Thixotropic ceramic paste material for stereolithography and preparation method thereof

A technology of stereolithography and thixotropy, which is applied in the field of ceramic additive manufacturing, can solve the problems of difficult printing process, damage to the surface quality of parts, and complex support, so as to simplify the time of removing support, ensure surface quality, and good surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

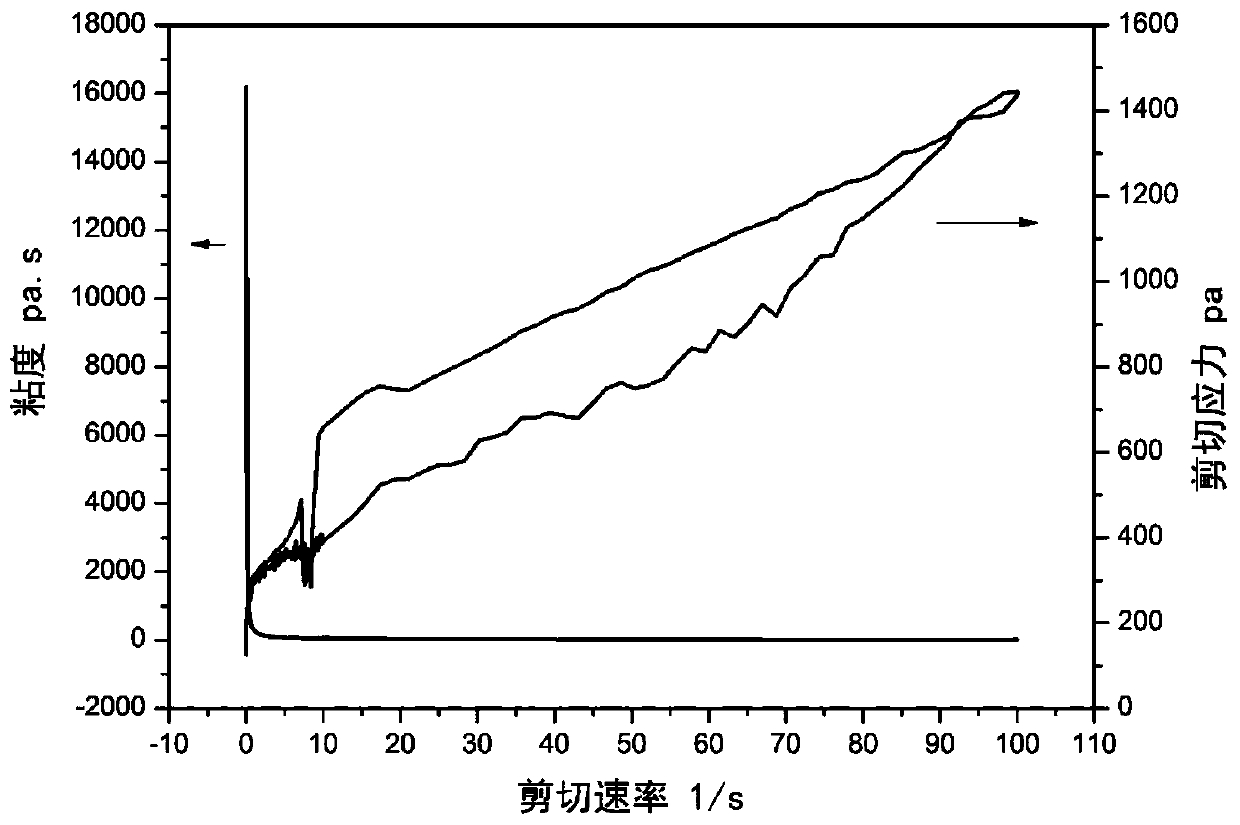

[0029] Prepare a high-energy planetary ball mill, and add an appropriate amount of zirconia balls, 16g of photocurable monomer tricyclodecanyl dimethanol diacrylate, and 0.24g of photoinitiator 2-hydroxy-2-methyl- Phenylacetone-1, 2.1706g phosphate ester dispersant, stir to make it mix and dissolve. Weigh 120g of β-tricalcium phosphate into the ball mill jar three times, each weighing 40g, and ball mill at 200r / min, 250r / min, and 250r / min for 1 hour respectively. After the ball milling, add 8.5g polyethylene glycol 300 thixotropic agent to the ball milling jar, and ball mill it for 2 hours at a speed of 300r / min or 350r / min to obtain a satisfactory paste, such as figure 1 , the rheological performance test shows that the shear rate of the paste is 0.01s -1 The viscosity is greater than 16000pa s, and the viscosity decreases rapidly with the increase of the shear rate, and the shear rate is 100s -1 The viscosity is less than 20pa·s, the yield stress is greater than 400pa, and...

