Patents

Literature

112results about How to "To achieve the purpose of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

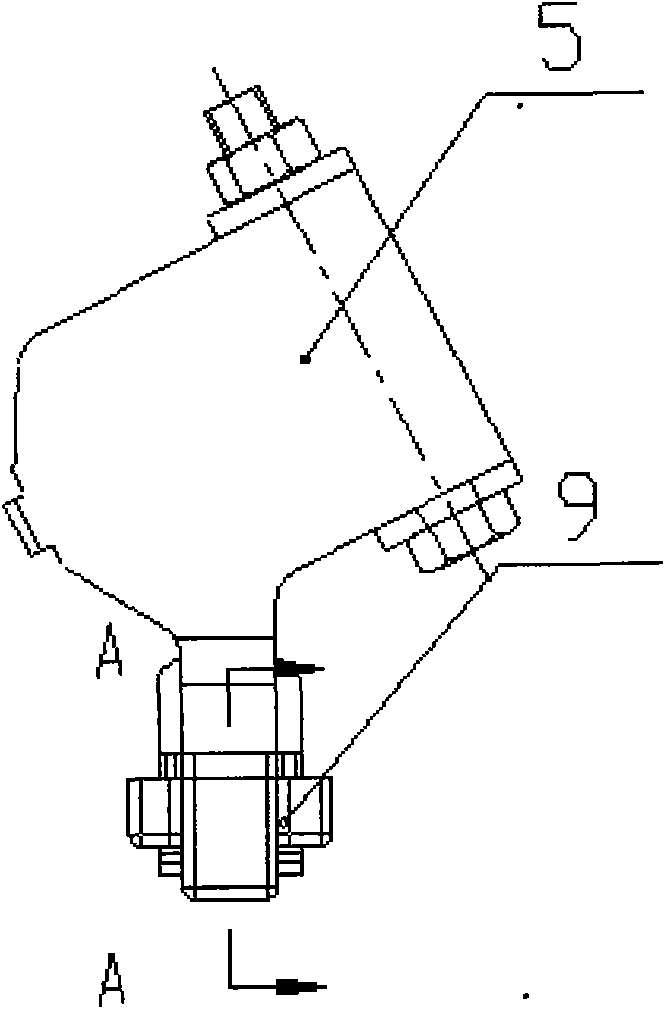

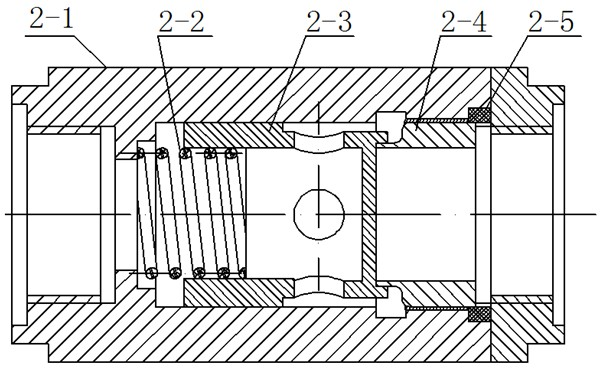

Hydraulic electricity generation shock absorber of vehicle

InactiveCN101865237AGuaranteed comfortSave energyMachines/enginesLiquid based dampersAutomotive engineeringElectric generator

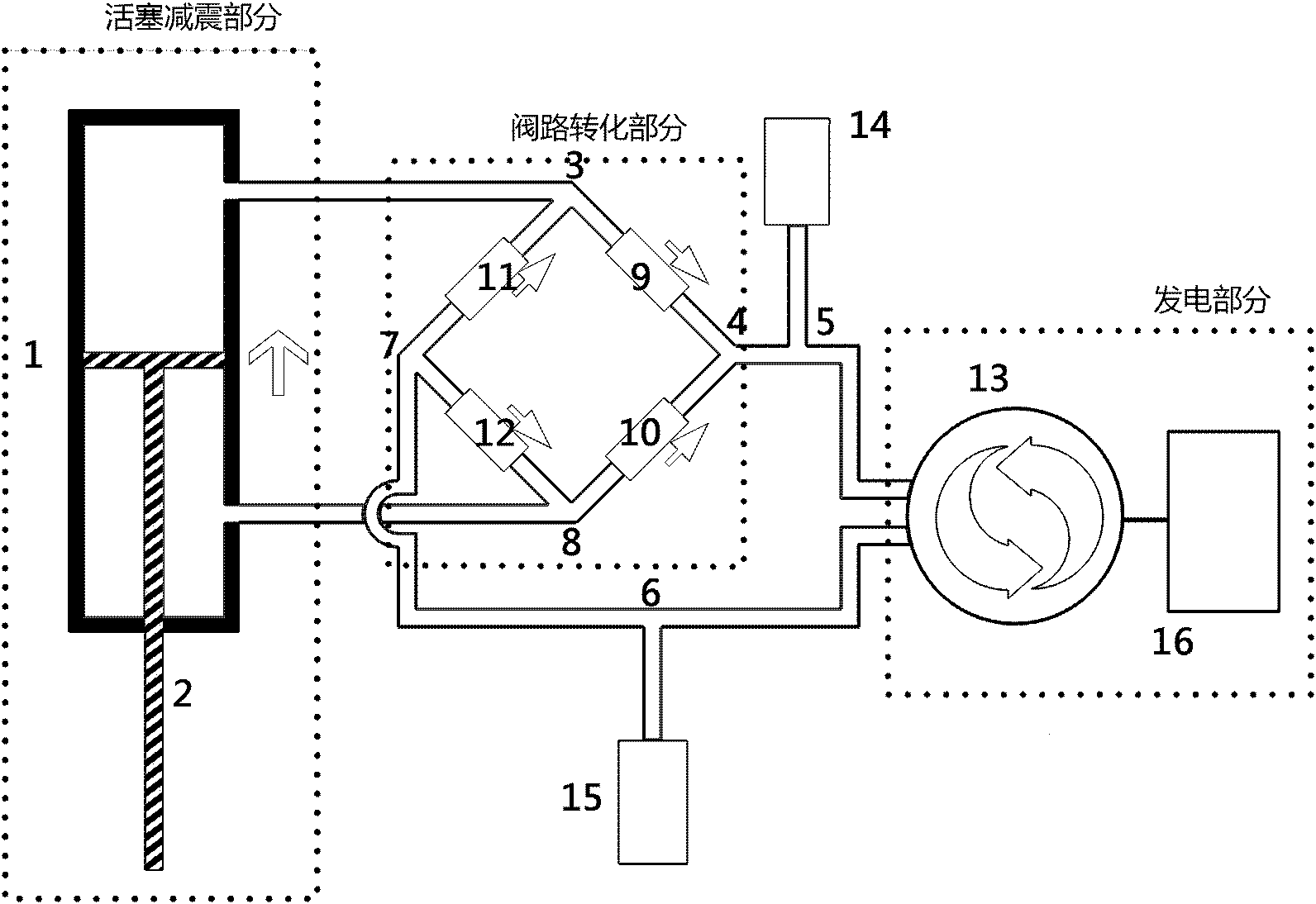

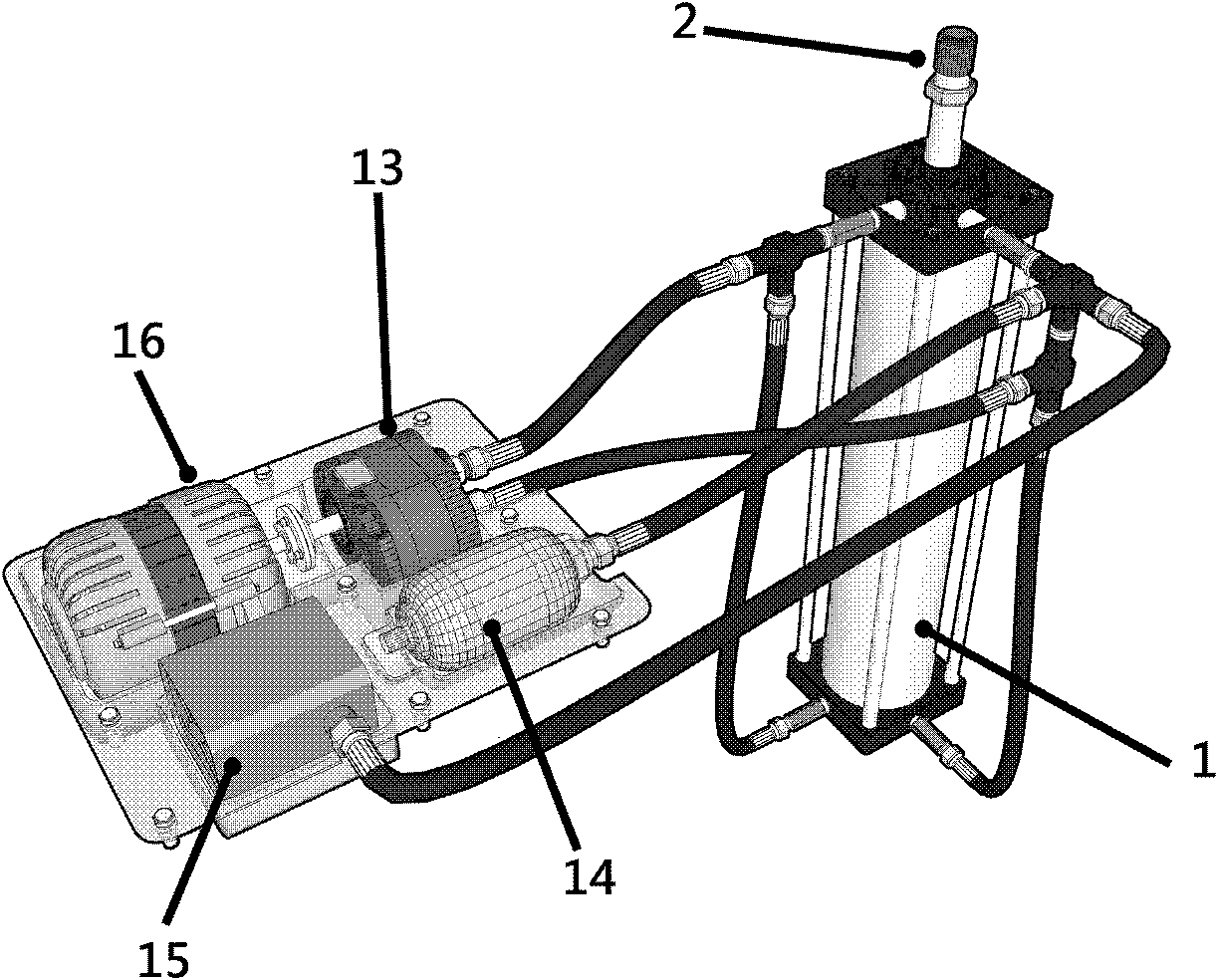

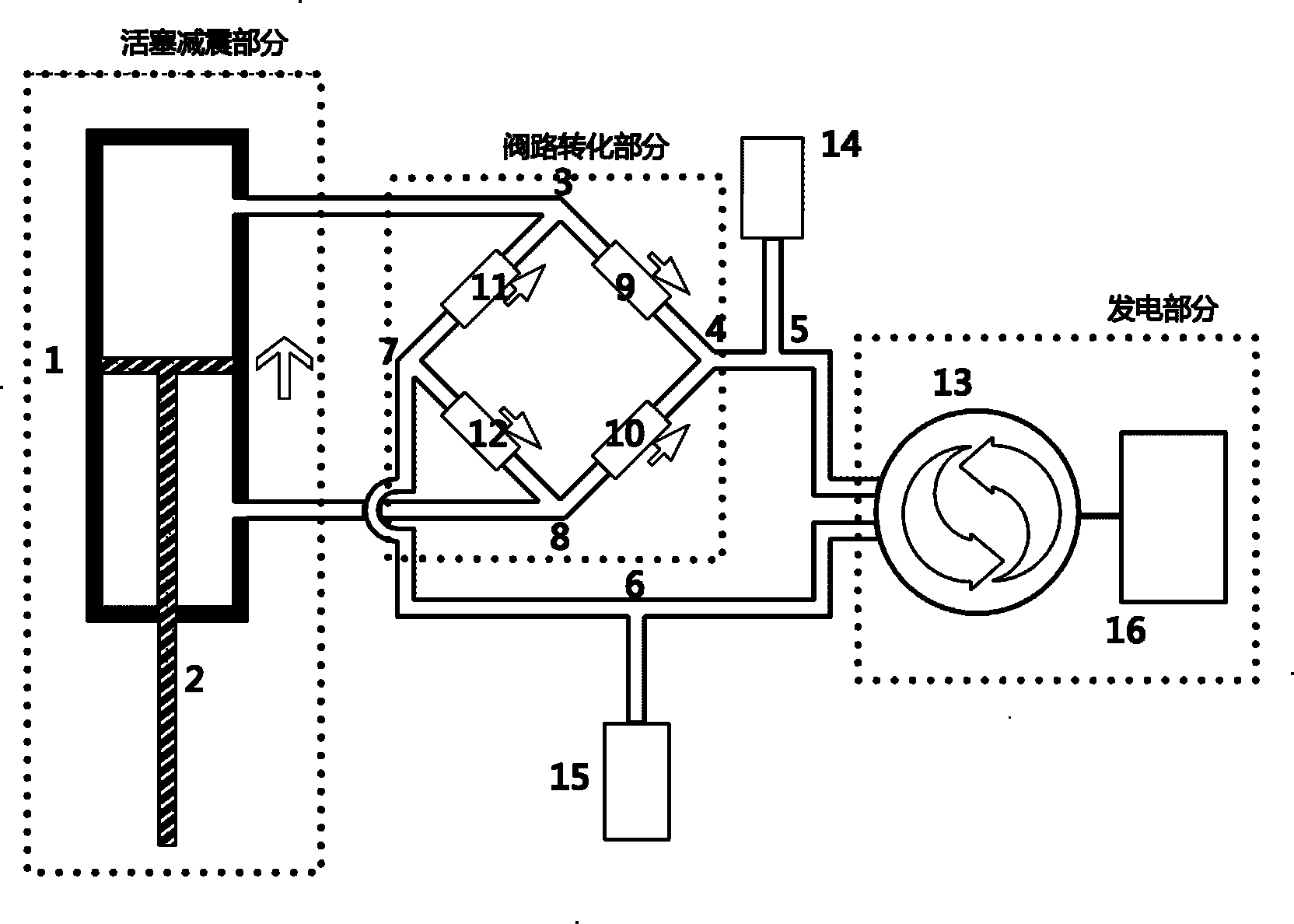

The invention discloses a hydraulic electricity generation shock absorber of a vehicle, belonging to the technical field of vehicle suspension systems and hydraulic transmission. The hydraulic power generation shock absorber of the vehicle generates electricity by utilizing pressure generated by hydraulic oil during shock absorption and comprises a piston shock absorption part, a valve path part and an electricity generation part, wherein the piston shock absorption part comprises a hydraulic cylinder (1) and a piston (2); the electricity generation part comprises a hydraulic motor (13) and an electric generator (16); and the piston (2) is pushed to move up and down in the hydraulic cylinder (1) during the shock absorption of the vehicle so that the hydraulic oil inside the hydraulic cylinder (1) is extruded out of the outlet of an upper cavity or a lower cavity of the hydraulic cylinder (1) and passes through the valve path part and then pushes the hydraulic motor (13) to drive the electric generator (16) to generate the electricity. The invention makes the hydraulic shock absorber of the vehicle possible have both stable shock absorption and electricity generation performance by adopting a reliable and mature hydraulic transmission technology and also provides a new research direction for the developed hydraulic shock absorber.

Owner:HUAZHONG UNIV OF SCI & TECH

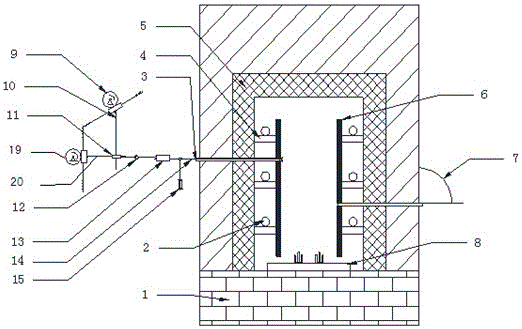

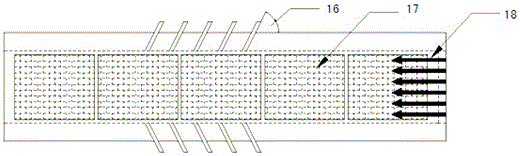

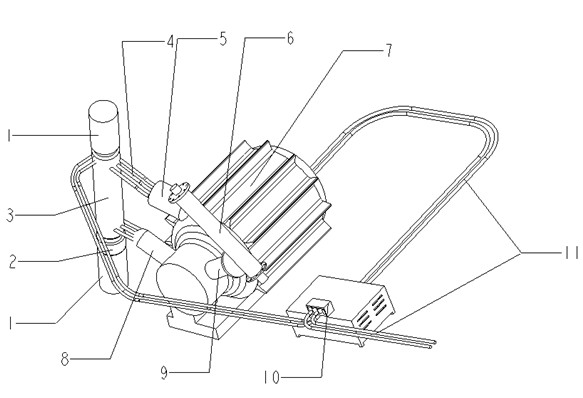

Tea dynamic drying machine

ActiveCN101238839AImprove space utilizationReasonable drying processPre-extraction tea treatmentAgricultural engineeringRunning time

The invention provides a tea dynamic dryer, the structure includes machine rack, drum, outer cover shell, tea inlet bucket, the drum upon the machine rack is placed on the friction wheel and supporting wheel, the lower part of the tea inlet bucket is adapted to one end of the drum tea inlet dynamic-static interval, which is characterized in that: the other end of the air inlet pipe is connected to the hot air transmitting pipe through the floating pipe; the cross sectional area of the central air pipe is gradually reduced from the air inlet end; outer ring surface of the drum is longitudinally equipped with many bar shaped plates; the machine rack is equipped on the machine rack through the swivel-pin, the machine rack horizontal angle modulation mechanism is equipped between the machine base and the machine rack. Under the conditions that the tea is in dynamic, suspending state and is desiccated, the machine has the advantages as follows: the utilization rate of equal diameter drum useful space is high, the waste hot wind is not easy to resort around the drum, the hot efficiency is high, the running time of tea in the drum can be effectively controlled according to the processing demand.

