Patents

Literature

91results about How to "Easy to vaporize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously preparing modified polyester

ActiveCN101735430AEvenly dispersedExtended stayMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentPolymer scienceEsterification reaction

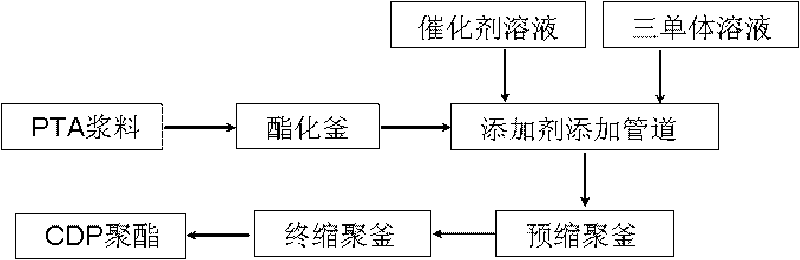

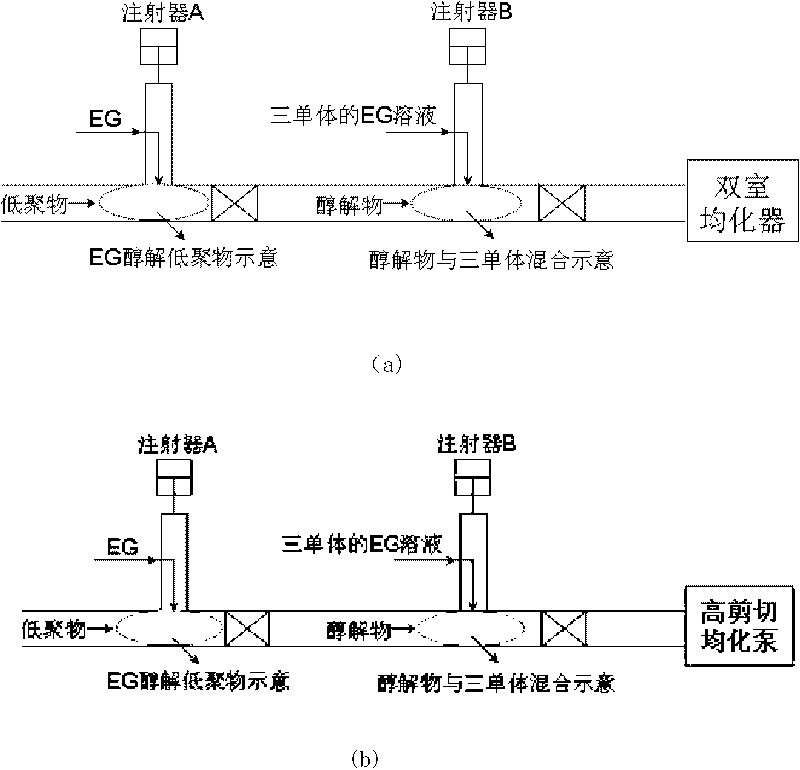

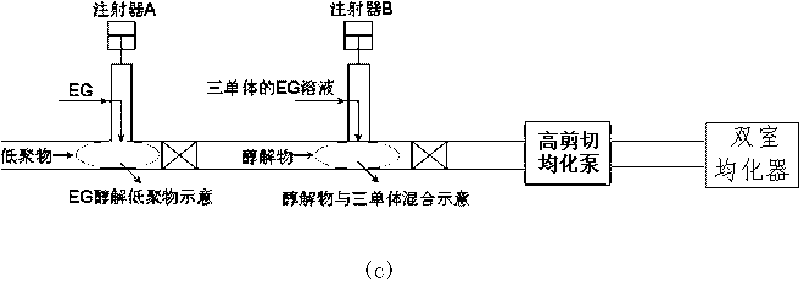

The invention relates to a method for continuously preparing modified polyester, comprising the following steps: conveying PET AND EG to an esterification autoclave from a feed port for esterification reaction, so as to obtain terephthalic acid ethylene glycol low polymer; then inputting the low polymer melt to a polycondensation autoclave through a pipeline for polymerization reaction with SIPM or multi-simplexes and addition agent, thus obtaining modified polyester melt and then carrying out granulation or direct spinning; wherein the two ends of the pipeline are respectively connected with the esterification autoclave and the polycondensation autoclave, when the low polymer melt flows through the pipeline, ethylene glycol solution of the SIPM or multi-simplexes and addition agent are added to the pipeline and mixed evenly with the low polymer melt in the pipeline, meanwhile the later-stage esterification reaction is carried out, and the mixture enters the polycondensation autoclave for polymerization reaction. With the method of the invention adopted, continuous industrialized production is realized, production cost is greatly reduced; in addition the SIPM or multi-simplexes with special groups are evenly distributed on the backbone of the polyester, as a result, high quality modified polyester products can be obtained for sure in the later stage.

Owner:SHANGHAI JUYOU CHEM ENG

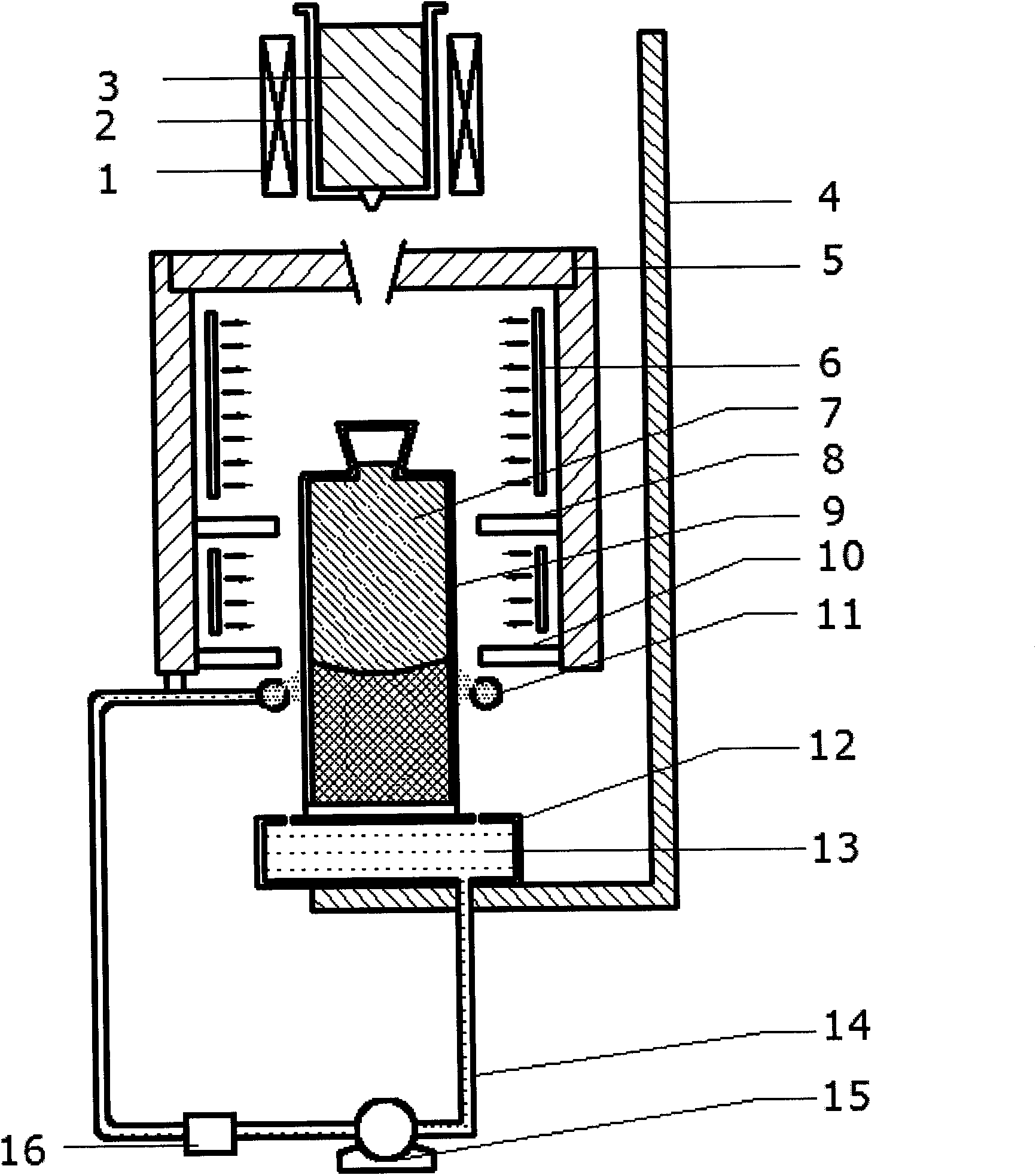

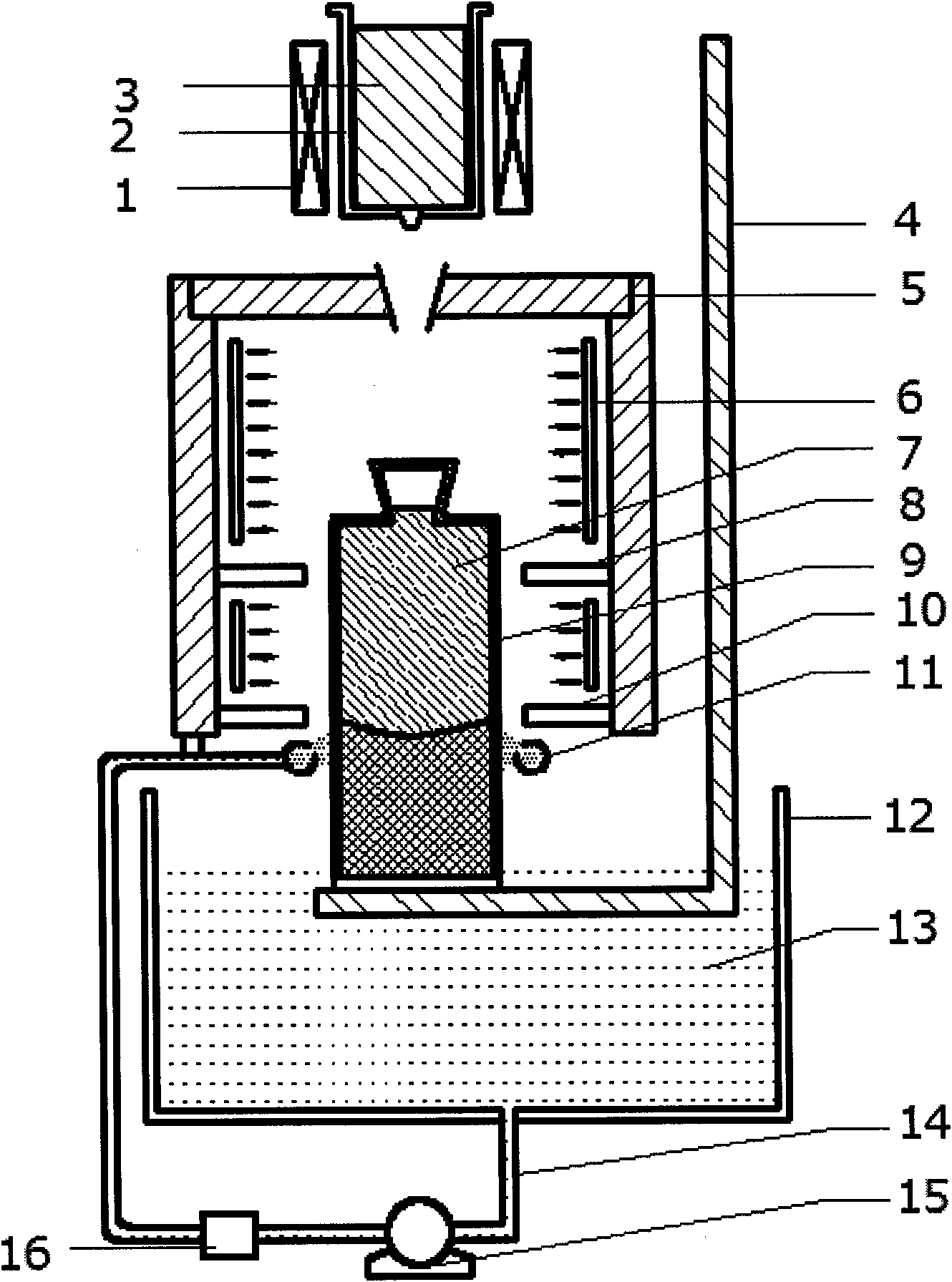

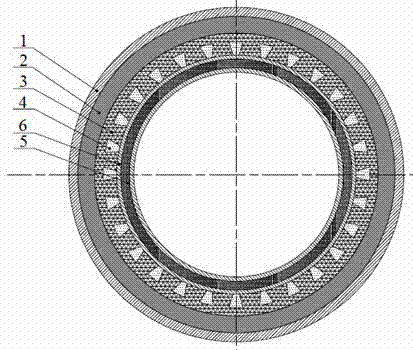

Cooling method used for directional solidification and cooling device therefor

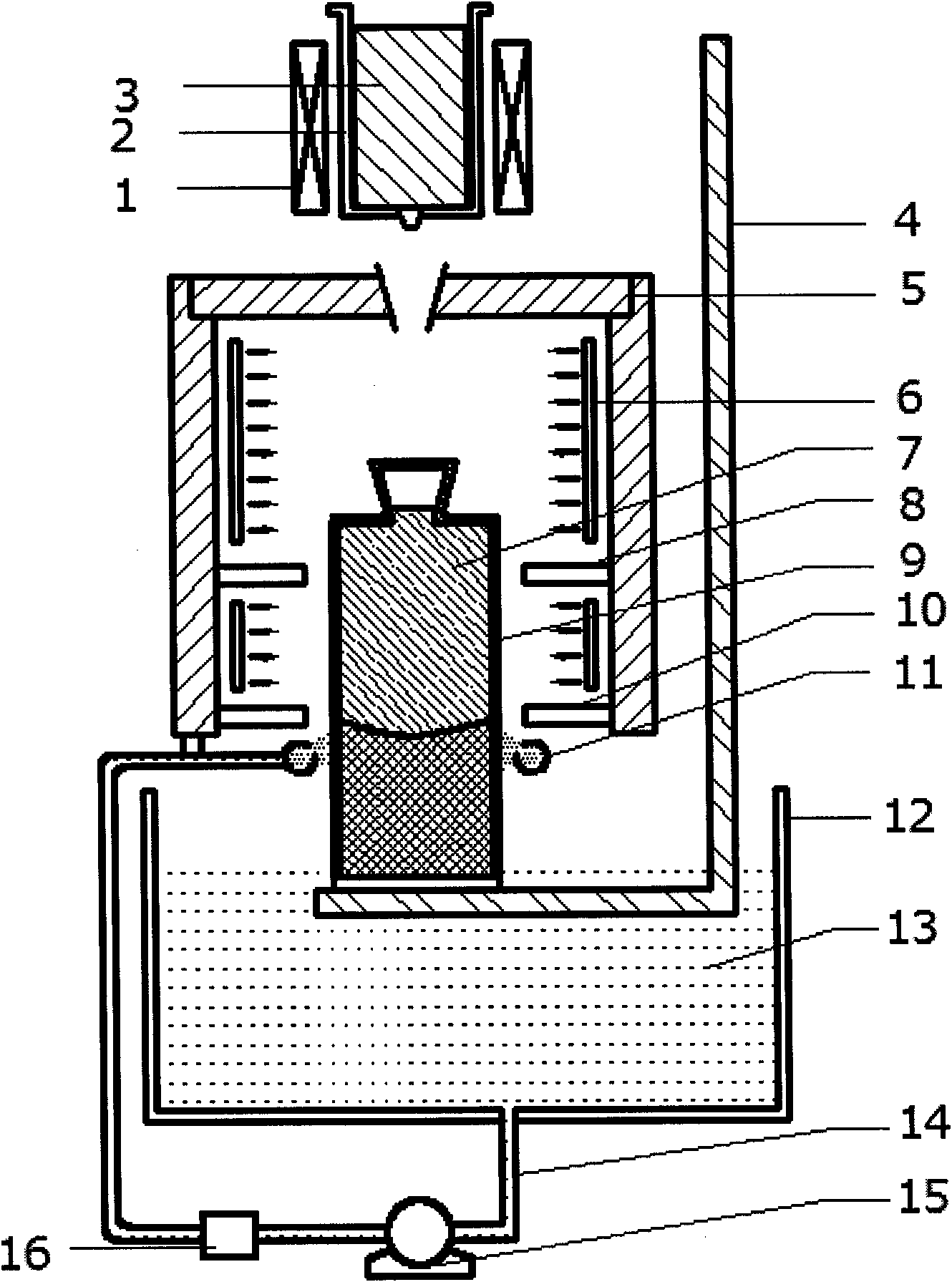

InactiveCN101786156ARaise the temperature gradientImprove heat transfer efficiencyLiquid stateLiquid metal

The invention relates to a cooling method used for directional solidification and a cooling device therefor. In the method, liquid metal is taken as cooling liquid, and a formwork is cooled by adopting the spray cooling method independently or adopting the spray cooling method and the immersion cooling method simultaneously. For the cooling device, a liquid metal spraying device is arranged under a direction solidification holding furnace, and the liquid metal is taken as the cooling liquid to cool the pull-down formwork by spraying independently or accompanying with the immersion. The invention has the advantages that the thermal radiation of a heating area and a cooling area for direction solidification can be insulated; and the cooling liquid is recycled, so as to cool the cooling liquid in cycling.

Owner:SHANGHAI UNIV

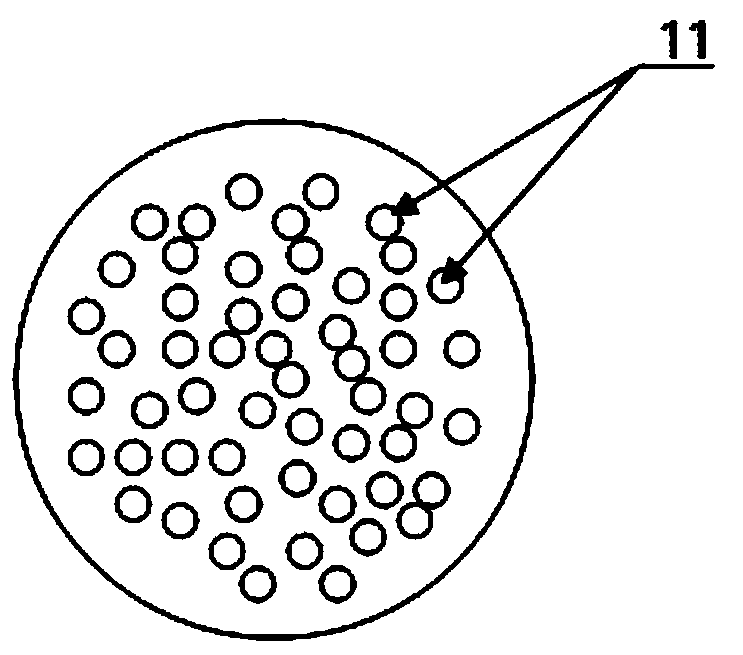

Spheroidizing agent of graphite

InactiveUS20070134149A1Inhibition formationOxidation easilyPigmenting treatmentGraphiteRare-earth elementGraphite

A graphite spheroidizing agent capable of spheroidizing graphite while preventing formation of chunky graphite is provided. The graphite spheroidizing agent of the present invention comprising silicon, magnesium, calcium and rare earth elements, wherein the graphite spheroidizing agent contains rare earth elements of 0.6 to 3.0 mass % and a calcium content of 1.3 to 4.0 mass %, respectively, relative to the total amount thereof, and a percentage of lanthanum in the rare earth elements is 50 mass % or more.

