0.05%, P≦0.1%, optionally: 0%≦Nb≦0.050%, 0.01%≦Ti≦0.1%, 0.0005%≦B≦0.005%, 0.0005%≦Ca≦0.005%. The semi-finished product is reheated to a temperature T1 in the range between 1050° C. and 1250° C., then subjected to a roughing rolling at a temperature T2 in the range between 1000 and 880° C., with a cumulative rate of reduction εa greater than 30%, to obtain a sheet with a completely recrystallized austenitic structure with an average grain size less than 40 micrometers and preferably less than 5 micrometers. The sheet is then partially cooled to prevent a transformation of the austenite at a rate VR1 greater than 2° C. / s to a temperature T3 between 600° C. and 400° C. in the metastable austenitic range, and subjected to a finishing hot rolling at the temperature T3 of the partially cooled sheet, with a cumulative rate of reduction εb greater than 30% to obtain a sheet that is then cooled at a rate VR2 which is greater than the critical martensitic quenching rate.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

InactiveUS20140311631A1High yield stressImprove abilitiesHot-dipping/immersion processesFurnace typesManganeseAlloy

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

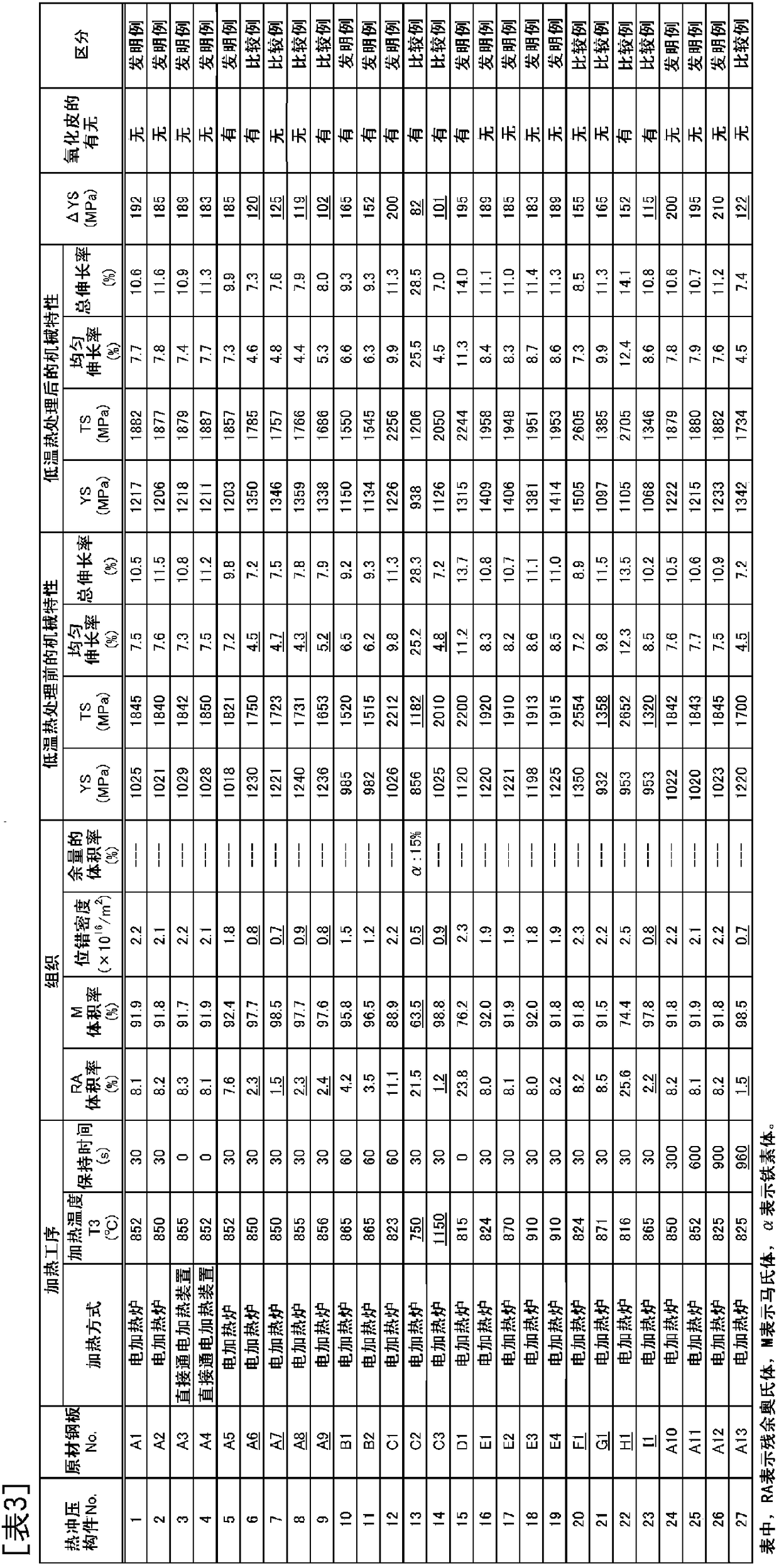

Hot press member and method for producing same

InactiveCN108138289AHigh strengthImprove ductilityHot-dipping/immersion processesFurnace typesVolumetric Mass DensityHigh intensity

Provided is a hot press member that is provided with all of the following properties: high strength, with tensile strength TS being 1,500 MPa or higher; high ductility, with uniform elongation uEL being 6.0% or higher; and excellent heat treatment curability, with yield stress YS increasing 150 MPa or more upon execution of a heat treatment (baking finish treatment). This hot press member is characterized by having a structure containing a prescribed component composition (specifically, a low C content of at least 0.090% and less than 0.30%, and a high Mn content of at least 3.5% and less than11.0%), a martensitic phase comprising 70.0 vol% or more, and a retained austenitic phase comprising 3.0-30.0 vol%, inclusive, and in that the dislocation density thereof is 1.0x10<16> m<2> or higher.

Owner:JFE STEEL CORP

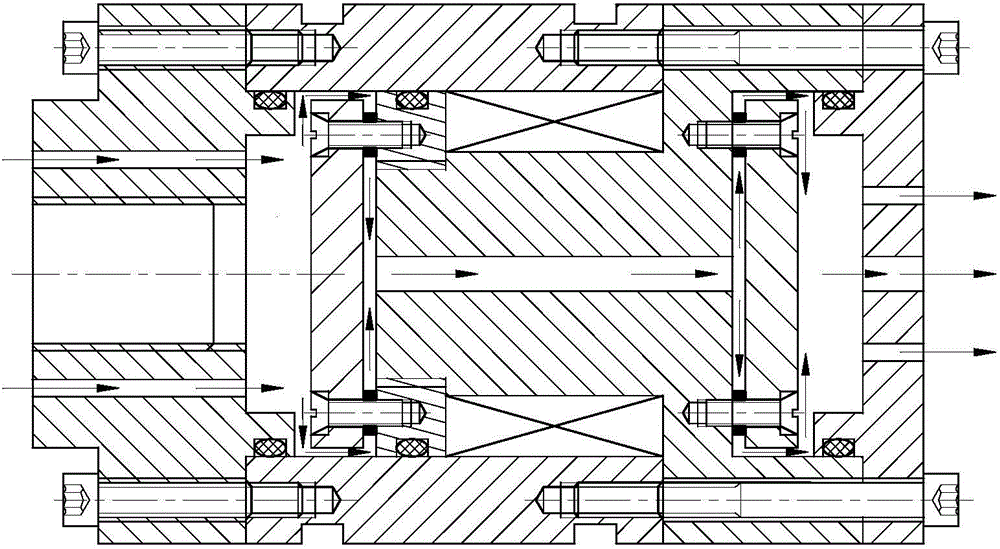

Continuous plastic processing forming die of magnesium alloy sectional material and forming method

The invention relates to a continuous plastic processing forming die of a magnesium alloy sectional material and a forming method. The forming die comprises a base, a concave die, an extruding needle and an extruding rod, wherein the base comprises a base plate and support plates; the concave die is mounted on the two support plates; a forming hole is formed in the middle of the concave die; the extruding needle penetrates through the forming hole to be fixedly connected with the base plate; the extruding rod adopts a tubular structure, the lower end of the extruding rod sleeves the extruding needle from the upper end of the extruding needle, the inner wall of the extruding rod is clung to the extruding needle and the outer wall of the extruding rod is clung to the concave die; the forming method comprises the following steps: 1) fixedly mounting the forming die on an extruding machine; 2) heating the concave die to a certain temperature; 3) placing a hollow billet in the forming hole of the concave die; 4) driving the extruding rod through a moving die of the extruding machine to extrude the hollow billet. According to the continuous plastic processing forming die of the magnesium alloy sectional material and the forming method, the forming of magnesium alloy pipes is easier, the pipe structure and texture uniformity is improved, the industrial production is realized, and the production efficiency is improved.