Owner:浙江上洋机械股份有限公司

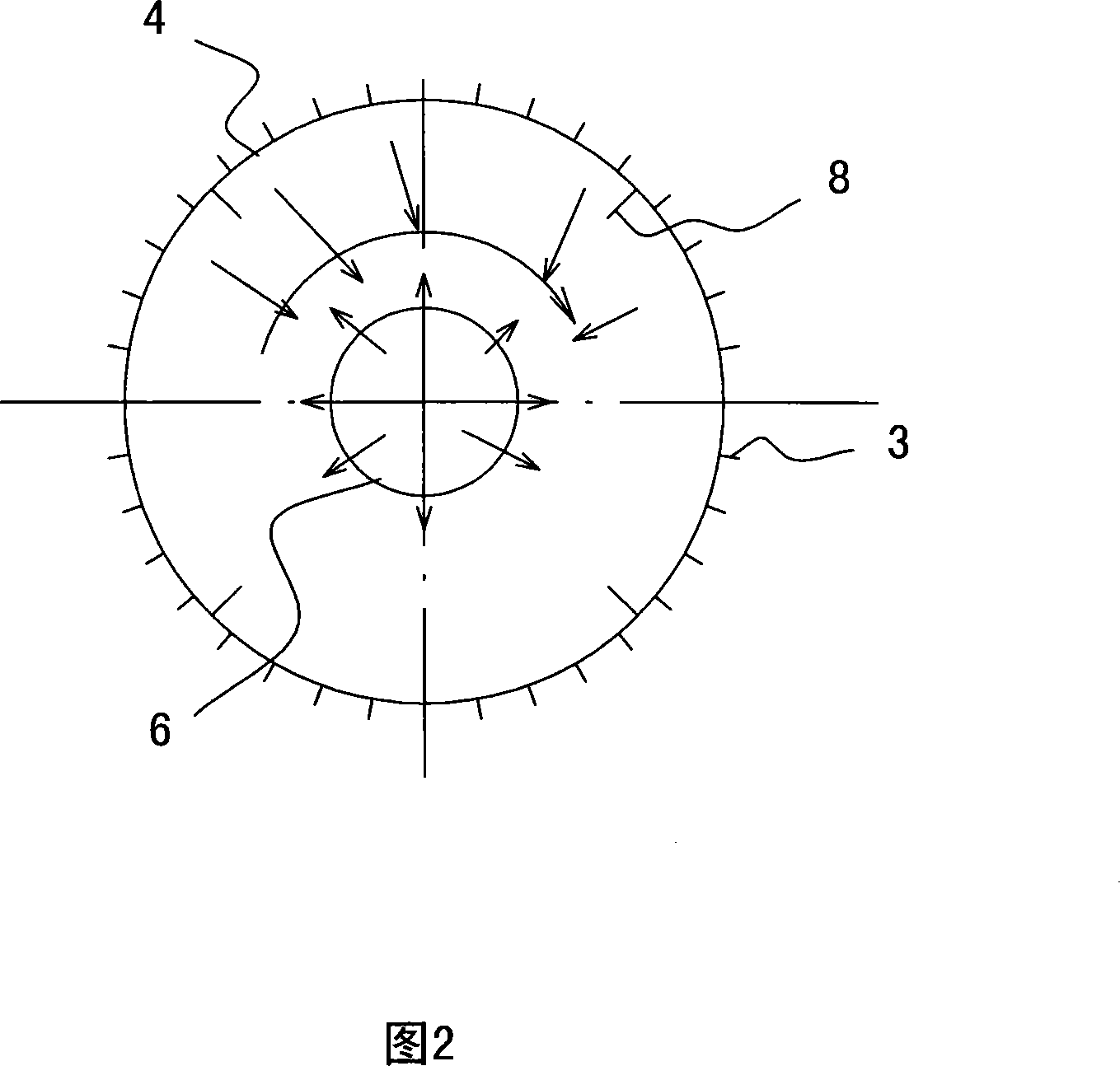

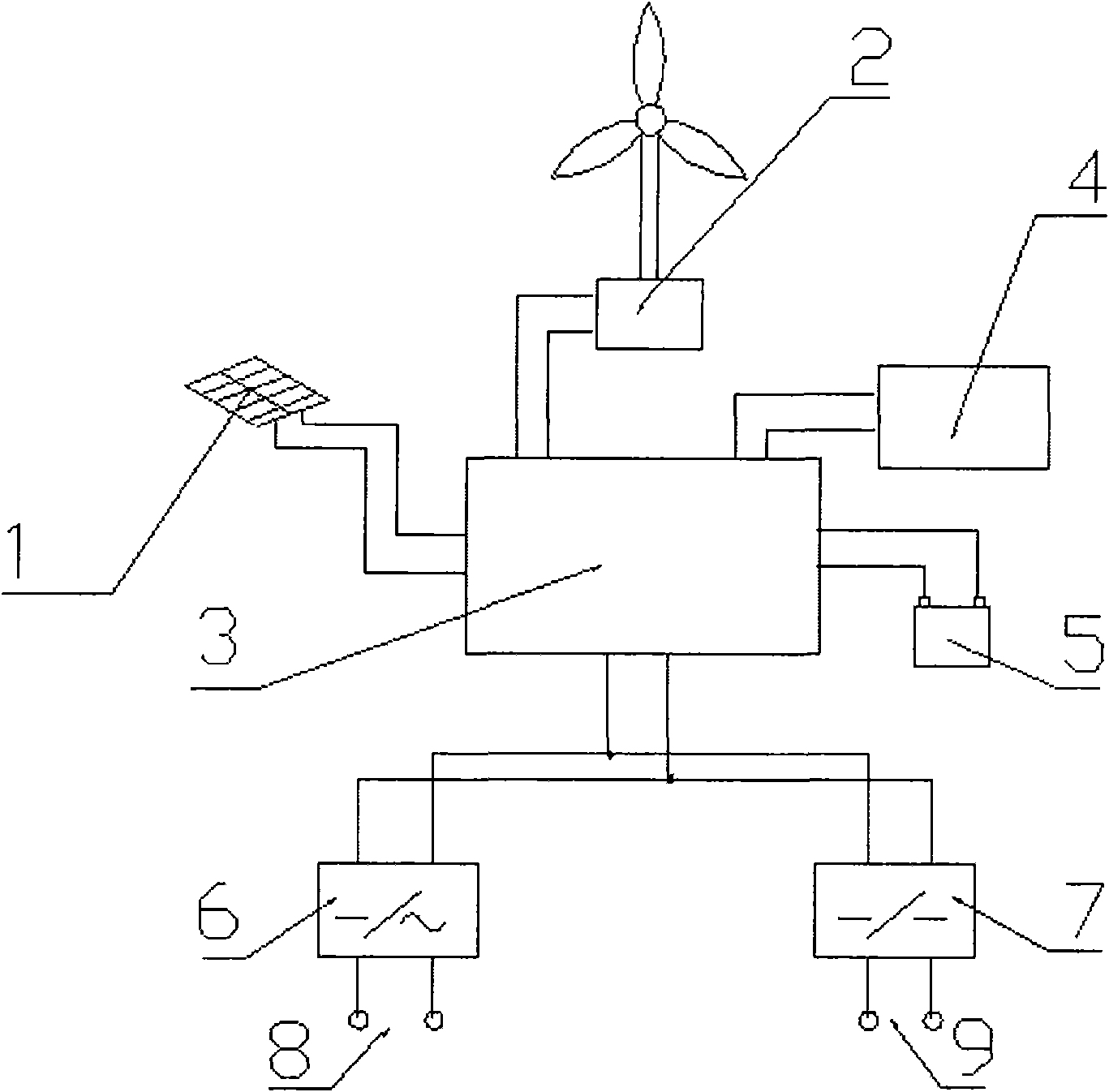

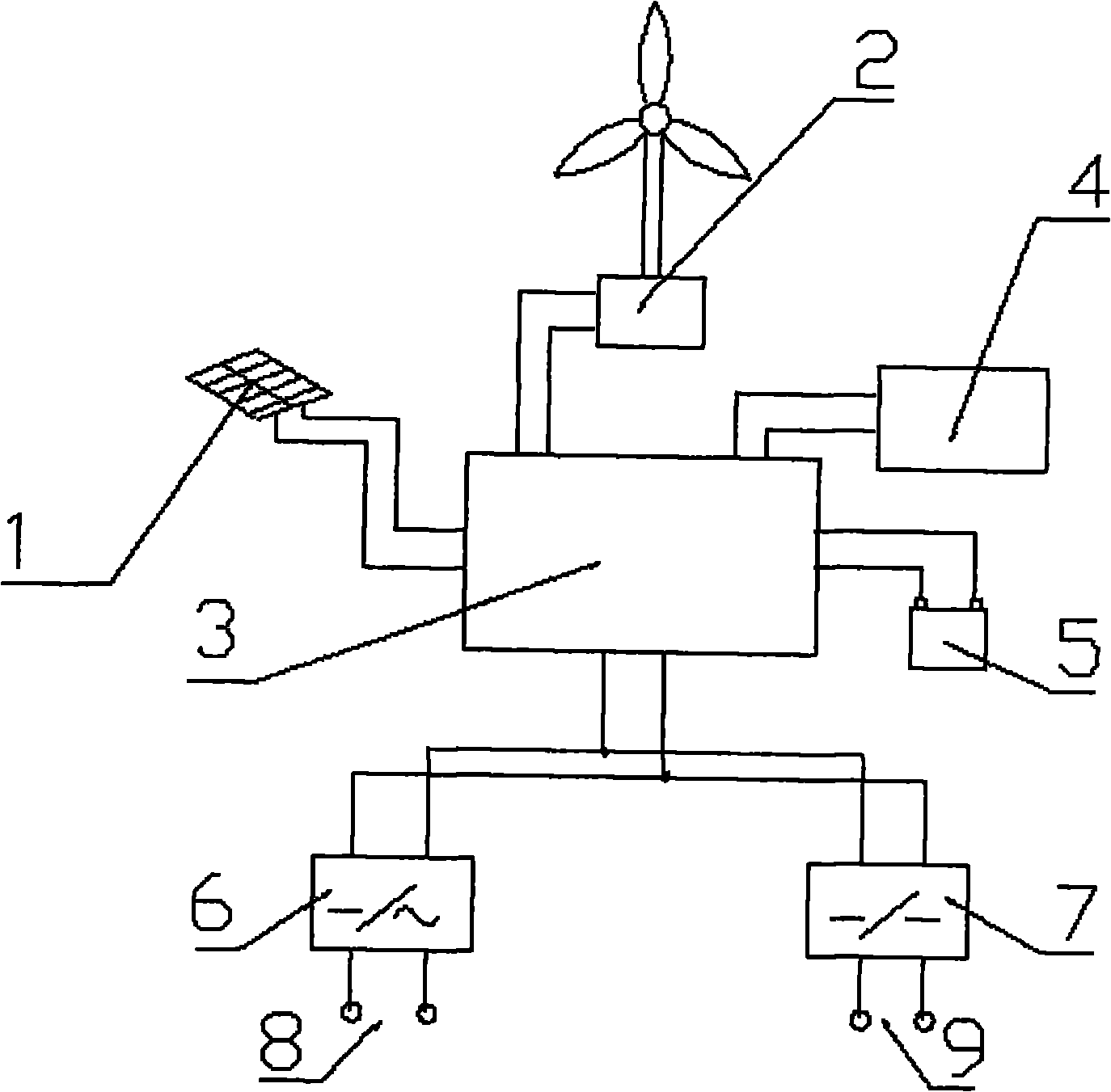

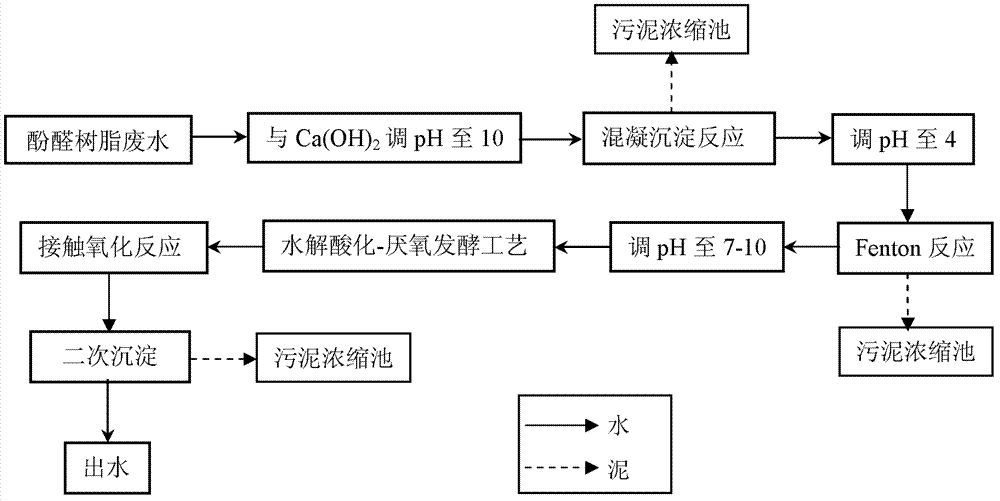

Integrated auxiliary energy supply system for wind and solar generator

InactiveCN101938225AProvide stableTo achieve the purpose of energy saving and emission reductionBatteries circuit arrangementsPV power plantsFuel oilAlternating current

The invention provides an integrated auxiliary energy supply system for a wind and solar generator, which comprises a solar battery array (1), a wind power generating set (2), a diesel generator (4), a storage battery (5), an auxiliary energy management system (3), an inverter system (6) which changes DC into AC, and a DC transformer system (7), wherein, electric energy output by the solar battery array (1), the wind power generating set (2) and the diesel generator (4) can be supplemented mutually by the auxiliary energy management system (3) for realizing priority use of solar energy and wind energy and stable supply of auxiliary energy, which can utilize the recyclable green energy such as the solar energy and the wind energy maximally, reduce fuel oil consumption and carbon emission, and realize energy supplement by the diesel generator under a windless and lightless severe generation condition so as to guarantee reliability for auxiliary energy supply.

Owner:邵汉琦

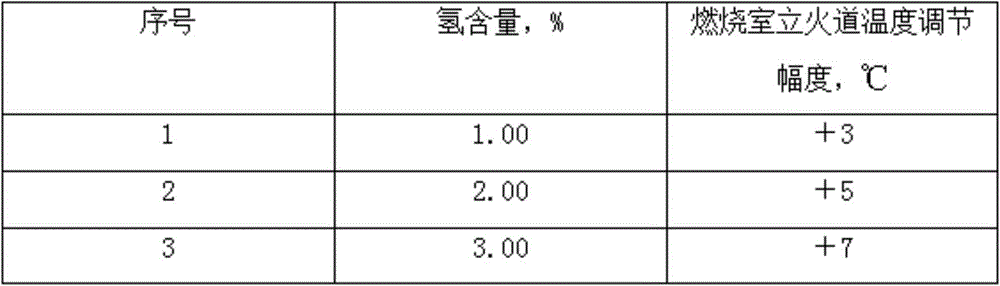

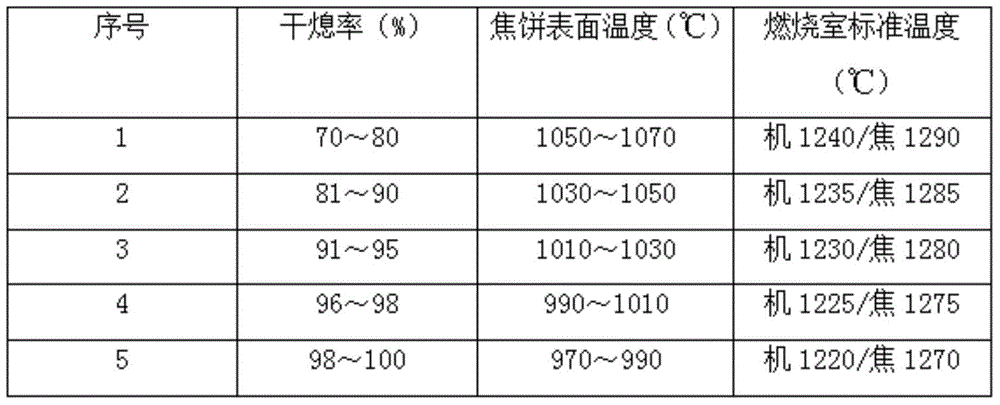

Method for regulating and controlling temperature of coke oven

ActiveCN104357065AReduce coking heat consumptionLow cost economical operationCombustible gas coke oven heatingTemperature controlCombustion chamber

The invention relates to a method for regulating and controlling the temperature of a coke oven. The method is characterized by comprising the following steps: (1) collecting data of a coke cake which is actually measured in a preset time, and formulating different coke cake center temperature control values according to the collected related data; (2) determining a corresponding combustion chamber vertical flame path standard temperature by combining different coke cake center temperature control values formulated according to the step (1) and the preset production data; (3) measuring and calculating the coke cake center temperature, the coke cake surface temperature and the difference value of the two temperatures of the same coking chamber, and replacing the coke cake center temperature by the coke cake surface temperature; (4) formulating combustion chamber vertical flame path standard temperatures corresponding to coke cake surface temperatures under different dry quenching rates according corresponding relationship among data determined by the step (1), (2) and (3); (5) formulating the coke oven heating system parameter according to the combustion chamber standard temperature determined in the step (4), measuring the coke cake surface temperature, and determining the maturity degree of red coke. According to the method, the coking heat consumption of the coke oven can be reduced, low-cost economical operation of the coke oven can be guaranteed, emission of NOX, CO2, SO2 and other harmful gases in waste gas of the coke oven can be reduced, and pollution of waste gas of the coke oven to the atmosphere can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

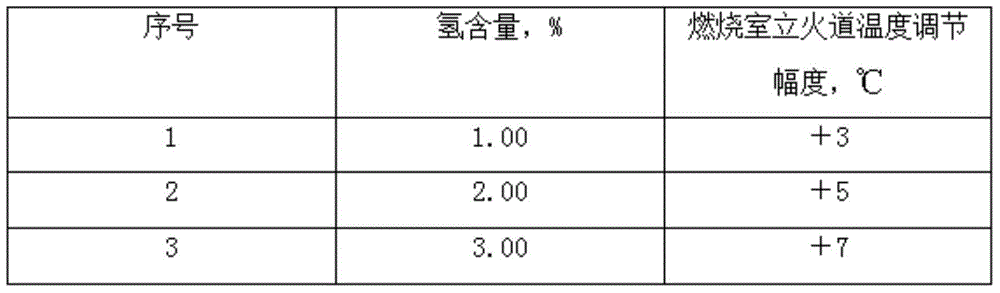

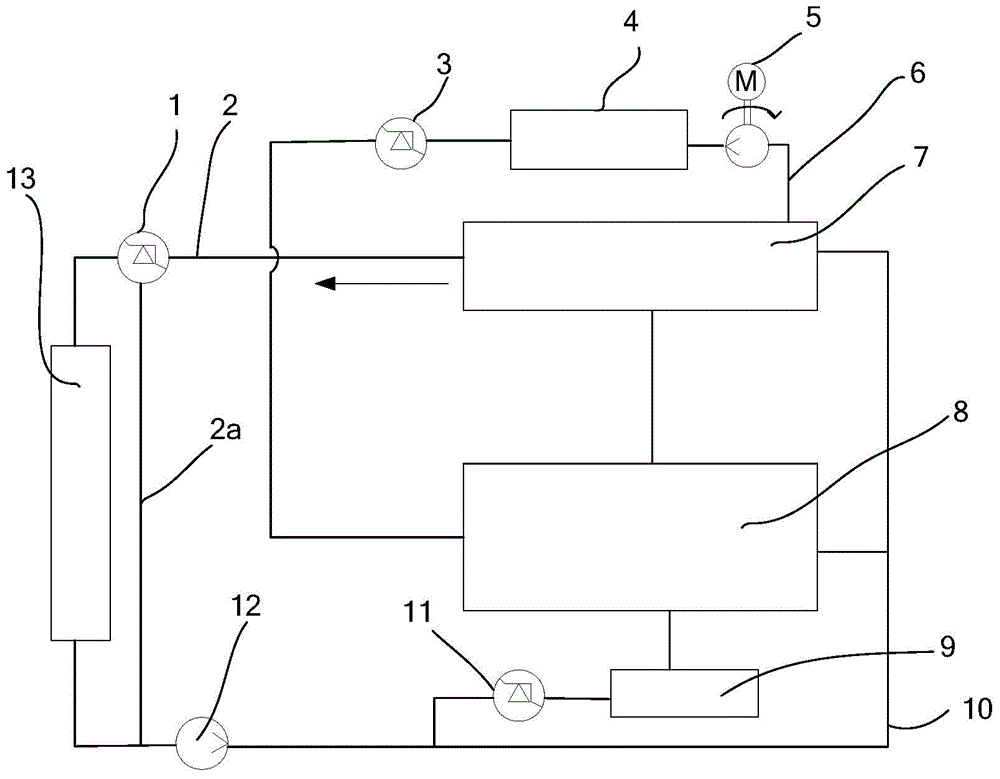

Adjustable cooling system of engine

InactiveCN104595003AAccurate real-time "thermal managementReduce frictionAir-treating devicesCoolant flow controlHeat managementWorking temperature

The invention relates to the field of engines, in particular to an adjustable cooling system of an engine. The system comprises a cooling main circulating pipeline. The cooling main circulating pipeline comprises a main path thermostat, an engine radiator, a main path water pump, a machine oil cooler, an engine cylinder body and a cylinder cover, which are communicated in sequence; a cooling circulating branch is arranged on the main circulating pipeline; one end of the cooling circulating branch is connected with the main path thermostat, and the other end of the cooling circulating branch is connected with one end of a water outlet of the engine radiator; and the main path thermostat can distribute the flows of cooling water in the cooling main circulating pipeline and the cooling circulating branch in real time according to the temperature of the cooling water. The adjustable cooling system can reasonably distribute the cooling water to precisely perform the real-time heat management for a whole vehicle, and can realize quick vehicle heating in a cold state of the engine when the engine reaches the normal working temperature as quickly as possible, so that the mechanical efficiency of the engine is improved, and the purposes of energy conservation and emission reduction are achieved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

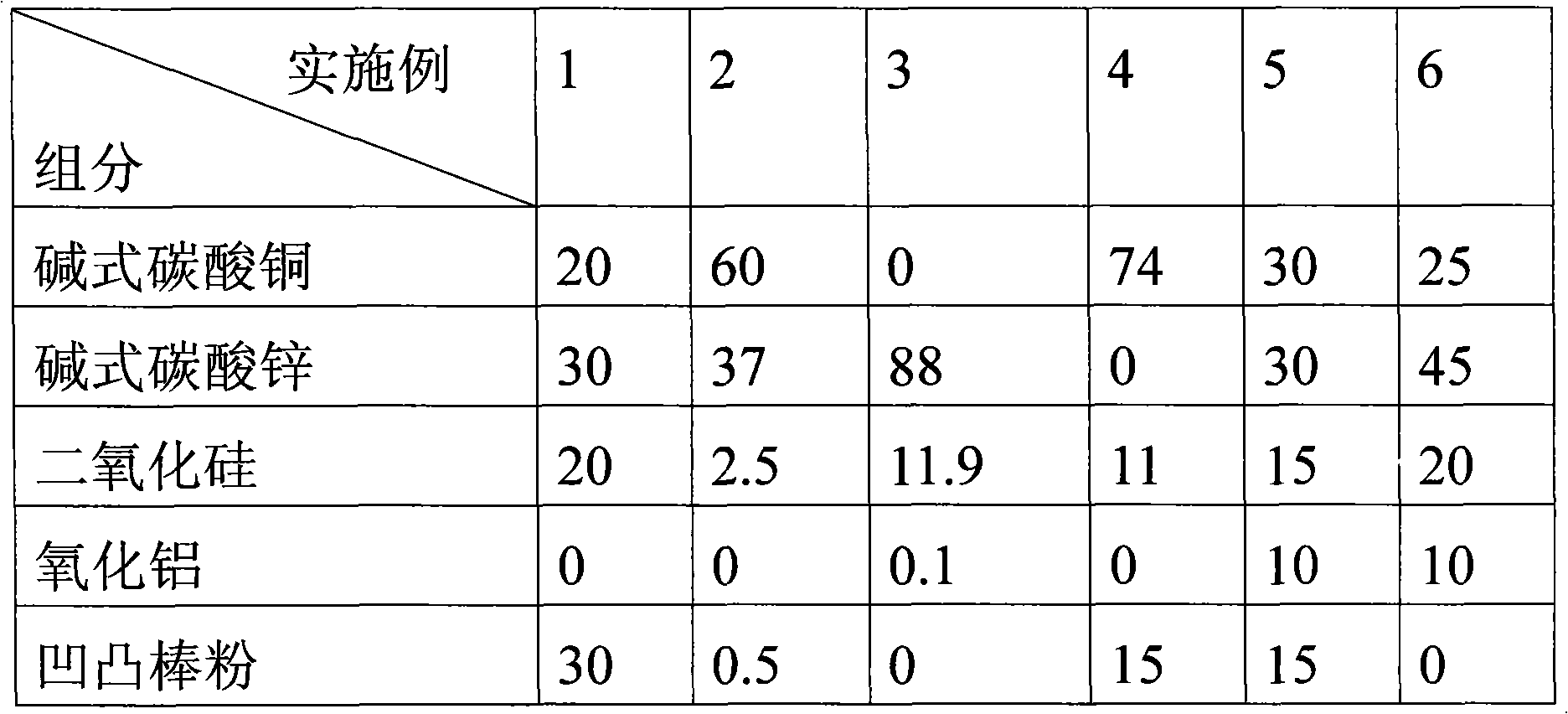

Desulfurizer

InactiveCN101961594AHigh precisionHigh sulfur capacityDispersed particle separationBASIC CUPRIC CARBONATEDecomposition

The invention discloses a desulfurizer which is composed of subcarbonate, silica and accessory ingredient. Based on the total weight of the desulfurizer, the desulfurizer comprises, in percentage by weight, 50-97 wt% of subcarbonate, 2.5-20 wt% of silica and 0.1-30 wt% of accessory ingredient, wherein the subcarbonate is at least one of basic cupric carbonate and basic zinc carbonate, and the accessory ingredient is at least one of alumina and attapulgite powder. The desulfurization (H2S) precision of the desulfurizer can be less than 0.05mg / M3, and sulphur content is about 20% (Wt / Wt). Because the raw material does not need high-temperature decomposition, energy consumption can be greatly lowered by more than 50%, thus obtaining the purpose of energy saving and emission reduction.

