Electrical heating numerical control incremental forming processing method and device for plate

A technology of incremental forming and processing methods, applied in the direction of digital control, electrical program control, etc., can solve problems such as incremental forming, and achieve the effect of increasing the forming angle range, reducing processing force, and overcoming the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

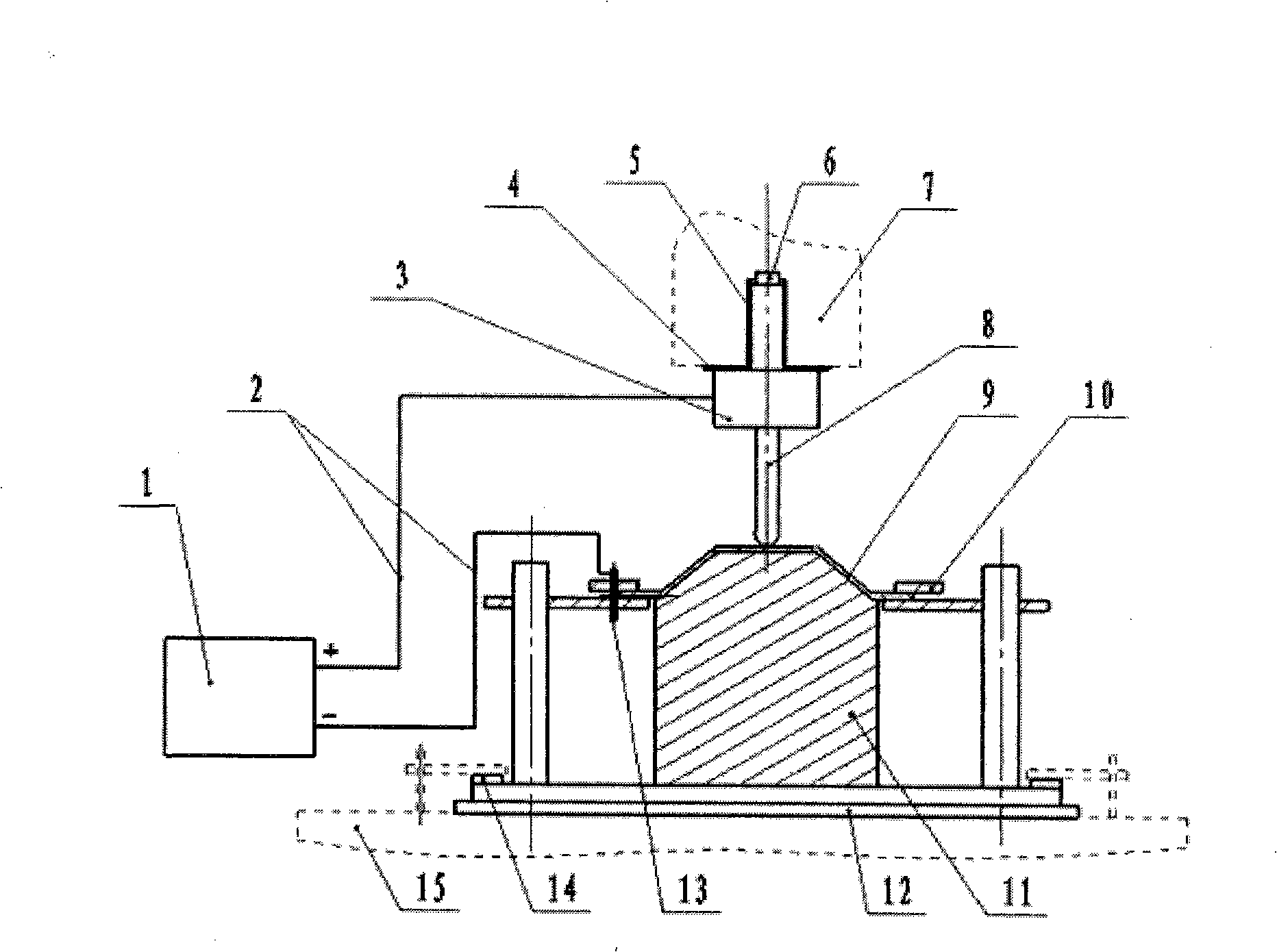

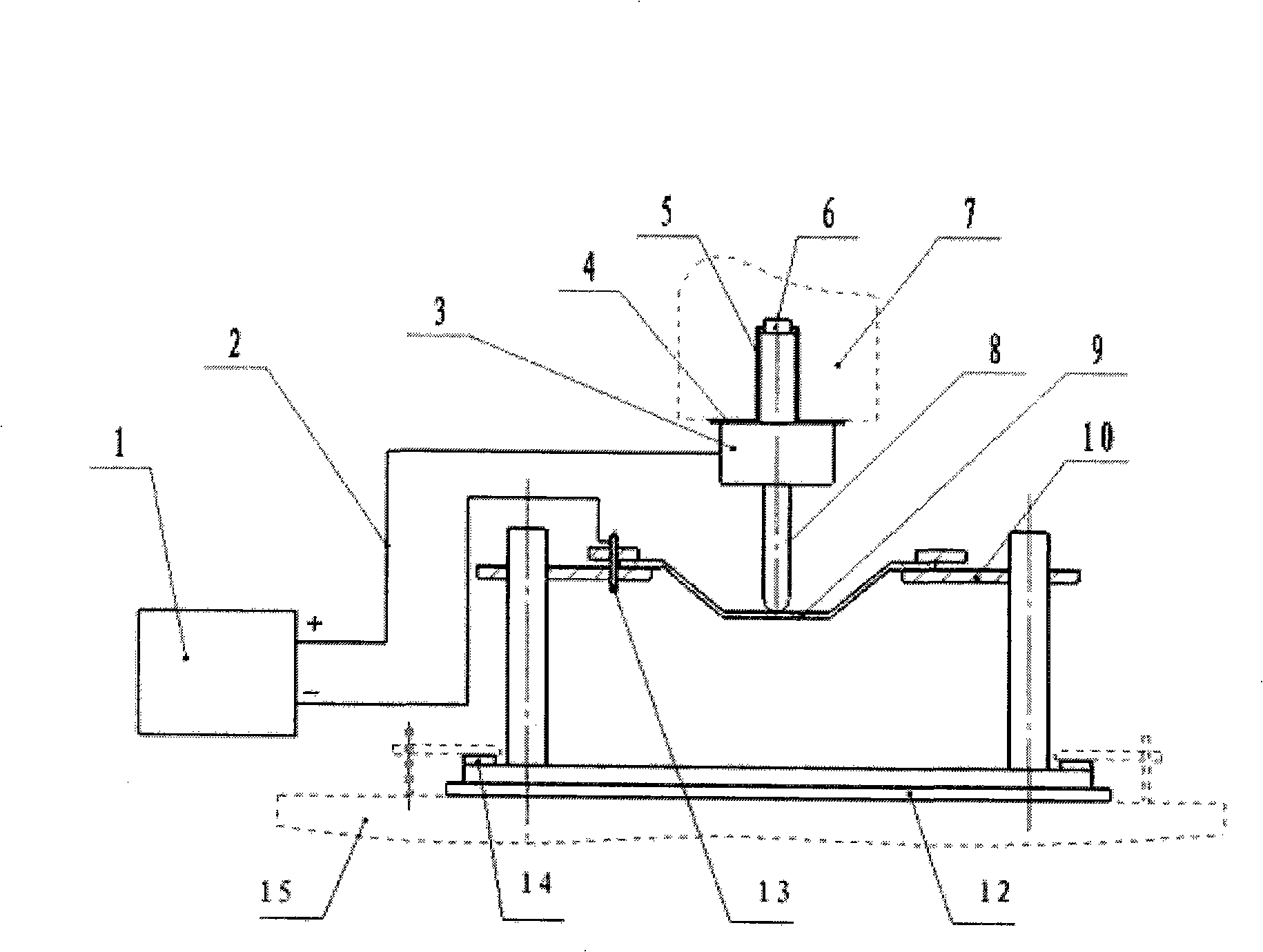

[0024] attached figure 1 And attached figure 2 They are schematic diagrams of sheet metal local self-resistance electric heating CNC progressive positive forming and negative forming. The device consists of a three-axis CNC progressive forming machine tool and an electric auxiliary heating device. The CNC incremental forming machine tool spindle clamps the indenter and moves along the processing track on the contour level, so that the sheet metal is deformed successively along the envelope surface of the forming indenter track, and finally the sheet is formed into the required workpiece. The electric auxiliary heating device is mainly composed of a low-voltage high-current adjustable DC power supply, an indenter handle, an indenter, a mold and a large current-carrying wire. The circuit is reliably insulated from the machine tool by using insulating gaskets and insulating sleeves.

[0025] the following to figure 1 As an example, incremental forming is described as positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com