Patents

Literature

49 results about "Quenching rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

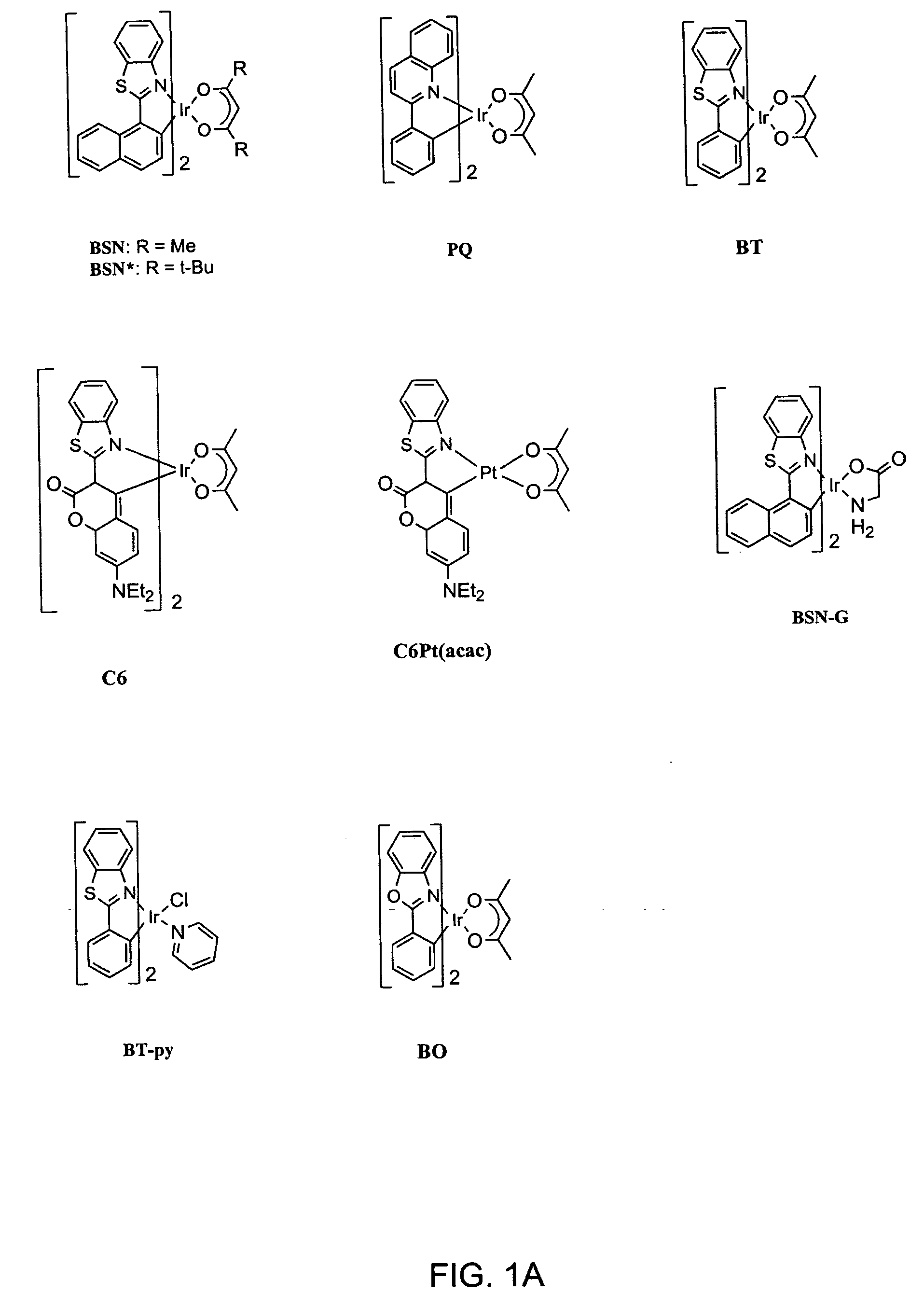

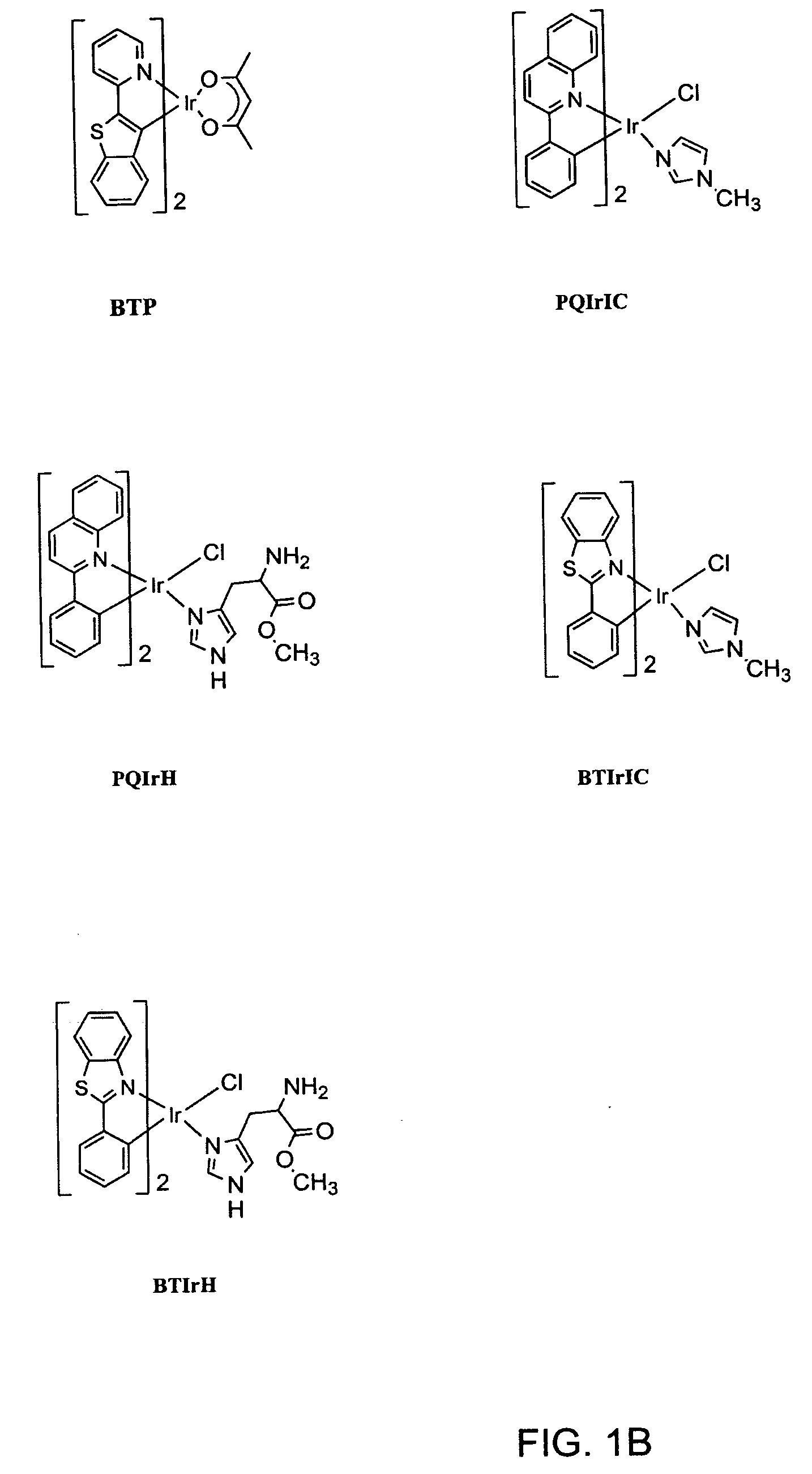

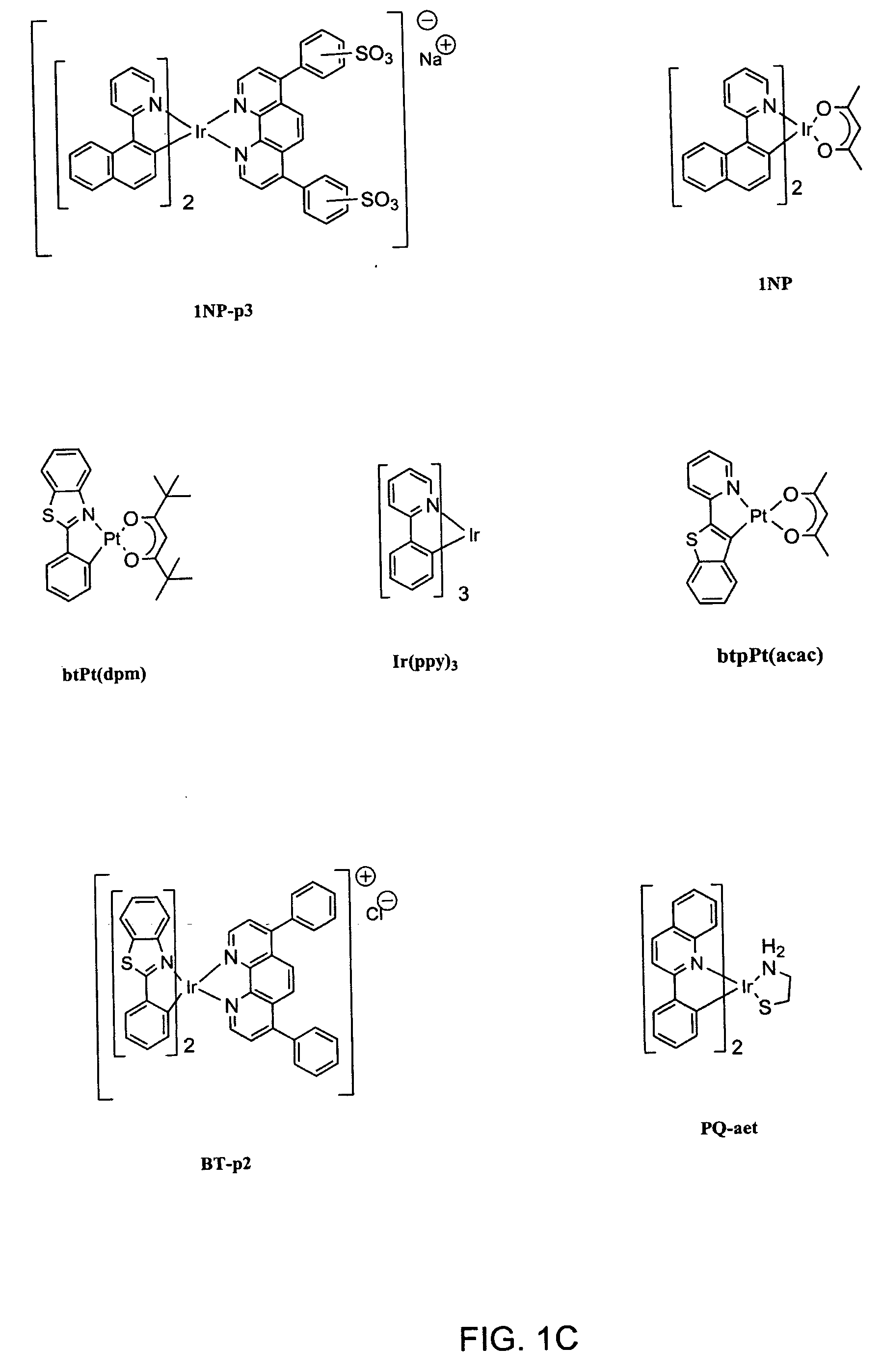

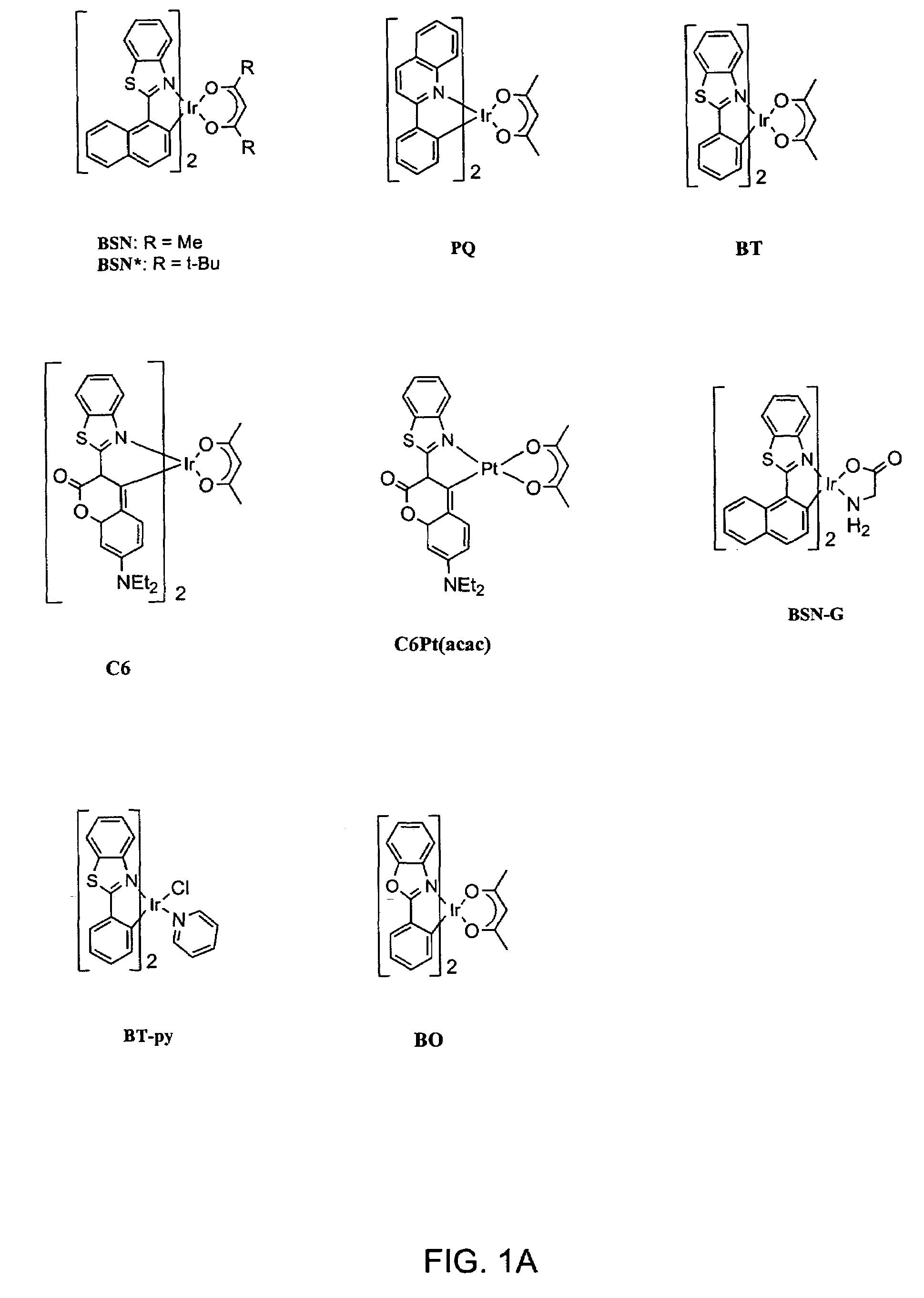

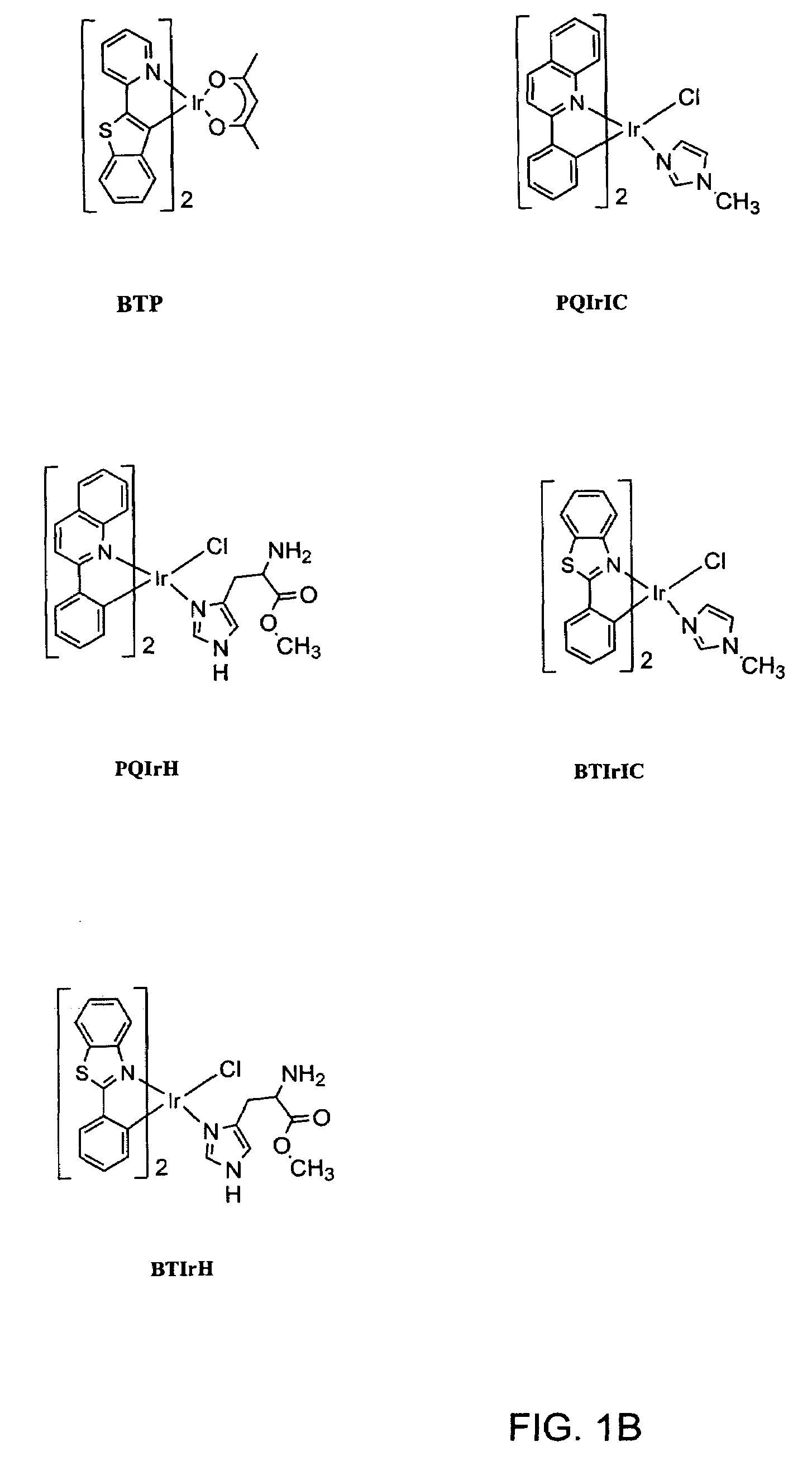

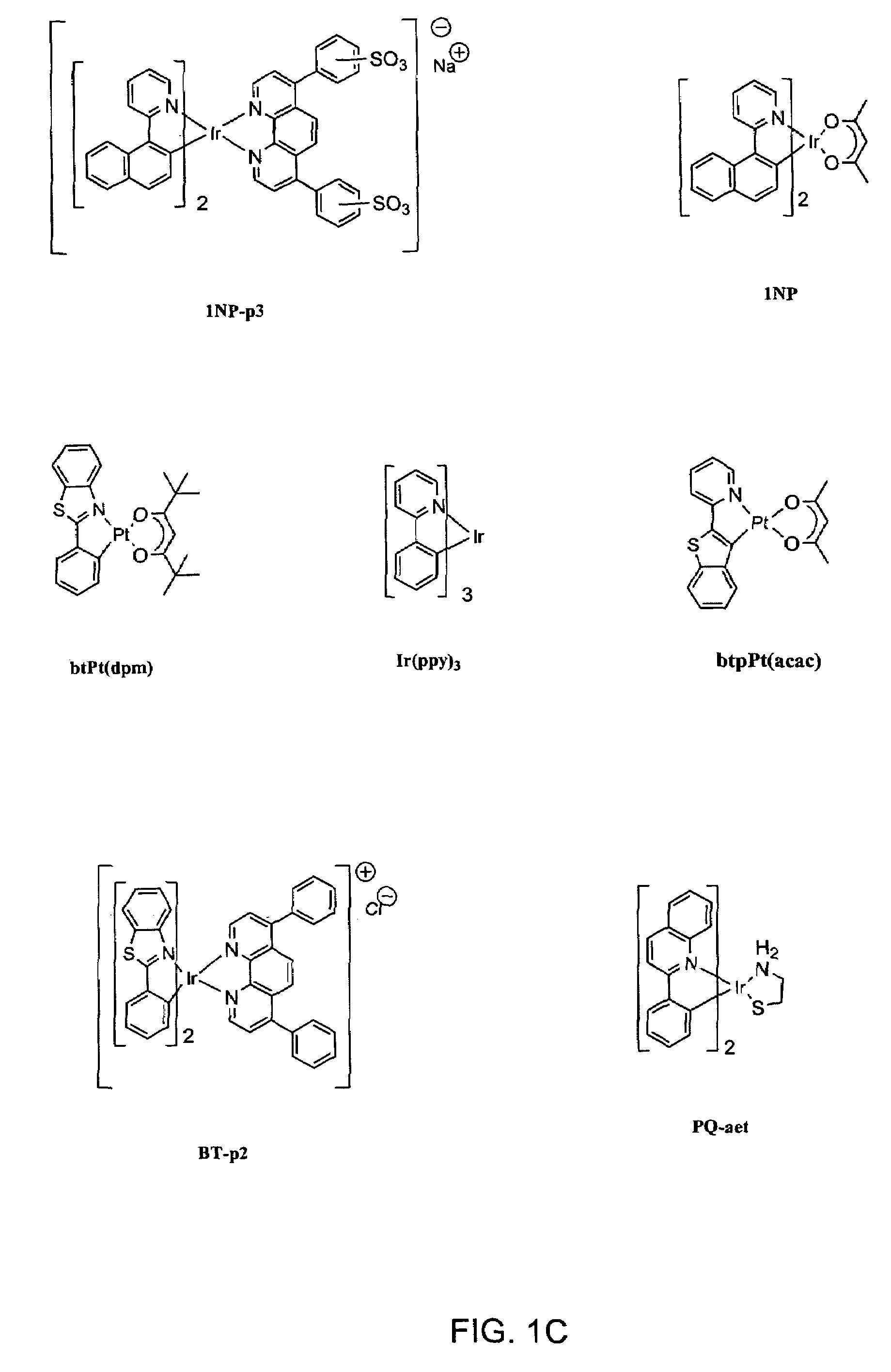

Organometallic complexes as singlet oxygen sensitizers

A series of organometallic complexes and the singlet oxygen sensitization properties of these complexes are provided. Complexes with acetylacetonate ligands give singlet oxygen quantum yields near unity, whether exciting the ligand-based state or the lowest energy excited state (MLCT+3LC). The singlet oxygen quenching rates for these β-diketonate complexes are small, roughly three orders of magnitude slower than the corresponding phosphorescence quenching rate. Similar complexes were prepared with glycine or pyridine tethered to the Ir(III) center (i.e. (bsn)2Ir(gly) and (bt)2Ir(py)Cl, where gly=glycine, and py=pyridine). The glycine and pyridine derivatives give high singlet oxygen yields.