Owner:CHONGQING UNIV OF TECH

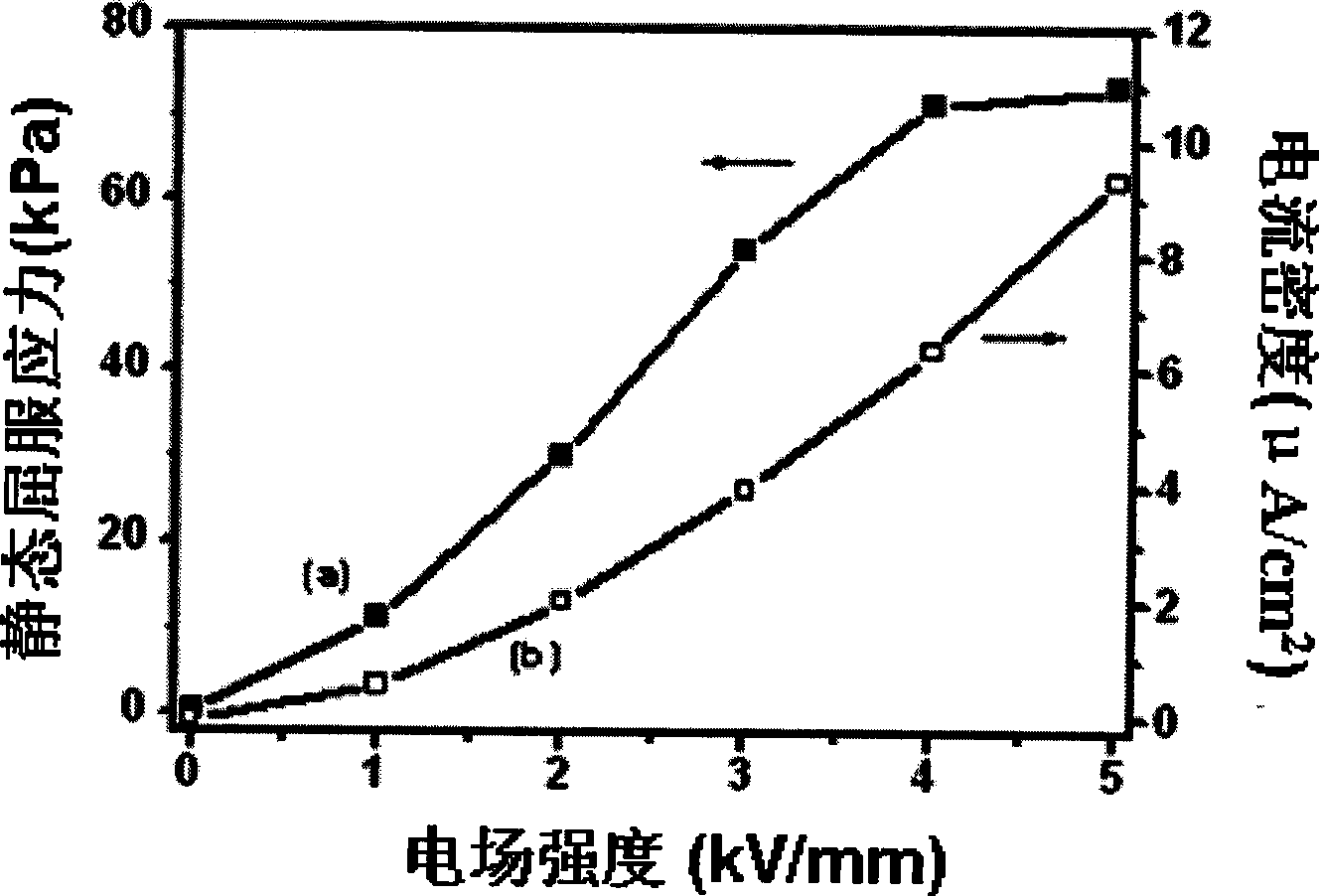

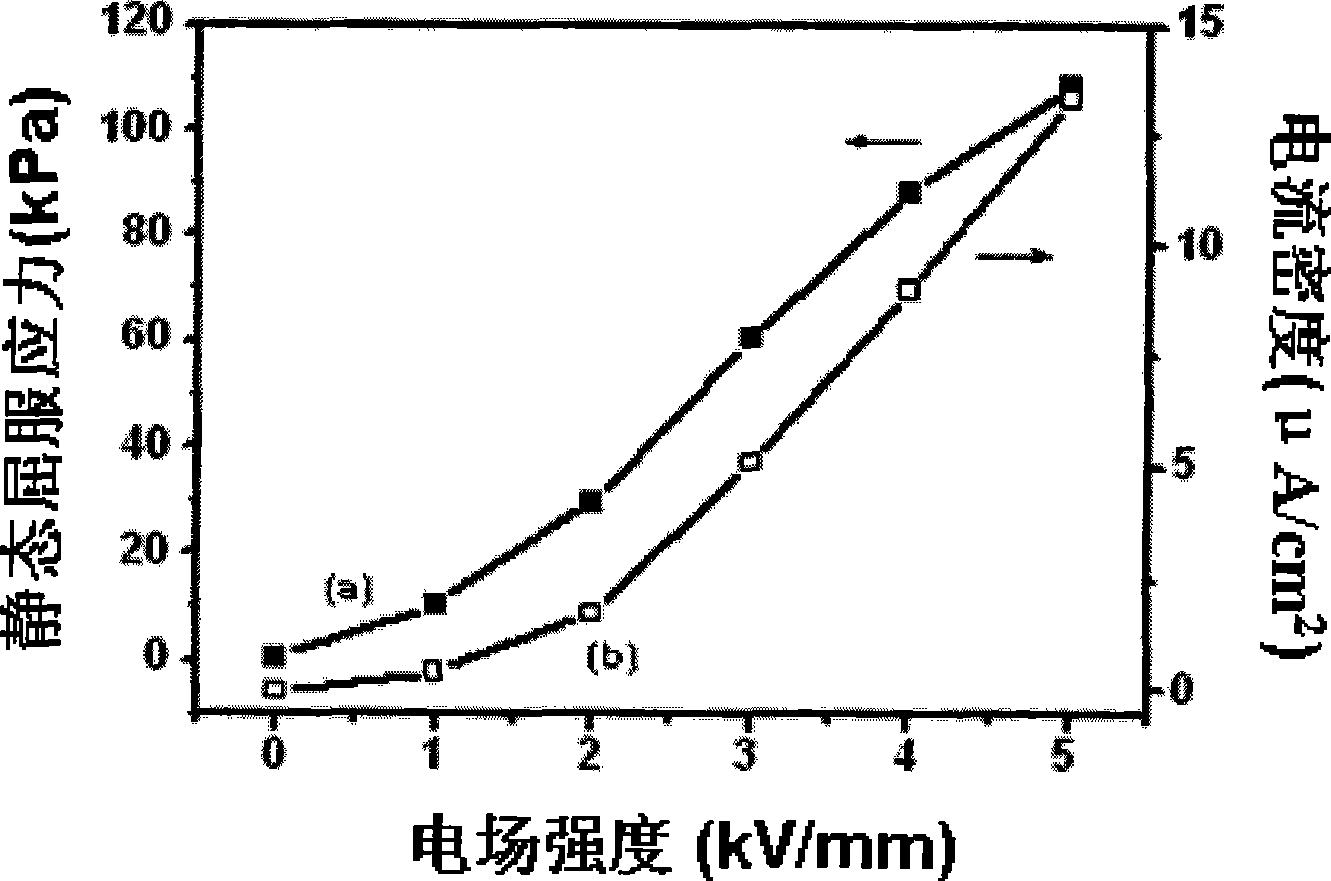

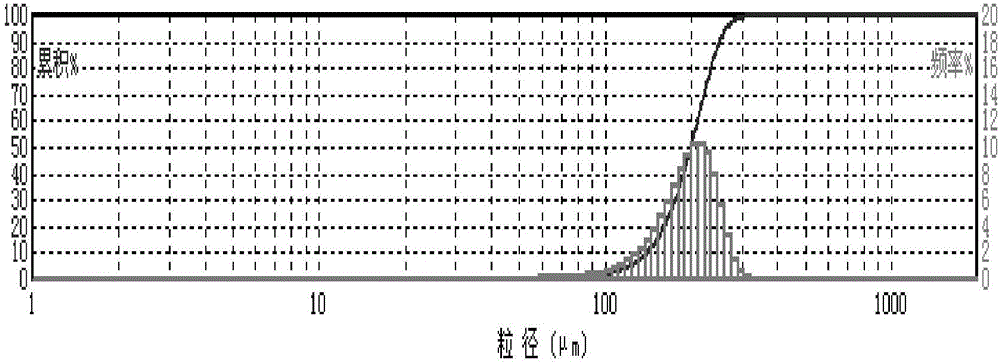

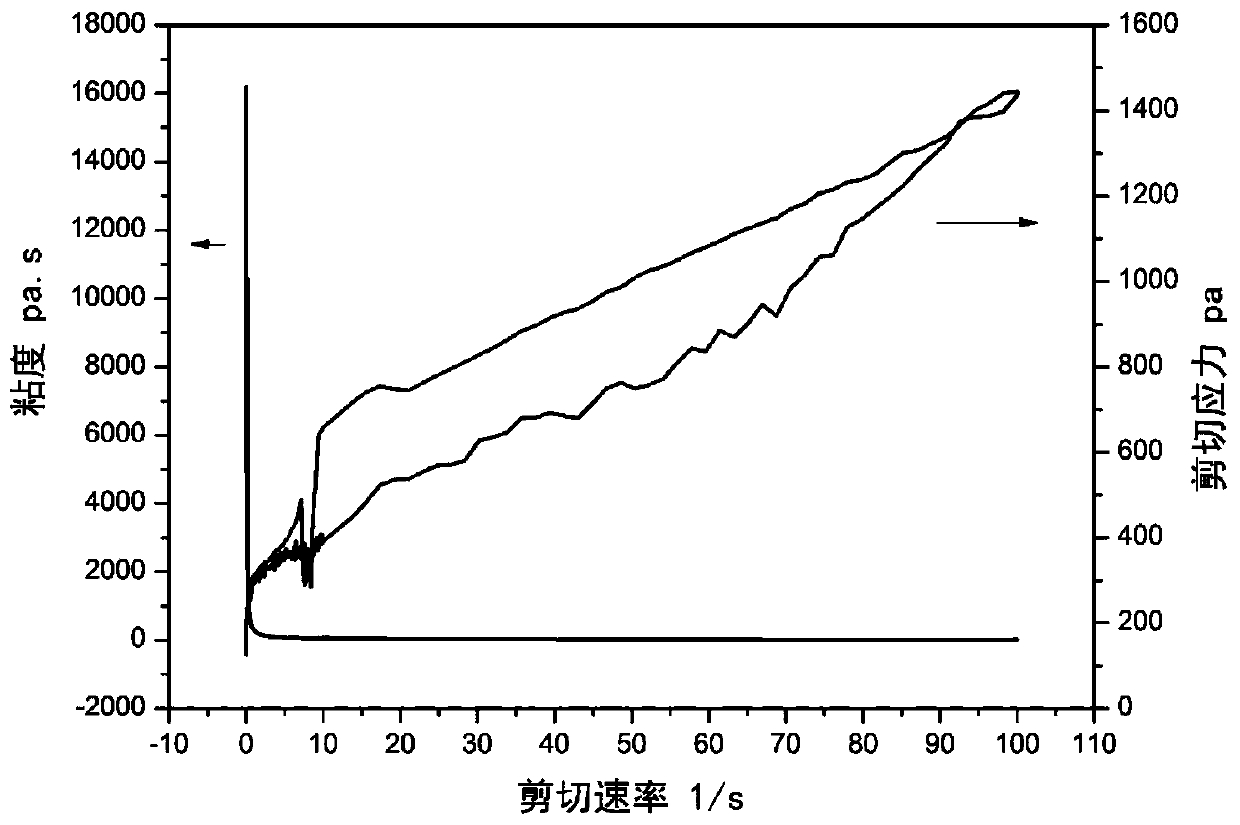

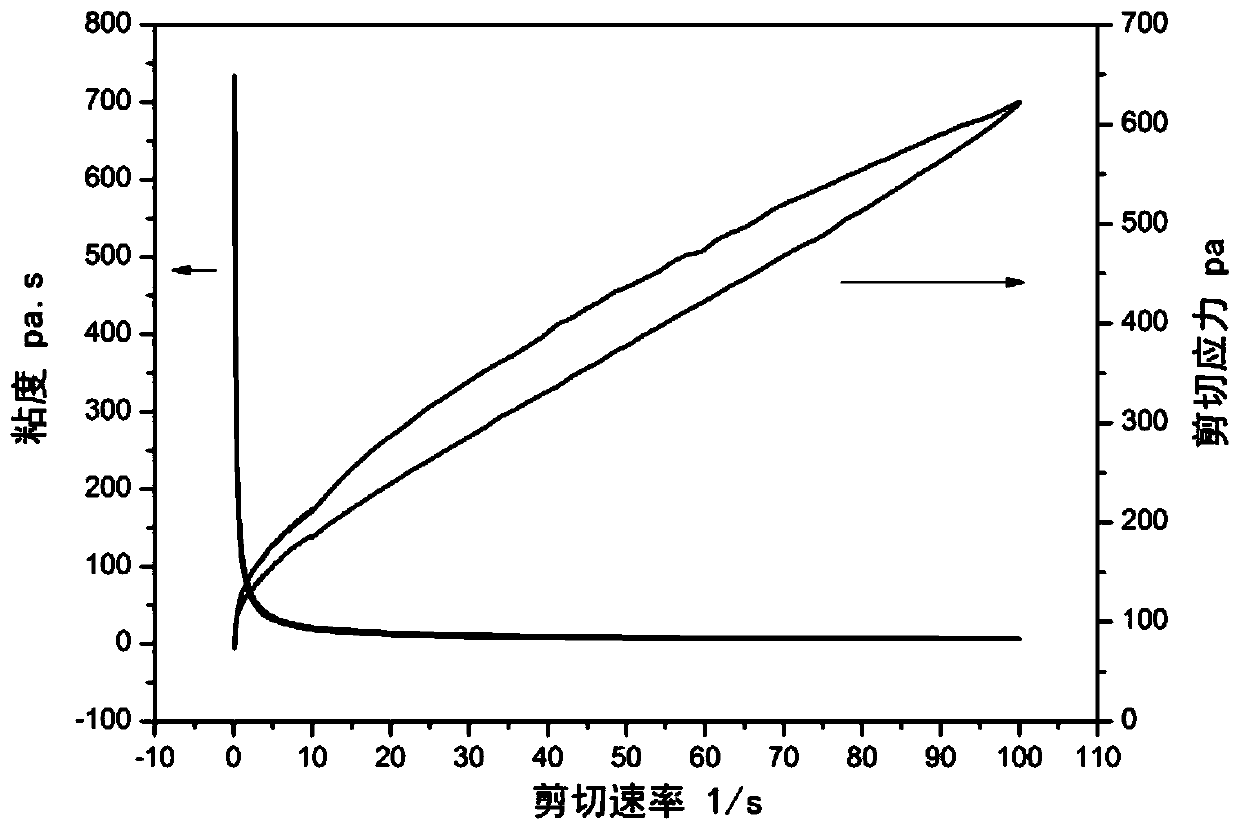

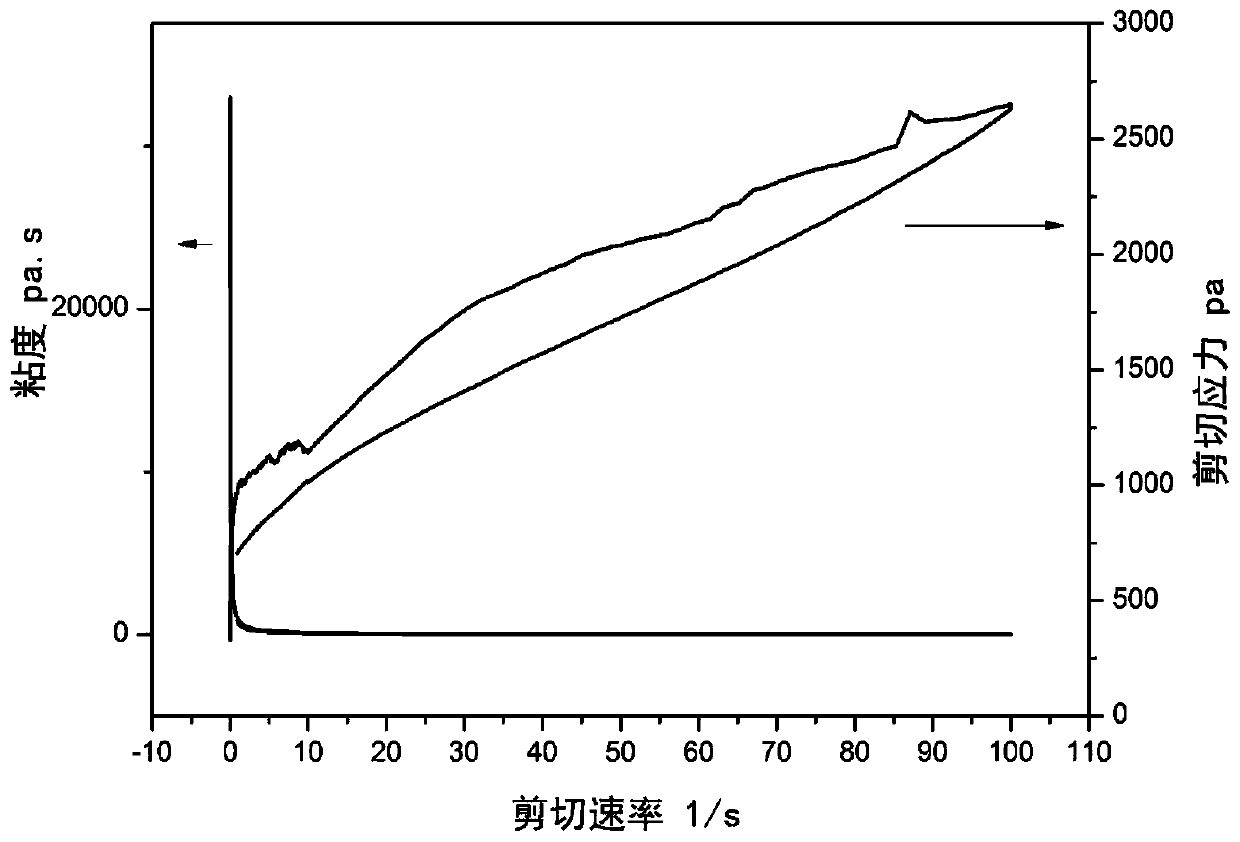

Bar-shaped perovskite deposited compound giant electrorheological fluid and preparation method thereof

The invention relates to a bar-shaped perovskite deposited compound giant electrorheological fluid and preparation method thereof, including a continuous phase using a liquid insulating medium and a disperse phase dispersed therein. The invention is characterized in that the disperse phase is nanometer bar-shaped perovskite deposited compound particles, and the mass concentration of the disperse phase is 10% to 75%. The preparation method is as follows: the bar-shaped perovskite deposited compound particles are firstly synthesized by coprecipitation method, and then mixed with the liquid insulating medium with low specific inductive capacity uniformly so that the perovskite compound giant electrorheological fluid is prepared. Compared with the existing technology, the perovskite compound giant electrorheological fluid provided by the invention has simple preparation method, easy operation, low material cost and short preparation period, and the obtained giant electrorheological fluid has the advantages of low initial viscosity, great stress yield, low leakage current density, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Kitchen oil dirt cleaner and preparation method thereof

