Data-oriented method for manufacturing lightweight thin-wall metal sheet

A light-weight technology for sheet metal parts, applied in the field of metal forming, can solve the problems of consuming a lot of time and energy, and achieve the effects of reducing heating time, reducing fuel consumption, and reducing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

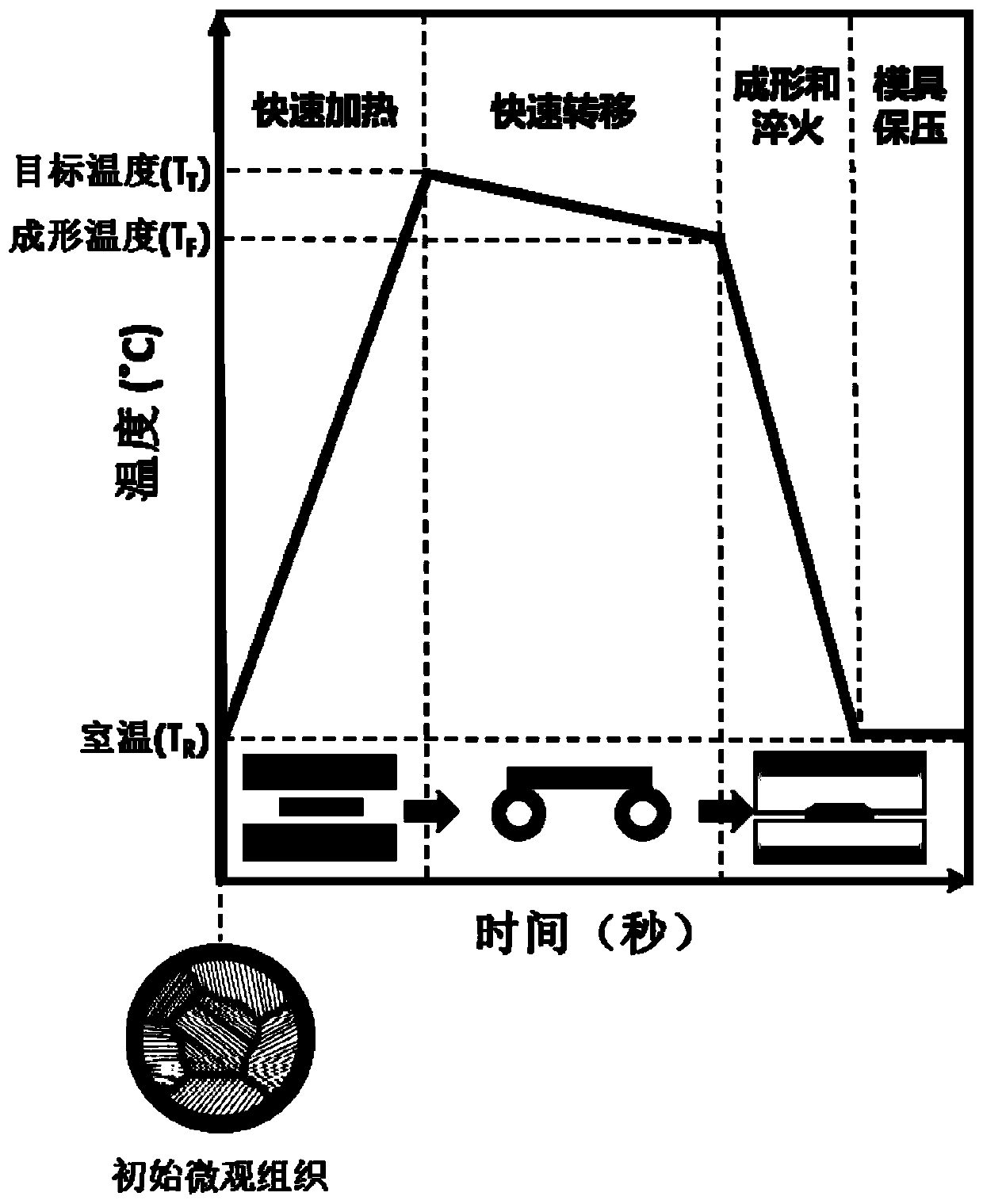

[0047] Specific implementation mode one: combine figure 1 Describe this embodiment, the shaping of parts is realized through following steps:

[0048] The information provided by the user is shown in the table below:

[0049]

[0050] 1. Obtain the sheet metal database through experimental verification in advance, and the sheet metal database includes the crystal phase of each sheet metal and its corresponding optimized forming processing parameters;

[0051] According to the data of the user (such as an automobile manufacturer) on the paint baking process, part design, plastic strain of the material during the manufacturing process, and performance requirements after forming, use a data-oriented method to analyze and select an initial sheet with a specific microstructure. The microstructure of the material can be confirmed by transmission electron microscopy (TEM) observation, thus meeting the specific microstructure requirements for data-oriented method matching.

[00...

specific Embodiment approach 2

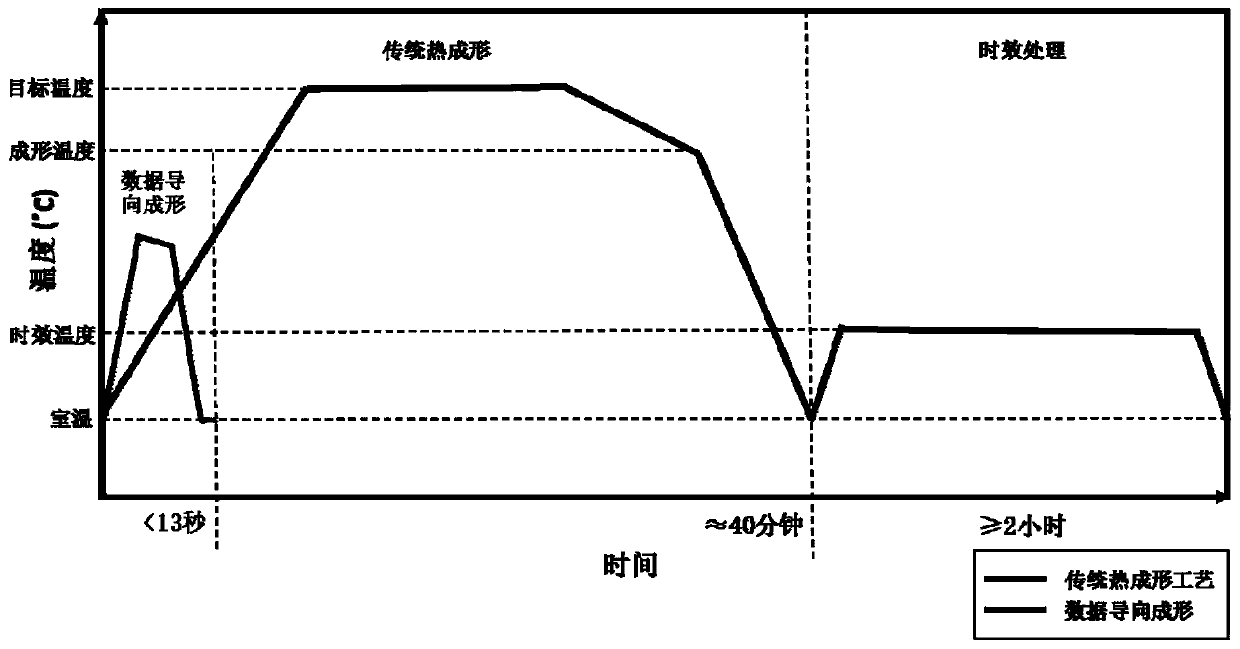

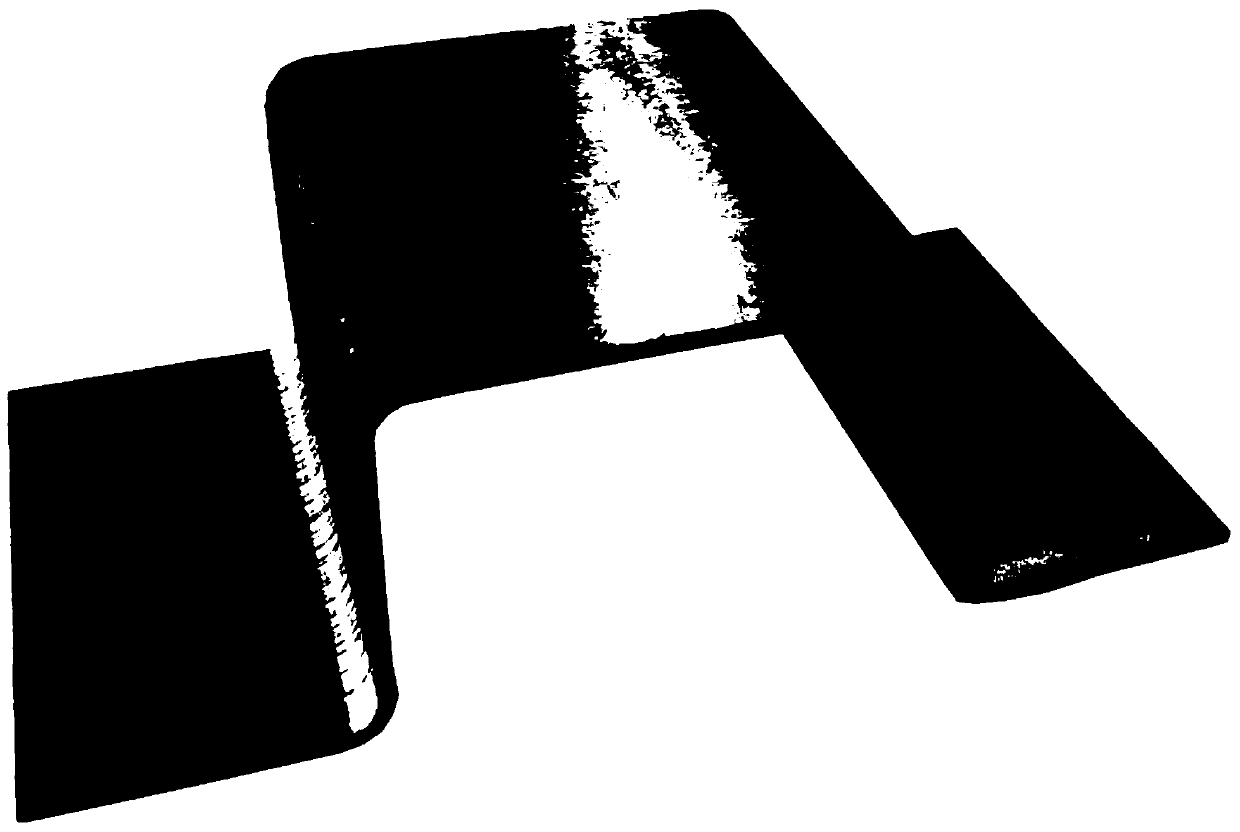

[0065] Specific implementation mode two: the following combination figure 1 , figure 2 and image 3 This embodiment will be specifically described. The difference between this embodiment and specific embodiment 1 is that the material of the thin-walled sheet metal part in this embodiment is AA6082 aluminum alloy material, and the thickness of the sheet metal is 2mm. Formed parts are "U" shaped members.