Owner:UNIV OF SOUTHERN CALIFORNIA

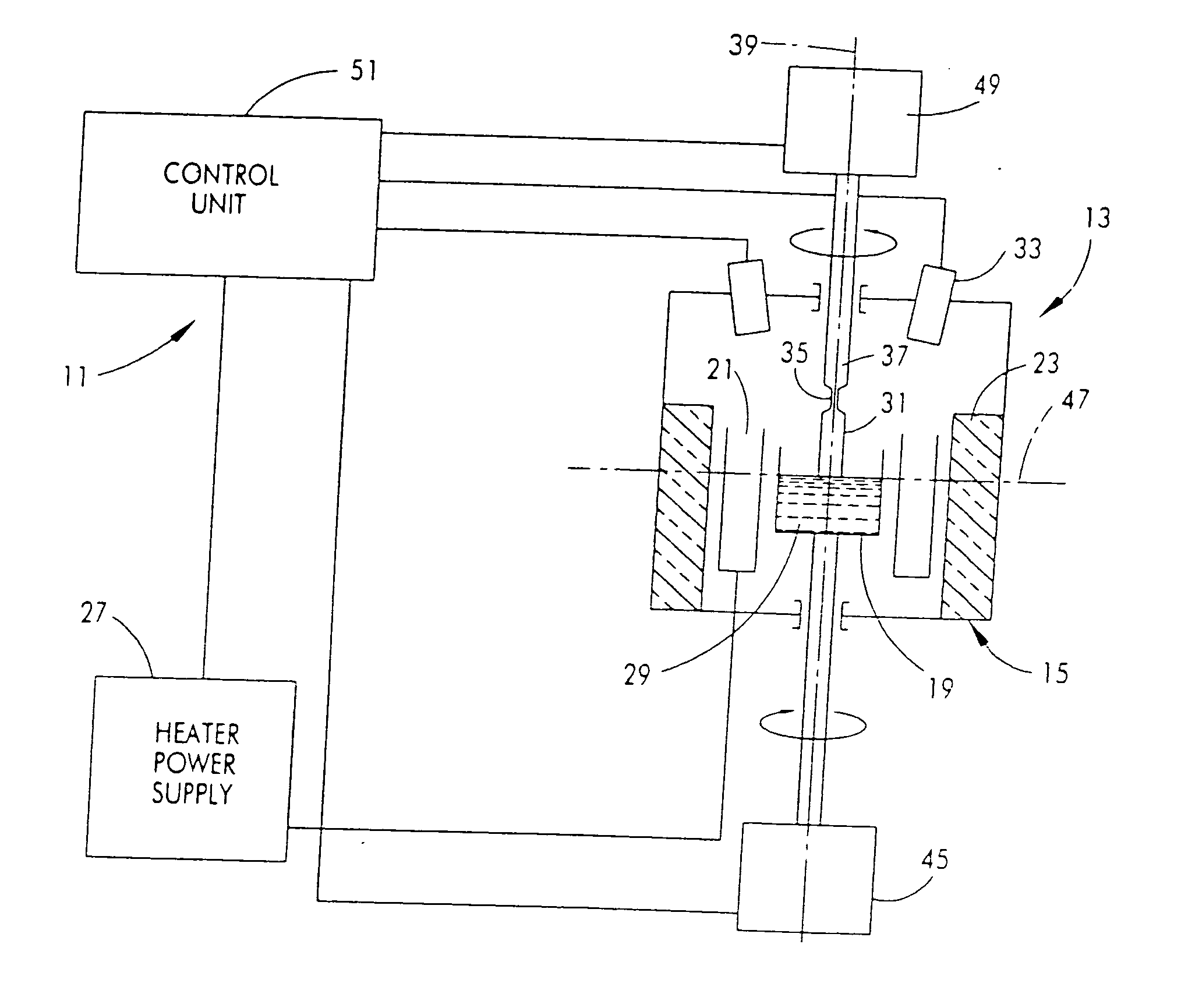

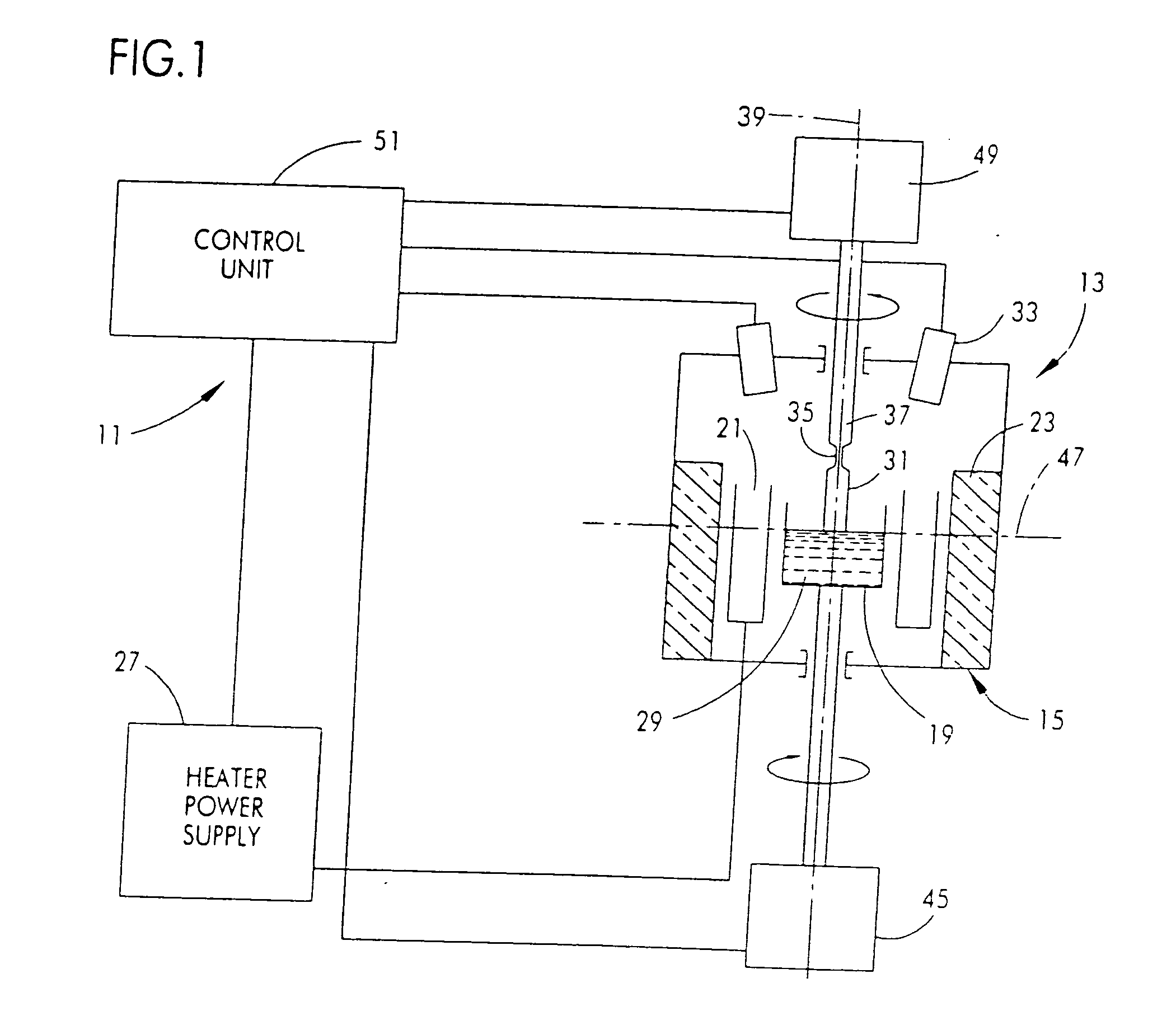

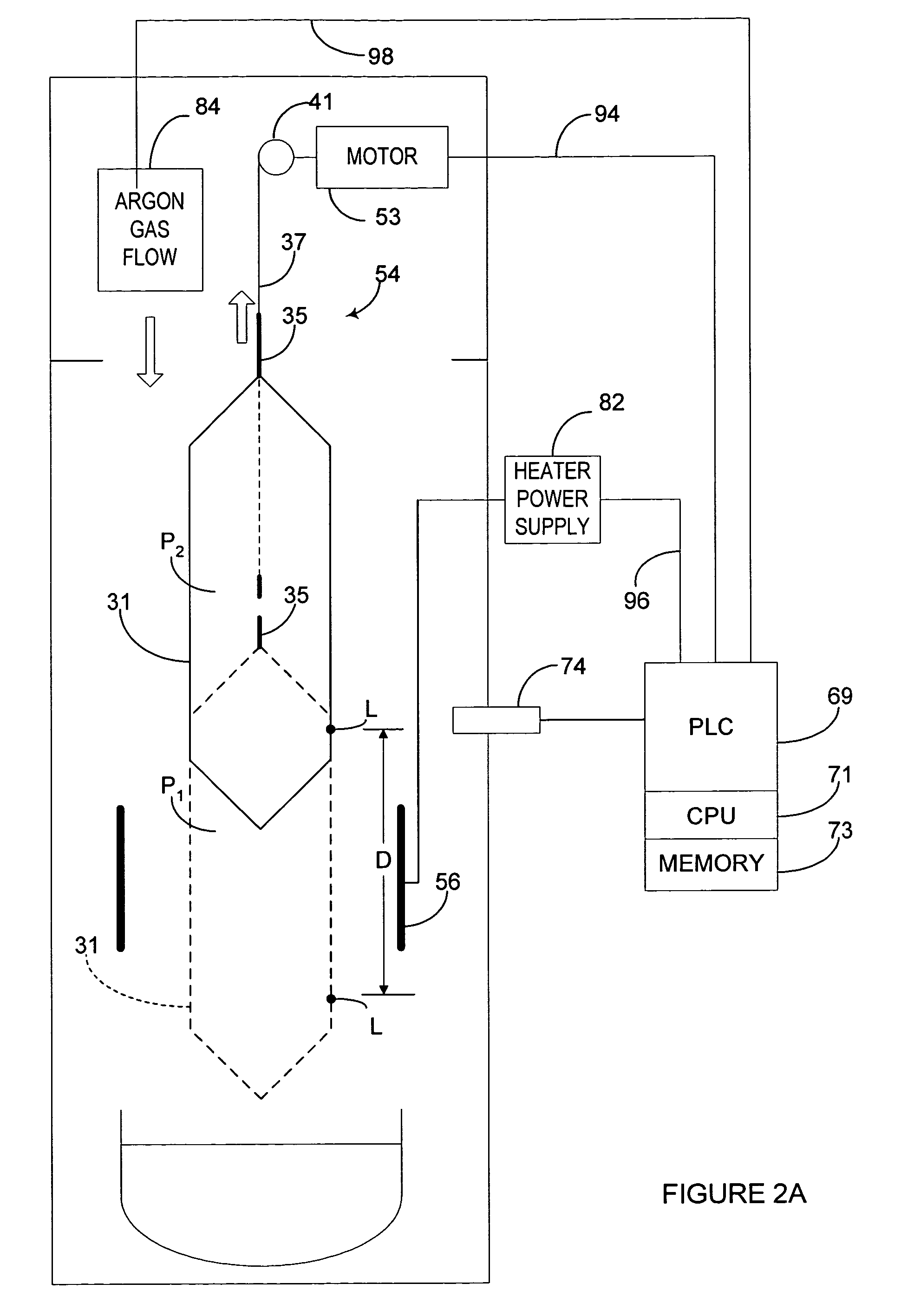

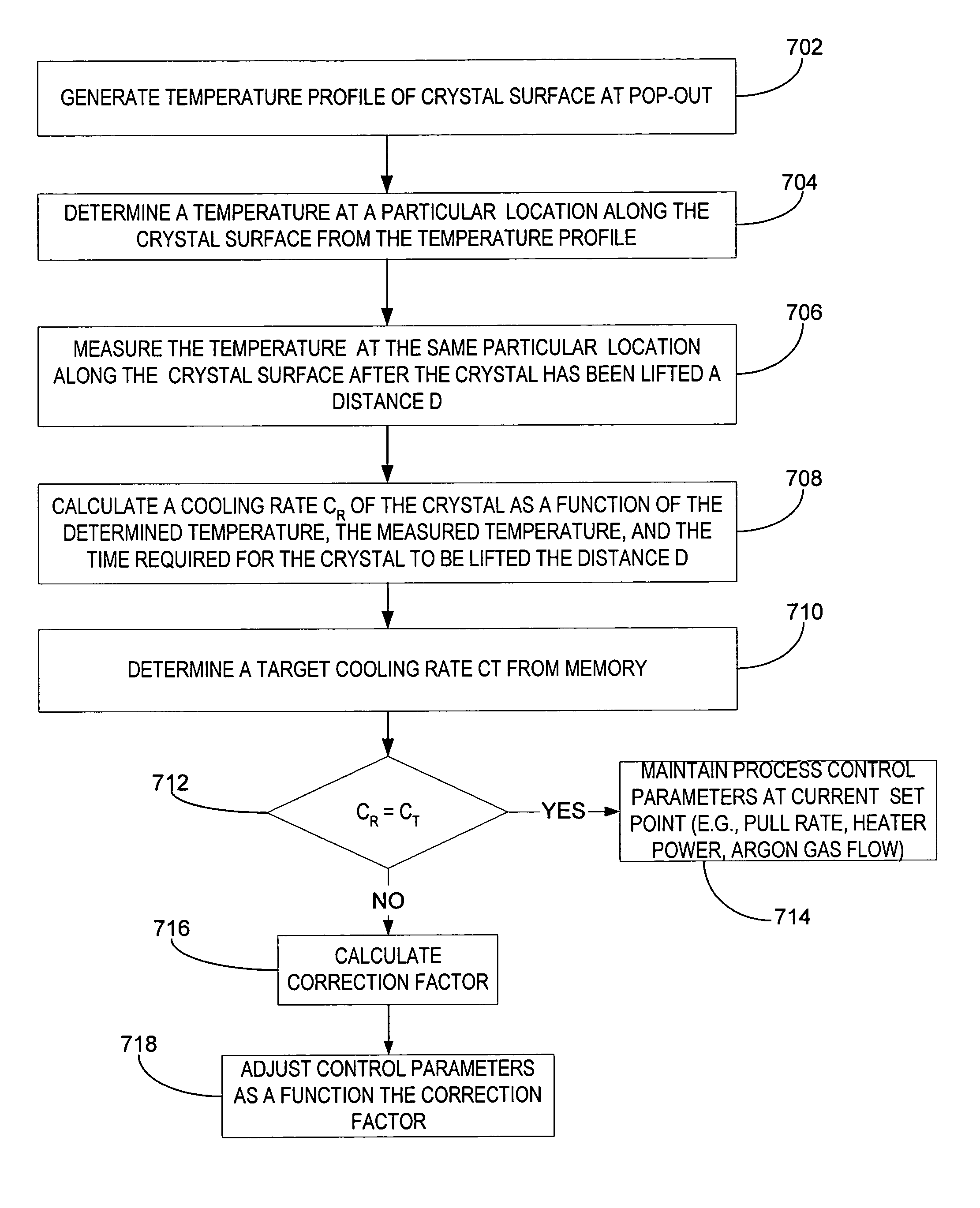

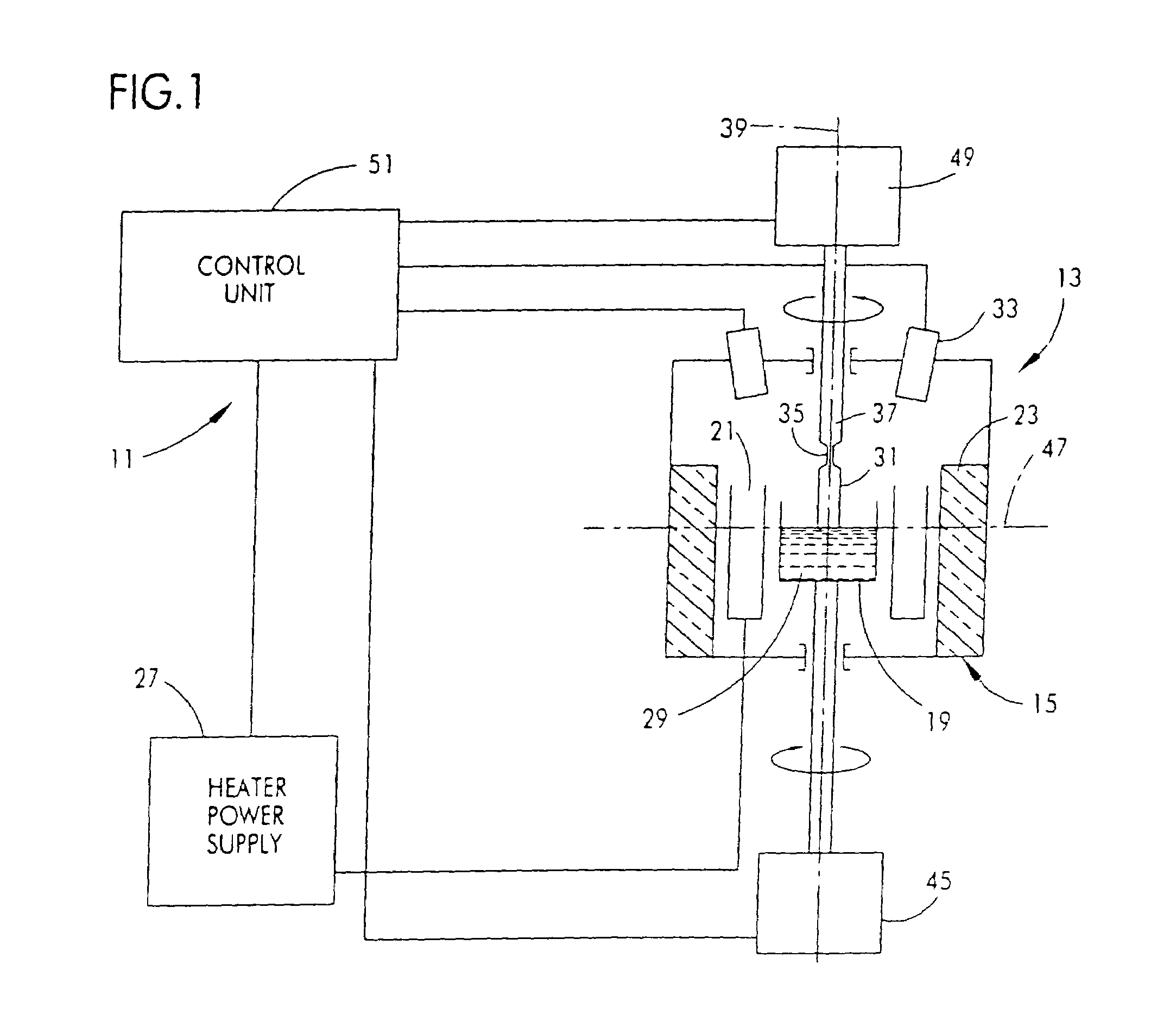

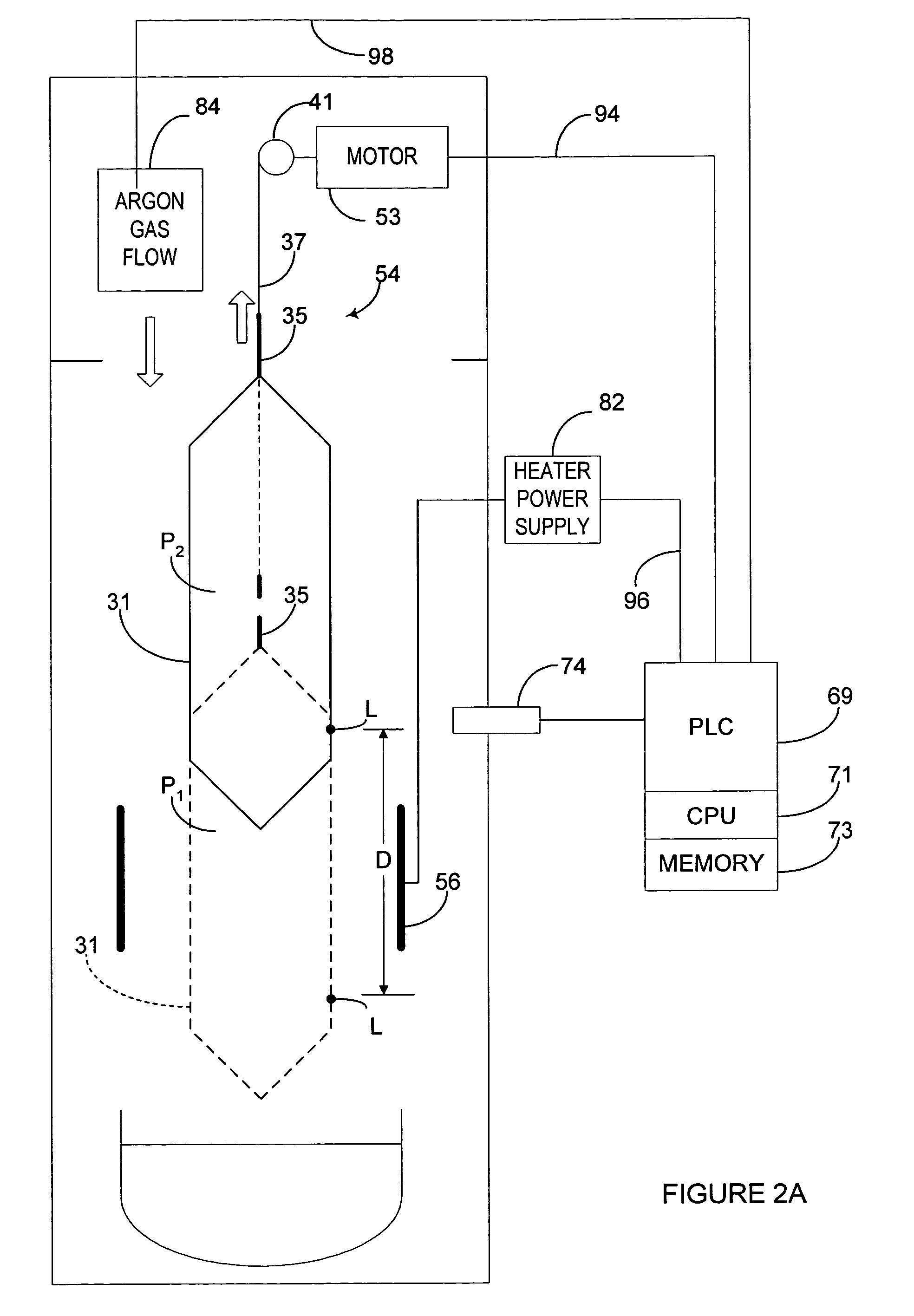

Method to monitor and control the crystal cooling or quenching rate by measuring crystal surface temperature

InactiveUS20050016443A1Promote growthAfter-treatment apparatusPolycrystalline material growthSingle crystalIngot

A method and apparatus for controlling the quenching rate of a monocrystalline ingot pulled from a melt by adjusting one or more post growth processing parameter. A temperature model generates a temperature profile that represents the surface temperature along the length of the ingot at the instant it is pulled from the melt. A first temperature at a particular location along the length of the crystal is determined from the temperature profile. A temperature sensor senses a second temperature at the same particular location. A PLC calculates a quenching rate of the crystal as a function of the first temperature and the second temperature. The PLC generates an error between a target quenching rate and a calculated quenching rate, and one or more post growth process parameters are adjusted as function of the error signal to optimize the quenching rate. Alternatively, temperature readings from the sensor are collected and the quenching rates of the crystal are calculated after crystal growth and post growth quenching. One or more post growth process parameters are modified and programmed for subsequent crystal growth and post growth quenching to achieve optimized quenching rate and crystal quality.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

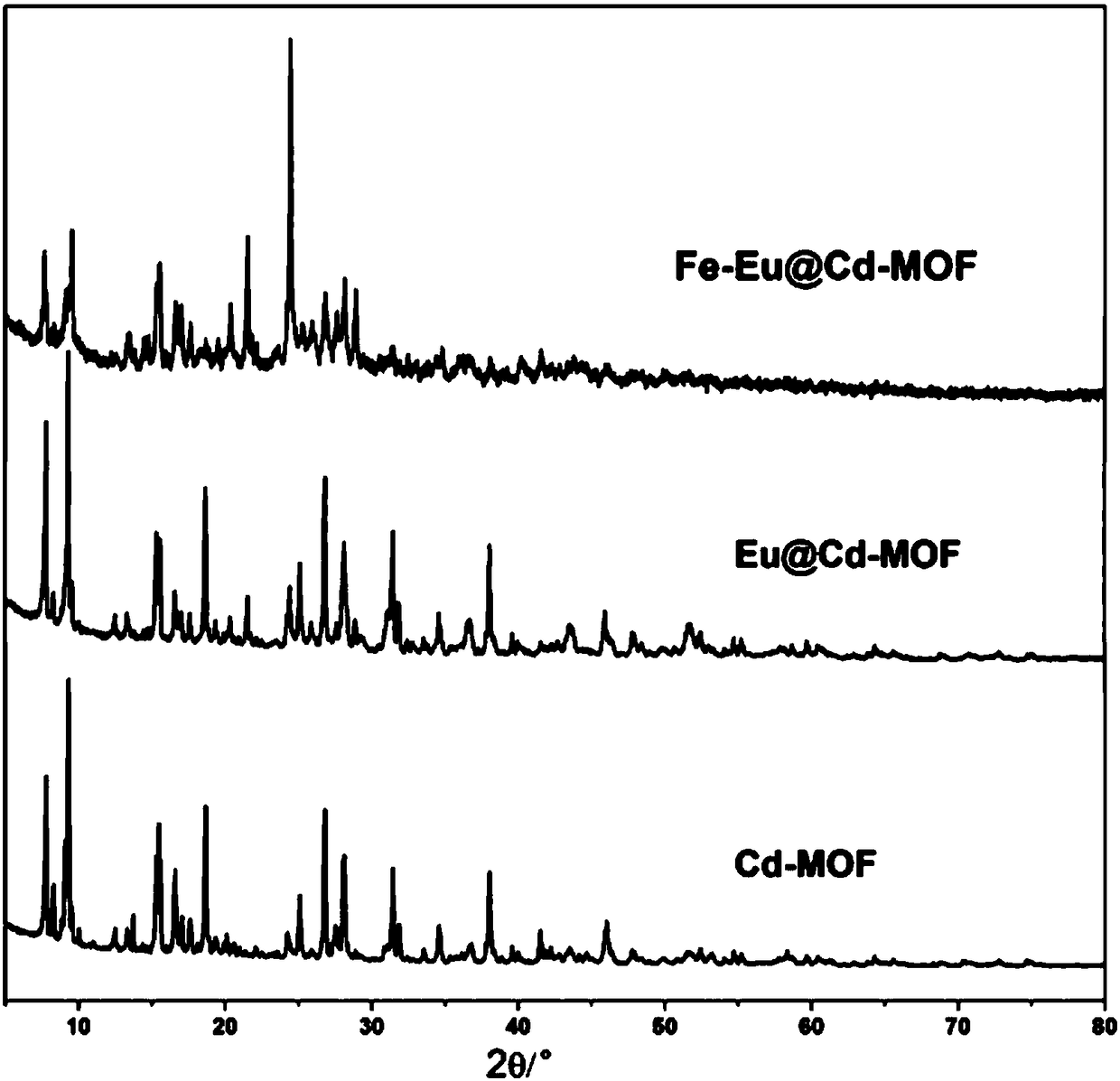

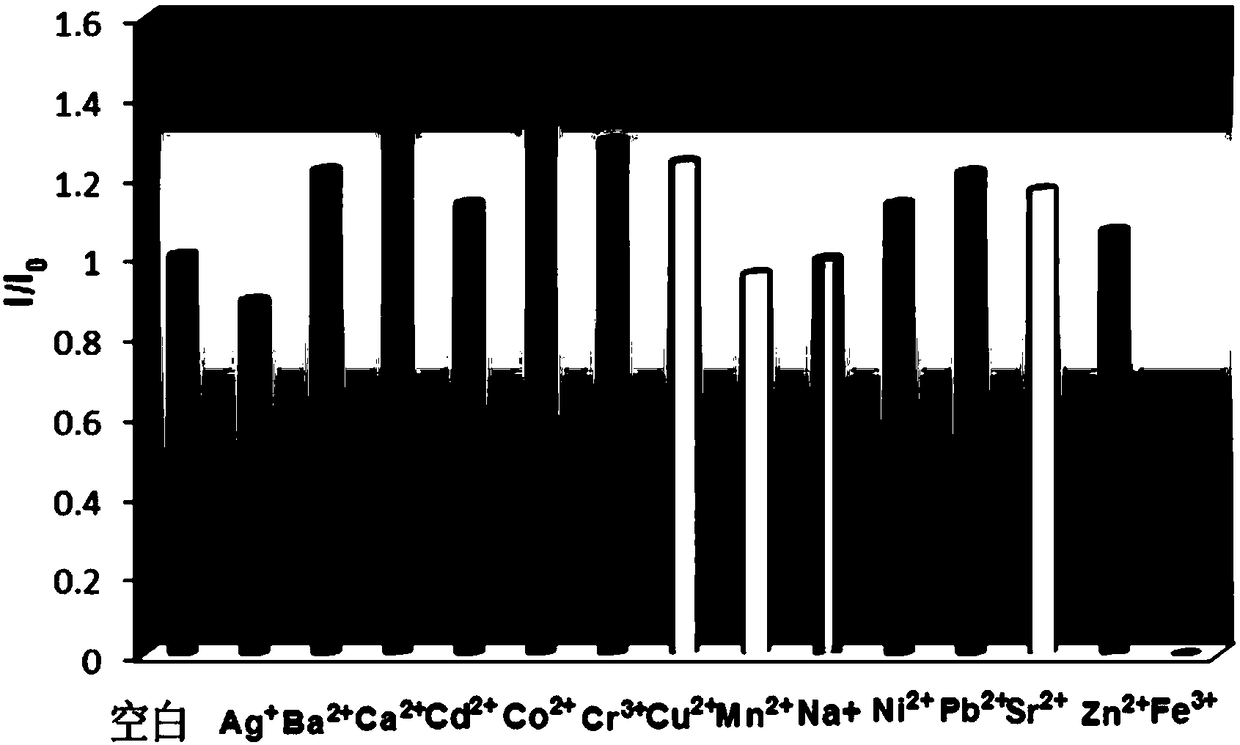

Fluorescence probe for recognizing iron ions in water body and preparation method and application thereof

ActiveCN108546551AEasy to synthesizeThe synthesis process is simpleFluorescence/phosphorescenceLuminescent compositionsProduction rateBlue emission

The invention discloses a fluorescence probe for recognizing iron ions in a water body and a preparation method and an application thereof. The preparation method of the invention includes the following steps of: 1) dispersing TPT, OH-H<2>BDC and cadmium nitrate tetrahydrate in a mixed solvent composed of DMA and water to prepare a precursor solution; 2) preparing a Cd-MOF material by subjecting the precursor solution to a solvothermal reaction; and 3) adding the Cd-MOF material to a Eu<3+> solution, and obtaining the fluorescence probe with Eu<2+> load through stirring, suction filtration anddrying, wherein Eu<3+> is "in-situ reduced" into Eu<2+> ions with specific blue emission during a functional "post-modification" process. The preparation method of the invention is simple, and the production rate is high; and a test sample of the fluorescence probe does not need pretreatment or the pretreatment is simple, the recognition on Fe<3+> ions is sensitive, the fluorescence quenching rate can reach 99%, and the fluorescence probe can be used for recognizing and detecting the Fe<3+> ions in the water body.

Owner:SHANGHAI INST OF TECH

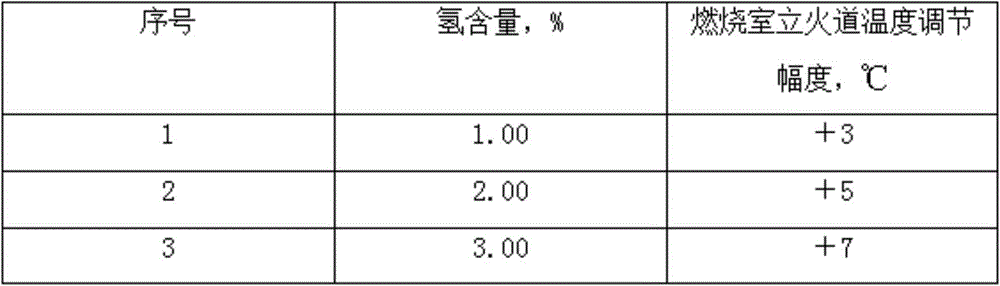

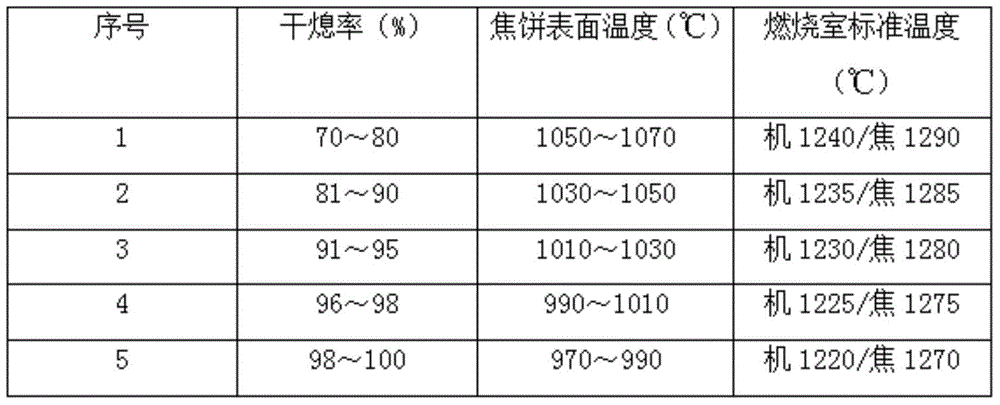

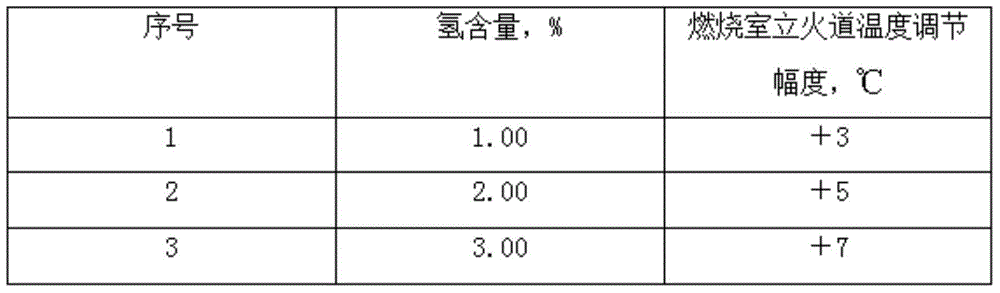

Method for regulating and controlling temperature of coke oven

ActiveCN104357065AReduce coking heat consumptionLow cost economical operationCombustible gas coke oven heatingTemperature controlCombustion chamber

The invention relates to a method for regulating and controlling the temperature of a coke oven. The method is characterized by comprising the following steps: (1) collecting data of a coke cake which is actually measured in a preset time, and formulating different coke cake center temperature control values according to the collected related data; (2) determining a corresponding combustion chamber vertical flame path standard temperature by combining different coke cake center temperature control values formulated according to the step (1) and the preset production data; (3) measuring and calculating the coke cake center temperature, the coke cake surface temperature and the difference value of the two temperatures of the same coking chamber, and replacing the coke cake center temperature by the coke cake surface temperature; (4) formulating combustion chamber vertical flame path standard temperatures corresponding to coke cake surface temperatures under different dry quenching rates according corresponding relationship among data determined by the step (1), (2) and (3); (5) formulating the coke oven heating system parameter according to the combustion chamber standard temperature determined in the step (4), measuring the coke cake surface temperature, and determining the maturity degree of red coke. According to the method, the coking heat consumption of the coke oven can be reduced, low-cost economical operation of the coke oven can be guaranteed, emission of NOX, CO2, SO2 and other harmful gases in waste gas of the coke oven can be reduced, and pollution of waste gas of the coke oven to the atmosphere can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