Owner:昆山市精细化工研究所有限公司

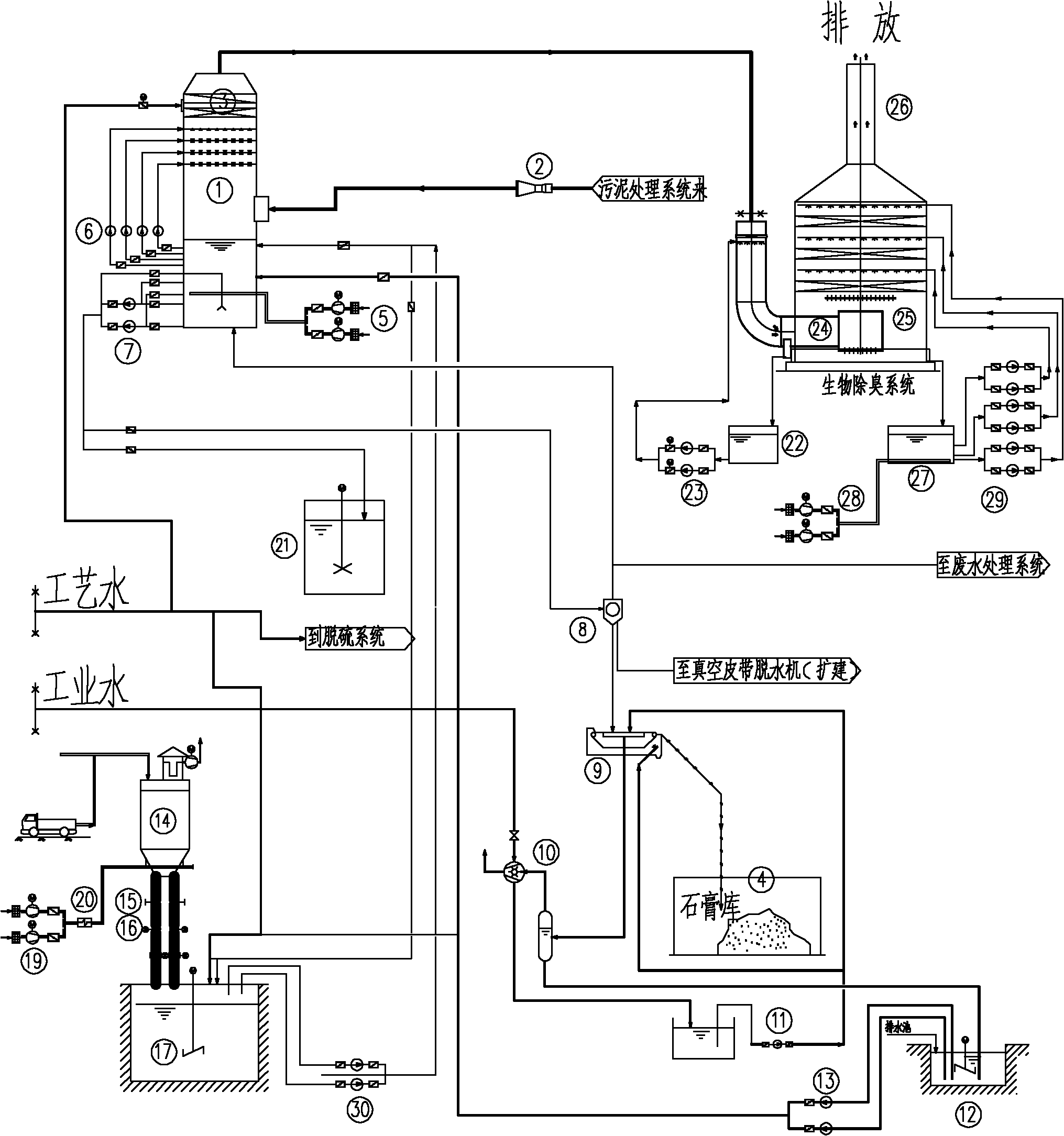

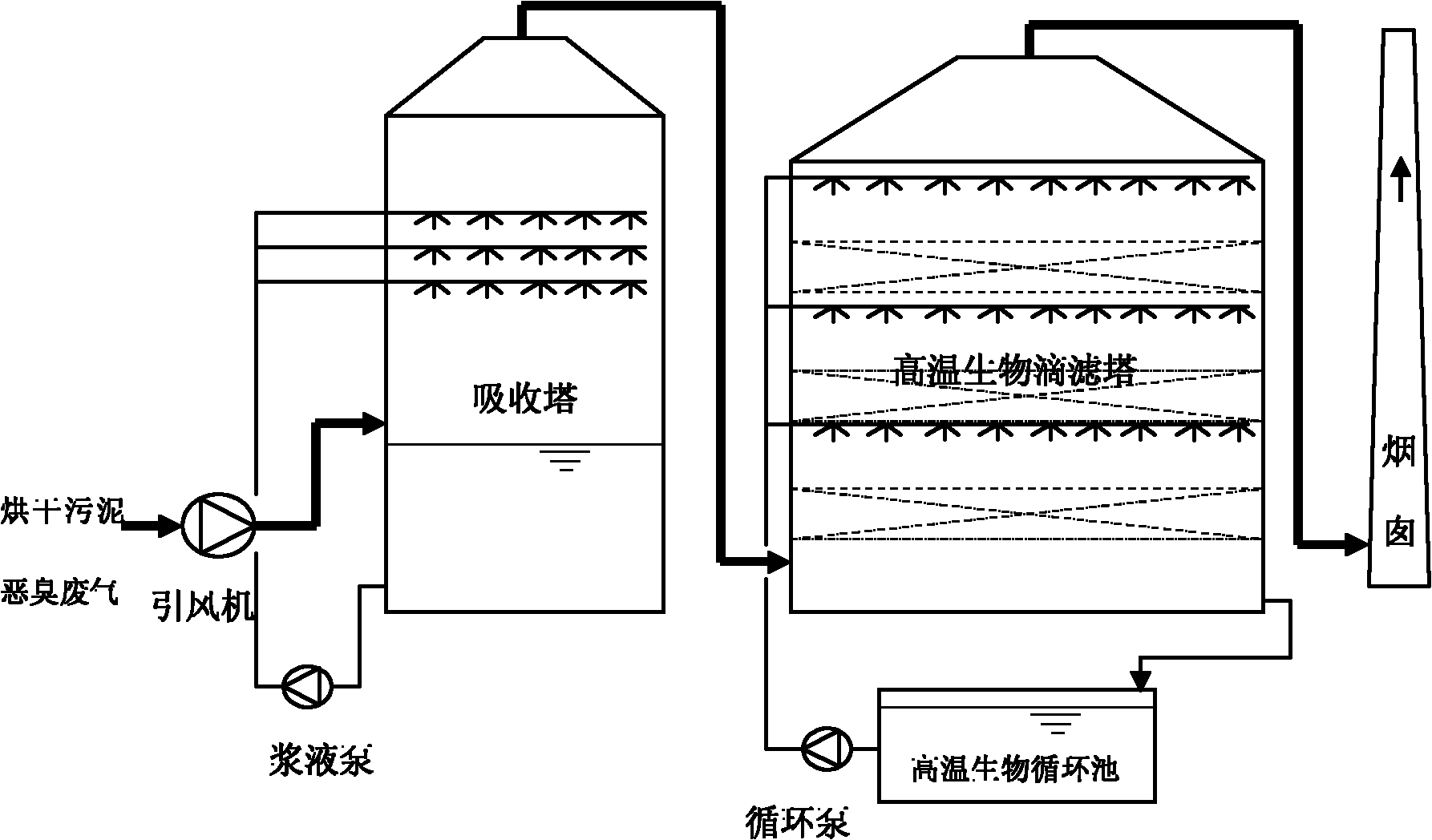

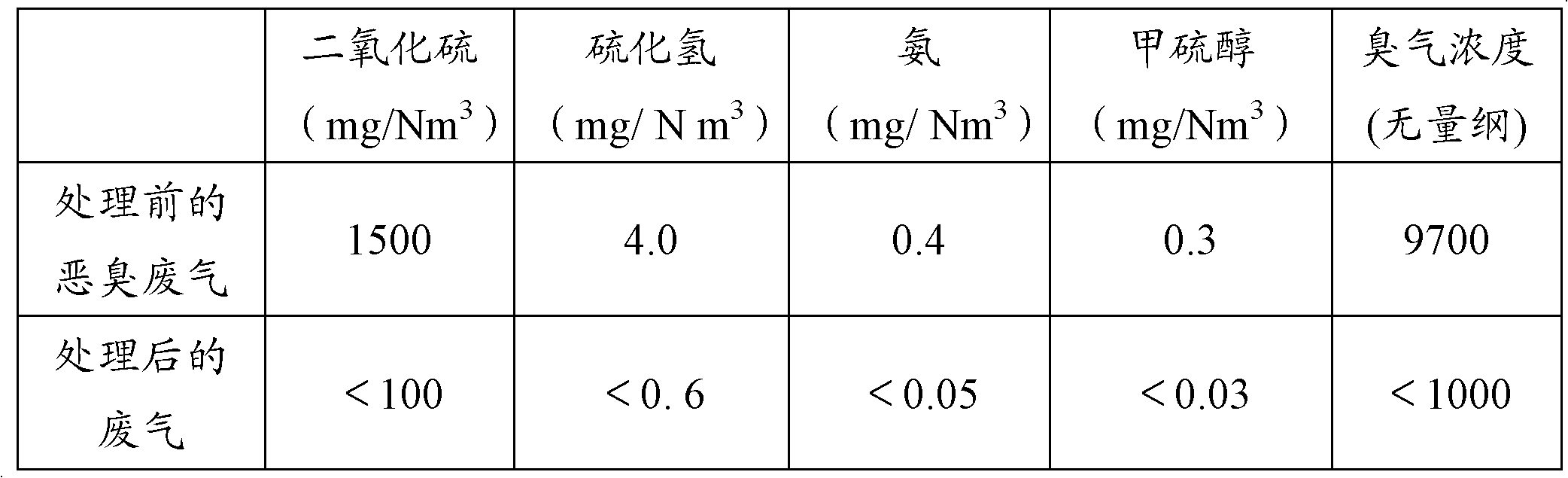

Purification method of odor waste gas produced by high-temperature dewatering of sludge

ActiveCN102179160AActiveGood low temperature survival performanceDispersed particle separationAir quality improvementPurification methodsSludge

The invention discloses a purification method of odor waste gas produced by high-temperature dewatering of sludge. In the process method, two parts, namely a limestone-gypsum desulfurization system and a high-temperature biological drop-filtering tower deodorizing system, are included, wherein SO2 in the odor waste gas is removed by a desulfurizing tower, and then high-temperature deodorizing thermophilic bacterium groups in biological fillers are used to degrade odor and organic components in the odor waste gas by the biological drop-filtering tower. The innovative combined process has the advantages that the deodorization effect is obvious, and a matched cooling system is not needed, so that a large amount of condensate water is prevented from being dissolved out, the investment is saved, the operating cost is low and no secondary pollution is caused.

Owner:广州市越堡水泥有限公司

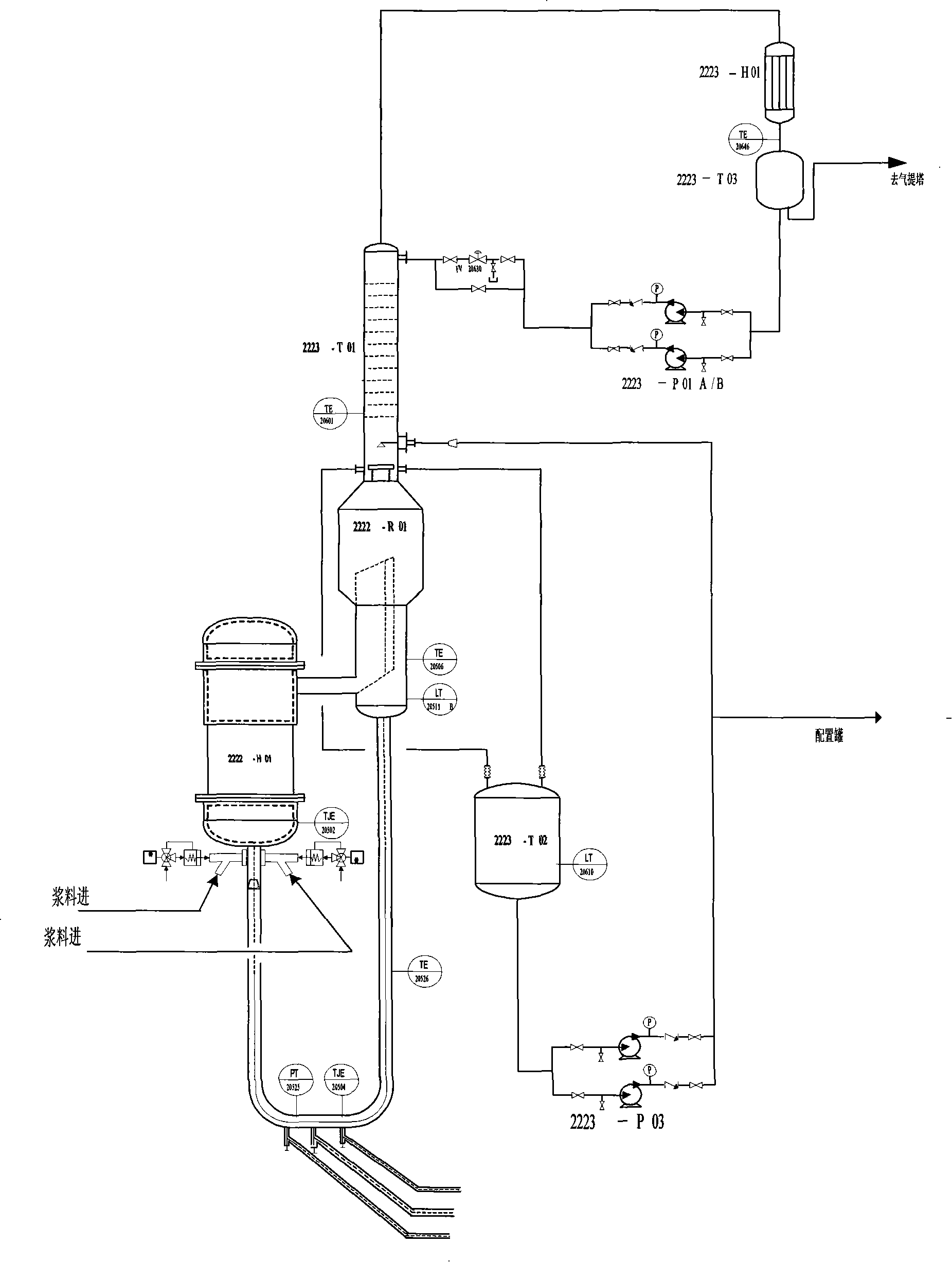

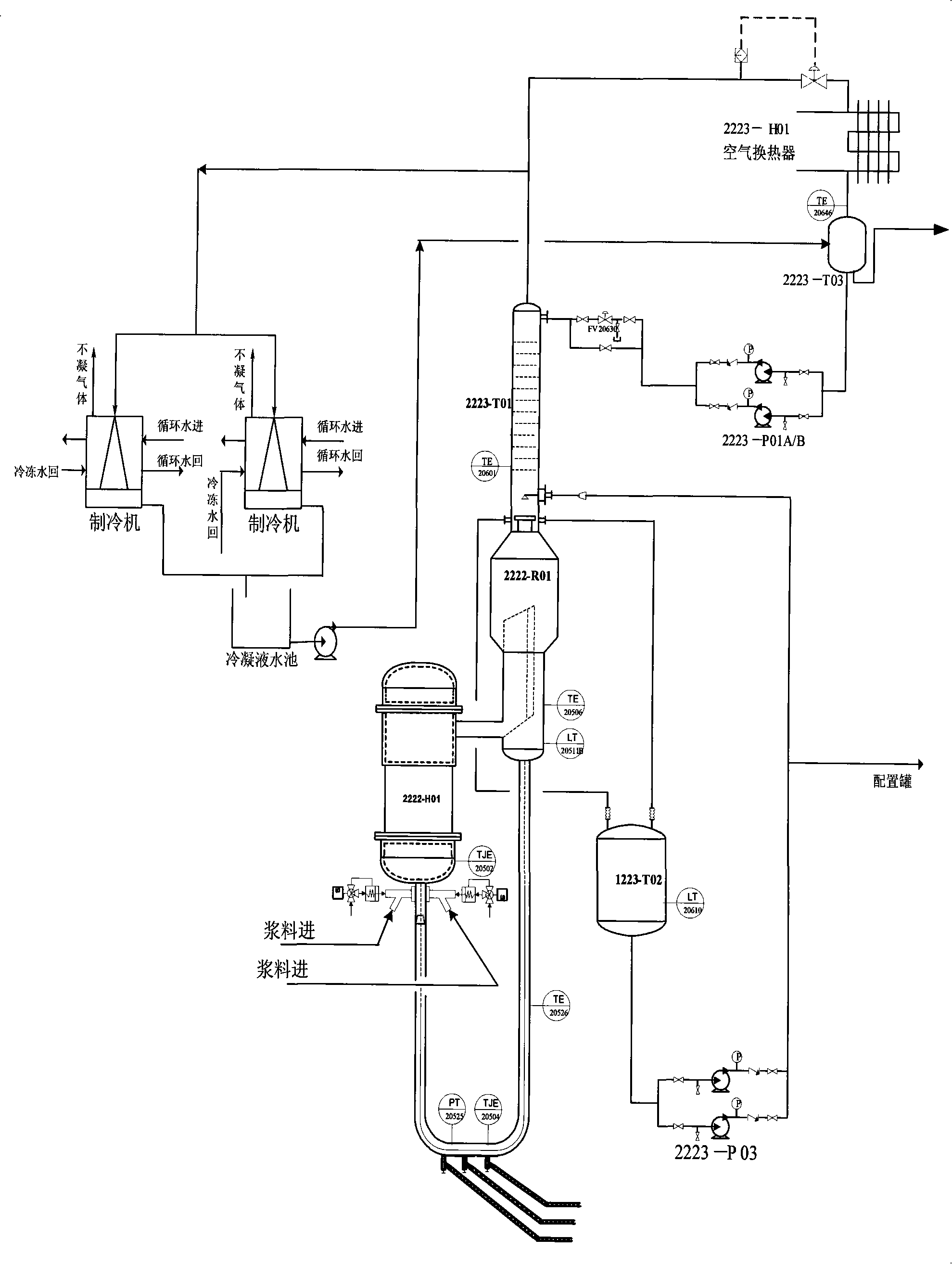

Polymerization esterification residual heat utilization method and apparatus

InactiveCN101250257AReduce wasteImprove utilizationEnergy efficient heating/coolingClimate change adaptationLithiumReflux

A utilization method of polymerization esterification residual heat and a device are disclosed. The method is that tower top waste steam of a knockout tower on the upper portion of an esterification reaction kettle is led out and supplied to at least one lithium brominate refrigerator as heat source, a collecting tank is arranged on the outlet of condensed water of the refrigerator, water is transmitted to a waste water collecting tank with a pump, a part of water is used as tower top reflux water, and the rest overflows into a stripping tower to be reclaimed. A pressure regulating valve is added on a pipe which is used to lead out waste steam from the top tower of the knockout tower, which can increase the steam pressure using as the heat source of the lithium brominate refrigerator. The device comprises at least one lithium brominate refrigerator, the top tower portion of the knockout tower on the upper portion of the esterification reaction kettle is connected on a condenser of the lithium brominate refrigerator through a steam pipe, a pressure regulating valve which can increase steam pressure in the steam pipe is connected in series on the steam pipe, and a steam branch pipe is further connected in parallel on the steam pipe, at least one air heat exchanger is connected on the steam branch pipe. The device has the characteristics of simple technology, safe, reliable and convenient usage and significant energy-saving effect, reduces the energy waste, increases the recycling usage of energy, and can really play the purpose of energy-saving and emission reduction.

Owner:RONGSHENG PETROCHEM

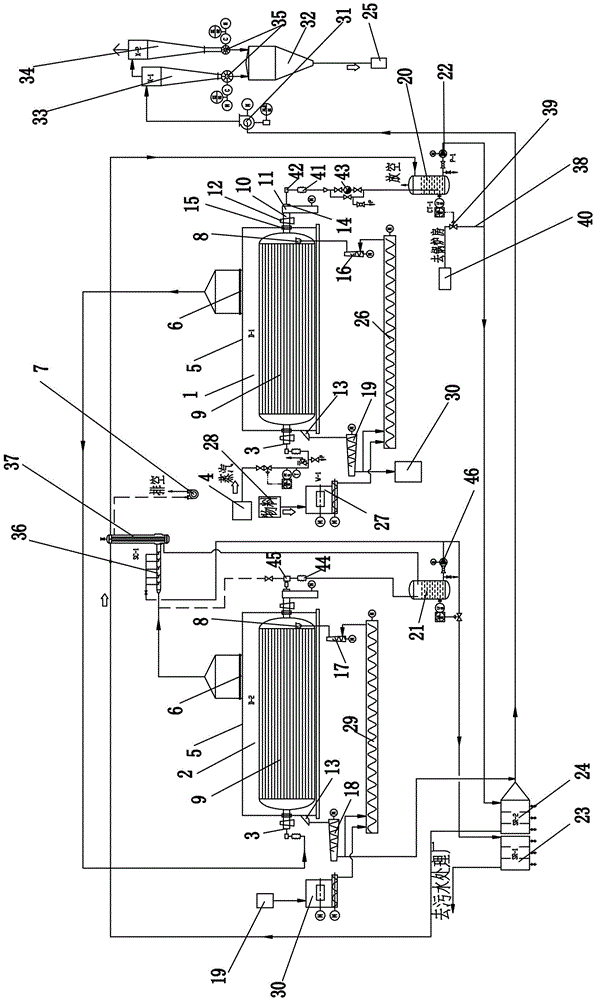

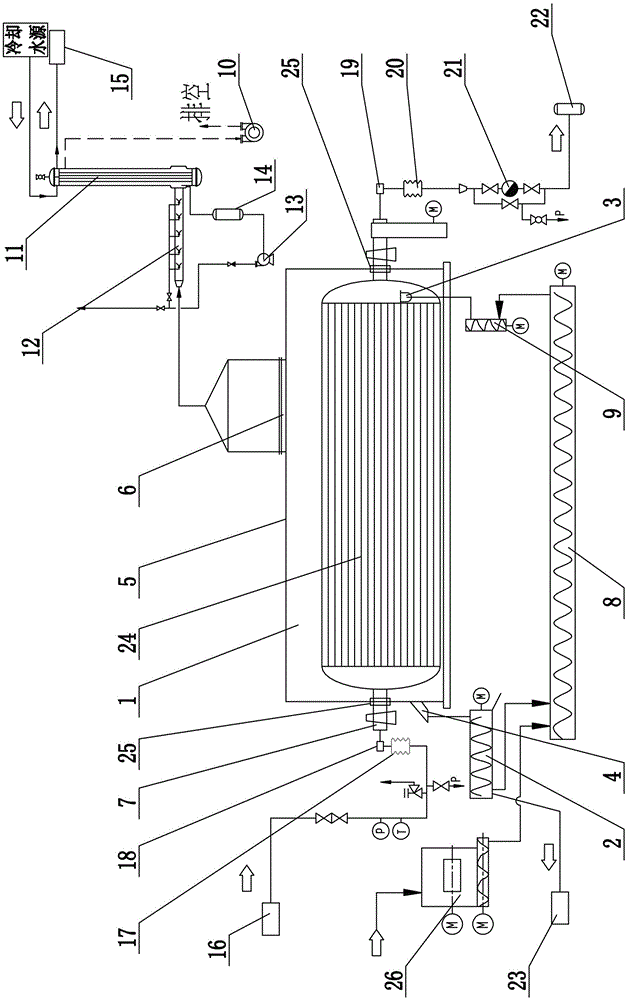

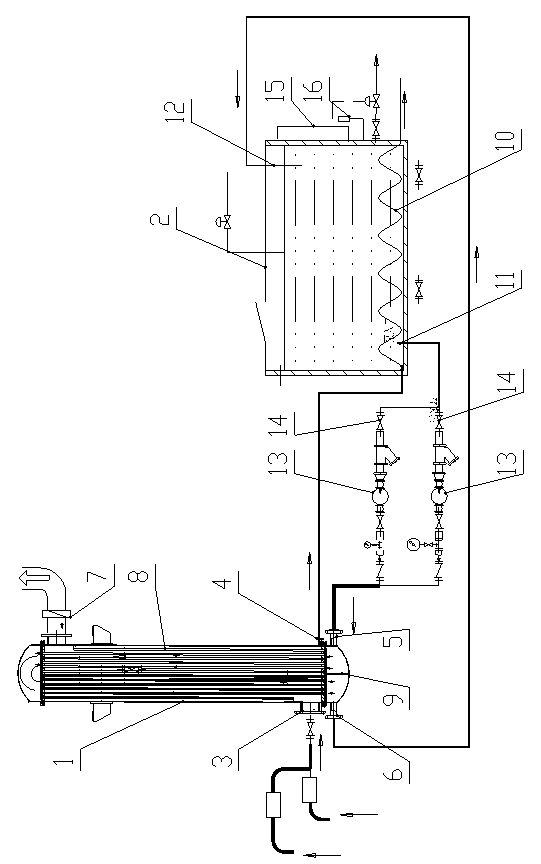

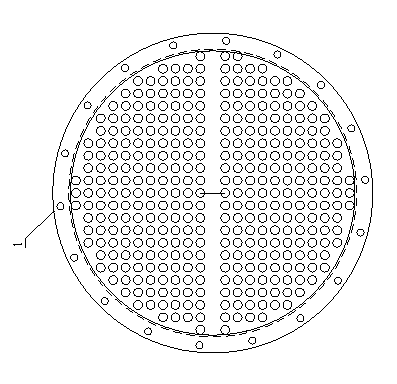

Double-effect vacuum tube bundle drying system

ActiveCN105466196AEasy to useReduce the temperatureDrying gas arrangementsDrying solid materialsThermodynamicsSteam condensation

The invention relates to a double-effect vacuum tube bundle drying system. The double-effect vacuum tube bundle drying system comprises a first-effect tube bundle drying machine and a second-effect tube bundle drying machine; the first-effect tube bundle drying machine and the second-effect tube bundle drying machine are both sealing tube bundle drying machines; secondary steam in shells of the two tube bundle drying machines is extracted through a vacuum pump; secondary steam in the first-effect tube bundle drying machine is conveyed to a steam inlet of the second-effect tube bundle drying machine, and serves as a heat source of drying of the second-effect tube bundle drying machine; a material dried by the first-effect tube bundle drying machine is fed in the second-effect tube bundle drying machine for secondary drying; and a heat source of secondary drying is secondary steam generated in the first-effect tube bundle drying machine. The double-effect vacuum tube bundle drying system performs two-stage double-effect gradient drying for the material, and continuously and gradiently uses the steam heat; the two tube bundle drying machines dry under vacuum condition to effectively reduce the needed drying temperature; waste steam and steam condensed water heat are recovered for further pneumatic drying; the heat is fully used; and the energy is saved.