InactiveCN106635456AHigh yield stressProlong the action timeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsInhalationEngineering

The invention relates to kitchen oil dirt cleaner and a preparation method thereof; the kitchen oil dirt cleaner is prepared from, by weight, 0.1-1.0% of polyacrylate copolymer, 1.0-15.0% of a surfactant, 1.0-20.0% of an oil dirt softener, 0.1-15.0% of an oil dirt hydrolyzing agent, 0.1-5.0% of a bactericide, 0.1-2.0% of an aid, and the balance of deionized water. The kitchen oil dirt cleaner can stay on a vertical surface for 1 min and longer, the cleaner has longer time to act with the dirt, and cleaning effect is improved; the kitchen oil dirt cleaner of the invention has large particle size for spraying, and is less atomized so that less irrigating smell and inhalation occurs; the kitchen oil dirt cleaner of the invention has a killing rate of > / =99.9% for Escherichia coli and Staphylococcus aureus, and can remove dirt and provide better bactericidal effect.

Owner:GUANGZHOU LIBY

Polymer networks

InactiveUS20060148960A1High crystallinityStrength and breaking elongation be lowPaper coatingCoatingsLong chainMechanical property

Polymer mixtures containing a first long-chain polymer and a second short-chain polymer. The structural parameters of the two polymers are coordinated in such a way that a polymeric material is obtained which is easier to process while being provided with improved mechanical properties and in part also improved thermal properties compared with the first polymer at suitable conditions for producing the polymer mixture as a result of networks being formed and heterocrystallization taking place.

Owner:INNOGEL AG

Thixotropic ceramic paste material for stereolithography and preparation method thereof

ActiveCN110330329AHigh solid contentReduce skimAdditive manufacturing apparatusCeramic shaping apparatusMetallurgySolid content

The invention relates to a thixotropic ceramic paste material for stereolithography and a preparation method thereof. The thixotropic ceramic paste material mainly comprises the following components by mass percentage: 70-85wt% of ceramic powder; 3-15wt% of a thixotropic agent; and 10-25wt% of light cured resin. The preparation method mainly includes the steps of: conducting ball-milling and stirring on the ceramic powder, light cured resin, a dispersant and a photoinitiator, then adding the thixotropic agent for further ball-milling and stirring so as to obtain the paste. The ceramic paste has the characteristics of high solid content, significant thixotropy, yield pseudoplasticity and the like, greatly facilitates the forming process and improves the quality of components, and can be used in medical, aerospace, national defense and industrial fields.