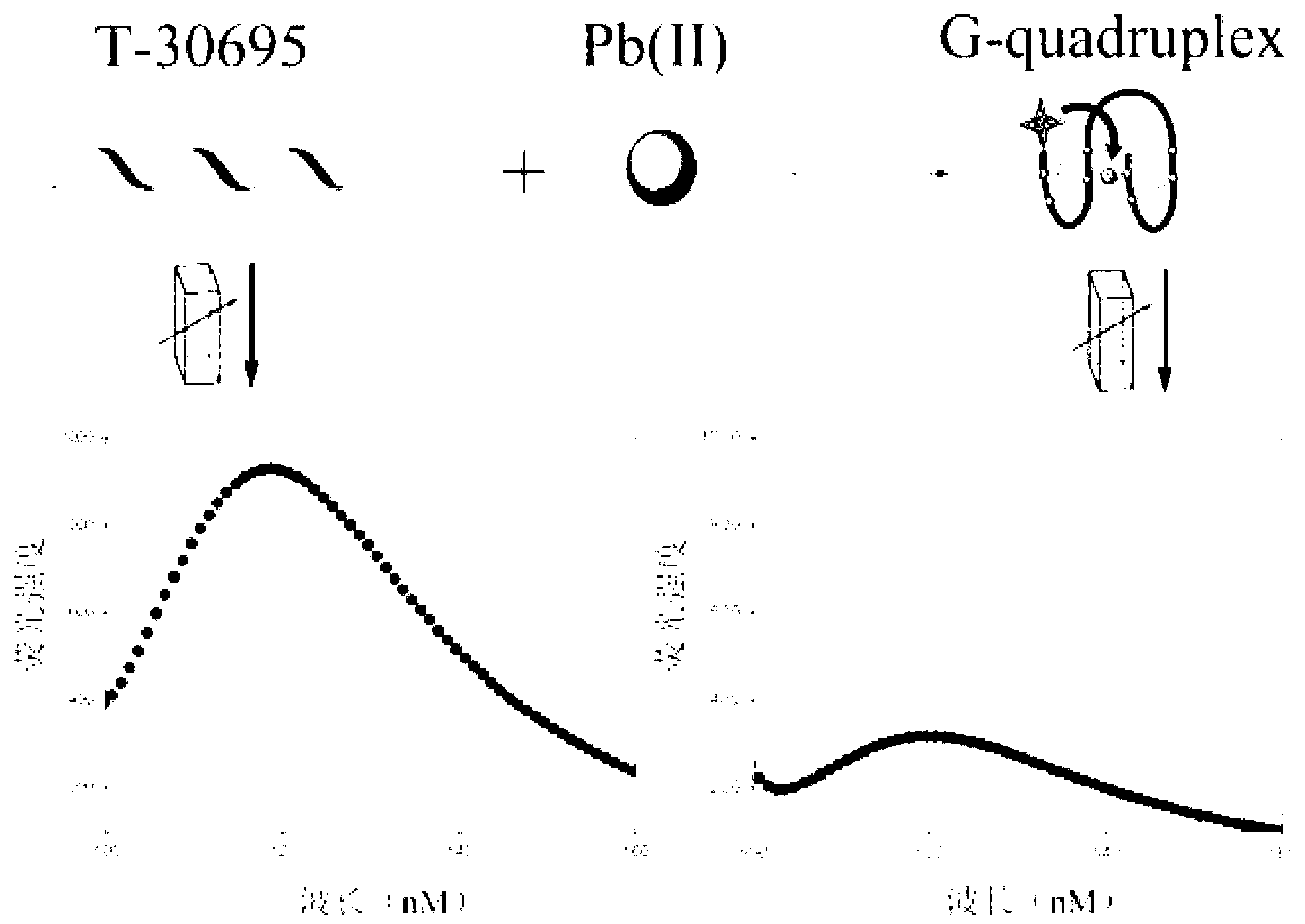

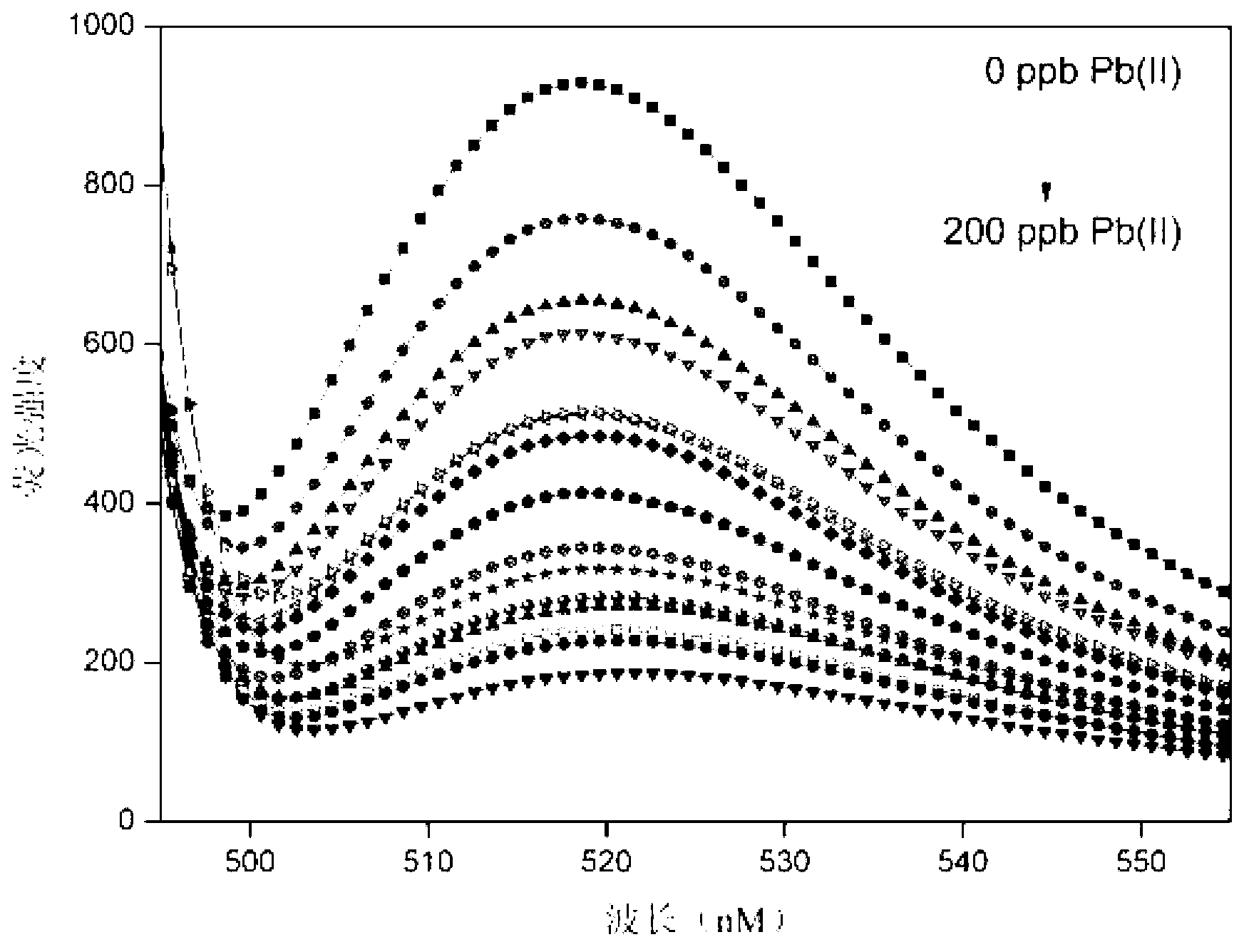

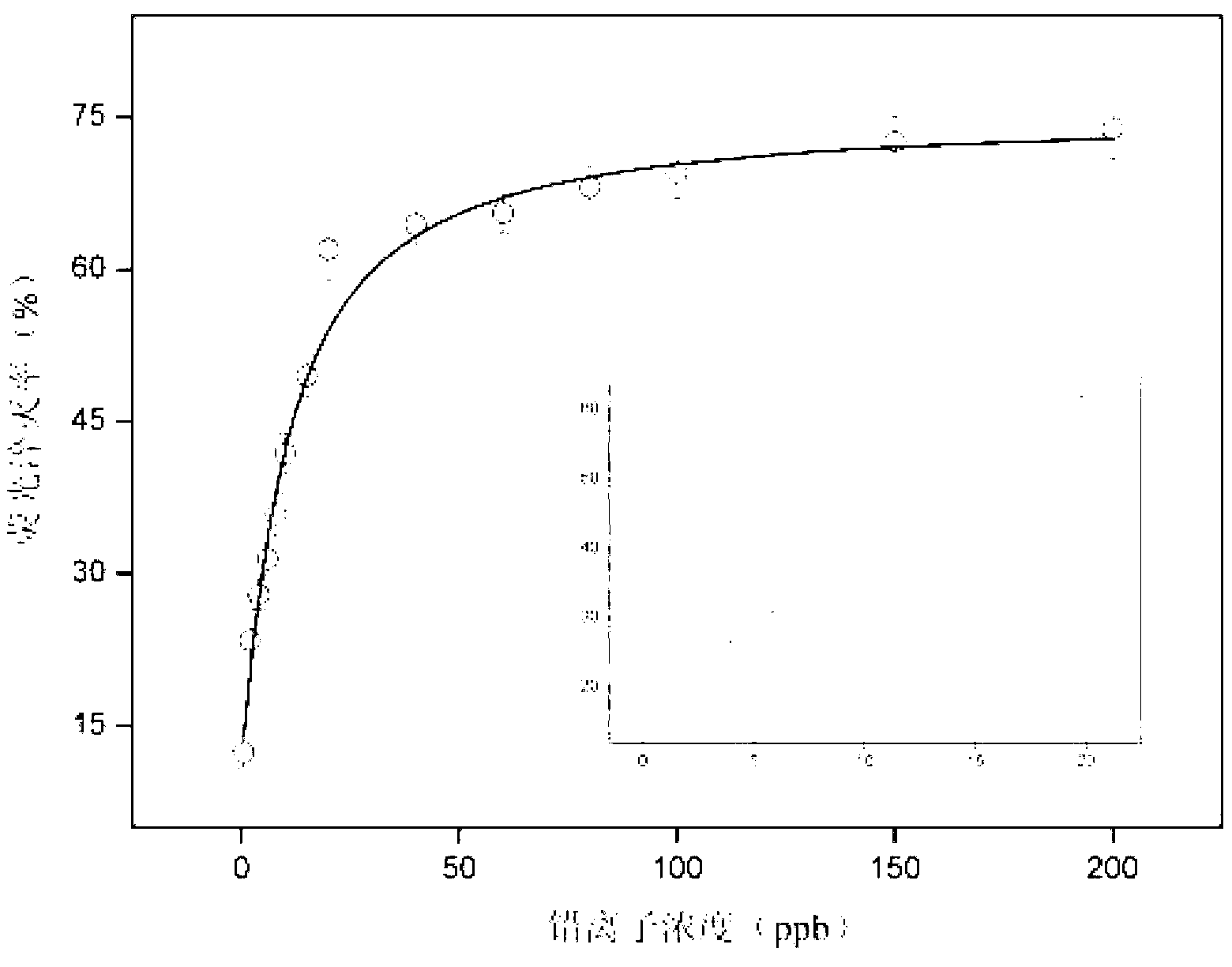

Method for detecting lead ions by forming G-quadruplex quenching fluorescent light by using functional nucleic acid

InactiveCN103245652ALower synthesis costShorten the lengthMicrobiological testing/measurementPreparing sample for investigationWater qualityFluorescent quenching

The invention relates to a method for detecting lead ions by forming G-quadruplex quenching fluorescent light by using functional nucleic acid, belonging to the technical field of water quality detection. The method comprises the following steps of: marking the functional nucleic acid by using carboxy fluorescein to construct a lead ion detection system, wherein when lead ions are added into the detection system, the lead ions promote the functional nucleic acid to form a G-quadruplex structure to cause fluorescence signals of the whole system to significantly change around 520nm, and the change of the fluorescence signals is in a positive relationship with the concentration of the lead ions; then carrying out fluorescence spectrum scanning by adopting a fluorescent photometer to obtain a fluorescence quenching rate standard curve; and mixing a water sample to be tested and ultrapure water, namely contrast samples, with a mother solution of the functional nucleic acid respectively, and comparing the fluorescence quenching rates of two mixed products at a part of which the wavelength is 480nm with the fluorescent quenching rate standard curve to obtain the concentration of the lead ions in the water sample to be tested. By adopting the method, the defects that a lot of assistants are needed to be introduced during the detection of the lead ions by using the existing functional nucleic acid, a complex catalytic reaction is related and the like are overcome, and efficient water body lead ion detection of which the lowest detection limit is 0.77ppb and the cost is low is realized by adopting simple operation.

Owner:SHANGHAI JIAO TONG UNIV

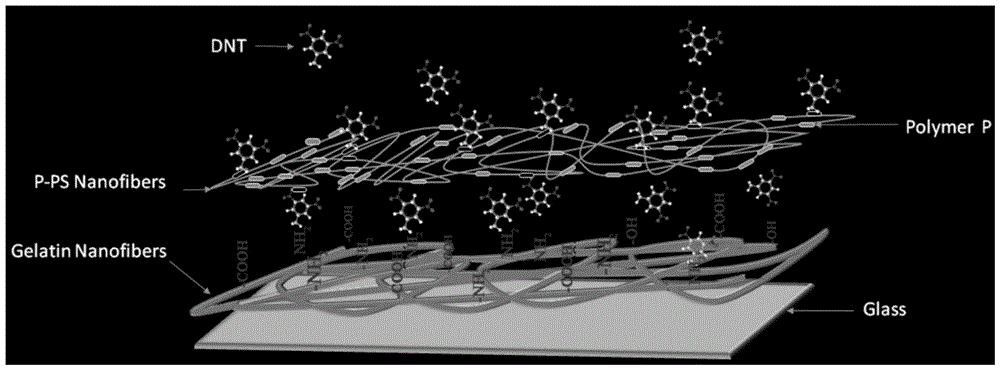

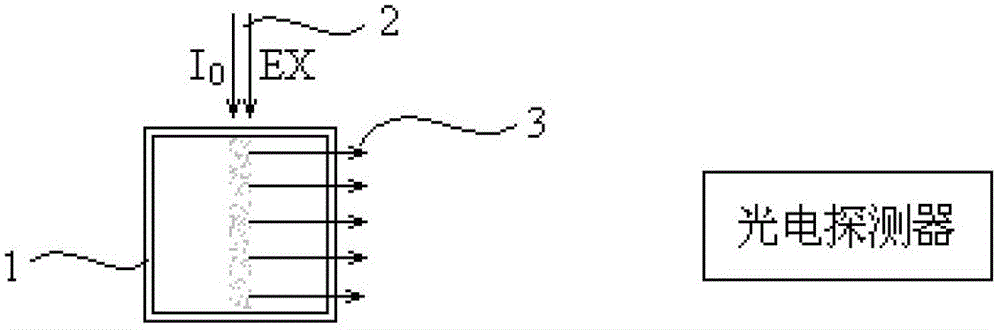

Application of double-layer electrostatic spun film sensor in detection of nitro-aromatic substances

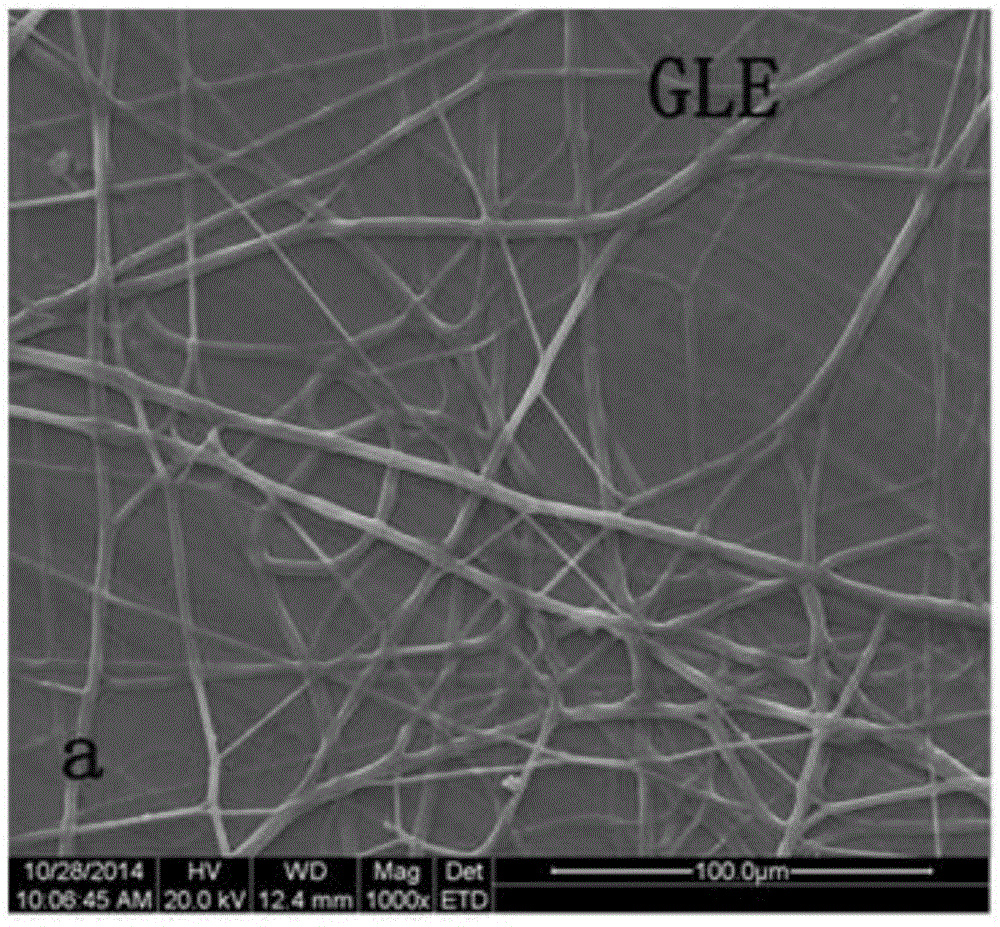

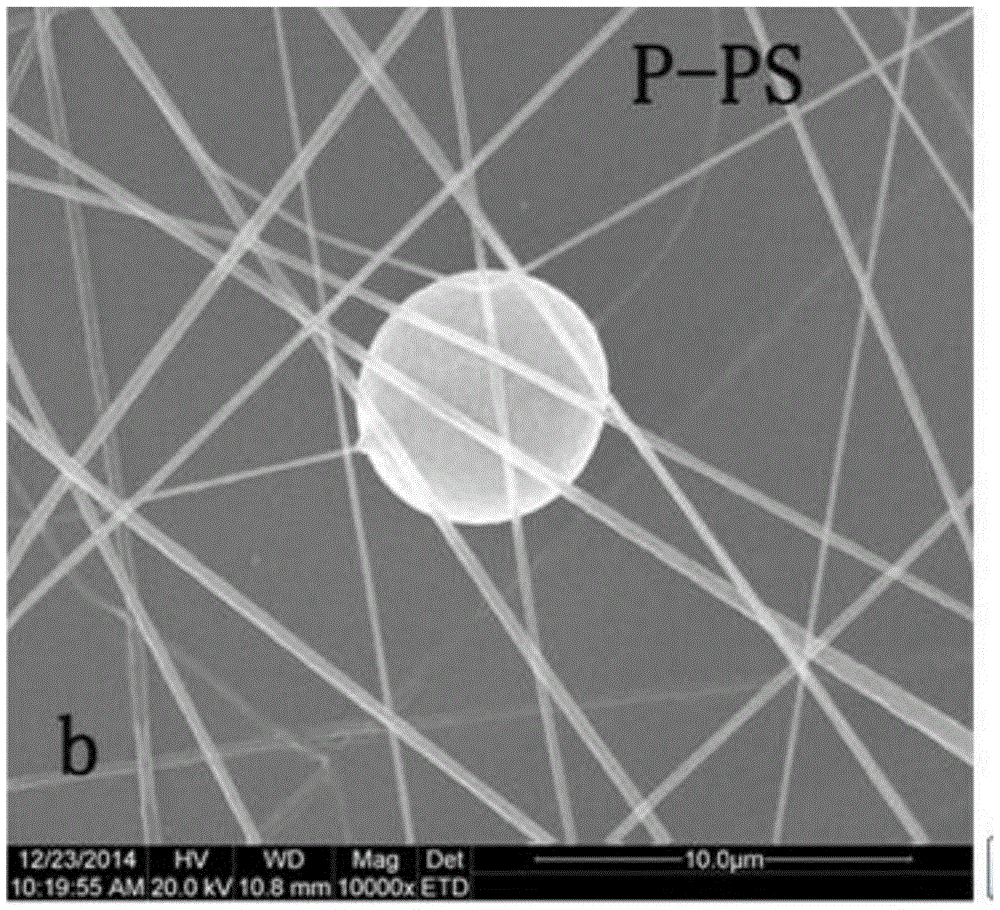

InactiveCN105588824AImprove Sensing PerformanceImprove permeabilityFluorescence/phosphorescencePolystyreneGlass sheet

The invention discloses an application of a double-layer electrostatic spun film sensor in detection of nitro-aromatic substances. The sensor comprises a double-layer film structure, wherein the bottom layer is a gelatin electrostatic spun film (GEL) and is taken as a framework layer to be arranged on the surface of a glass sheet; the top layer adopts PS (polystyrene) as a carrier which is blended with a fluorescent sensing polymer P described in the claim 1, an electrostatic spun film PS-P is prepared, and the layer is a sensing layer. The application of the double-layer electrostatic spun film sensor has the advantages as follows: i) the gelatin contains a large quantities of amino groups and hydroxyl groups, nitro-aromatic compounds are enriched through hydrogen bond interaction between the nitro-aromatic compounds and the gelatin, so that the nitro-aromatic compounds are gathered on the PS-P sensing layer, and the quenching rate is increased; ii) as a porous framework below the PS-P layer, the GEL layer allows upper and lower simultaneous diffusion of nitro-aromatic molecules on the PS-P layer, and the permeability of the PS-P layer is improved greatly.

Owner:QILU UNIV OF TECH

Method for short-time on-line replacement of coke dry quenching furnace water sealed tank

The invention discloses a method for short-time on-line replacement of a coke dry quenching furnace water sealed tank. Through material level lowering, circulating fan ceaselessness, circulating air volume reduction, and heat preservation, the method can finish replacing a water sealed tank in a short time. And the method comprises: before replacing, lowering a material level, keeping a circulating fan operating, reducing a circulating air volume, and discharging coke in a small amount for heat preservation and pressure maintaining; welding lifting lugs on the peripheries of the water sealed tank, passing a wire rope through the lifting lugs, and transversely shifting a coke pot cover to a position over the water sealed tank with a hoisting device; letting an operator hoist the water sealed tank to a position higher than a loading device with a hand-chain hoist, then utilizing the hoisting device to shift a coke pot and the water sealed tank transversely to a hoisting headframe, and placing them on a beforehand made trolley under the headframe; and installing a new water sealed tank, and placing it into place accurately, thus finishing replacing the water sealed tank. The method of the invention realizes replacement of a water sealed tank in a shortest time without stopping the furnace, thus guaranteeing the relative enhancement of dry quenching rate, steam quantity and power generation.

Owner:NANJING IRON & STEEL CO LTD

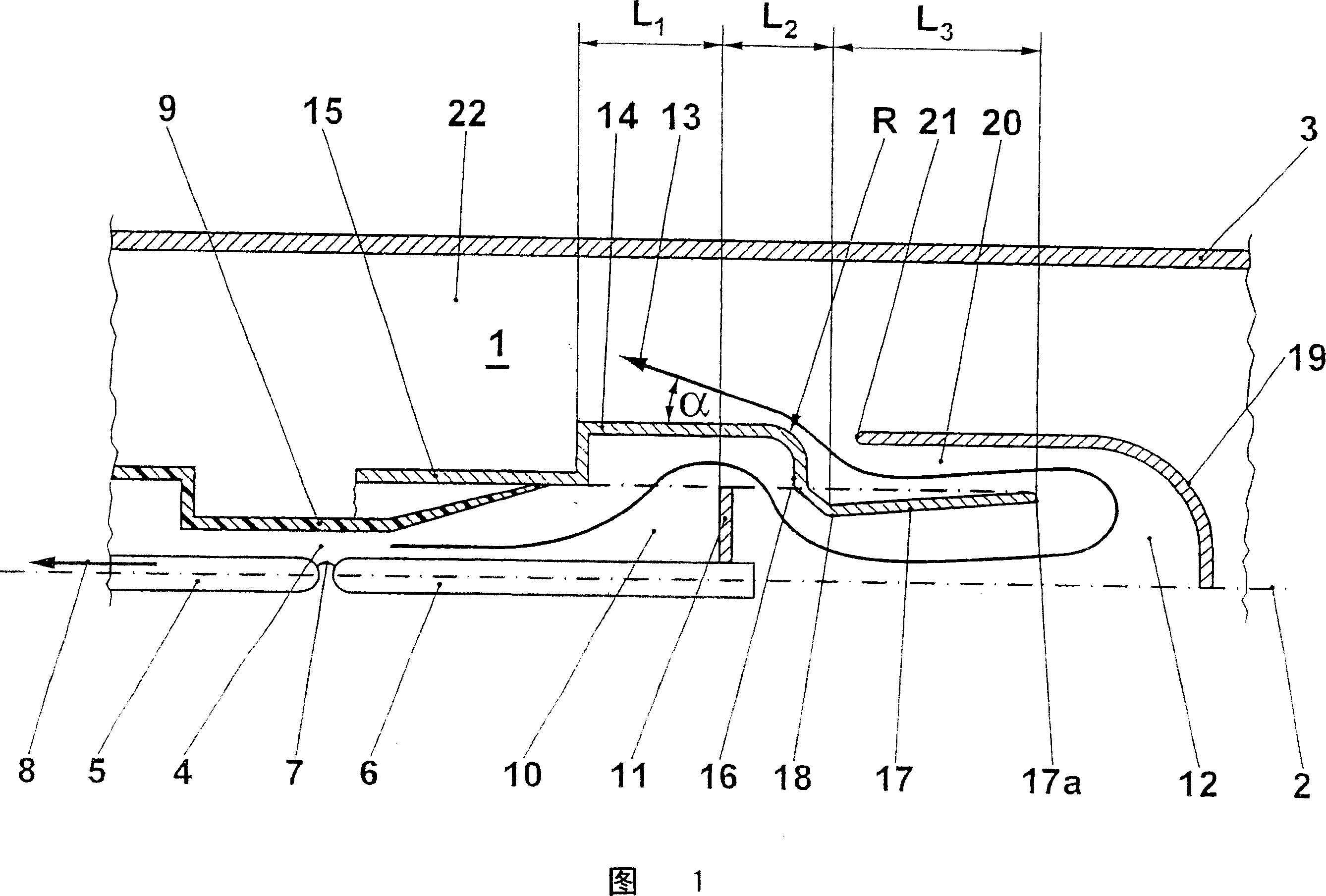

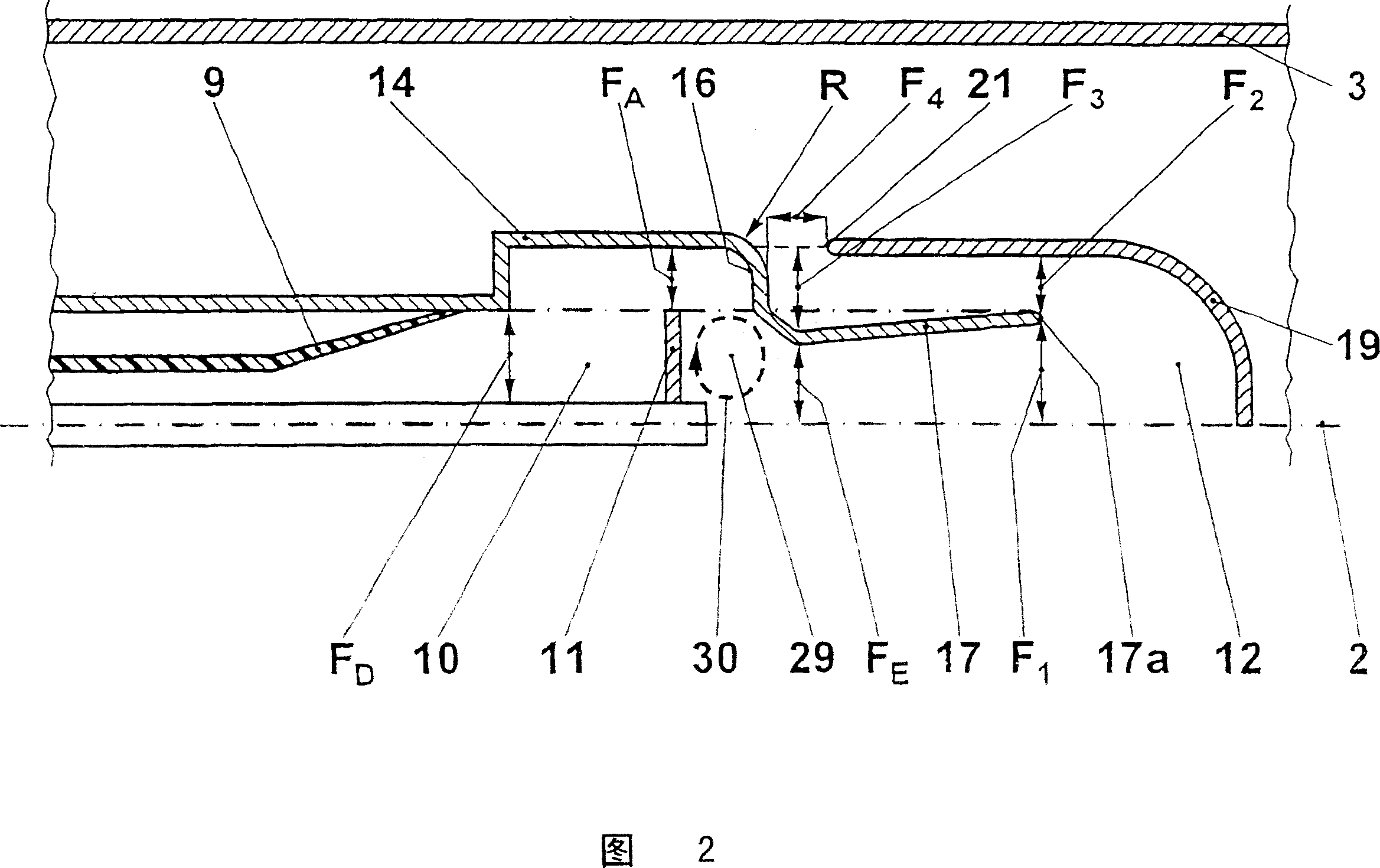

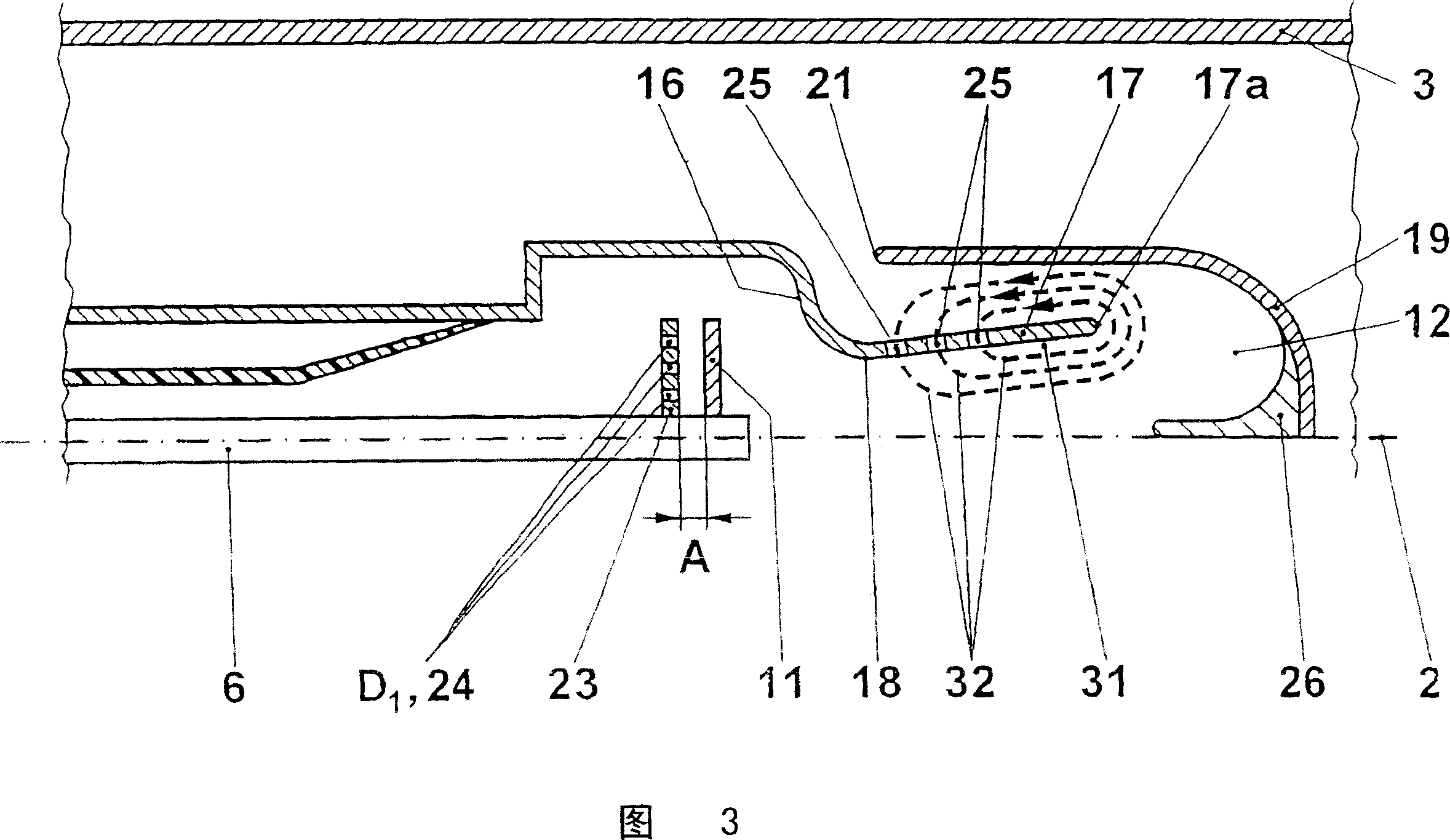

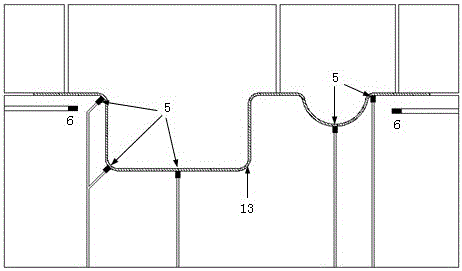

Circuit breaker

ActiveCN1965382AImprove thermal airflow resistanceIncrease flow resistanceHigh-tension/heavy-dress switchesAir-break switchesFunctional connectivityEngineering

The invention relates to a power switch which comprises, encapsulated together with an insulating gas, at least one substantially radially symmetrical extinction chamber (1) filled with the insulating gas which extends along a longitudinal axis (2) and contains at least two power contacts (5, 6) and an arc quenching chamber (4) associated therewith. The arc quenching chamber (4) is functionally linked with at least one exhaust having an exhaust volume (12), which is adapted to cool the hot gases produced when the switch is switched off. The exhaust is linked with an arc quenching chamber volume (22). The aim of the invention is to substantially improve the arc quenching rate of power switches and to provide an exhaust which is comparatively simple and expensive in design. For this purpose, at least one forced recirculation area (29) increasing the flow resistance of the hot gases is provided in the area of the exhaust.

