Phenolic resin wastewater processing method and special-purposed device

A phenolic resin and wastewater treatment technology, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as inability to discharge directly, unstable effluent, and easy secondary pollution. Achieve the effect of less control conditions, simple operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

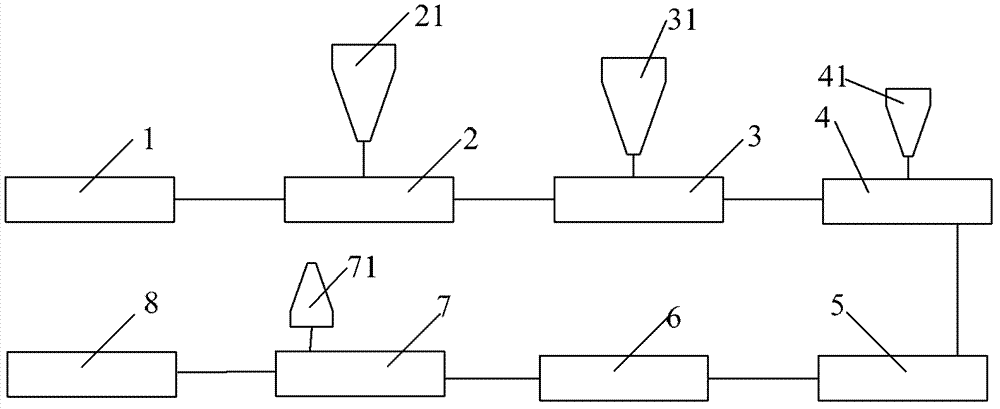

[0038] Such as figure 1 As shown, the present invention provides a kind of special equipment of phenolic resin waste water treatment method, and it mainly comprises the waste water feeding pond 1 that is connected successively, is provided with the coagulation sedimentation reaction pond 2 of the first feeder 21, is provided with the second inlet The Fenton reaction device 3 of the feeder 31, the solid-liquid separation device 4 provided with the third feeder 41, the hydrolytic acidification tank 5, the anaerobic fermentation tank 6, the contact oxidation reaction tank 7 provided with the aeration device 71 and the secondary sedimentation Pool 8. Wherein, described coagulation-sedimentation reaction tank 2, Fenton reaction device 3, solid-liquid separation device 4 and secondary settling tank 8 are conventionally said equipment in the art, and generally all include a waste water inlet, a waste water outlet and a solid waste water outlet. Mud outlet (not shown in the figure), ...

