Lanthanum-supported composite oxide solid catalyst as well as preparation method and applications of catalyst

A solid catalyst, composite oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as no stable industrialized production methods, and achieve Easy to achieve industrialization, mild reaction conditions, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

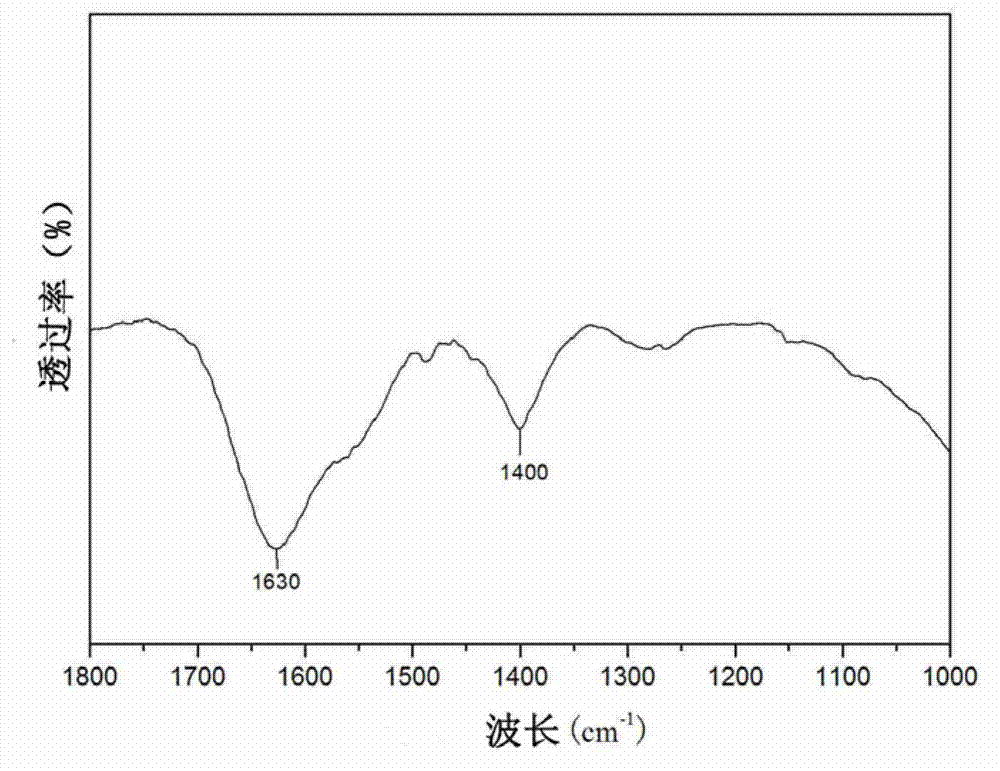

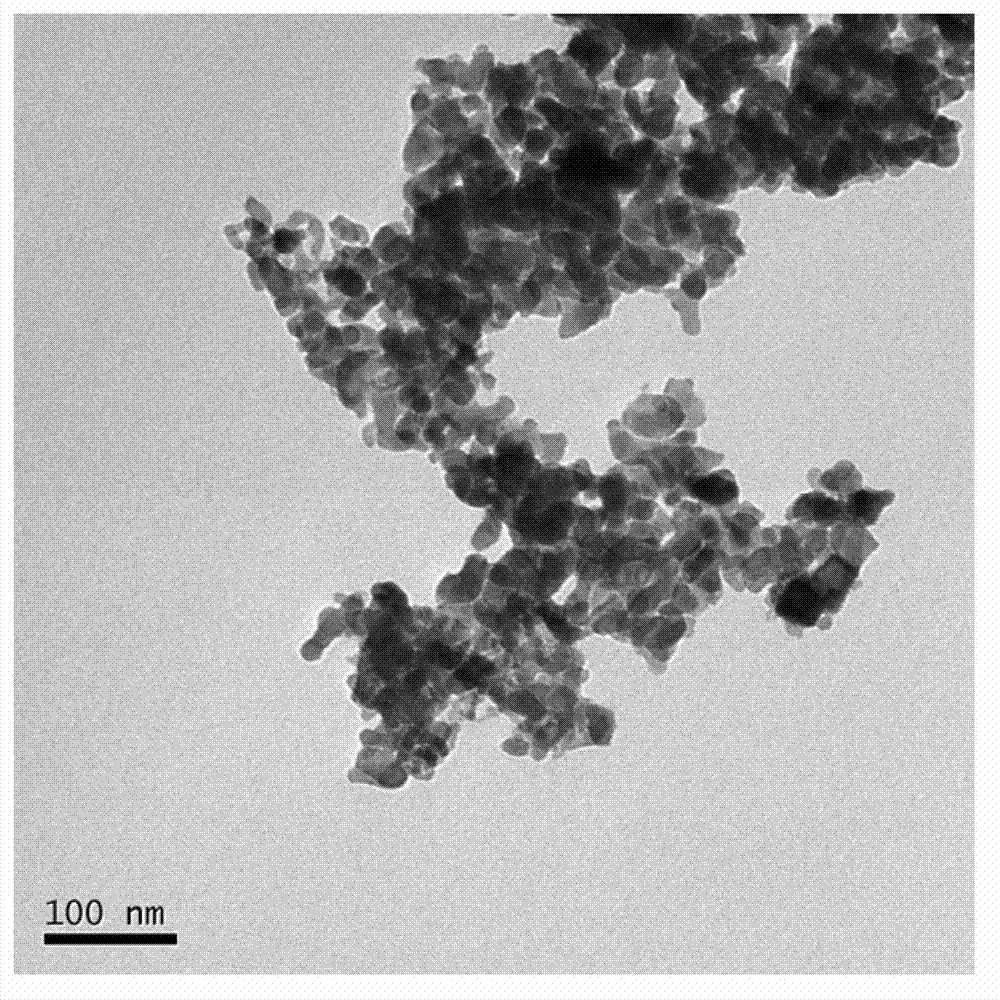

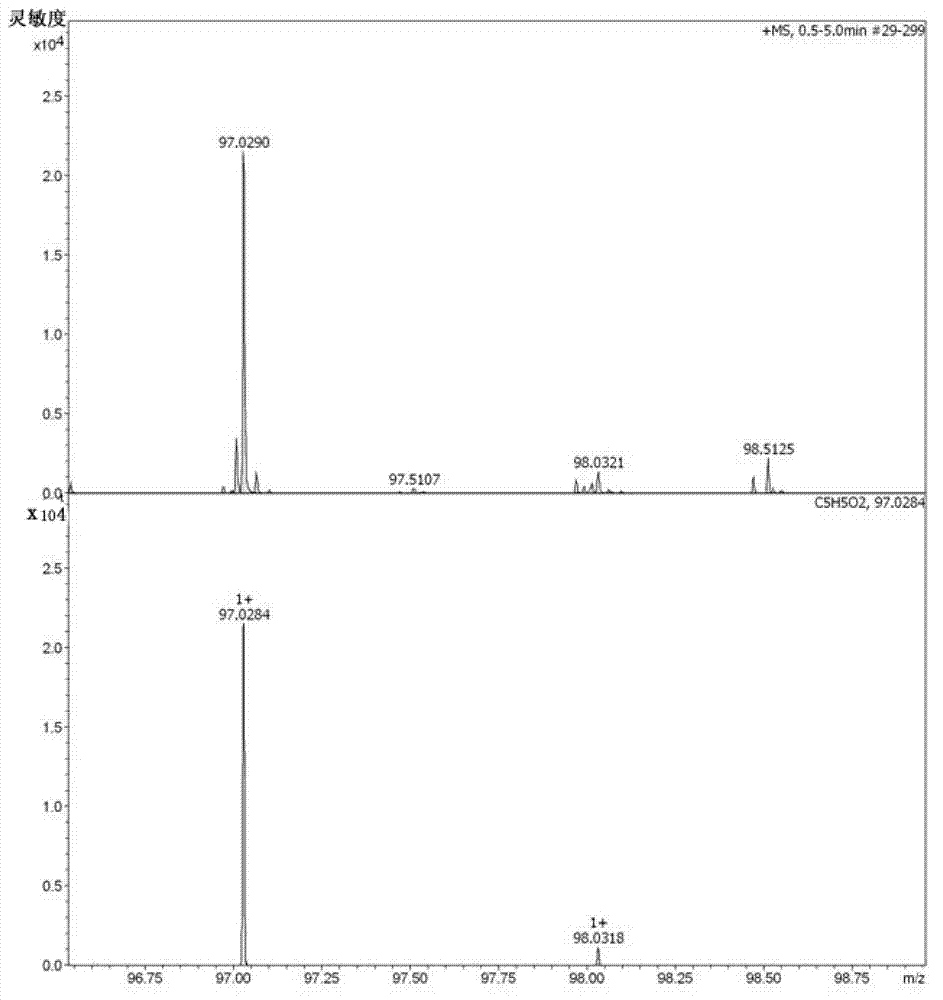

[0022] (1) Preparation of composite oxide solid catalyst by co-precipitation method: 6.445g ZrOCl 2 .8H 2 O, 0.013g La(NO 3 ) 3 .6H 2 O was dissolved in 100mL ultrapure water, and 3.7938g of TiCl was added dropwise while stirring 4 Solution, and then adjust the pH to 8 with concentrated ammonia water, stand still at 25°C for 16h, dry at 100°C for 16h, grind, and calcinate at 450°C for 3h in a muffle furnace to obtain TiO 2 -ZrO 2 / La; figure 1 Be the infrared spectrogram of gained product, figure 11400cm -1 is a solid catalyst TiO 2 -ZrO 2 characteristic absorption peaks. figure 2 It is a transmission electron microscope picture of the obtained product, and it can be seen from the figure that the obtained product is a nano-scale round particle and has a strong aggregation effect.