Owner:WUHAN UNIV OF TECH

Iron-based steel powder composition, method for producing a sintered component and component

ActiveUS8398739B2Easy to processHigh yield stressConnecting rodsTransportation and packagingImpurityFerric

A composition comprising water atomised prealloyed iron-based steel powder is provided which steel powder comprises by weight-%: 0.2-1.5 Cr, 0.05-0.4 V, 0.09-0.6 Mn, less than 0.1 Mo, less than 0.1 Ni, less than 0.2 Cu, less than 0.1 C, less than 0.25 O, less than 0.5 of unavoidable impurities, the balance being iron. A method of forming a sintered component, and component additionally are provided.

Owner:HOGANAS AB

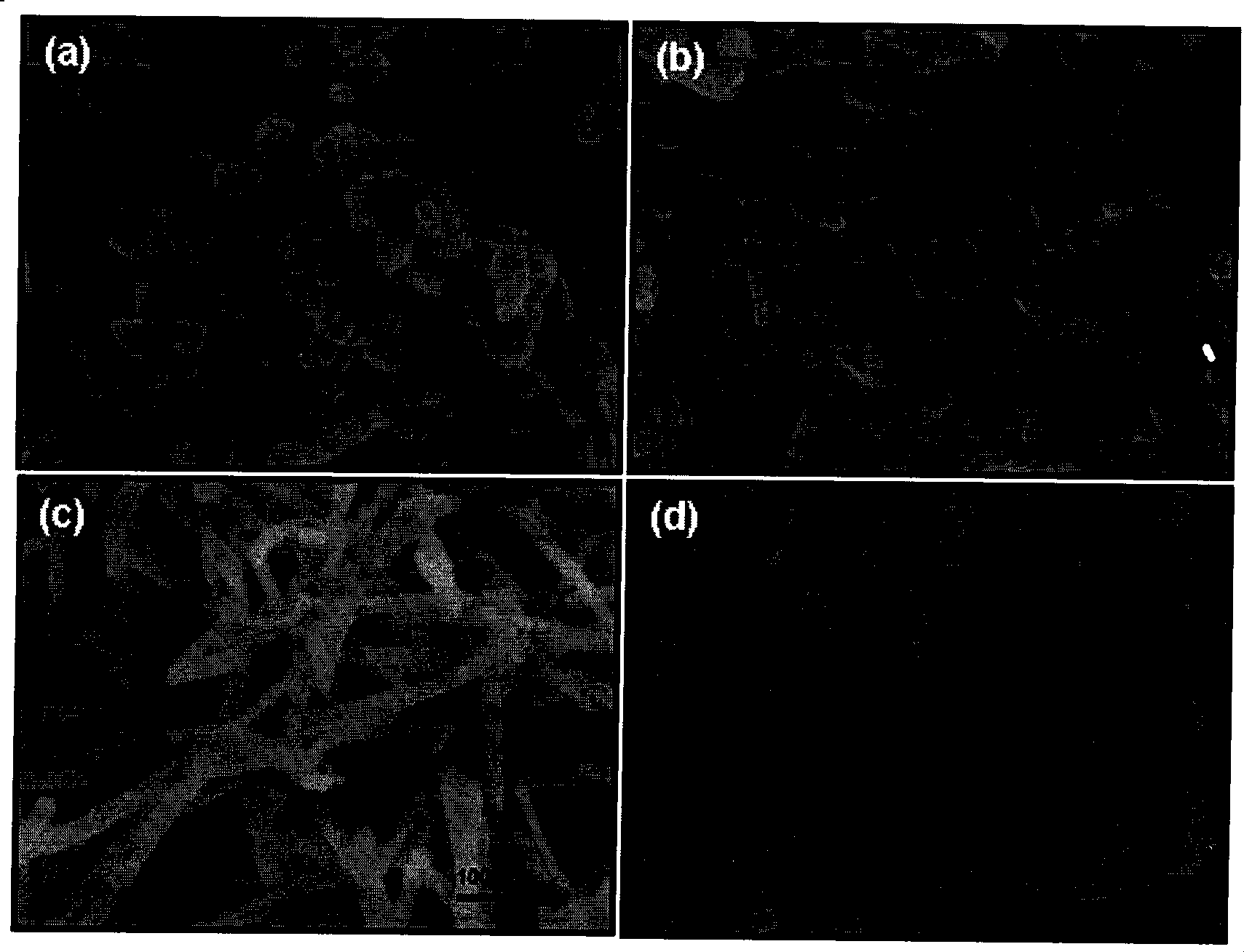

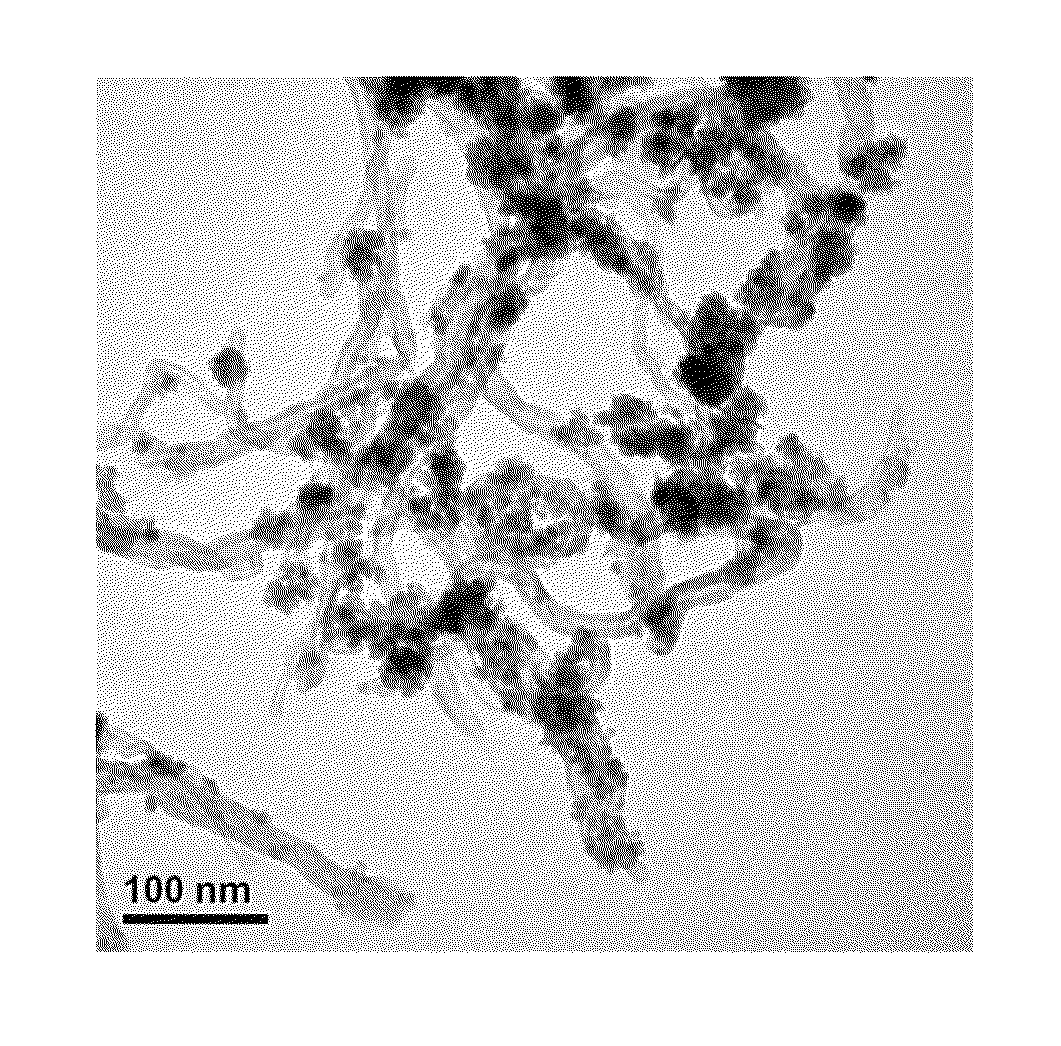

Magnetorheological fluid composition and method for forming the same

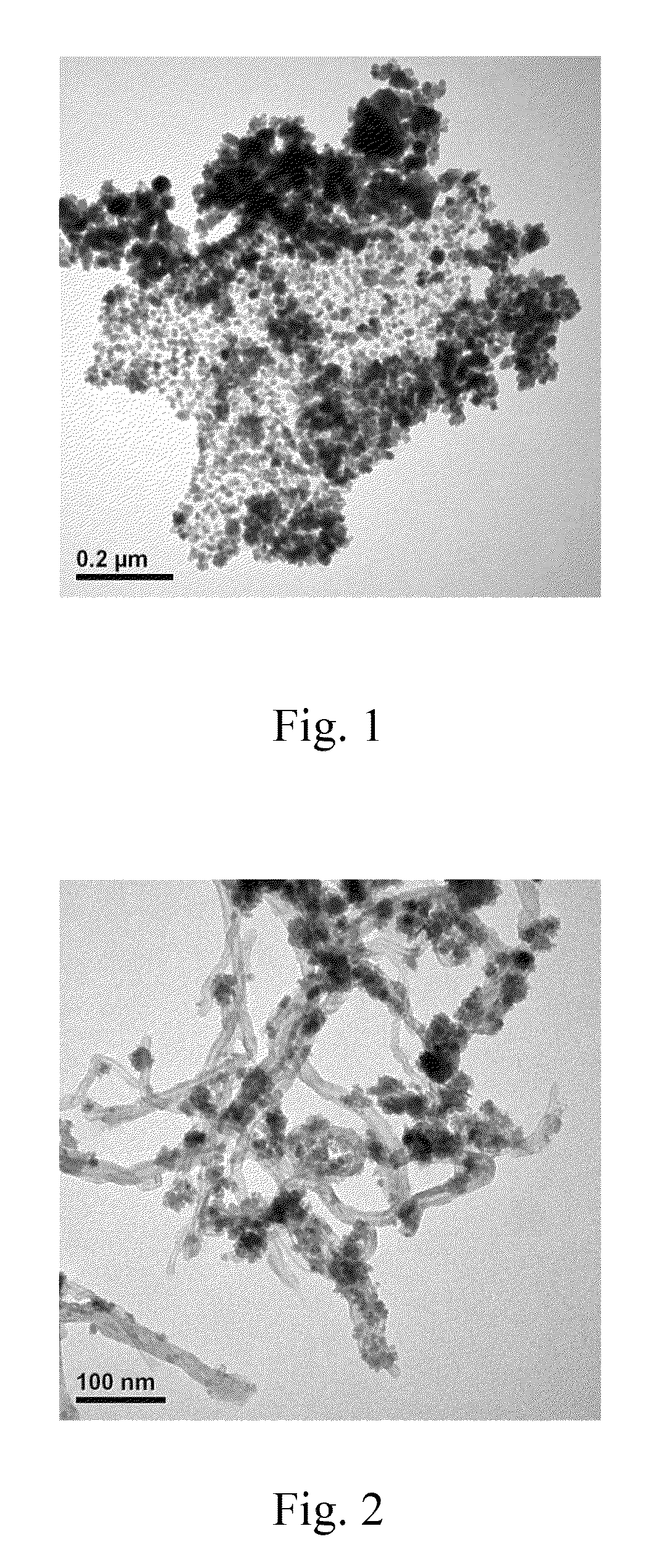

The present invention provides a magnetorheological fluid composition and method for forming the same. The magnetorheological fluid composition comprises a carrier fluid and a nano-magnetic-responsive composite dispersed uniformly in the carrier fluid. The nano-magnetic-responsive composite is formed by having carbonyl iron microparticles react with a grafting agent to form a modified carbonyl iron nanoparticles and blending the modified carbonyl iron nanoparticles with acid-treated graphene or carbon nanotubes.

