Preparation and application of metal organic framework material

A metal-organic framework, a technology of zinc nitrate hexahydrate, which is applied to the preparation of metal-organic framework materials and the application field of selective fluorescent probes, can solve the problems of high cost, lack of portability, etc., and achieves easy raw materials and preparation methods. Simple, highly sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

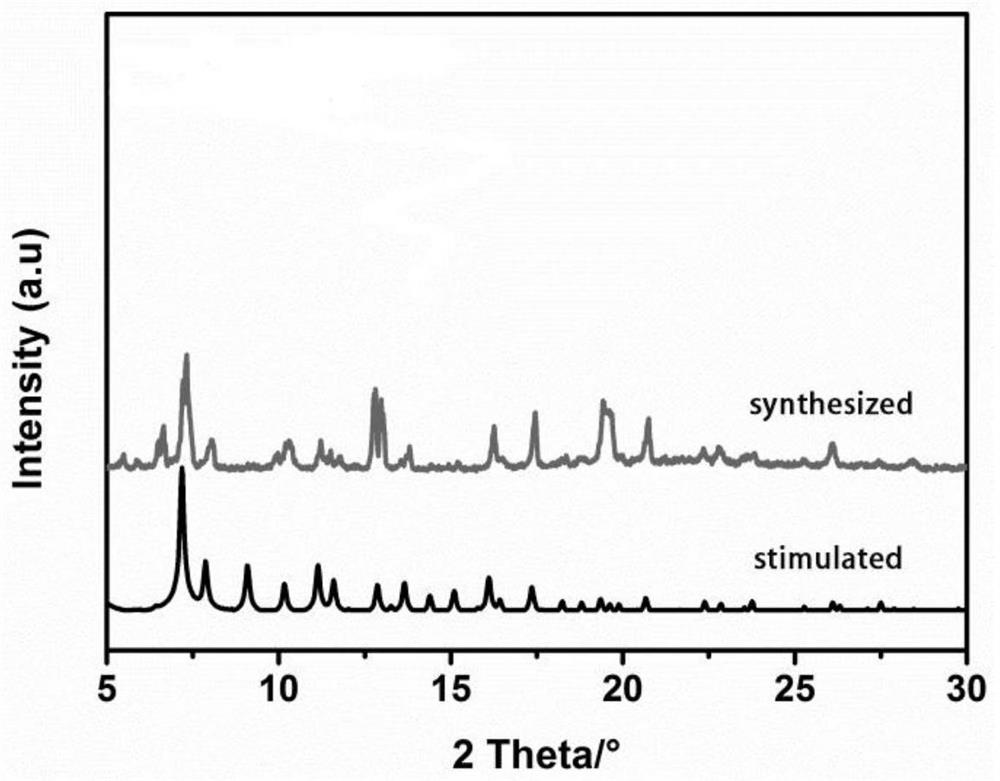

[0025] A method for preparing a metal-organic framework material, the specific preparation process comprising:

[0026] S1: Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), benzimidazole and 2,6-dihydroxyterephthalic acid are sequentially added in the beaker according to the molar ratio of 3:0.6:0.4, then N,N-dimethylacetamide (DMAc) is added, and ultrasonically treated to make it Fully dissolve.

[0027] S2: Use a dropper to draw 5mL of the solution in the above step S1 into a glass bottle with a cap, then add 1mL of anhydrous ethanol solution, tighten it, put it in an oven, and react at 80°C for 24h, with a red color Blocky crystals were formed, filtered, and dried at 65 °C for 8 h to obtain the metal organic framework material.

Embodiment 2

[0029] A method for preparing a metal-organic framework material, the specific preparation process comprising:

[0030] S1: Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), benzimidazole and 2,6-dihydroxyterephthalic acid are sequentially added in the beaker according to the molar ratio of 3:1.2:0.9, then N,N-dimethylacetamide (DMAc) is added, and ultrasonically treated to make it Fully dissolve.

[0031] S2: Use a dropper to draw 5mL of the solution in the above step S1 into a glass bottle with a cap, then add 1mL of absolute ethanol solution, tighten it, put it in an oven, and react at 150°C for 48h, with a red color Blocky crystals were formed, filtered, and dried at 65 °C for 8 h to obtain the metal organic framework material.

Embodiment 3

[0033] A method for preparing a metal-organic framework material, the specific preparation process comprising:

[0034] S1: Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), benzimidazole and 2,6-dihydroxyterephthalic acid are sequentially added into the beaker according to the molar ratio of 3:0.7:0.5, then N,N-dimethylacetamide (DMAc) is added, and ultrasonically treated to make it Fully dissolve.

[0035] S2: Take 5mL of the solution in the above step S1 with a dropper and add it to a glass bottle with a cap, then add 1mL of absolute ethanol solution, tighten it, put it in an oven, and react at 90°C for 30h, with a red color Blocky crystals were formed, filtered, and dried at 65 °C for 8 h to obtain the metal organic framework material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com