Owner:ASAHI TEC CORP

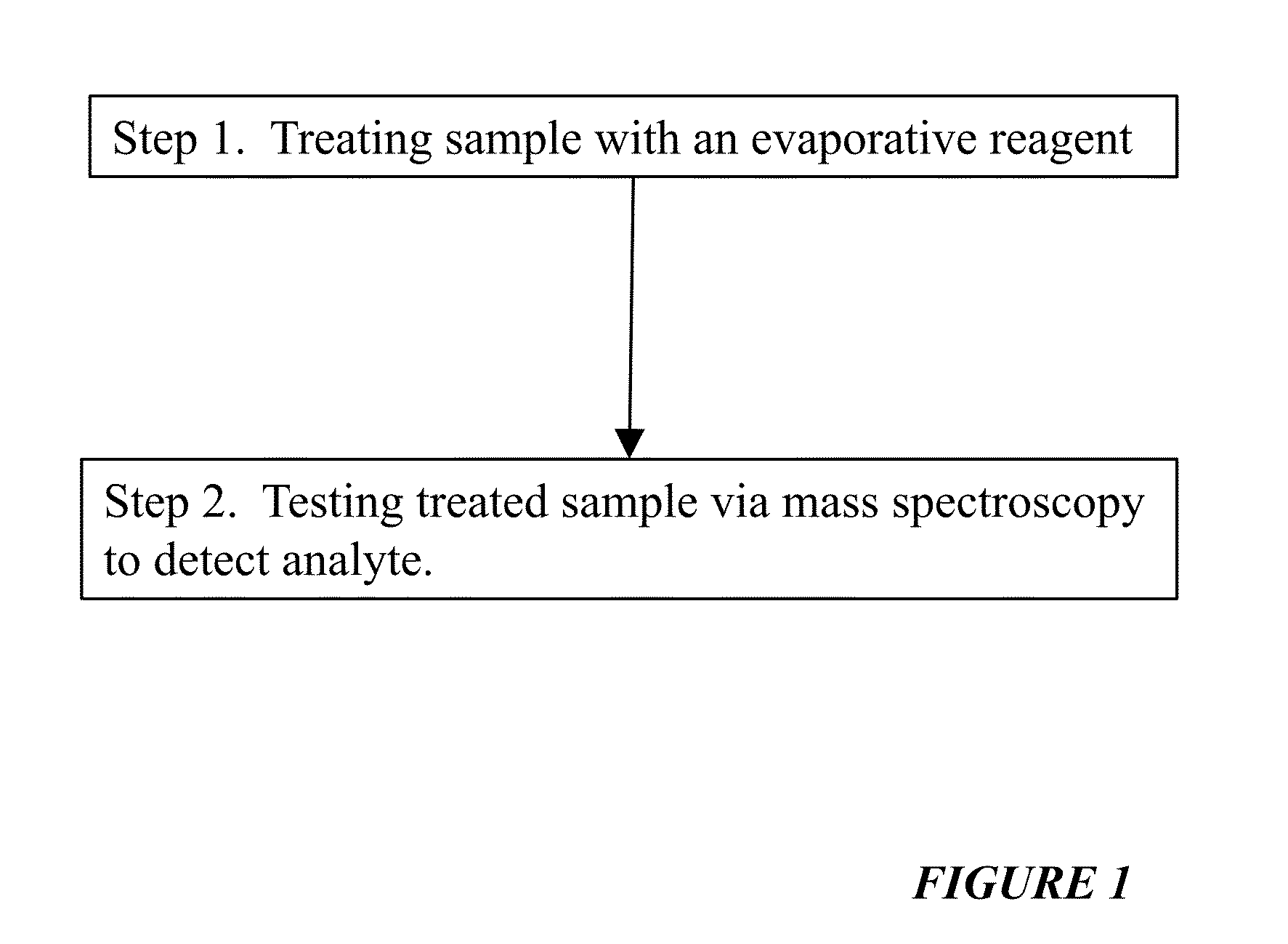

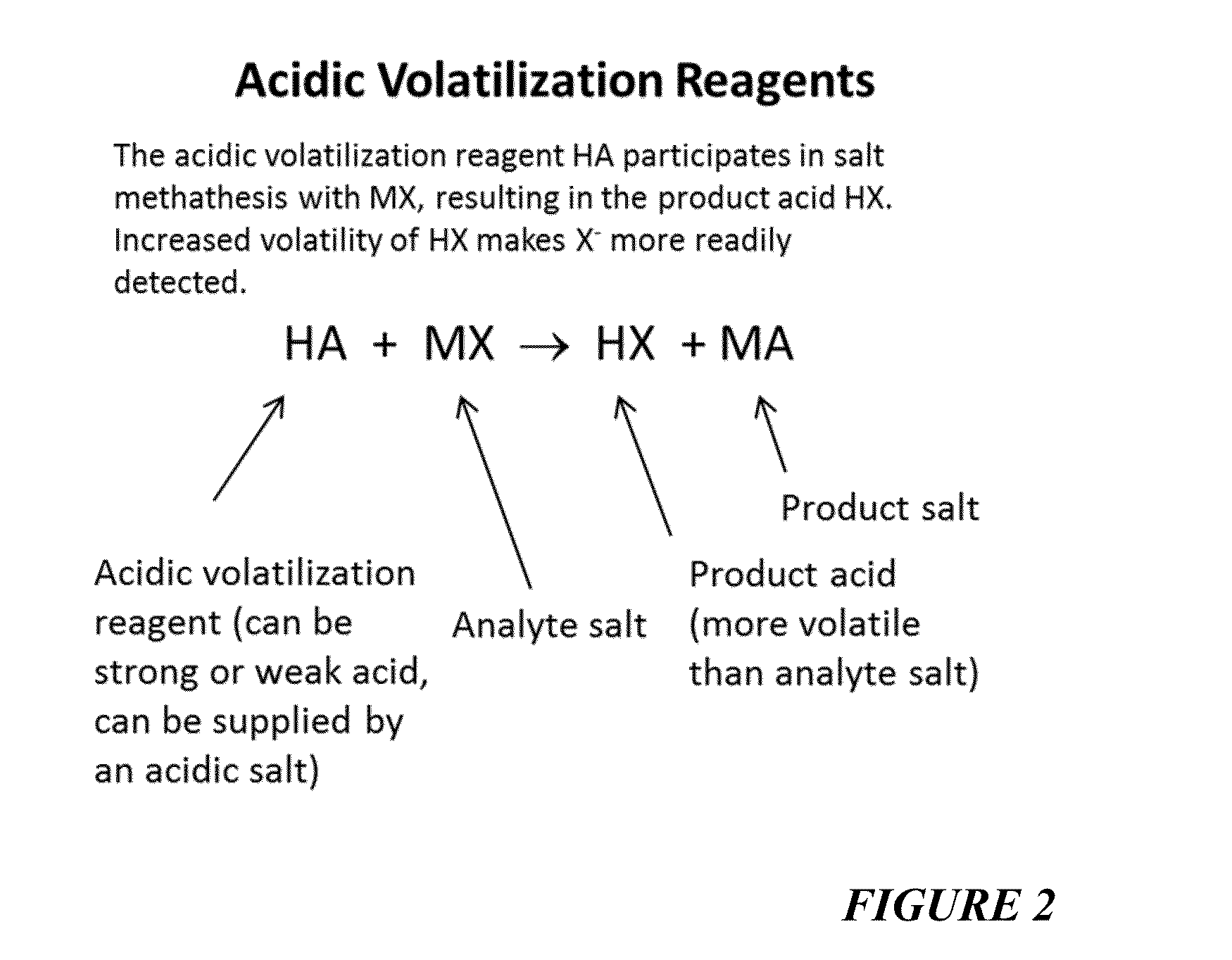

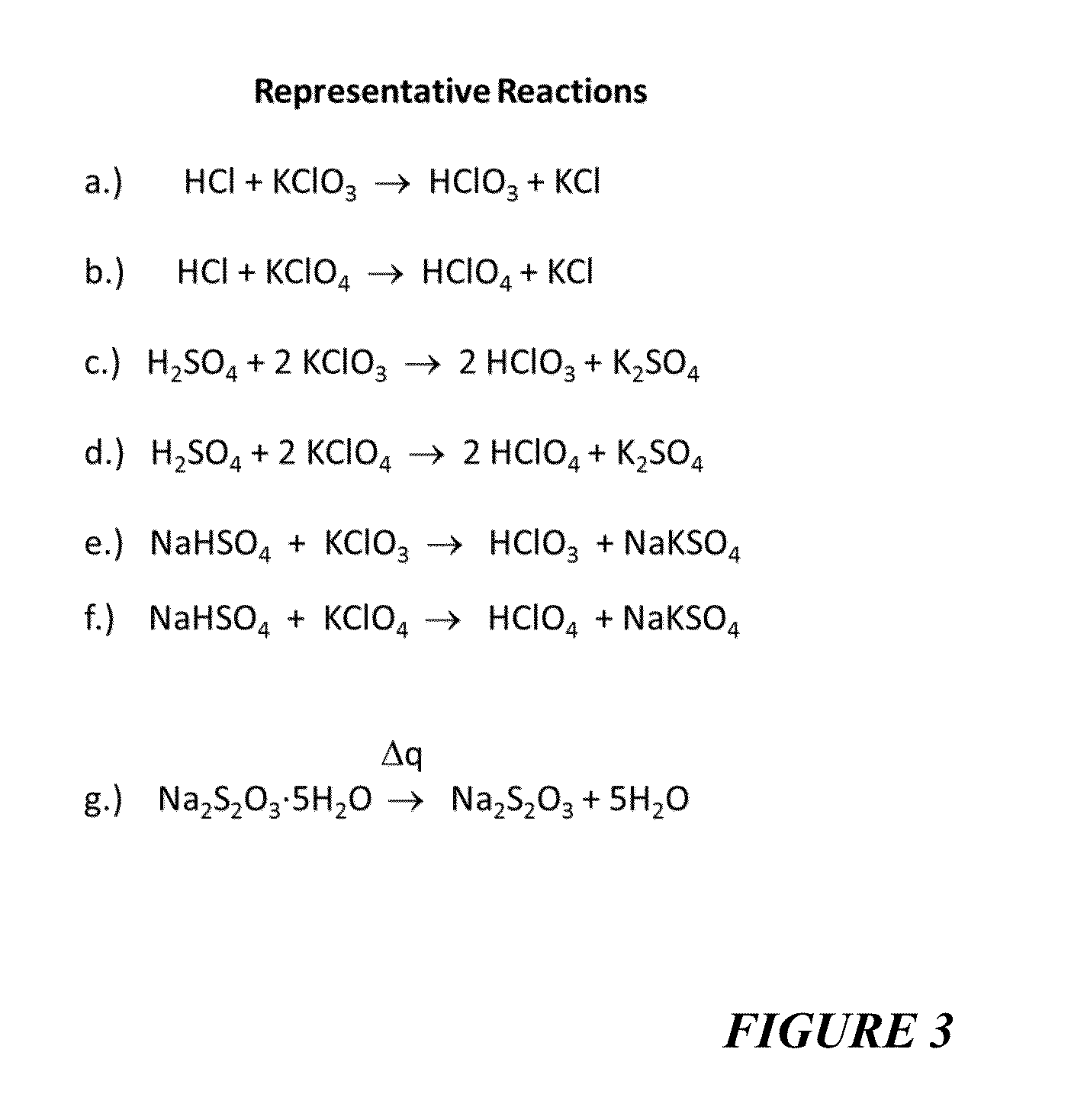

Reagents For Enhanced Detection Of Low Volatility Analytes

ActiveUS20150285780A1Easy to detectEasy to evaporateFuel testingMaterial analysis by electric/magnetic meansOrganic acidInorganic salts

The use of volatilization reagents is disclosed for improved detection of inorganic oxidizers such as, but not limited to, chlorates and perchlorates. Detection methods are disclosed whereby a reagent can transfer a proton to the anion (i.e., chlorate, perchlorate, etc.) of an inorganic salt analyte, forming an acid (i.e., chloric acid, perchloric acid) that is easier to detect by a mechanism whereby the acidified reagent is more easily vaporized, and hence, more easily detected. Concurrently, the anion of the acid forms a new salt with the cation released from the salt that was acidified. The reagents can also include acidic salts or cation-donators, more generally. In some embodiments, hydrated reagents or co-reagents that can release water can be employed. In another aspect of the invention, a class of reagents including polmeric acids, polymeric organic acids and polymeric sulfonic acids are disclosed that can carry out this method. In various embodiments, these reagents can be embedded in a swipe or other substrate, delivered as a liquid infused via nebulizer, or otherwise introduced to a sample to be tested for the presence of a target analyte.

Owner:MASSACHUSETTS INST OF TECH

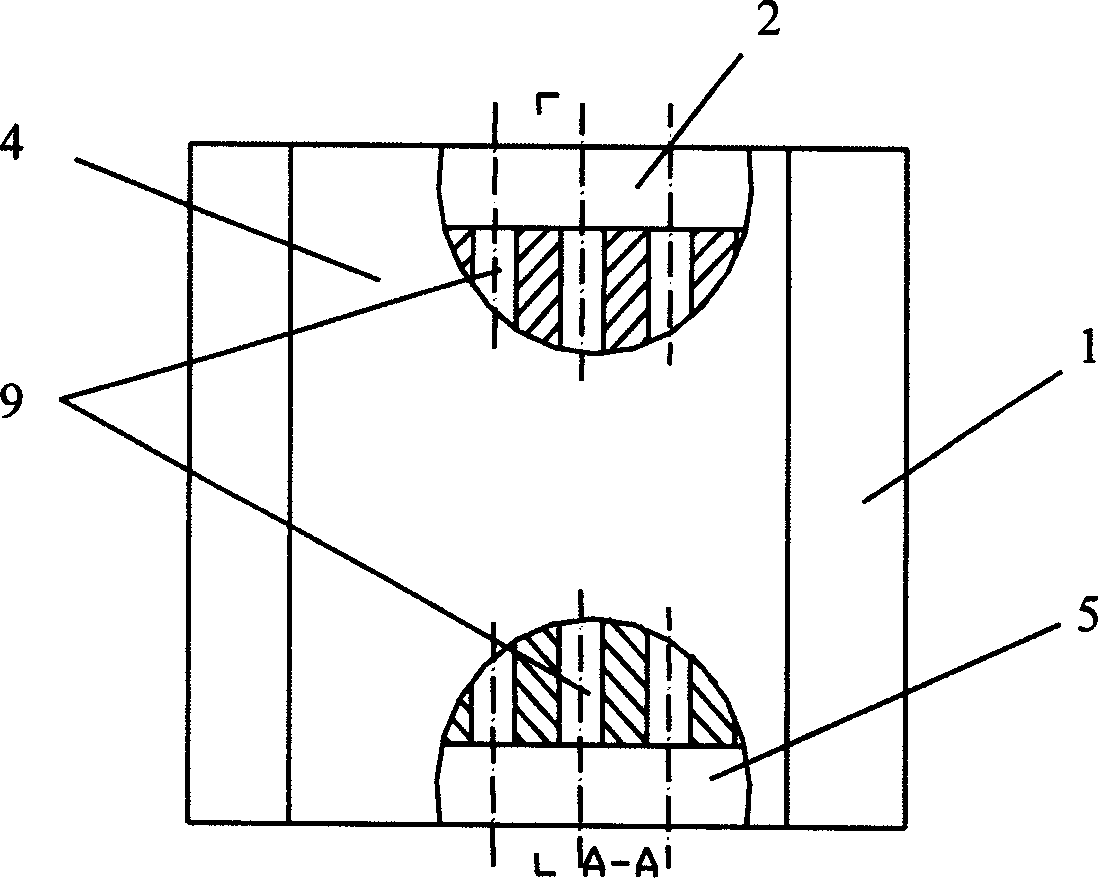

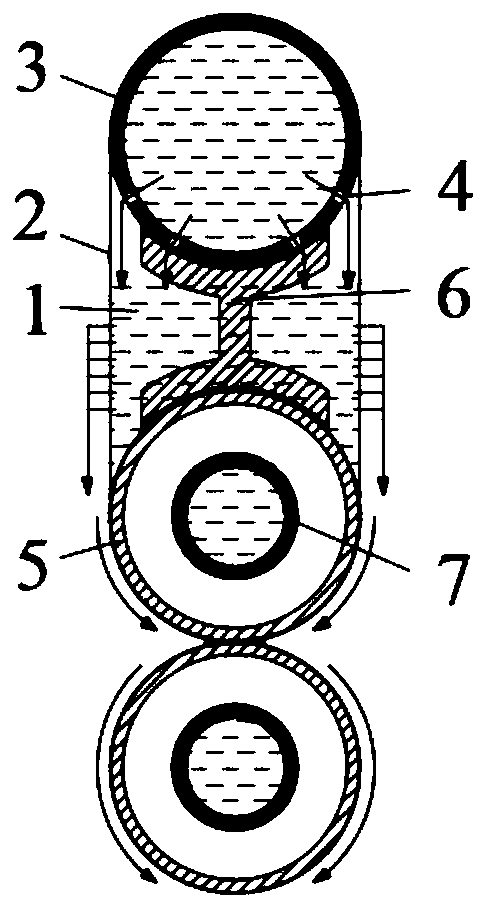

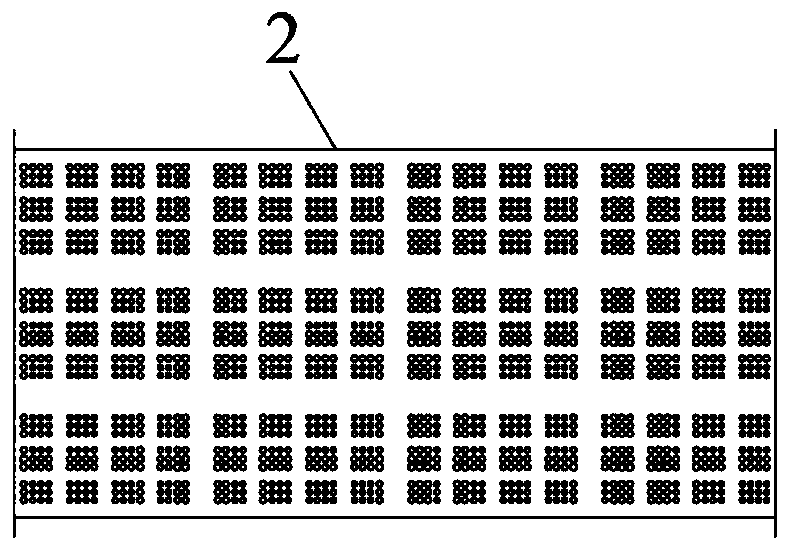

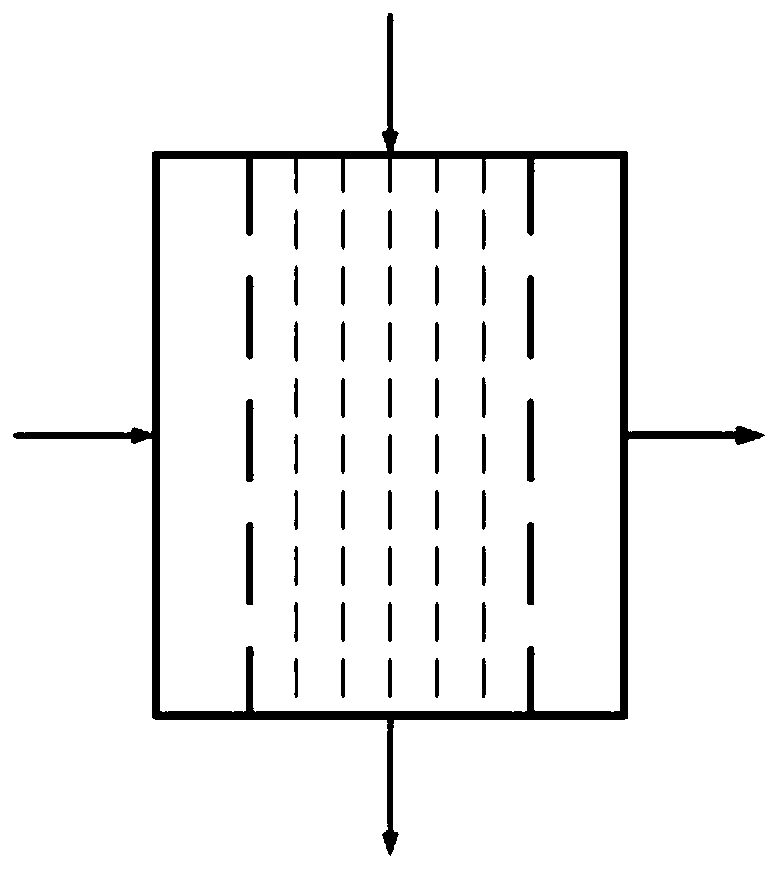

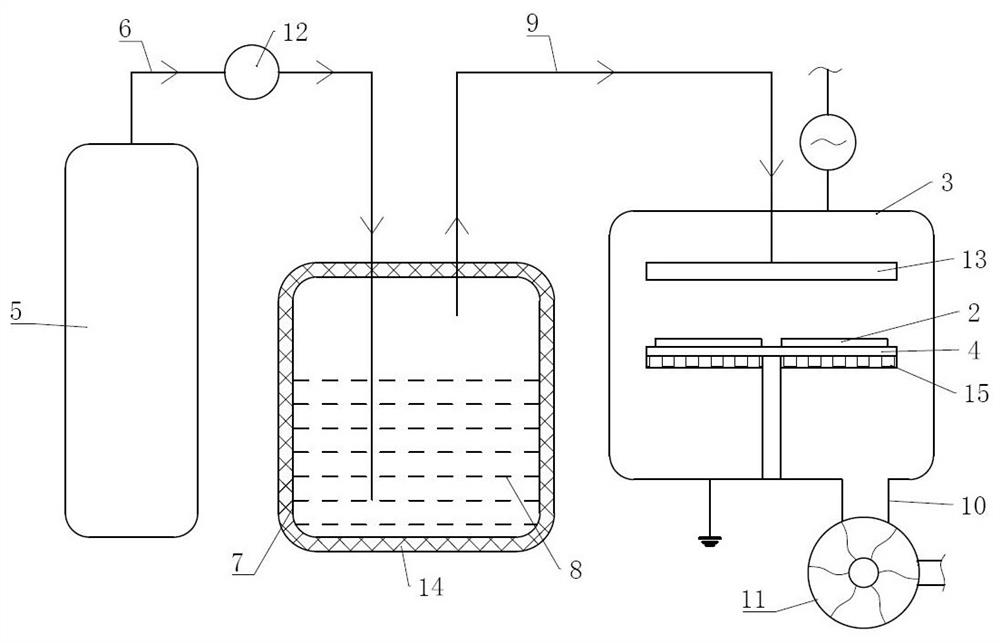

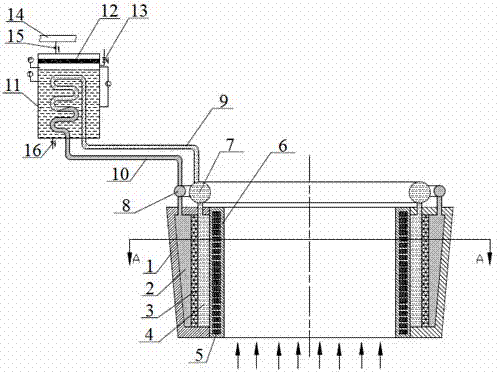

Evaporator for separated heat tube

InactiveCN1535748AIncrease the evaporative heat transfer areaSave the amount of working fluidEvaporationEvaporationEngineering

The present invention discloses an evaporator for separated heat pipe. It includes parallel-connected channels and metal plate. Said parallel-connected channels are integrally formed in the interiour of metal plate along the vertical direction. The top portion of the metal plate is equipped with a steam header formed into a hollow cavity communicated with upper end hole of the described channel, on the top cover of the steam header a steam outlet is set. The metal plate also includes a reflux system including recycle tube and liquid header formed into hollow cavity, the liquid header is communicated with exteriour of metal plate by means of recycle tube, and said liquid header is communicated with the described channel. Said invention also provides a reflux system correspondent to falling-film evaporation, the liquid header is positioned in the lower portion of upper end hole of the channel and close to upper end hole of the channel, and the upper end hole of liquid header is communiated with upper end hole of channel by means of steam header.

