Desulfurizer

A technology of desulfurization agent and auxiliary agent, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of energy consumption, desulfurization accuracy and low sulfur capacity, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

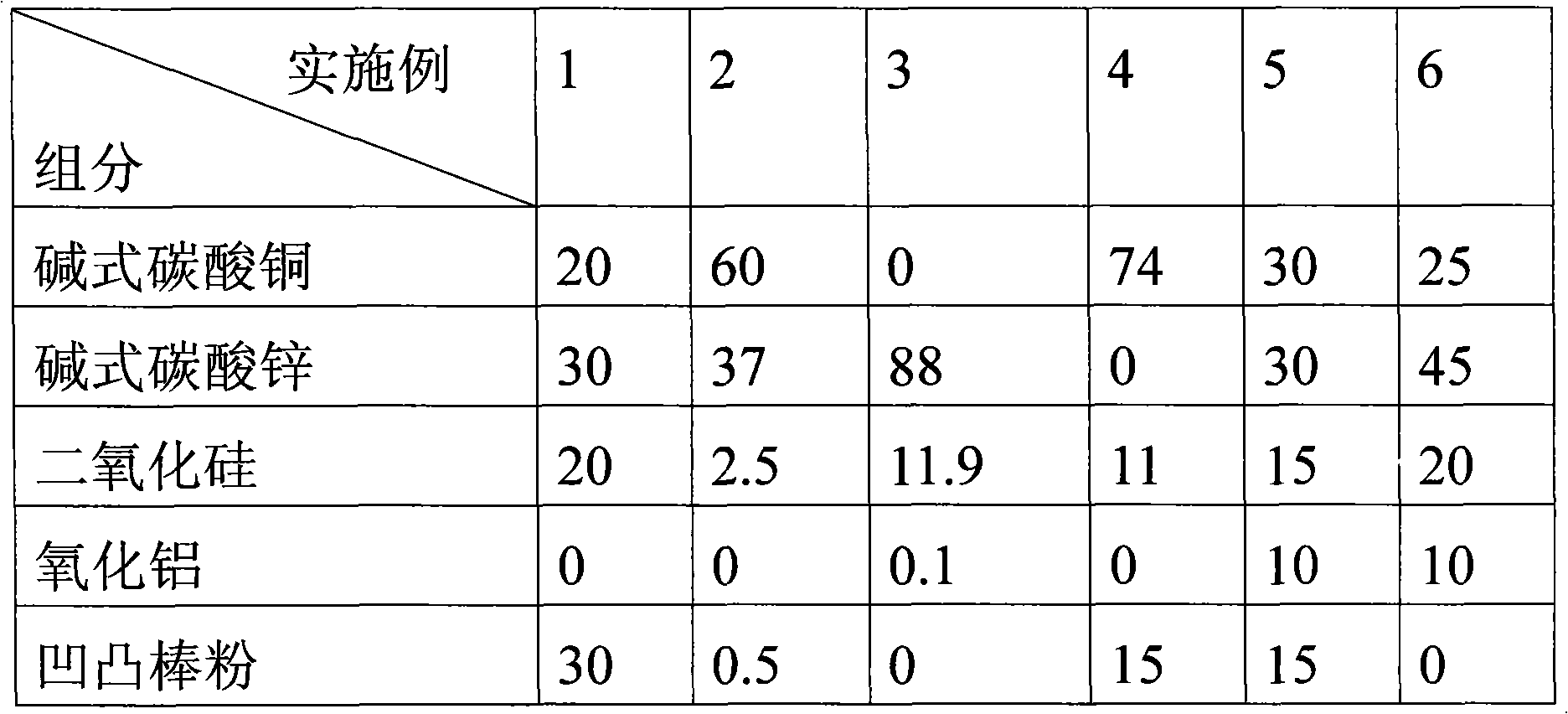

[0007] The embodiment formula of the present invention is shown in Table 1:

[0008] Table 1: (unit: account for the total weight percentage of desulfurizer, %)

[0009]

[0010] The preparation method of desulfurizing agent of the present invention is as follows:

[0011] Mix the powdered basic carbonate and powdered additives evenly, and then spray the silica sol (that is, the hydrate of silicon dioxide, mSiO 2 nH 2 O), formed by ball rolling or extrusion, and then dried at 80-200°C to obtain the finished desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com