Owner:郑州博大浓缩干燥设备有限公司

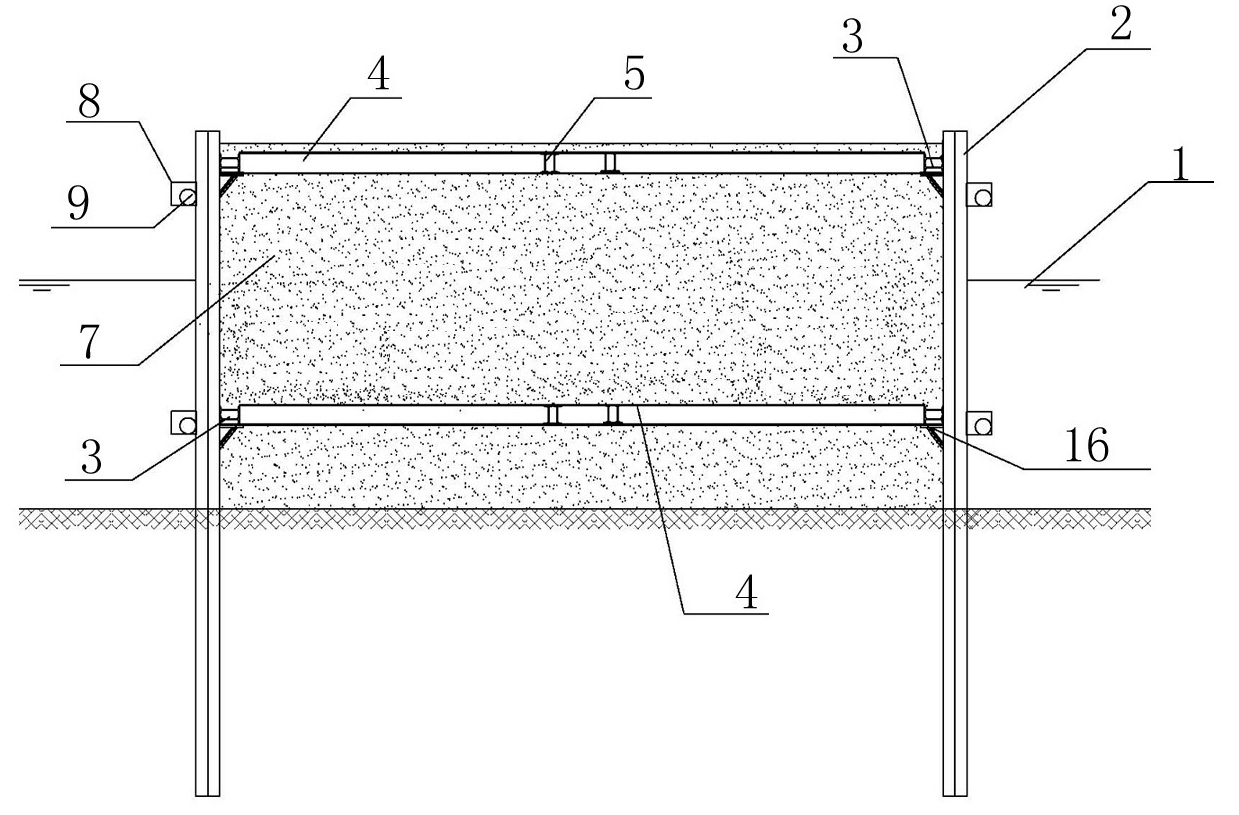

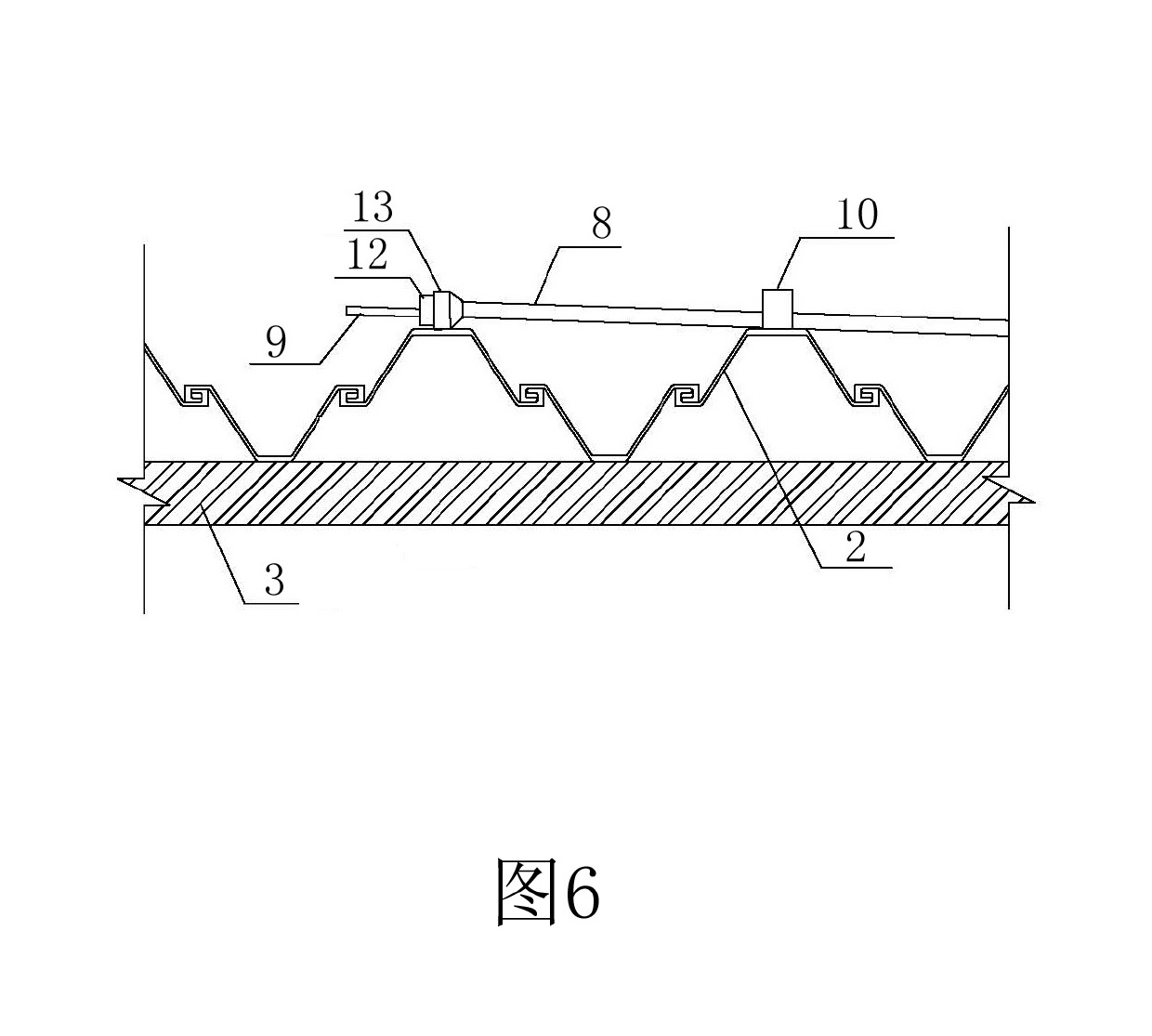

Hooping type steel sheet pile cofferdam platform and integrated construction method depending on cofferdam platform

The invention relates to a hooping type steel sheet pile cofferdam platform and an integrated construction method depending on the cofferdam platform. Fillers are filled in the inner space of a cofferdam; at least two circles of steel tendons are arranged around the periphery of the cofferdam; one end of each steel tendon is fixed on an anchor bearing plate at the fixed end through an anchor device at the fixed end, and the other end of each steel tendon is fixed on an anchor bearing plate at the stretching end through an anchor device at the stretching end; and the steel tendons also pass through a positioning ring which is fixed at the convex part of the periphery of a steel sheet pile. By additionally providing facilities and measures for reinforcing the steel sheet pile cofferdam, the construction of the underwater pile foundation can be finished only depending on the steel sheet pile cofferdam required for the platform construction under the condition that a waterborne overhead pile drilling platform does not need to be arranged, and the integrated construction of the platform can be finished only depending on the steel sheet pile cofferdam arranged in the construction of the underwater pile foundation without additionally arranging a steel sheet pile cofferdam. The method of the invention has the advantages of saving the overall cost of the engineering, shortening the construction period, reducing the unsafe factors in construction, saving the energy, reducing the emission, and the like. The invention can be widely applied to construction of engineering, such as underwater bridges, wharfs, and the like.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

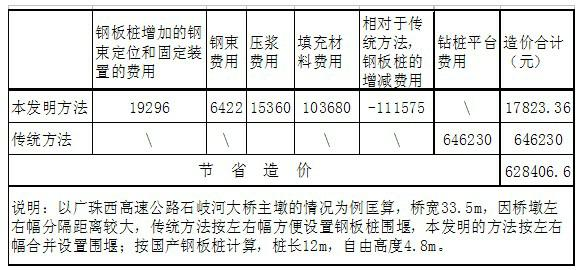

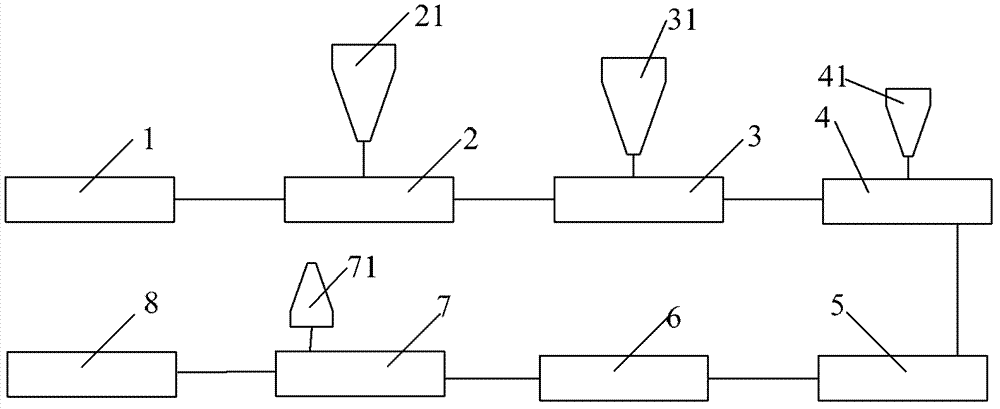

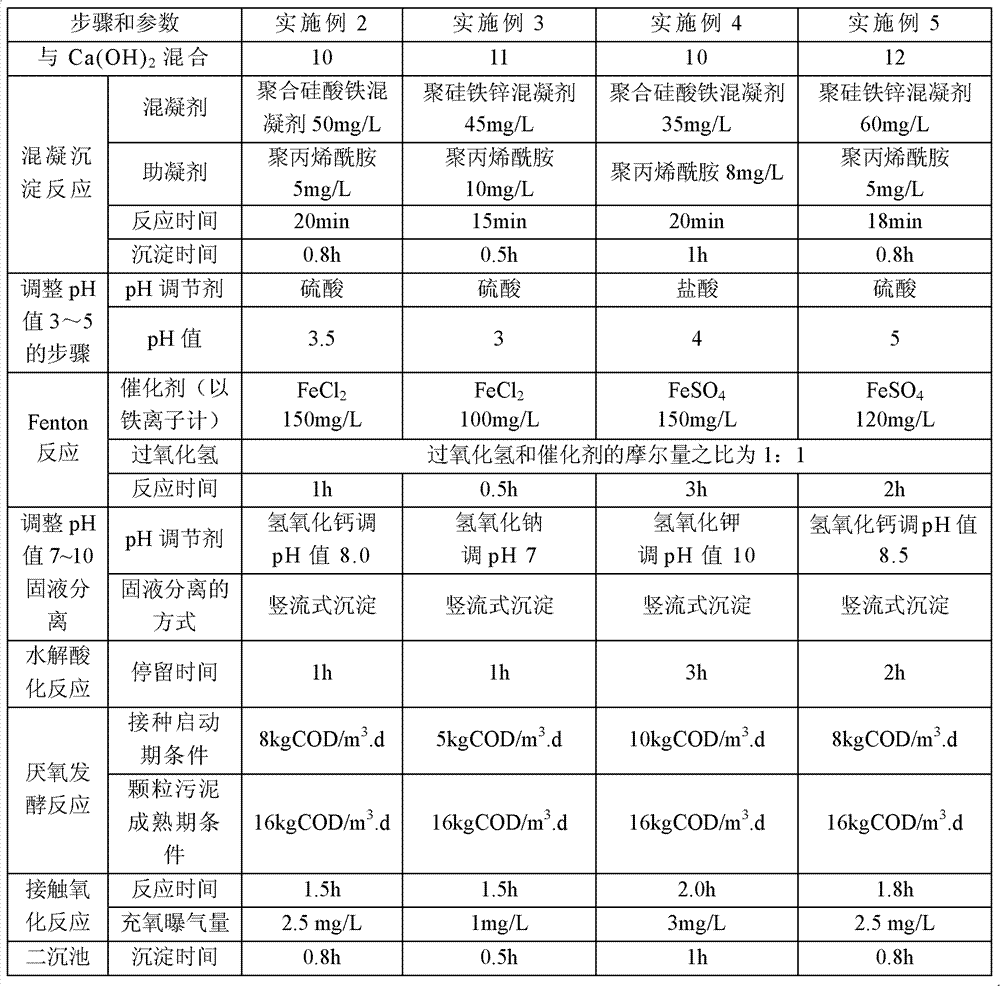

Phenolic resin wastewater processing method and special-purposed device

InactiveCN103086562ASimple and fast operationFew control conditionsMultistage water/sewage treatmentNature of treatment waterFenton reactionWastewater

The invention discloses a phenolic resin wastewater processing method and a special-purposed device. The phenolic resin wastewater processing method comprises the following steps: phenolic resin wastewater is mixed with Ca(OH)2, and a pH value is regulated to 10-12; a coagulation and sedimentation reaction is carried out; a pH value is regulated to 3-5; a Fenton reaction is carried out; a pH value is regulated to 7-10, and solid-liquid separation is carried out; a hydrolytic acidification-anaerobic fermentation process is carried out; a contact oxidation reaction is carried out; and secondary sedimentation is carried out. The special purposed device comprises the sequentially connected components of: a wastewater feeding tank, a coagulation and sedimentation reaction rank with a first feeder, a Fenton reaction device with a second feeder, a solid-liquid separation device with a third feeder, a hydrolytic acidification tank, an anaerobic fermentation tank, a contact oxidation reaction rank with an aeration device, and a secondary sedimentation tank. With the processing method, pollutant content in the processed wastewater reaches a discharge standard. The operation is simple, control conditions are less, and cost is low.

Owner:SHANGHAI BODAN ENVIRONMENTAL ENG TECH

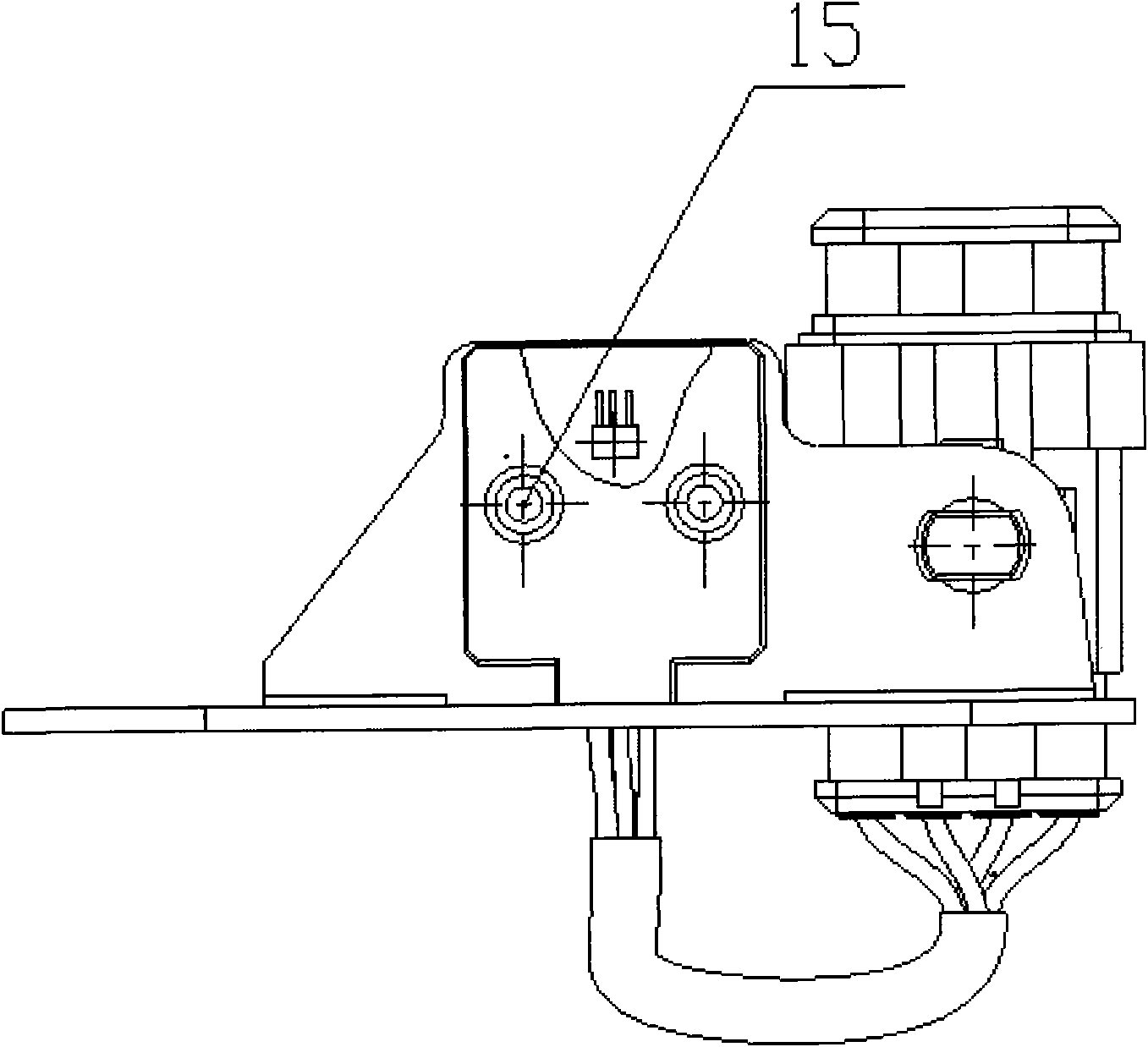

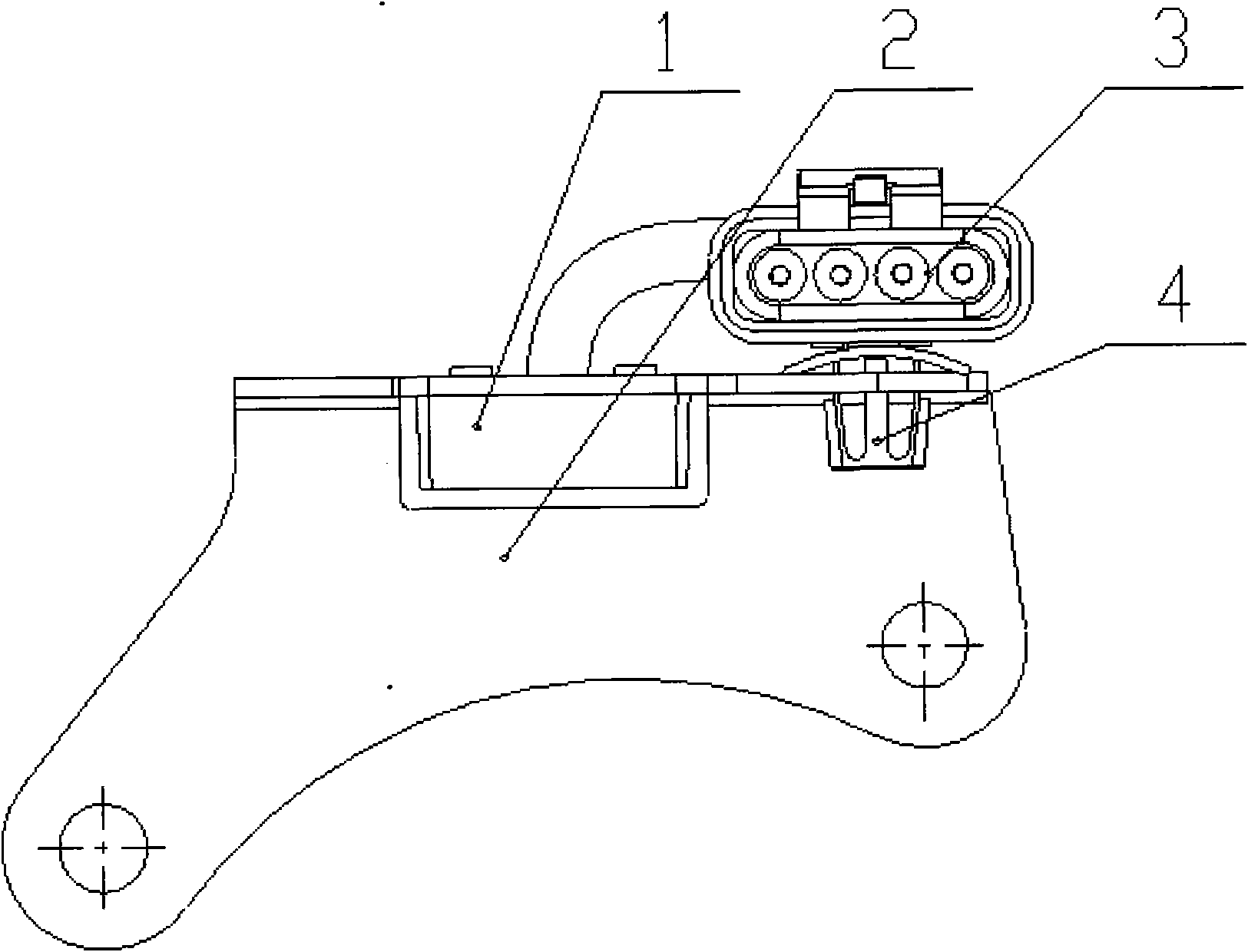

Neutral position identification sensor of start-stop system of car

The invention provides a neutral position identification sensor of a start-stop system of a car, comprising a neutral sensor assembly and a neutral magnetic head assembly, wherein the neutral magnetic head assembly is connected with a gear box selector; and the neutral sensor assembly is connected with a gear box body. The invention has neutral and gear identification functions and can be used for hybrid electric vehicles or vehicles with start-stop functions and also achieve the purposes of energy saving and emission reduction; an engine identifying a neutral signal automatically flames out during waiting a red light signal; two-path signals are utilized and respectively controlled by two magnetic Hall sensors, one path is the neutral signal, the other path is a relay control signal in a transmission chain state, the two-path signals are in a normally open and normally close interlocking state, and a signal acquisition end can be used for verifying the two paths of signals, therefore a fault state is judged.

Owner:哈尔滨宏泰伟业科技有限公司

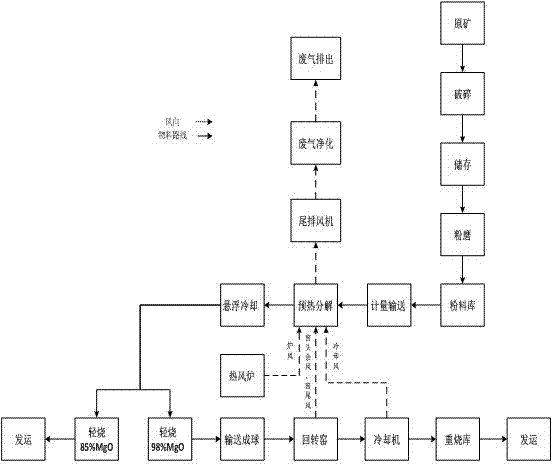

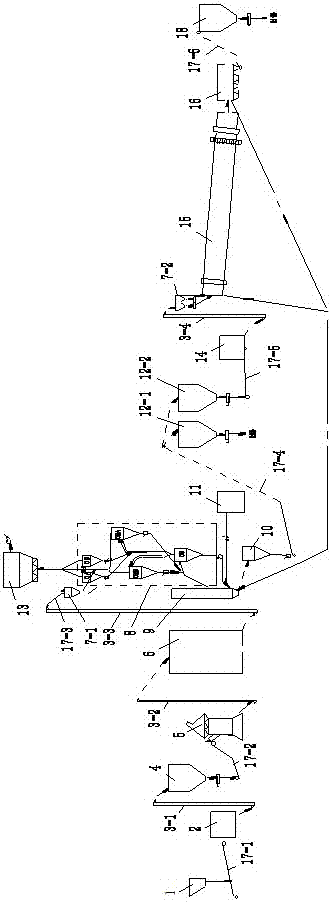

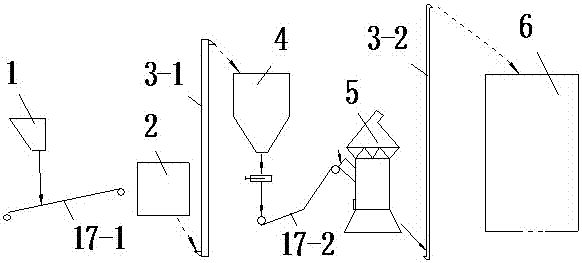

Complete set and method of light-calcined magnesia and heavy-calcined magnesia production line by magnesite

InactiveCN107265890ATo achieve the purpose of energy saving and emission reductionSimple processLime productionProduction linePollution

The invention belongs to magnesite calcining equipment and methods and relates to a complete set and method of a light-calcined magnesia and heavy-calcined magnesia production line by magnesite. The complete set comprises a pulverizing device, a light calcining device and a heavy calcining device connected in sequence. The method comprises the steps of (1) crushing and pulverizing magnesite, and feeding the resulting material into a powder cabin; (2) metering the material in the powder cabin, feeding the material to a multistage suspension preheating system, and performing reservoir calcining in a decomposing furnace; (4) pelleting the material in a light calcining reservoir, feeding pellets to a rotary kiln for calcining, cooling, and performing heavy calcining to obtain heavy calcined material; (3) subjecting the calcined material to suspension cooling to finish light calcining so as to generate light calcined magnesia, and feeding the light calcined magnesia; using waste heat of the rotary kiln and a cooling unit in the decomposing furnace and the multistage suspension preheating system, and allowing the two systems to produce in the same so that energy conservation and emission reduction are achieved. The complete set and method have the advantages, for example, light calcining and heavy calcining processes are combined, the technical process is simple, energy consumption is low, and zero pollution is discharged.