Owner:中科热科技江苏有限公司

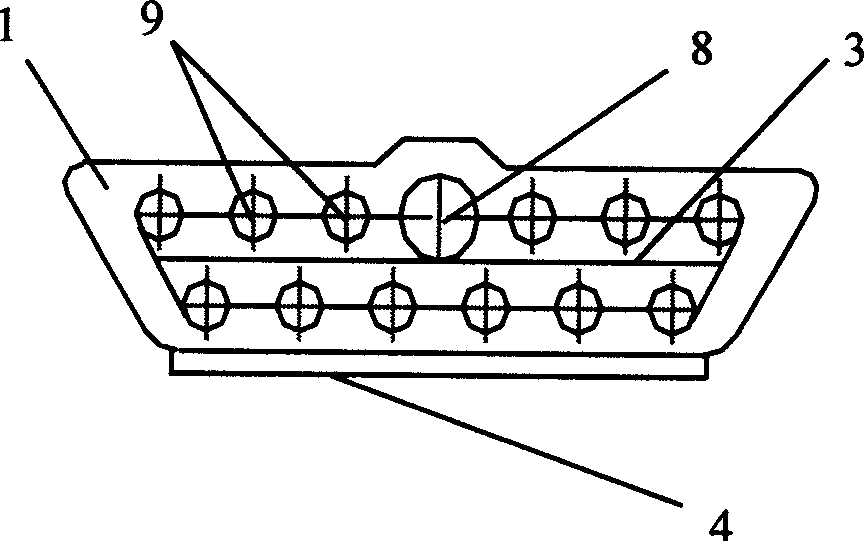

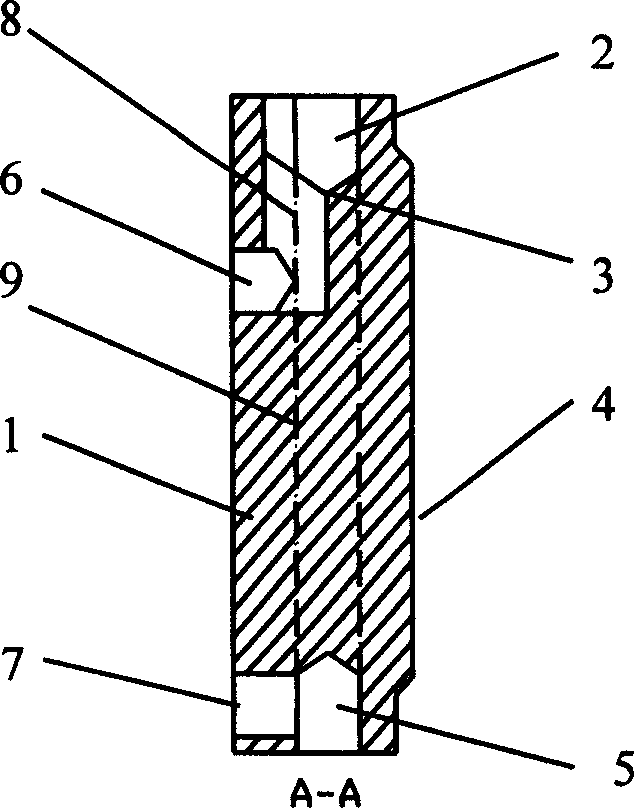

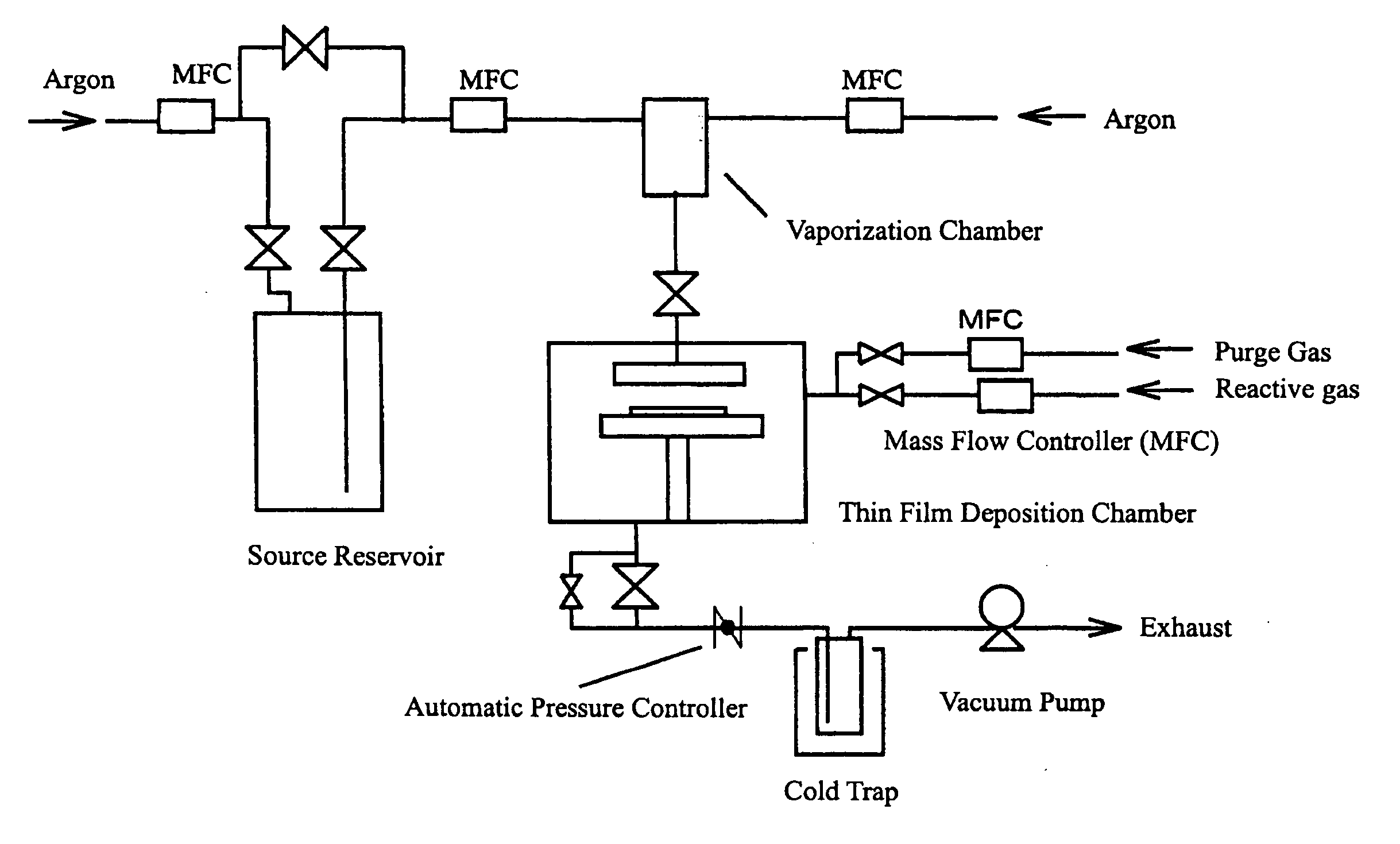

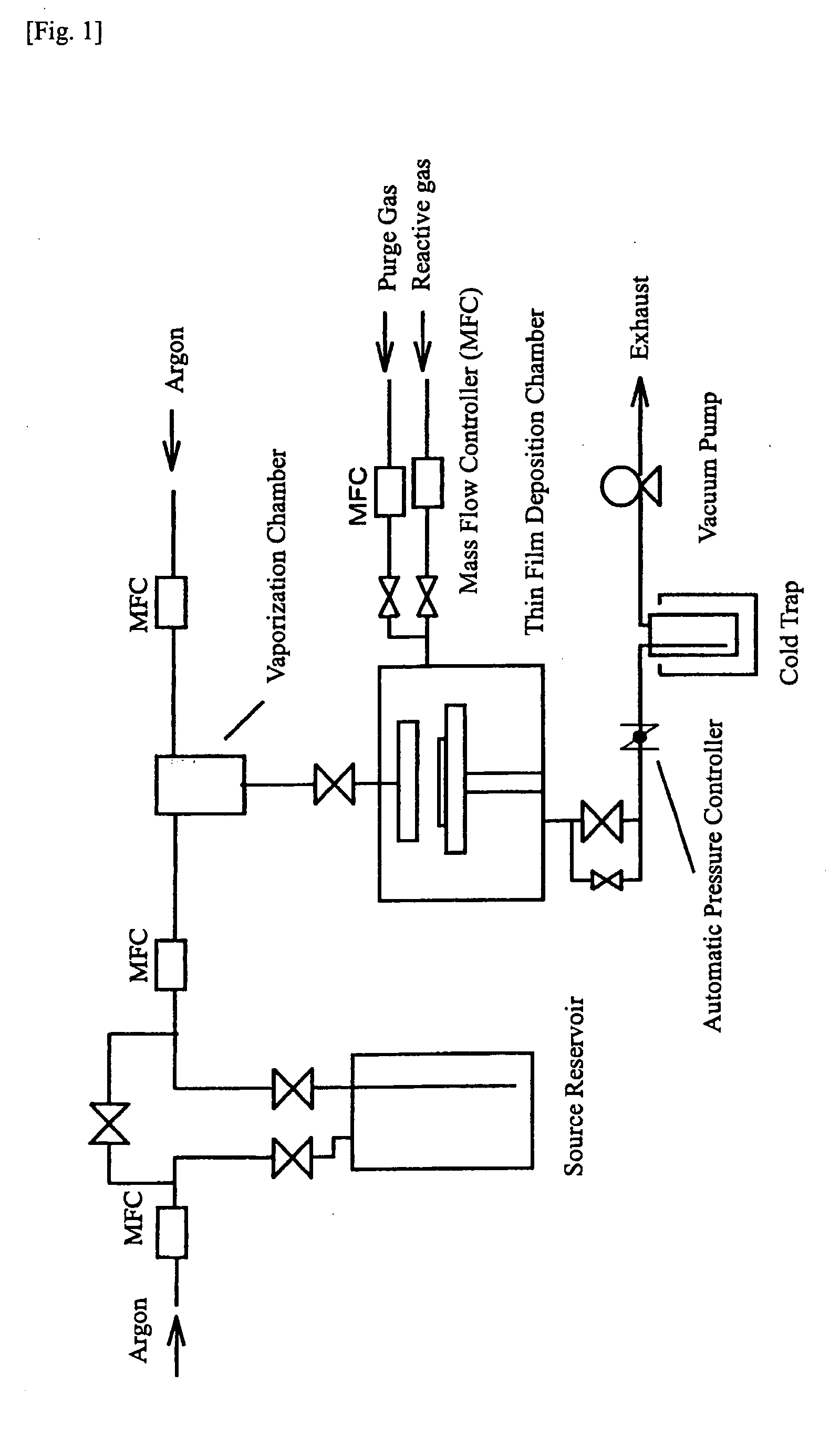

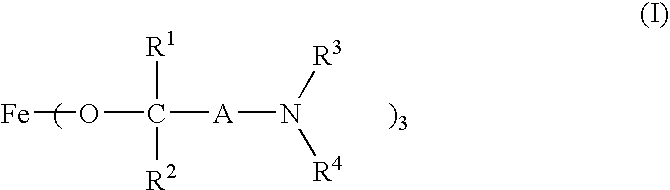

Alkoxide Compound, Thin Film-Forming Material And Method For Forming Thin Film

ActiveUS20080085365A1High vapor pressureEasy to vaporizeIron organic compoundsSemiconductor/solid-state device manufacturingVapor pressureLiquid state

The alkoxide compound of the present invention is represented by general formula (I) below. The alkoxide compound of the present invention is an iron compound that can be delivered in a liquid state and is easily vaporized due to its high vapor pressure. The compound particularly enables production of thin films with excellent composition controllability, and hence is suitable for producing multi-component thin films by CVD. (In the formula, R1 and R2 each independently represent a hydrogen atom or C1-4 alkyl group, R3 and R4 each represent a C1-4 alkyl group, and A represents a C1-8 alkanediyl group.)

Owner:ADEKA CORP

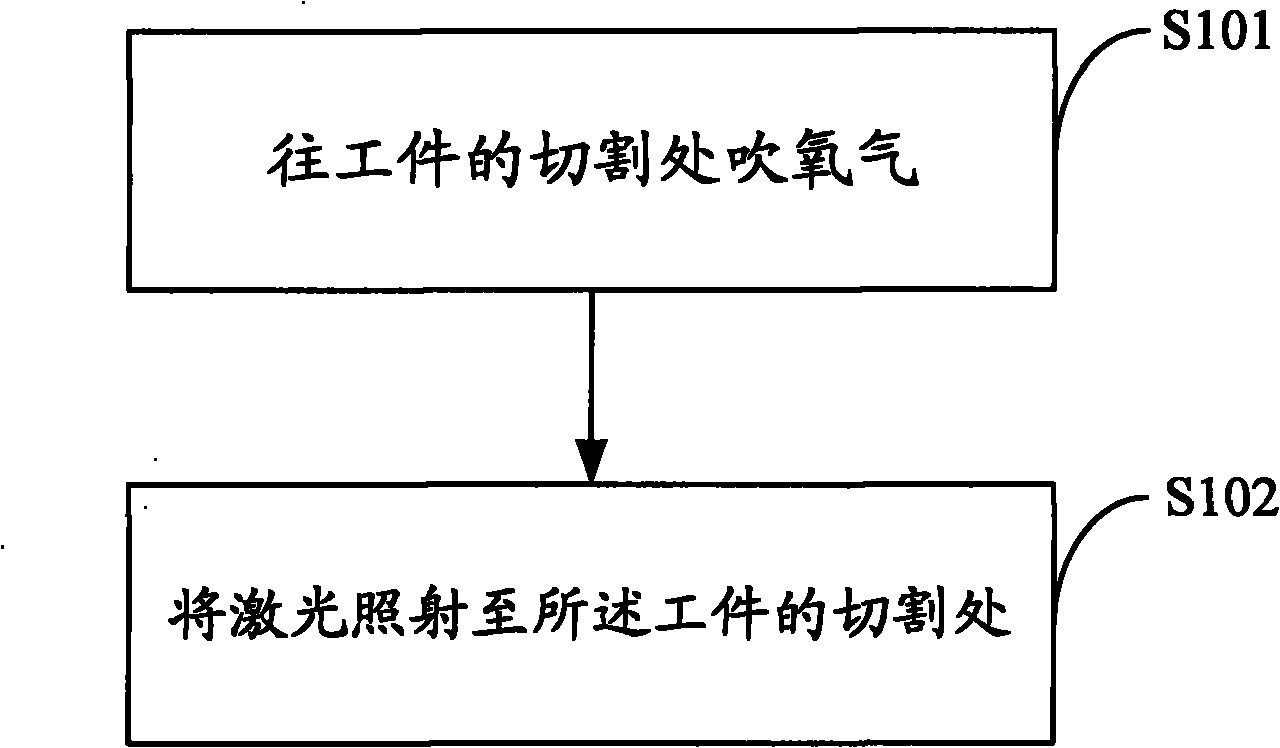

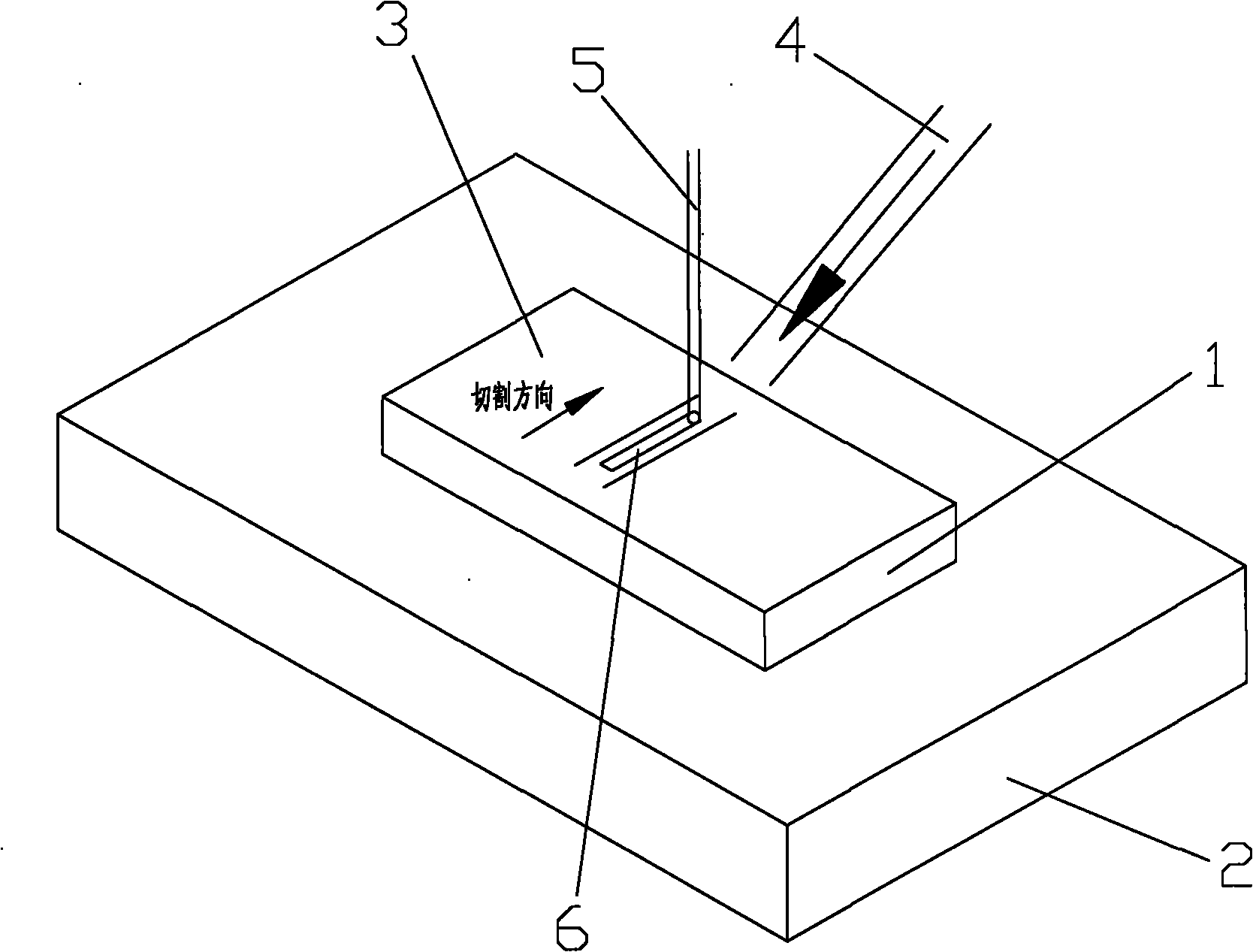

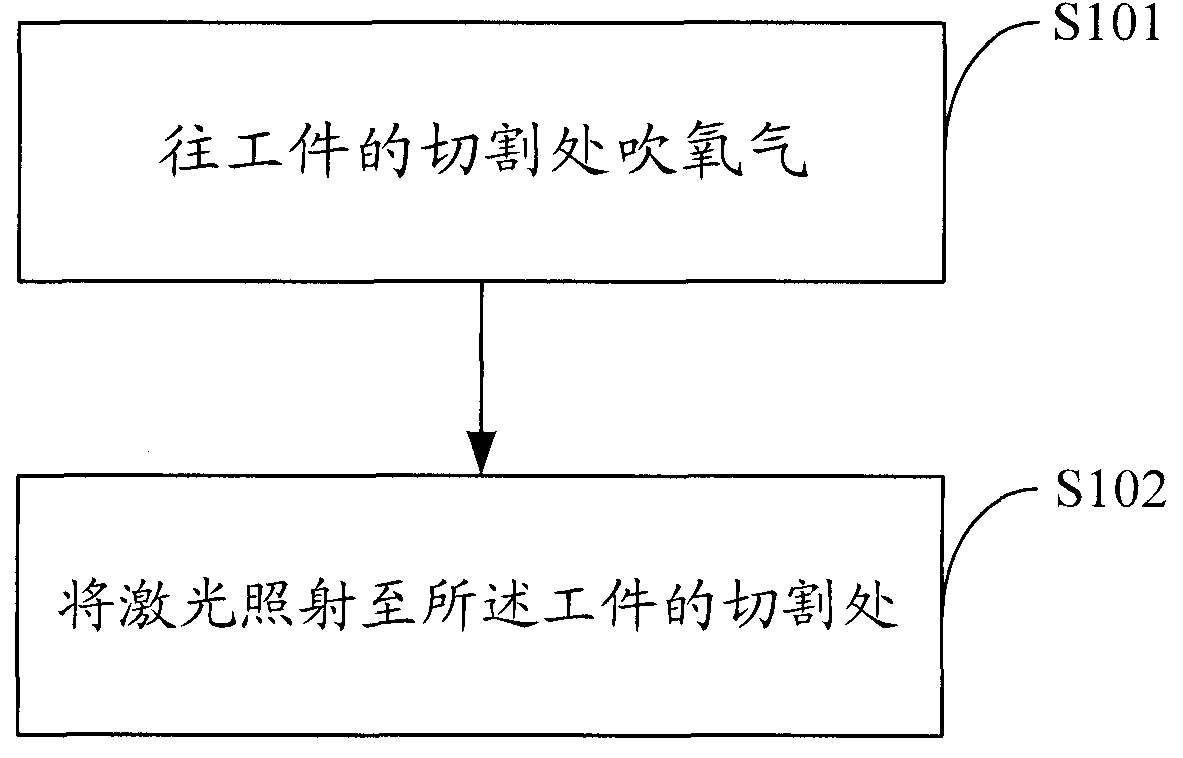

Laser cutting method and equipment

ActiveCN102211255AImprove the beam spectral absorption factorEasy to vaporizeLaser beam welding apparatusHeat-affected zoneLight beam

The invention is suitable for laser cutting, and provides a laser cutting method and laser cutting equipment. The method comprises the following steps of: blowing oxygen to a cut position of a workpiece; and irradiating laser to the cut position of the workpiece. The equipment comprises a gas blowing device for blowing the oxygen to the cut position of the workpiece, and a laser for irradiating the laser to the cut position of the workpiece. In the laser cutting method provided by the embodiment of the invention, the oxygen is blown to the cut position of the workpiece, so that a workpiece material is fully contacted with the oxygen and is quickly vaporized under the action of the laser, an oxide film generated by reacting the workpiece material with the oxygen improves the beam spectral absorption factor of a reflecting material in the workpiece, the blown oxygen takes molten oxide and vapor away and disperses heat outside the cut position simultaneously, a heat affected zone is small, a cut edge is difficult to carbonize, and product quality is high.

Owner:HANS CNC SCI & TECH

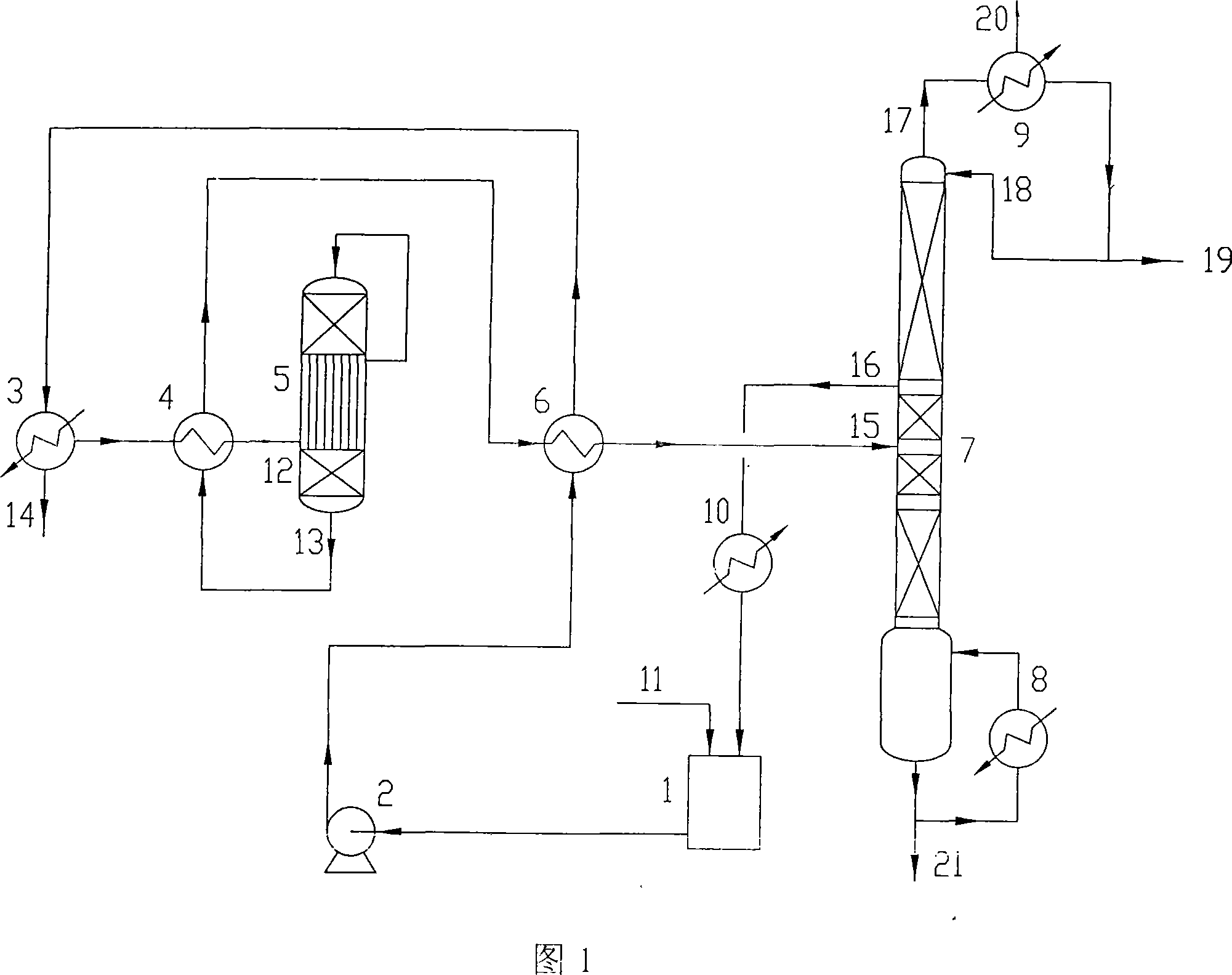

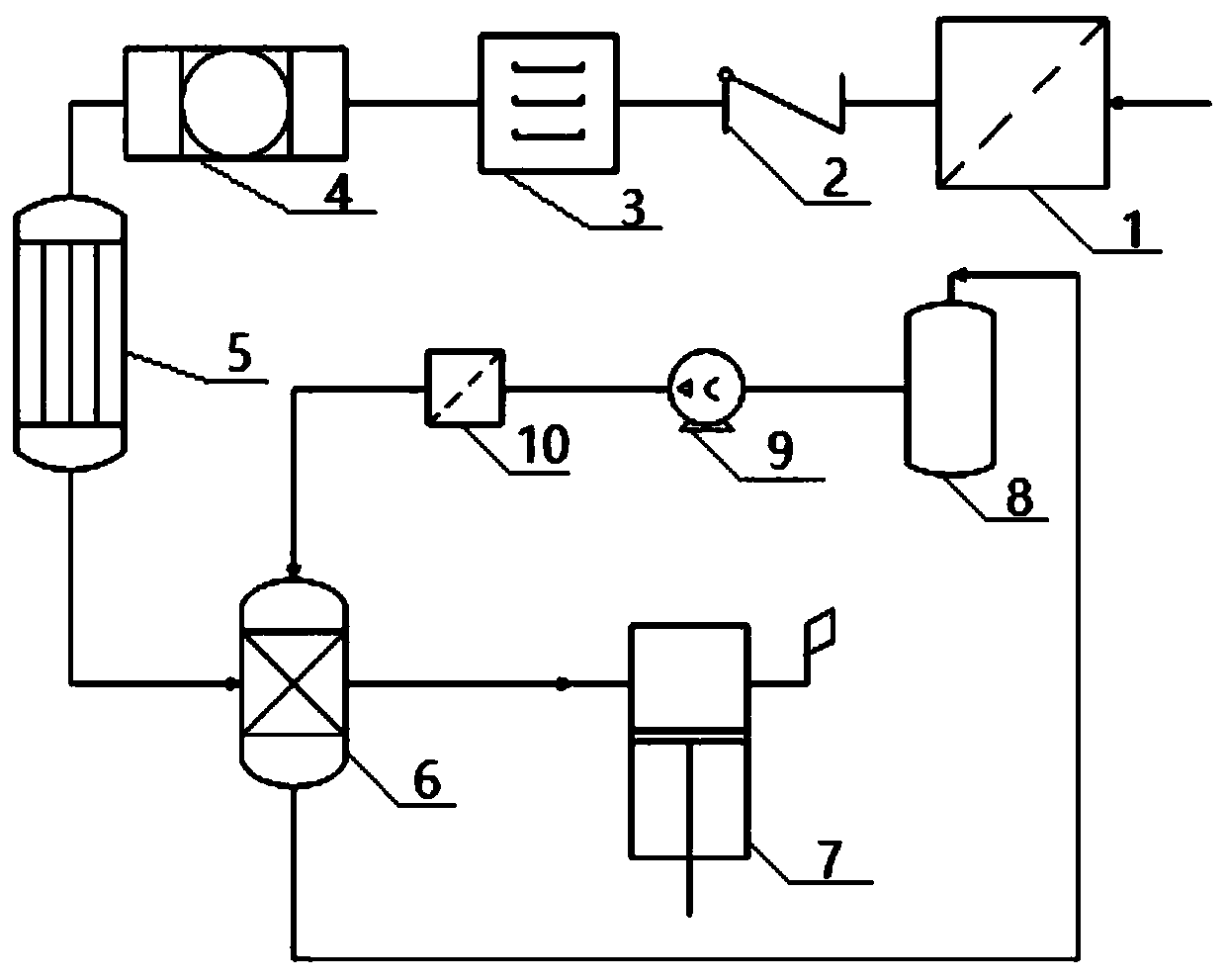

Method for producing dimethyl ether with methanol gas-phase dehydration

ActiveCN101195561AEasy to vaporizeLess external heat supplyEther preparation by compound dehydrationGas phaseWastewater

The invention provides a method for preparing dimethyl ether by methanol vaporphase dehydration, which solves the problem of long technical flow path, high investment and large energy consumption of the prior similar method. Carbinol is gasified to enter in the dehydration reactor (5) to do dehydrating reaction and the dehydrated reaction crude product enters in the dimethyl ether rectifying tower (7). The dimethyl ether product is obtained from the upper or top of the rectifying tower (7). The liquid-phase carbinol is returned to the system from the rectifying tower as raw material to be used and the liquid-phase carbinol in the carbinol storage tank (1) after gasifying in the evaporator (3) exchanges heat with high temperature of the dehydration reactor (5) in the heat exchanger (4) and then enters into the dehydration reactor (5) to having dehydration. The carbinol in the high-temperature crude product after exchanging heat in the heat exchanger (4) enters in the middle part of dimethyl ether rectifying tower (7), and dimethyl ether vapor enters in the tower top condenser (9) from the top or upper of the dimethyl ether rectifying tower. The liquid-phase or gas-phase carbinol is produced from the area above the reaction crude product feed inlet of the dimethyl ether rectifying tower or the tower board of the below area, which is returned in the carbinol storage tank (1) through cooling or condensing as raw material. The waste water is generated from bottom discharge reaction of the dimethyl ether rectifying tower and a slight quantity of non-condensible tail gas is discharged from the top of the condenser (9).

Owner:成都天成碳一化工有限公司

Vacuum tube bundle drying machine

ActiveCN105466174AAvoid pollutionEasy to vaporizeDrying solid materialsDrying machines with non-progressive movementsThermodynamicsMechanical engineering

The invention relates to a vacuum tube bundle drying machine. A feed port is formed in one side of the tube bundle drying machine, and a discharge port is formed in the other side; a waste steam outlet is formed in a shell of the tube bundle drying machine; rotating shafts at two ends of a tube bundle of the tube bundle drying machine are movably connected with the shell through mechanical seals; one ends of the rotating shafts are connected with transmission devices; the rotating shafts are hollow shafts, and inner cavities thereof are communicated with the tube bundle of the tube bundle drying machine; the rotating shaft on one side of the discharge port of the tube bundle drying machine is communicated with a steam intake device; the rotating shaft on one side of the feed port of the tube bundle drying machine is communicated with a condensed water drainage device; the feed port of the tube bundle drying machine is communicated with a feeding device; the discharge port of the tube bundle drying machine is communicated with a discharge device; and a waste steam outlet of the tube bundle drying machine is communicated with a waste steam treatment device. The vacuum tube bundle drying machine is simple in structure, convenient for use, low in manufacturing cost and wide in application range, can preferably reduce the steam temperature needed by material drying, reduces the energy consumption, reduces the waste steam emission, and achieves the purposes of energy conservation and emission reduction.