Owner:HITACHI ENERGY LTD

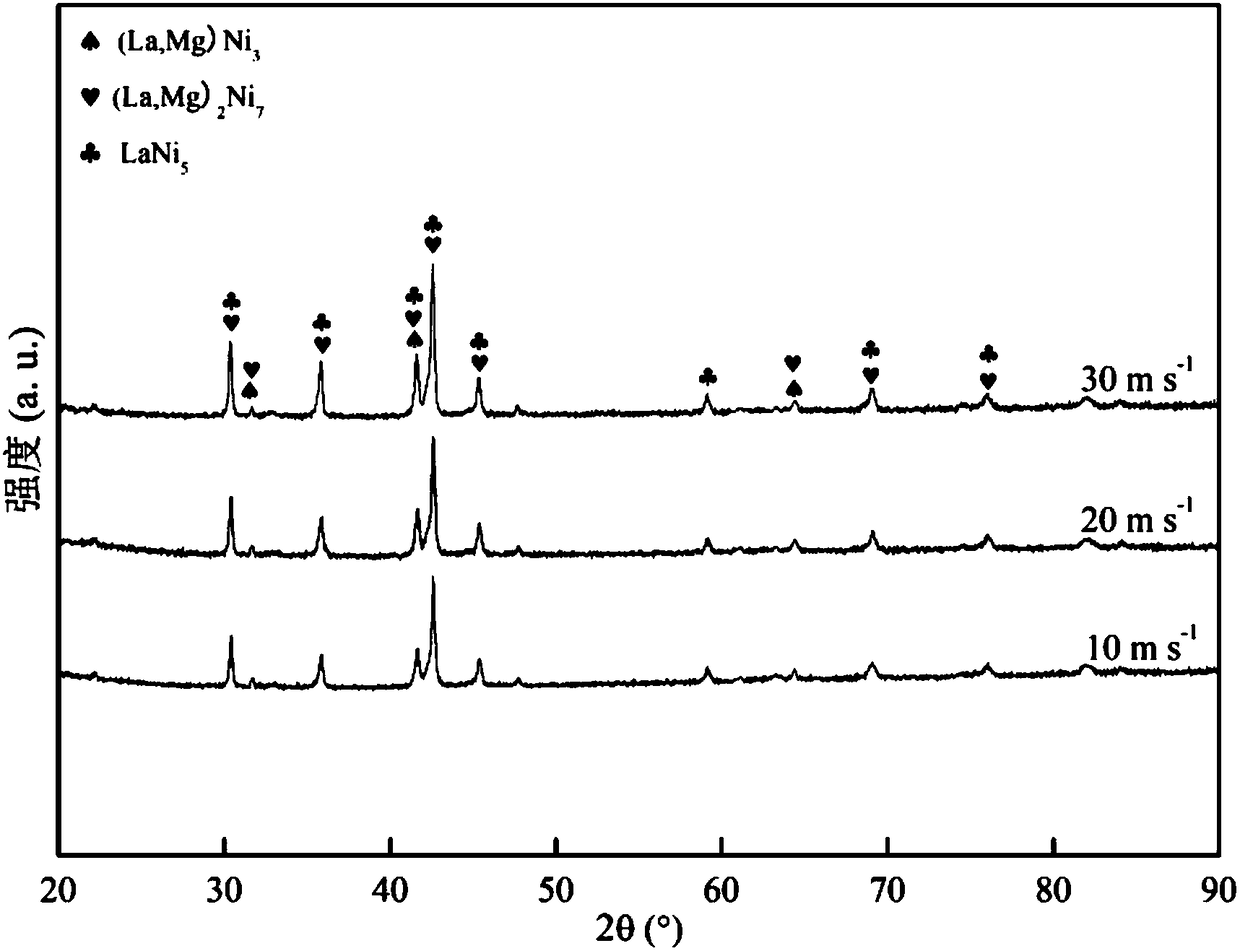

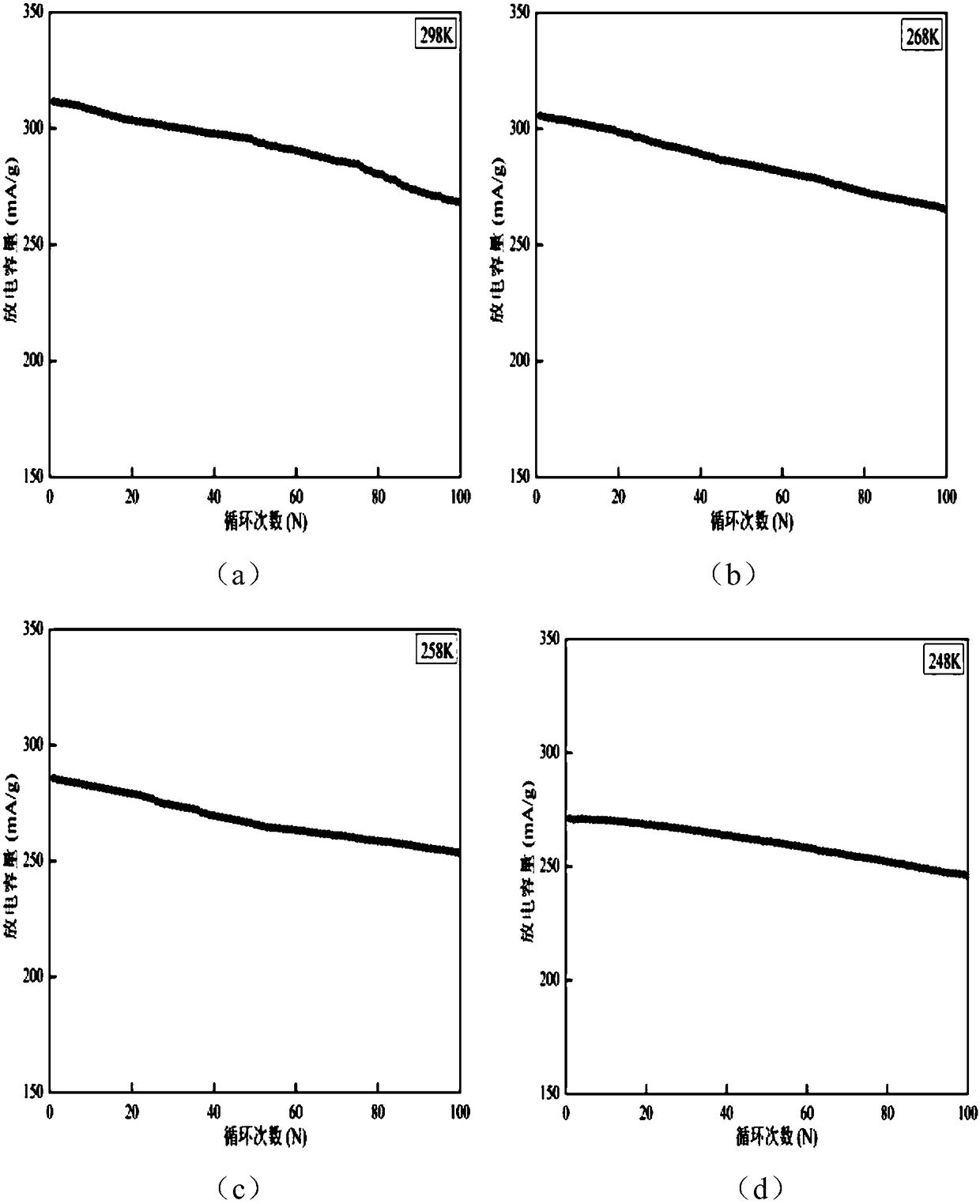

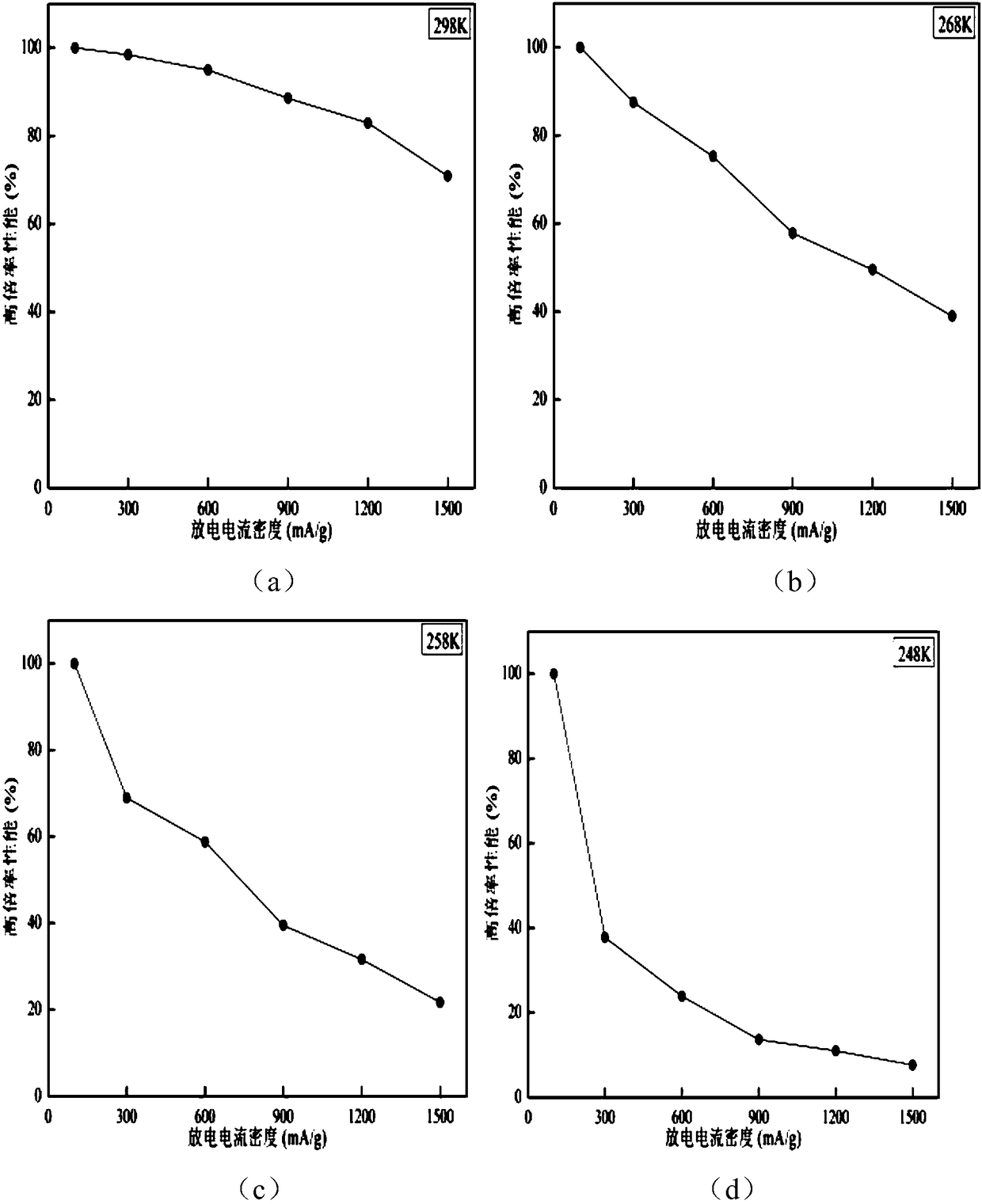

La-Mg-Ni series hydrogen storage alloy for low-temperature nickel-hydrogen battery and preparation method of La-Mg-Ni series hydrogen storage alloy

The invention discloses a La-Mg-Ni series hydrogen storage alloy for a low-temperature nickel-hydrogen battery and a preparation method of the La-Mg-Ni series hydrogen storage alloy. The chemical component of the alloy is La<0.75-x>CexMg0.25Ni3Co0.5, wherein the subscripts in the chemical component are atomic ratios of corresponding constituents, and the value range of x is 0.09-0.11. The preparation method of the alloy comprises the following steps of raw material preparation; smelting and casting; alloy thin strip preparation; and grinding and screening. The alloy prepared by the method hashigh low-temperature electrochemical performance, and under the condition of 248K, at the quenching rate of 10 m.s<-1>, when charging and discharging are circulated 100 times, the discharge capacity of the alloy reaches the maximum value of 245.9 mAh.g<-1>. An alloy material prepared by the preparation method is particularly suitable for being used under the condition of zero DEG C or below, particularly under the condition of minus 25 DEG C and even under the condition of minus 30 DEG C.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method for cerium-base metallic organic framework material, application thereof in Co(II) recognition and fluorescence detection method

ActiveCN108948373AAdapt to real-time detectionEasy to operateFluorescence/phosphorescenceLuminescent compositionsCeriumMetal-organic framework

The invention discloses a preparation method for a cerium-base metallic organic framework material, an application thereof in Co(II) recognition and a fluorescence detection method. The preparation method comprises the following steps: adding 5-aminoiophthalic acid and 4,4'-(1,3-propylene) bipyridine into water, and then adding cerium nitrate hexahydrate, stirring and reacting under preset temperature for preset reaction time, thereby acquiring the cerium-base metallic organic framework material. The fluorescence detection method for the prepared cerium-base metallic organic framework materialin Co(II) recognition comprises the following steps: gradually dropwise adding the cerium-base metallic organic framework material into a newly prepared 1mmol / L Co(II) ethanol solution till the fluorescence intensity is free from dramatic decline, thereby acquiring a fluorescence quenching rate of Co(II) for the cerium-base metallic organic framework material, and meanwhile, processing and fitting a fluorescence test data, thereby acquiring a working curve and a quenching constant of Co(II). The fluorescence detection method has the advantages of real time detection, simple operation and highsensitivity.

Owner:HOHAI UNIV

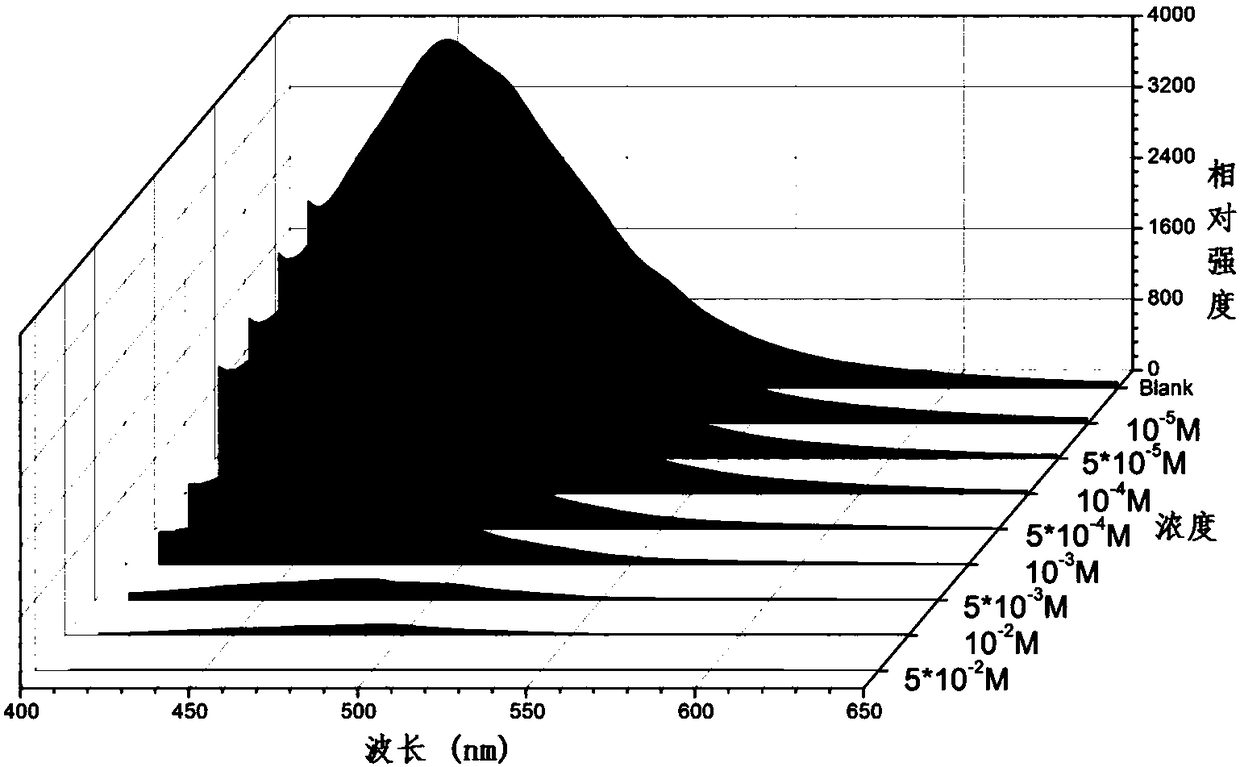

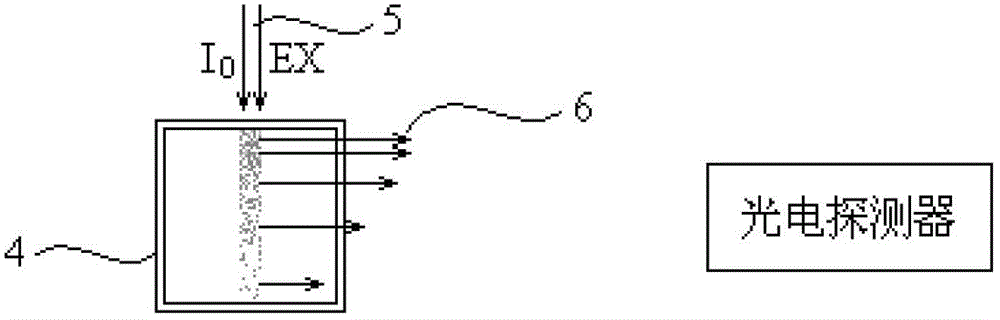

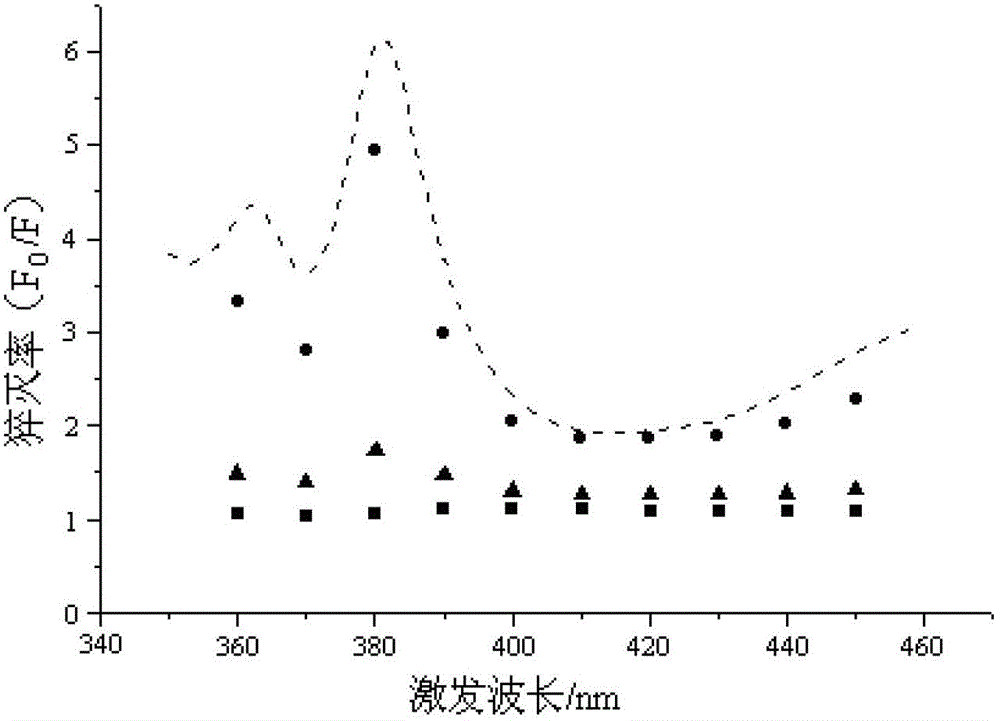

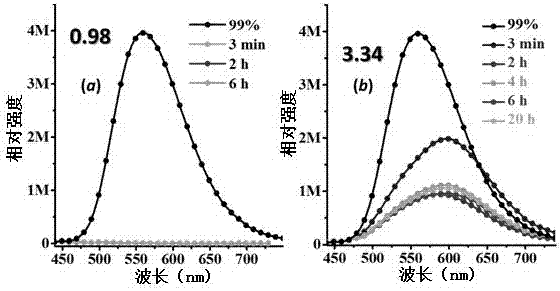

Accurate correction method of fluorescence quenching rate in inner filtering efficiency process of fluorescence quenching system

InactiveCN102914529AAccurate correctionThe calibration method is simpleFluorescence/phosphorescenceLighting spectrumCorrection method

The invention discloses an accurate correction method of a fluorescence quenching rate in an inner filtering efficiency process of a fluorescence quenching system, and the method is characterized by comprising the following steps of: firstly, correcting influences of competitive absorption on a light spectrum; then, correcting the influences of absorption on the light spectrum; and correcting the influences of absorption distribution on the light spectrum. The method disclosed by the invention can be used for carrying out combined correction on the influences caused by a fluorescence inner filtering efficiency and absorption distribution, so as to ensure that the light spectrum of the quenching system is accurately corrected; and the fluorescence quenching rate in the quenching process is really reflected.

Owner:HEFEI UNIV OF TECH

Organometallic complexes as singlet oxygen sensitizers

Owner:UNIV OF SOUTHERN CALIFORNIA

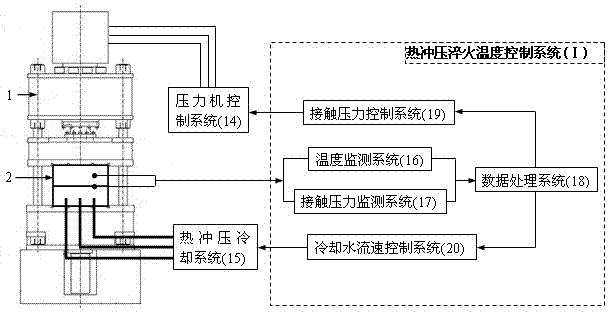

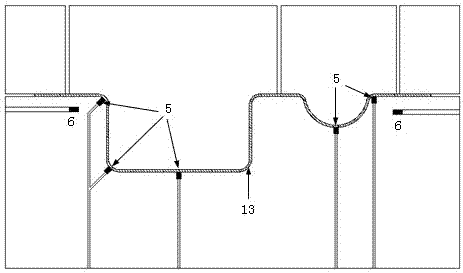

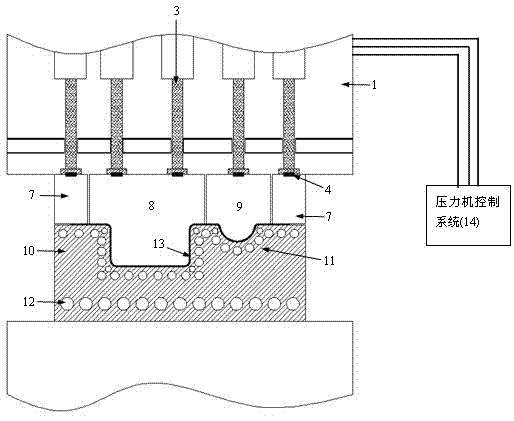

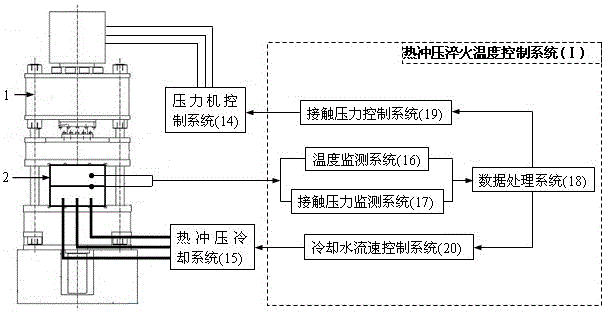

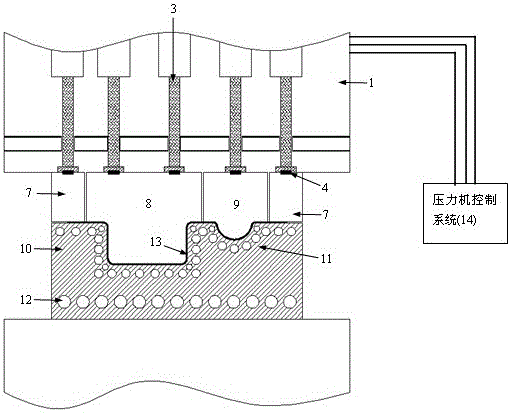

Heat stamping apparatus used for quenching control

InactiveCN104294020AEvenly distributedHomogeneous martensiteHeat treatment process controlQuenching devicesContact pressureControl system

The invention provides a heat stamping apparatus used for quenching control, which belongs to the technical field of heat stamping. A purpose of the present invention is to solve the problems that in a heat stamping technology, in the quenching process of a high-temperature forming part, uniform distribution of surface temperature of the forming part can not be guaranteed on the condition that quenching uniformity is guaranteed, and the invention provides the heat stamping apparatus used for heat stamping quenching control. The heat stamping apparatus enables real time monitoring on the temperature value of selected measurement points during a high-temperature plate shaping process, the quenching rate and temperature difference between the selected measurement points can be obtained through data processing; when the quenching rate can not satisfy the condition or the temperature difference is large, a control system is capable of adjusting contact pressure and cooling water flow velocity of the forming parts and mold surface with pertinence according to the trigger condition, then the quenching rate of the high-temperature forming parts can satisfy the requirement, and the temperature of the forming parts can be equalized, so that the intensity quality requirement and the forming precision requirement of the final forming parts can be ensured.