Owner:徐州贝克福尔节能环保技术有限公司

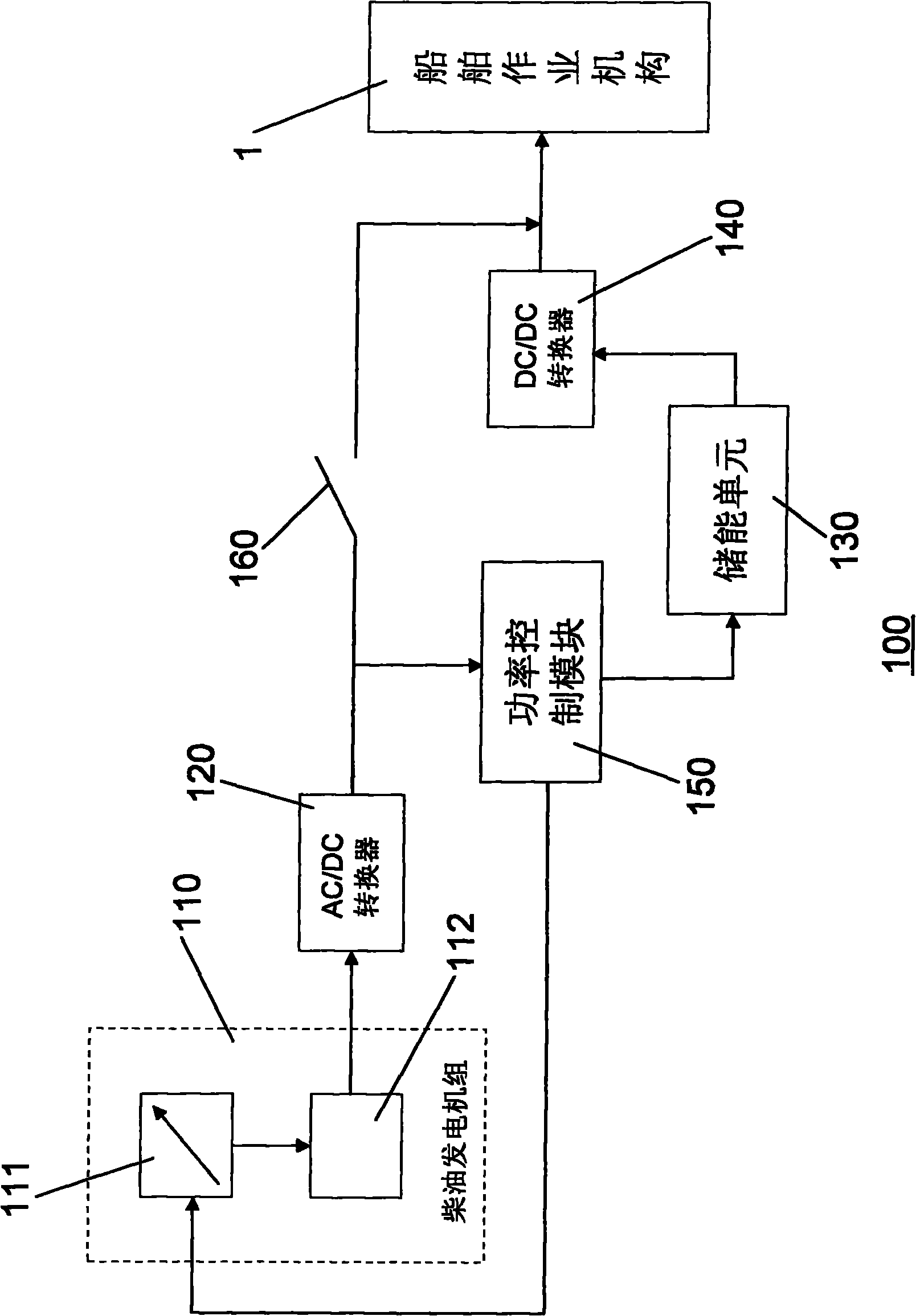

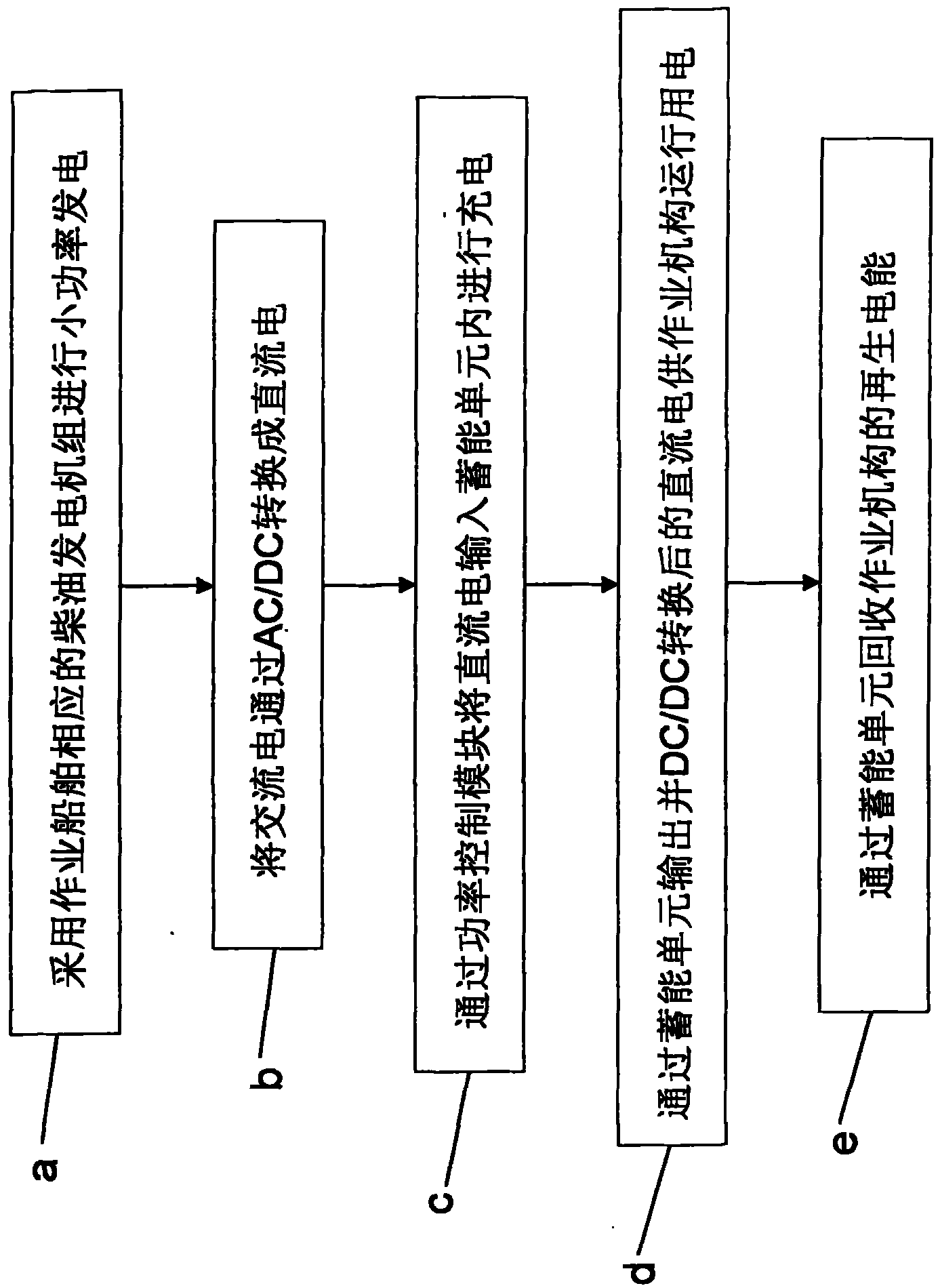

Power supply system and method of shipping work

InactiveCN101920780ASave fuelReduce pollutionBatteries circuit arrangementsAuxillariesElectric energyDiesel engine

The invention provides a power supply system of shipping work, which supplies small power electric energy by using a diesel engine electric generating set as an electric energy supply source and meets high power energy requirement for operation of a work mechanism by using an energy accumulating unit as a power supply source of the work mechanism. The invention also provides a power supply method of the shipping work. By adopting the power supply system and the method of the invention, compared with the traditional power supply scheme, the invention can save the fuel by over 40-60 percent, thereby the power and the oil consumption of the diesel engine unit are obviously reduced, and emission pollution is greatly reduced to achieve the aim of saving energy and reducing emission.

Owner:孙枫

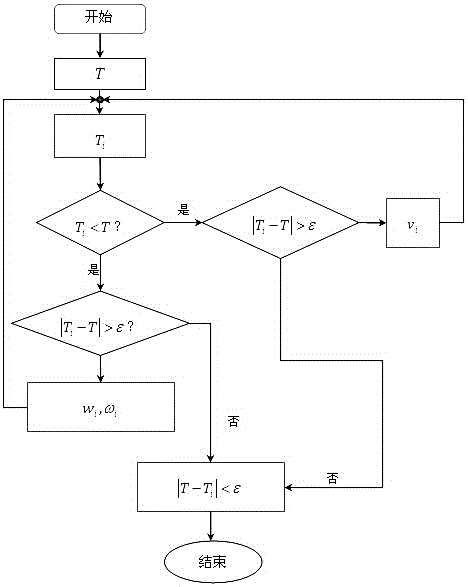

Tunnel kiln environment conditioning method and device of automatically adjusting temperature in kiln

ActiveCN106444914AImprove intelligenceGood energy saving effectTemperatue controlTunnel kilnEngineering

The invention discloses a tunnel kiln environment conditioning method and a device of automatically adjusting the temperature in a kiln. The tunnel kiln environment conditioning method includes the following steps: S1, environmental information acquisition equipment is arranged in a tunnel kiln, wherein the environmental information acquisition equipment is used for acquiring environmental parameters of the environment to be conditioned in the tunnel kiln and sending the environmental parameters to a controller; S2, the controller generates an environment conditioning command according to the environmental parameters acquired by the environmental information acquisition equipment, and sends the environment conditioning command to an environment conditioning execution mechanism; and S3, the environment conditioning execution mechanism conditions the environment in the tunnel kiln according to the environment conditioning command sent from the controller. The tunnel kiln environment conditioning method can control the angle of a temperature adjustment burner, the combustion gas injection rate, the angular rate of the temperature adjustment burner, the kiln tail blast rate, and the like, of the tunnel kiln, and can perform sintering research on various refractory materials, thus increasing diversity of research.

Owner:YANCHENG INST OF TECH

Thermal insulation filler and thermal insulation building block as well as manufacturing method of thermal insulation building block

InactiveCN101805202AShort maintenance timeIncrease productivityConstruction materialCeramicwareSodium bicarbonateThermal insulation

The invention discloses a thermal insulation filler, a thermal insulation building block as well as a manufacturing method of the thermal insulation building block. The thermal insulation filler is prepared by mixing the following components in percentage by weight: 30-38 percent of fly ash, 52-58 percent of early-strength double-fast cement, 1.8-2.1 percent of foaming agent, 1.7-2.2 percent of foam stabilizer and 6.2-8 percent of water repellent; wherein the foaming agent is one or more of lauryl sodium sulfate, sodium bicarbonate or dichlorotetrafluoroethane; the foam stabilizer is one or more of rigid polyurethane foams, polyacrylamide or sodium dodecyl benzene sulfonate; and the water repellent is one or more of methyl polyhydrosiloxane, paraffin or magnesium stearate. The thermal insulation filler has filling density lower than 200kg / m<3>, heat conductivity coefficient lower than 0.06w / m.k and combustion performance reaching grade A in a filling carrier. The thermal insulation fillers can be fully bonded with the inner wall of a filler carrier after being subjected to foaming and has difficult shedding.

Owner:CHONGQING KAIKANG TECH

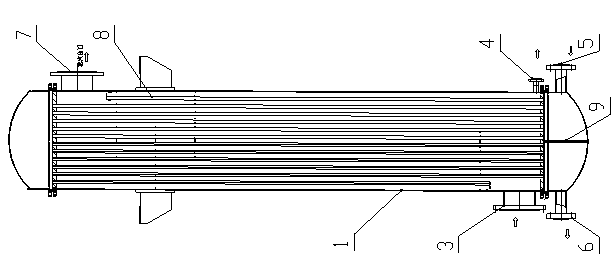

Vacuum tube bundle drying machine

ActiveCN105466174AAvoid pollutionEasy to vaporizeDrying solid materialsDrying machines with non-progressive movementsThermodynamicsMechanical engineering

The invention relates to a vacuum tube bundle drying machine. A feed port is formed in one side of the tube bundle drying machine, and a discharge port is formed in the other side; a waste steam outlet is formed in a shell of the tube bundle drying machine; rotating shafts at two ends of a tube bundle of the tube bundle drying machine are movably connected with the shell through mechanical seals; one ends of the rotating shafts are connected with transmission devices; the rotating shafts are hollow shafts, and inner cavities thereof are communicated with the tube bundle of the tube bundle drying machine; the rotating shaft on one side of the discharge port of the tube bundle drying machine is communicated with a steam intake device; the rotating shaft on one side of the feed port of the tube bundle drying machine is communicated with a condensed water drainage device; the feed port of the tube bundle drying machine is communicated with a feeding device; the discharge port of the tube bundle drying machine is communicated with a discharge device; and a waste steam outlet of the tube bundle drying machine is communicated with a waste steam treatment device. The vacuum tube bundle drying machine is simple in structure, convenient for use, low in manufacturing cost and wide in application range, can preferably reduce the steam temperature needed by material drying, reduces the energy consumption, reduces the waste steam emission, and achieves the purposes of energy conservation and emission reduction.

Owner:郑州博大浓缩干燥设备有限公司

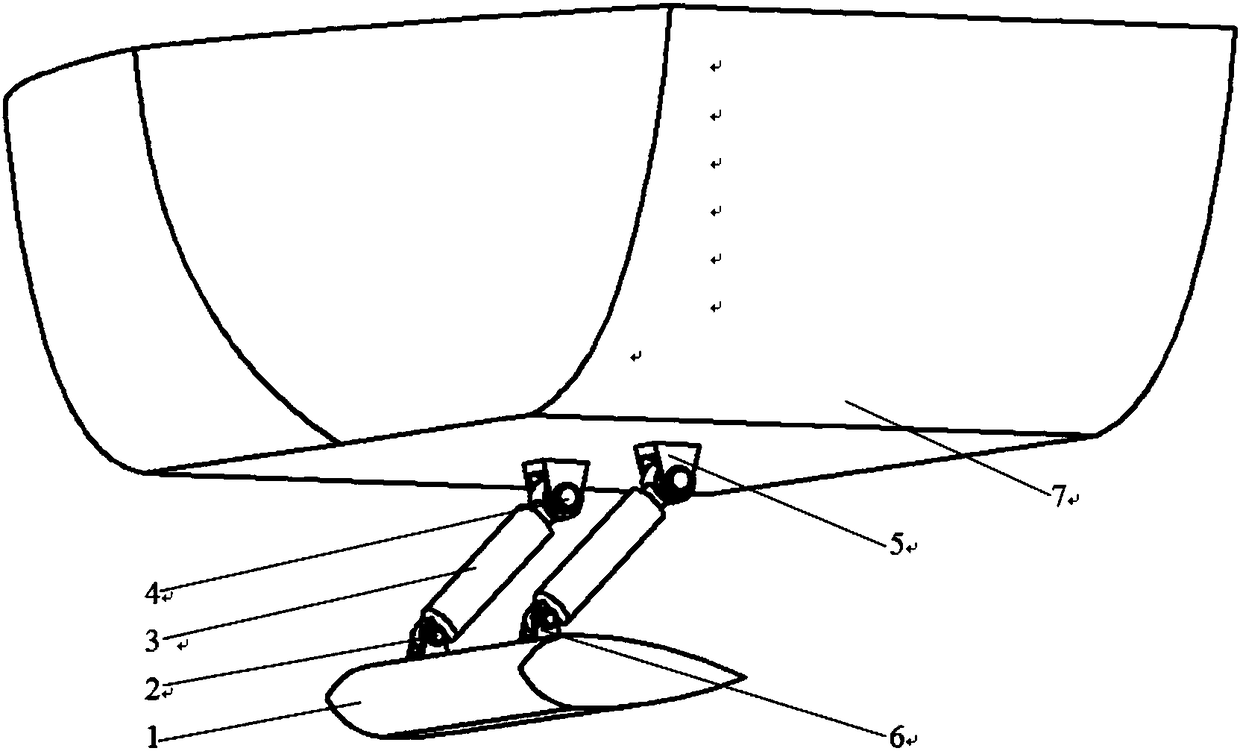

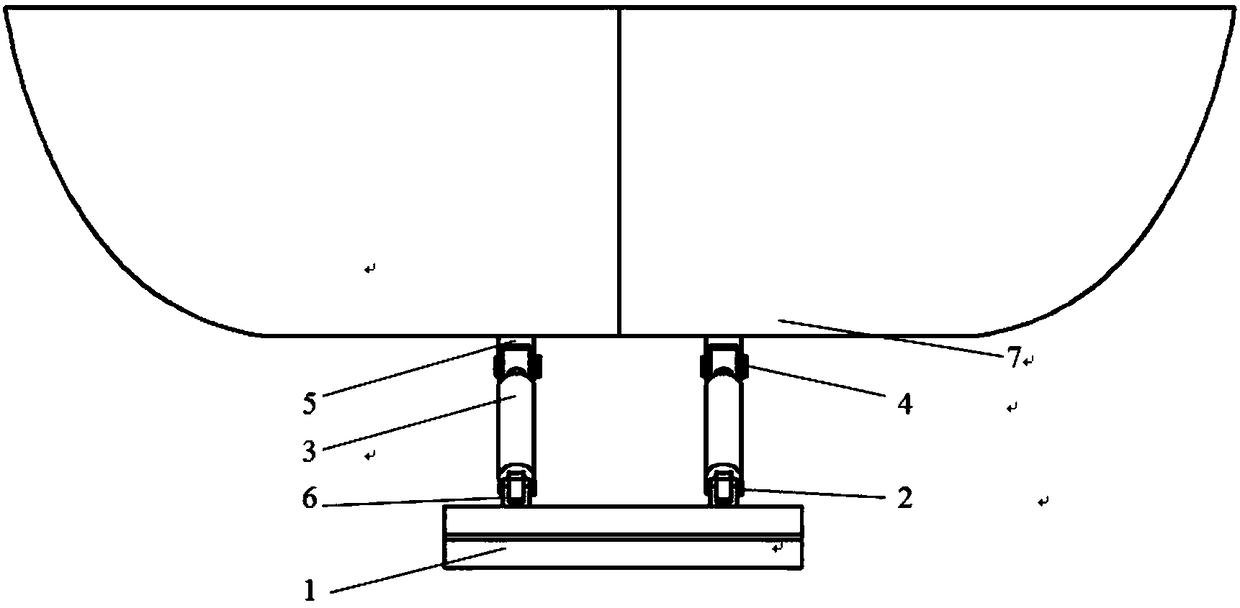

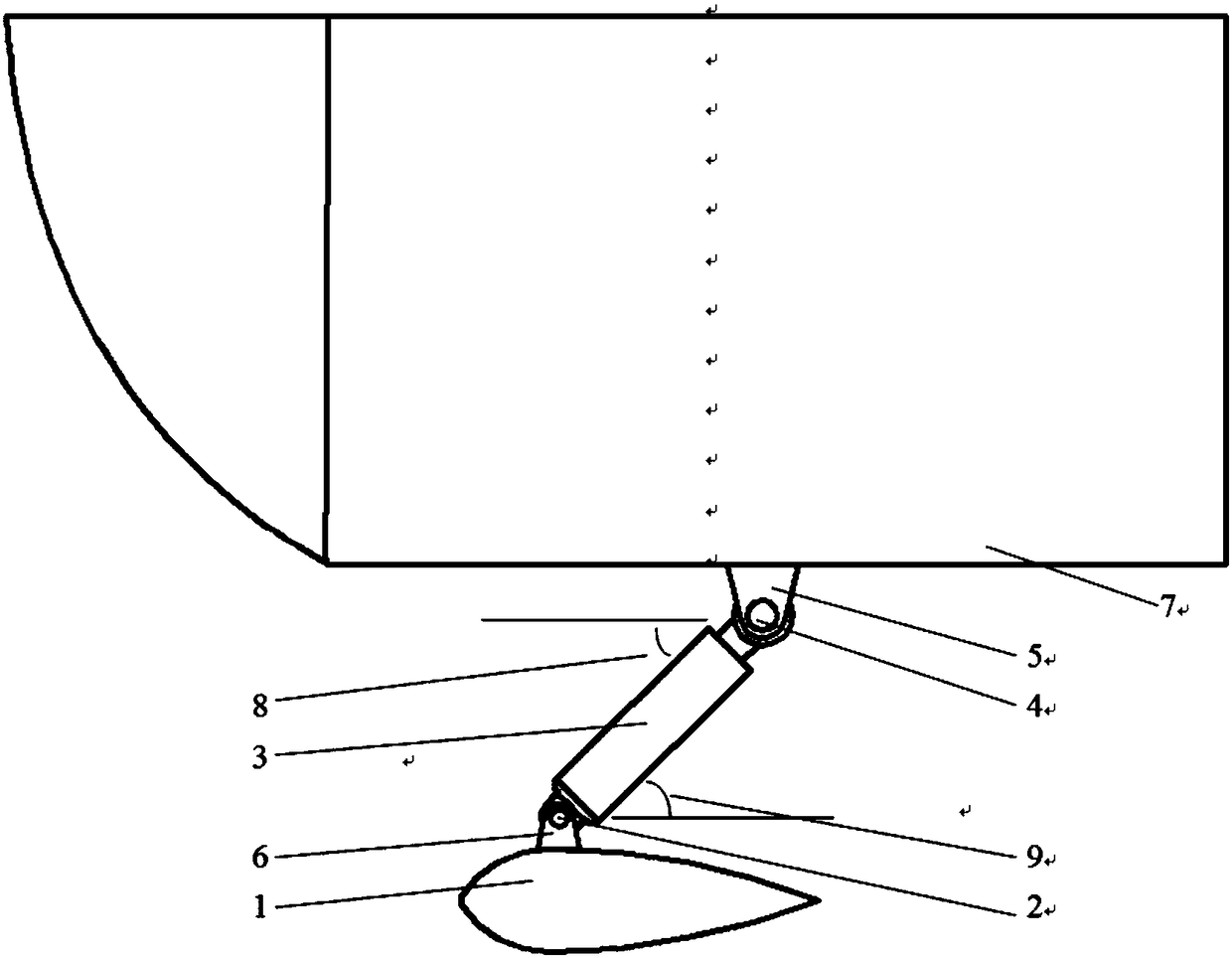

Marine adjustable hydrofoil device

InactiveCN108482575ASmall draftReduce resistanceHydrodynamic/hydrostatic featuresHydraulic cylinderEngineering

The invention provides a marine adjustable hydrofoil device. The marine adjustable hydrofoil device comprises a hull, a hydrofoil, a first hydraulic cylinder and a second hydraulic cylinder. A first hinge support and a second hinge support are fixed to the lower part of the hull, and a third hinge support and a fourth hinge support are fixed to the upper part of the hull. The top end of the firsthydraulic cylinder is connected with the first hinge support through a first rotating shaft, and the bottom end of the first hydraulic cylinder is connected with the third hinge support through a second rotating shaft. The top end of the second hydraulic cylinder is connected with the second hinge support through a third rotating shaft, and the bottom end of the second hydraulic cylinder is connected with the fourth hinge support through a fourth rotating shaft. The marine adjustable hydrofoil device can enable a ship installing the same to control the distance between the hydrofoil and the bottom of the ship and the angle of attack of the hydrofoil under different speed conditions, so as to reduce the draught of the ship and reduce the resistance of the ship in the sailing process to achieve the goal of energy saving and emission reduction.

