Hydraulic electricity generation shock absorber of vehicle

A hydraulic power generation and shock absorber technology, which is applied in liquid shock absorbers, machines/engines, mechanical equipment, etc., can solve problems such as low reliability, difficult use of electric energy for vehicles, and high production costs, so as to ensure comfort and reduce energy , the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

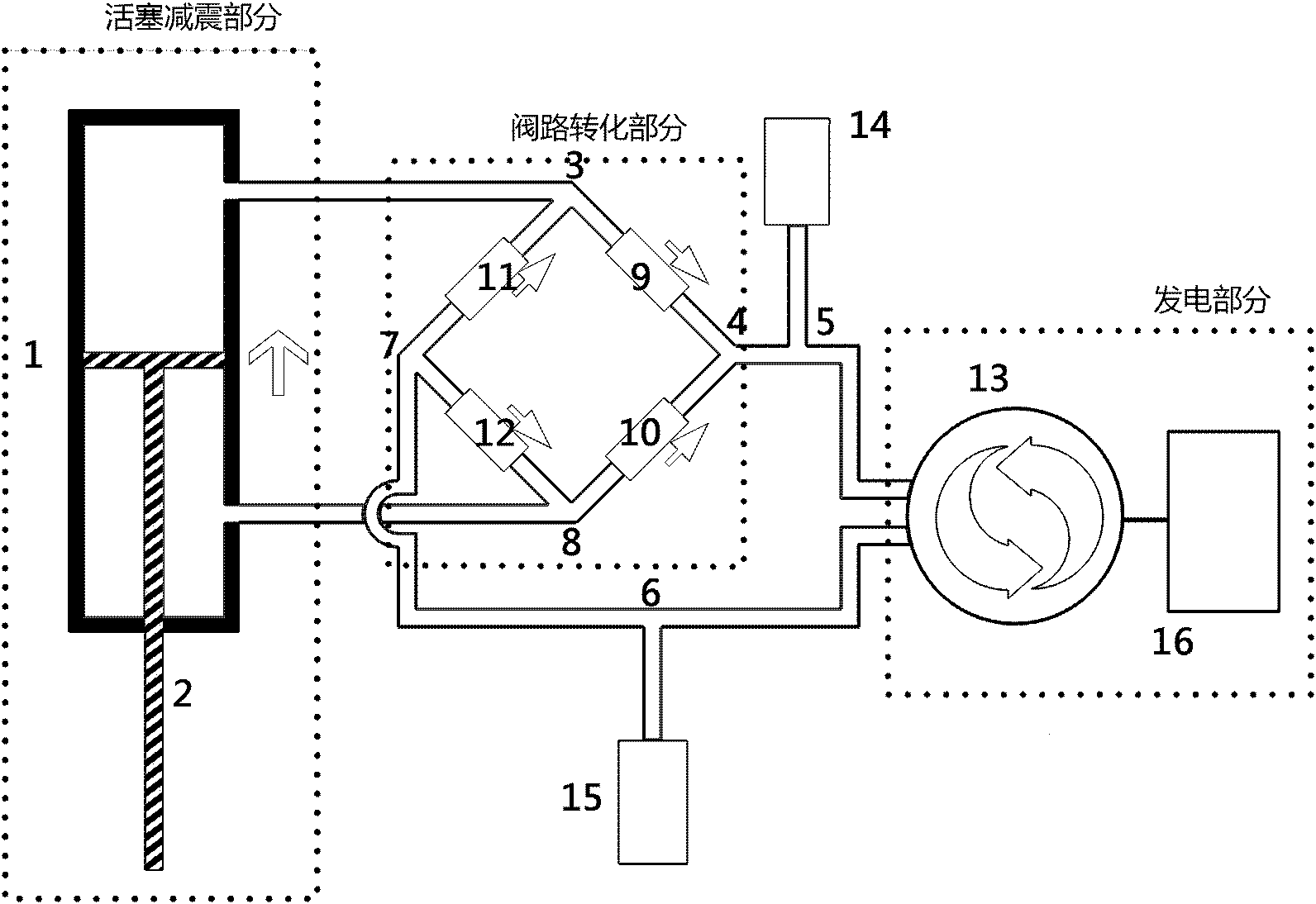

