Coal humidifying and whirling machine of compound fluidized bed and novel humidifying technology

A technology of coal humidity control and compound flow, which is applied in the new humidity control process, cyclone, and compound fluidized bed coal humidity control field, can solve the problems of high operating cost, high investment, low heat transfer efficiency, etc. Density, pollution reduction, and the effect of expanding coking coal sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

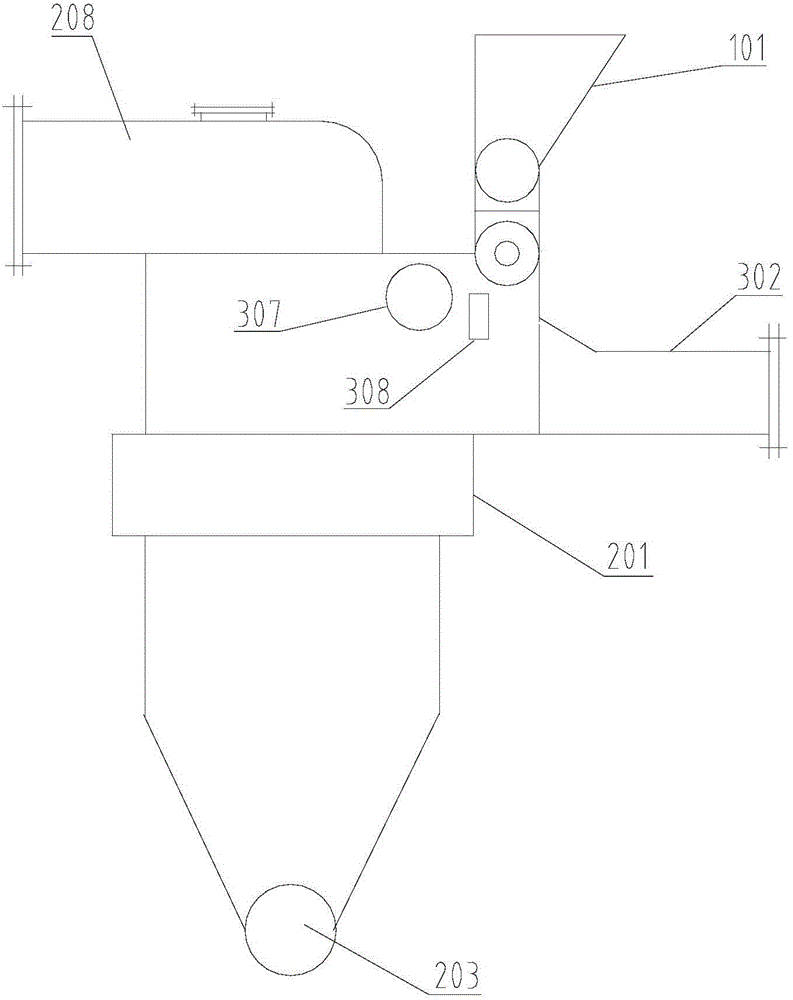

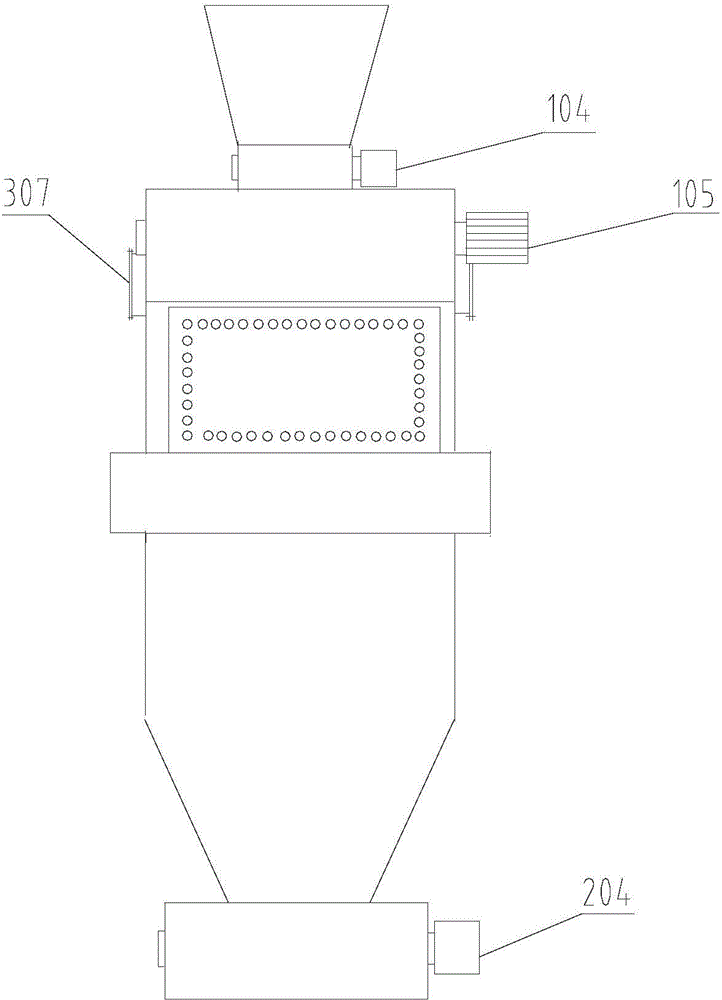

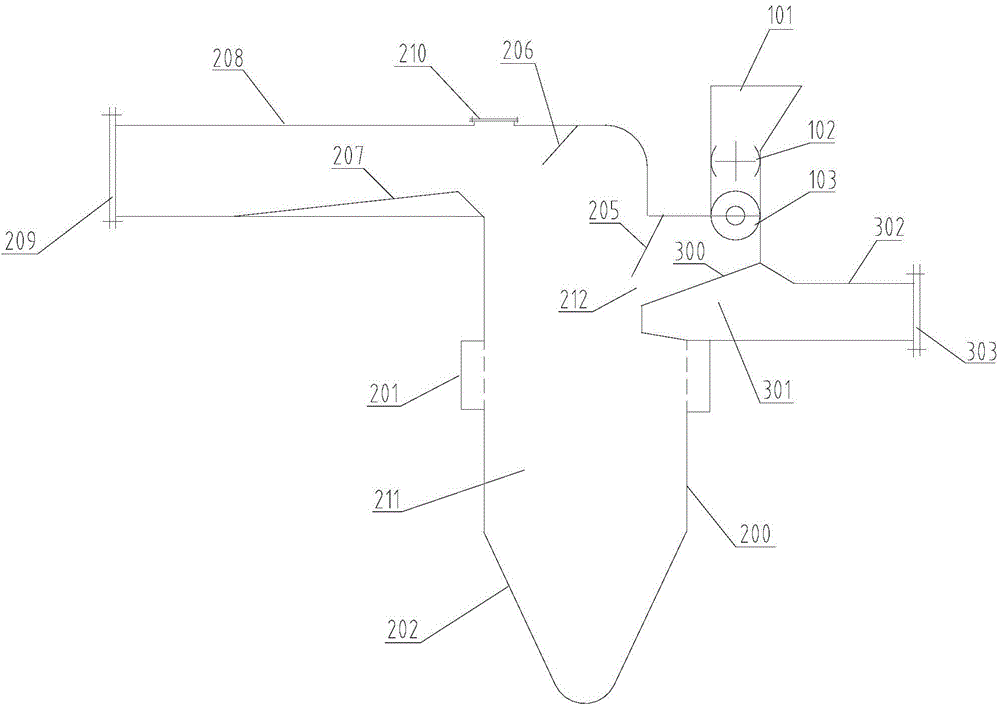

[0024] In conjunction with the accompanying drawings, a compound fluidized bed coal humidity control and cyclone machine includes a housing 200, and a hot fluid delivery pipeline 302, a hot fluid gas chamber 301, a fluid distributor 300, and a dried material are arranged inside the housing 200. Conveying pipeline 211 , swirl bed body 201 , dried material storage bin 202 and waste gas discharge pipeline 208 .

[0025] The hot fluid chamber 301 communicates with the hot fluid delivery pipe 302, the fluid distributor 300 is obliquely arranged above the hot fluid chamber 301, the initial end of the fluid distributor 301 is high, and the end is low. A raw material silo 101 is arranged above the housing, and the material in the raw material silo 101 is conveyed directly above the initial end of the fluid distributor 300 through a star feeder 102 and a spiral slot feeder 103 . A fluidized bed outlet partition 205 is arranged above the fluid distributor 300 , the upper end of the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com