Owner:NAT TAIPEI UNIV OF TECH

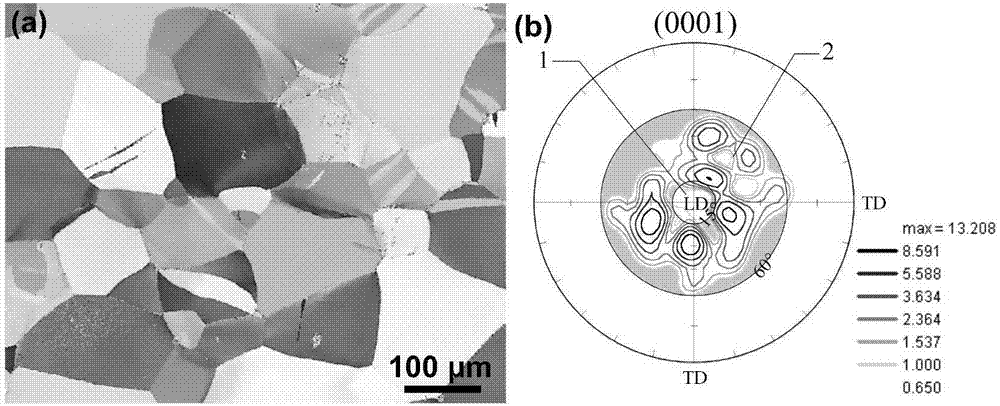

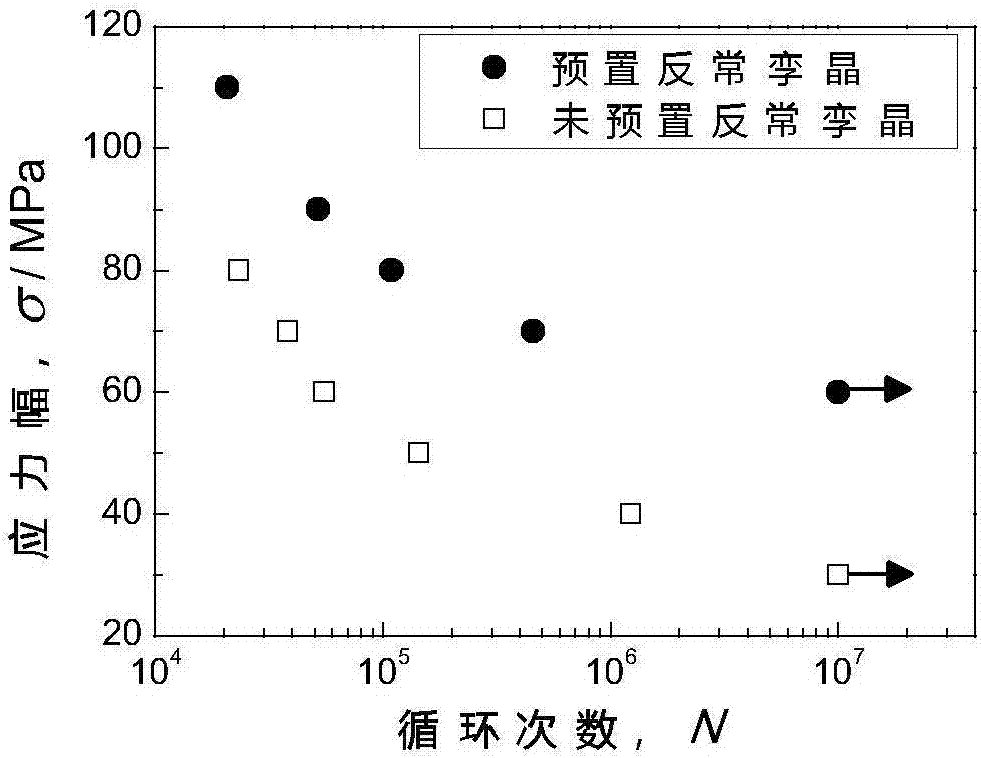

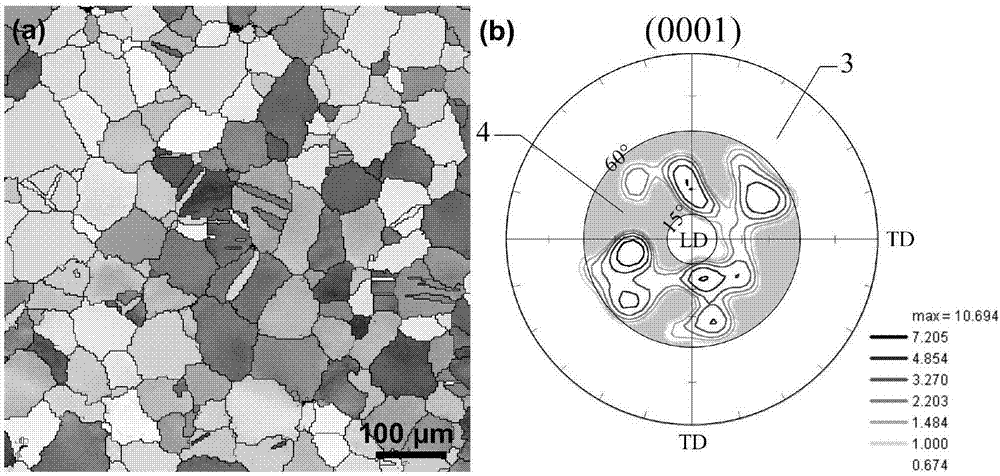

Method for improving fatigue performance of rare earth magnesium alloy by utilizing abnormal twin crystals

InactiveCN107190220AImprove fatigue performanceWide range of applicable materialsCrystal twinningAbnormal twins

The invention discloses a method for improving the fatigue performance of rare earth magnesium alloy by utilizing abnormal twin crystals. The method comprises the following steps: performing pre-deformation treatment on the rare earth magnesium alloy in the direction which forms an angle of 15 to 80 degrees with the normal direction of a base plane at 15 to 300 DEG C, wherein the true strain is 0.0005 to 0.1; arranging {10, 12} abnormal twin crystals in the rare earth magnesium alloy in advance through pre-deformation; performing fatigue test on the rare earth magnesium alloy with or without the abnormal twin crystals; compared with the rare earth magnesium alloy without the abnormal twin crystals, the fatigue limit of the rare earth magnesium alloy with the abnormal twin crystals is improved obviously; the fatigue life is prolonged; and the fatigue performance is obviously improved. The method is a process which is reasonable in design, simple in equipment requirement, convenient to operate, low in cost and high in efficiency and improves the fatigue performance of the rare earth magnesium alloy stably.