Owner:HARBIN ENG UNIV

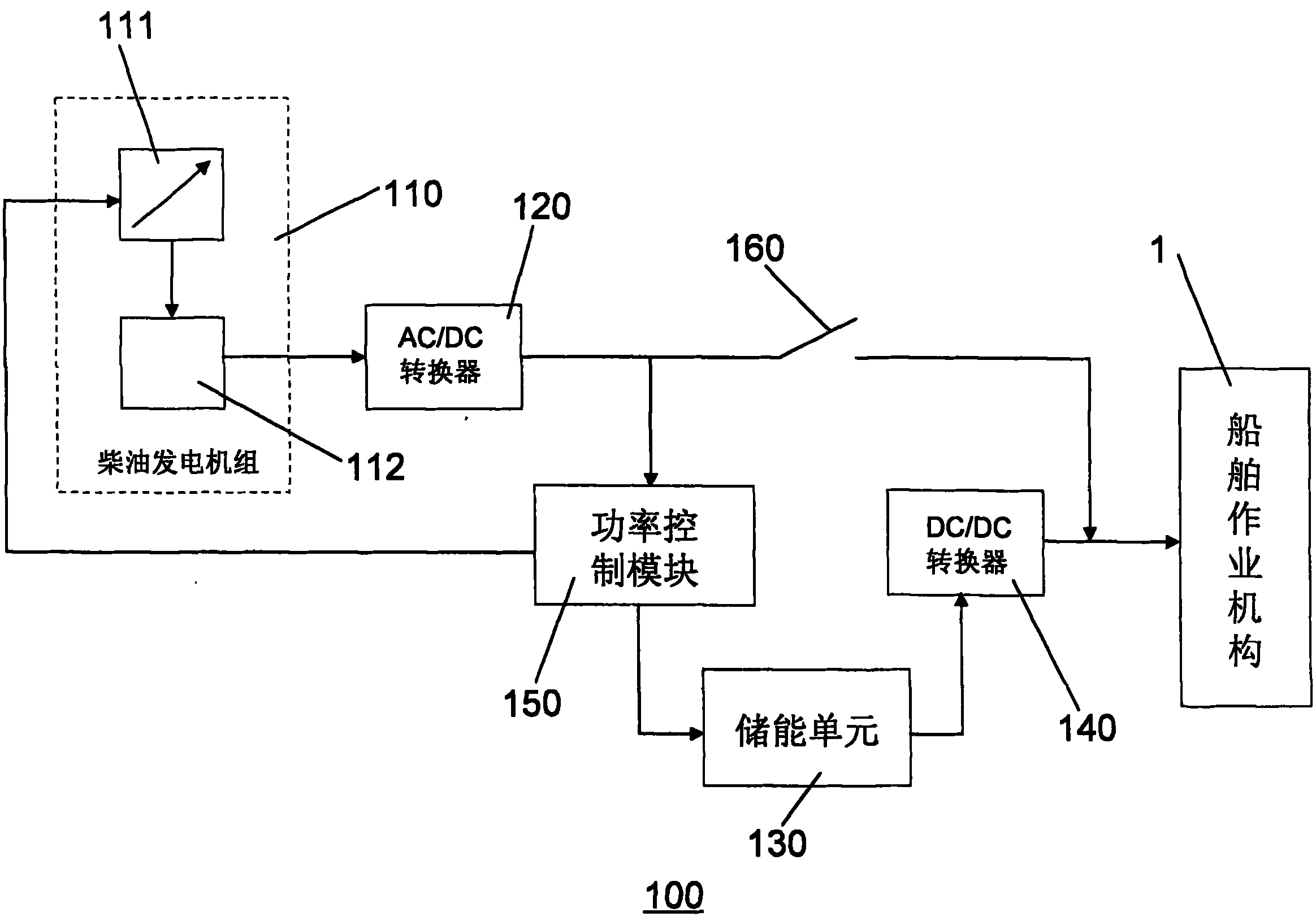

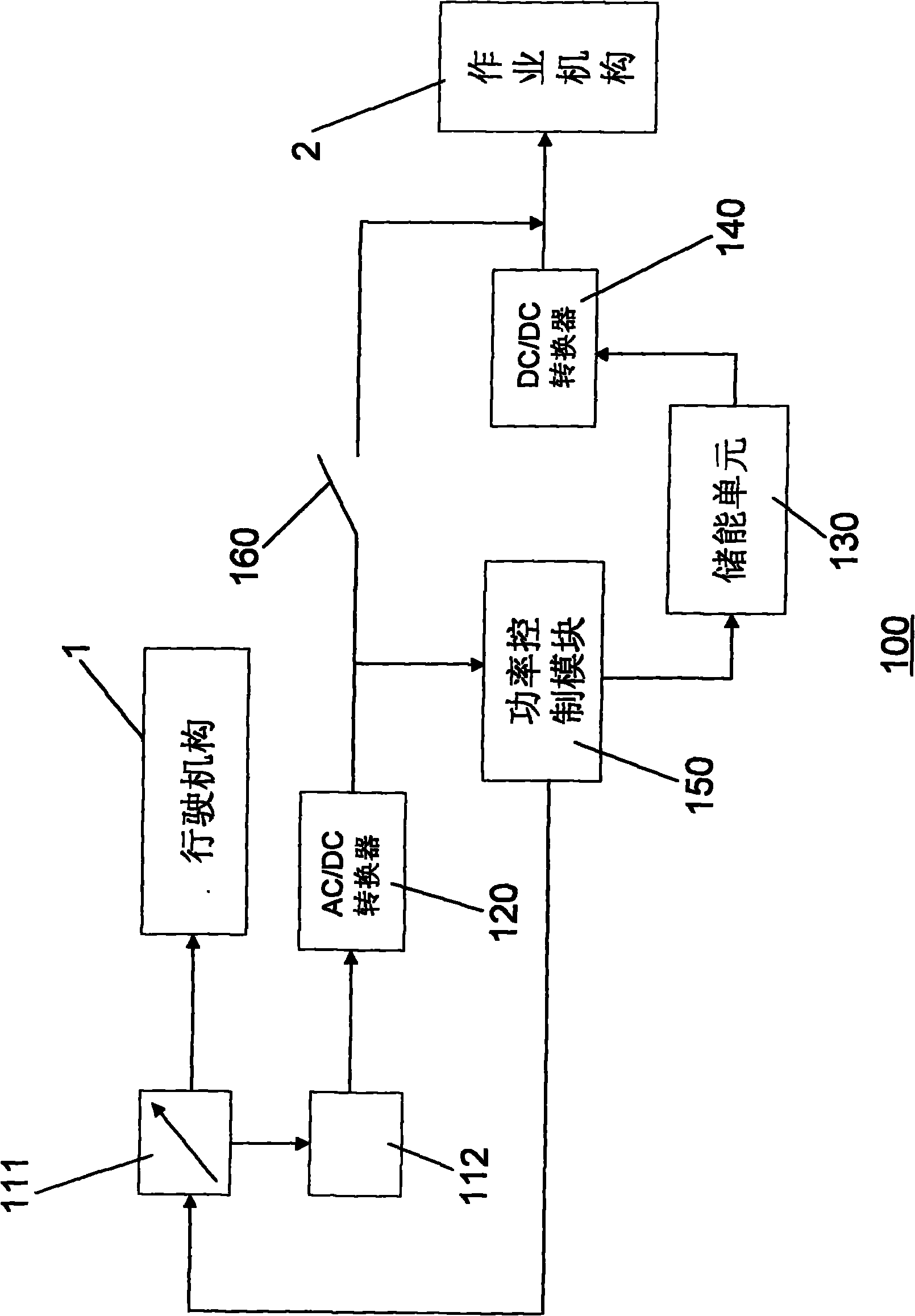

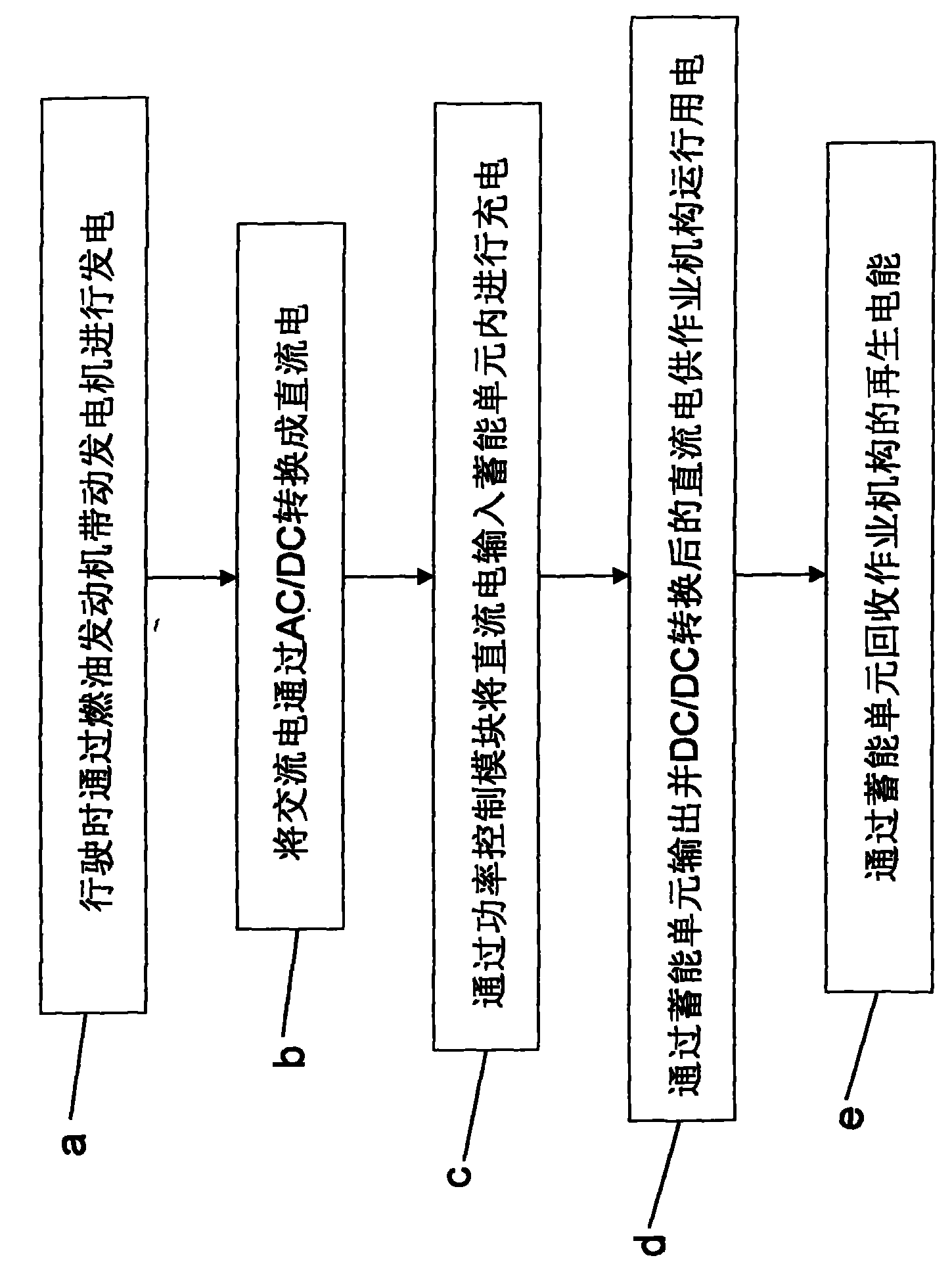

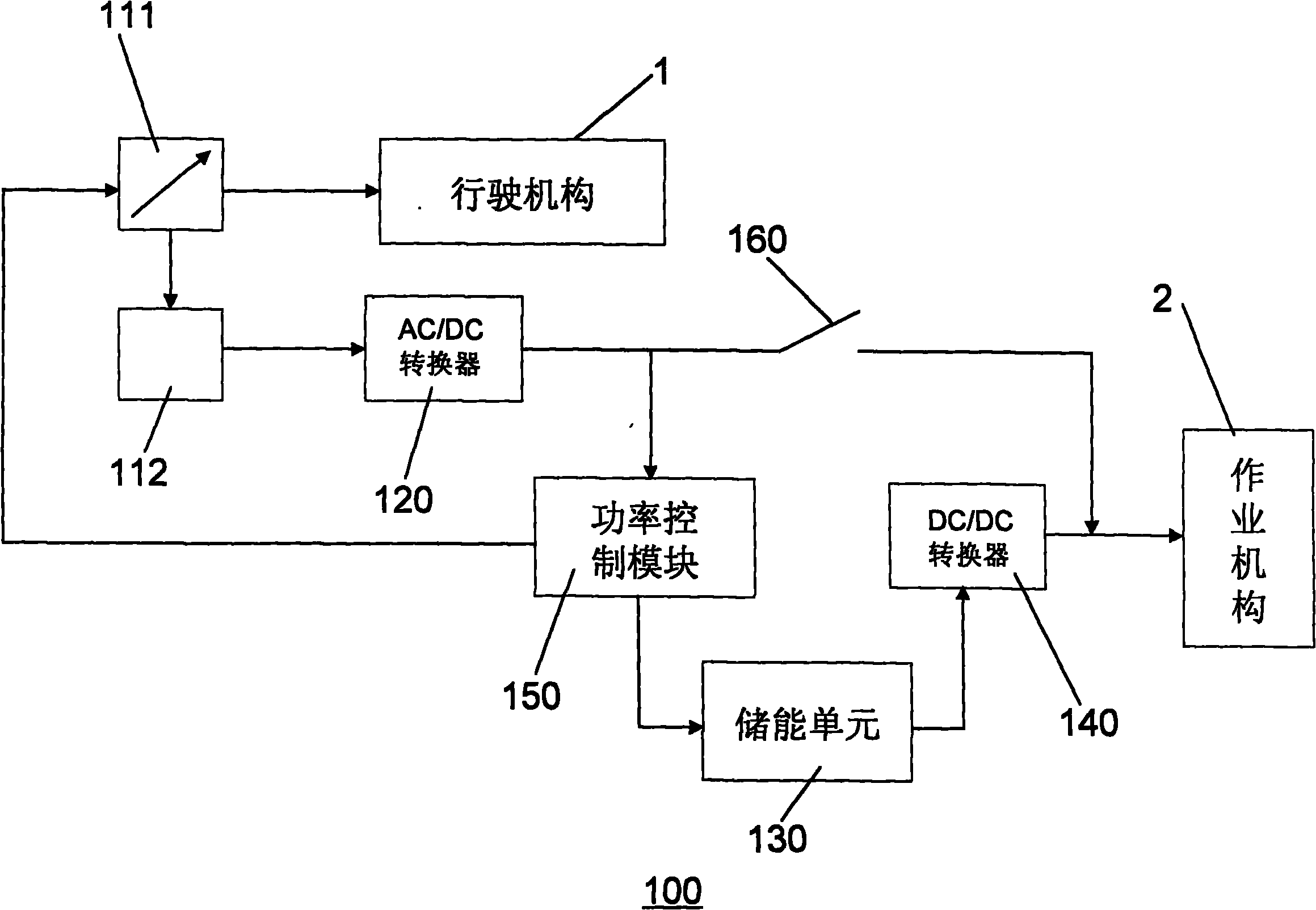

Power supply method and system for mobile type engineering machine

InactiveCN101920660AReduce power generationReduce pollutionBatteries circuit arrangementsSoil-shifting machines/dredgersElectricityElectric power system

The invention provides a power supply system for a mobile type engineering machine. The power supply system supplies power to a running mechanism by a fuel engine, drives a generator to generate electricity, charges an energy storage unit, supplies electric power to an operating mechanism by using the energy storage unit as a power supply source, and, when the running mechanism stop running, also can drive the generator to generate small-power electricity by controlling the rotation speed of the fuel engine so as to continuously charge the energy storage unit. The invention also provides a power supply method for the mobile type engineering machine. When the power supply method and the power supply system of the invention are used, the energy storage unit supplies the electric power to the operating mechanism, so that generation power can be reduced in operation considerably, over 40 to 60 percent of fuel can be saved, emission of pollutants can be reduced, and obvious social and economical benefit is created.

Owner:孙枫

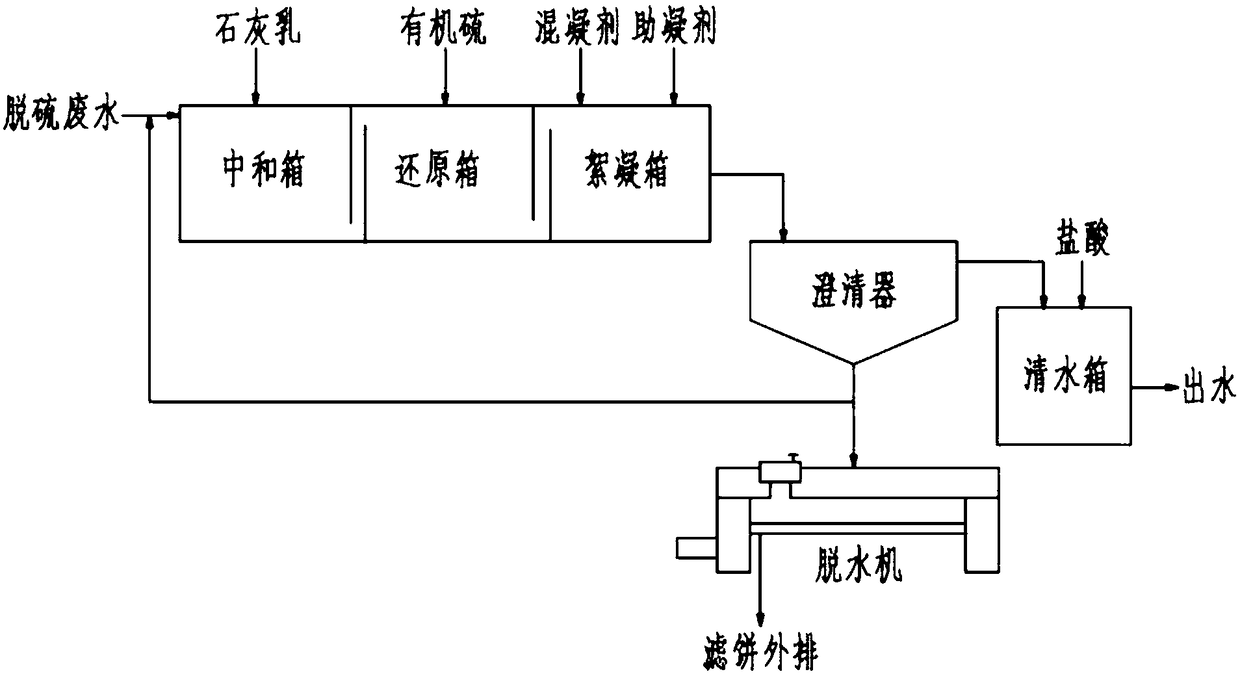

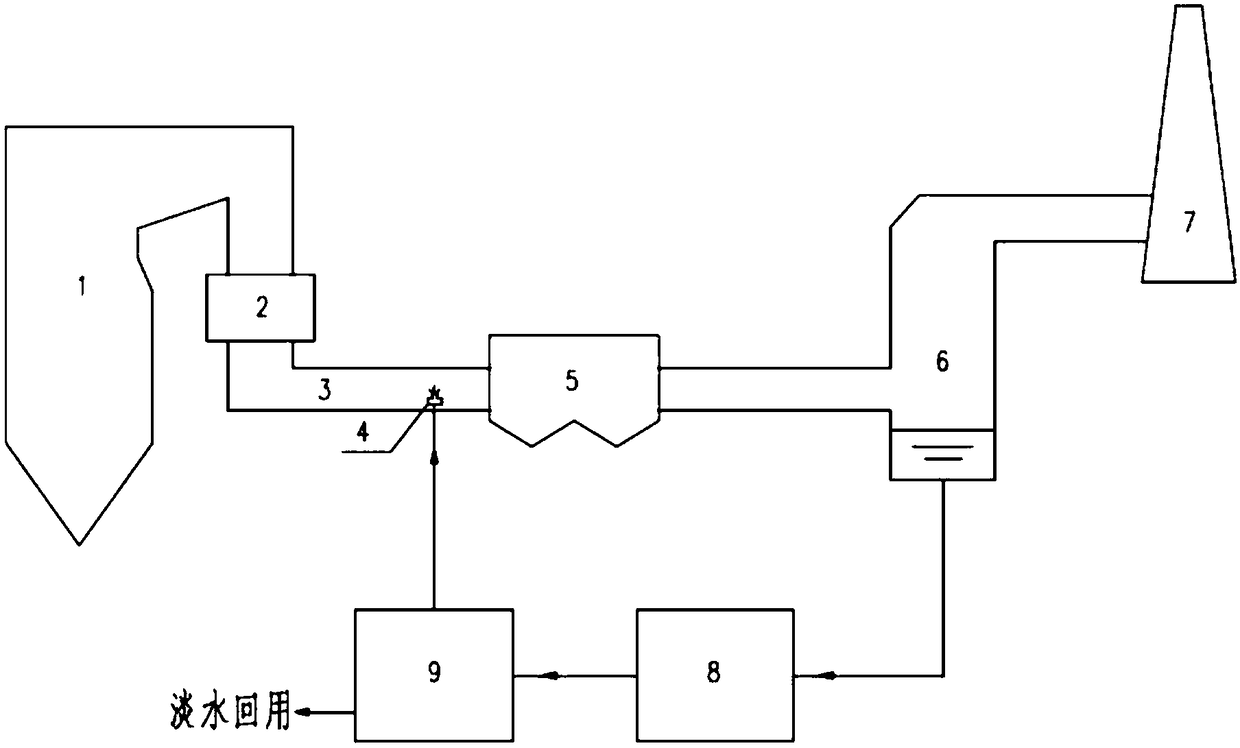

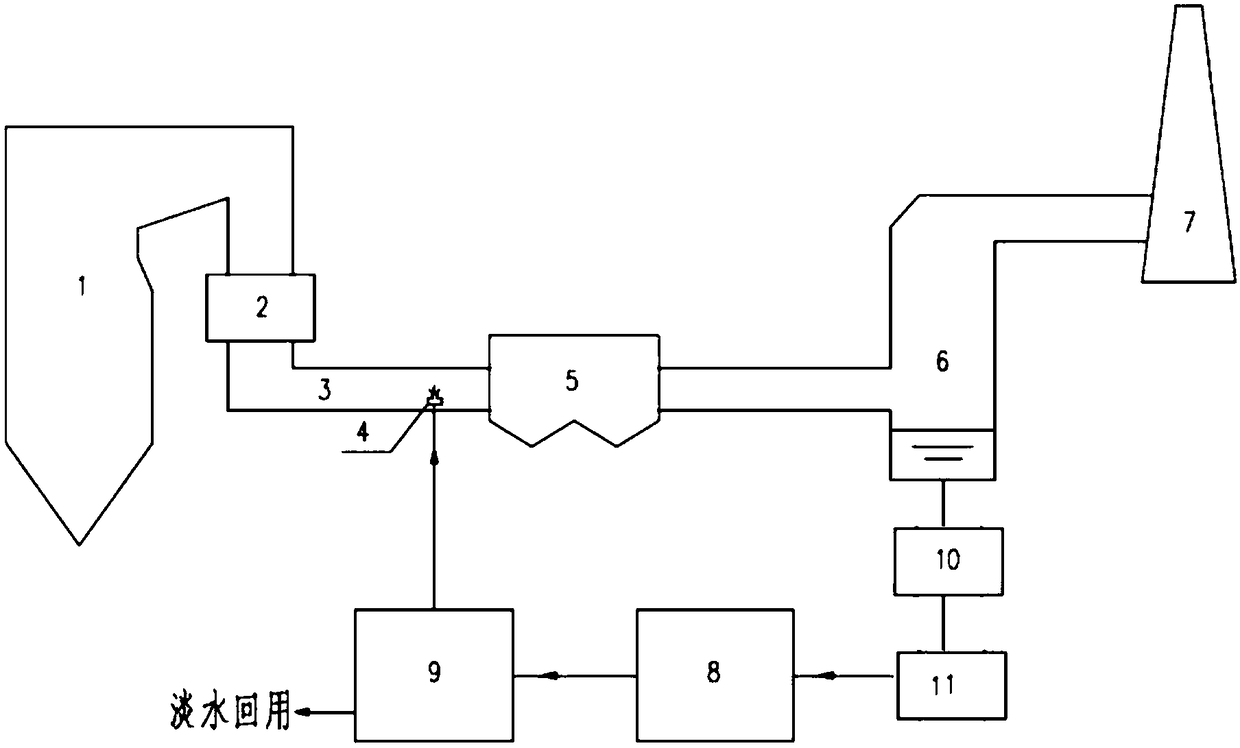

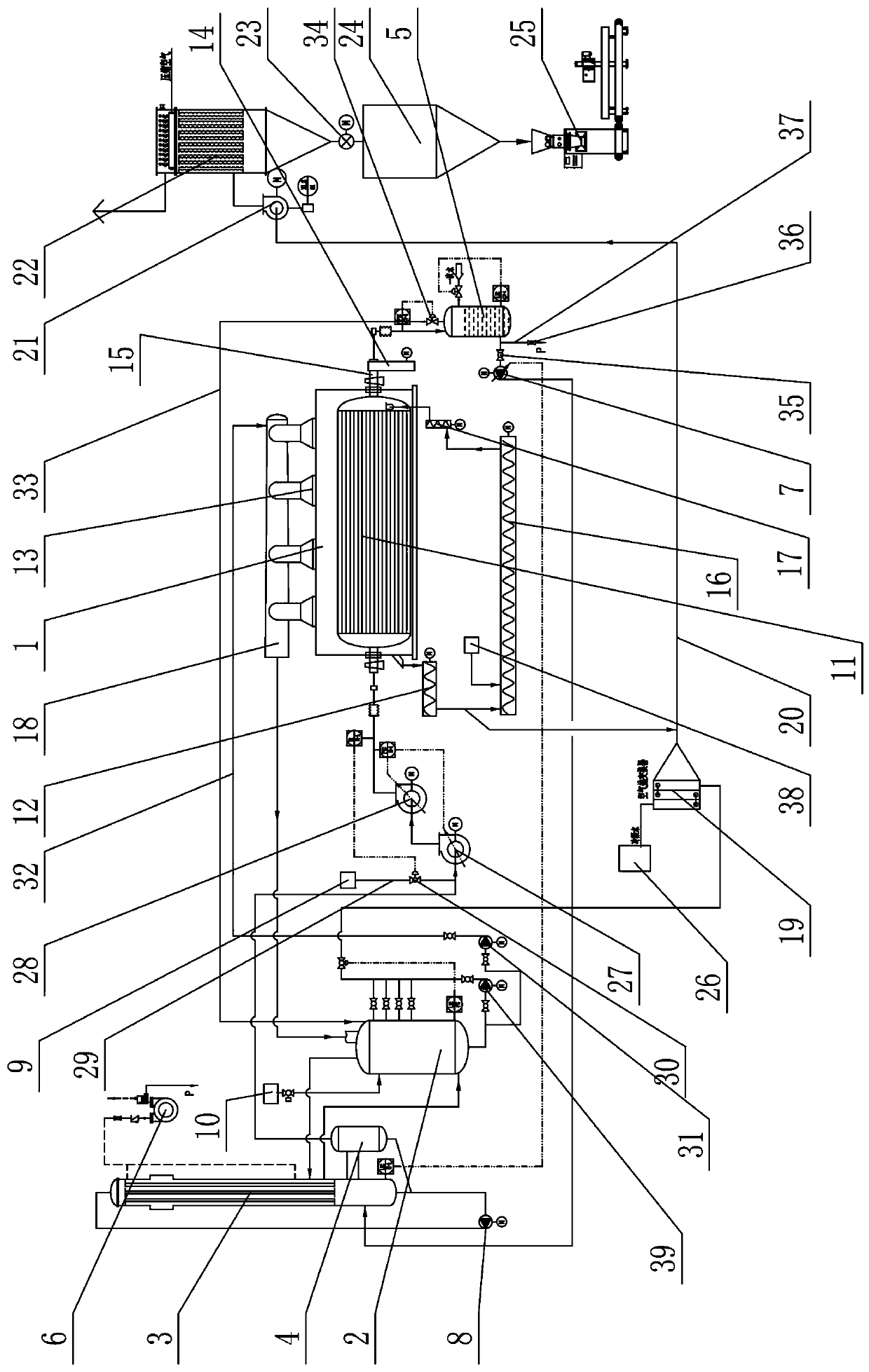

Desulfurization waste water treatment system and process

PendingCN108529808AAchieving zero emissionsProtect water resourcesWater/sewage treatment by centrifugal separationSludge treatmentAir preheaterAfter treatment

The invention provides a desulfurization waste water treatment system suitable for a coal-fired power plant. The desulfurization waste water treatment system comprises a boiler, an air preheater, a flue, a dust remover, a desulfurization tower, a waste water chemical adding treatment device and a concentration device. Turbid waste water drained by a desulfurization system enters the waste water chemical adding treatment device to be preliminarily treated, and clear water obtained after treatment is conveyed to the concentration device through a clear water pump. Thick-thin separation is carried out in the concentration device, the clear water which is separated out is recycled, thick water is conveyed into the flue in front of the dust remover behind the air preheater of the boiler througha pump, and a spraying device is arranged in the flue to atomize the waste water to evaporate the waste water by waste heat of flue gas; after liquid-state components in the desulfurization waste water are evaporated, remaining solid matter is removed from the dust remover, and steam formed after the liquid-state components in the desulfurization waste water are evaporated enters the desulfurization tower along with the flue gas and then is exhausted by a chimney. Zero release of the desulfurization waste water of the coal-fired power plant can be achieved, the desulfurization waste water isevaporated by fully utilizing the waste heat of the flue gas of the coal-fired power plant, it is not needed to consume other heat sources, and energy saving and emission reduction are achieved.