[0023] (2) Hydrolysis reaction: put 0.2 xylose and 0.01 g of the composite oxidation catalyst prepared in step (1) into a three-necked flask, add 10 mL of distilled water, and react at 10...

Embodiment 2

[0031] (1) Composite oxidation catalyst prepared by co-precipitation method: 6.445g ZrOCl 2 .8H 2 O, 0.65g La(NO 3 ) 3 .6H 2 O was dissolved in 100mL ultrapure water, and 7.5876g of TiCl was added dropwise while stirring 4 Solution, and then adjust the pH to 10 with concentrated ammonia water, stand at 30°C for 24h, dry at 110°C for 30h, grind, and calcinate in a muffle furnace at 550°C for 5h to obtain TiO 2 -ZrO 2 / La;

[0032] (2) Hydrolysis reaction: put 0.2 xylose and 0.1 g of the composite oxidation catalyst ore prepared in step (1) into a three-necked flask, add 60 mL of distilled water, and react at 140 ° C for 8 h;

[0033] (3) Post-treatment: After the reaction in step (2), cool naturally, filter with suction, distill and concentrate the filtrate, extract with dichloromethane, and distill to obtain furfural.

[0034]Calculated by the method described in Example 1, the yield of furfural in this example is 766.5 μmol / g, and the conversion rate of xylose is 44%. ...

Embodiment 3

[0036] (1) Composite oxidation catalyst prepared by co-precipitation method: 6.445g ZrOCl 2 .8H 2 O, 1.3g La(NO 3 ) 3 .6H 2 O was dissolved in 100mL ultrapure water, and 11.3814g of TiCl was added dropwise while stirring 4 Solution, then adjust the pH to 12 with concentrated ammonia water, stand still at 40°C for 36h, dry at 120°C for 40h, grind, and calcinate in a muffle furnace at 650°C for 3h to obtain TiO 2 -ZrO 2 / La;

[0037] (2) Hydrolysis reaction: put 0.2 xylose and 0.02 g of the composite oxidation catalyst ore prepared in step (1) into a three-necked flask, add 100 mL of distilled water, and react at 180 ° C for 12 h;

[0038] (3) Post-treatment: After the reaction in step (2), cool naturally, filter with suction, distill and concentrate the filtrate, extract with dichloromethane, and distill to obtain furfural.

[0039] Calculated by the method described in Example 1, the yield of furfural in this example is 1022.8 μmol / g, and the conversion rate of xylose i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com