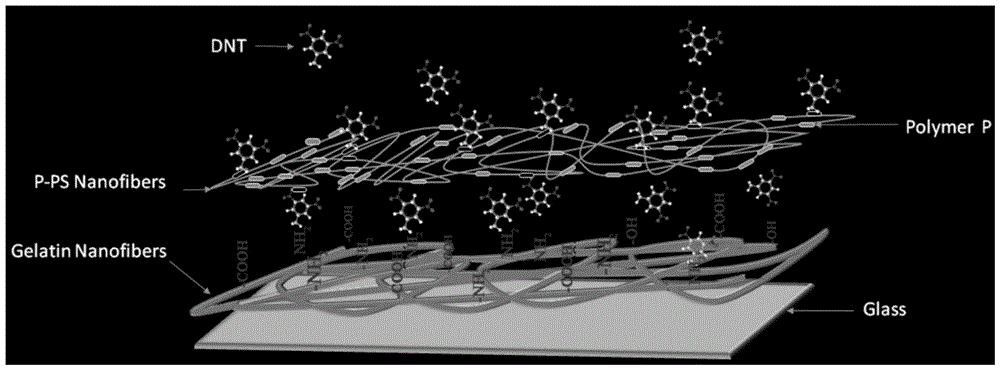

Application of double-layer electrostatic spun film sensor in detection of nitro-aromatic substances

A thin-film sensor and electrospinning technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that the application of double-layer electrospun thin film sensor materials has not been found, so as to reduce the detection limit, improve the response sensitivity, and facilitate transmission. The effect of sensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A synthetic method for fluorescent sensing polymer P, comprising the following steps:

[0066] 2,5-dibromothiophene (200mg, 0.9mmol), polyphenylene vinylene polymer (376mg, 0.9mmol) and 2,7-dibromo-9,9-diphenylfluorene (426.6mg, 0.9mol) Dissolve in anhydrous diisopropylamine (DIPA, 2mL) and anhydrous toluene (30mL), place in a 50ml three-necked flask. Pass through argon for 30 minutes, add PdCl 2 (PPh 3 ) 2 (36mg, 2.6×10 -2 mmol), PPh 3 (270mg, 0.90mmol) and CuI (40.5mg, 0.3mmol). 100 ° C reflux reaction for 24h. Then, according to the purification, the fluorescent sensor polymer P is obtained, and the structural formula is shown in Formula 1 of the present invention.

[0067] Fluorescent sensor polymer P: dark yellow solid (400mg, 69%). 1 HNMR: (CDCl 3 ,400MHz), δ(ppm):0.0-2.0(m,20H),7.0-7.2(m,3H),7.4(d,1H,J=7.2HZ),6.0(d,3H,J=5.5HZ) ,7.6-7.9(m,2H).FT-IR(KBr):3060,2967,2921,2850,2198,1710,1600,1452,1414,1259,1103,1026,886,823,753,692,513cm -1 Calcdfor(C 58 h ...

Embodiment 2

[0068] Embodiment 2 A synthetic method of fluorescent sensing polymer P, comprising the following steps:

[0069] 2,5-dibromothiophene (210mg), polyphenylene vinylene polymer (378mg) and 2,7-dibromo-9,9-diphenylfluorene (438mg) were dissolved in anhydrous diisopropylamine (DIPA, 2.5mL) and anhydrous toluene (22mL), placed in a 50ml three-necked flask. Argon protection was passed through for 40 minutes, and PdCl was added 2 (PPh 3 ) 2 (21mg), PPh 3 (252mg) and CuI (63mg). 90 ° C reflux reaction for 36h. Then, according to the purification, the fluorescent sensor polymer P is obtained, and the structural formula is shown in Formula 1 of the present invention.