Owner:郑州博大浓缩干燥设备有限公司

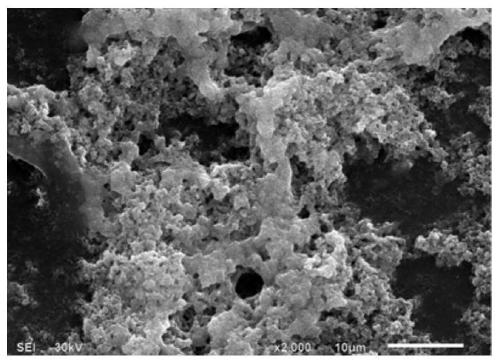

Coal water slurry prepared by utilizing waste activated carbon, organic wastewater and coal and preparation method thereof

PendingCN109135854ASolve processing problemsRealize resource utilizationLiquid carbonaceous fuelsActivated carbonCoal water

The invention discloses coal water slurry prepared by utilizing waste activated carbon, organic wastewater and coal and a preparation method thereof. The coal water slurry comprises the following components in percentage by weight: 54-60% of coal, 11-17% of waste activated carbon, 23-30% of water, 1-3% of organic wastewater, 0.5-2% of a slurry making additive and 0.05-0.15% of an ash-water dispersing agent. The coal water slurry is prepared by utilizing the waste activated carbon and the organic wastewater, so that the treatment difficulties of the waste activated carbon and the organic wastewater can be effectively solved, and the waste resource utilization can be realized at the same time. The cola water slurry is prepared by utilizing the waste activated carbon, so that the high carboncontent of the waste activated carbon can be sufficiently utilized and the dosage of slurry making coal powder is decreased. The coal water slurry is prepared by utilizing the organic wastewater, so that moisture of the organic wastewater can be sufficiently utilized and the dosage of slurry making water is decreased.

Owner:ZHEJIANG UNIV OF TECH

Dimethyl ether engine efficient, ultra-low emission combustion system

InactiveCN1470758AEasy to spreadWell formedInternal combustion piston enginesFuel supply apparatusExhaust fumesChiller

The dimethyl ether engine high-efficiency ultralow-discharge combustion system belongs to the field of internal combustion engine. The invented DME storage tank is connected with low-pressure fuel conveying pump by means of liquid outlet valve, the output of the low-pressure fuel conveying pump is connected with intensified fuel-spraying pump via one end of T-junctor and fuel filter, the outlet of intensified fuel-spraying pump is connected with ultramultinozzle fuel-spraying device via high-pressure fuel pipe, said ultramultinozzle fuel-spraying device is set on the cylinder cover of engine and is matched with combustion chamber, the outlet of waste gas recirculation control valve is connected with inlet of waste gas recirculation cooling device, and its inlet is connected with dischargetube.

Owner:SHANGHAI JIAO TONG UNIV

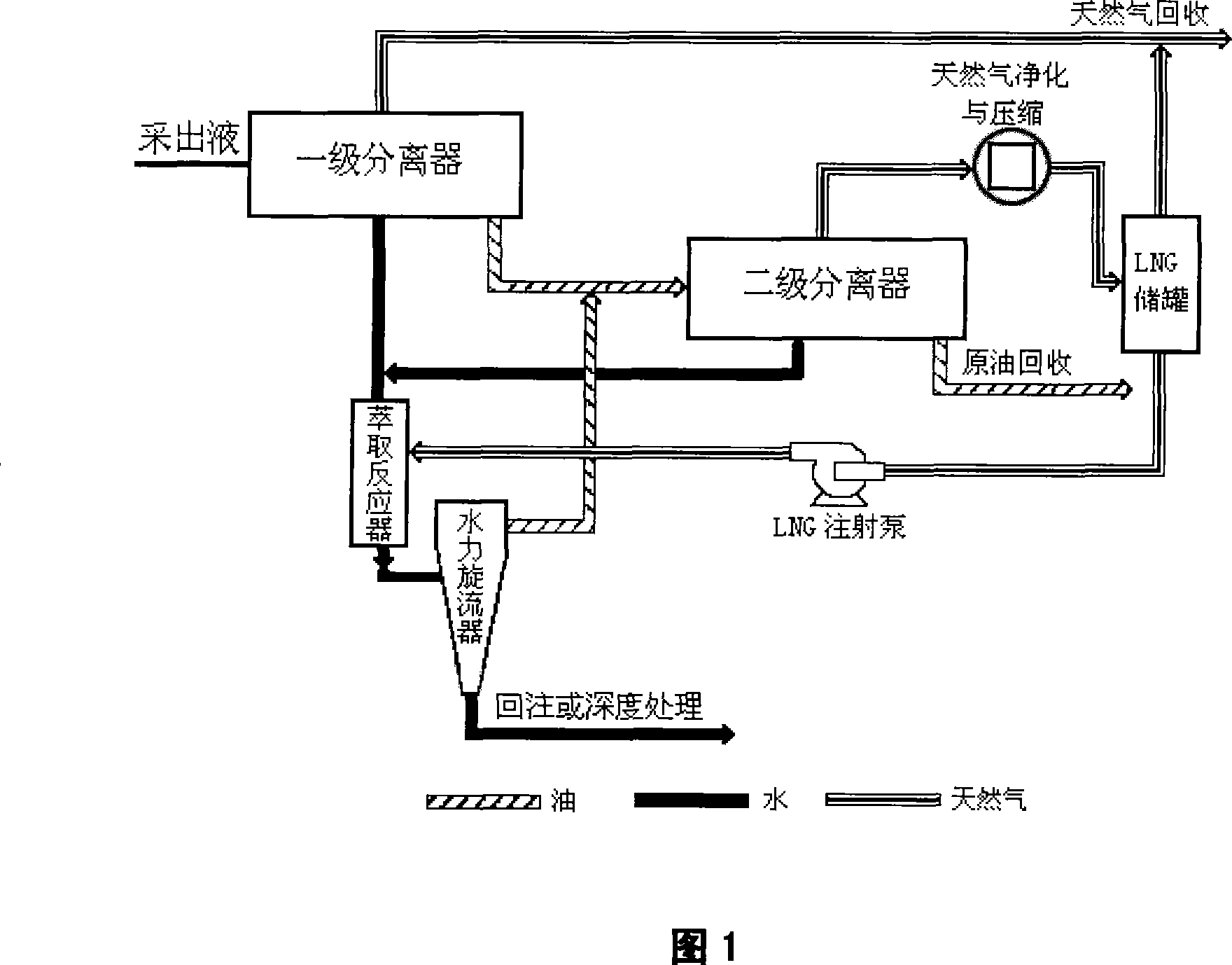

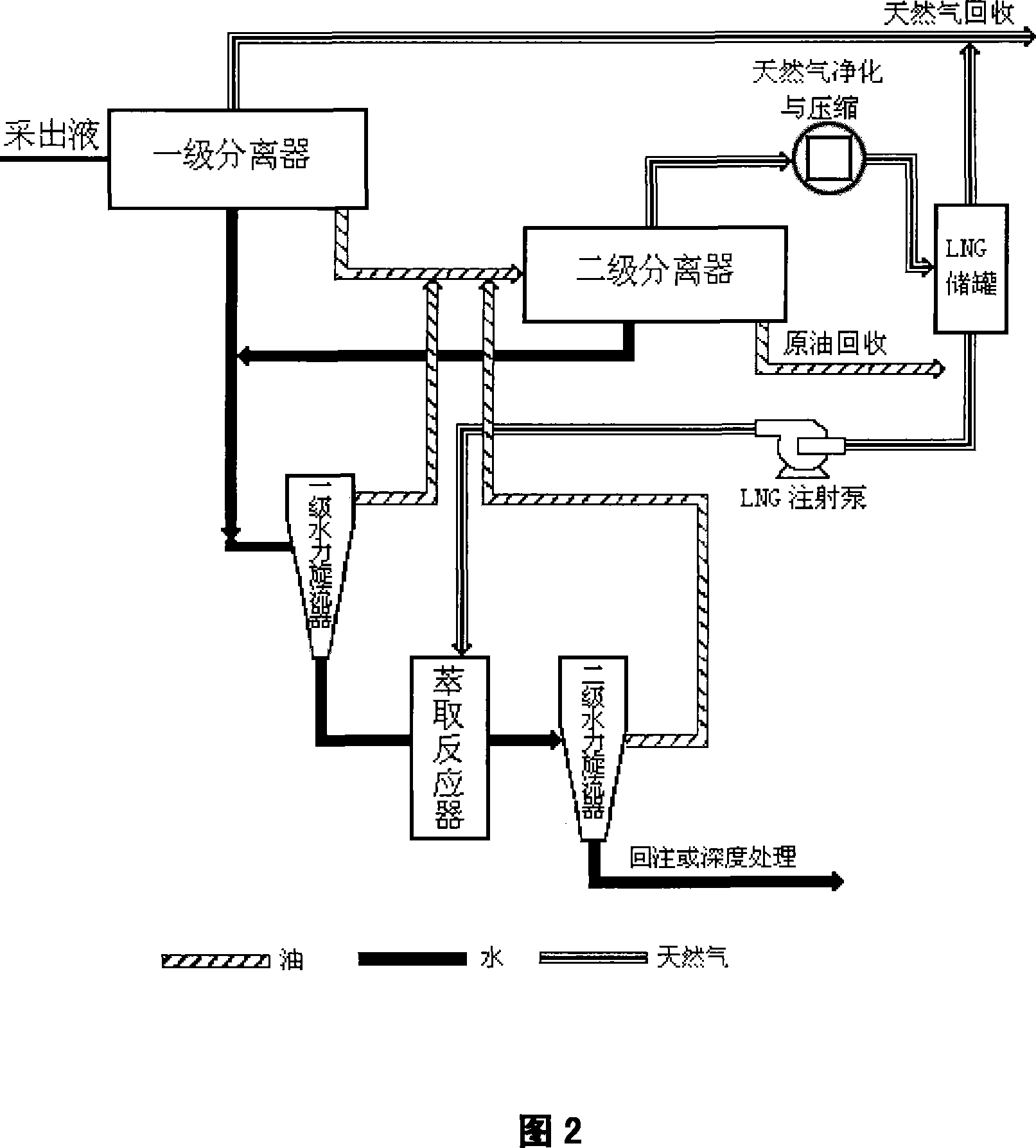

Oil field extracted water deoiling process by using supercritical liquid extraction technique

InactiveCN101186350AEasy to vaporizeEasy to separateWater/sewage treatment by extractionSmall footprintSolvent

The invention relates to a new technique of the oil removal of oilfield-produced water, which utilizes a solvent extraction technology. The novel technique is invented to quickly condense the micro oil drop of dispersed oil, emulsible oil and soluble oil in the water into the oil drop with a larger dimension, thus realizing quick and high-effective oil removing from the oilfield-produced water. The novel technique relates to the application of supercritical fluid extraction technology which adopts liquefied natural gas (LNG) as the solvent. The whole technique process mainly comprises units of a primary separator, a natural gas purification and liquefaction system, a second stage separator, an extraction reactor, a hydrocyclone, etc. The invention has the advantages that: the oil removal effect is good, the detention time of each unit is short, the solvent can be recycled and repeatedly used and the floor area of the device is small, which is especially applicable to ocean or sea beach oil-production platform. The technique is applicable to the oil removal of effluent from heavy oil produced water and polymer flooding produced water.

Owner:程海鹰 +1

Deep drying and dewatering method

ActiveCN103868330AEasy to vaporizeKeep dryDrying solid materials without heatToxic materialPollution

The invention provides a deep drying and dewatering method of solid materials. The method includes the following steps that firstly, drying reagents which are lower than water in polarity, surface tension and boiling point are fed into a container where dried objects are placed; secondly, after the drying reagents are fed in, the container is vacuumized; thirdly, inert gas with high purity and for drying is fed into the container to remove residual drying reagents. By means of competitive adsorption of the drying reagents and water on surfaces of dried materials, hydrone on the surfaces of the dried materials is displaced, accordingly, the drying effect on the solid materials is greatly improve, a better dewatering effect is realized, drying can be carried out more thoroughly, higher requirements for the drying effect of certain industries can be met, and especially production bottlenecks caused by the fact the requirement for water is very high in industries such as lithium electricity industry can be broken; according to the method, energy is saved, the environment is protected, toxic substances cannot be produced, and the method is free from pollution, environmentally friendly and efficient.

Owner:VIGOR GAS PURIFICATION TECHNOLOGIES (SUZHOU) CO LTD

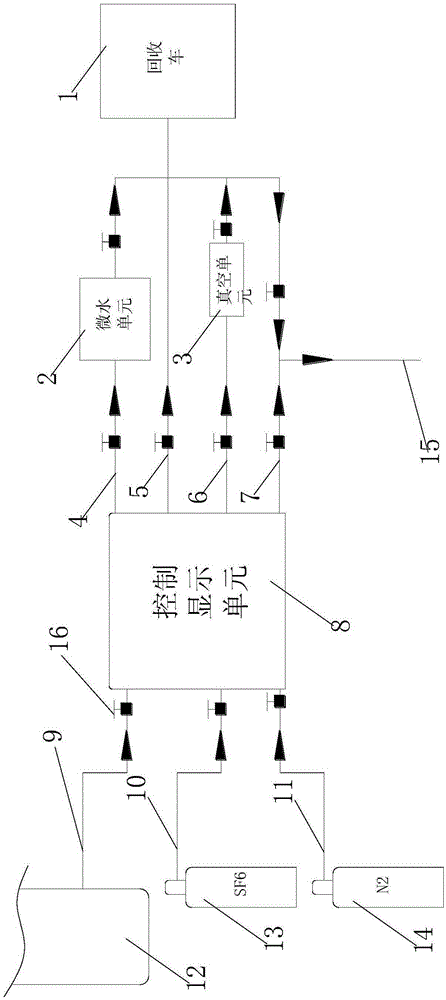

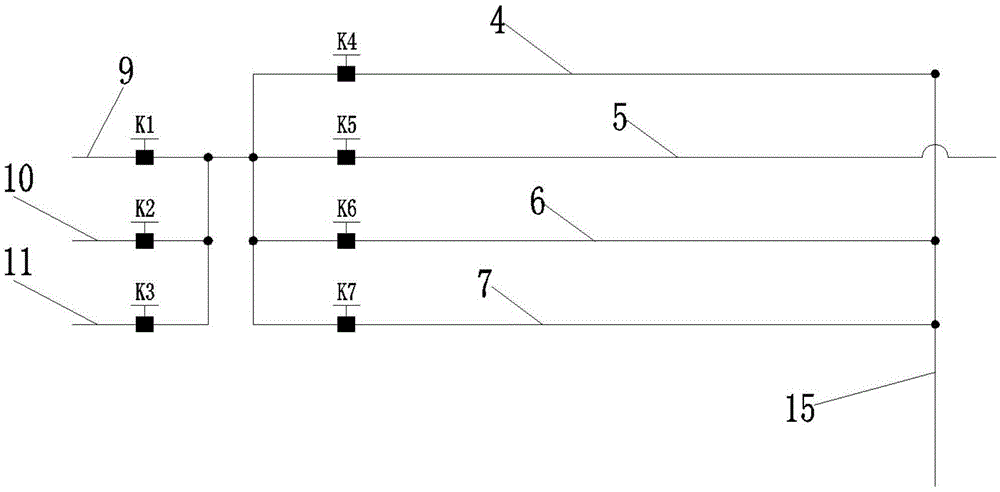

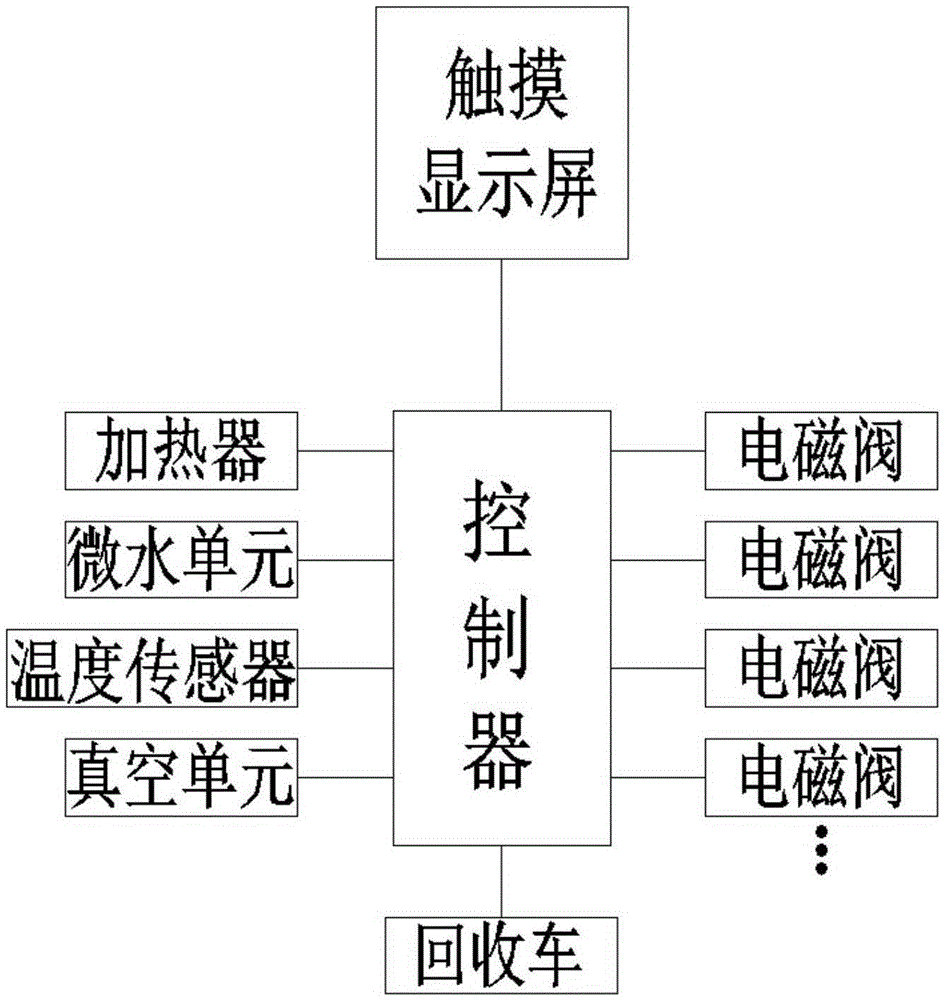

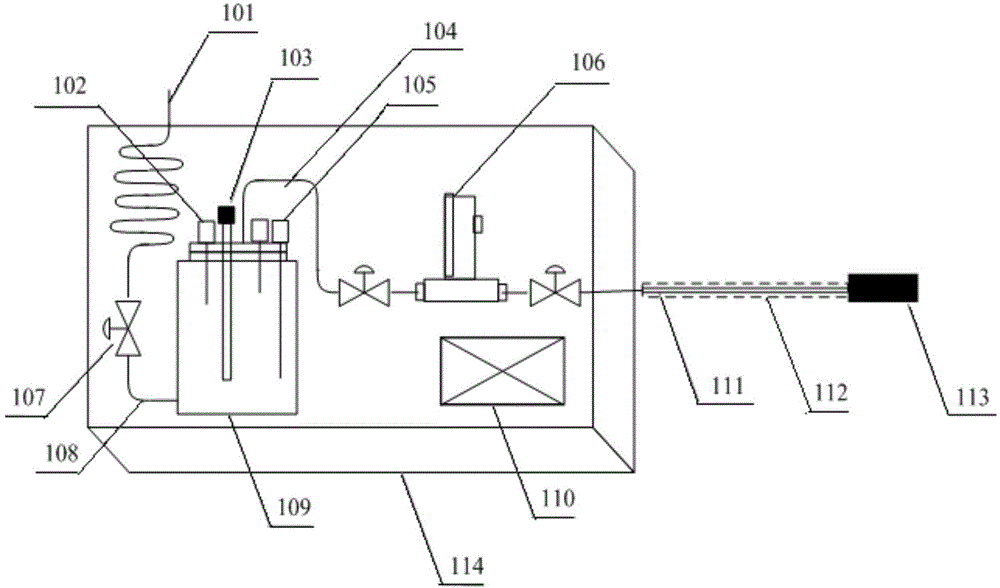

Treatment system for micro water of GIS air chamber

ActiveCN105387342AThorough treatmentEasy to vaporizeContainer filling methodsGas handling/storage effectsWater treatment systemSulfur hexafluoride

The invention discloses a treatment system for micro water of a GIS air chamber. The treatment system is used for treating micro water in the air chamber of a GIS device to reach the standard value. The system comprises a main pipeline communicated with the air chamber of the GIS device, and a micro water detection pipeline, a sulfur hexafluoride recycling pipeline, a vacuumizing pipeline and a nitrogen exhausting pipeline are connected to the main pipeline in parallel. The far end of the micro water detection pipeline, the far end of the vacuumizing pipeline and the far end of the nitrogen exhausting pipeline are connected to an emptying pipeline; a micro water unit for detecting micro water is arranged on the micro water detection pipeline; a vacuum unit for vacuumizing is arranged on the vacuumizing pipeline, and the far end of the sulfur hexafluoride recycling pipeline is connected to a sulfur hexafluoride gas recycling vehicle; a sulfur hexafluoride filling pipeline and a nitrogen filling pipeline are further arranged on the main pipeline; the system further comprises a heater for heating the air chamber of the GIS device; each pipeline is provided with an electromagnetic valve; and the electromagnetic valves are connected with a controller of a control display unit.

