Humidity conditioning device for coking coal

A technology for pulverized coal and coke oven flue, which is used in coke ovens, lighting and heating equipment, petroleum industry, etc., can solve the problems of high operating cost, complex process, expensive technology, etc., and achieves high volumetric heat transfer coefficient and obvious economical and social benefits, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

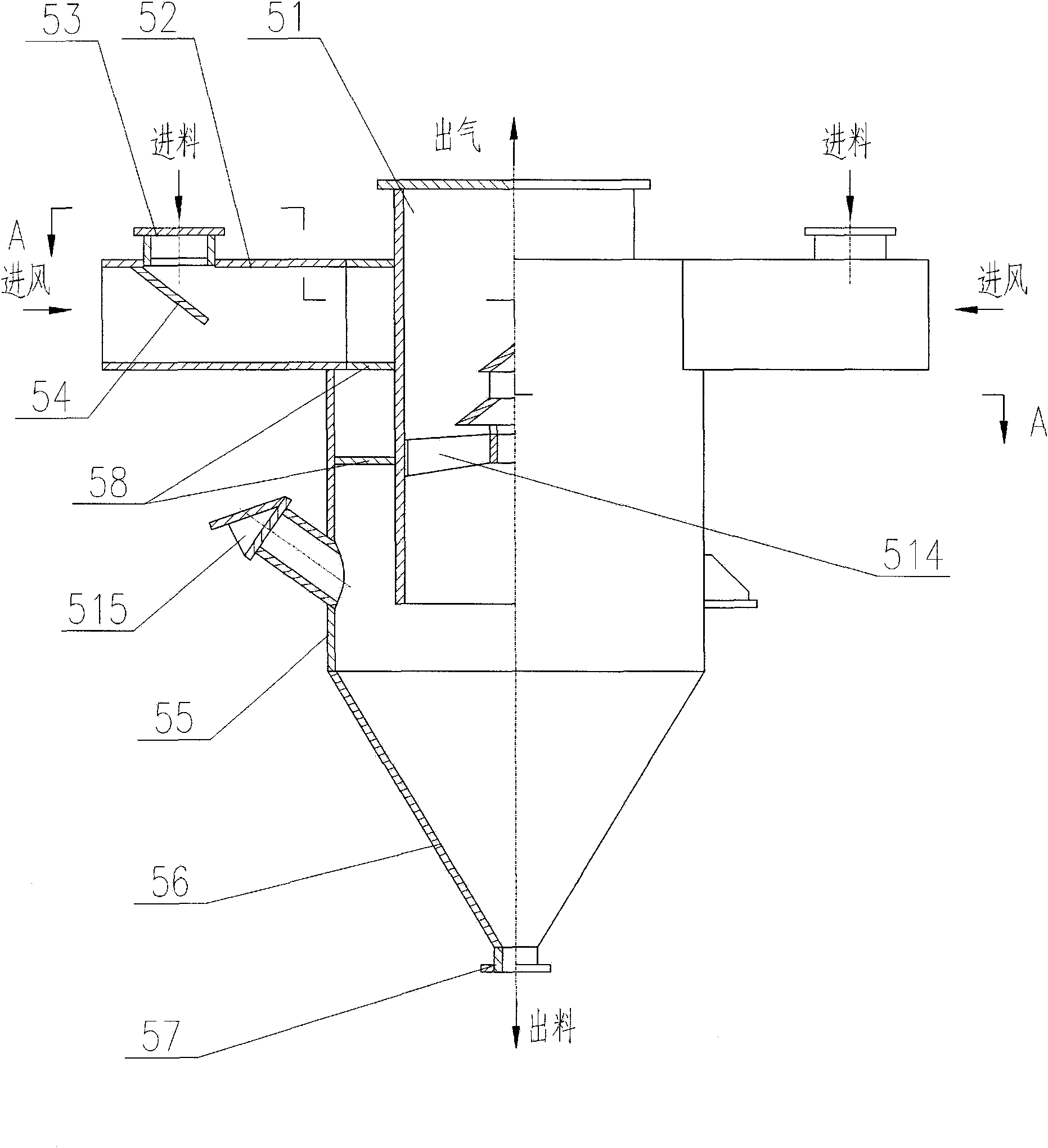

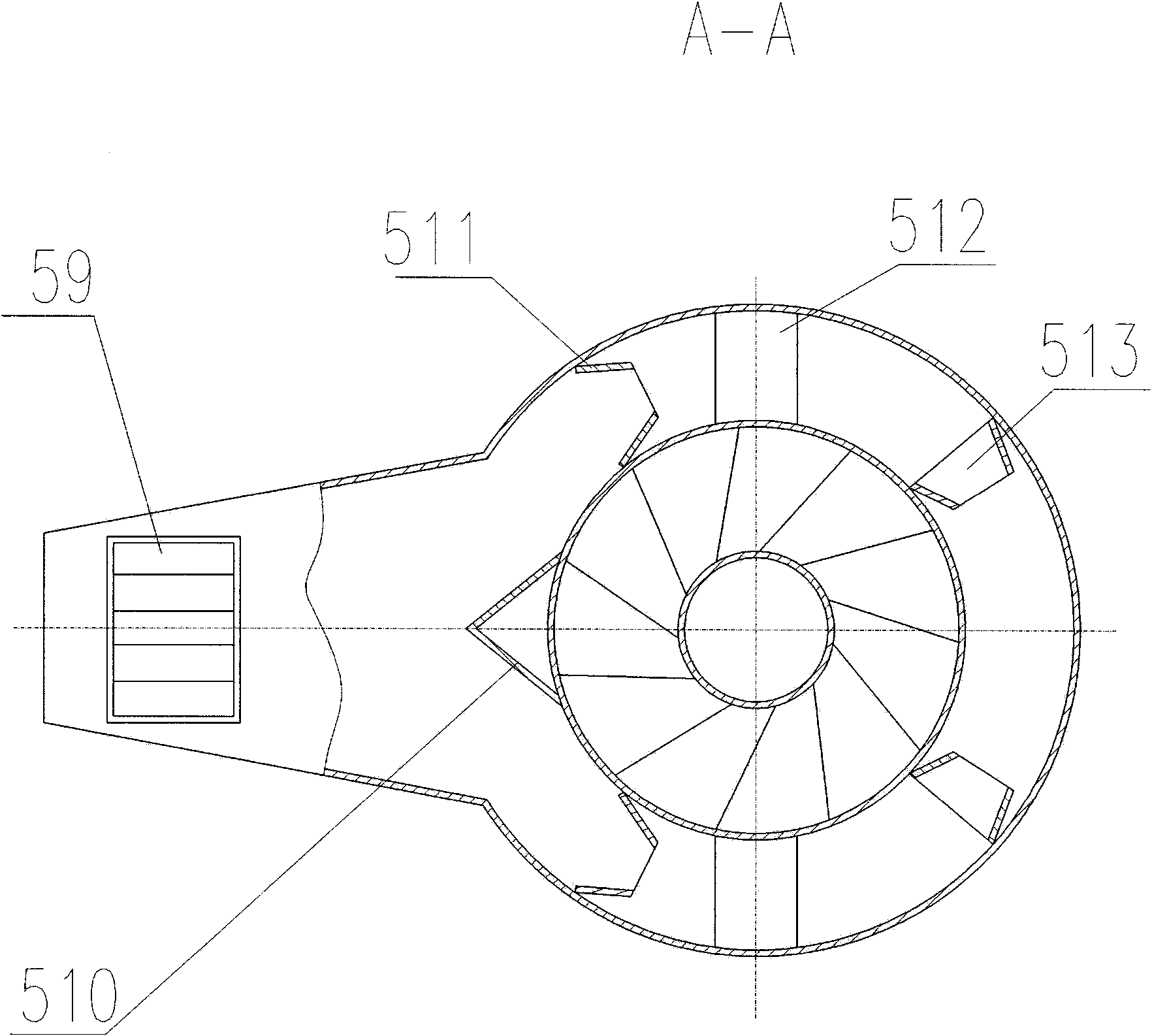