Embodiment 3

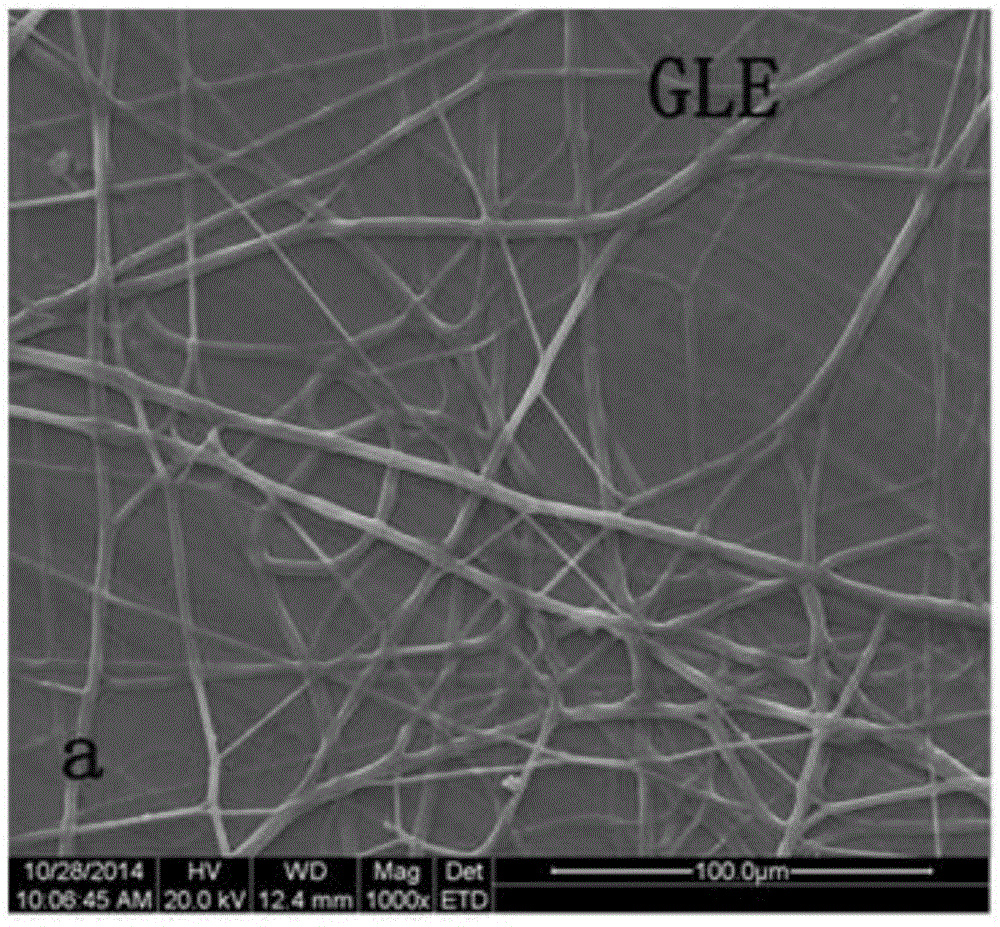

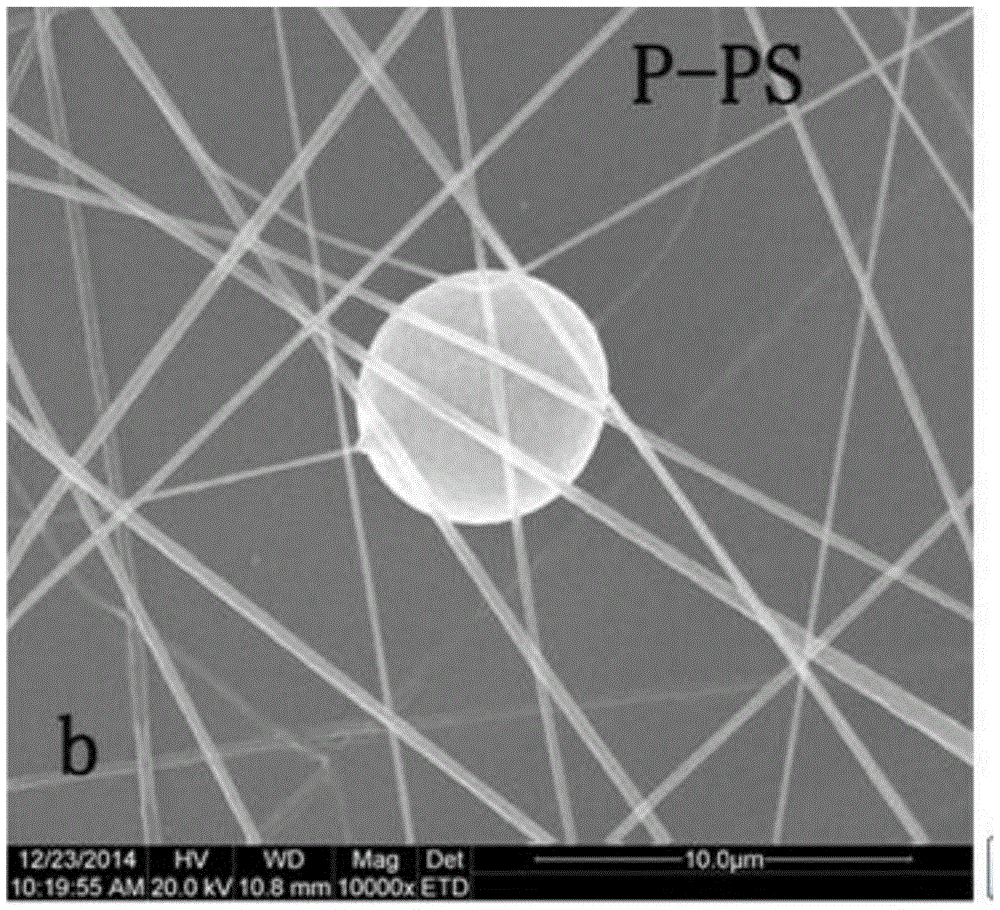

[0071] Preparation of electrospun P-PS films: fluorescent sensing polymers P (0.4 mg) and PS (0.4 g) were dissolved in 4 mL of mixed solution (DMF:THF=3:1) and stirred for 24 hours. Transfer the resulting solution to the syringe of the electrospinning device. Electrospinning was performed with a spinning voltage of 20 kV and a receiving distance of 25 cm. The flow rate of the solution was 1mLH via a syringe pump -1 Control at a constant rate. Finally, an electrospun nanofibrous membrane was formed on a glass slide (1.0 cm×1.7 cm). The electrospun nanofibrous membrane (20 μm) was vacuum dried at 30° C. for 10 hours to remove residual organic solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com