Owner:MAINTENANCE COMPANY OF STATE GRID XINJIANG ELECTRIC POWER COMPANY +1

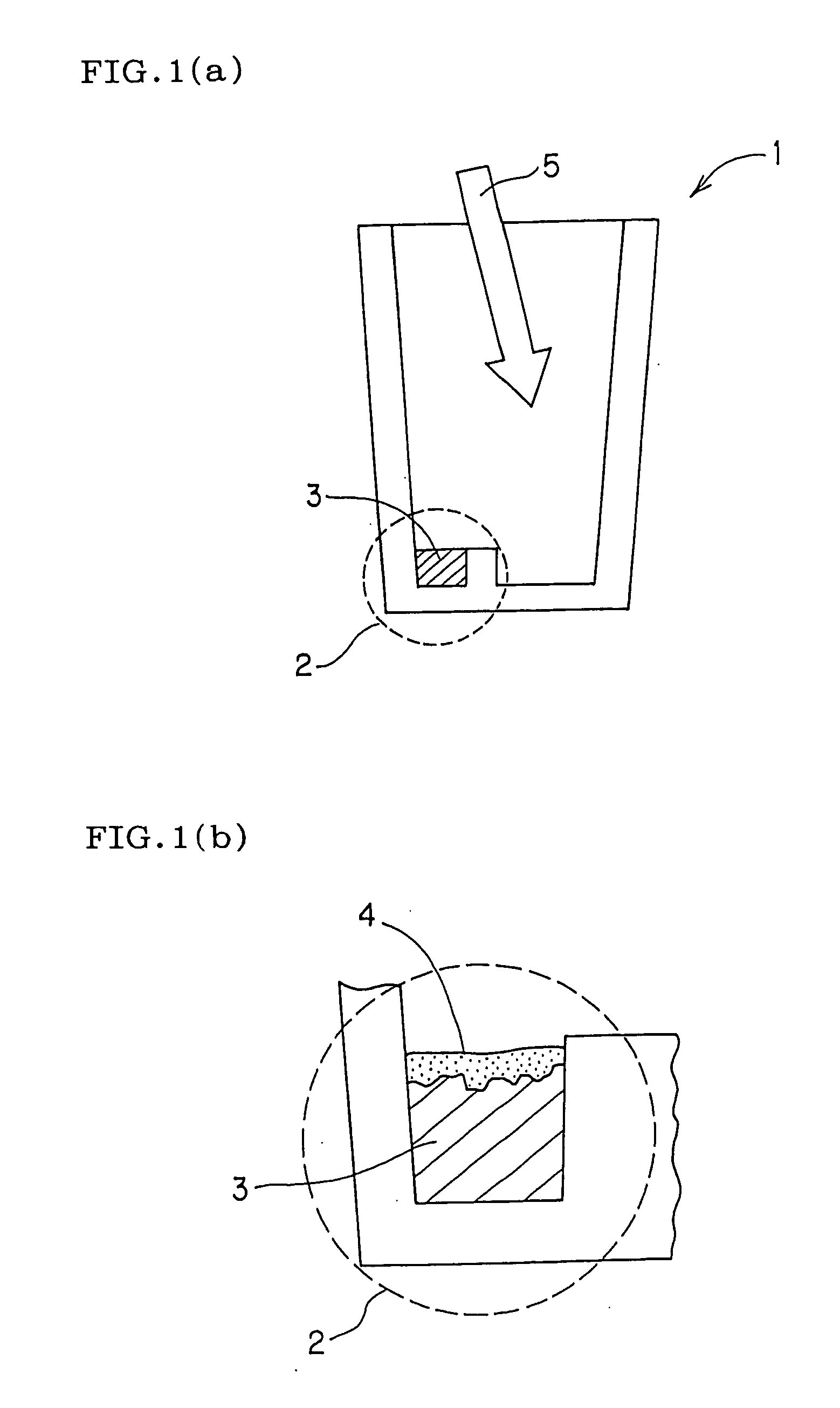

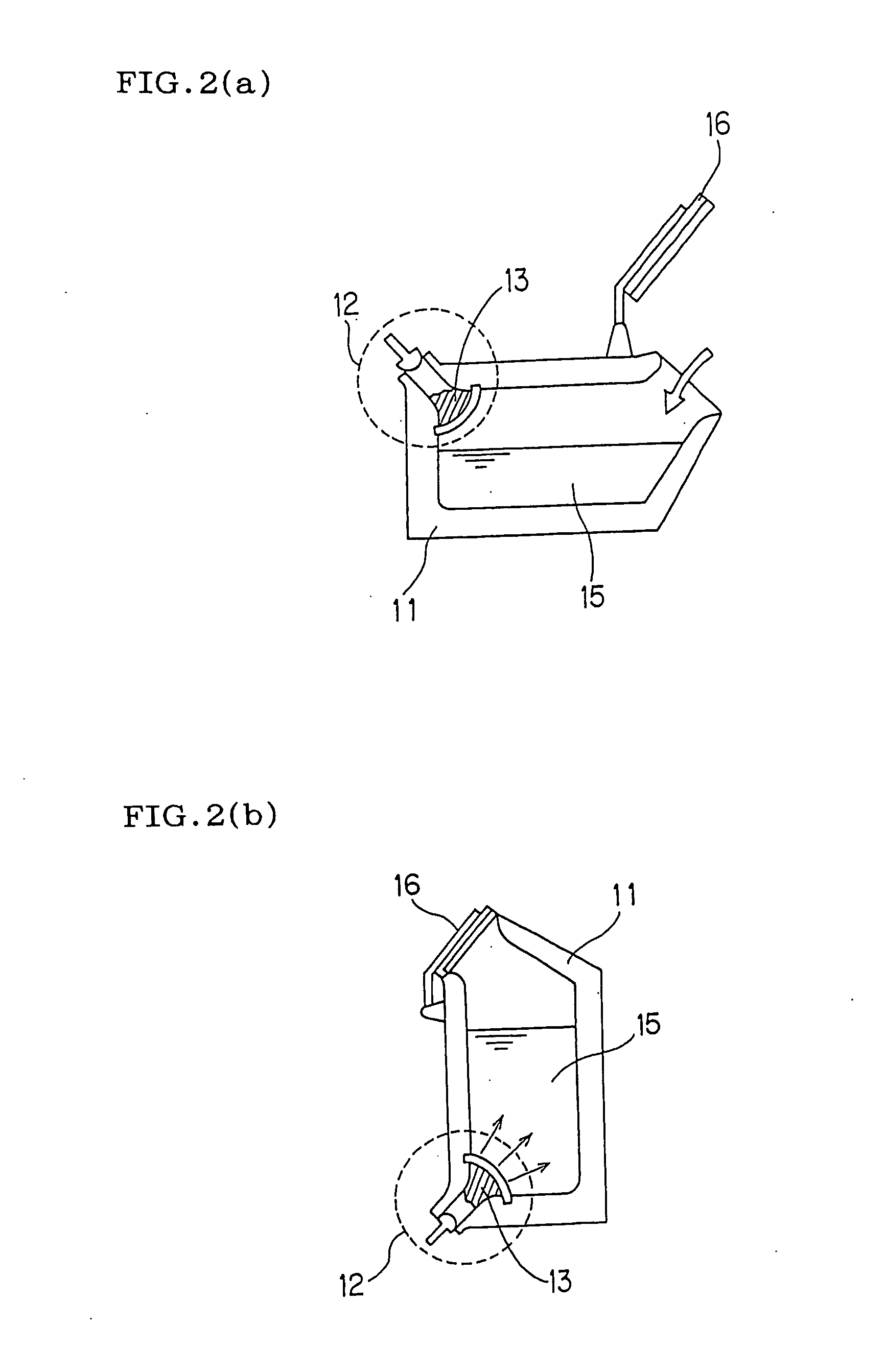

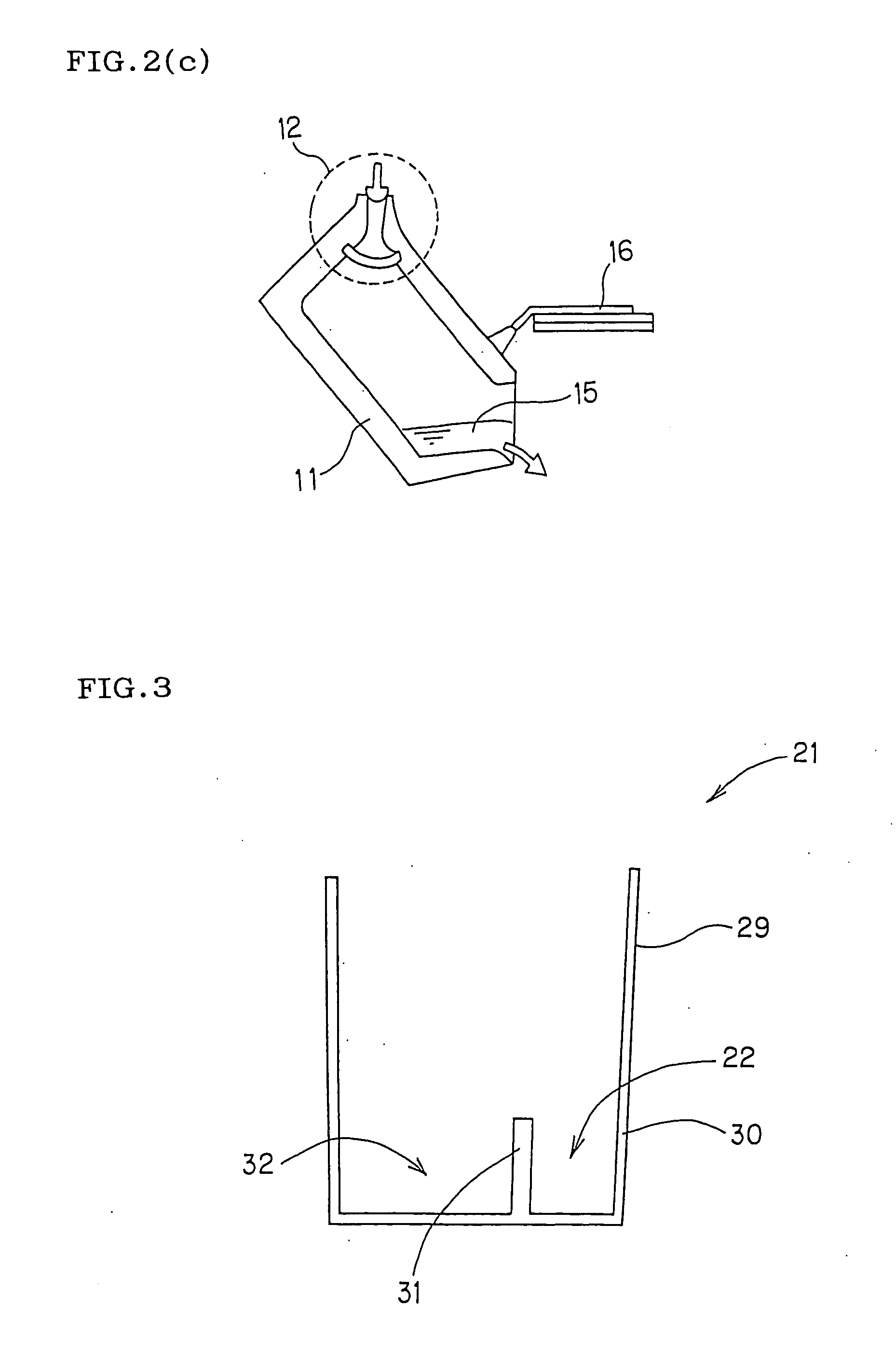

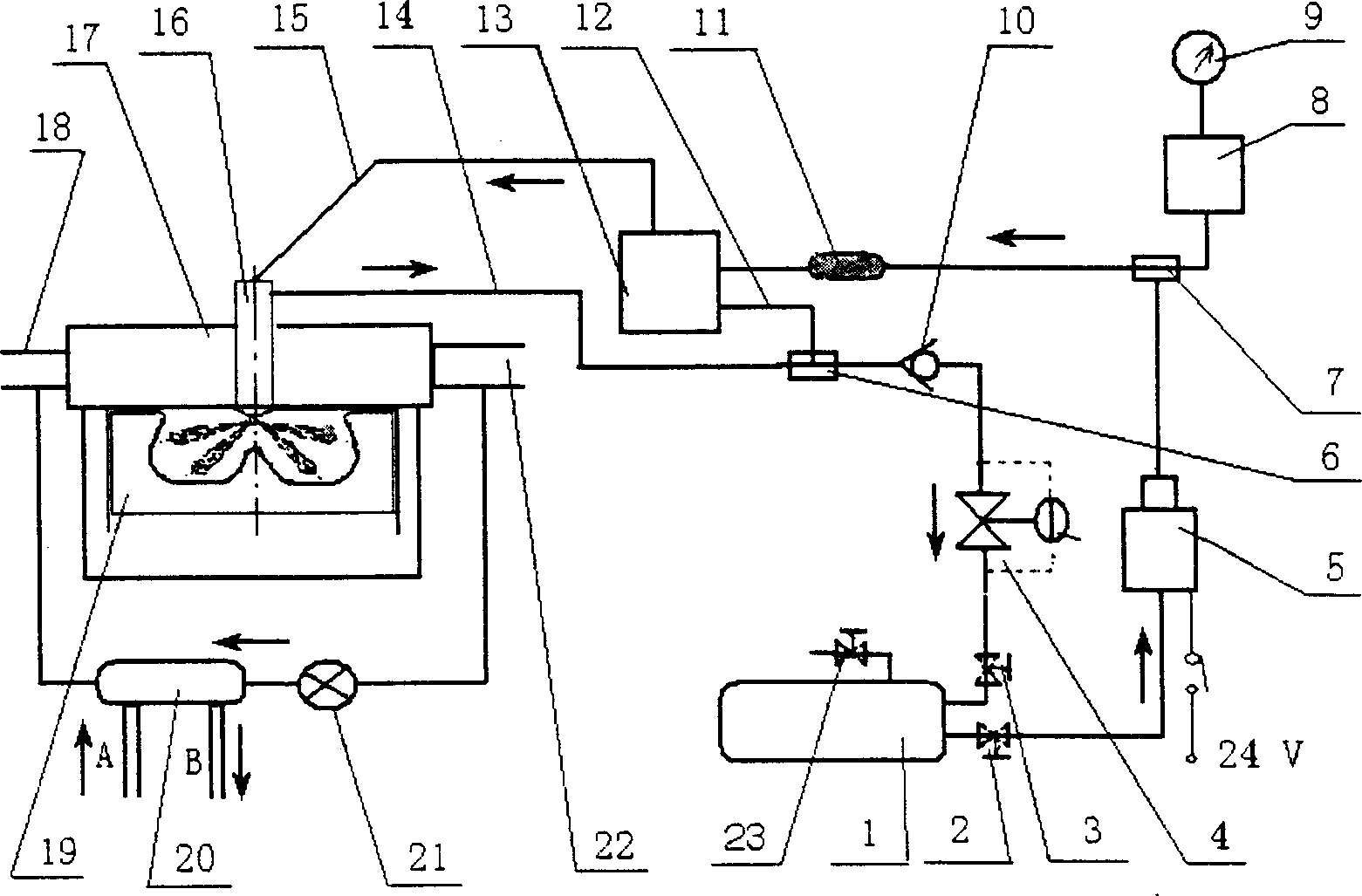

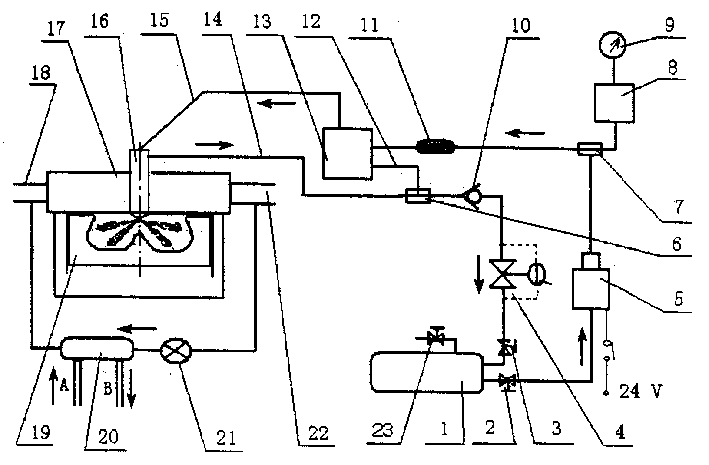

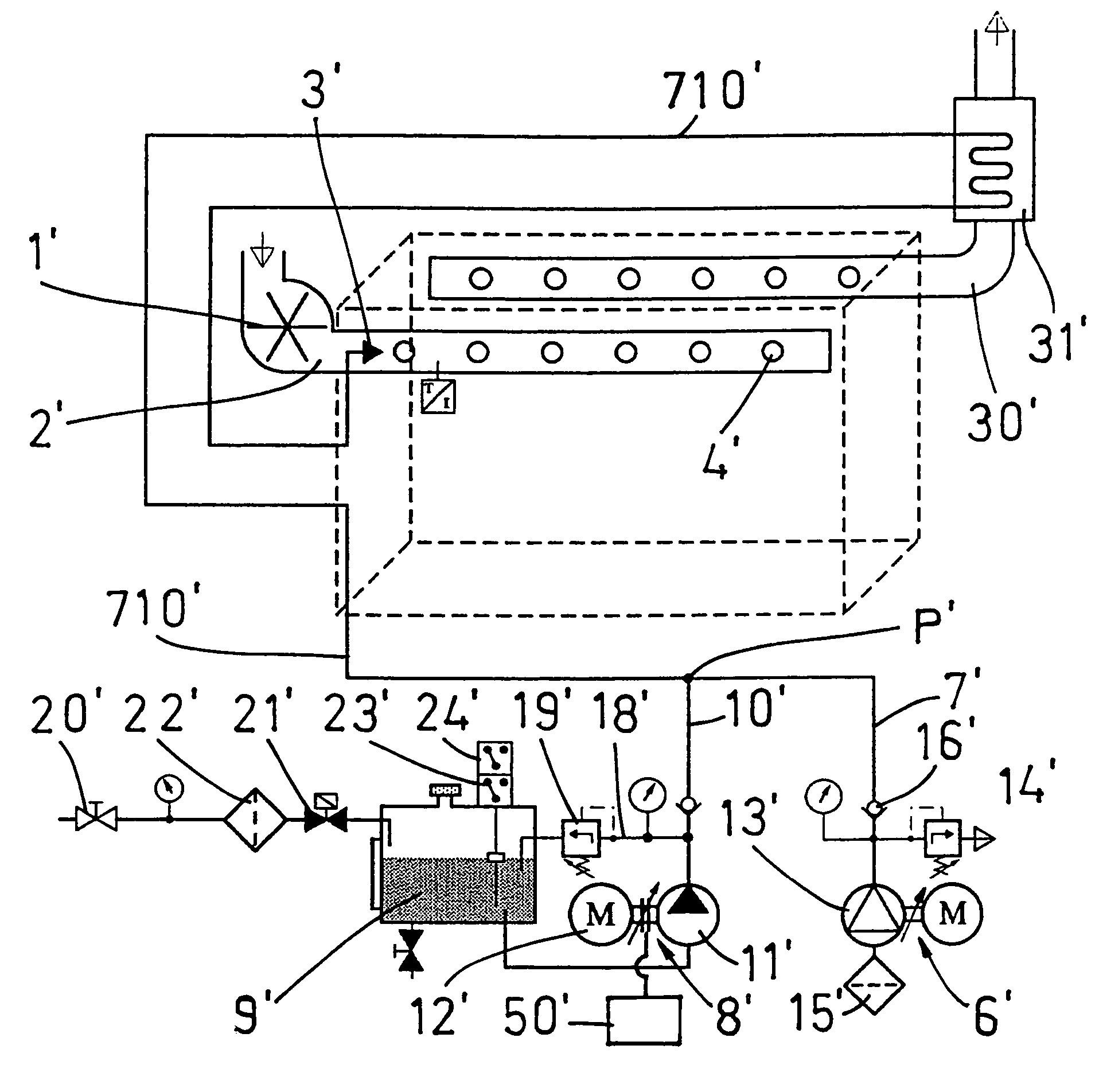

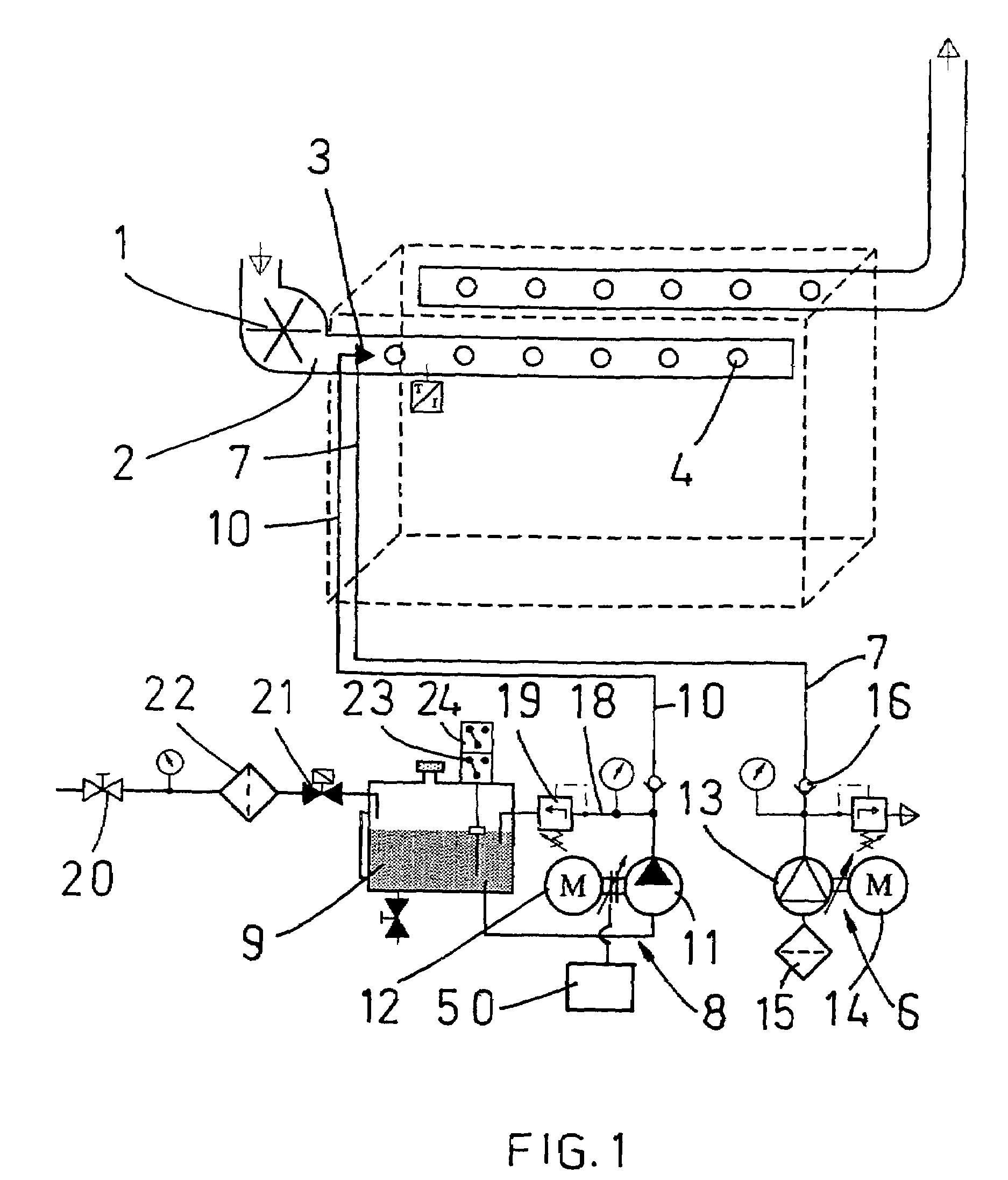

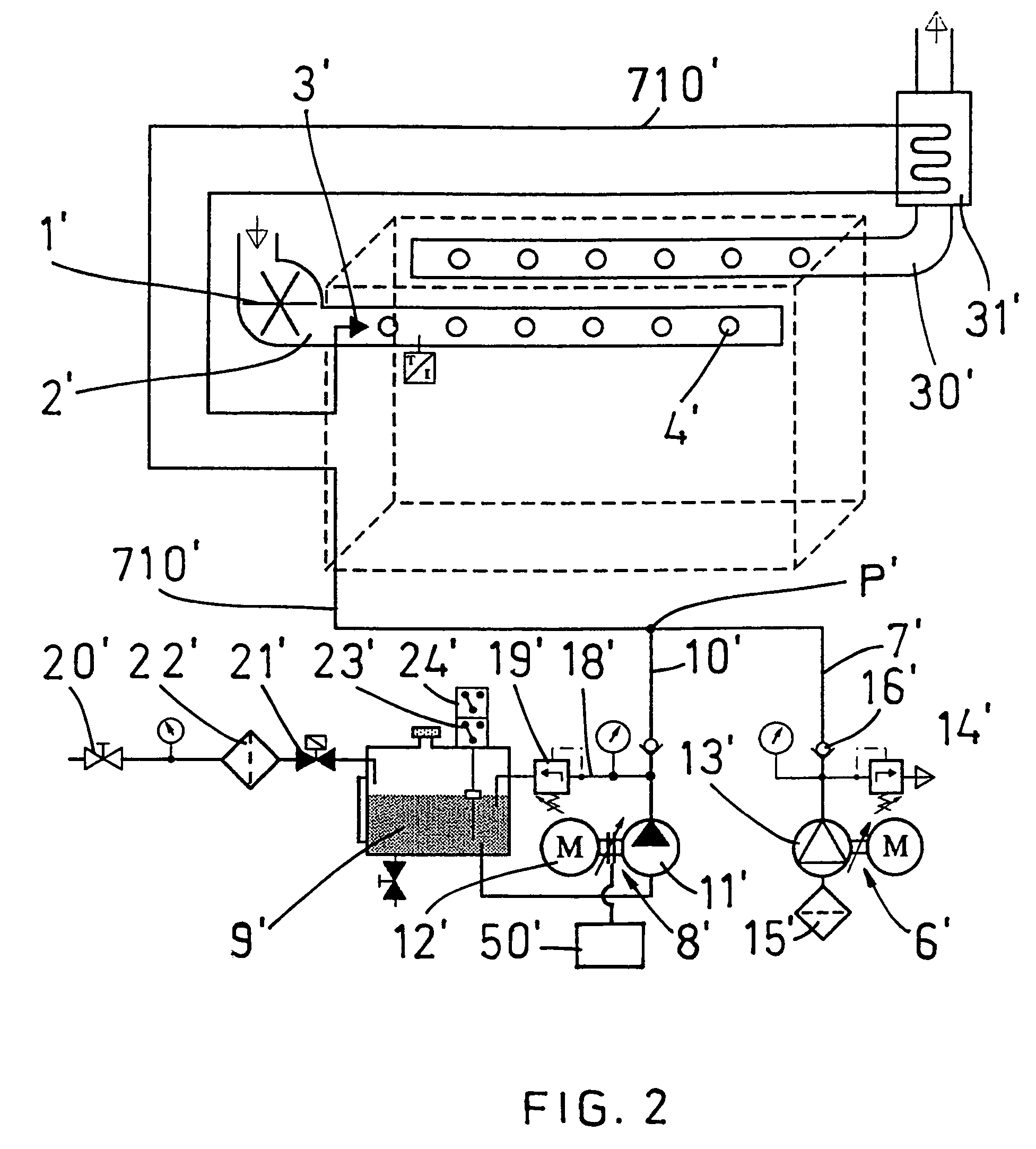

Method and apparatus for reducing combustion engine emissions

InactiveUS7231893B2Reduce nitrogen emissionsEasy to installInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberProduct gas

The invention relates to a method for cleaning exhaust gases from a combustion engine, in which method humid air is fed into the combustion chamber of the combustion engine. In order to reduce nitrogen emissions effectively, particularly when a diesel engine is running at partial power, and in order for the method to be very accurately adjustable to meet the requirements of each particular engine application and use, in accordance with the invention, a mixture of gas and aqueous mist is fed with a spray head (3) into a space (2), which leads to the combustion chamber. The method can be readily implemented by an apparatus, which can be mounted in a small space without having to make substantial changes in the combustion engine. The invention also relates to an apparatus for cleaning exhaust gases from a combustion engine.