Embodiment 2

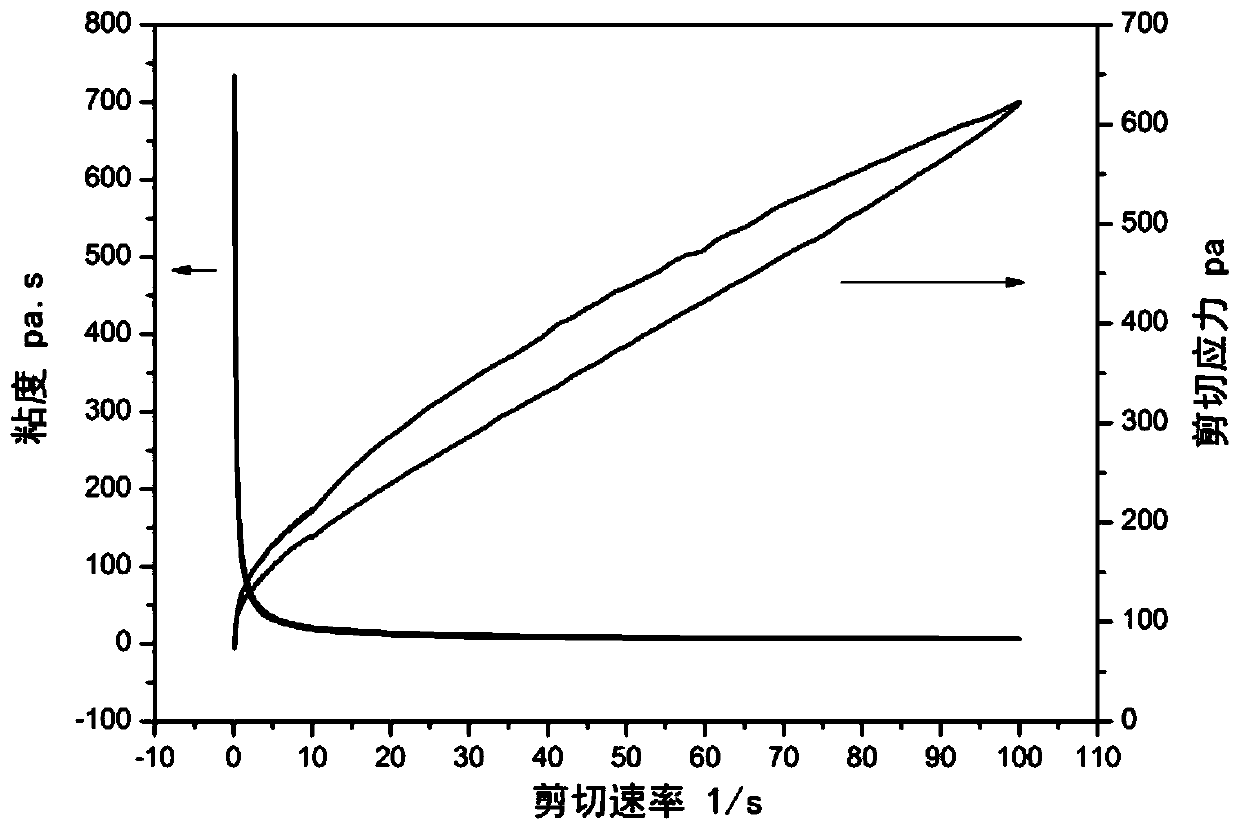

[0031] Prepare a high-energy planetary ball mill, and add an appropriate amount of zirconia balls, 20g of photocurable monomer 1,6-ethylene glycol diacrylate, and 0.16g of photoinitiator 2-hydroxy-2-methyl -Phenylacetone-1, 1.2g of phosphate ester dispersant, stirred to mix and dissolve. Weigh 48g of β-tricalcium phosphate and 12g of biological glass powder in three times in the ball mill jar, weigh 16g of β-tricalcium phosphate and 4g of biological glass powder each time, and turn them at 200r / min, 250r / min, 250r / min Each ball milled for 0.5h at the rotating speed. After the ball milling, add 4g of hydrophobic fumed silica thixotropic agent into the ball milling tank, and ball mill for 2 hours at a speed of 300r / min or 350r / min to obtain a paste that meets the requirements. Such as figure 2 , the rheological performance test shows that the shear rate of the paste is 0.01s -1 When the viscosity is greater than 700pa s, the viscosity decreases rapidly with the increase of t...