Owner:南京东大能源工程设计院有限公司

MVP vacuum pipe bundle drying system with waste steam conversion device

PendingCN110671907AEnable recyclingNo emissionsDrying solid materialsDrying machines with non-progressive movementsSteam condensationDust control

The invention relates to an MVP vacuum pipe bundle drying system with a waste steam conversion device. A last closed vacuum sealed space with the pressure lower than the barometric pressure is transformed inside a machine shell of a pipe bundle dryer, meanwhile, after secondary steam generated when wet materials are dried is subjected to dust removal washing, the secondary steam is fed into an evaporator, condensate water generated when steam in a pipe bundle of the pipe bundle dryer is condensed is fed into the evaporator, the secondary steam is used for heating the condensate water to generate steam, after the steam is pressurized and heated two times, the steam enters the pipe bundle dryer to dry the materials, the condensate water is recycled, waste heat in the secondary steam is recycled, raw steam is barely used in the whole drying process, waste water is barely drained, and energy saving and emission reduction are truly achieved.

Owner:郑州博大浓缩干燥设备有限公司

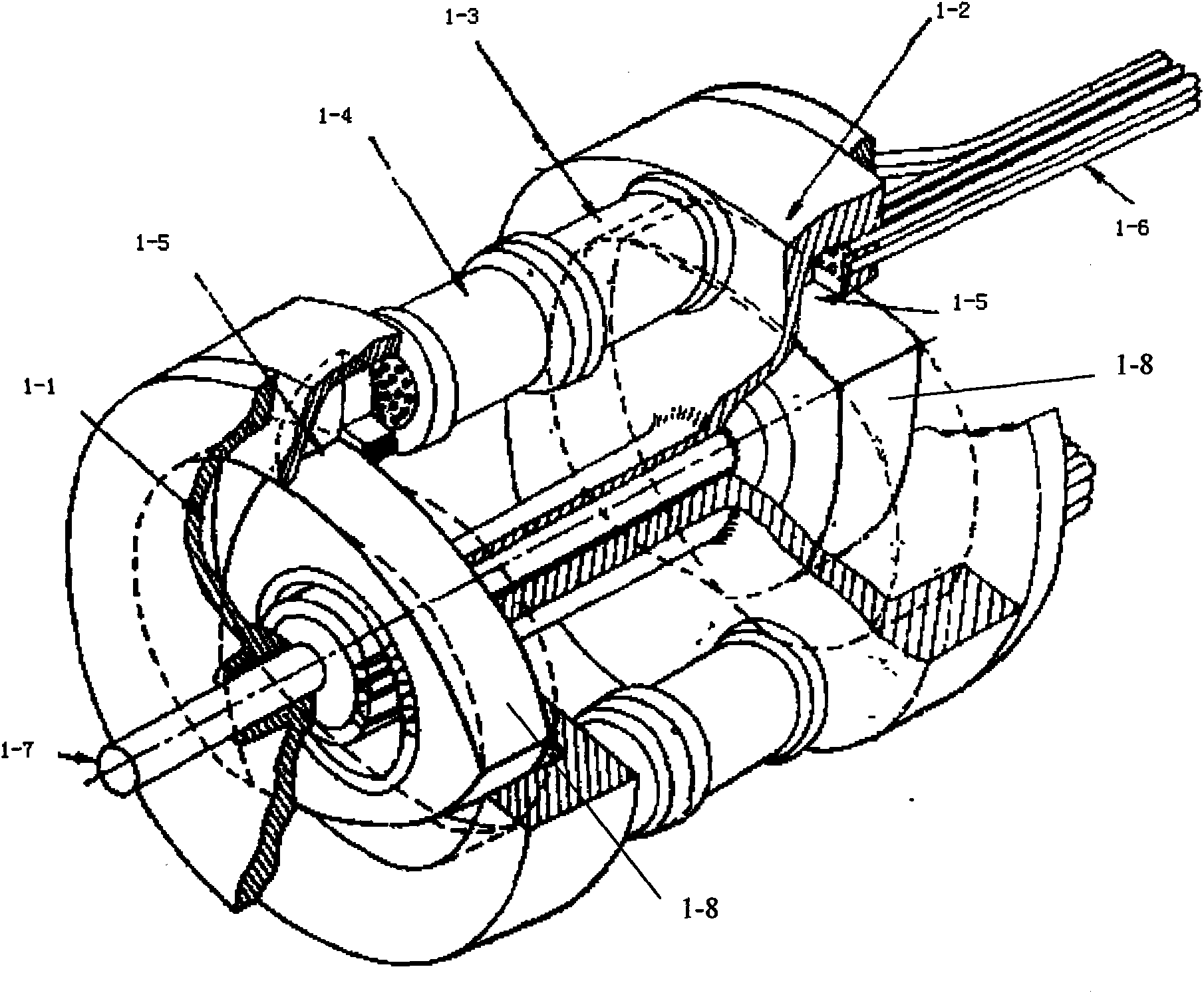

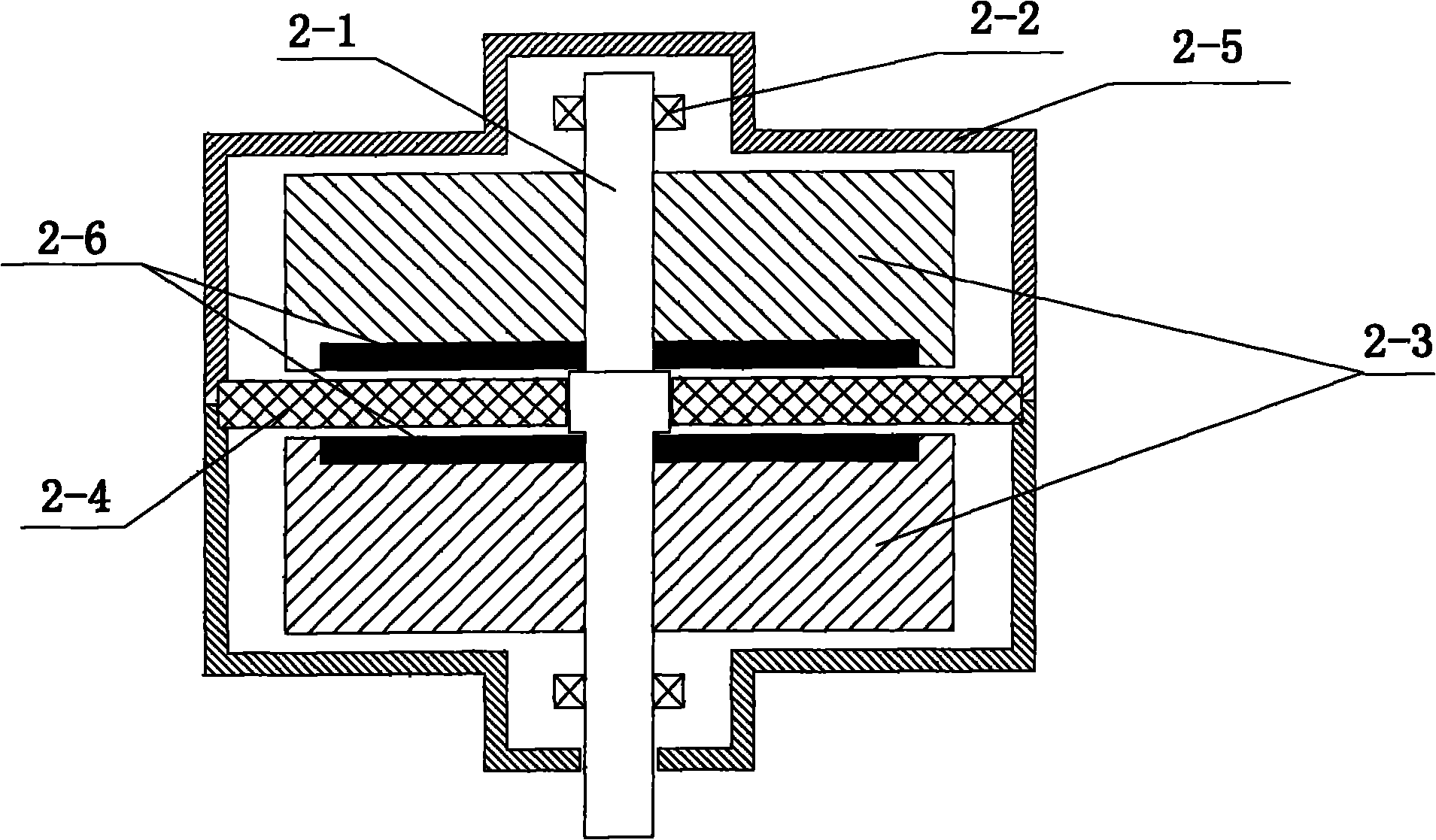

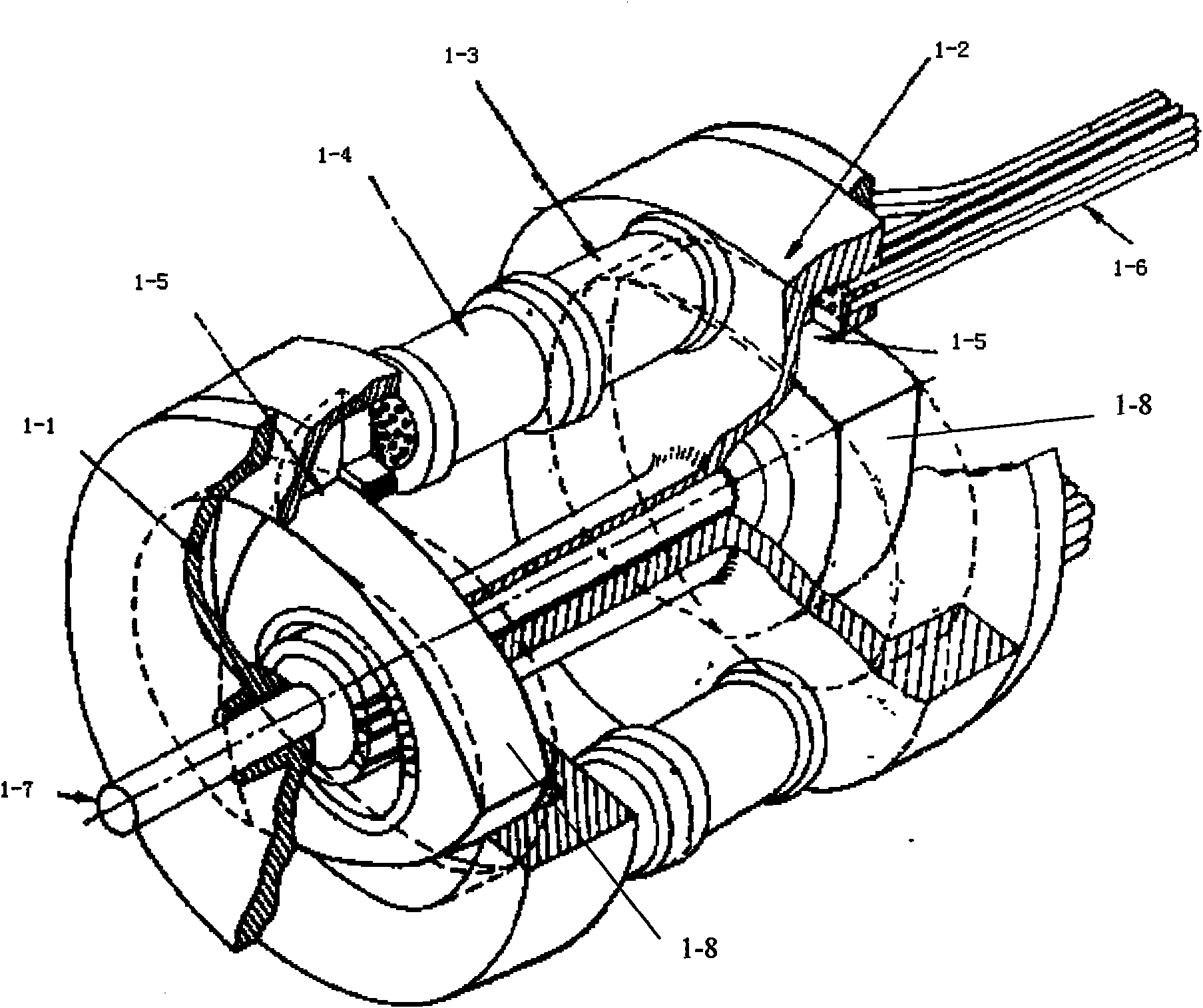

Vehicle exhaust waste heat generating system

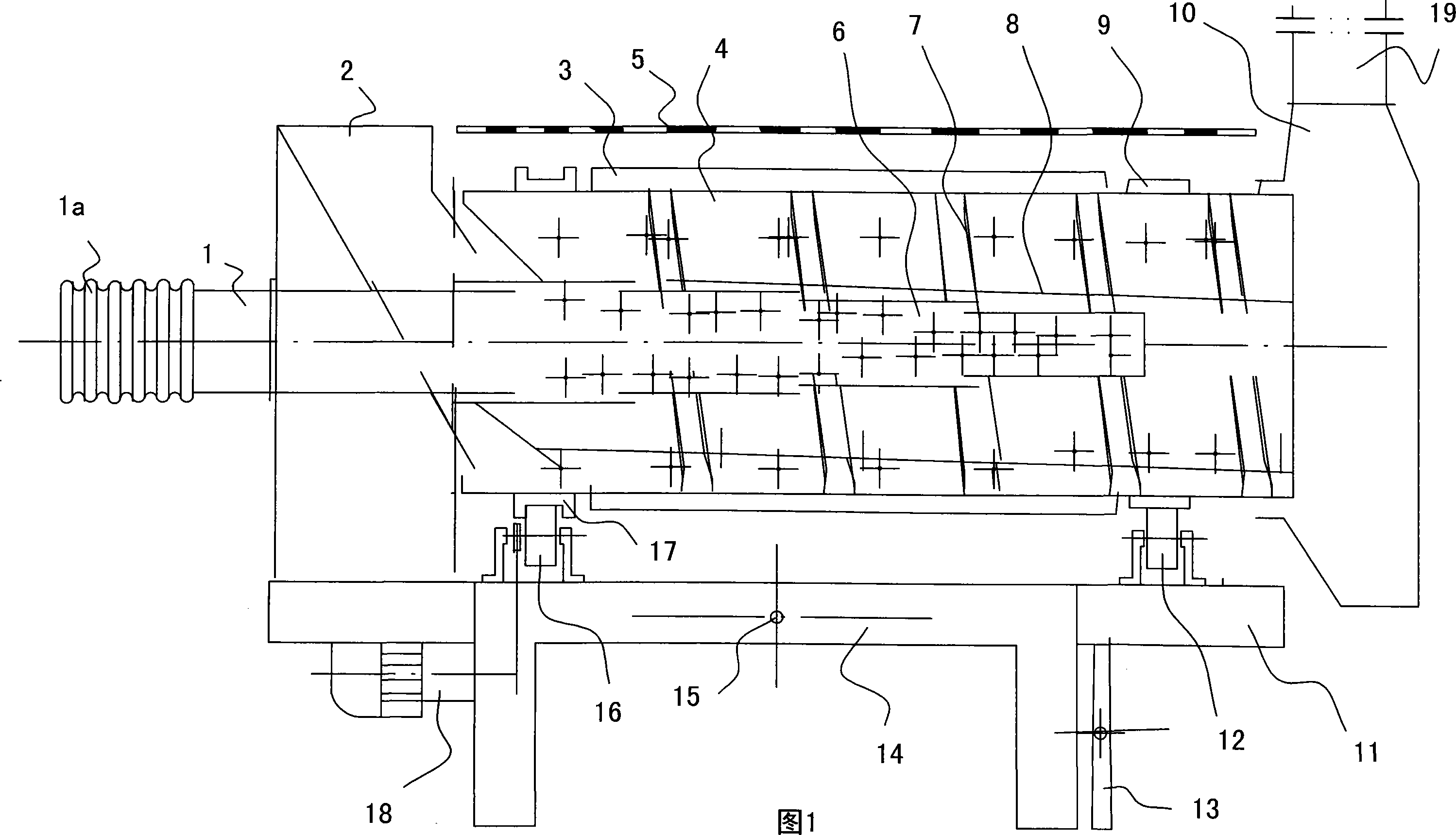

InactiveCN101892924AHigh thermal efficiencyEmission reductionInternal combustion piston enginesEngine componentsStator coilExhaust fumes

The invention provides a vehicle exhaust waste heat generating system, comprising a heat engine unit and a flywheel battery unit which are connected; a cooling chamber and an expanding chamber in the heat engine unit are respectively arranged at the two ends of a mechanic work output shaft, the interiors of the cooling chamber and the expanding chamber are respectively divided into three independent air chambers by rotors, two corresponding air chambers in the cooling chamber and the expanding chamber are connected by virtue of a water cooling heat exchanger and a heat regenerator, and a heating air tube is connected with the expanding chamber; the rotary shaft in the flywheel battery unit is connected with the mechanic work output shaft, the two ends of the rotary shaft are respectively provided with a bearing, a stator coil is arranged at the middle part of the rotary shaft, the two sides of the stator coil are respectively provided with a flywheel rotor provided with a permanent magnet, and the rotary shaft, the bearing, the flywheel rotor and the stator coil are respectively arranged in a battery case. The invention can effectively solve the problem that massive thermal is dissipated as vehicle exhaust is directly discharged, vehicle thermal efficiency is improved in large scale and energy conservation and emission reduction of vehicle is achieved while discharge of massive waste gas is reduced.

Owner:SOUTH CHINA UNIV OF TECH

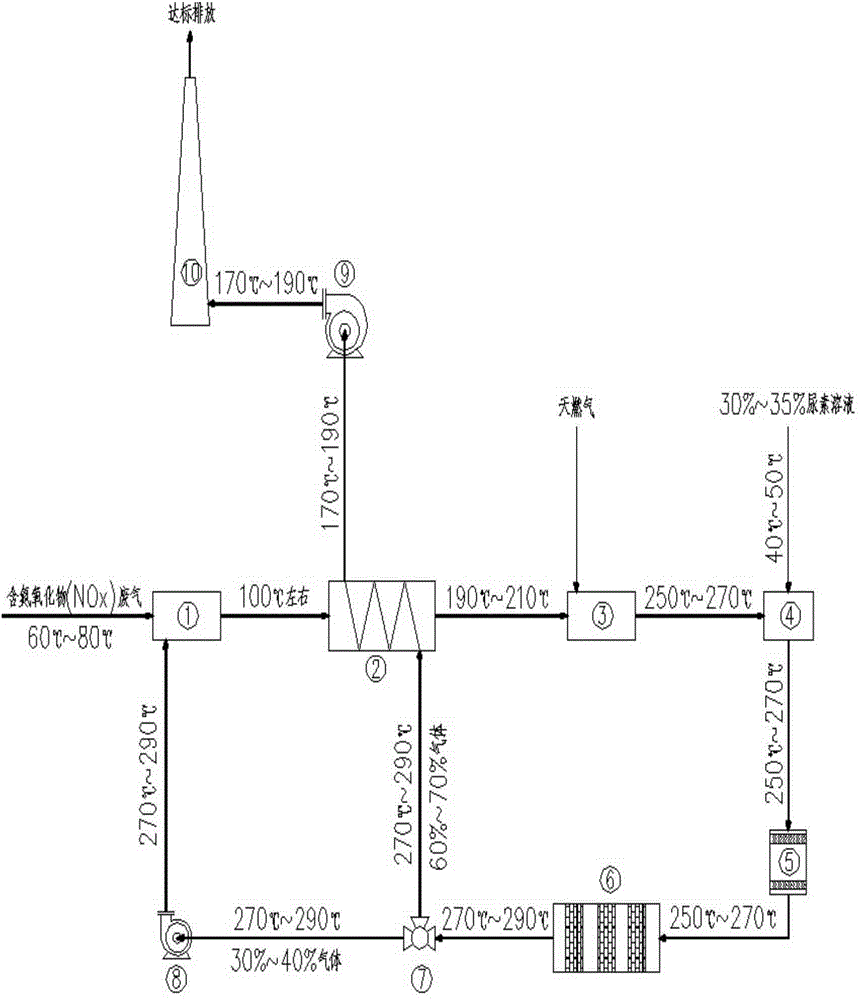

Catalyst for flue gas denitrification at 250-270 DEG C, and preparation method and application thereof

InactiveCN106031874AReduce usageReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIonFlue gas

The invention belongs to the technical field of environmental protection, and relates to a catalyst for flue gas denitrification at 250-270 DEG C, a preparation method thereof and application thereof in the denitration treatment of exhaust gas containing nitrogen oxide. The catalyst comprises a catalyst coating and honeycomb ceramic, wherein the catalyst coating coats on the surface of honeycomb ceramic. The catalyst coating includes deionized water and a slurry group comprising the following components by weight: 40-60% of zeolite, 10-30% of nanometer alumina, and 10-30% of a catalytic active component, wherein the deionized water is added by the liquid-solid ratio of 1-3:1. The preparation method comprises the steps of: (1) mixing components of catalyst coating; (2) conducting ball milling on the mixed components to obtain the coating slurry; (3) coating; and (4) roasting. The invention provides application of the catalyst in the denitration treatment of exhaust gas containing nitrogen oxide. The denitration catalyst prepared by the method has high denitration efficiency at 250 to 270 DEG C, reduces the reaction temperature required in the existing SCR technology; and the application method that reduces the energy consumption and reduces thermal pollution emission.