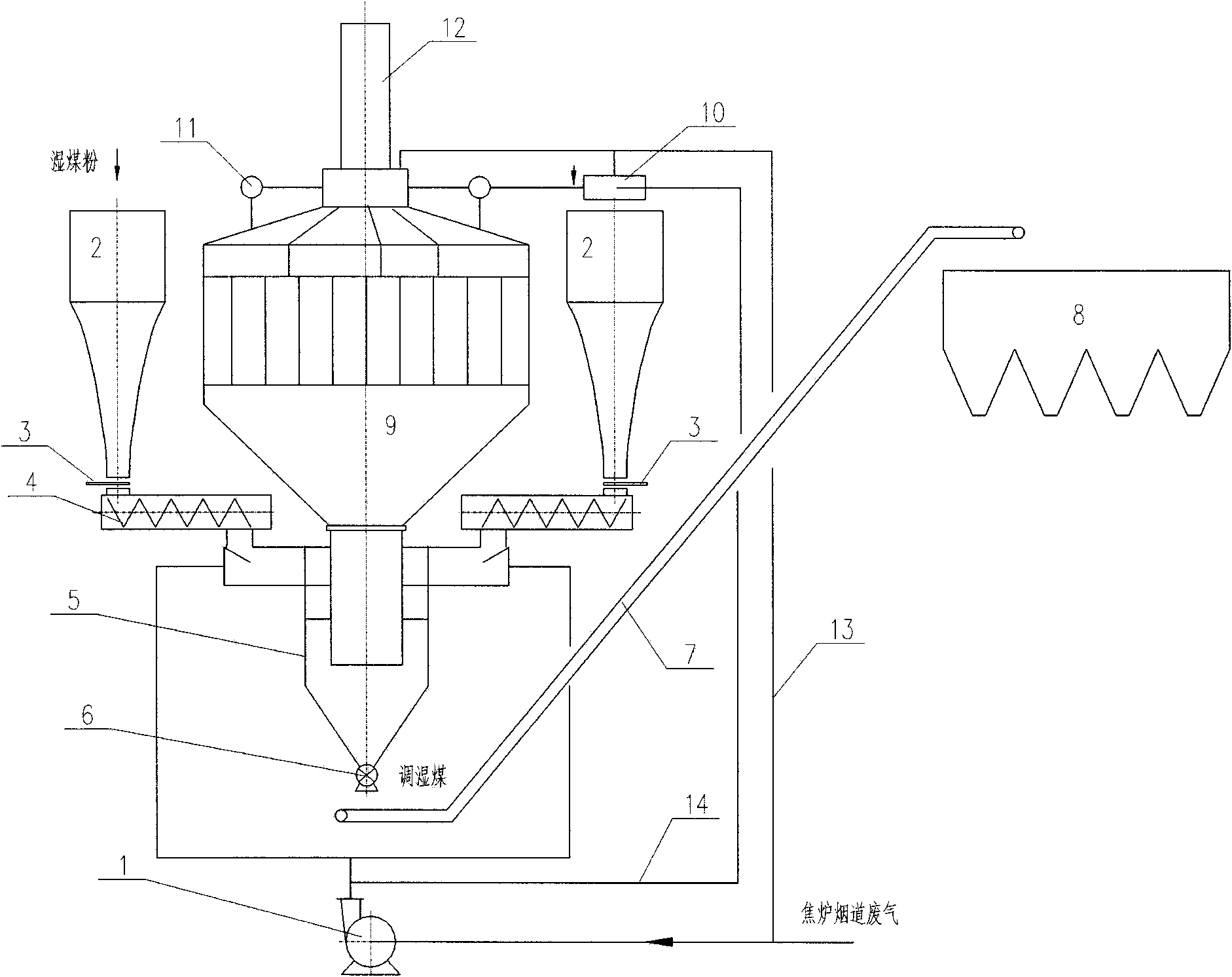

[0017] figure 1 , figure 2 It represents an embodiment of the humidity control device for coking coal provided by the present invention. The humidity control device has an inlet part, which is preferably arranged symmetrically, including a pulverized coal inlet 53 and an air inlet pipe 52 . In order to avoid pulverized coal from agglomerating and hardening, a coal comb grid 59 can be set at the pulverized coal inlet 53 to comb the pulverized coal. Preferably, coke oven flue gas is used as the drying gas. The temperature of the flue gas is about 200°C, and the moisture content of the pulverized coal to be adjusted is about 10% to 11%. The inlet part also includes a slide plate 54. The pulverized coal falls on the upper surface of the slide plate 54 from the inlet 53, slides down along the slide plate 54, and is blown away by the flue exhaust gas that is throttled and accelerated by the slide plate 54 and hits the splitter part 510, and the flow is split. Enter the annular ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com