Owner:MARIOFF CORP OY

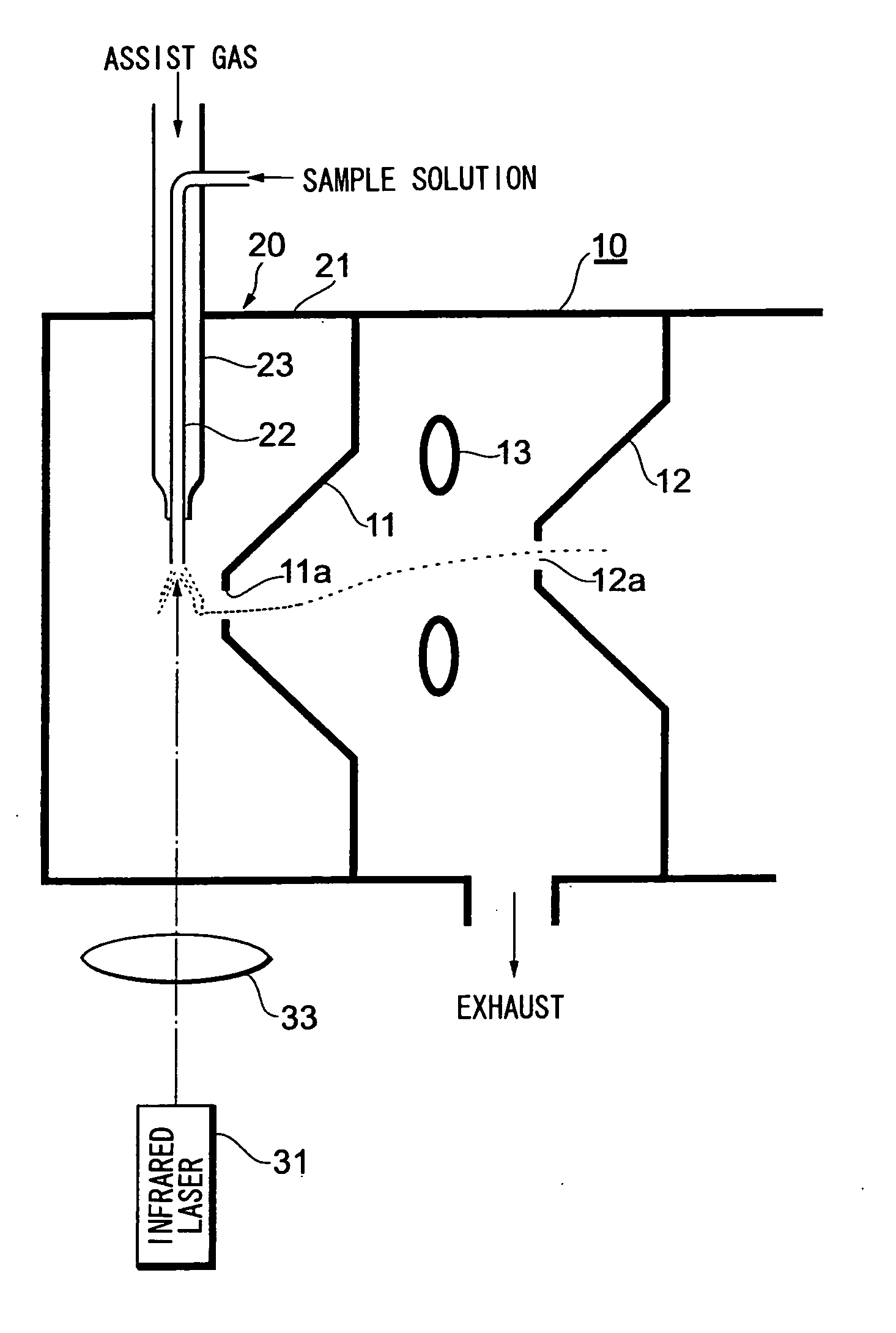

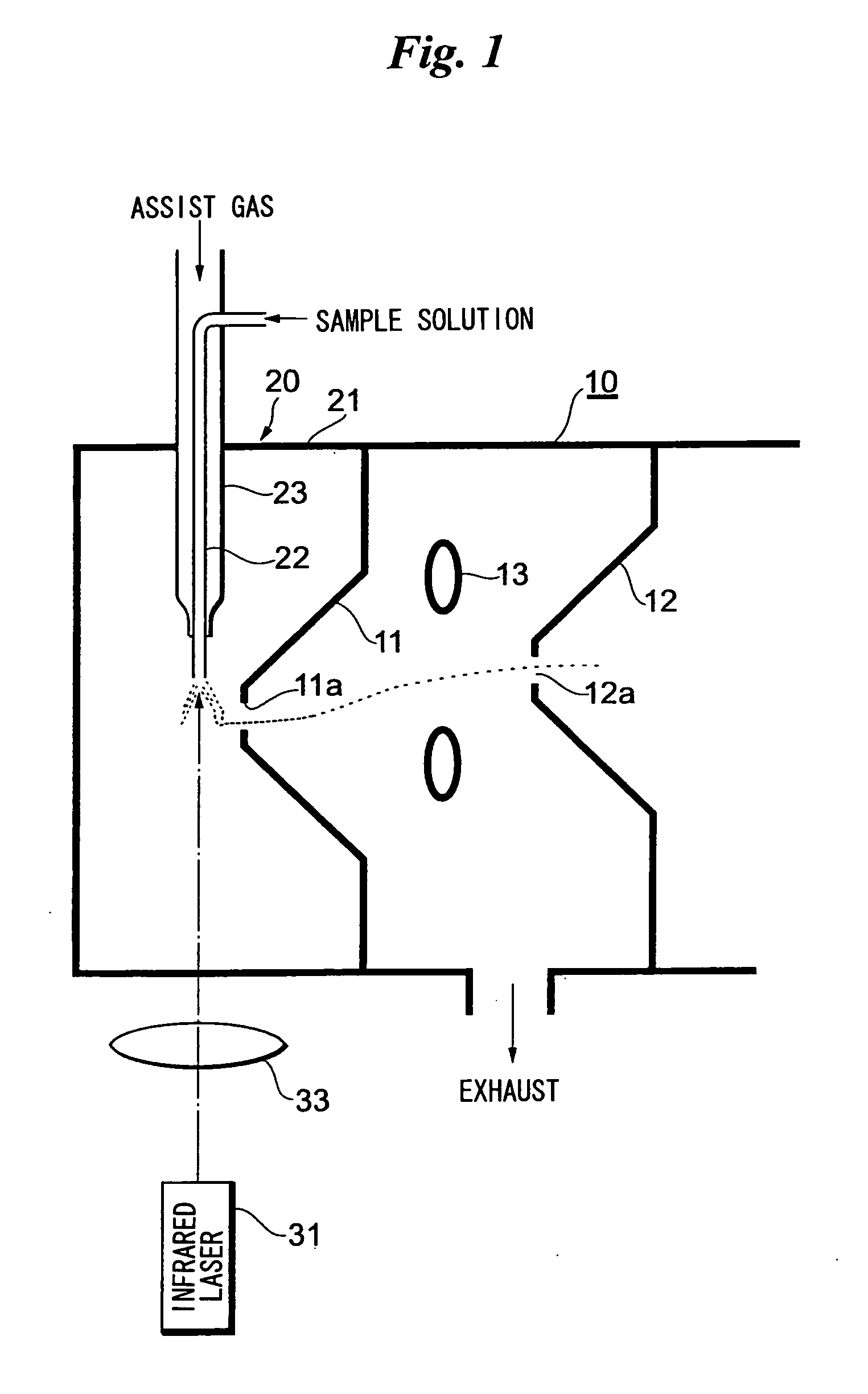

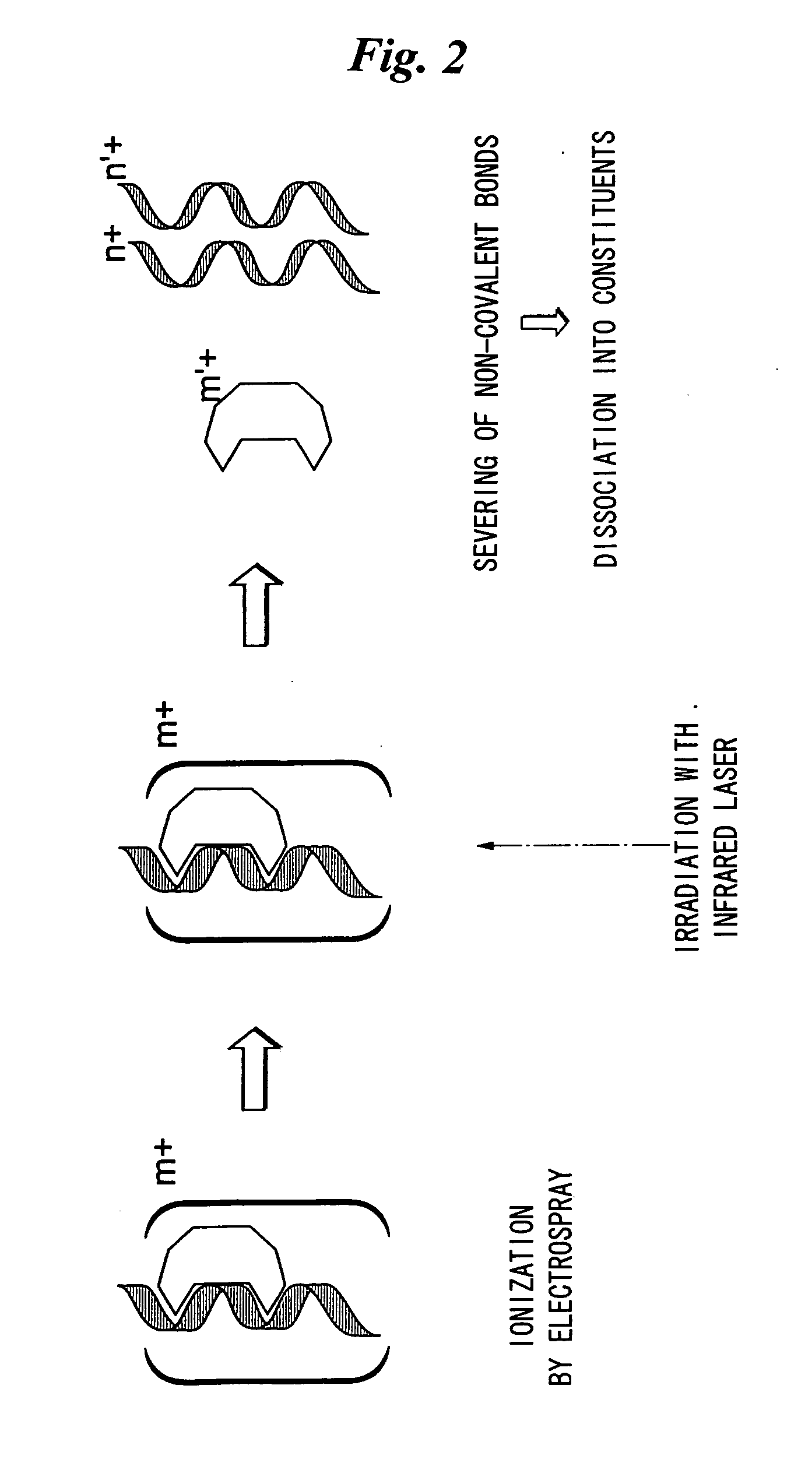

Method and apparatus for selectively severing and analyzing non-covalent and other bonds of biological macromolecules

ActiveUS20090071815A1Difficult to measureHigh sensitivity detectionSludge treatmentMaterial analysis by electric/magnetic meansInfrared laser beamBiological macromolecule

A biological sample solution is ionized by electrospray and the sample solution is irradiated with an infrared laser beam to dissociate biological macromolecules into the constituents thereof. As a result, only non-covalent bonds of the biological macromolecules can be selectively severed and analyzed.

Owner:UNIVERSITY OF YAMANASHI

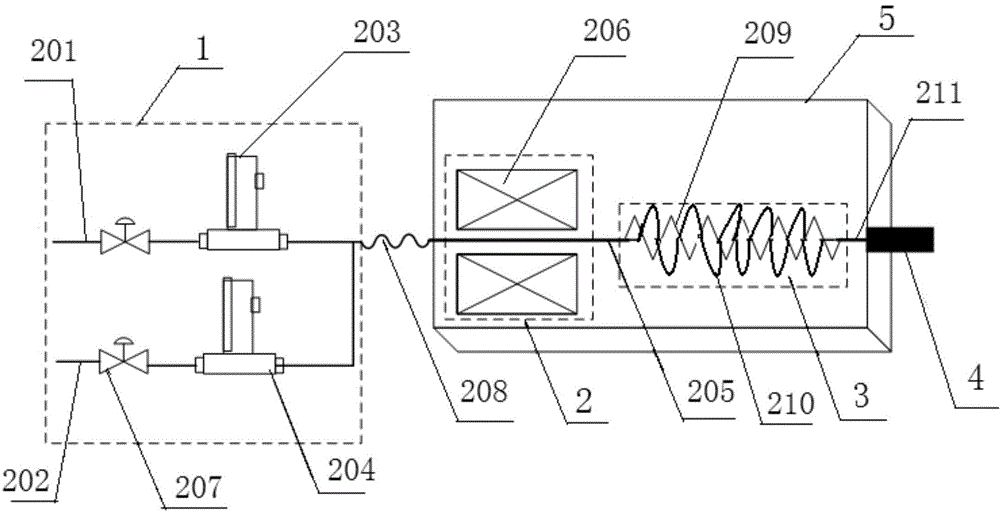

Feeding system for optical fiber preform production

ActiveCN104803597AAvoid long distance transportStable evaporation pressureGlass making apparatusEvaporationTorch

The invention provides a feeding system for optical fiber preform production. The feeding system comprises a gas-liquid mixing part, an ultrasonic atomizing part, a heating part, a torch lamp and a torch lamp position adjusting platform, wherein the gas-liquid mixing part comprises a liquid material charge pipe, a gas carrying charge pipe, a liquid flowmeter and a gas flowmeter; the ultrasonic atomizing part comprises an atomizing part charge pipe and an ultrasonic generator for atomizing a gas-liquid mixture in the atomizing part charge pipe; the atomizing part charge pipe is communicated with a middle conveying charge pipe which is communicated with both the liquid material charge pipe and the gas carrying charge pipe; the heating part comprises a heater used for evaporating the atomized gas-liquid mixture into mixed gas; the atomized gas-liquid mixture is conveyed to the heater through a heating part charge pipe communicated with the atomize part charge pipe; the torch lamp is used for conducting sedimentation of the mixed gas on an optical fiber preform; the mixed gas is conveyed to the torch lamp through a final charge pipe communicated with the heating part charge pipe; the torch lamp position adjusting platform is used for bearing the ultrasonic atomize part, the heating part and the torch lamp. The feeding system has the advantages that the vapor conveying pipeline is short; the evaporation pressure is stable; the leakage possibility is low; the position of the torch lamp is convenient to adjust.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

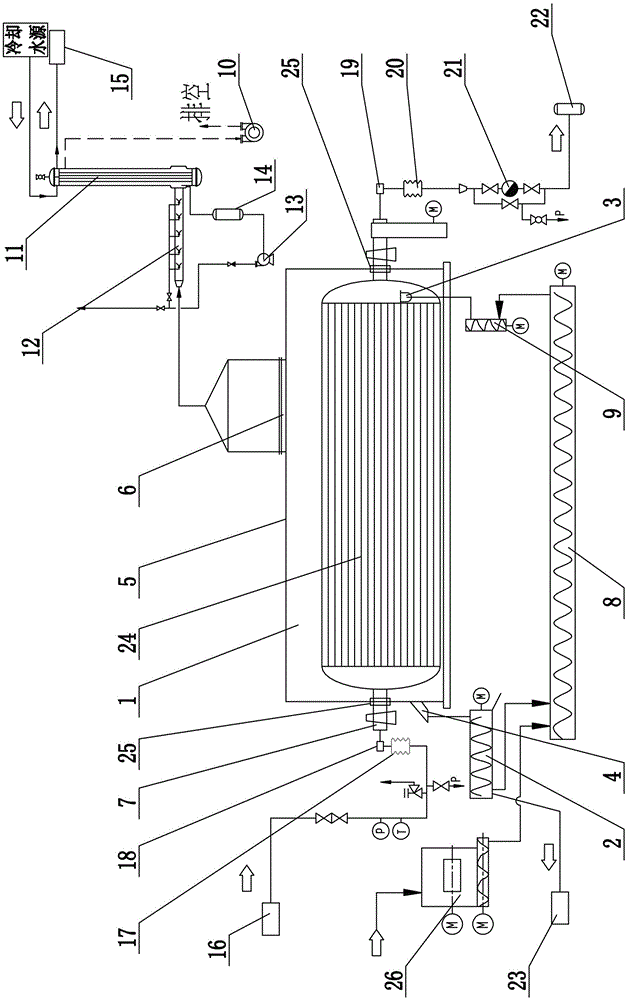

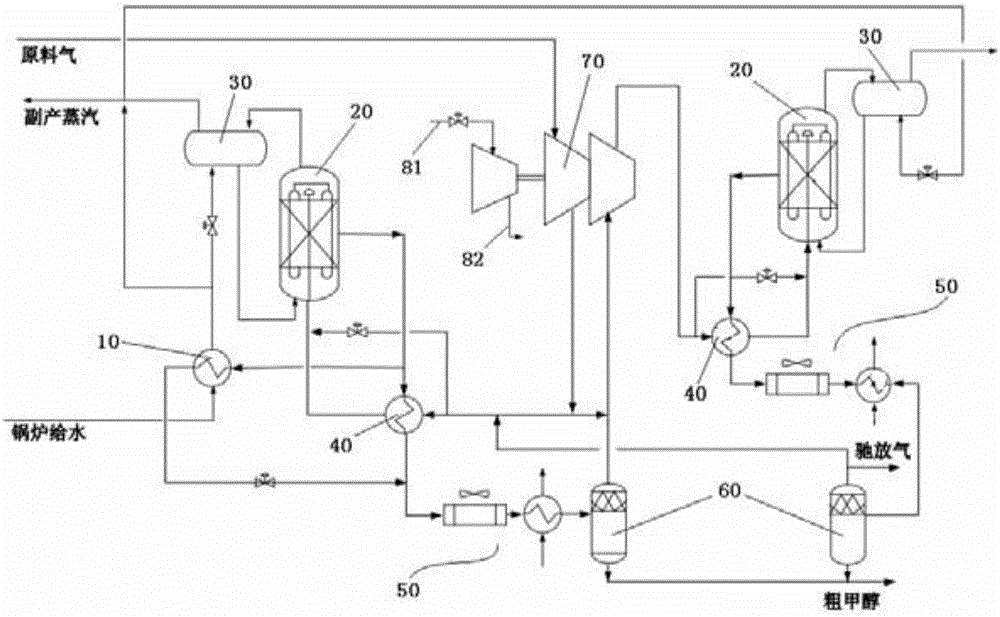

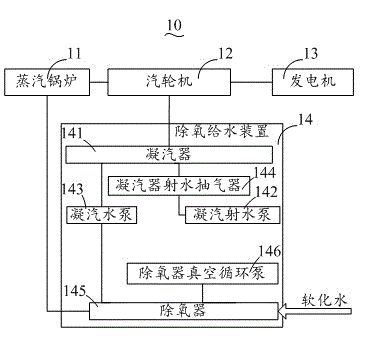

Methanol synthesis system and steam dilatation method of methanol synthesis system

ActiveCN105111042AReduce the temperatureEasy to vaporizeSteam generation heating methodsOrganic compound preparationGas phasePre treatment

The invention provides a methanol synthesis system and a steam dilatation method of the methanol synthesis system. The methanol synthesis system comprises a feed gas pretreatment device connected with a feed gas delivery pipe, a methanol synthesis reactor connected with the feed gas pretreatment device, and a boiler feed water pipe connected with the methanol synthesis reactor to enable boiler feed water to perform heat exchange in the methanol synthesis reactor so as to output byproduct steam, wherein a boiler feed water preheater is arranged on the boiler feed water pipe, and a heat supply inlet of the boiler feed water preheater is connected with a gaseous product output port of the methanol synthesis reactor so as to preheat the boil feed water in the boiler feed water preheater with a gaseous product in the methanol synthesis reactor and then output the gaseous product. By means of the technical scheme, the problem that heat output from the methanol synthesis reactor in the prior art cannot be effectively carried away or utilized and accordingly the temperature of waste heat of an output product is high can be solved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

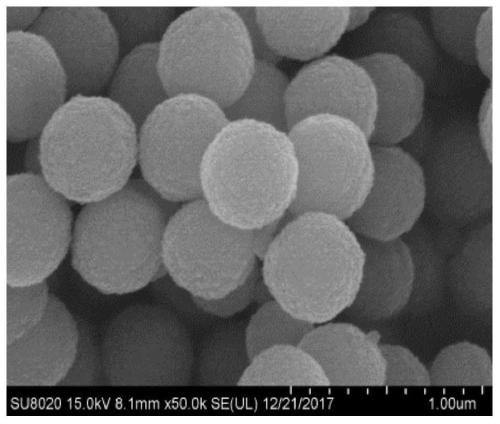

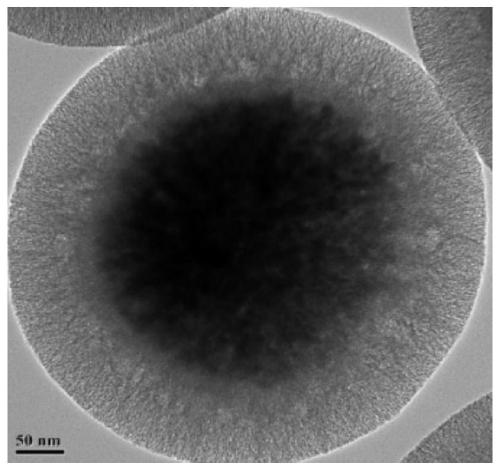

Silicon hydroxyl magnetic bead and preparation method and application thereof

InactiveCN110304662AUniform particle sizeParticle size controllableMaterial nanotechnologyInorganic material magnetismTrisodium citrateNanometre

The invention discloses a preparation method of a silicon hydroxyl magnetic bead. The preparation method comprises the following steps that ferric trichloride, trisodium citrate, sodium acetate and polyhydric alcohol are mixed evenly to obtain a mixed solution, and Fe3O4 nanoparticles are prepared by a solvothermal method; and the surface of the Fe3O4 nanoparticles is coated with SiO2 films by atomic layer deposition to obtain the silicon hydroxyl magnetic bead. The Fe3O4 nanoparticles prepared by the solvothermal method are coated with the SiO2 films by atomic layer deposition (ALD), the SiO2films are plated on the surface of the Fe3O4 nanoparticles in the form of a monatomic film, the SiO2 films laminated by the method can grow at a constant speed on the surface and at defects of the Fe3O4 nanoparticles, the SiO2 films on the surface are a whole after coating, and the coating compactness of the SiO2 films on Fe3O4 is good and the SiO2 films are not prone to falling off, therefore, coating defects on the surface of the magnetic bead can be prevented from being generated. In addition, by adjusting the deposition conditions and the number of cycles, the thickness of the SiO2 filmscan be precisely controlled, the process is simple, operation can be standardized, no complicated operation is required, errors are small, and later screening of the magnetic bead is avoided, so thatthe purpose of improving the product quality and the stability of magnetic bead batches is achieved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

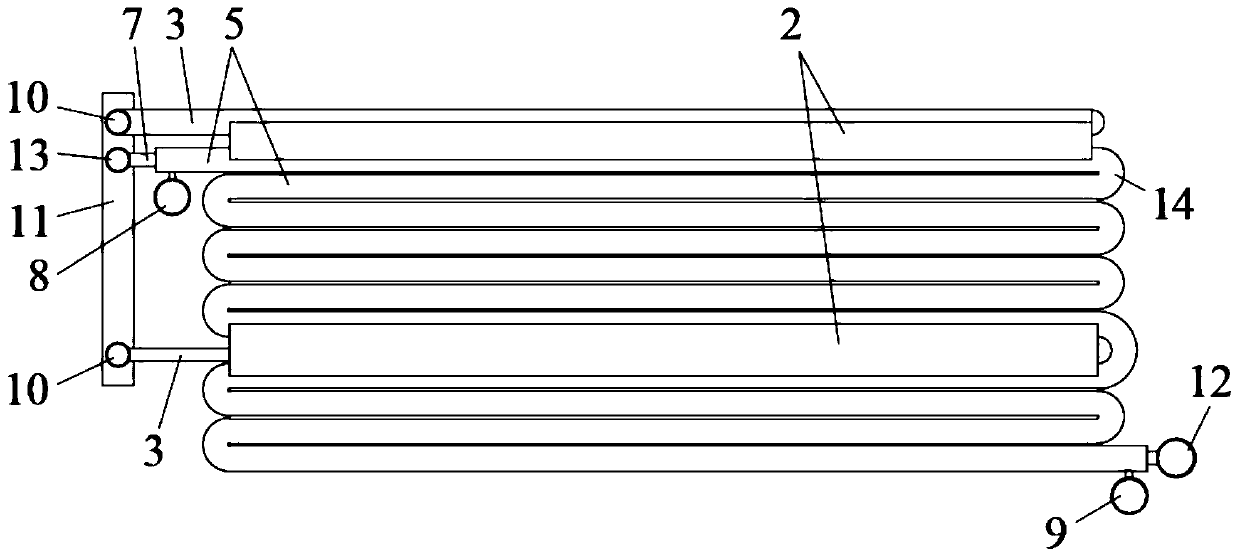

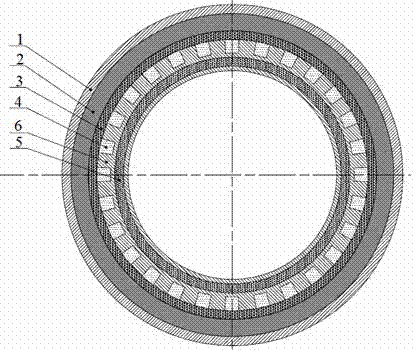

Cascade evaporation and condensation heat exchanger

PendingCN111473665AReduce volumeIncrease the heat exchange areaEvaporators/condensersStationary tubular conduit assembliesMicrowell PlateEngineering

The invention relates to a cascade evaporation and condensation heat exchanger. The cascade evaporation and condensation heat exchanger comprises at least one heat exchange unit, wherein each heat exchange unit is of a plate-shaped structure formed by arranging a plurality of condensation pipe horizontal sections, at least one refrigerant heat exchange channel is formed, and the two faces of eachplate-shaped structure form an evaporation heat exchange face; a cooling outer pipe is further arranged above the condensation pipe horizontal section on the uppermost side; a water distribution groove is further formed between the cooling outer pipe and the condensation pipe horizontal sections; water distribution micropore plates are arranged on the two sides of the water distribution groove; the upper ends and the lower ends of the water distribution micropore plates are connected with the pipe wall of the cooling outer pipe and the pipe wall of the condensation pipe horizontal sections correspondingly; the cooling outer pipe is provided with a plurality of water outlet holes communicating with the water distribution groove; and a cooling inner pipe is further arranged in each refrigerant heat exchange channel in a penetrating manner. The cascade evaporation and condensation heat exchanger integrates two heat exchange manners of water cooling heat exchange and evaporation cooling heat exchange, and the cascade heat exchange effect is shown; the embedded hidden type water distribution groove can form the water curtain type water distribution effect, and the evaporation efficiencyis improved; and free water cannot be generated, and the phenomena of water flying and water floating are avoided.