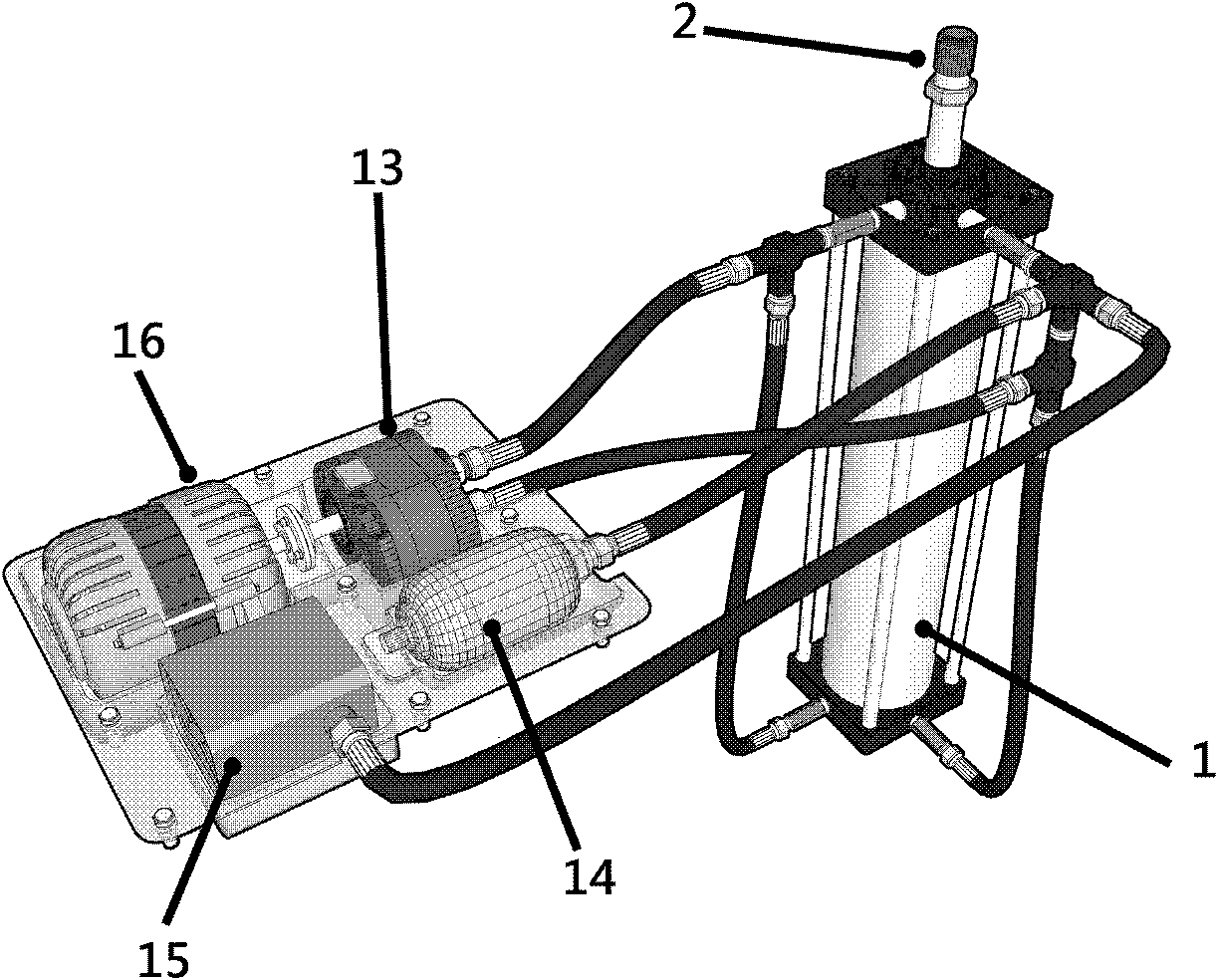

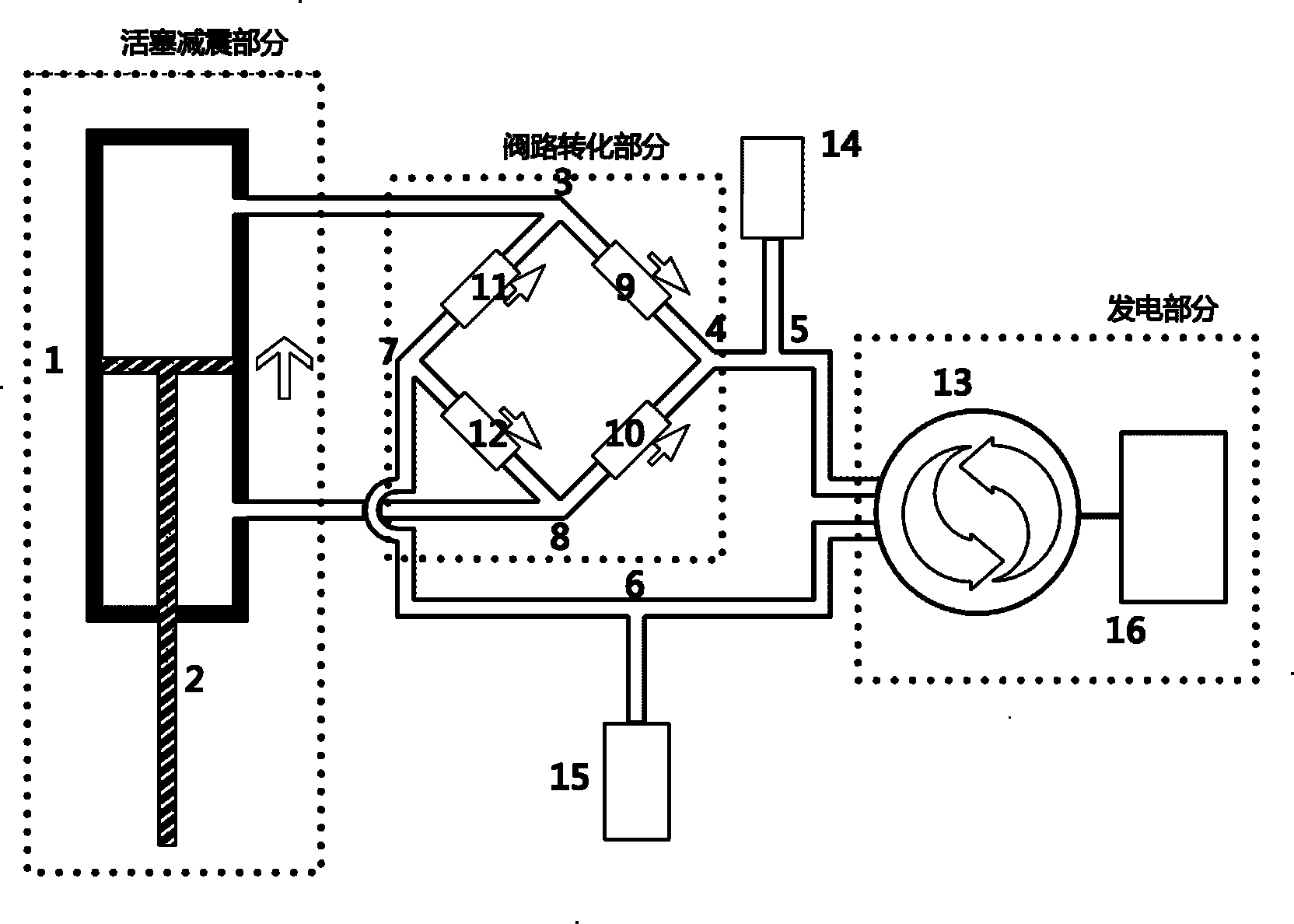

[0019] Such as figure 1 Among them, the vehicle hydraulic power generation shock absorber of the present invention includes a piston damping part, a valve circuit part and a power generation part.

[0020] The piston damping part is composed of a hydraulic cylinder 1 and a piston 2. The upper and lower chambers of the hydraulic cylinder each have a port connected with a copper tube. When the vehicle encounters road bumps and generates vibration or starts and brakes, it will cause relative movement between the vehicle frame and the wheels. At this time, the shock absorber piston 2 will go up or down correspondingly under the action of force, and the hydraulic The oil is pressed out from the outlet of the corresponding upper chamber and sucked in from the outlet of the lower chamber, or the hydraulic oil is pressed out from the outlet of the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com