Method for regulating and controlling temperature of coke oven

A technology of temperature regulation and control method, which is applied in the directions of coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve the problems of increasing coking production cost, high heat consumption of coke oven coking, and aggravating air pollution, etc. The effect of labor intensity, reducing heat consumption, and simplifying temperature measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below, which is a preferred embodiment among various implementations of the present invention.

[0054] In a preferred embodiment, include the following steps:

[0055] (1) Collect data such as the measured coke cake center temperature, actual CDQ and coke quality indicators within a period of time. According to the collected relevant data, on the premise of ensuring the quality of coke, formulate different coke corresponding to the CDQ. Cake center temperature control value, the center temperature of the coke cake is regulated in sections.

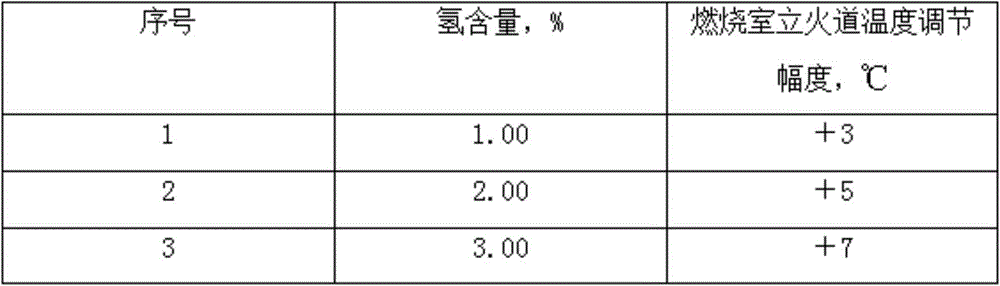

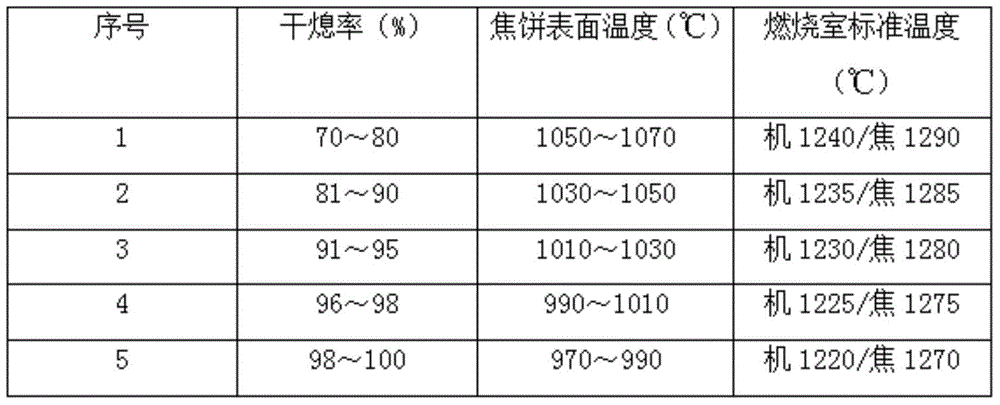

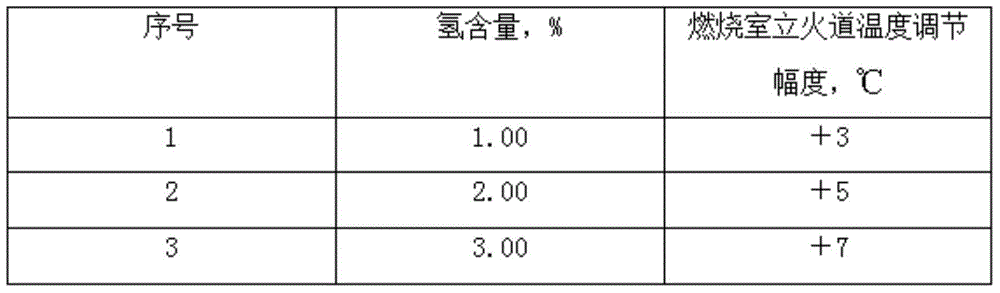

[0056] ⑵According to the control value of different coke cake center temperature formulated in step ⑴, combined with the specified coking time and other relevant production data to determine the corresponding standard temperature of the combustion chamber vertical fire channel.

[0057] (3) Measure and calculate the coke cake center temperature, coke cake surface temperature and the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com