Hooping type steel sheet pile cofferdam platform and integrated construction method depending on cofferdam platform

A technology of steel sheet pile cofferdam and steel sheet pile, which is applied in basic structure engineering, construction and other directions to achieve the effect of simplifying construction procedures, saving cost and construction period, and reducing construction unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

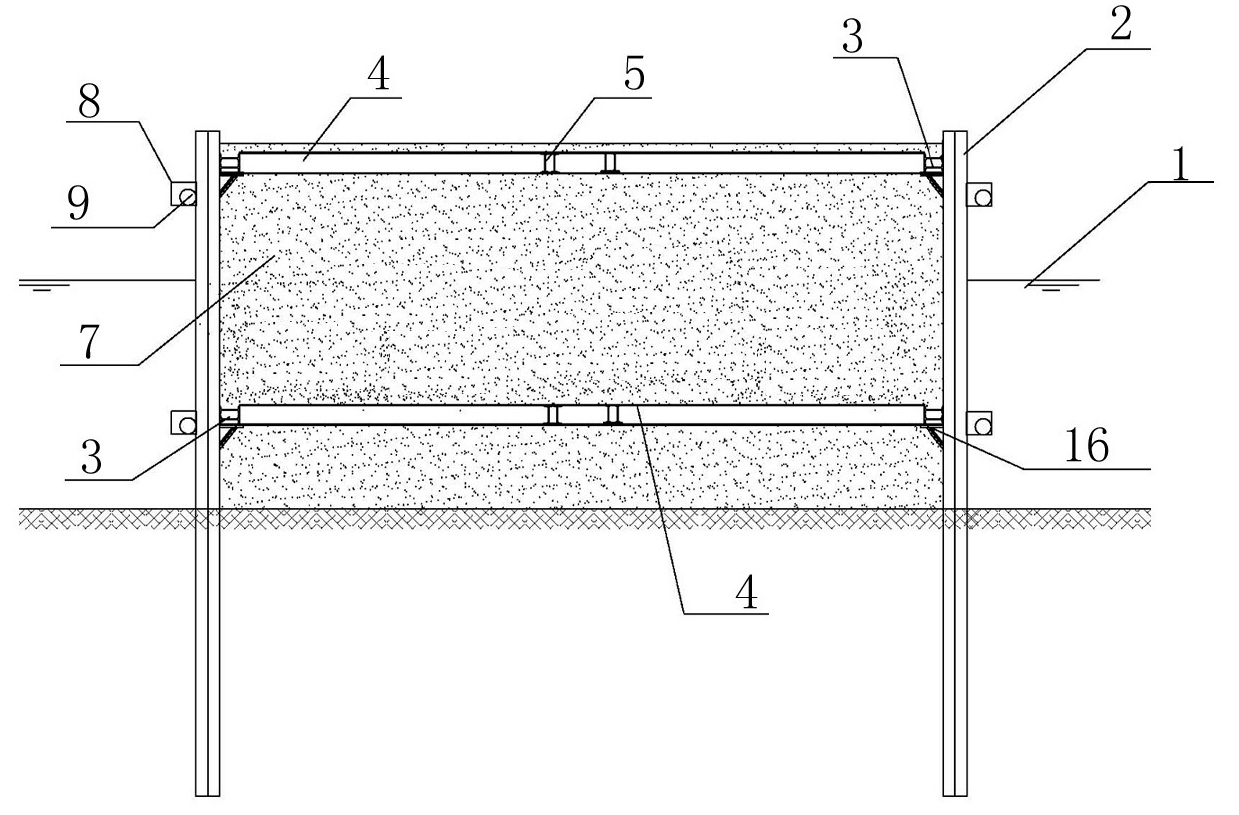

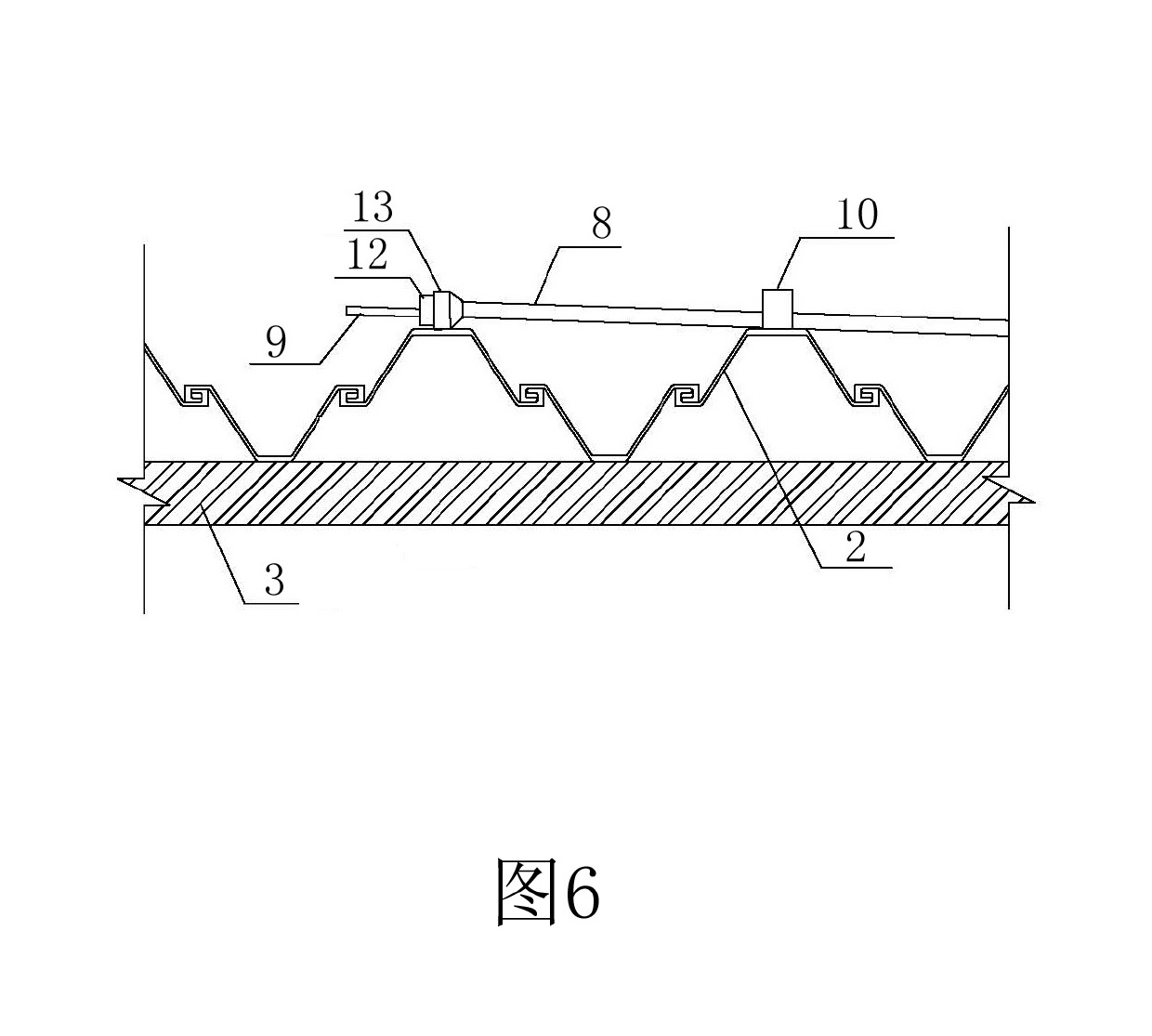

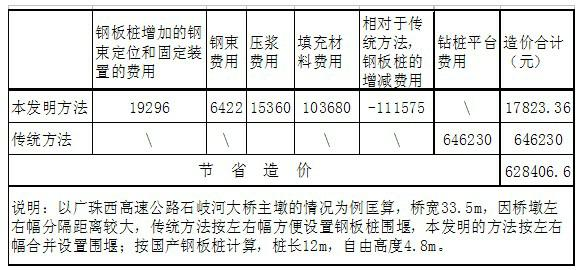

[0041] Examples see Figure 1-8 As shown, a hoop-type steel sheet pile cofferdam platform includes a cofferdam formed by a group of densely enclosed steel sheet piles 2 and an internal support system. The internal support system is supported inside the cofferdam, and the roots of the steel sheet piles 2 extend to the cofferdam. Below the base of the weir, the top of the steel sheet pile 2 is higher than the water surface 1, and the adjacent sides of the adjacent steel sheet piles are engaged with each other. The inner space of the cofferdam is filled with fillers 7, and there is at least a circle of steel beams 9 around the outer circumference of the cofferdam, one end of which passes through The fixed-end anchor 12 is fixed on the fixed-end anchor backing plate 13, and the other end is fixed on the tension-end anchor backing plate 15 through the tension-end anchor 14. positioning ring 10. The filling range of the filler 7 is from the bottom of the river bed to above the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com