Owner:JIANGSU UNIV

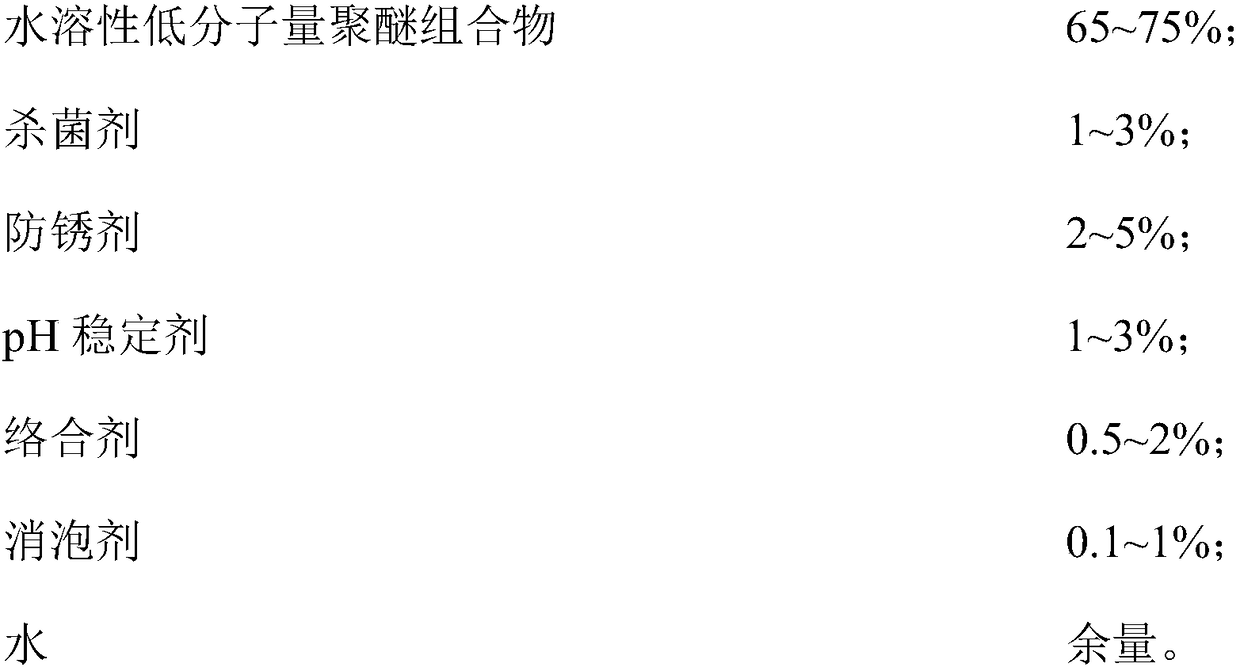

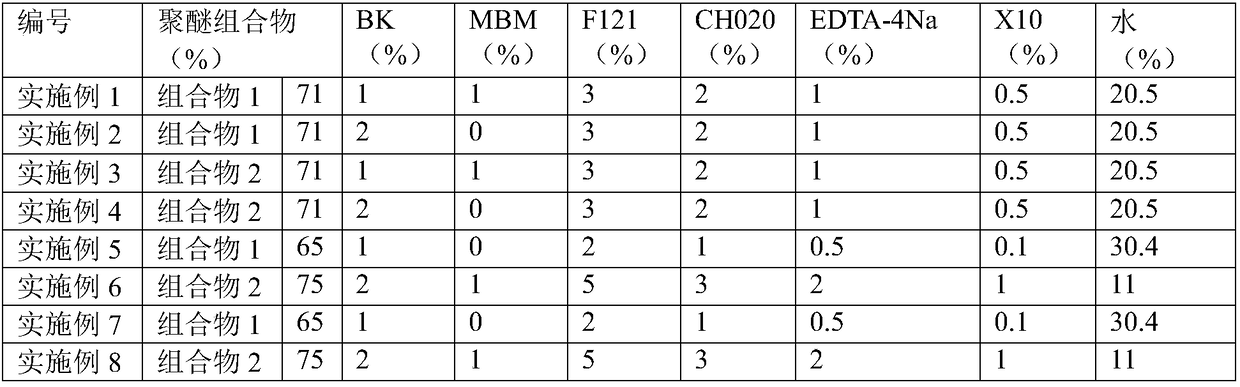

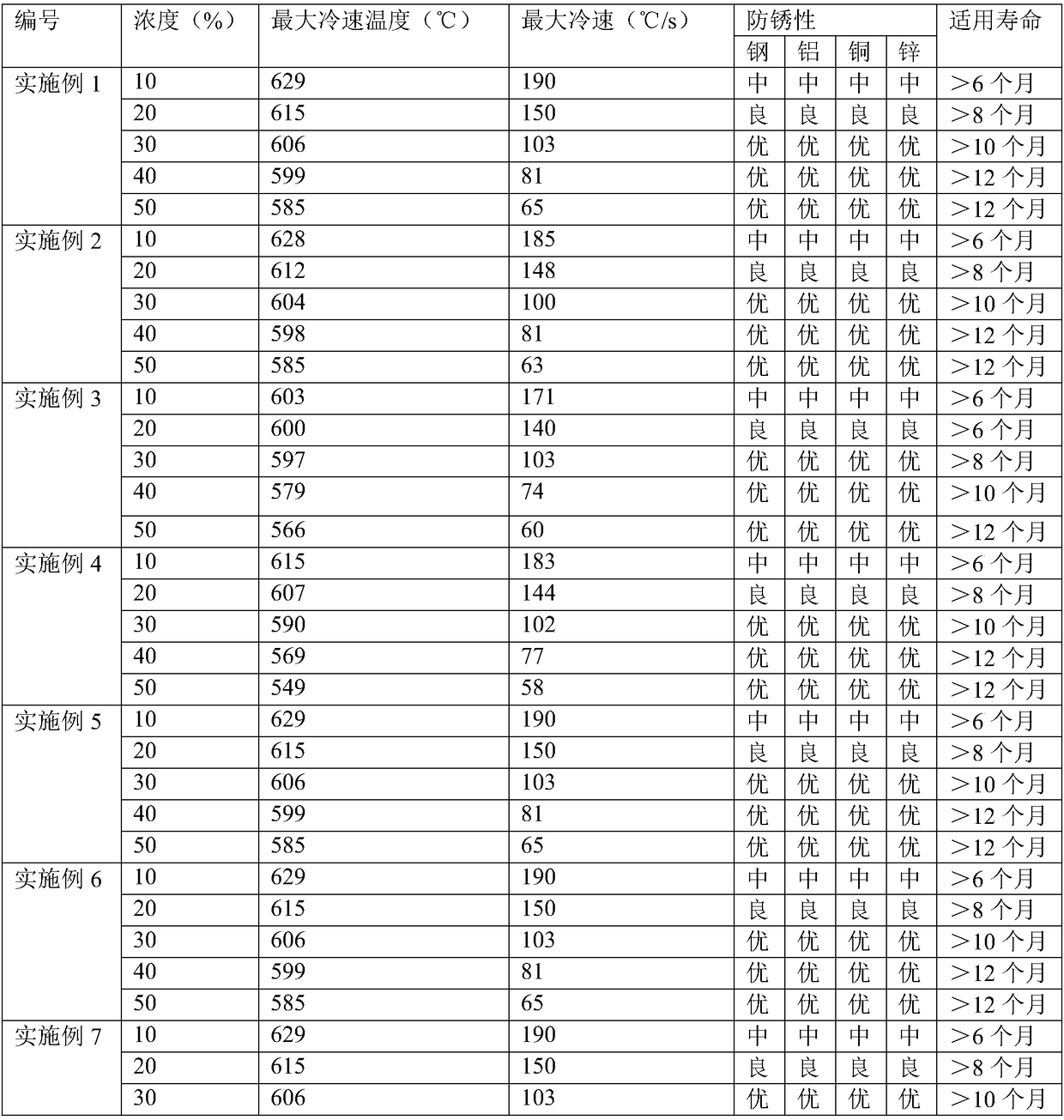

Environment-friendly type water-based quenching liquid composition as well as preparation method thereof and using method thereof

ActiveCN108588357ASuitable for quenching process requirementsImprove cooling effectQuenching agentsWater basedSteel ball

Owner:辽宁宝瑞科技有限公司 +1

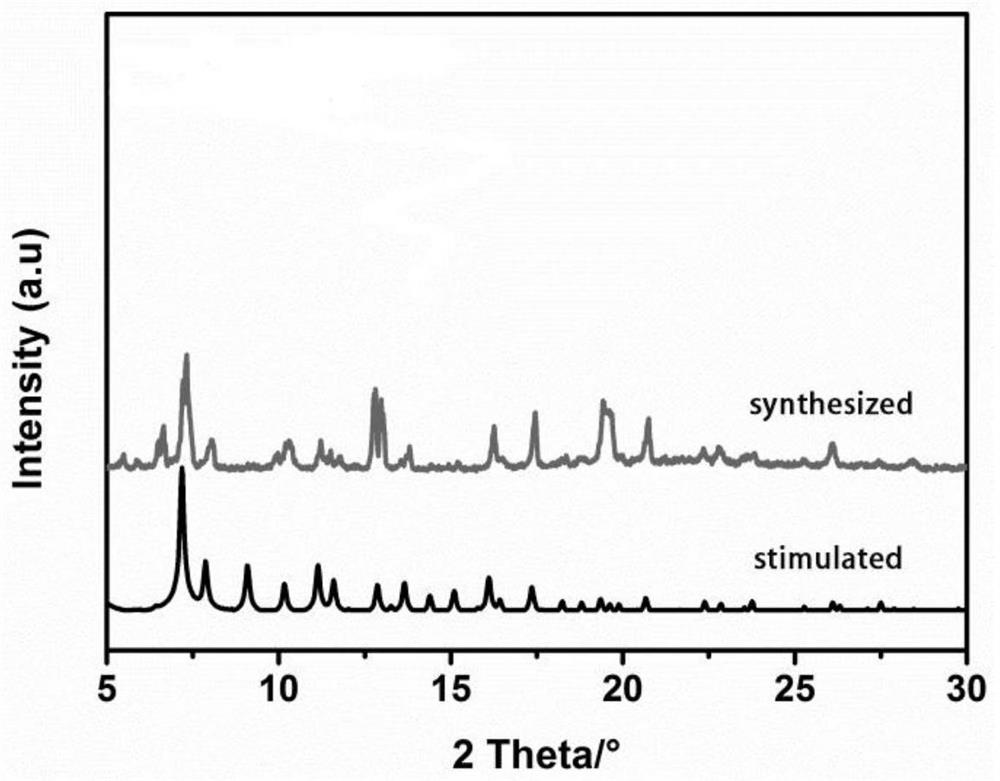

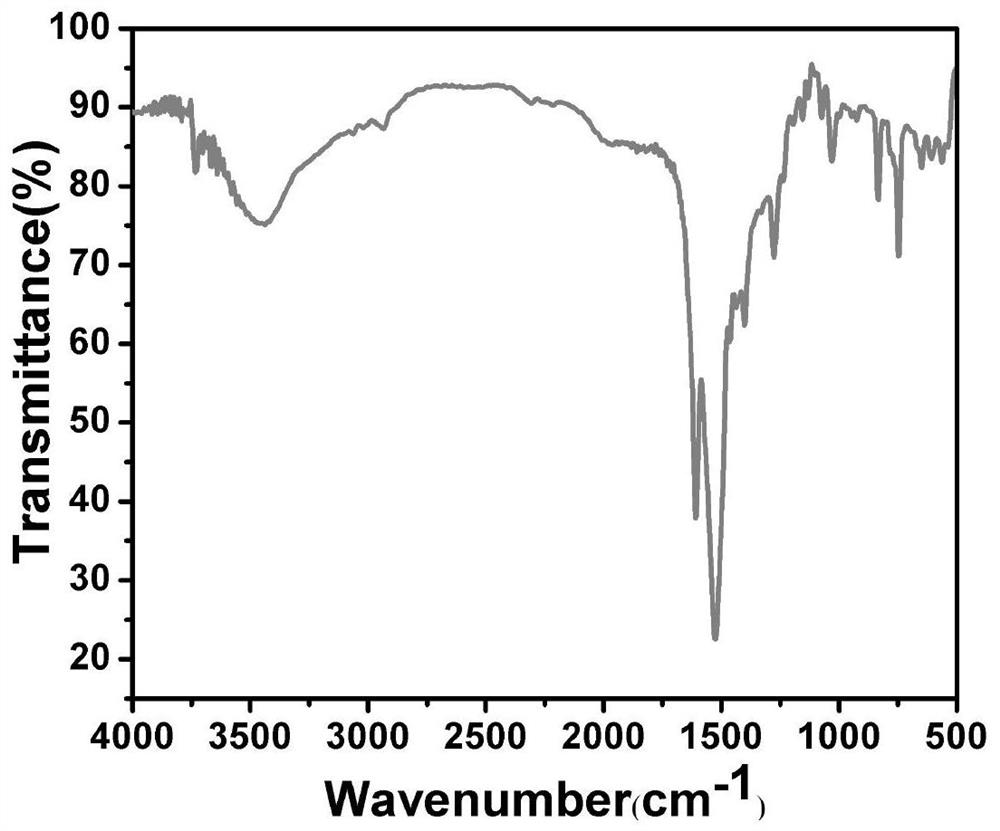

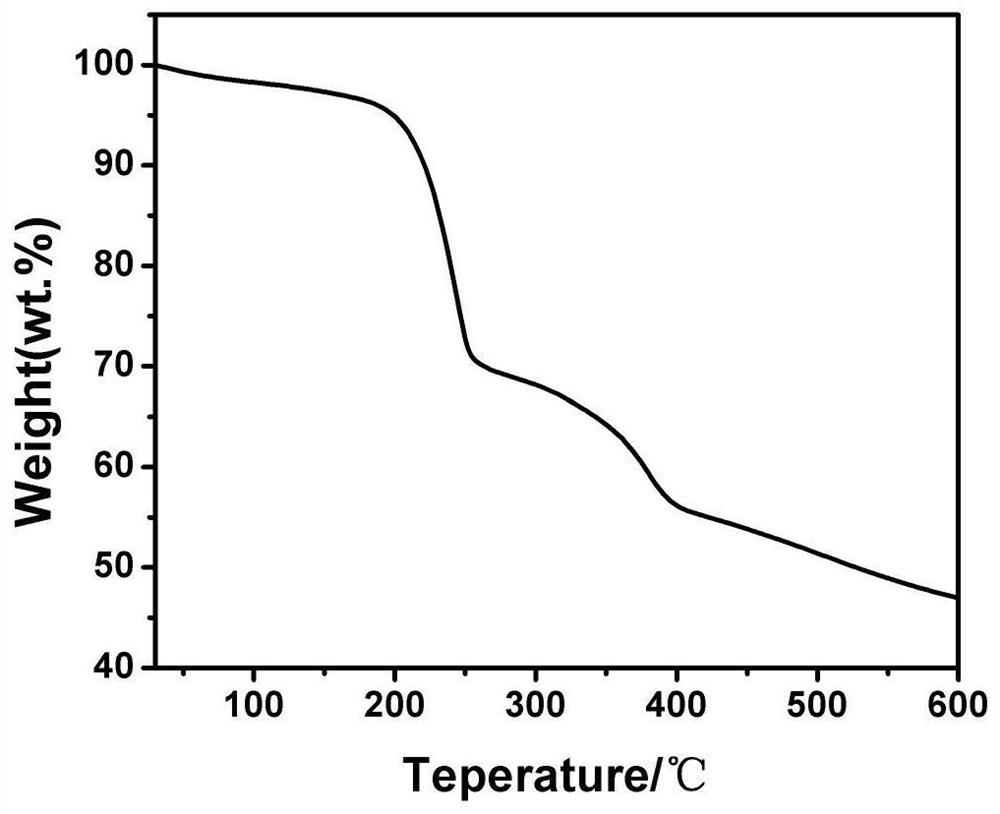

Preparation method and application of triphenylamine derivative and doped thin film thereof

InactiveCN106883168AWith compressionThe synthesis method is simpleOrganic chemistryFluorescence/phosphorescenceSynthesis methodsAniline

The invention discloses a triphenylamine derivative having acid stimulation response color and fluorescence double change and an SEBS (Styrene-Ethylene / Butadiene-Styrene Copolymer)-doped thin film thereof. The reversible acid-alkali stimulation response color and fluorescence properties of the SEBS-doped thin film of the triphenylamine derivative respectively have the characteristics of large chromatic aberration and high fluorescence quenching rate; the mechanical property of the thin film has the characteristics of tensibility, bending performance, compression performance and restorability; the thin film is simple in synthesis method, and the reality of a reversible acid stimulation fluorescent change material in sensors is greatly broadened.

Owner:HUZHOU TEACHERS COLLEGE

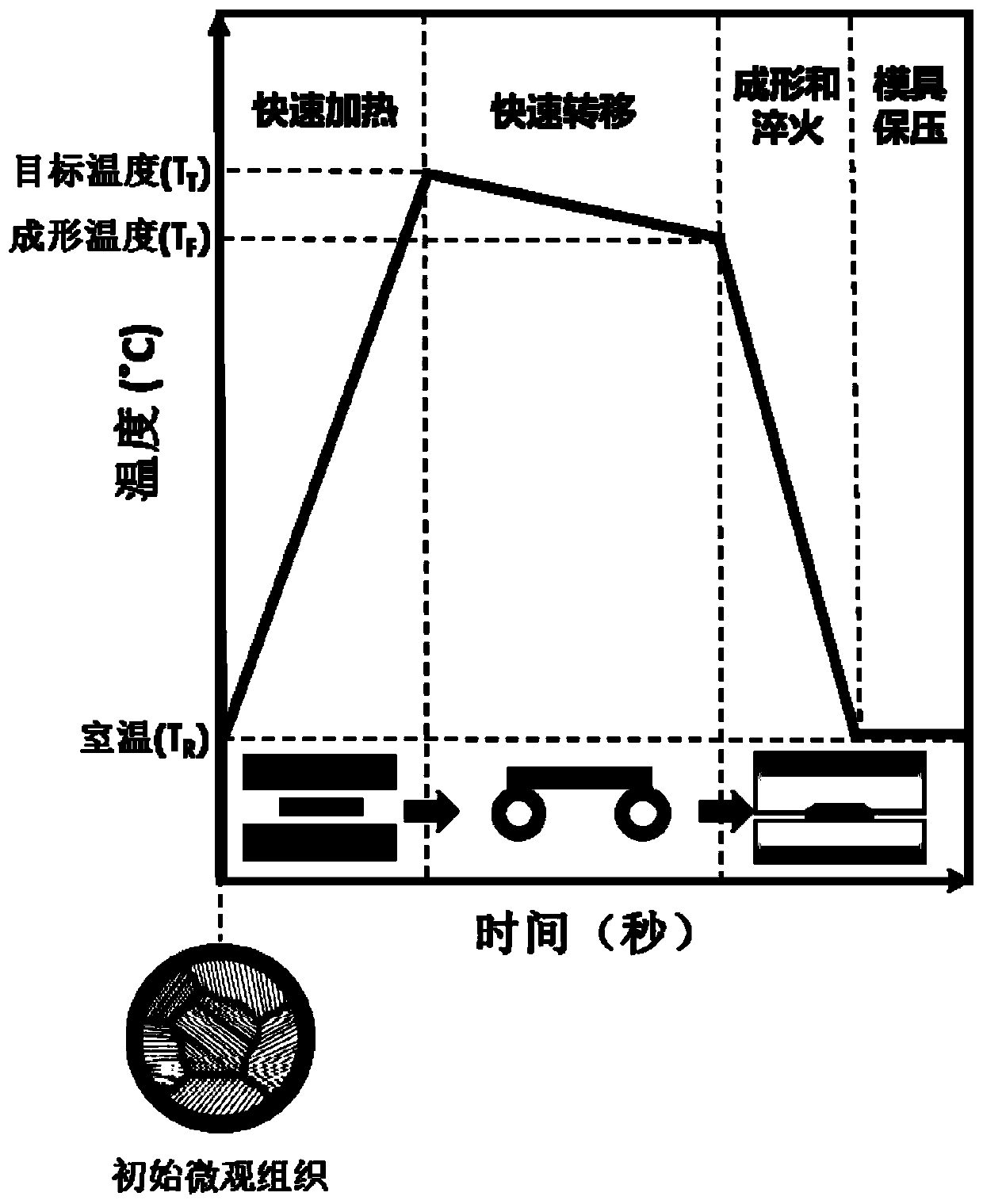

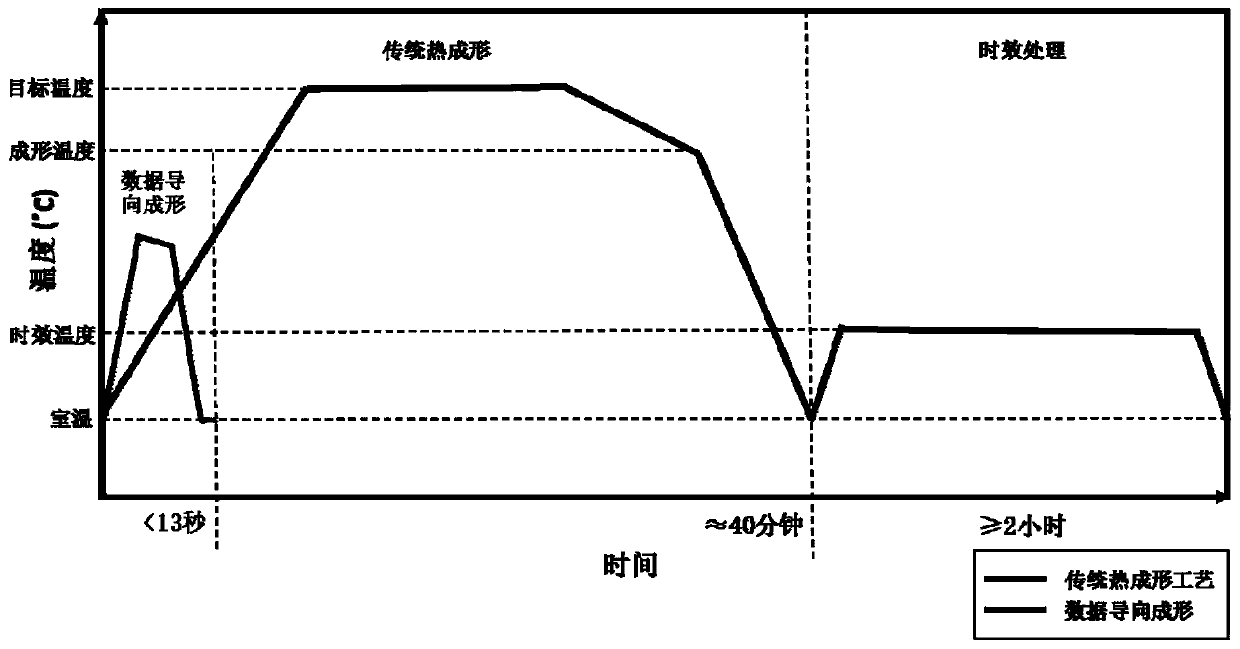

Data-oriented method for manufacturing lightweight thin-wall metal sheet

ActiveCN110465573AImprove production and processing efficiencyShorten the durationShaping toolsMetal working apparatusMicro structureHot stamping

The invention relates to a data-oriented method for manufacturing a lightweight thin-wall metal sheet, and belongs to the field of metal sheet forming. The method solves the problems that a large amount of time and cost are spent in traditional hot stamping forming. The method comprises the following steps of according to data such as the baking finish process, the part design, the plasticity dependent variable of a material in the manufacturing process and the performance requirement after forming of a user, performing analyzing by using a data-oriented method, selecting a metal sheet containing a specific micro-structure, and performing retrieving in a database verified through experiments to obtain the optimized forming parameters; and rapidly heating the metal sheet to a target temperature, controlling the heating rate, rapidly transferring the metal sheet into a cooling mold, performing stamping forming, and quenching the formed metal sheet at a rate not lower than the critical quenching rate. The data-oriented rapid hot forming method is used for manufacturing high-strength steel, a high-strength aluminum alloy and a titanium alloy part which are complex in shape, and meets the requirement of large-scale production of parts in industry.

Owner:帝国理工创新有限公司

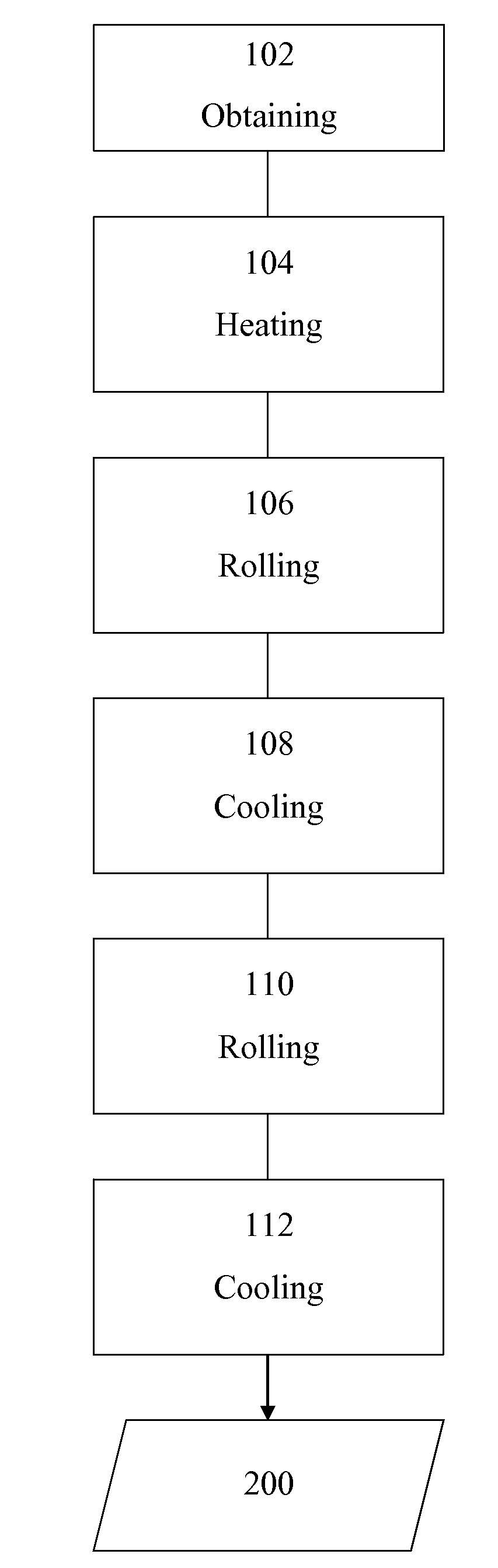

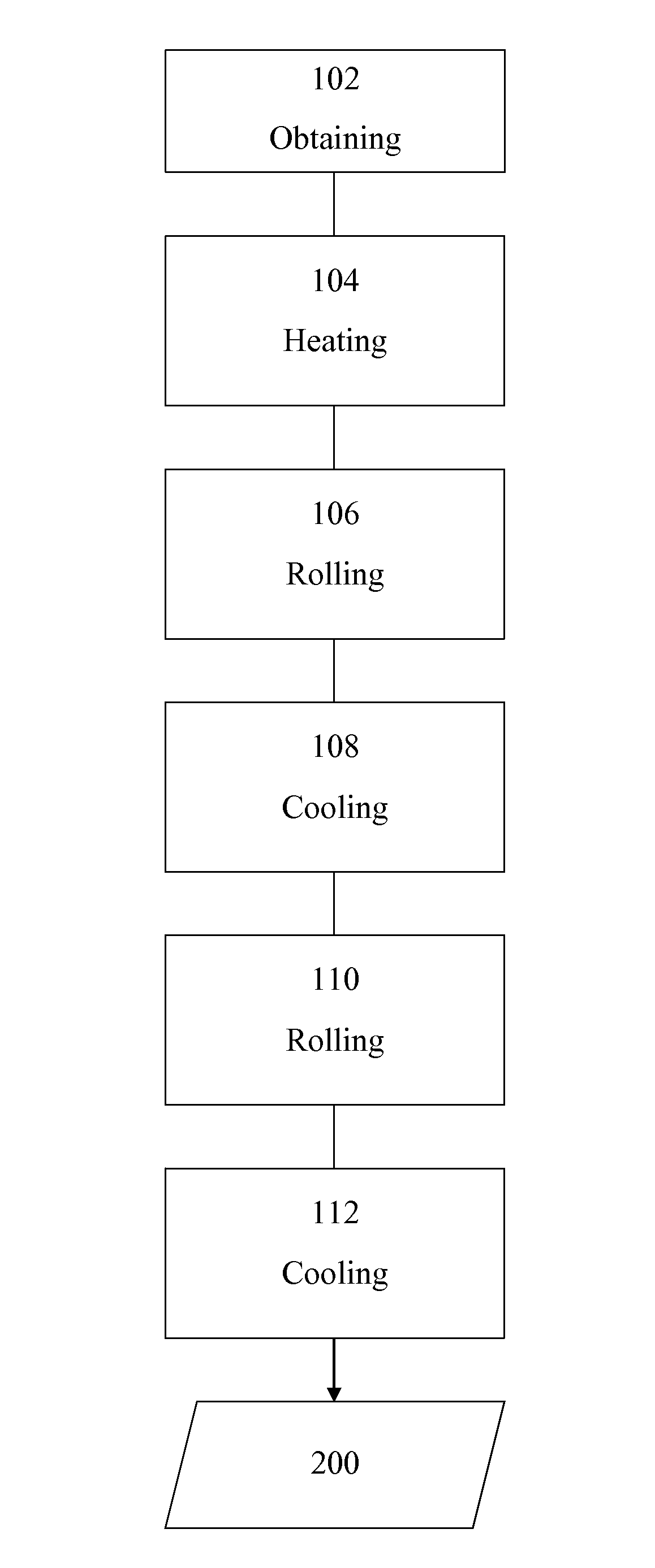

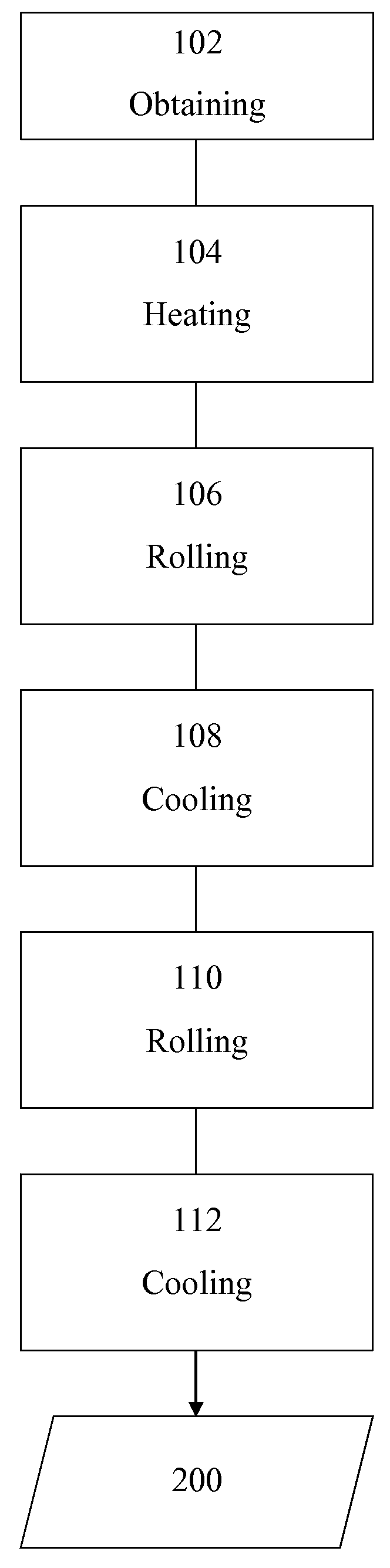

Method for production of martensitic steel having a very high yield point and sheet or part thus obtained