Owner:CENT SOUTH UNIV

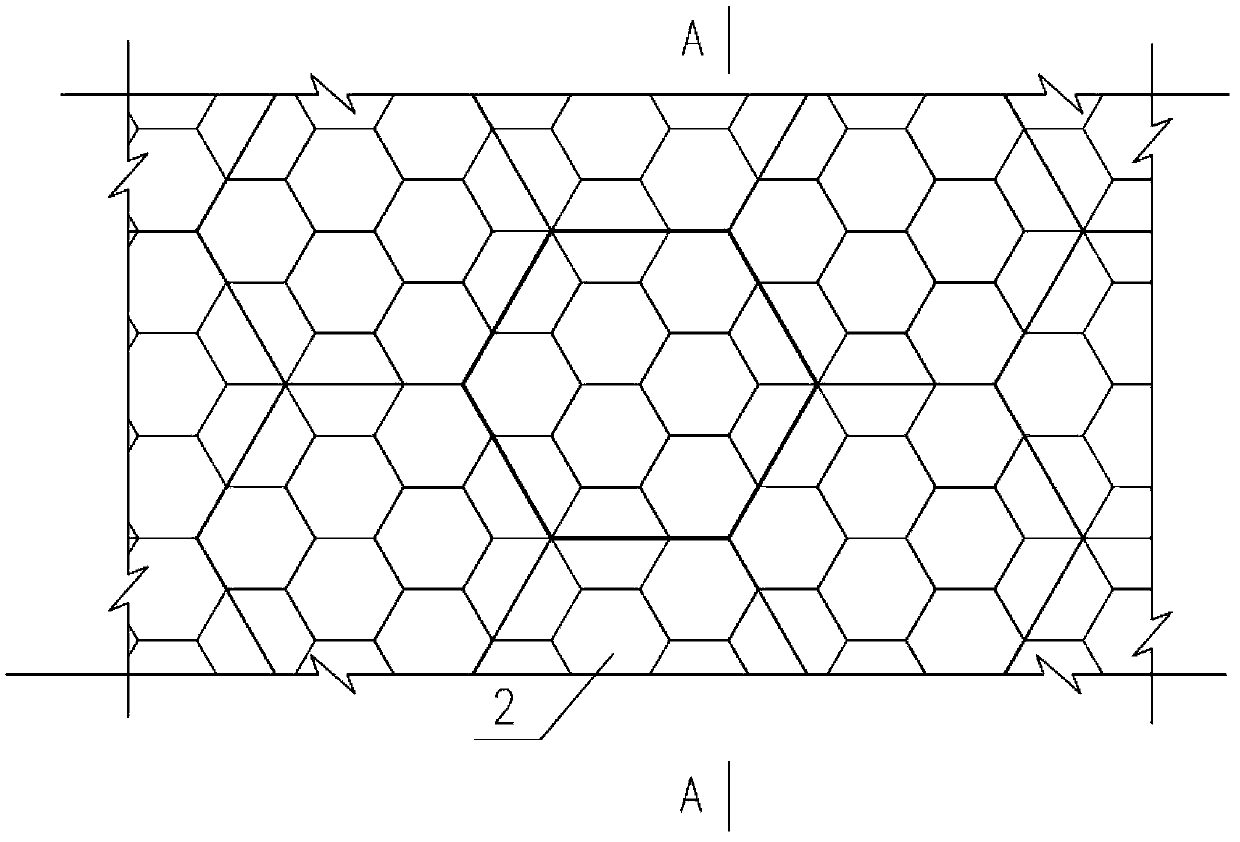

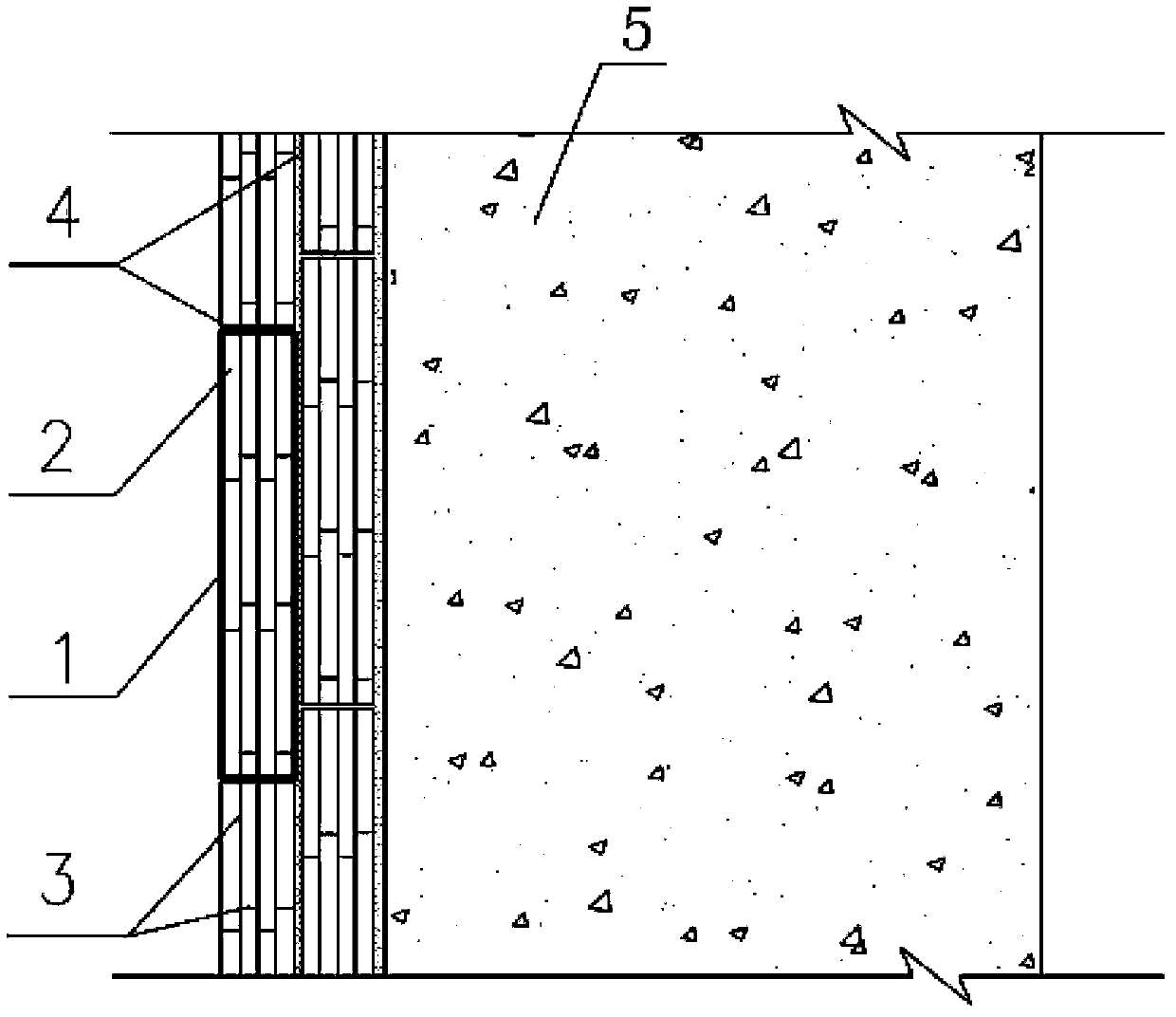

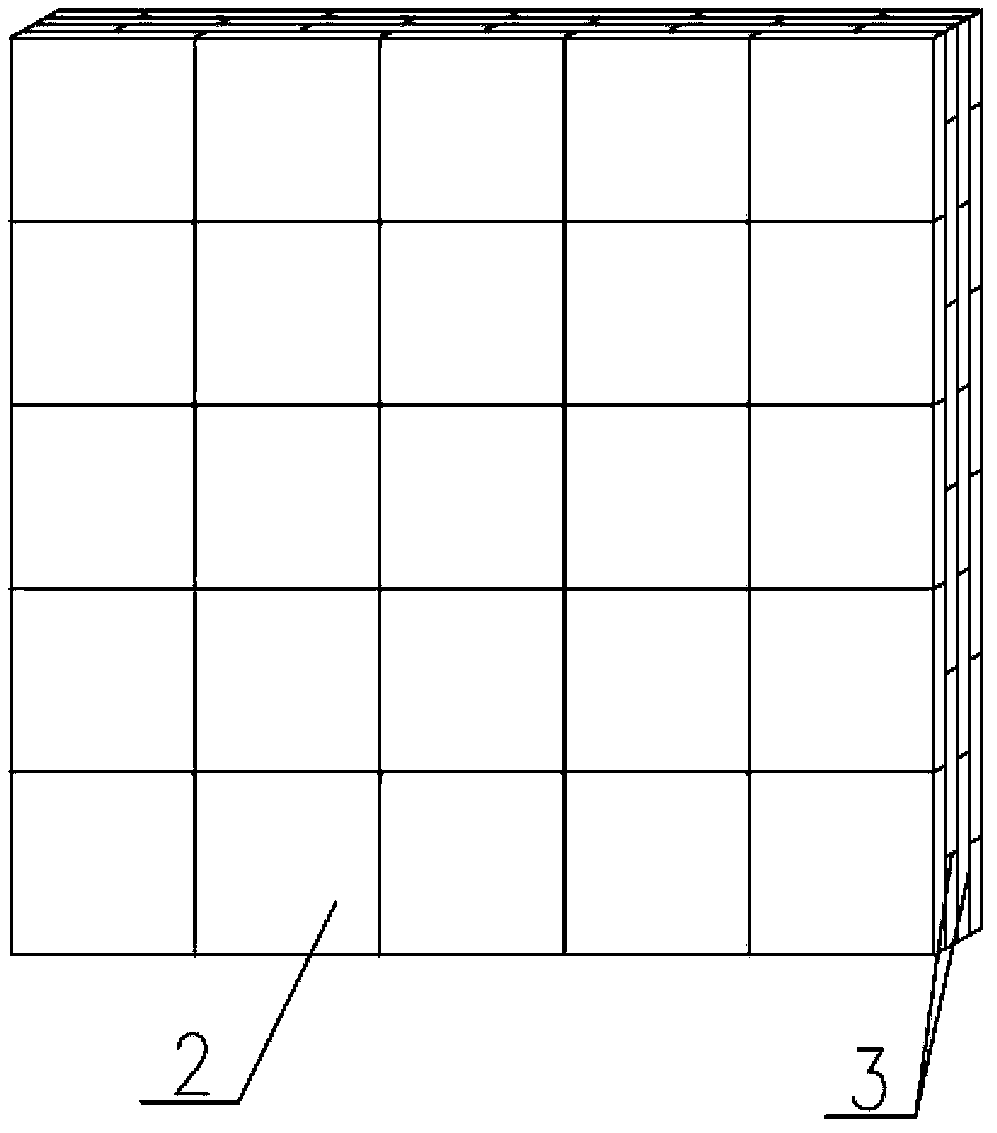

Wall tile protection structure with bullet-proof and explosion-proof functions

ActiveCN103388388AWith bulletproof and explosion-proof functionReduce depthCovering/liningsClimate change adaptationBrickBlocking layer

The invention discloses a wall tile protection structure with bullet-proof and explosion-proof functions. A plurality of wall tile units (1) are paved in a staggered way, and are bonded into a layered structure by adopting a bonding substance (4); and each wall tile unit (1) has a separate multilayer structure, namely, the wall tile units (1) are overlapped alternatively by using sheet block layers (2) and bonding substance layers (3), and the transverse sections are formed in a layered form. The protection structure has the advantages of attractiveness and easy-cleaning function of ordinary wall tiles, and capability of improving the high-speed impact resistance of building wall bodies (built or newly-built). The wall tile protection structure is low in manufacturing cost, is manufactured with a simple process, and is suitable for factory prefabrication and field rapid splicing.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com