Embodiment 3

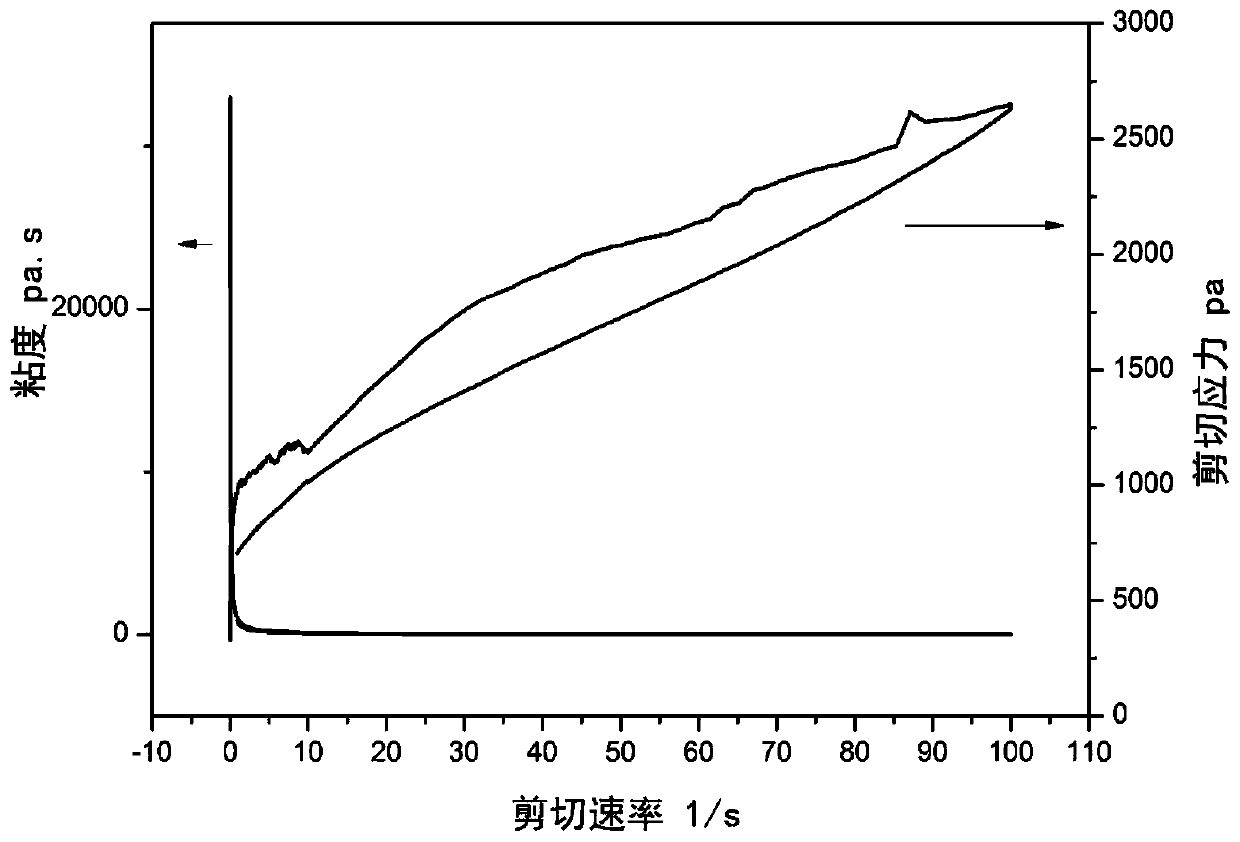

[0033] Prepare a high-energy planetary ball mill, and add an appropriate amount of zirconia balls, 20g of photocurable monomer ethoxylated trimethylol triacrylate, and 0.16g of photoinitiator 2-hydroxy-2-methyl Base-phenylacetone-1, 1.05g polyacrylate, stir to mix and dissolve. Weigh 70g of alumina in three times into a ball mill jar, each time weigh 23.3g of alumina, and ball mill at 200r / min, 250r / min, and 250r / min for 1 hour respectively. After the ball milling, add 2g of polyamide wax powder thixotropic agent into the ball milling tank, and ball mill for 2 hours at a speed of 300r / min or 350r / min to obtain a paste that meets the requirements, such as image 3 , the rheological performance test shows that the shear rate of the paste is 0.01s -1 When the viscosity is greater than 30000pa s, the viscosity decreases rapidly with the increase of the shear rate, and the shear rate is 100s -1 When the viscosity is less than 30pa·s, the yield stress is greater than 320pa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com