Circuit breaker

一种功率开关、功率的技术,应用在电开关、高压/大电流开关、高压空气断路器等方向,能够解决费事成形、费事保持、昂贵等问题,达到高功率开关断开功率、提高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

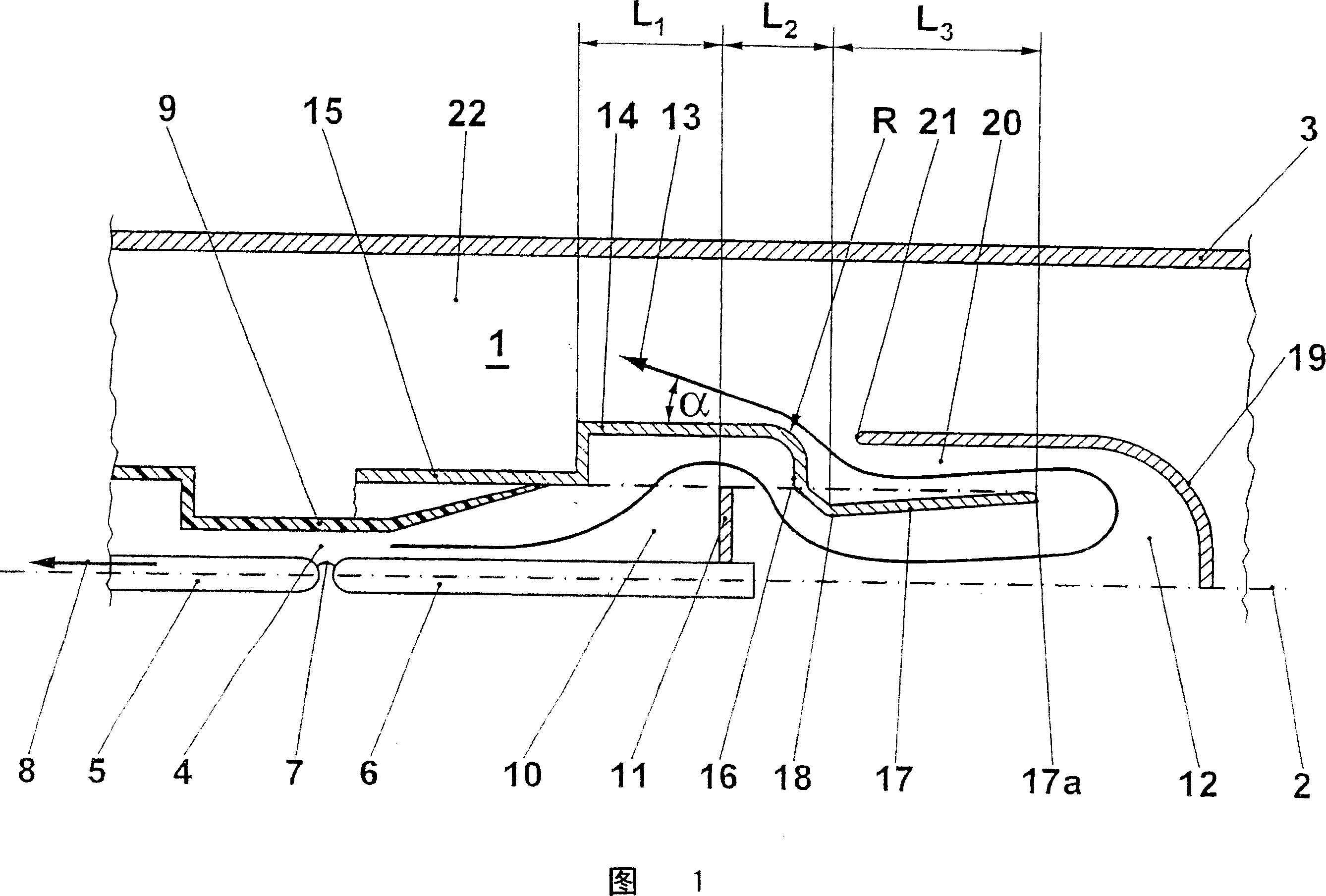

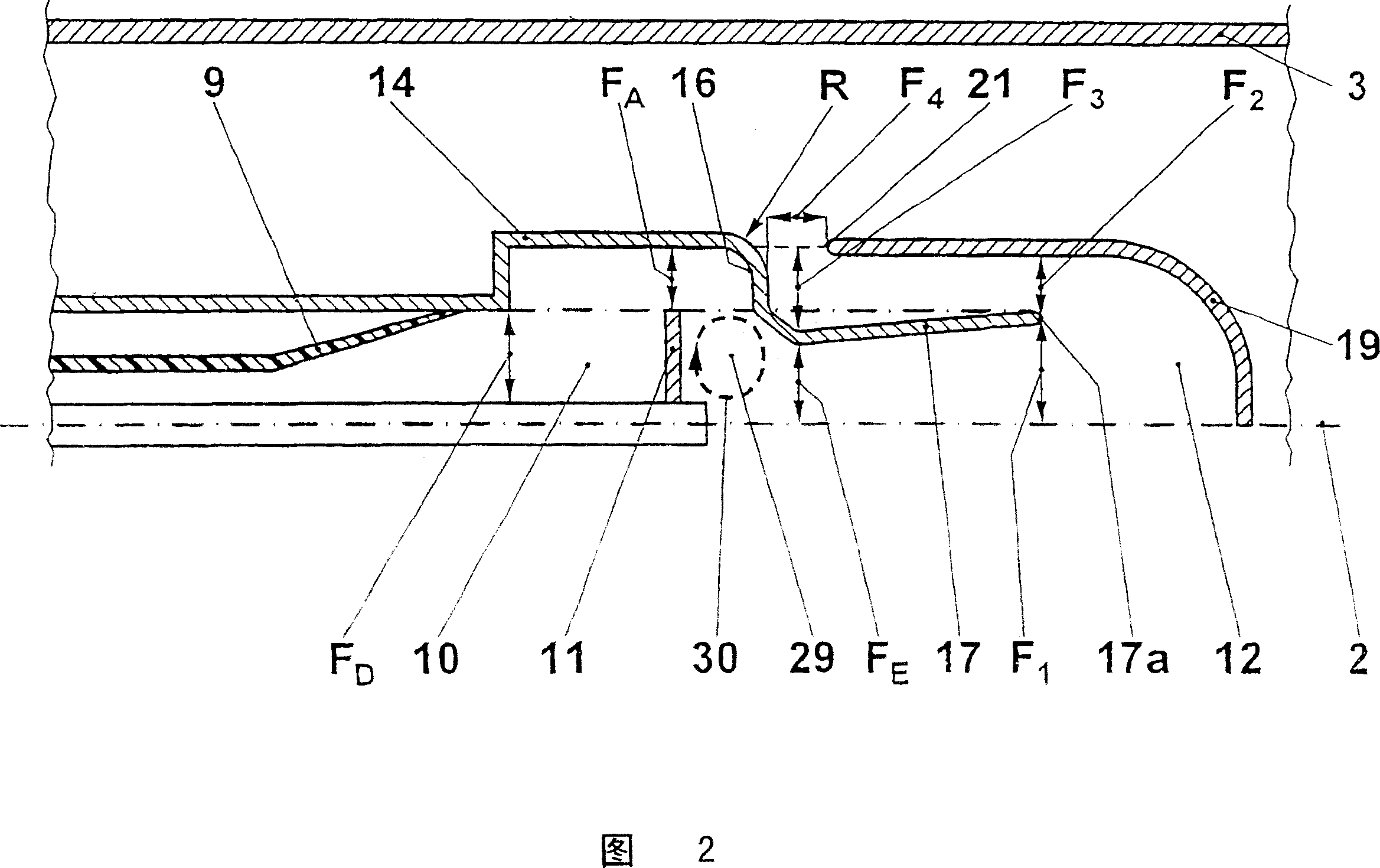

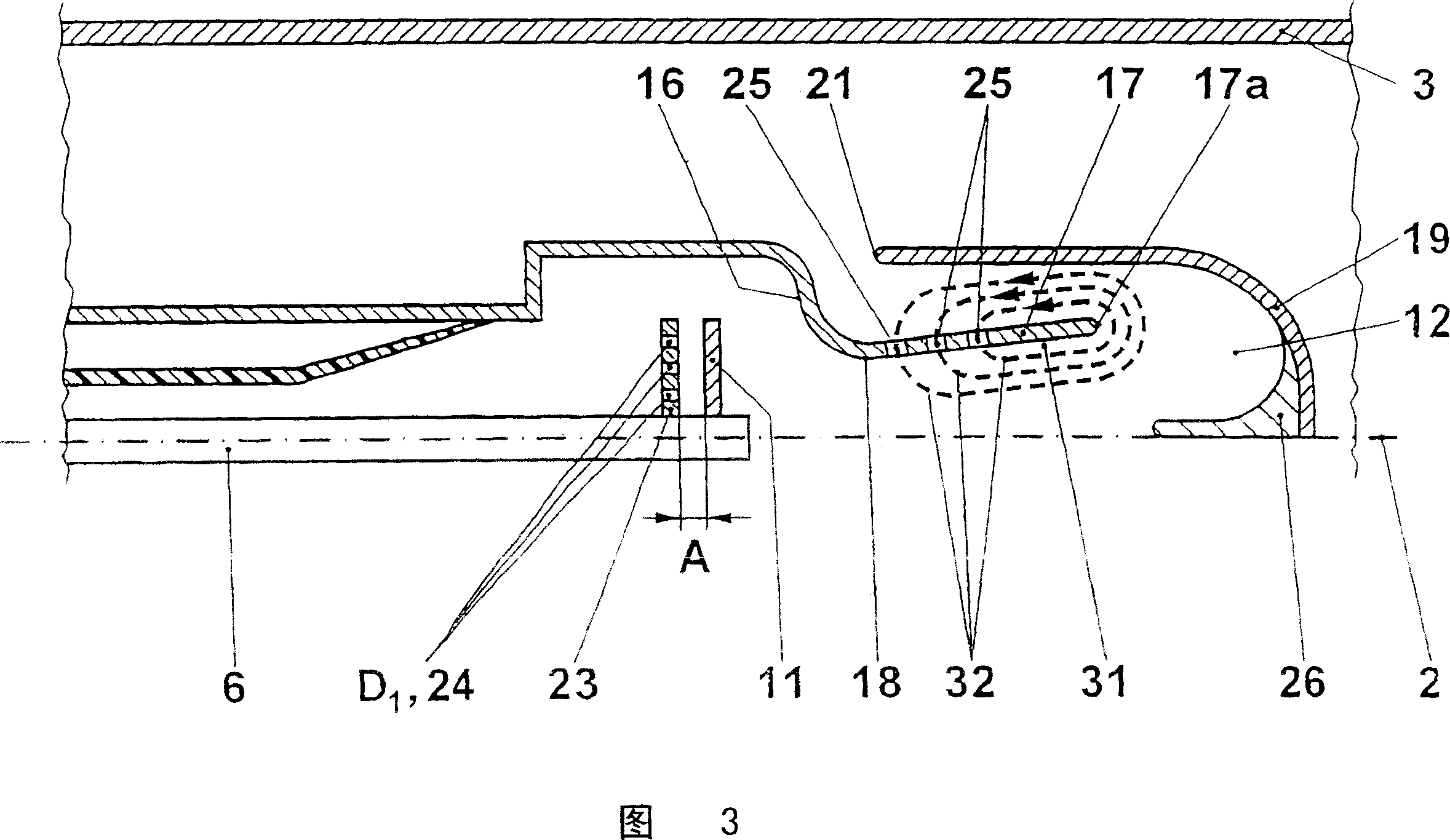

[0018] Elements with the same function are provided with the same reference symbols in all figures. All elements not necessary for a direct understanding of the invention are not shown and are not described.

[0019] A power switch can have one or more series-connected interrupters filled with insulating gas, which operate according to the conventional switching principle, that is, for example as an automatic blowing chamber, as an automatic blowing chamber with at least one additional compression piston arrangement Or as a simple compression piston switch. The power switch is formed as a covered power switch, wherein metal or plastic can be selected as the material of the cover. The power switch can also be an open-air switch, ie a part of a gas-insulated switchgear covered by a metal or a circuit breaker. FIG. 1 is a particularly simplified and schematically illustrated partial cross-sectional view of a first embodiment of a power switch during the switching-off process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com