ActiveUS20140144559A1High yield stressFurnace typesHeat treatment furnacesSheet steelWork in process

The present invention provides a method for the fabrication of a martensitic steel sheet with a yield stress greater than 1300 MPa. The method includes the steps of obtaining a semi-finished steel product, the composition of which includes, whereby the contents are expressed in percent by weight: 0.15%≦C≦0.40%, 1.5%≦Mn≦3%, 0.005%≦Si≦2%, 0.005%≦Al≦0.1%, S≦0.05%, P≦0.1%, 0.025%≦Nb≦0.1%, and optionally: 0.01%≦Ti≦0.1%, 0%≦Cr≦4%, 0%≦Mo≦2%, 0.0005%≦B≦0.005%, 0.0005%≦Ca≦0.005%. The remainder of the composition is iron and the inevitable impurities resulting from processing. The semi-finished product is reheated to a temperature T1 in the range between 1050° C. and 1250° C., then the reheated semi-finished product is subjected to a roughing rolling at a temperature T2 in the range between 1050 and 1150° C., with a cumulative rate of reduction εa greater than 100%, to obtain a sheet with a not totally recrystallized austenitic structure with an average grain size less than 40 micrometers and preferably less than 5 micrometers. The sheet is then cooled to prevent a transformation of the austenite at a rate VR1 greater than 2° C. / s to a temperature T3 in the range between 970° C. and Ar3+30° C., is then subjected to a finishing hot rolling at the temperature T3 of the cooled sheet, with a cumulative rate off reduction εb greater than 50% to obtain a sheet, then the sheet is cooled at a rate VR2 which is greater than the critical martensitic quenching rate. Steel sheets are also provided.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

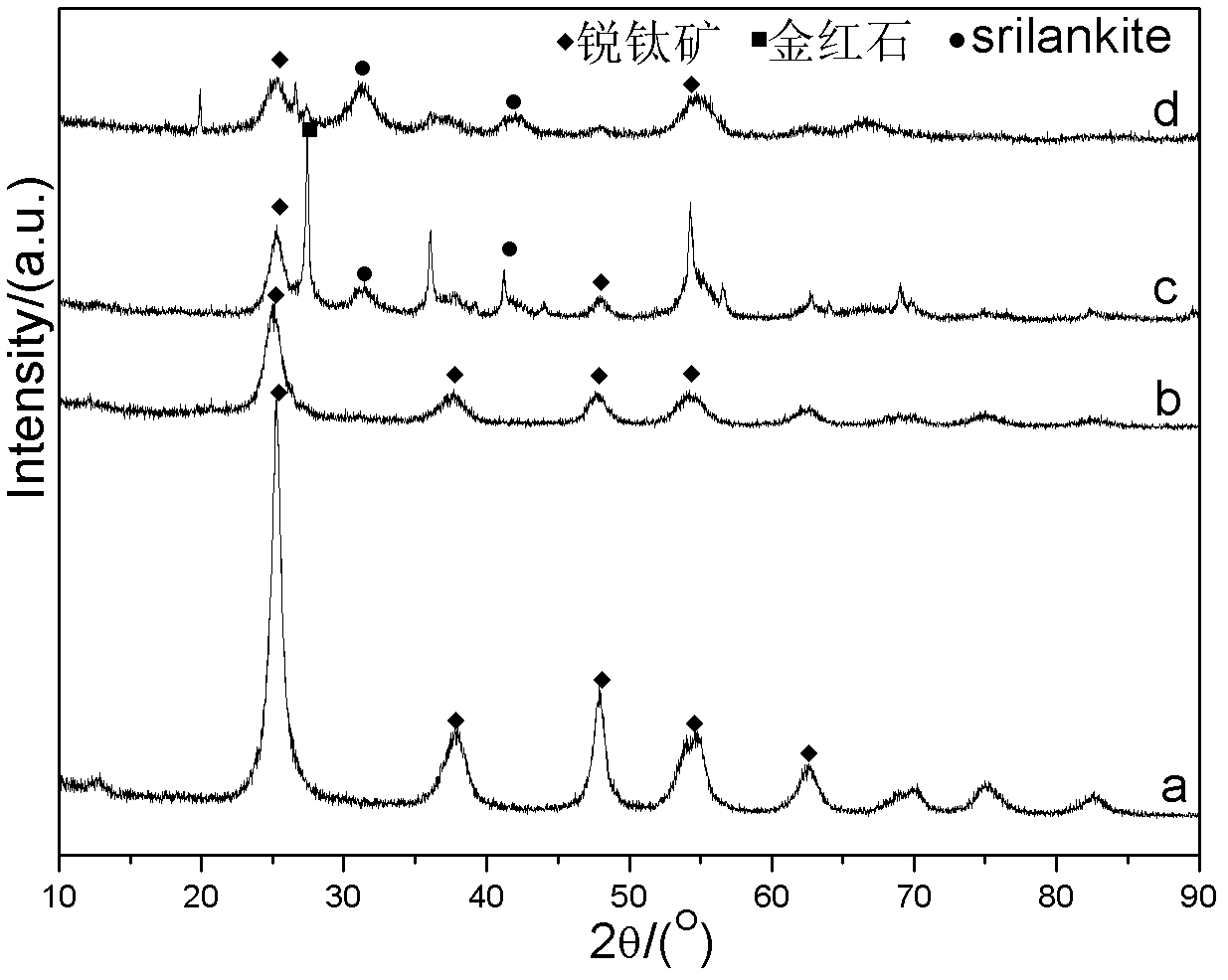

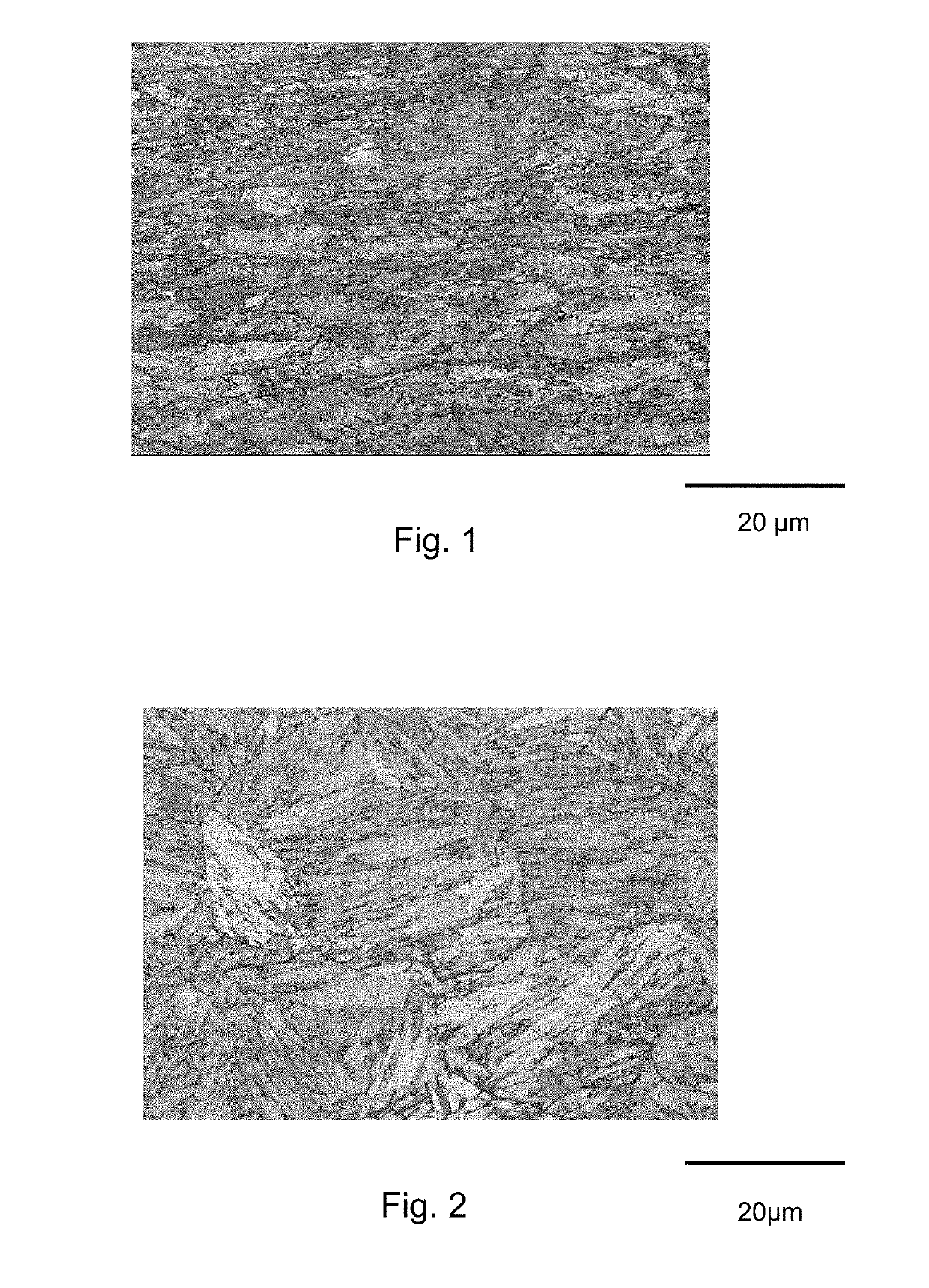

Technological method for producing high-performance neodymium iron boron bonding magnetic powder

ActiveCN102990057AEvenly distributedImprove performanceInorganic material magnetismQuenching rateMaterials science

The invention relates to a technological method for producing high-performance neodymium iron boron bonding magnetic powder. The technological method is characterized by comprising the steps of: classifying rapid-quenched neodymium iron boron magnetic powder into three types, namely over-quenched magnetic powder, under-quenched magnetic powder and reasonable-quenching-rate magnetic powder, in terms of the distinctions of crystal microstructures and the average size of inner crystals of the magnetic powder; separating the magnetic power according to the classification standard; and carrying out thermal treatment on the tree types of separated magnetic powder with different quenching rates under different temperature and time conditions for crystallization thermal treatment so as to obtain the magnetic powder with the optimal magnetic performance. The technological method has the advantages that a magnetic-separation grading method with accuracy in calculation is used to classify the magnetic powder with different quenching rates, then, the thermal treatment manners with different temperature and time conditions for crystallization thermal treatment are adopted to make crystal gains uniform in distribution so as to obtain the optimal grain size, thus, the optimal magnetic performance can be obtained, and the high-performance bonding magnetic powder can be produced. The technological method can be used for improving the performances of like magnetic powder by more than 15-20%.

Owner:BAOTOU KERUI MICRO MAGNET NEW MATERIALS CO LTD

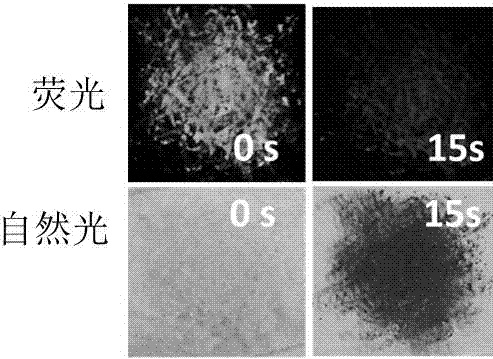

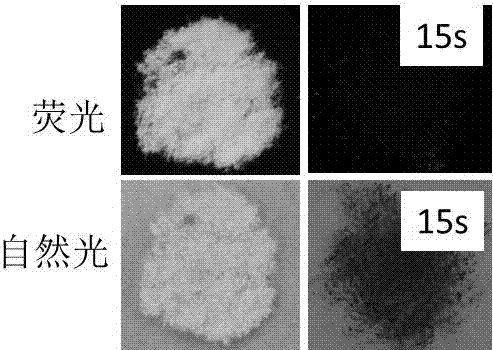

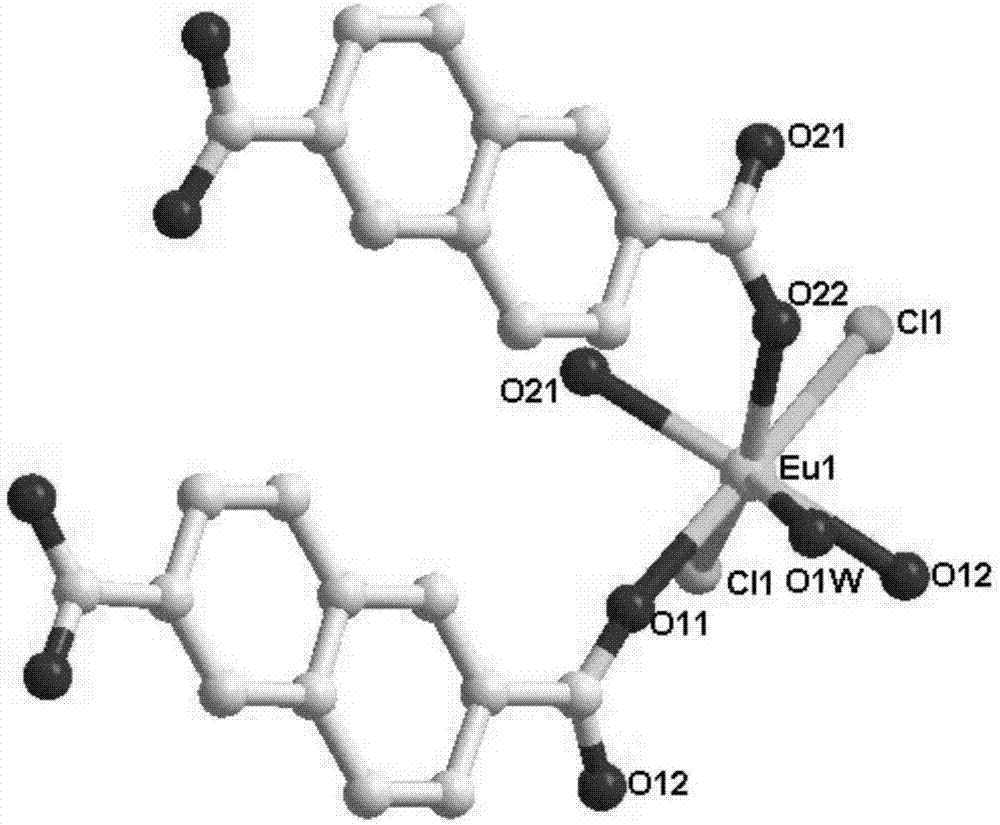

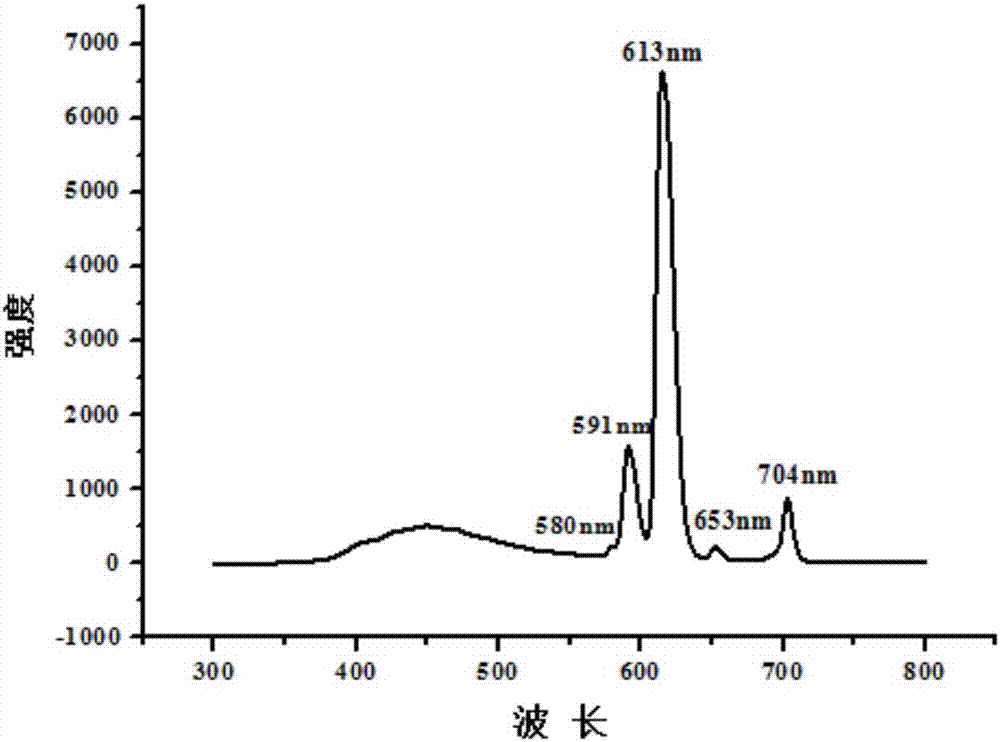

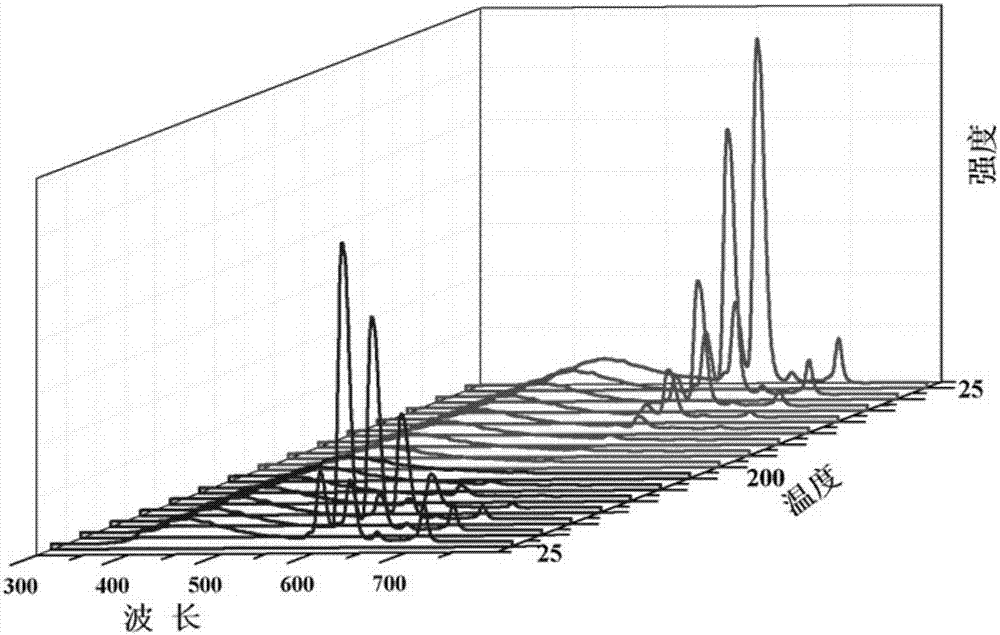

Naphthalene acid-europium fluorescent material based on 2,6-naphthalene dicarboxylic acid and application thereof in merchandise anti-counterfeiting marks

ActiveCN106883253AGood reversibilityImprove thermal stabilityGroup 3/13 organic compounds without C-metal linkagesLuminescent compositionsUltraviolet lightsCarboxylic acid

The invention discloses a naphthalene acid-europium fluorescent material based on 2,6-naphthalene dicarboxylic acid and application of the naphthalene acid-europium fluorescent material as a merchandise anti-counterfeiting mark material. The structural unit of the fluorescent material is Eu(NDC)(H2O)Cl, wherein NDC indicates 2,6-naphthalene dicarboxylate radical without two protons on carboxyl. The fluorescent material disclosed by the invention has an excellent red fluorescence quenching-recovery performance, under the irradiation of an ultraviolet light, bright red is displayed, the temperature is increased to 200 DEG C from 25 DEG C, the fluorescence quenching rate reaches 100%, the temperature is decreased to 25 DEG C from 200 DEG C, the fluorescence intensity is almost recovered to original intensity, and little time is consumed; under the irradiation of the ultraviolet lamp, the fluorescent material is heated by using a lighter and can be completely quenched within about several seconds, when the lighter is moved away, extremely high fluorescence intensity can be recovered within about twenty seconds, and the process is repeated for several times, so that the fluorescence intensity is still relatively high, the heat resistance is high, the repeatability is high, and the fluorescent material can be used as an anti-counterfeiting mark material used for merchandise anti-counterfeiting marks in commerce.

Owner:SHAANXI NORMAL UNIV

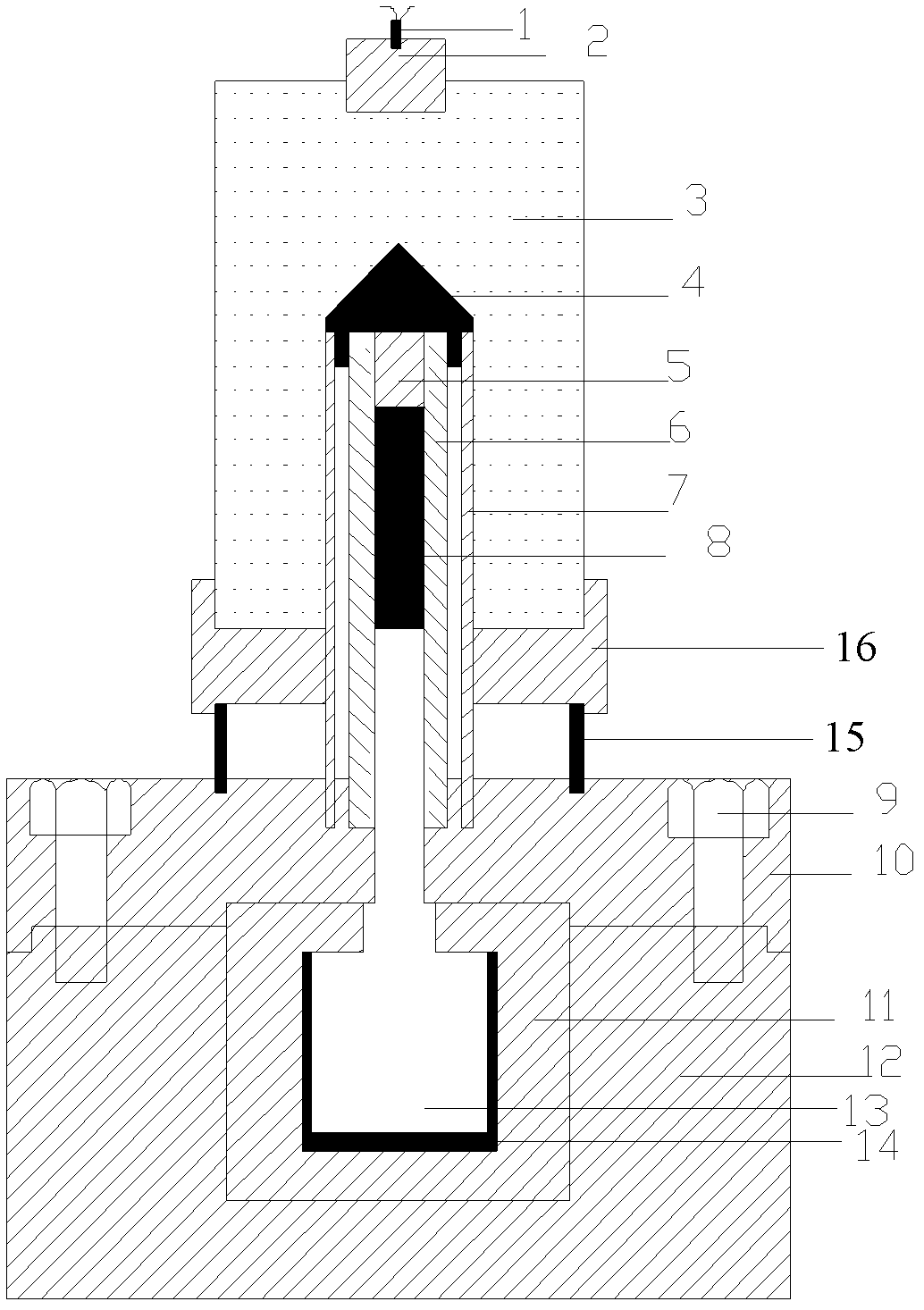

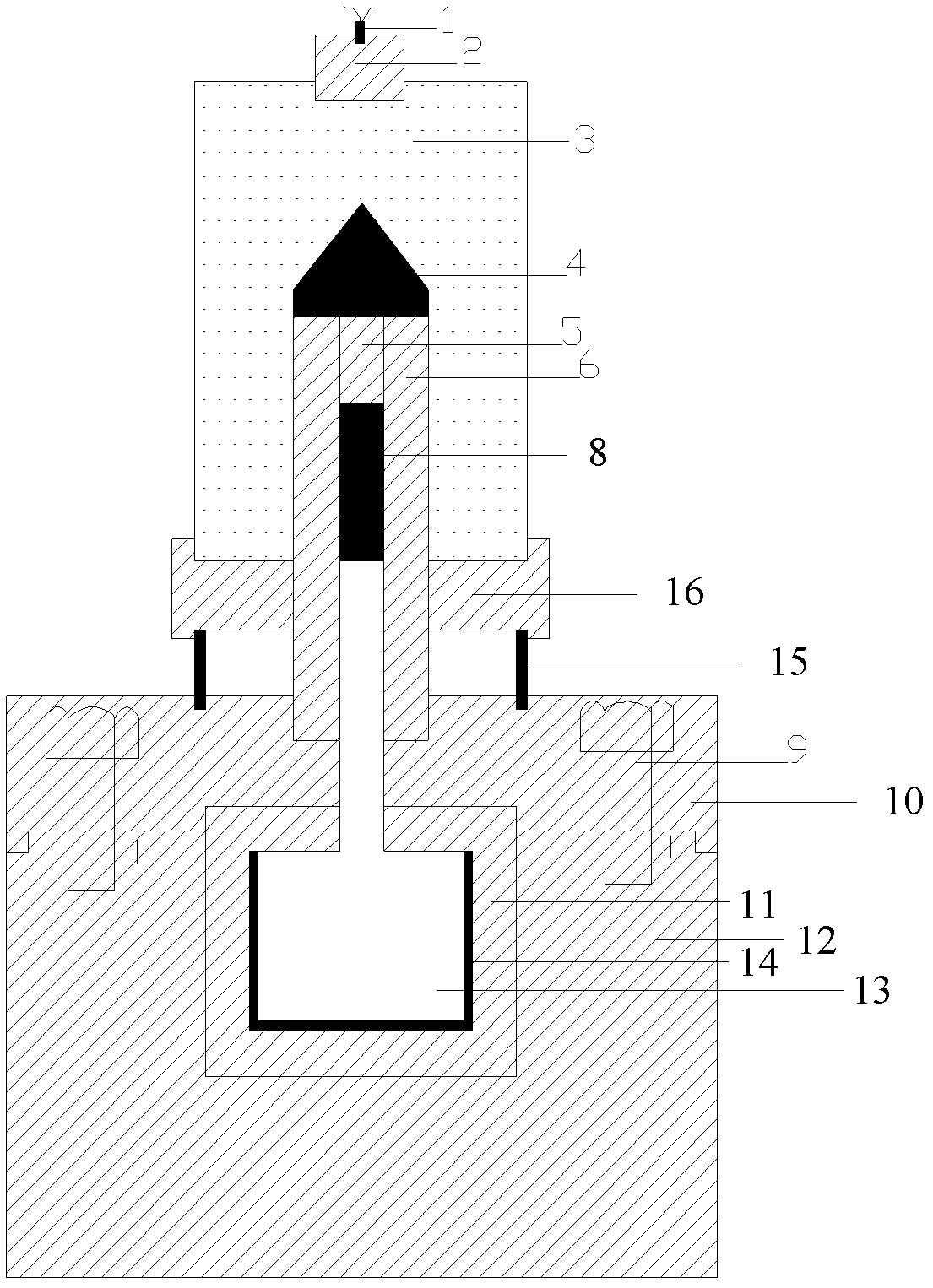

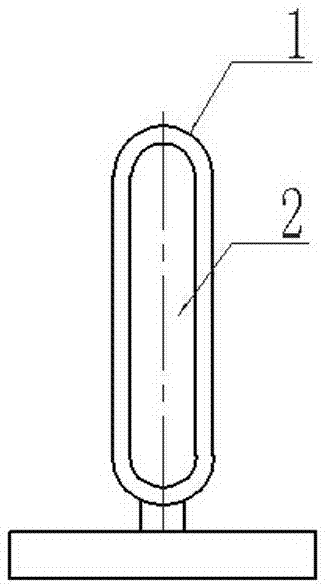

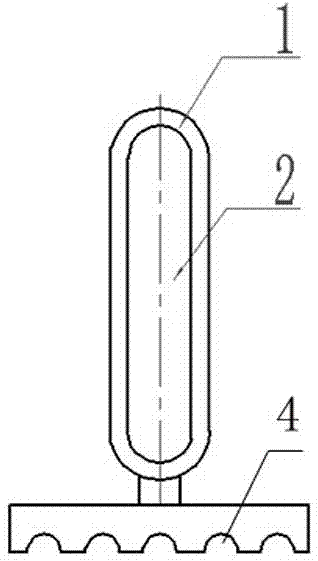

High-quenching-rate material impact synthesis and recovery device

InactiveCN102600769AGood effectIncrease impact pressureUltra-high pressure processesQuenching rateEngineering

The invention discloses a high-quenching-rate material impact synthesis and recovery device, which comprises a cylindrical impact loading unit and a sample cooling and recovery unit. In the sample cooling and recovery unit, a sample box is installed in a steel base, the sample box is in transition fit with the steel base, and a steel top cover is pressed on the sample box and is hermetically connected with the steel base through bolts. The lower end of a sample pipe in the cylindrical impact loading unit is open and is connected with the steel top cover through a thread. A through hole which is communicated with the sample pipe and the inner chamber of the sample box is arranged on the steel top cover. The axis of the sample pipe and the axis of the inner chamber of the sample box are on the same time. A positioning ring which is arranged on the upper surface of the steel top cover is used for supporting a lower base in the cylindrical impact loading unit and limiting the lower base to move in a plane which is perpendicular to the axis of the sample pipe. Cooling mediums are filled in the sample box. The high-quenching-rate material impact synthesis and recovery device has the advantages that the sample extraction process is simplified, more importantly, the mechanical cutting process is avoided, the introduced impurities are reduced and the cost is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