[0066] Based on the information provided by users 1 and 2, the specific microstructure requirements and optimized forming process parameters obtained according to the data-oriented method are as follows:

[0067]

[0068]

[0069] In this embodiment, the parts of user 1 are used for experimental verification.

[0070] Step 2 Select the microstructure of aluminum alloy containing 25% pre-β" phase, 25% GP phase, 40% β" phase and 10% β phase, and heat it rapidly at a heating rate of 45-55°C / s to make the sheet Rapidly warm up to the target temperature (T T ).

[007...

specific Embodiment approach 3

[0075] Specific implementation mode three: the following combination figure 1 , figure 2 and Figure 4 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the material of the thin-walled sheet metal parts in this embodiment is ultra-high strength steel, and the thickness of the sheet metal is 2 mm. Formed parts are "U" shaped members.

[0076] Based on the information provided by users 1 and 2, the specific microstructure requirements and optimized forming process parameters obtained according to the data-oriented method are as follows:

[0077]

[0078] In this embodiment, the parts of user 1 are used for experimental verification.

[0079] Step 2 Select the microstructure of ultra-high-strength steel containing 87% martensite, 12% ferrite and 1% austenite, and conduct rapid heating at a heating rate of 55-65°C / s to rapidly heat up the sheet metal to the target temperature (T T ).

[0080] Forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com