Embodiment 2

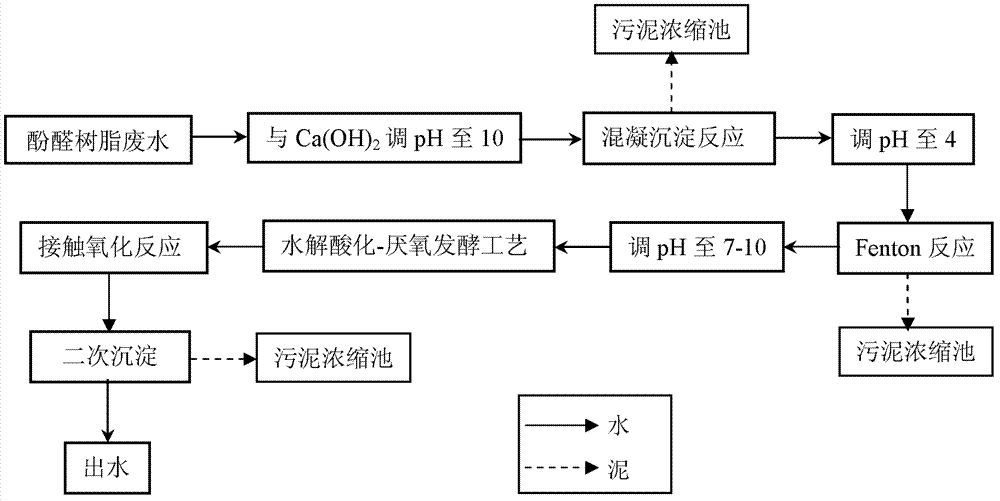

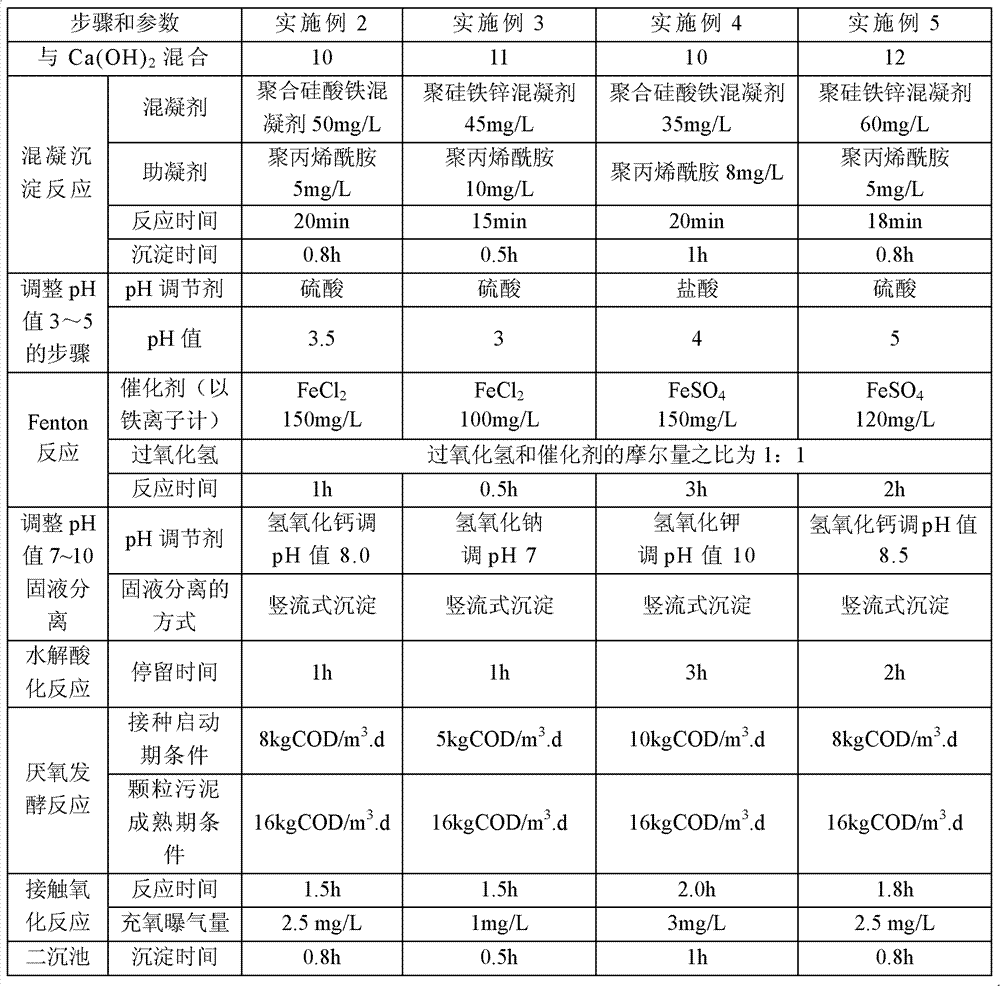

[0046] Wastewater source: Wastewater from the production of phenolic resin for automobile foundry in Nantong, the composition indicators are shown in Table 1. Concrete device uses the equipment of above-mentioned embodiment 1, and its concrete process is as follows figure 2 shown.

[0047] Table 1 The water quality of phenolic resin wastewater

[0048] Detection Indicator

unit

Example 2

Example 3

Example 4

Example 5

Chemical oxygen demand (CODc r )

mg / L

38000.00

30000

50000

40000

Biochemical Oxygen Demand (BOD 5 )

mg / L

6200.00

2000

4800

4000

Volatile phenol

mg / L

12380.00

10000

15000

14000

mg / L

7306.00

5000

8000

6000

pH

--

1.50

5.0

1.5

3.0

[0049] Simultaneously according to the technical process described in the embodiment, its specific process st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com