Coal humidity control instrument detection and humidity control method for desalinated water heat exchange using coke oven flue gas

A control method and instrument detection technology, applied in coke ovens, energy input, petroleum industry, etc., can solve problems such as difficulty in furnace installation, backward humidity control technology, distortion of process parameter monitoring, etc., to save coking heat energy consumption and detection methods. Practical and reliable, the effect of improving the production capacity of coke oven

Active Publication Date: 2021-09-24

广西华锐工程设计有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Not only does it cause a great waste of energy, the humidity changes greatly, and the expected effect cannot be achieved; the instrument detection point is set improperly, and the process parameter monitoring is distorted; the humidity control technology is backward, and the operation is difficult; at the same time, there is no clear target value for the degree of coal dryness. Sometimes it is too dry, resulting in difficulties in furnace loading, unsmooth operation, frequent accidents, etc., so production has been stopped one after another

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

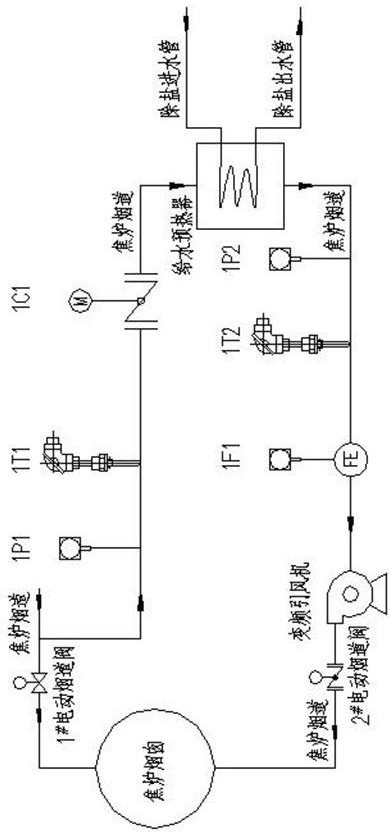

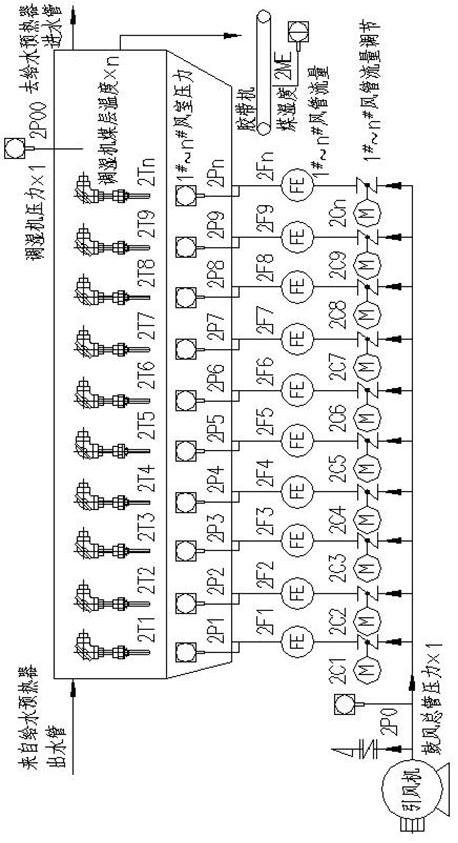

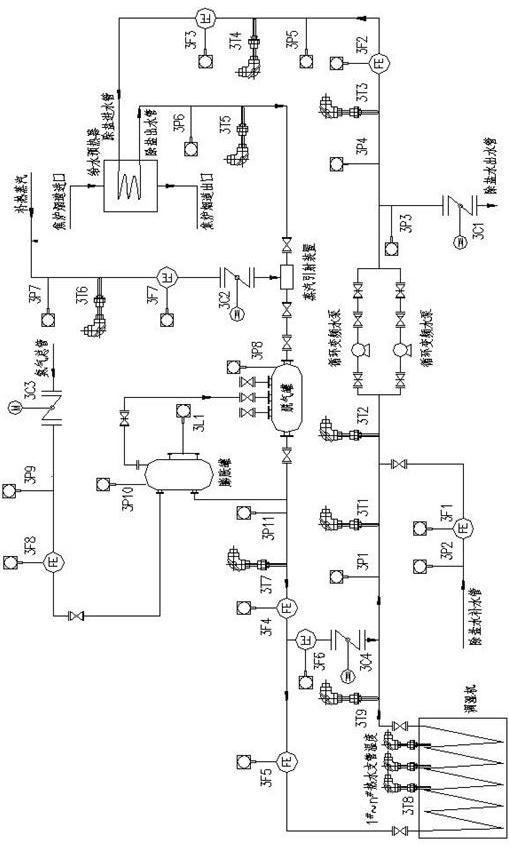

[0075] The coke oven flue gas instrument detection and humidity control method of the present invention comprises:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A coal humidity control instrument detection and humidity control method using coke oven flue gas for heat exchange of desalinated water, using waste heat of coke oven flue gas for heat exchange of desalinated water, coke oven flue gas negative pressure humidity control method adopts two Two methods: one is the control method of the negative pressure regulating valve at the flue gas inlet, the other is the negative pressure variable frequency regulation control method at the flue gas inlet, the coal humidity control method includes the humidity control method of the air chamber pressure of the humidifier, the flow rate of the air pipe, and the steam compensation method. Heat regulation control method, nitrogen supplement pressure regulation and control method, bypass flow regulation and control method, desalinated water replenishment regulation and control method, circulating water frequency conversion regulation method, etc. Its advantage is that the use of flue gas as a heat source can reduce the amount of water vapor used, reduce the burden of coking wastewater treatment, and greatly save coking heat energy consumption; the social benefit of energy saving is to reduce greenhouse gas emissions, and the stability of coal moisture can be maintained The stable operation of the coke oven is beneficial to prolong the life of the coke oven, increase the production capacity of the coke oven, and improve the quality of coke.

Description

technical field [0001] The present invention relates to the automatic control and instrumentation technology in the metallurgical industry based on the heat exchange of desalinated water by using the waste heat of coke oven flue gas, and in particular to a coal humidity control instrument detection and humidity control method for heat exchange of desalinated water by using coke oven flue gas . Background technique [0002] At present, the most widely used coal humidity control device at home and abroad uses steam or hot blast stove as the heat source. Not only does it cause a great waste of energy, the humidity changes greatly, and the expected effect cannot be achieved; the instrument detection point is not set properly, and the process parameter monitoring is distorted; the humidity control technology is backward, and the operation is difficult; at the same time, there is no clear target value for the degree of coal dryness. Sometimes it is too dry, which causes problems ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10B57/10C10B57/00

CPCY02P20/129

Inventor 滕树满申世武廖峰峰金闯黎晓亮黄小刚张德钦毕俊韩瑞蒙伟莫中元侯军蒋远辉张锐博周芸

Owner 广西华锐工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com