Owner:HANRUN UNITED HIGH TECH DEV BEIJING CO LTD

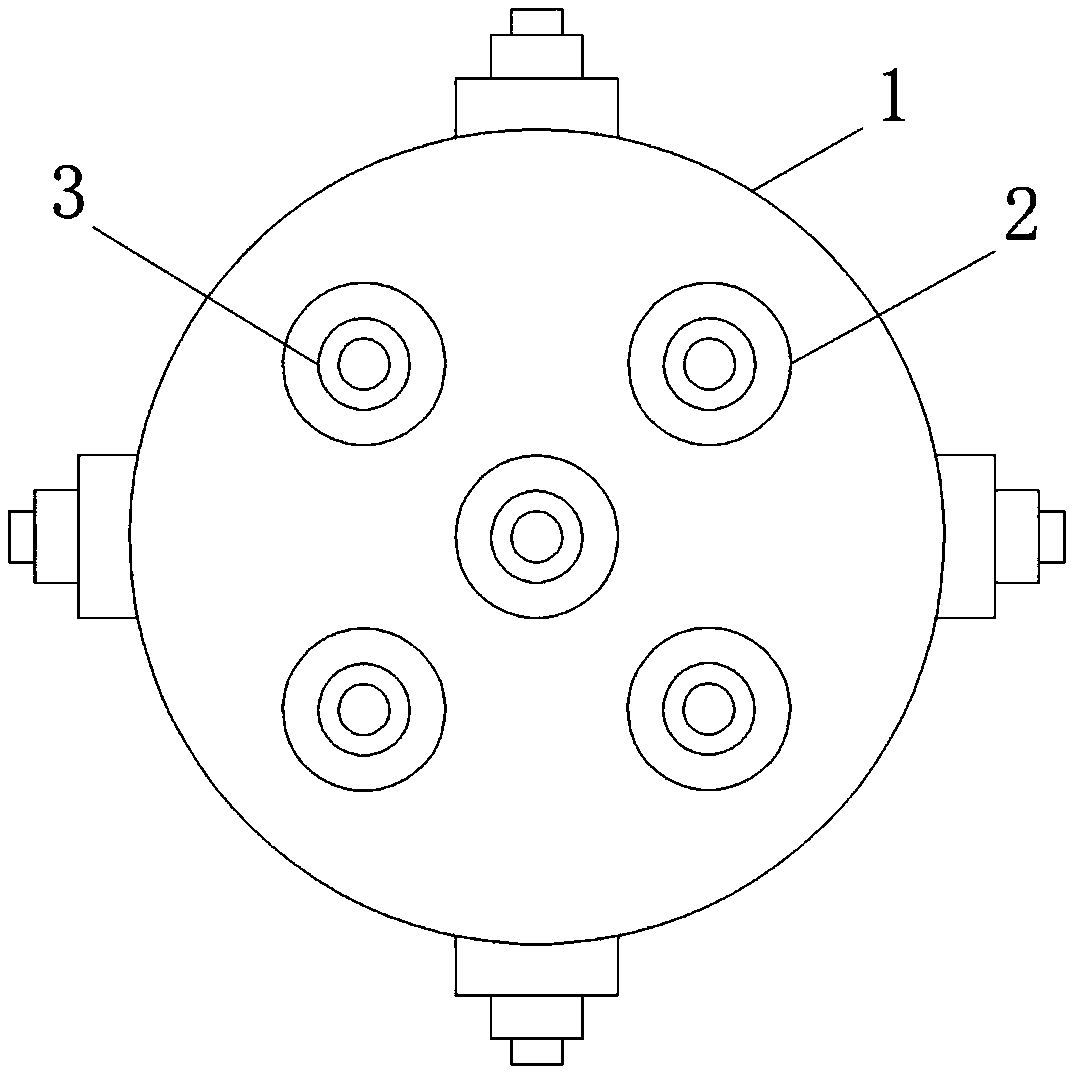

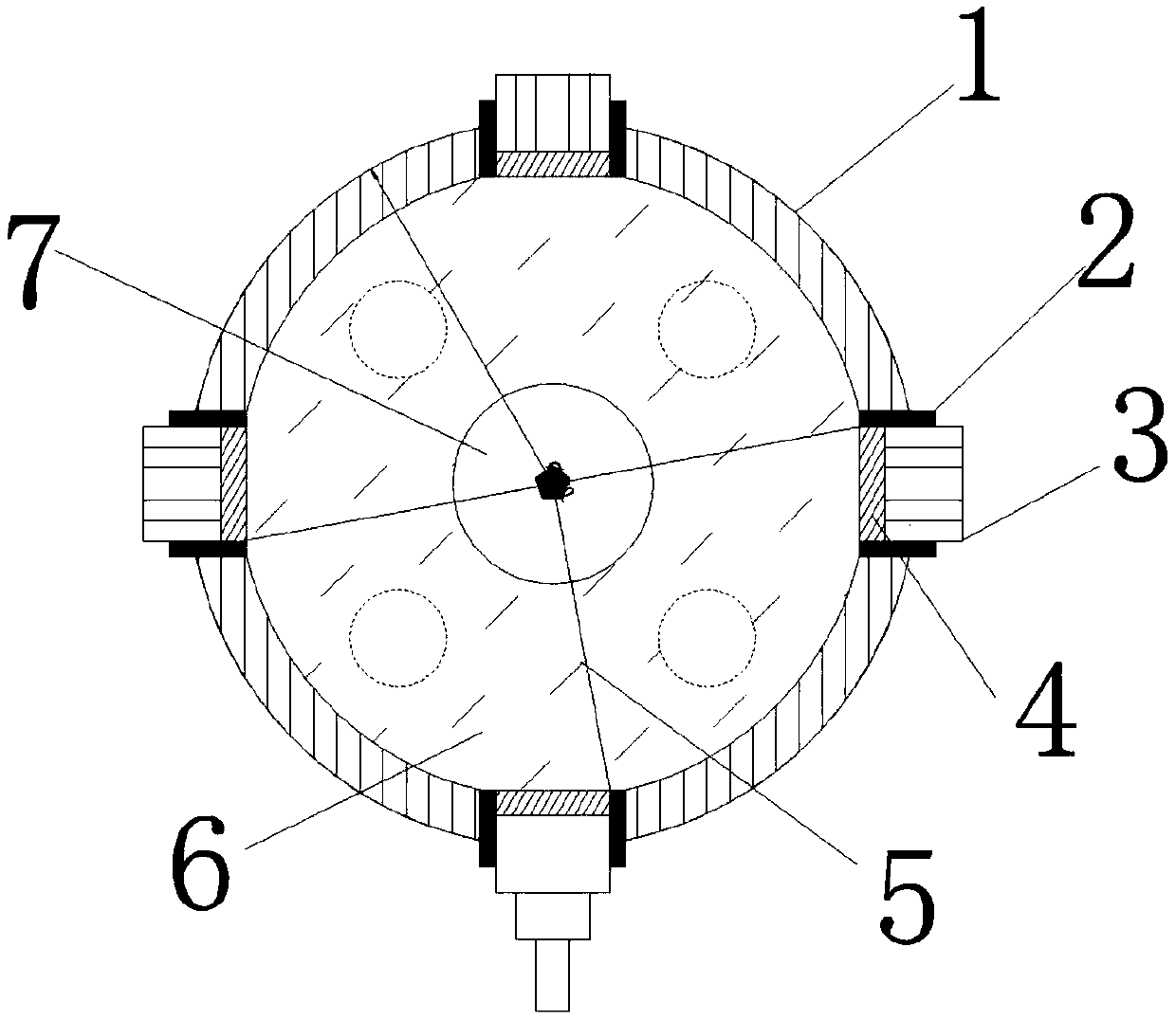

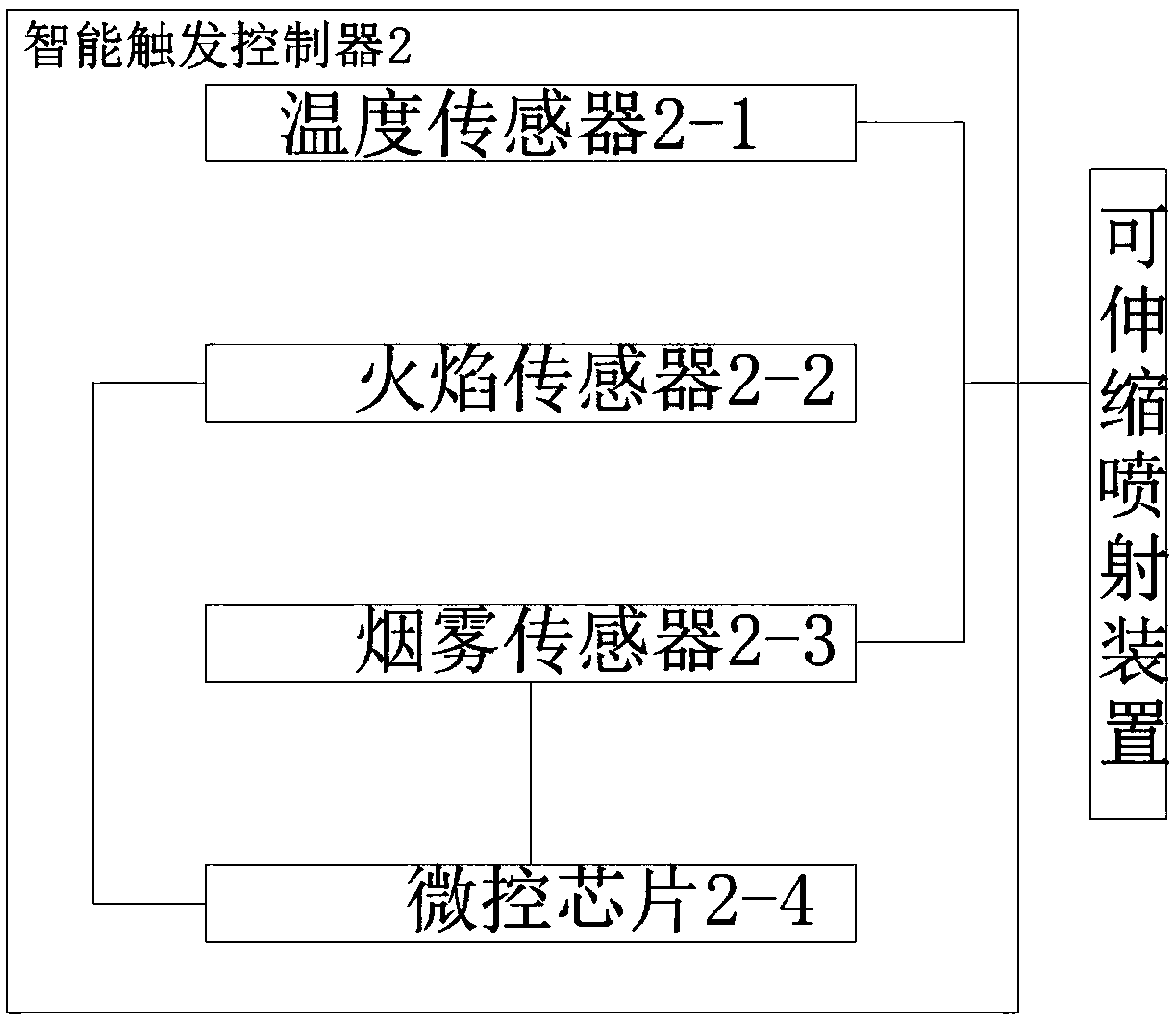

Liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device

The invention relates to a liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device and belongs to the technical field of fire protection and fire extinguishing machinery. The liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device comprises a spherical shell, intelligent trigger controllers, a perfluoro-hexanone fire extinguishing agent and a gas generating agent. The spherical shell is uniformly provided with telescopic jetting devices, and jet orifices of the telescopic jetting devices are sealed through aluminum foil. The intelligent trigger controllers are mounted on the outer portions of the telescopic jetting devices on the spherical shell. Each intelligent trigger controller comprises a fire detection sensor and a microcontrol chip connected with the fire detection sensor. The microcontrol chips judge whether a fire occurs or not according to signals transmitted from the fire detection sensors. The gas generating agent is located at the sphere center position of the spherical shell. The spherical shell is filled with the perfluoro-hexanone fire extinguishing agent. The perfluoro-hexanone fire extinguishing agent is isolated from the gas generating agent. The microcontrol chips of the intelligent trigger controllers are connected to the gas generating agent through electric ignitionwires. When judging that the fire occurs, the microcontrol chips trigger the electric ignition wires to ignite the gas generating agent. The liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device conducts fire extinguishing in a total flooding heat absorbing physical manner and is intelligent, safe, friendly to environment, convenient to use and high in efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

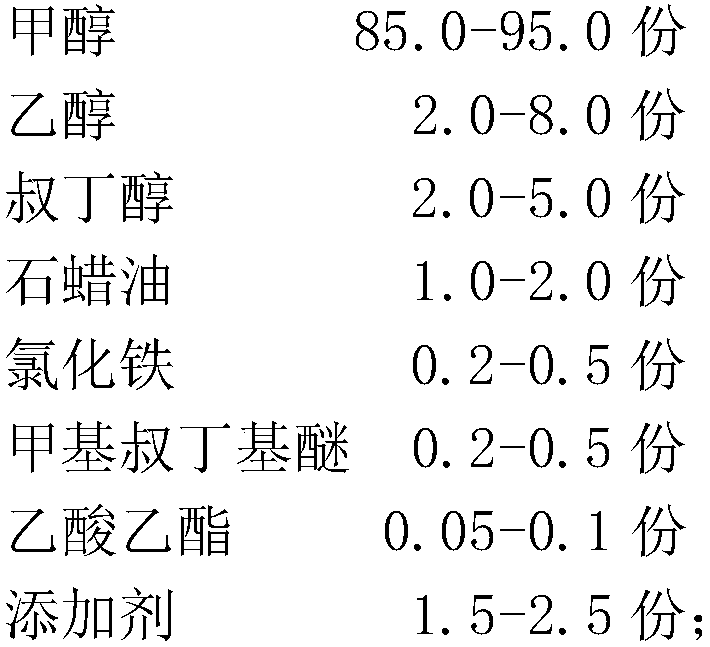

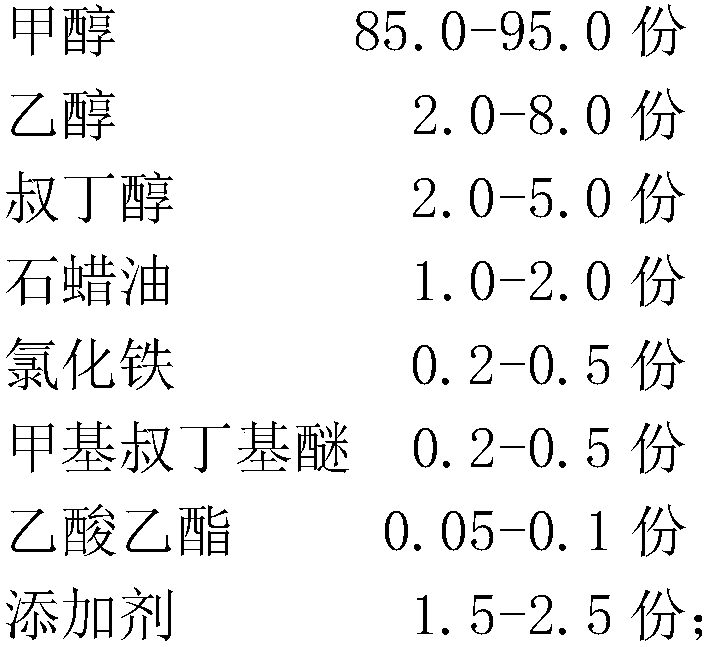

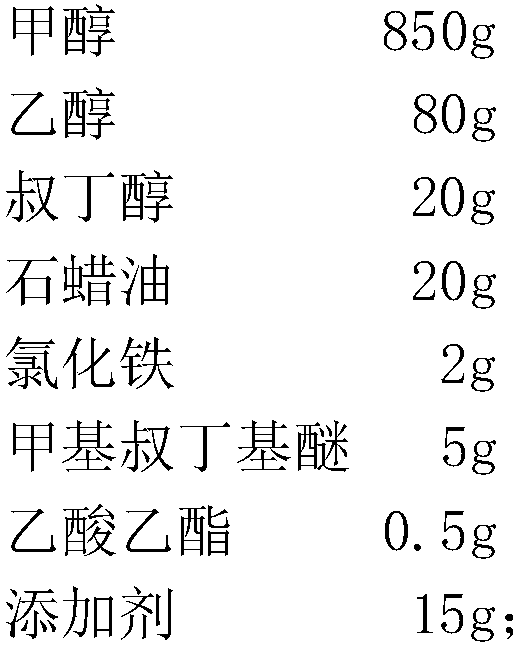

Alcohol-based fuel without eye fumigation in use

InactiveCN107723036AStable combustionBoost octaneLiquid carbonaceous fuelsFuel additivesDistillationOil phase

The invention discloses alcohol-based fuel without eye fumigation in use. The alcohol-based fuel is characterized by being prepared from the following ingredients in parts by weight: 85.0 to 95.0 parts of methyl alcohol, 2.0 to 8.0 parts of ethyl alcohol, 2.0 to 5.0 parts of tertiary butanol, 1.0 to 2.0 parts of paroline, 0.2 to 0.5 part of ferric chloride, 0.2 to 0.5 part of methyl tertiary butylether, 0.05 to 0.1 part of ethyl acetate and 1.5 to 2.5 parts of additive. The additive is prepared from the following preparation method which comprises the steps: (1) forcing treatment: putting water-extracted folium eriobotryae residues into a high-pressure tank, forcing to 3kg / cm<2> to enable pressure to be even, maintaining and then releasing the pressure instantly; (2) distillation treatment: putting the materials obtained in the step (1) into a distiller, heating, burning or introducing steam at the bottom of the distiller, guiding the steam into a condenser through a condensing pipe when the distiller is full of the hot steam and then collecting an oil phase through an oil-water separator; (3) high-shear homogenizer treatment: processing the oil phase obtained in the step (2) by ahigh-shear homogenizer to be prepared into nanoemulsion to obtain the additive.

Owner:桂林淦隆环保设备有限责任公司

Vacuum fiber membrane type oil dewatering treatment device

The invention discloses a vacuum fiber membrane type oil dewatering treatment device which comprises an oil tank, wherein the oil outlet of the oil tank is connected with the inlet of a low-pressure oil pump through a pipeline; the outlet of the low-pressure oil pump is connected with the inlet of a granule filter through a pipeline; the outlet of the granule filter is connected with the oil inletend of a fiber membrane oil-water separator through a pipeline; the oil return end of the fiber membrane oil-water separator is connected with the oil inlet of the oil tank through a pipeline; the exhaust hole of the fiber membrane oil-water separator is connected with a vacuum pump through a pipeline; and a hydrophilic hollow fiber membrane is mounted inside the fiber membrane oil-water separator. The vacuum fiber membrane type oil dewatering treatment device disclosed by the invention is capable of simply, conveniently and effectively removing moisture in oil without changing the state of the oil, the whole device operates at low pressure, electricity consumption and oil seepage risks can be reduced, the air is not in direct contact with the oil, and thus the oil has no oxidation risk.

Owner:中电智为(北京)科技有限公司

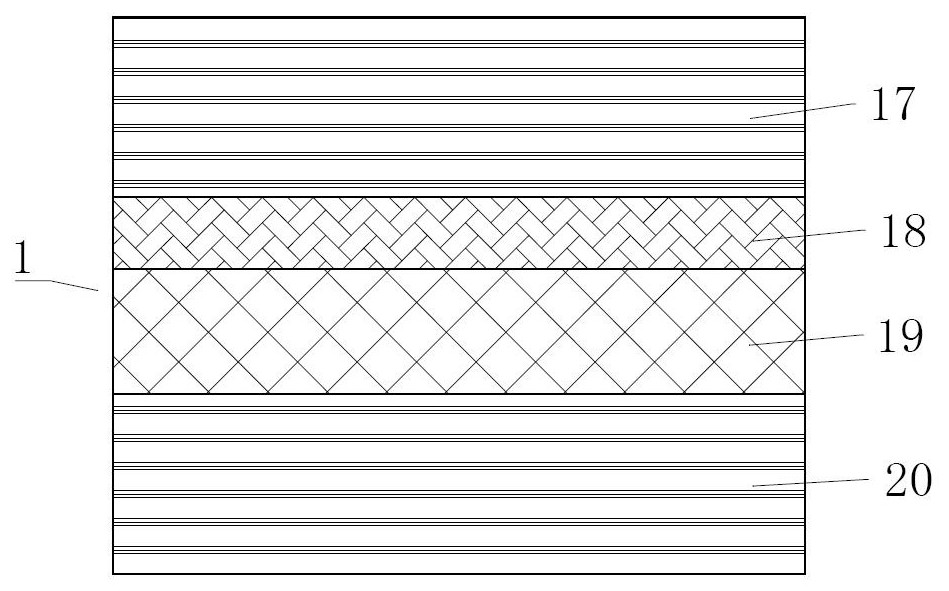

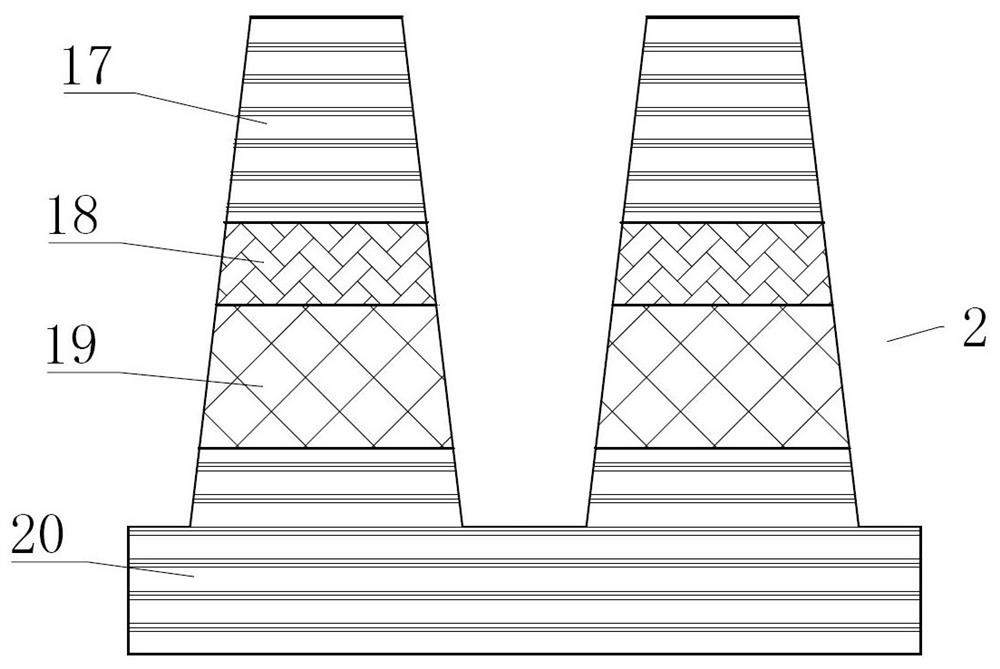

Low-temperature oxidation method of VCSEL chip

PendingCN111834891AConsistent oxidation depthAchieve Uniformity ControlLaser detailsSemiconductor lasersHigh energyEngineering

The invention relates to the technical field of VCSEL chip oxidation preparation, and provides a low-temperature oxidation method for a VCSEL chip, and the method comprises the following steps: etching an epitaxial wafer of the VCSEL chip into a step, and enabling an aluminum-rich AlGaAs layer of the VCSEL chip to be exposed; placing the VCSEL chip on a slide holder of a plasma cavity, and vacuumizing the plasma cavity; communicating argon with a container through a first gas pipeline, and communicating the container with the plasma cavity through a second gas pipeline; electrifying the plasmacavity to generate an electric field inside, ionizing the deionized water into active oxide particles, and reacting the active oxide particles with the aluminum-rich AlGaAs layer to generate an Al2O3layer and volatile byproducts; communicating the plasma cavity with a vacuum pump through a third gas pipeline, and enabling the vacuum pump to discharge volatile by-products to the outer side of thecavity. According to the invention, the problems of non-uniform oxidation of the VCSEL chip, the low production yield, high cost and high energy consumption which are easily caused by difficult control of temperature uniformity in the traditional high-temperature wet oxidation process are solved.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

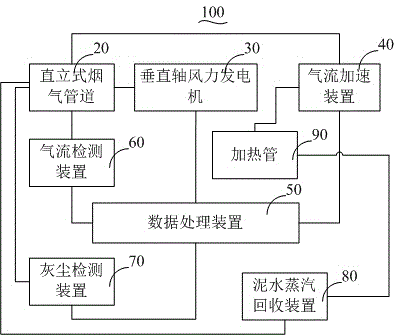

Energy-saving power generating and heating system using submerged arc furnace waste heat

ActiveCN104315870ASimple structureLow costEnergy industryIncreasing energy efficiencyWind drivenVertical axis wind turbine

A energy-saving power generating and heating system using submerged arc furnace waste heat comprises a vertical smoke pipeline, a vertical-axis wind driven generator, an air flow accelerating device, a data processing device and a muddy water steam recycling device. The vertical-axis wind driven generator is fixed with the vertical smoke pipeline. The blades of the vertical-axis wind driven generator are located in the vertical smoke pipe. The air flow accelerating device penetrates a second fixing hole and is fixed with the vertical smoke pipeline. The spray nozzle of the air flow accelerating device is located in the vertical smoke pipeline. The spray nozzle comprises a base, a first nozzle body, a second nozzle body and a third nozzle body. The second nozzle body is vertical to the central axis of the vertical smoke pipeline. The first nozzle body points to the blades of the vertical-axis wind driven generator. The third nozzle body points to the bottom of the vertical smoke pipeline. The data processing device controls the air flow accelerating device to work. Heat exchanging pipes are further arranged on the inner wall of the vertical smoke pipeline. The muddy water steam recycling device recycles steam reaching the upper end of the vertical smoke pipeline to obtain muddy water.