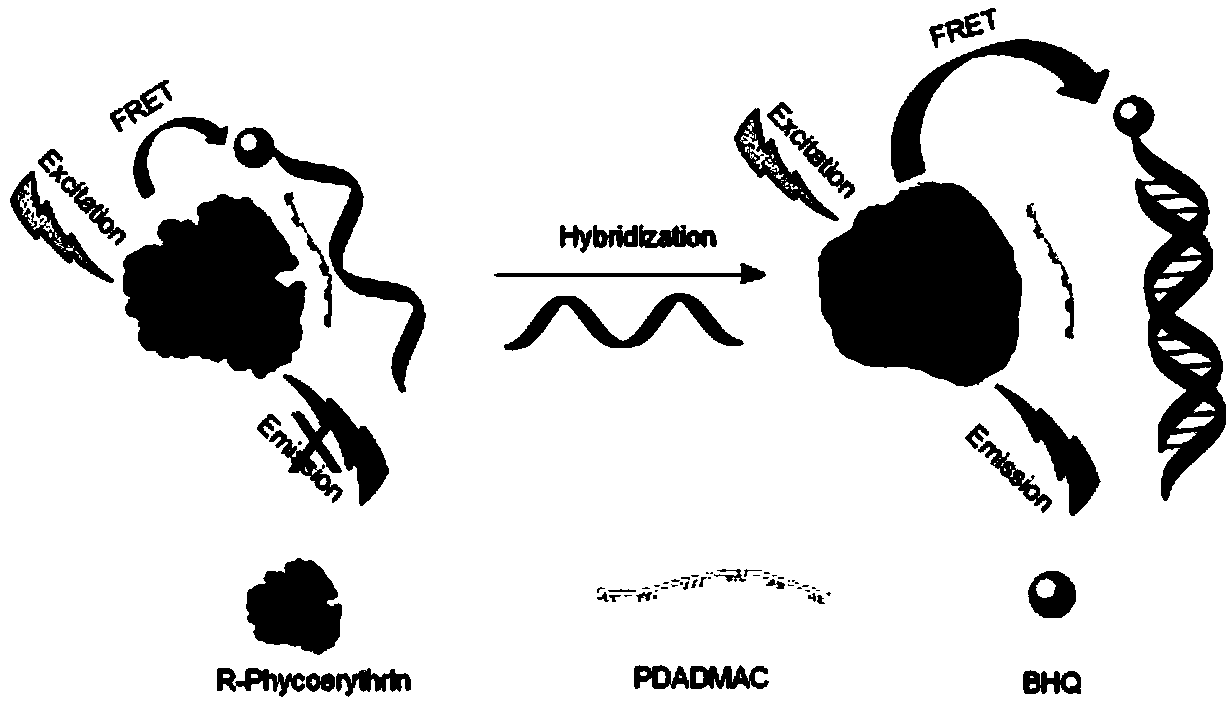

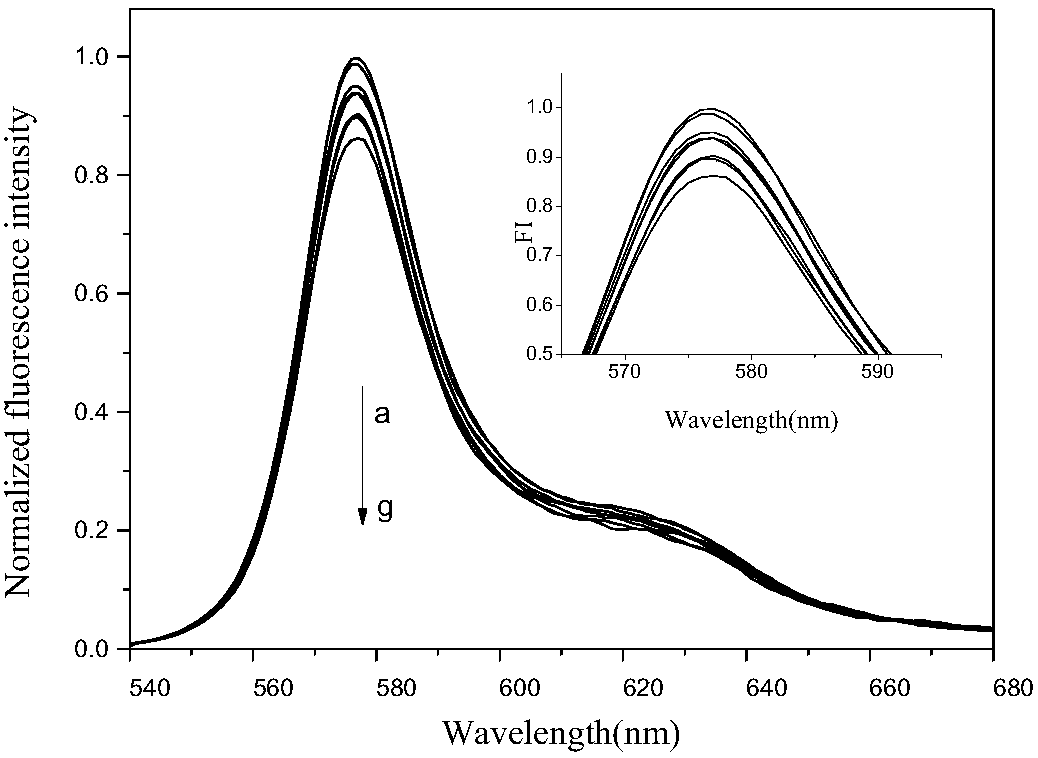

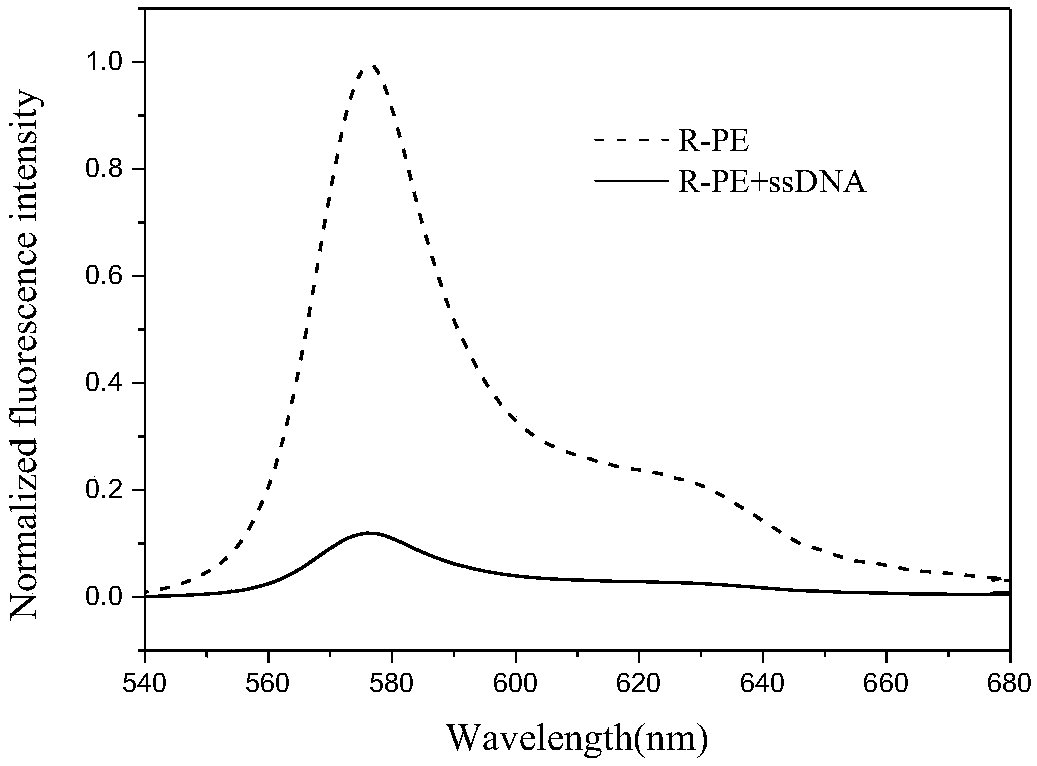

Method for detecting DNA hybridization by surface cationized R-phycoerythrin

ActiveCN108037103AShort preparation timeSimple stepsMicrobiological testing/measurementBiological testingUltrafiltrationPhycoerythrin

The invention belongs to the technical field of nucleic acid detection and discloses a method for detecting DNA hybridization by surface cationized R-phycoerythrin. The method includes steps: subjecting R-phycoerythrin to centrifugal ultrafiltration, desalination and dilution; adding a cationic polymer PDADMAC (polydimethyldiallyl ammonium chloride) for realizing protein surface positive charges;adding quenching group BHQ2 modified DNA single chains, wherein the fluorescence quenching rate is up to 88% approximately; adding complete complementary chains in different concentrations to enable continuous fluorescence release. The method has advantages that the natural vegetable protein R-PE and BHQ2 modified nucleic acid chains serve as donors and receptors in fluorescence resonance energy transfer, and FRET efficiency can be improved by adding of the cationic polymer; fluorescence is quenched in a free state and recovers as long as combining with target chains, high sensitivity is realized, and accordingly DNA hybridization detection is realized.

Owner:SHANGHAI OCEAN UNIV

Method to monitor and control the crystal cooling or quenching rate by measuring crystal surface temperature

InactiveUS6960254B2Promote growthAfter-treatment apparatusPolycrystalline material growthSingle crystalIngot

A method and apparatus for controlling the quenching rate of a monocrystalline ingot pulled from a melt by adjusting one or more post growth processing parameter. A temperature model generates a temperature profile that represents the surface temperature along the length of the ingot at the instant it is pulled from the melt. A first temperature at a particular location along the length of the crystal is determined from the temperature profile. A temperature sensor senses a second temperature at the same particular location. A PLC calculates a quenching rate of the crystal as a function of the first temperature and the second temperature. The PLC generates an error between a target quenching rate and a calculated quenching rate, and one or more post growth process parameters are adjusted as function of the error signal to optimize the quenching rate. Alternatively, temperature readings from the sensor are collected and the quenching rates of the crystal are calculated after crystal growth and post growth quenching. One or more post growth process parameters are modified and programmed for subsequent crystal growth and post growth quenching to achieve optimized quenching rate and crystal quality.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

Method for production of martensitic steel having a very high yield point and sheet or part thus obtained

The present invention provides a method for the fabrication of a martensitic steel sheet with a yield stress greater than 1300 MPa. The method includes the steps of obtaining a semi-finished steel product, the composition of which includes, whereby the contents are expressed in percent by weight: 0.15%≤C≤0.40%, 1.5%≤Mn≤3%, 0.005%≤Si≤2%, 0.005%≤Al≤0.1%, S≤0.05%, P≤0.1%, 0.025%≤Nb≤0.1%, and optionally: 0.01%≤Ti≤0.1%, 0%≤Cr≤4%, 0%≤Mo≤2%, 0.0005%≤B≤0.005%, 0.0005%≤Ca≤0.005%. The remainder of the composition is iron and the inevitable impurities resulting from processing. The semi-finished product is reheated to a temperature T1 in the range between 1050° C. and 1250° C., then the reheated semi-finished product is subjected to a roughing rolling at a temperature T2 in the range between 1050 and 1150° C., with a cumulative rate of reduction ϵa greater than 100%, to obtain a sheet with a not totally recrystallized austenitic structure with an average grain size less than 40 micrometers and preferably less than 5 micrometers. The sheet is then cooled to prevent a transformation of the austenite at a rate VR1 greater than 2° C. / s to a temperature T3 in the range between 970° C. and Ar3+30° C., is then subjected to a finishing hot rolling at the temperature T3 of the cooled sheet, with a cumulative rate off reduction ϵb greater than 50% to obtain a sheet, then the sheet is cooled at a rate VR2 which is greater than the critical martensitic quenching rate. Steel sheets are also provided.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Preparation and application of metal organic framework material

InactiveCN112159530AEasy to prepareRaw materials are readily availableFluorescence/phosphorescenceLuminescent compositionsNitrobenzeneMetal-organic framework

The invention discloses preparation and application of a metal organic framework material. The preparation method comprises the following steps: adding zinc nitrate hexahydrate (Zn(NO3)2.6H2O), benzimidazole and 2,6-dihydroxyl terephthalic acid into an N,N-dimethyl acetamide (DMAc) and ethanol solution in a certain volume ratio according to a certain molar ratio, and synthesizing the metal organicframework material by adopting a solvothermal method. The chemical formula of the metal organic framework material is C26H29N2O6Zn3, the space group is C2 / m, the material belongs to a triclinic system, a liquid fluorescence detection means is adopted, a compound suspension is prepared, fluorescence quenching is performed on nitrobenzene selectively, when the concentration of nitrobenzene reaches120 ppm, the fluorescence quenching rate of the solution reaches 86.6%, and the compound can be used as a fluorescence probe for detecting nitrobenzene.

Owner:何雅贵

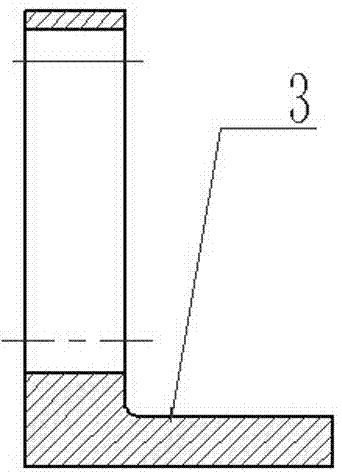

Quenching chuck for straight section on end portion of automobile plate spring

InactiveCN106987696AFix low conversion ratesIncrease contact areaFurnace typesHeat treatment furnacesSlow coolingStraight segment

The invention relates to a quenching collet used for the straight section of the end of an automobile leaf spring, comprising a quenching collet, a U-shaped installation hole is vertically arranged on the quenching collet, and a quenching collet is vertically arranged on the bottom of the quenching collet The straight section at the end, the quenching chuck is installed and positioned on the body of the quenching swinging machine by the bolt through the U-shaped mounting hole, and the straight section at the end of the quenching chuck is evenly equipped with multiple full-through oil grooves with arc-shaped cross-sections . The invention solves the problem that the cooling speed of the leaf spring end is slowed down due to the contact surface during quenching and forming, resulting in a lower quenching structure conversion rate. Through the multi-channel all-through oil grooves uniformly arranged under the straight section of the end of the quenching chuck, It can increase the contact area between the quenching medium and the end of the leaf spring, and ensure the cooling rate so as to solve the problem of the transformation rate of the quenching structure.

Owner:东风汽车悬架弹簧有限公司

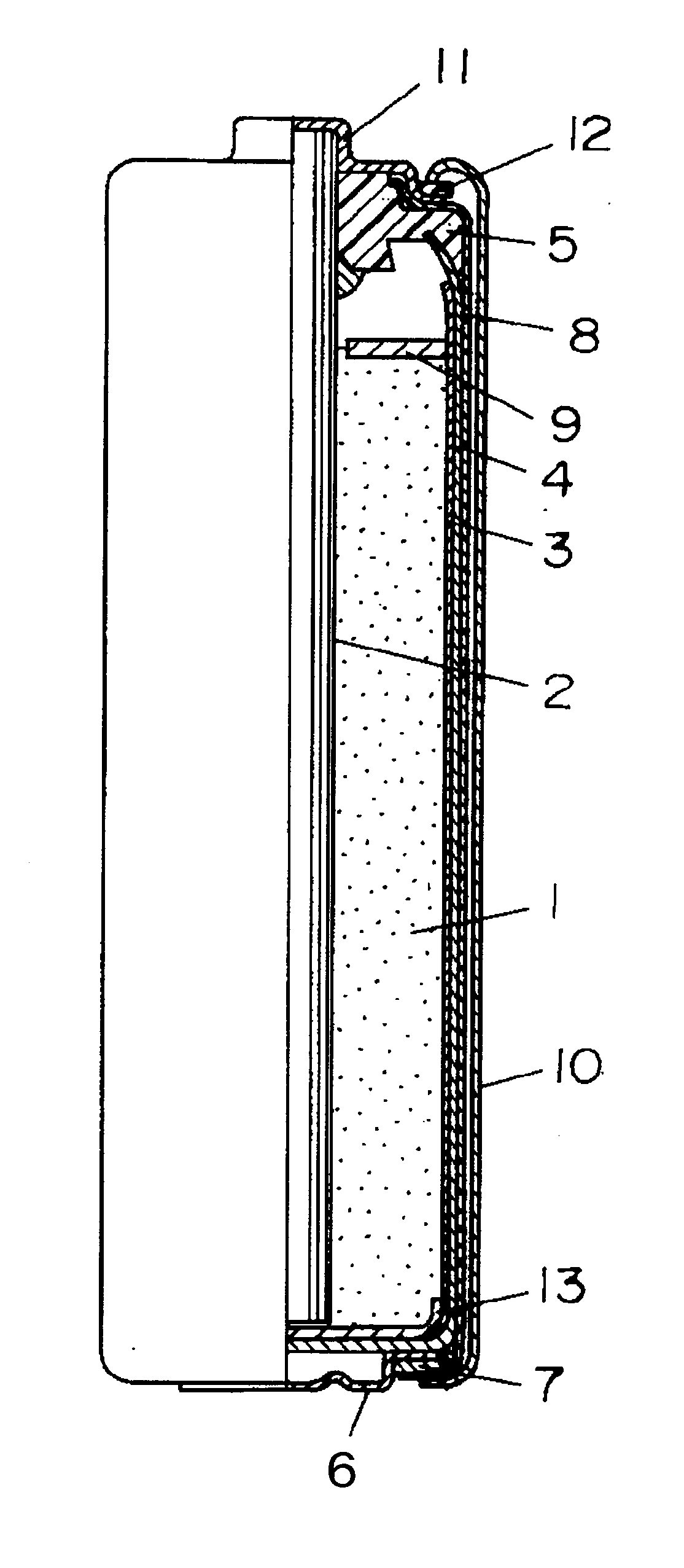

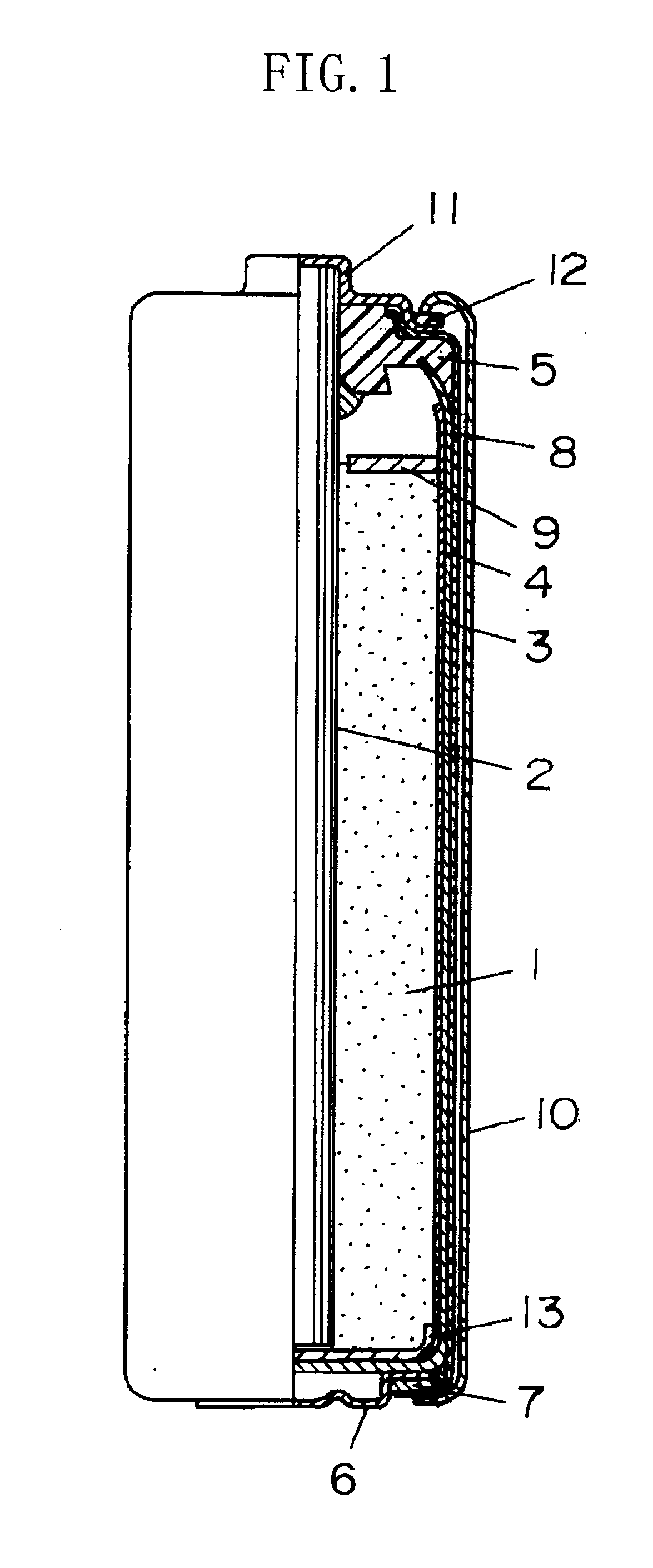

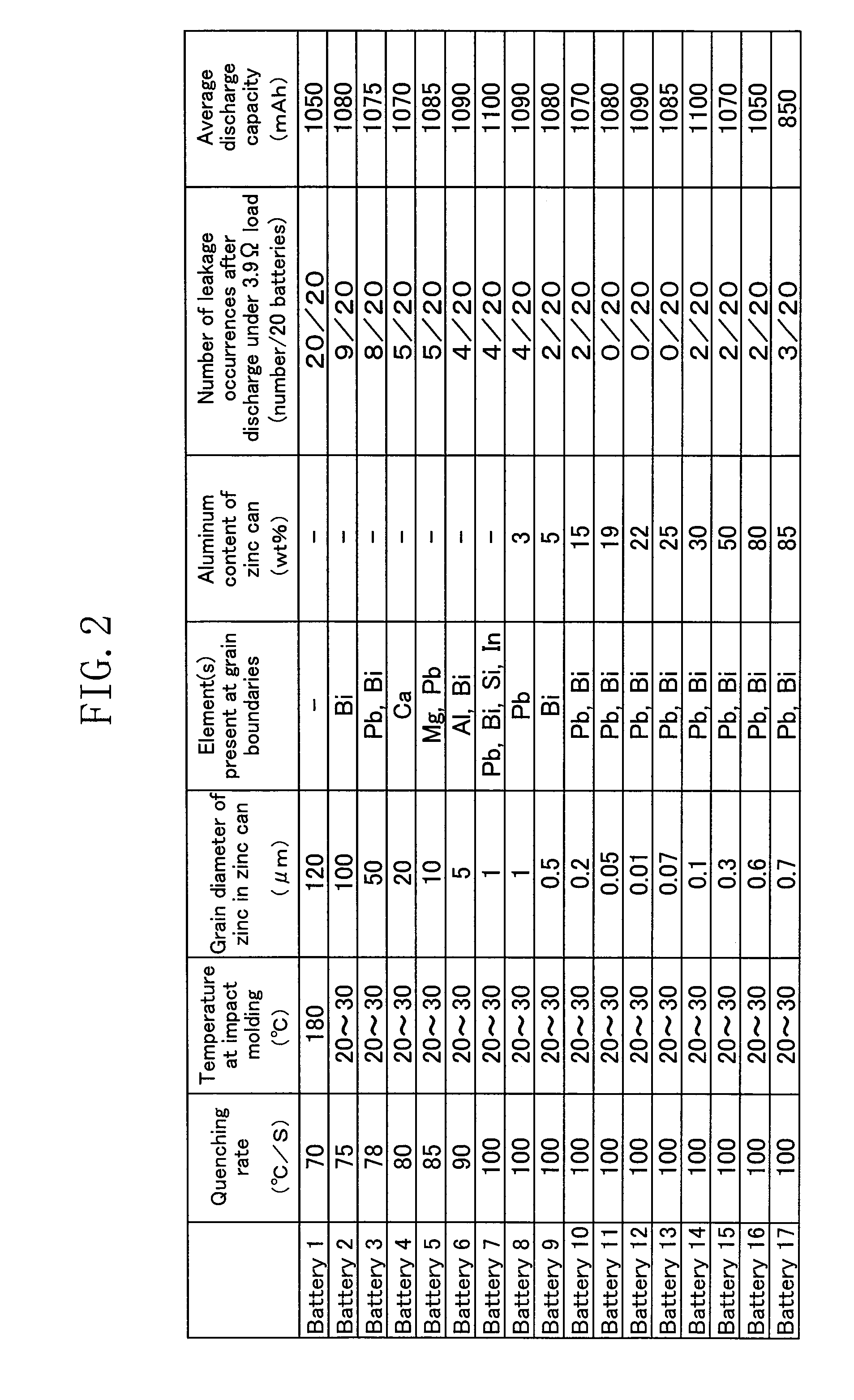

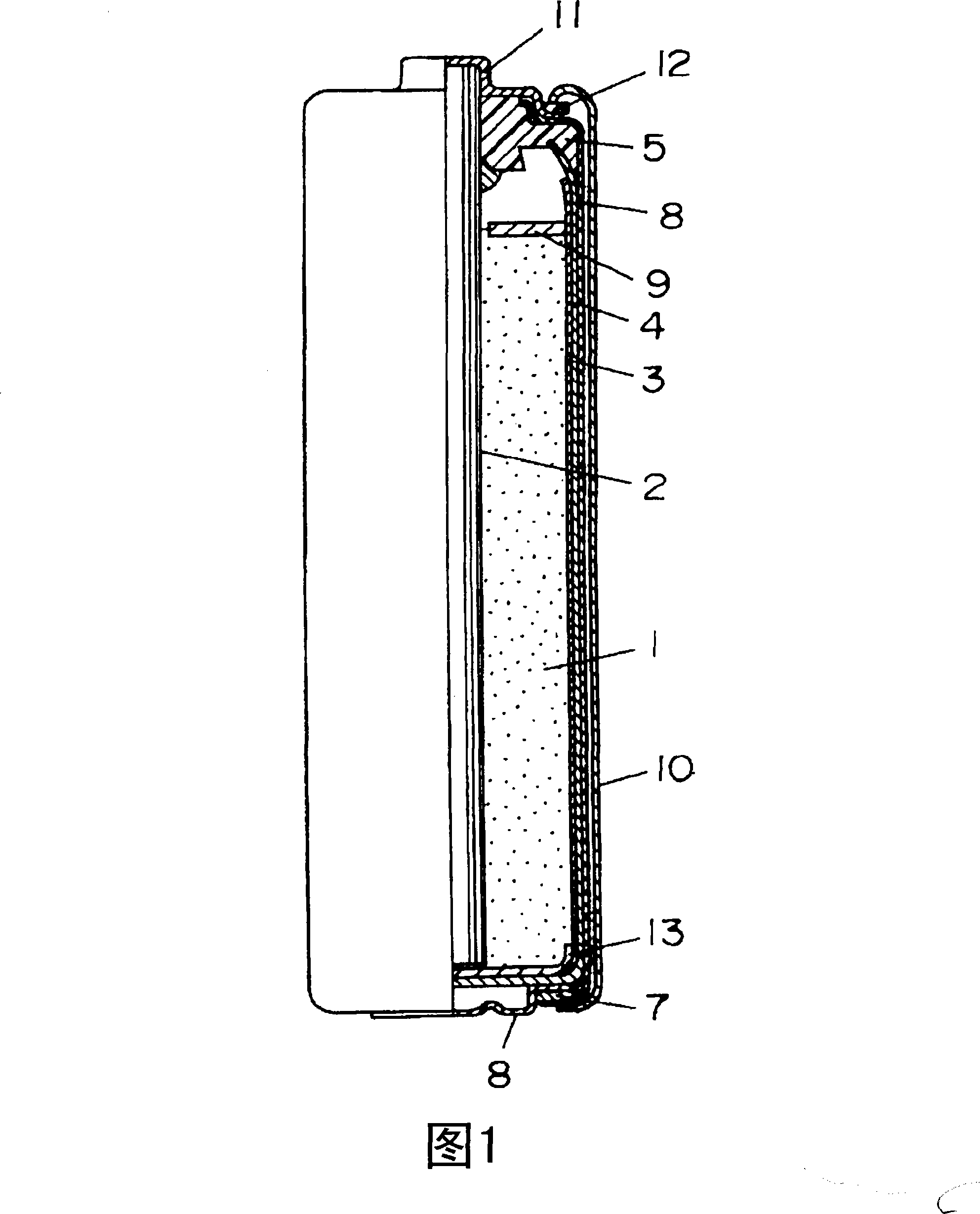

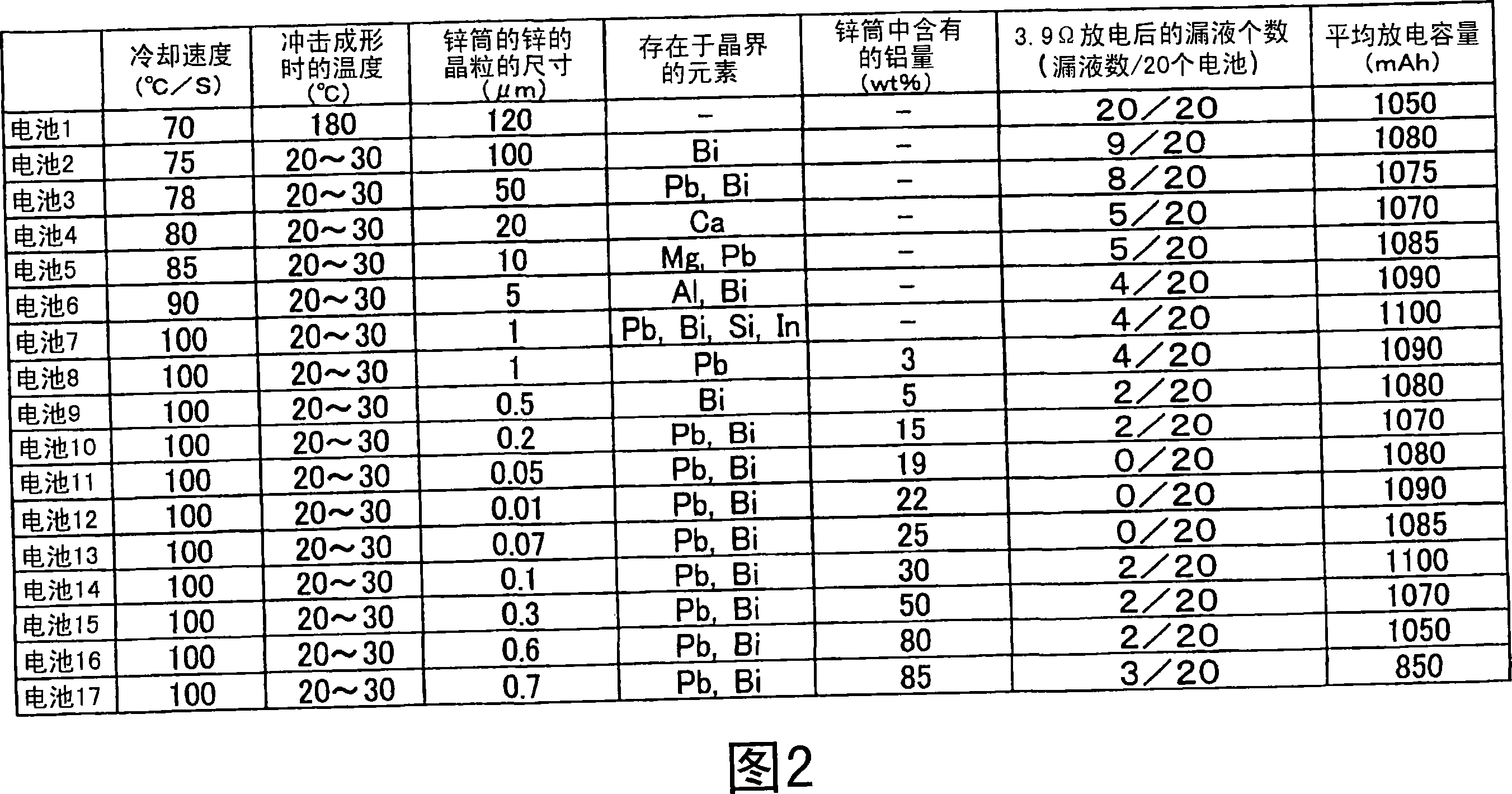

Manganese dry battery and manganese dry battery manufacturing method

InactiveUS20080170962A1Containment leakSuppress zinc reactionCell electrodesJackets/cases materialsManganeseZinc

An added element other than zinc is yielded at the grain boundaries of zinc forming a negative electrode zinc can. The added element includes at least one element selected from the group of Pb, Bi, Ca, Mg, Si, Al, and In. The zinc can is formed in such a manner that: melted zinc containing the added element is quenched at a quenching rate of 75 to 100° C. / second for casting into a zinc plate; and the thus cast plate is subjected to impact molding at a temperature in the range between 20 and 30° C.

