Preparation method of sulfated carbonized corn cob catalyst and method for preparing furfural from xylose in presence of catalyst

A corncob and catalyst technology, which is applied in the field of catalyzing xylose to prepare furfural and sulfonating and carbonizing corncob catalysts, can solve problems such as lack of economical applicability, and achieve the advantages of low production cost, reduced production cost and avoidance of equipment corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

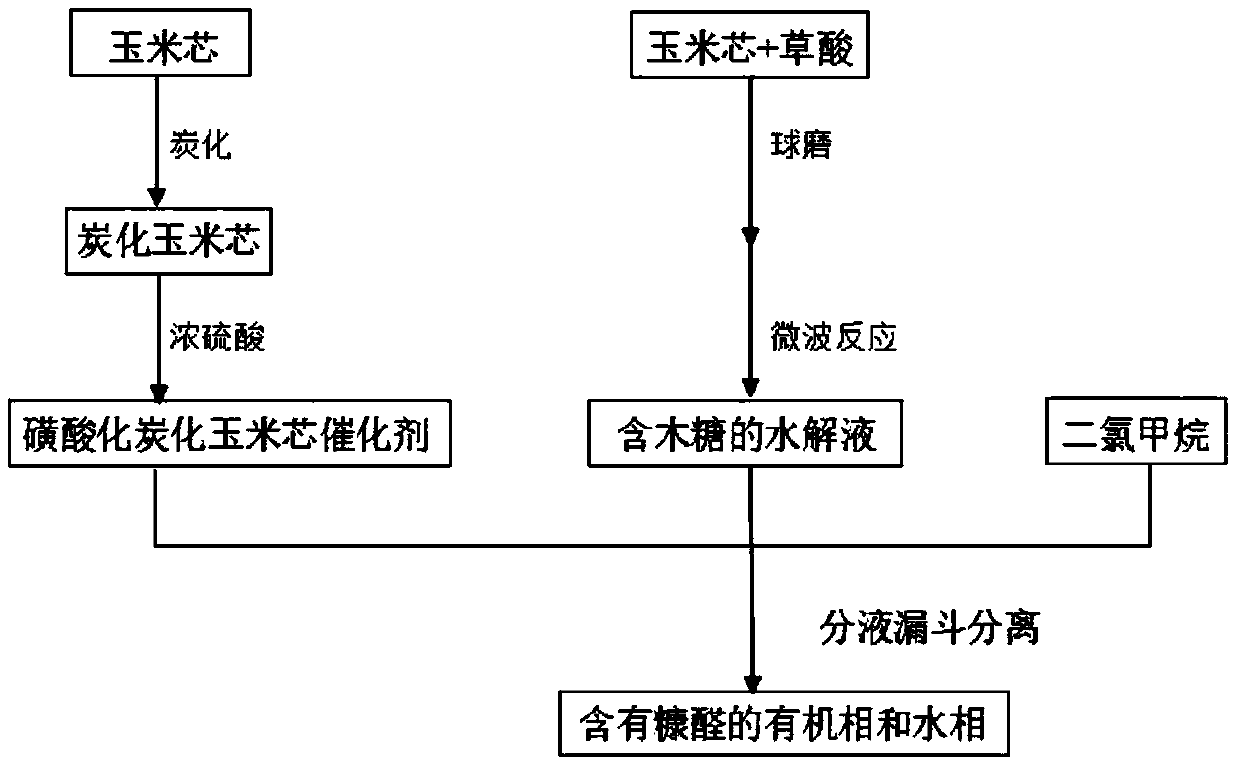

[0026] The preparation of a kind of sulfonated carbonized corn cob catalyst of the present embodiment and the method for preparing furfural by catalyzing xylose, its process flow chart is as follows figure 1 shown. Concrete preparation steps are as follows:

[0027] (1) Preparation of carbonized corn cobs: Add 5 g of dry corn cobs (80 mesh) into a ceramic crucible, place them in a vacuum tube furnace and seal them well, pass nitrogen gas at a flow rate of 40 mL / min, and carbonize at 400 °C. The time is 4h;

[0028] (2) Preparation of sulfonated carbonized corncob catalyst: add 0.8 g of the carbonized corncob obtained in step (1) and 24 mL of concentrated sulfuric acid into a tetrafluoroethylene reaction tank, place it in an oven at 145° C. for 14 hours, and after the reaction , cooled, filtered, the solid was washed until the pH was 6.8, and dried in an oven for 10 hours;

[0029] (3) Preparation of xylose-containing hydrolyzate: corn cob and oxalic acid are ball milled, th...

Embodiment 2

[0036] The preparation of a kind of sulfonated carbonized corn cob catalyst of the present embodiment and the method for preparing furfural by catalyzing xylose, its process flow chart is as follows figure 1 shown. Concrete preparation steps are as follows:

[0037] (1) Preparation of carbonized corn cobs: Add 6 g of dry corn cobs (100 mesh) into a ceramic crucible, place them in a vacuum tube furnace and seal them well, pass nitrogen gas at a flow rate of 50 mL / min, and carbonize at 450 °C. The time is 5h;

[0038] (2) Preparation of sulfonated carbonized corncob catalyst: add 1.0 g of the carbonized corncob obtained in step (1) and 30 mL of concentrated sulfuric acid into a tetrafluoroethylene reaction tank, place it in an oven at 150° C. for 15 hours, and after the reaction , cooled, filtered, the solid was washed until the pH was 7.0, and dried in an oven for 12 hours;

[0039] (3) Preparation of xylose-containing hydrolyzate: corn cob and oxalic acid are ball-milled, t...

Embodiment 3

[0046] The preparation of a kind of sulfonated carbonized corn cob catalyst of the present embodiment and the method for preparing furfural by catalyzing xylose, its process flow chart is as follows figure 1 shown. Concrete preparation steps are as follows:

[0047] (1) Preparation of carbonized corn cobs: Add 7 g of dry corn cobs (120 mesh) into a ceramic crucible, place them in a vacuum tube furnace and seal them well, pass nitrogen, the nitrogen flux is 60 mL / min, and the carbonization temperature is 500 ° C. The time is 6h;

[0048](2) Preparation of sulfonated carbonized corn cob catalyst: add 1.2 g of the carbonized corn cob obtained in step (1) and 36 mL of concentrated sulfuric acid into a tetrafluoroethylene reaction tank, place it in an oven and react at 155 ° C for 16 h, after the reaction , cooled, filtered, the solid was washed until the pH was 7.2, and dried in an oven for 14 hours;

[0049] (3) Preparation of xylose-containing hydrolyzate: corn cob and oxalic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com