Owner:TONGJI UNIV +1

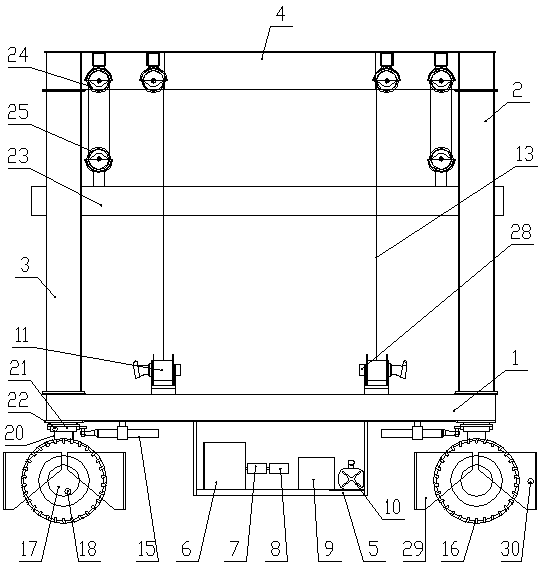

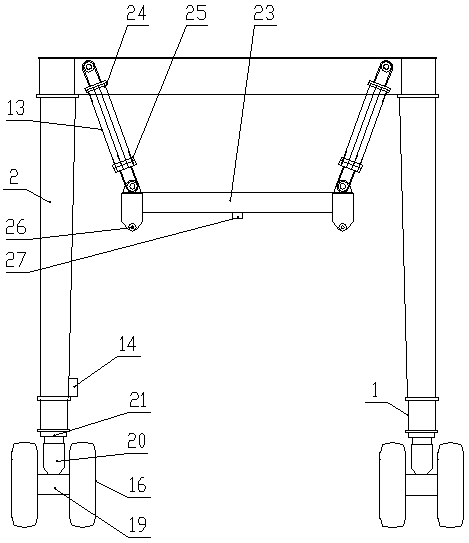

Wireless remote control full-hydraulic drive tyre type gantry crane

InactiveCN103482482ATo achieve the purpose of energy saving and emission reductionReach bus communicationTrolley cranesTravelling gearWireless dataLift system

The invention discloses a wireless remote control full-hydraulic drive tyre type gantry crane. The wireless remote control full-hydraulic drive tyre type gantry crane comprises two low vertical beams which are arranged horizontally, wherein a front portal frame is arranged between the front ends of the two low vertical beams; a back portal frame is arranged between the rear ends of the two lower vertical beams; two sides of the front portal frame and the back portal frame are provided with an upper vertical beam respectively; the lower surfaces of the front end and the rear end of each lower vertical beam are provided with a walking-steering system respectively; a support frame is arranged under one lower vertical beam and provided with an engine, a lifting hydraulic pump, a walking-steering hydraulic pump, a hydraulic oil tank and a fuel oil tank; each lower vertical beam is provided with two hydraulic winches respectively; the front portal frame or the back portal frame is provided with a wireless data receiving-sending module which is used for controlling the walking and steering of the walking-steering system and the lifting of a lifting system;. By using a full wireless remote control operation manner and a full-hydraulic power drive manner, the large-tonnage goods can be lifted; the wireless remote control full-hydraulic drive tyre type gantry crane is capable of performing the operation of transferring the large goods in a short distance in a factory and has functions of walking transversely and vertically, rotating in 360 degrees on site, braking, winding and lifting heavy goods.

Owner:郑州贝龙液压技术有限公司

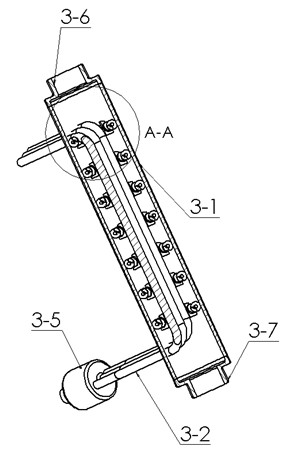

Waste heat recovery system of vacuum damping machine

ActiveCN103251123AReduce tube resistanceMeet instantTobacco preparationFinal product manufactureWaste heat recovery unitEngineering

A waste heat recovery system of a vacuum damping machine comprises a condenser and a circulation water tank. A steam inlet, a condensate water outlet, a circulation water inlet and a circulation water outlet are formed in the lower portion of the condenser, the condensate water outlet and the circulation water outlet are connected with the circulation water tank through pipelines, the circulation water inlet is connected with the circulation water tank through a circulating pump, heat radiating tubes are arranged in the circulation water tank, and the condensate water outlet is connected with the heat radiating tubes through pipelines. The waste heat recovery system of the vacuum damping machine aims to reduce heat exchanger tube resistance and improve heat exchange efficiency, and meets the fact that the surplus steam of steam inject exhausting of the ejecting type vacuum damping machine has the characteristics of being instant, intermittent and mass-flow. A heat radiator is used as a condenser of the surplus steam to carry out structural design, and the waste heat recovery system of the vacuum damping machine can be used as auxiliary products for the vacuum damping machines of the mentioned type.

Owner:CHINA TOBACCO HENAN IND

Exhaust waste heat power generation and exhaust purification system based on Stirling generator

InactiveCN102678385AImprove efficiencyShort thermoelectric conversion timeInternal combustion piston enginesExhaust apparatusElectrical resistance and conductanceParticulates

The invention relates to an exhaust waste heat power generation and exhaust purification system based on a Stirling generator. The exhaust waste heat power generation and exhaust purification system based on the Stirling generator comprises an exhaust emission purification unit and an exhaust waste heat power generation unit which are connected with each other. The exhaust emission purification unit comprises a first exhaust pipe, a one-way valve, a secondary combustion and heat exchange device, and a second exhaust pipe, which are connected in sequence. The exhaust waste heat power generation unit comprises the Stirling generator, a radiator, a cold-hot gas exchanger, a hot cavity pipe extending into the secondary combustion and heat exchange device, and a regulated adaptor. High-temperature exhaust passes through the exhaust pipe and the one-way valve and enters the secondary combustion and heat exchange device, large solid particles in the exhaust are combusted by instant high heat generated by a spiral resistance wire, and the requirement of exhaust emission of PM2.5 (particulate matter 2.5) is met. The hot cavity pipe penetrates through a ring center of the spiral resistance wire and is heated by the high-temperature exhaust, the high-temperature spiral resistance wire also releases heat to increase temperature of a hot cavity of the Stirling generator, and accordingly thermal efficiency of the Stirling generator is improved.

Owner:SOUTH CHINA UNIV OF TECH

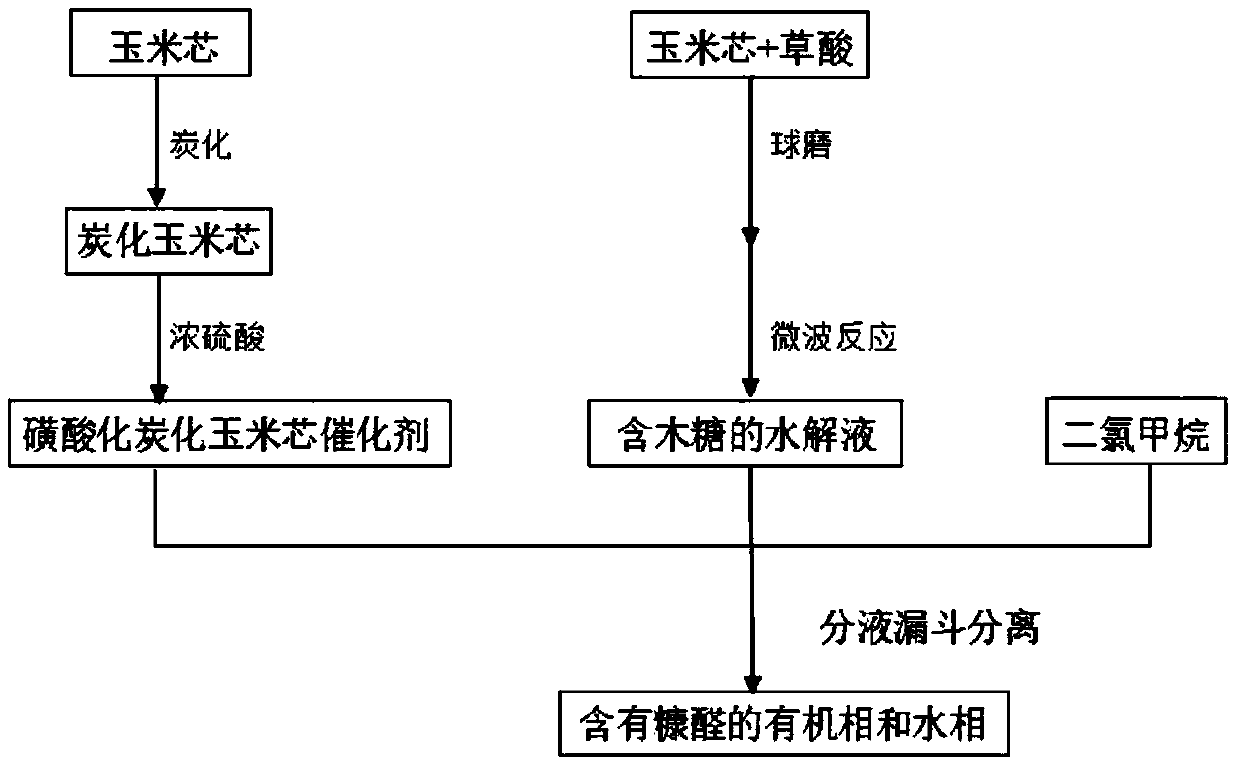

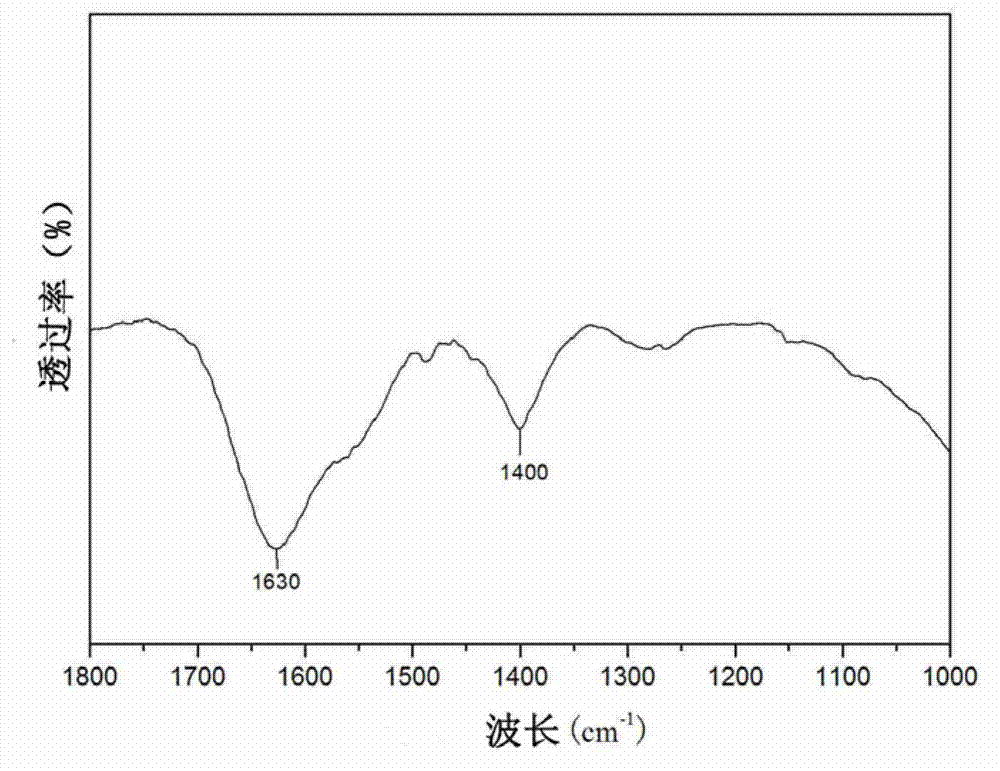

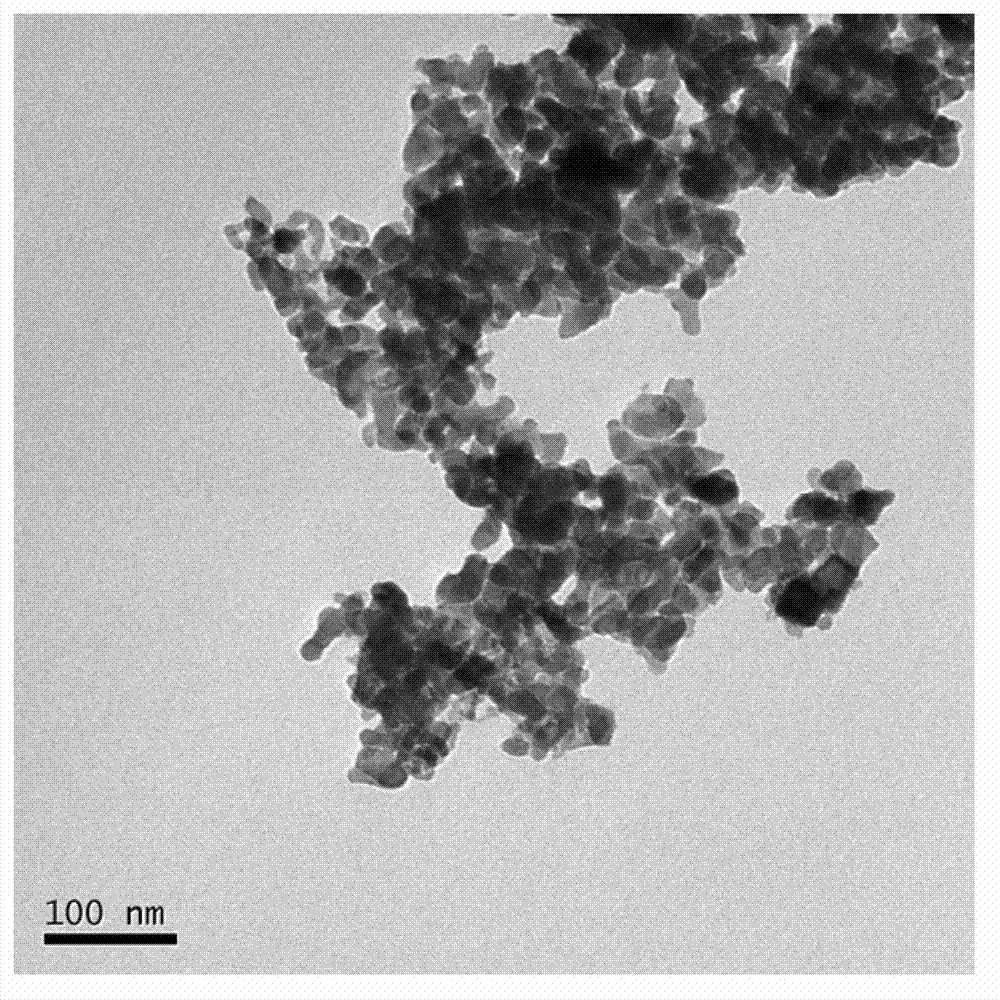

Preparation method of sulfated carbonized corn cob catalyst and method for preparing furfural from xylose in presence of catalyst

InactiveCN105498801AHigh catalytic efficiencyGood choicePhysical/chemical process catalystsOrganic chemistryCarbonizationCompound (substance)

The invention belongs to the technical field of preparation of biomass-based chemicals and discloses a preparation method of a sulfated carbonized corn cob catalyst and a method for preparing furfural from xylose in presence of the catalyst. The method comprises the steps of heating absolutely dry corn cob powder in a carbonization furnace to 400-500 DEG C in an atmosphere of nitrogen gas and carbonizing for 4-6h to obtain carbonized corn cob; adding the carbonized corn cob and concentrated sulfuric acid into a reactor and reacting at 145-155 DEG C for 14-16h; washing and drying the reaction product to obtain the sulfated carbonized corn cob catalyst; placing xylose-containing hydrolysis liquid, the sulfated carbonized corn cob catalyst and dichloromethane in the reactor and reacting at 160-180 DEG C for 1.5-2.5h, and performing separation and purification on the reaction product to obtain furfural. The sulfated carbonized corn cob catalyst has high catalytic efficiency, is low in cost, and can remarkably improve the yield of furfural and reduce the production cost of furfural when used for preparing furfural from xylose.

Owner:SOUTH CHINA UNIV OF TECH

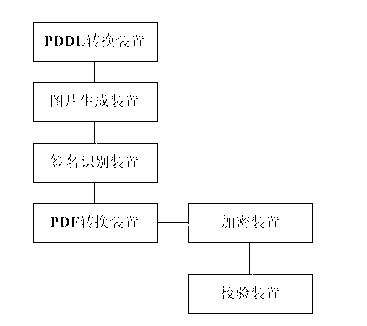

Tamper-resistant system for electronic signature

InactiveCN102799809AImprove securityTo achieve the purpose of energy saving and emission reductionComputer security arrangementsModifying/creating image using manual inputPlanning Domain Definition LanguageIdentification device

The invention discloses a tamper-resistant system for an electronic signature. The tamper-resistant system for the electronic signature comprises a planning domain definition language (PDDL) conversion device, a picture generation device, a signature identification device and a portable document format (PDF) conversion device, wherein the PDDL conversion device is used for converting acceptance form data into the PDDL data; the picture generation device is used for generating an acceptance form picture according to the PDDL data; the signature identification device is used for identifying a handwritten signature of a user; and the PDF conversion device is used for converting the acceptance form picture which is signed by handwriting by the user into a PDF file. By defining a PDDL data protocol, supporting the generation of a general acceptance form data picture, and directly signing on the picture by handwriting, what you see is what you get, the signature is synthesized directly without storing signature data, so that the security of the signature is improved; paperless office and electronic data management are realized; and the aims of saving energy and reducing emission are fulfilled.

Owner:陈娇 +18

Lanthanum-supported composite oxide solid catalyst as well as preparation method and applications of catalyst

ActiveCN103084162AHigh catalytic efficiencyGood choiceOrganic chemistryChemical industryRare earthFurfural

The invention discloses a lanthanum-supported composite oxide solid catalyst as well as a preparation method and applications of the catalyst. The preparation method comprises the steps of: adding ZrOCl2. 8H2O in distilled water, stirring for dissovling, dripping a TiCl4 solution, then adding nitrate La(NO3)3.6H2O of rare-earth metal lanthanum, adjusting pH by using stronger ammonia water, standing for 16-36hours at the temperature of 20-40 DEG C, filtering, settling, washing with distilled water until chloride ions do not exist, drying in a drying oven, and then calcining in a muffle furnace at the temperature of 450-650 DEG C, thus obtaining the lanthanum-supported composite oxide solid catalyst. The prepared catalyst consists of titanium dioxide, zirconium dioxide and lanthanum, and the supporting capacity of the lanthanum is controlled between 0.1% and 10%. The composite oxide solid catalyst is stable in chemical property, strong in catalysis capability and recyclable. Under the action of the composite oxide solid catalyst, a technology of converting xylose to furfural is high in reaction efficiency, moderate in reaction conditions and low in energy consumption in process; and the composite oxide solid catalyst is environment-friendly and capable of achieving the aim of saving energy and reducing emission.

Owner:SOUTH CHINA UNIV OF TECH

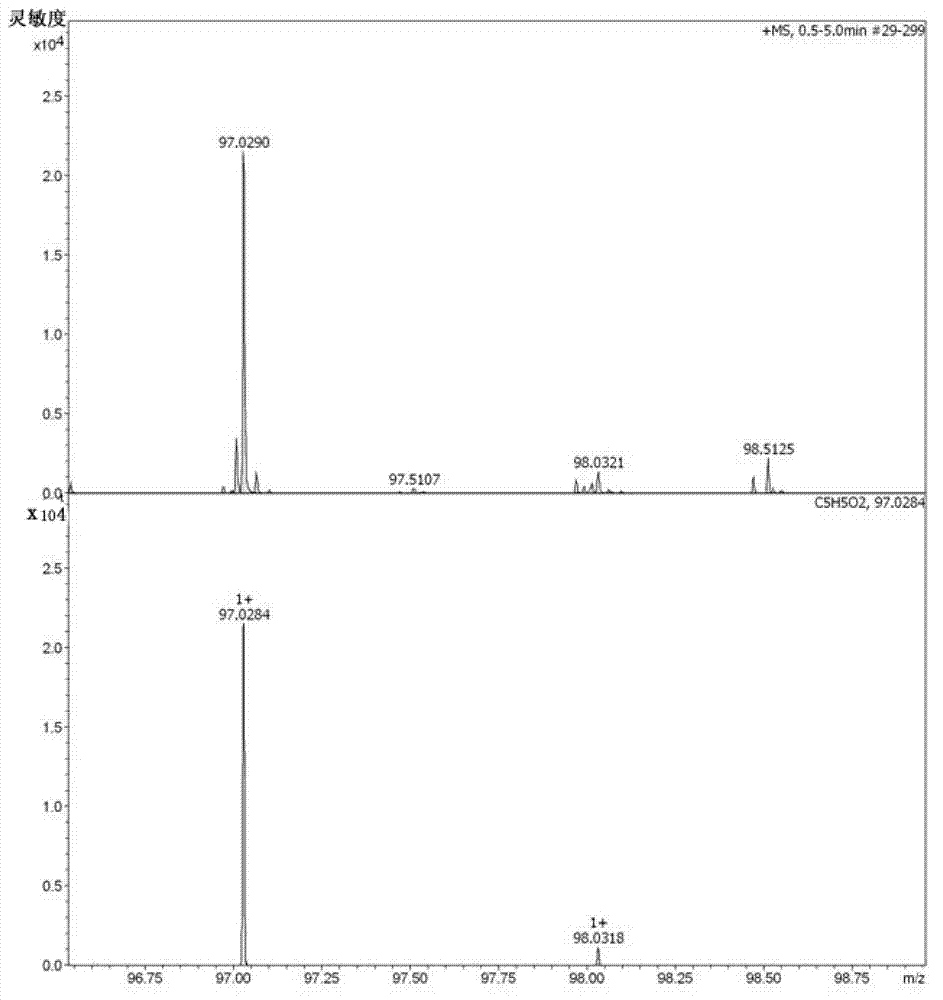

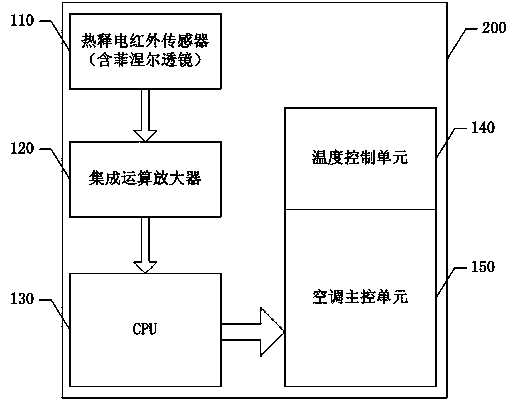

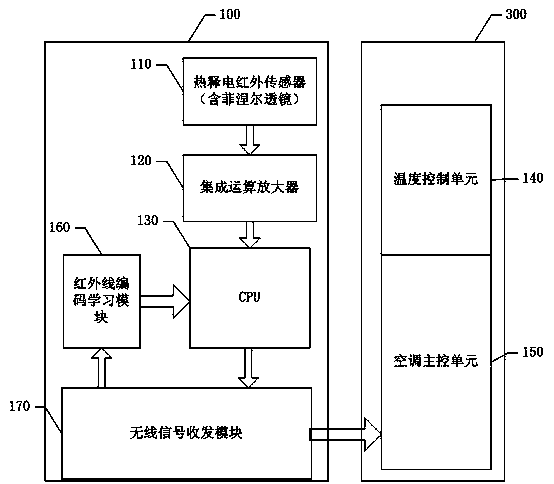

Intelligent-induction temperature adjustment device for air-conditioner and air-conditioner with intelligent-induction temperature adjustment function

InactiveCN103712314AWork reasonably and save energyTo achieve the purpose of energy saving and emission reductionSpace heating and ventilation safety systemsLighting and heating apparatusFresnel lensTemperature control

The invention discloses an intelligent-induction temperature adjustment device for an air-conditioner and the air-conditioner with the intelligent-induction temperature adjustment function. The air-conditioner comprises a pyroelectric infrared sensor comprising a Fresnel lens, an integrated operational amplifier, a CPU, an air-conditioner main control unit and a temperature control unit, wherein the pyroelectric infrared sensor comprising the Fresnel lens, the integrated operational amplifier, the CPU, the air-conditioner main control unit and the temperature control unit are arranged inside the air-conditioner. The CPU is connected with the integrated operational amplifier and used for carrying out comparison processing on amplified electrical signals and judging whether the human body is in the activity state or enters the sleep state, if the human body is in the activity state, processing is not carried out, and if the human body enters the sleep state or the unmanned state is determined, the CPU emits preset temperature adjustment signals to the air-conditioner main control unit. The intelligent-induction temperature adjustment device for the air-conditioner can increase the temperature appropriately when the human activity is not induced, and therefore the work of the air-conditioner is reasonable and saves the energy when nobody moves, and the purposes of energy conservation and emission reduction are achieved.

Owner:吴根佑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com