Owner:PANASONIC CORP

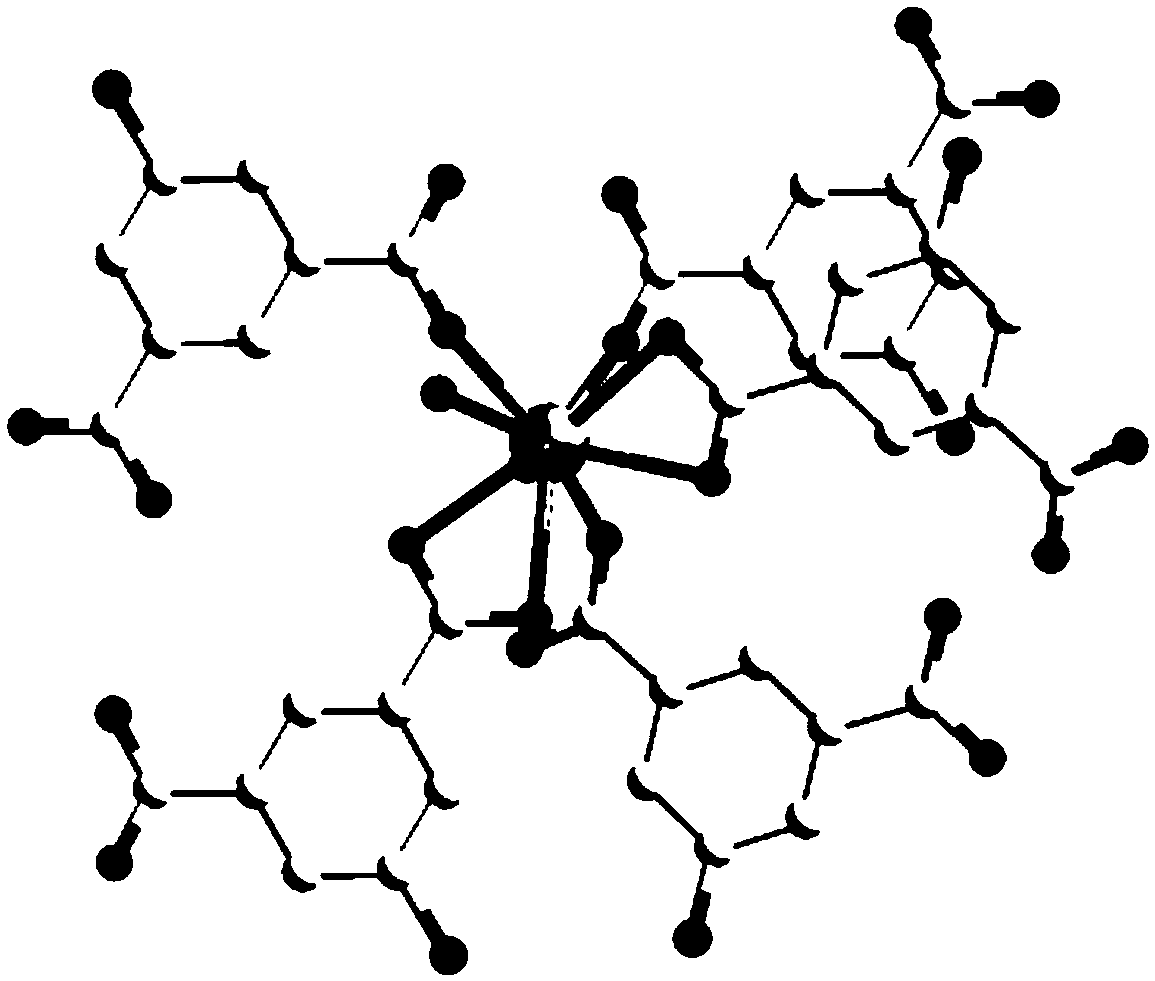

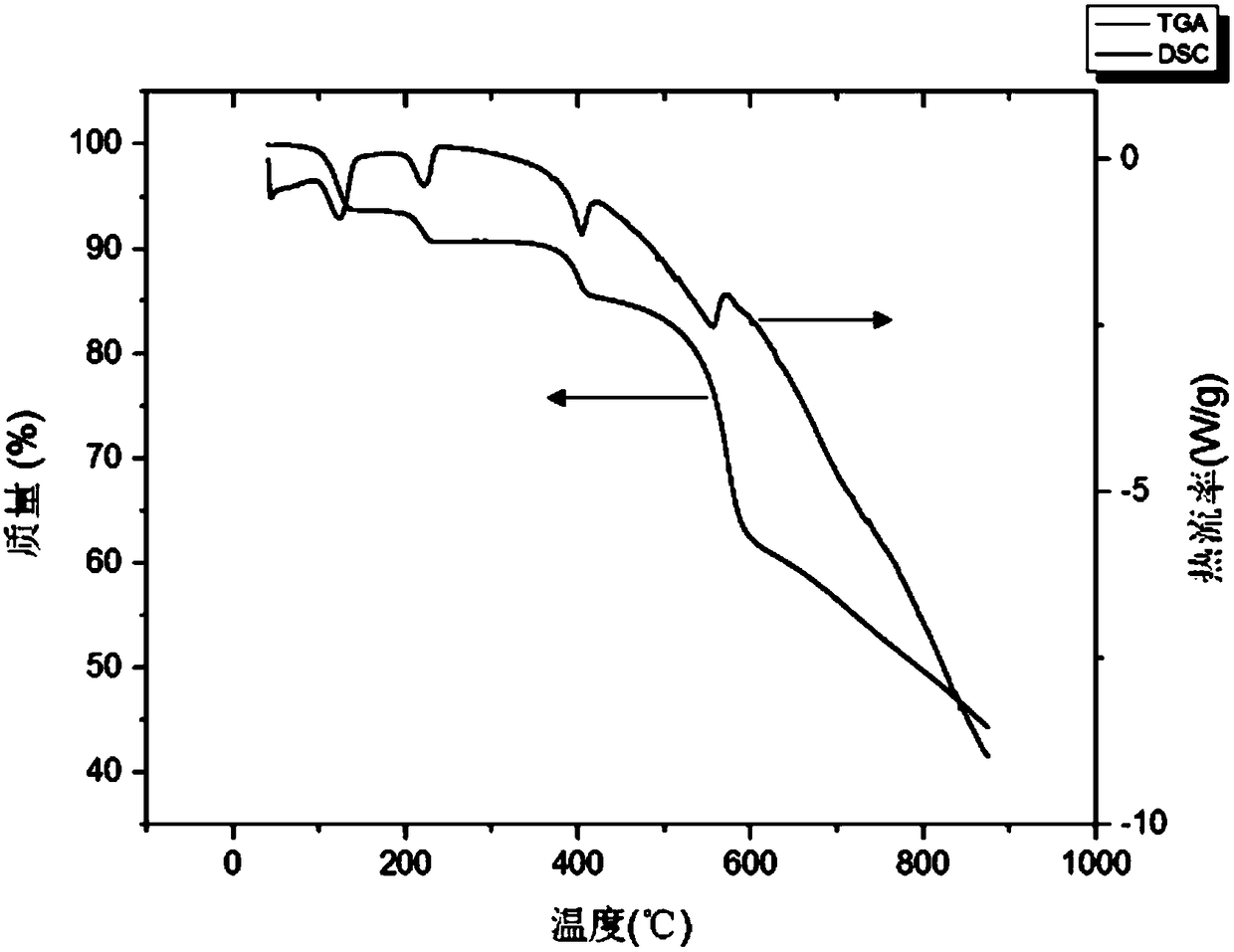

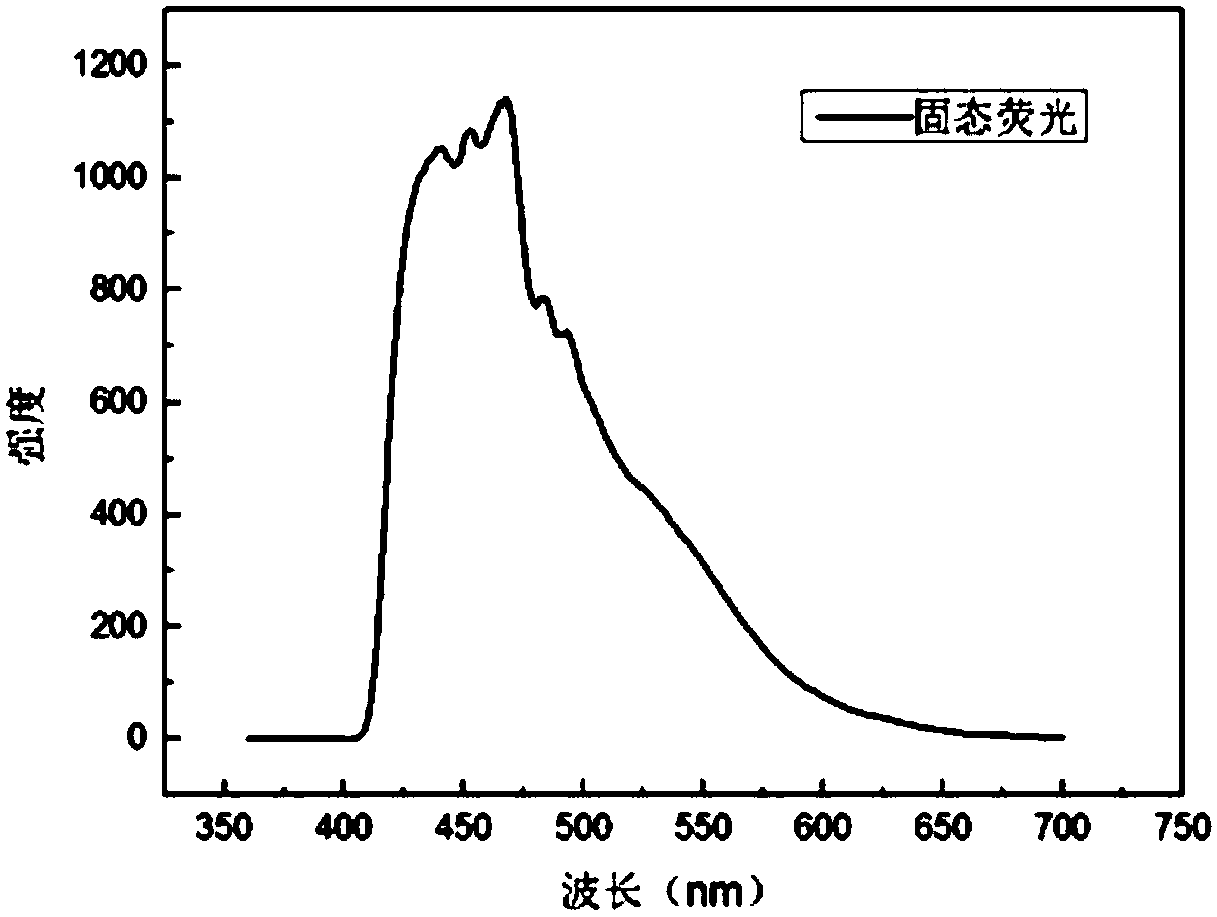

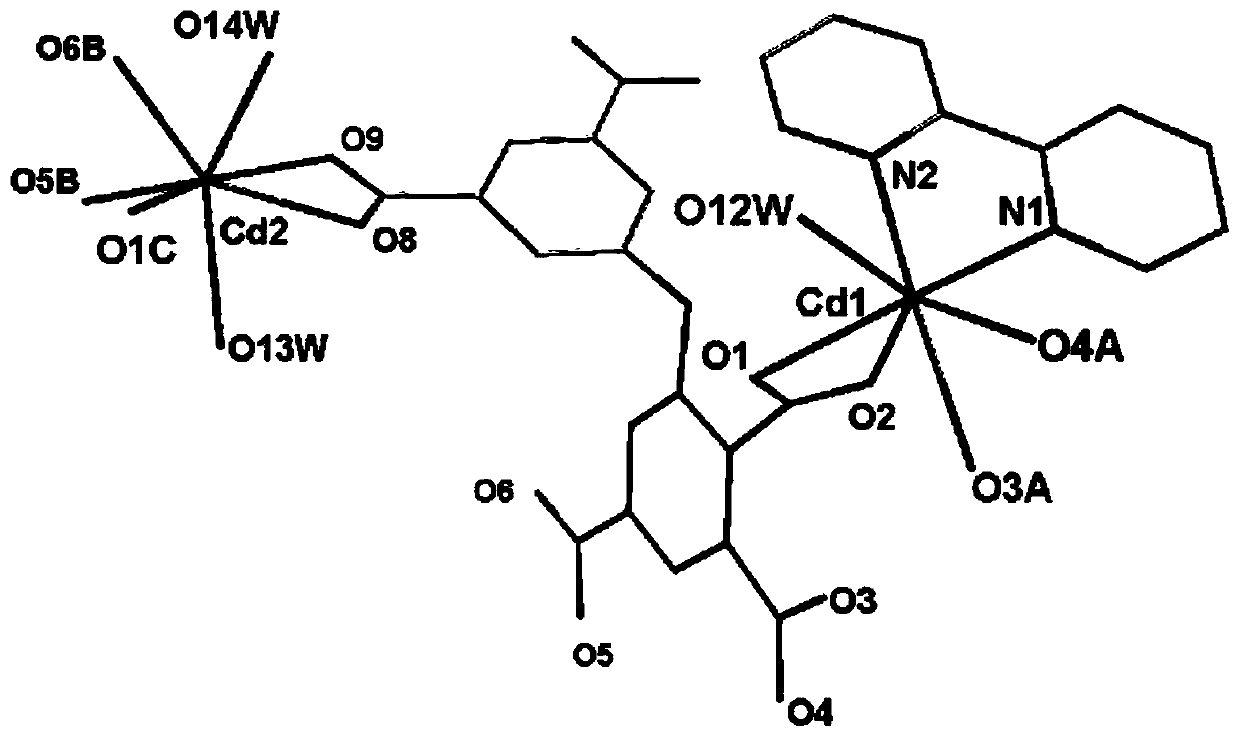

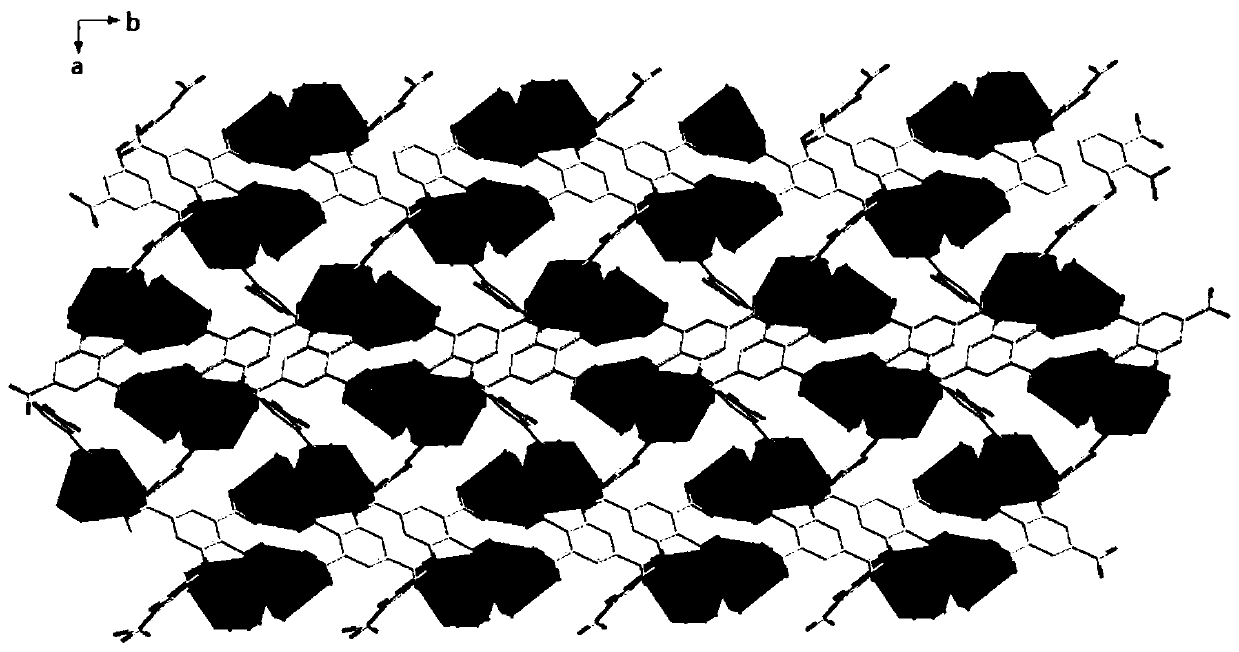

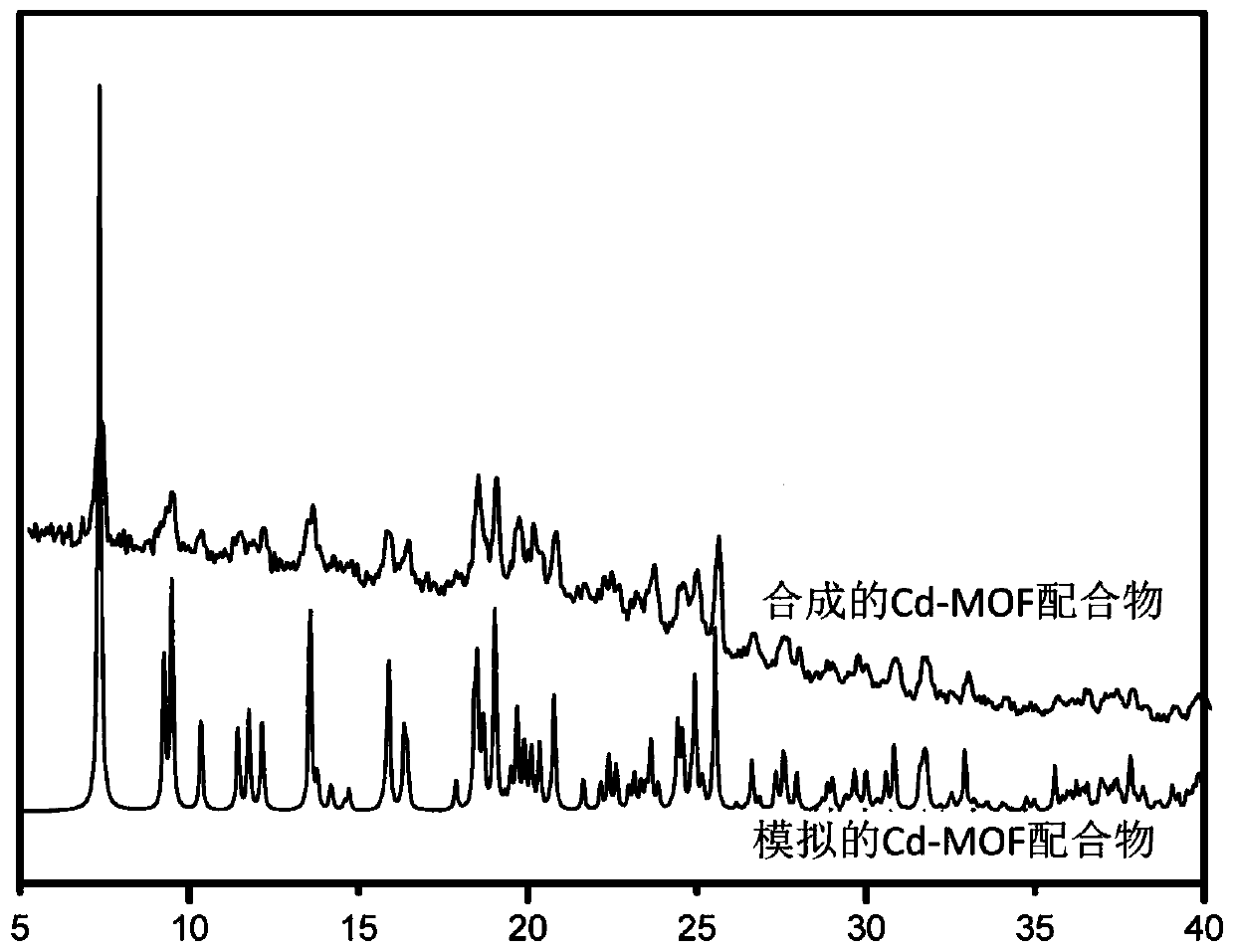

Cd-MOF complex as well as preparation method and application thereof

ActiveCN111471191AHigh crystallinityAvoid pollutionFluorescence/phosphorescenceLuminescent compositionsPhenyl EthersMetal-organic framework

The invention provides a Cd-MOF complex as well as a preparation method and application thereof, and belongs to the technical field of metal organic framework materials. The chemical composition of the Cd-MOF complex provided by the invention is Cd2<2+> (DEPA)<4->(2, 2 '-bpy). 3H<2>O. Each asymmetric unit in the Cd-MOF complex provided by the invention contains two crystallographically independentCd < 2 + >, an incompletely deprotonated ion of 2, 3, 3 ', 5, 5'-diphenyl ether pentacarboxylic acid, a 2, 2 '-dipyridyl and three coordinated water molecules. The Cd-MOF complex provided by the invention is relatively high in fluorescence quenching rate on metal ions and small organic molecules, and can realize fluorescence detection on the metal ions and the small organic molecules.

Owner:YANAN UNIV

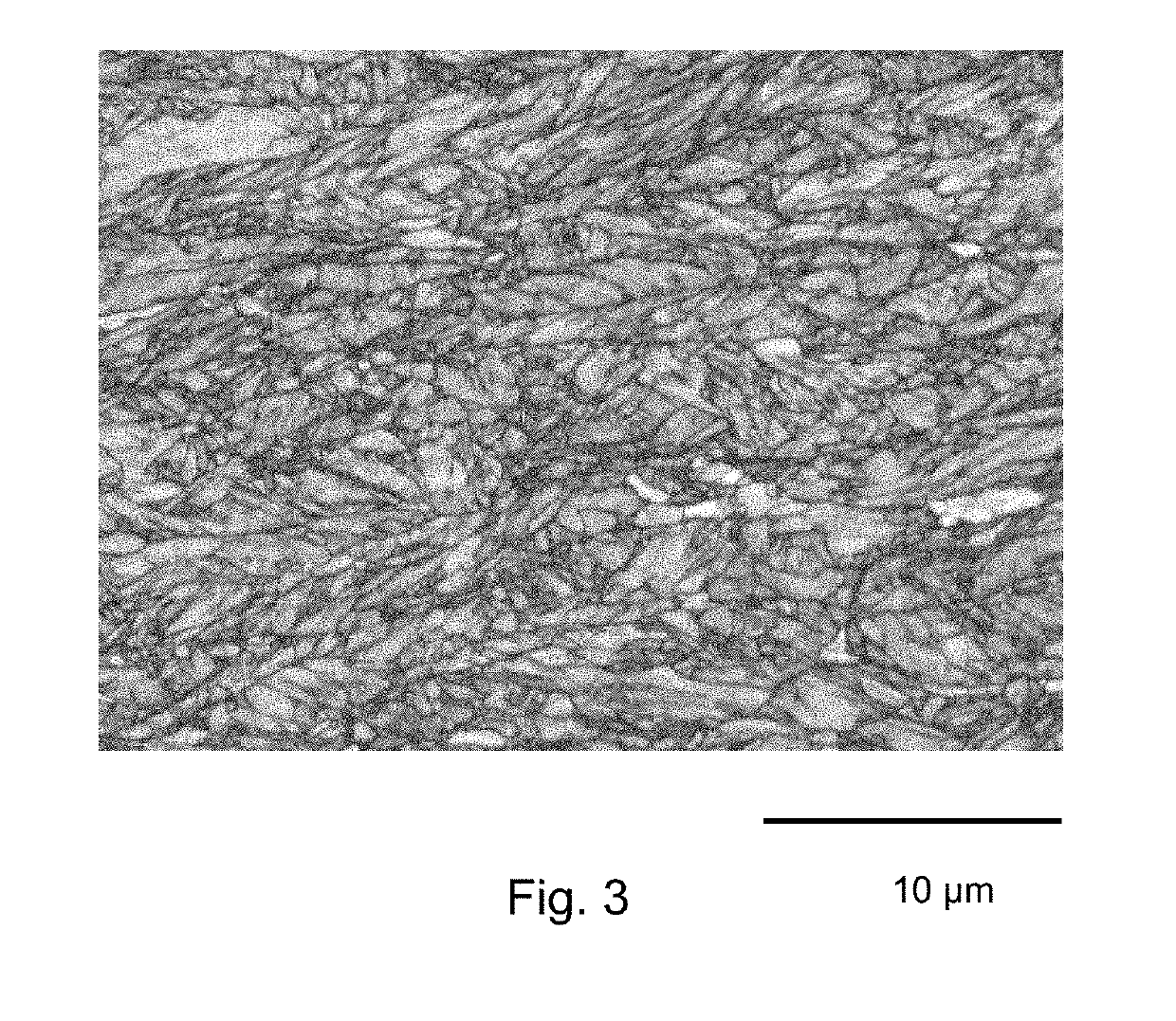

Very High Strength Martensitic Steel or Part and Method of Fabrication

ActiveUS20190226060A1High mechanical strengthReduce carbon contentFurnace typesHeat treatment furnacesMaximum dimensionSheet steel

The present invention provides a method for the fabrication of a steel sheet with a completely martensitic structure which has an average lath size of less than 1 micrometer and an average elongation factor of the laths is between 2 and 5. The elongation factor of a lath is defined as a maximum dimension lmax divided by and a minimum dimension lmin. The steel sheet has a yield stress greater than 1300 MPa and a mechanical strength greater than (3220(C)+958) megapascals. A composition of a semi-finished steel product includes, expressed in percent by weight, is, 0.15%≤C≤0.40%, 1.5%≤Mn≤3%, 0.005%≤Si≤2%, 0.005%≤Al≤0.1%, 1.8%≤Cr≤4%, 0%≤Mo≤2%, whereby: 2.7% 0.5 (Mn)+(Cr)+3(Mo)≤5.7%, S≤0.05%, P≤0.1%, optionally: 0%≤Nb≤0.050%, 0.01%≤Ti≤0.1%, 0.0005%≤B≤0.005%, 0.0005%≤Ca≤0.005%. The semi-finished product is reheated to a temperature T1 in the range between 1050° C. and 1250° C., then subjected to a roughing rolling at a temperature T2 in the range between 1000 and 880° C., with a cumulative rate of reduction εa greater than 30%, to obtain a sheet with a completely recrystallized austenitic structure with an average grain size less than 40 micrometers and preferably less than 5 micrometers. The sheet is then partially cooled to prevent a transformation of the austenite at a rate VR1 greater than 2° C. / s to a temperature T3 between 600° C. and 400° C. in the metastable austenitic range, and subjected to a finishing hot rolling at the temperature T3 of the partially cooled sheet, with a cumulative rate of reduction εb greater than 30% to obtain a sheet that is then cooled at a rate VR2 which is greater than the critical martensitic quenching rate.

Owner:ARCELORMITTAL SA

A hot stamping device for quenching control

InactiveCN104294020BEvenly distributedHomogeneous martensiteHeat treatment process controlQuenching devicesContact pressureControl system

The invention provides a heat stamping apparatus used for quenching control, which belongs to the technical field of heat stamping. A purpose of the present invention is to solve the problems that in a heat stamping technology, in the quenching process of a high-temperature forming part, uniform distribution of surface temperature of the forming part can not be guaranteed on the condition that quenching uniformity is guaranteed, and the invention provides the heat stamping apparatus used for heat stamping quenching control. The heat stamping apparatus enables real time monitoring on the temperature value of selected measurement points during a high-temperature plate shaping process, the quenching rate and temperature difference between the selected measurement points can be obtained through data processing; when the quenching rate can not satisfy the condition or the temperature difference is large, a control system is capable of adjusting contact pressure and cooling water flow velocity of the forming parts and mold surface with pertinence according to the trigger condition, then the quenching rate of the high-temperature forming parts can satisfy the requirement, and the temperature of the forming parts can be equalized, so that the intensity quality requirement and the forming precision requirement of the final forming parts can be ensured.

Owner:JIANGSU UNIV

Manganese dry battery and manganese dry battery manufacturing method

InactiveCN101226997AImprove corrosion resistanceJackets/cases materialsPrimary cell electrodesManganeseZinc

An added element other than zinc is yielded at the grain boundaries of zinc forming a negative electrode zinc can. The added element includes at least one element selected from the group of Pb, Bi, Ca, Mg, Si, Al, and In. The zinc can is formed in such a manner that: melted zinc containing the added element is quenched at a quenching rate of 75 to 100° C. / second for casting into a zinc plate; and the thus cast plate is subjected to impact molding at a temperature in the range between 20 and 30° C.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com