Owner:中卫市胜金北拓建材有限公司

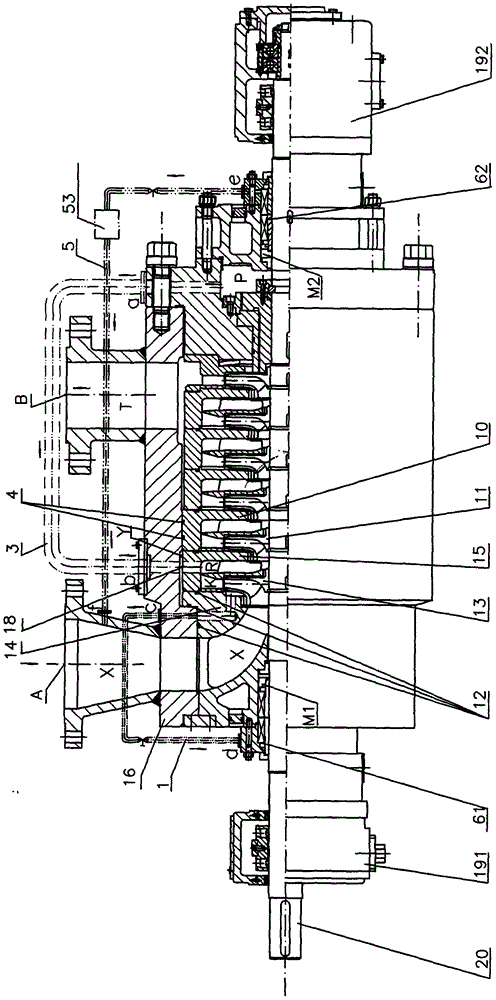

Multistage centrifugal high pressure liquefied hydrocarbon pump

ActiveCN105864093AGuaranteed uptimeImprove cooling effectSpecific fluid pumpsPump componentsRubber ringImpeller

The invention relates to a multistage centrifugal high pressure liquefied hydrocarbon pump. The multistage centrifugal high pressure liquefied hydrocarbon pump comprises an axial force balance mechanism, a mechanical seal self-flushing mechanism and a rotating shaft, wherein a liquid return hole is formed in a first-stage middle section of the pump, a second-stage middle section sealing rubber ring is arranged between a second-stage middle section of the pump and an outer barrel, and a suction box body sealing rubber ring is arranged among a suction box body, the outer barrel and the first-stage middle section; one end of a balance liquid return pipe assembly is connected with a balance chamber, and the other end of the balance liquid return pipe assembly is connected with a second-stage impeller suction chamber by virtue of the outer barrel; one end of a forward flushing pipe assembly is connected with an outlet of a first-stage impeller, the other end of the forward flushing pipe assembly is connected with a driving side mechanical seal assembly, one end of a backward flushing pipe assembly is connected with a suction chamber, and the other end of the backward flushing pipe assembly is connected with a non-driving side mechanical seal assembly. The multistage centrifugal high pressure liquefied hydrocarbon pump also comprises an automatic control reflux type thermal control mechanism. The multistage centrifugal high pressure liquefied hydrocarbon pump has the advantages that vaporization of pumping medium can be prevented, cooling and lubricating properties of a mechanical seal end face are improved, quantity of minimum continuous thermal limited flows can be reduced, energy consumption can be reduced, and safe and reliable operation of the pump is guaranteed.

Owner:ZHEJIANG KEER PUMP

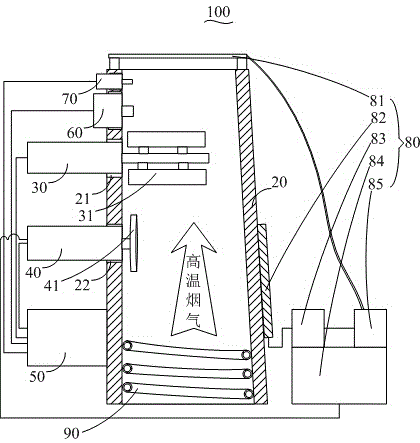

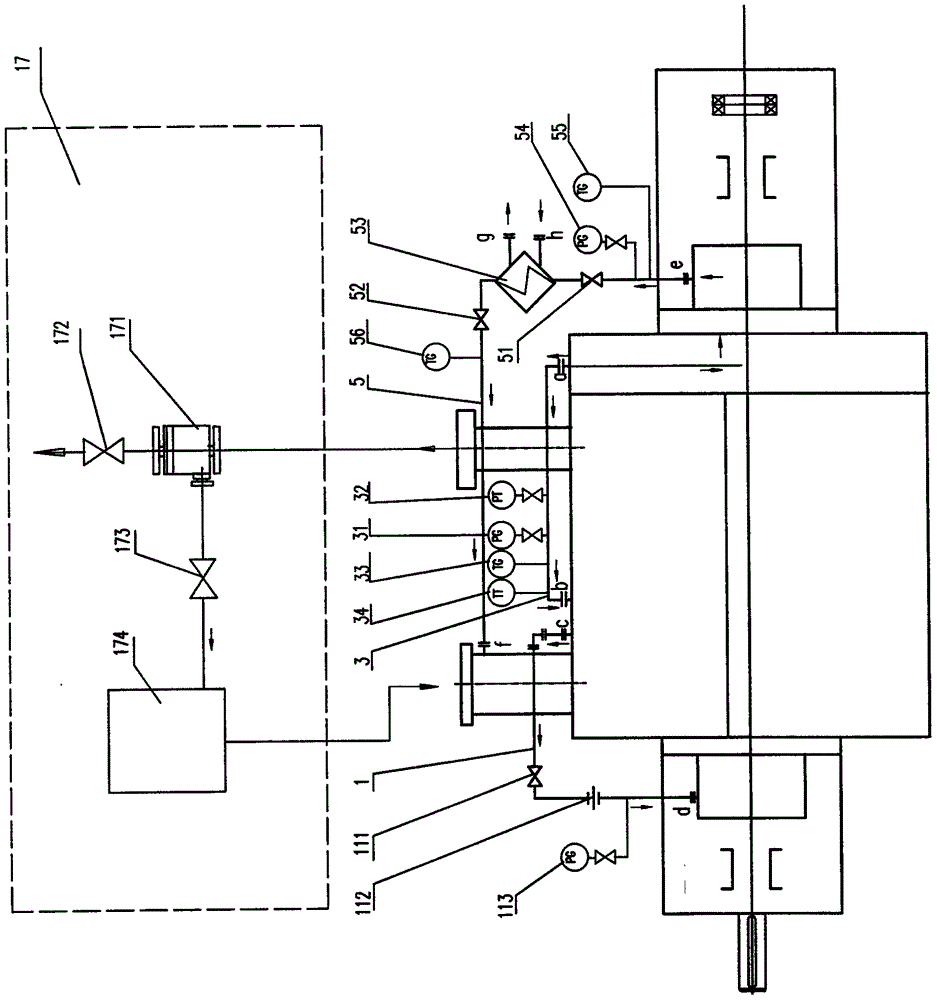

Coke oven gas waste heat recovery system

ActiveCN104845645AAvoid damageImprove waste heat recovery effectEnergy inputDistillation gas withdrawalWaste heat recovery unitProduct gas

The invention relates to a coke oven gas waste heat recovery system. The coke oven gas waste heat recovery system comprises a split-type heat pipe, the split-type heat pipe comprises an evaporator device and a condenser, the evaporator device comprises a heat absorbing surface region formed by a coke oven gas guiding pipeline, the condenser comprises a steam pocket and a condenser pipeline arranged in the steam pocket, the inlet end of the condenser pipeline is communicated with a working medium outlet of the evaporator device via a gas working medium pipeline, the outlet end of the condenser pipeline is communicated with a working medium inlet of the evaporator device via a liquid working medium pipeline, a fill cavity is arranged in the heat absorbing region, and a phase-change material layer is arranged in the heat absorbing region. The coke oven gas waste heat recovery system has the advantages that by means of reconstructing the coke oven gas guiding pipeline (an ascension pipe and a bridge pipe) into the evaporator with the split-type heat pipe, coke oven gas waste heat can be recovered by the split type heat pipe; by means of arranging the phase-change material layer in the heat absorbing region, generation of periodic heat shock to a waste heat recovery device can be avoided, and waste heat recovery and production stability are improved effectively.

Owner:WISDRI ENG & RES INC LTD

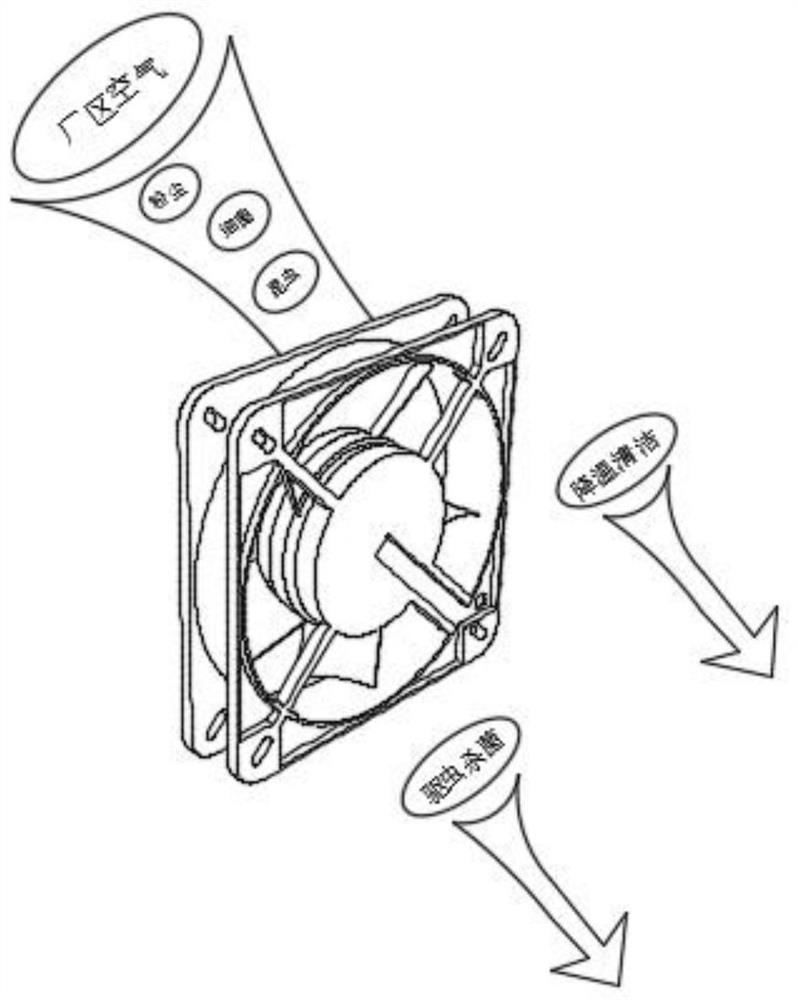

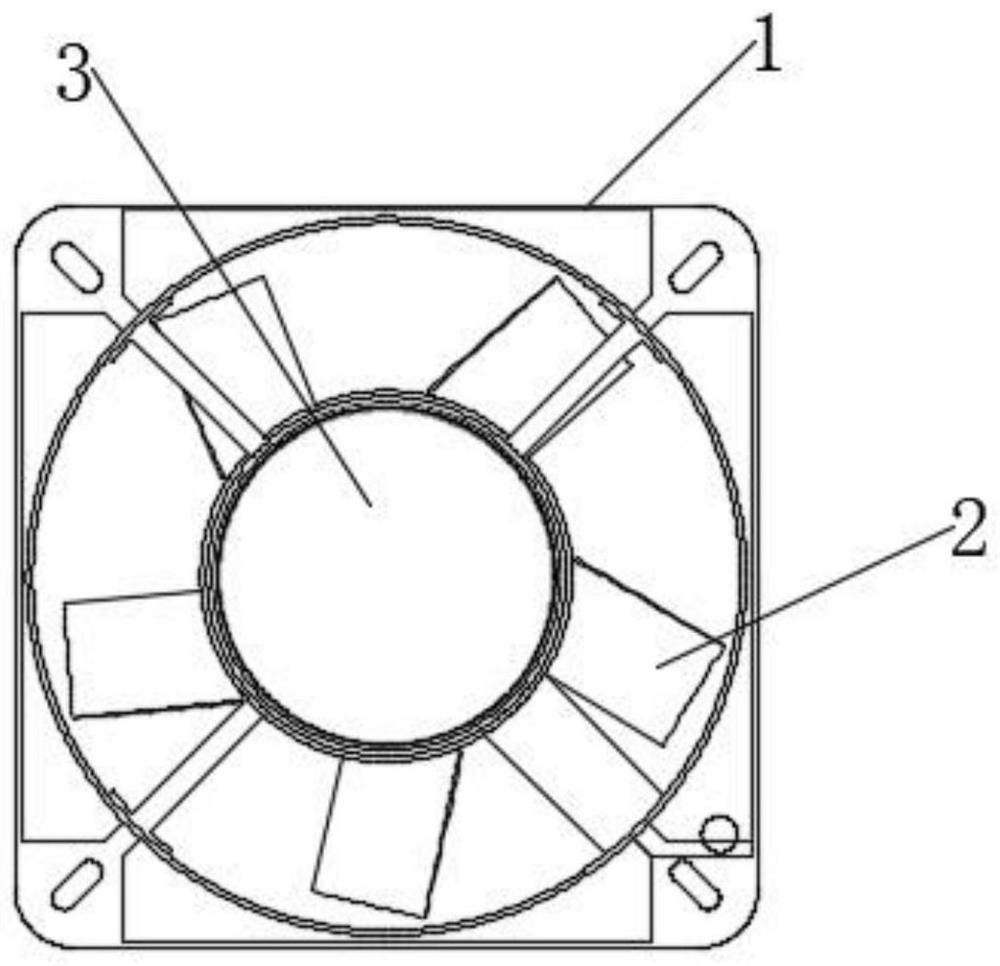

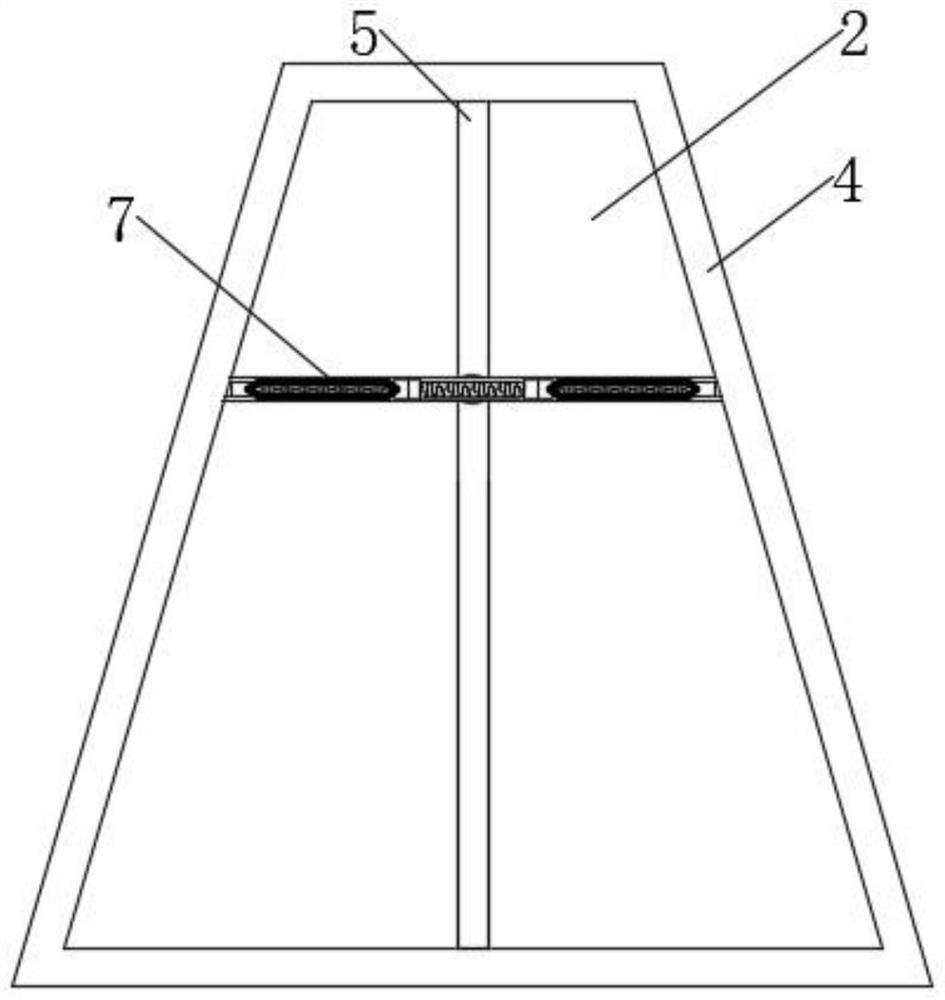

Novel self-cleaning type multifunctional industrial fan

PendingCN111980948AReduce breedingGuaranteed surface cleanlinessPump componentsPump controlDisinfectantSurface cleaning

The invention discloses a novel self-cleaning type multifunctional industrial fan, and belongs to the field of industrial fan equipment. According to the novel self-cleaning type multifunctional industrial fan, a timing motor controller controls a three-phase motor to enable fan blades to start to rotate, a balancing weight does centrifugal motion away from the timing motor controller under the action of centrifugal force, a cleaning brush head cleans dust on the surfaces of the fan blades, the surface cleanliness is maintained, and the possibility of bacterium breeding is reduced; under the stretching action of a second connecting block, a compression film shrinks, the inner diameter is reduced, and therefore a compression ball is extruded; an atomization spray head atomizes and sprays out disinfectant and clear water, the clear water can wet the dust to enable the dust to be prone to sedimentation, the atomized clear water is prone to vaporization and heat absorption for cooling, theevenly-spread disinfectant can sterilize and disinfect the space, and the healthy air environment is maintained; and the timing motor controller can control the three-phase motor to periodically andintermittently run, a side sliding block is pulled and dragged to reset along a side sliding groove under the elastic force action of an extension spring, and one-time periodic sterilization and cleaning are completed.

Owner:ANHUI JINWAN PUMP TECH CO LTD

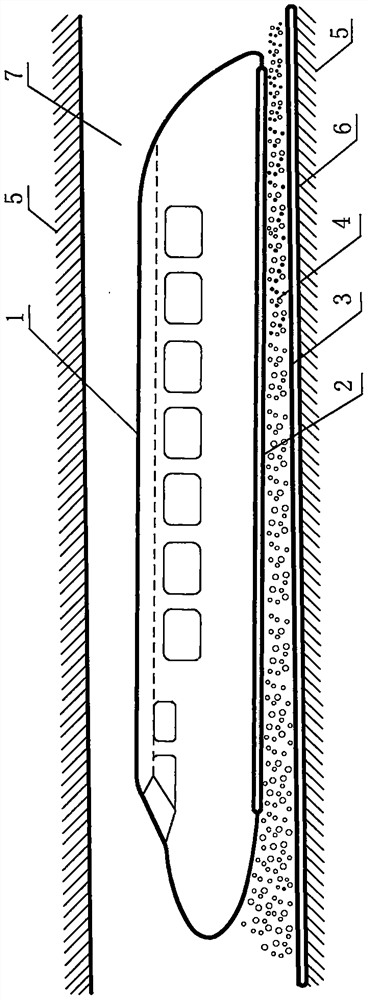

Vacuum pipeline fluid film suspension vehicle system

PendingCN112829771ALow densityDriving at high speedRailway tunnelsSliding/levitation railway systemsViscous flowSuspension (vehicle)

The invention relates to a vacuum pipeline fluid film suspension vehicle system, which combines a low-pressure vacuum pipeline with a fluid film suspension vehicle, and the fluid film suspension vehicle directly forms a pressure fluid film between a chassis and a track surface by virtue of a fluid dynamic pressure effect so as to suspend and run in the vacuum pipeline. The density of gas in the pipeline, the viscosity of fluid in the fluid film and the boiling point of the fluid in the fluid film are reduced by reducing the gas pressure in the vacuum pipeline. The pressure difference resistance in the driving process can be reduced by reducing the gas density; the viscosity resistance on the train chassis can be reduced by reducing the viscosity of the fluid in the fluid film; the reduction of the boiling point of the fluid in the fluid film can promote the fluid film to automatically generate a phase change process under the pneumatic heating action so as to increase the thickness of the fluid film, improve the loading capacity, reduce the viscosity of the fluid film and reduce the viscous resistance of a train chassis. According to the vacuum pipeline fluid film suspension train, the running resistance can be reduced to the maximum extent, and high-speed, efficient and stable suspension running of the train is achieved.

Owner:崔彬

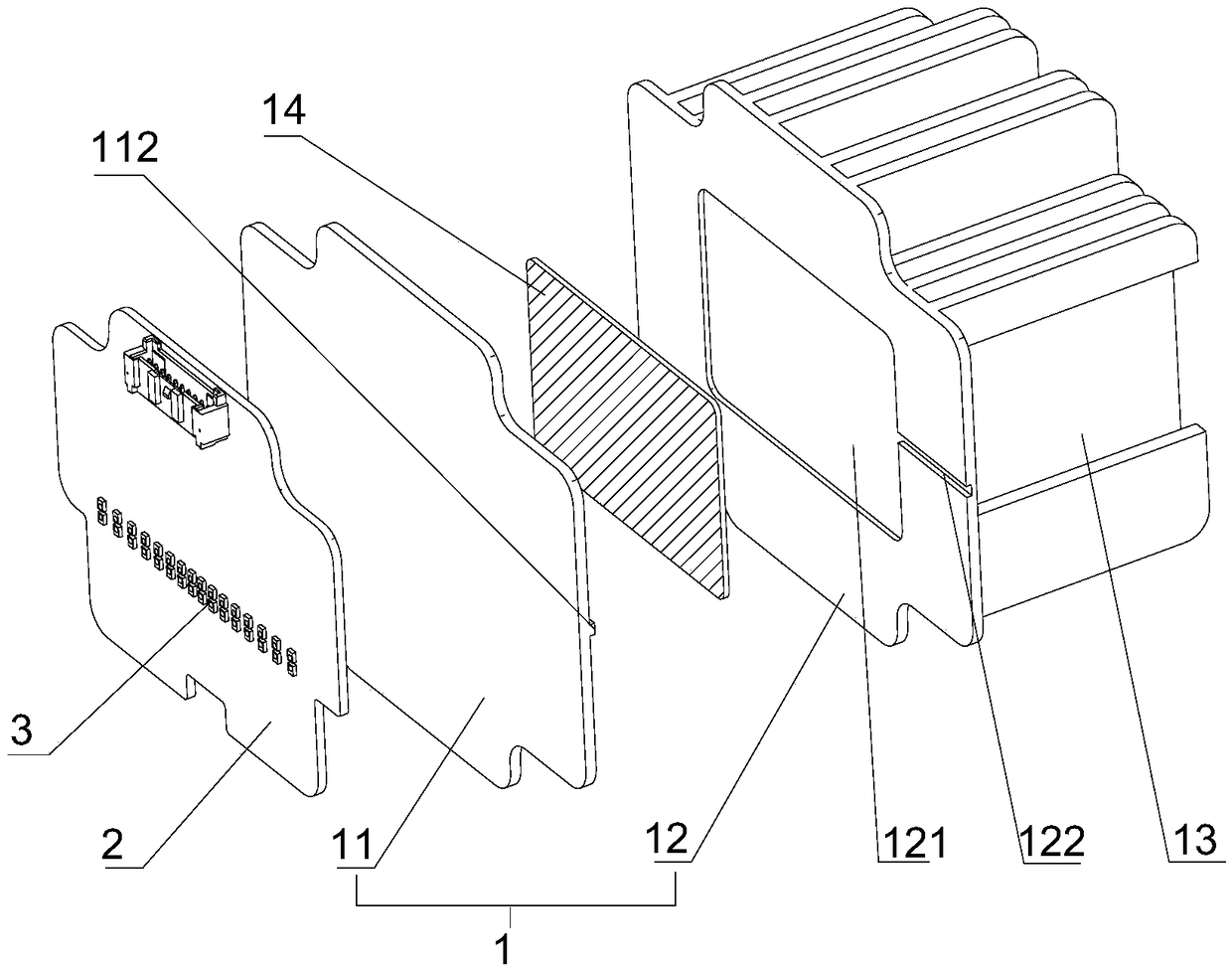

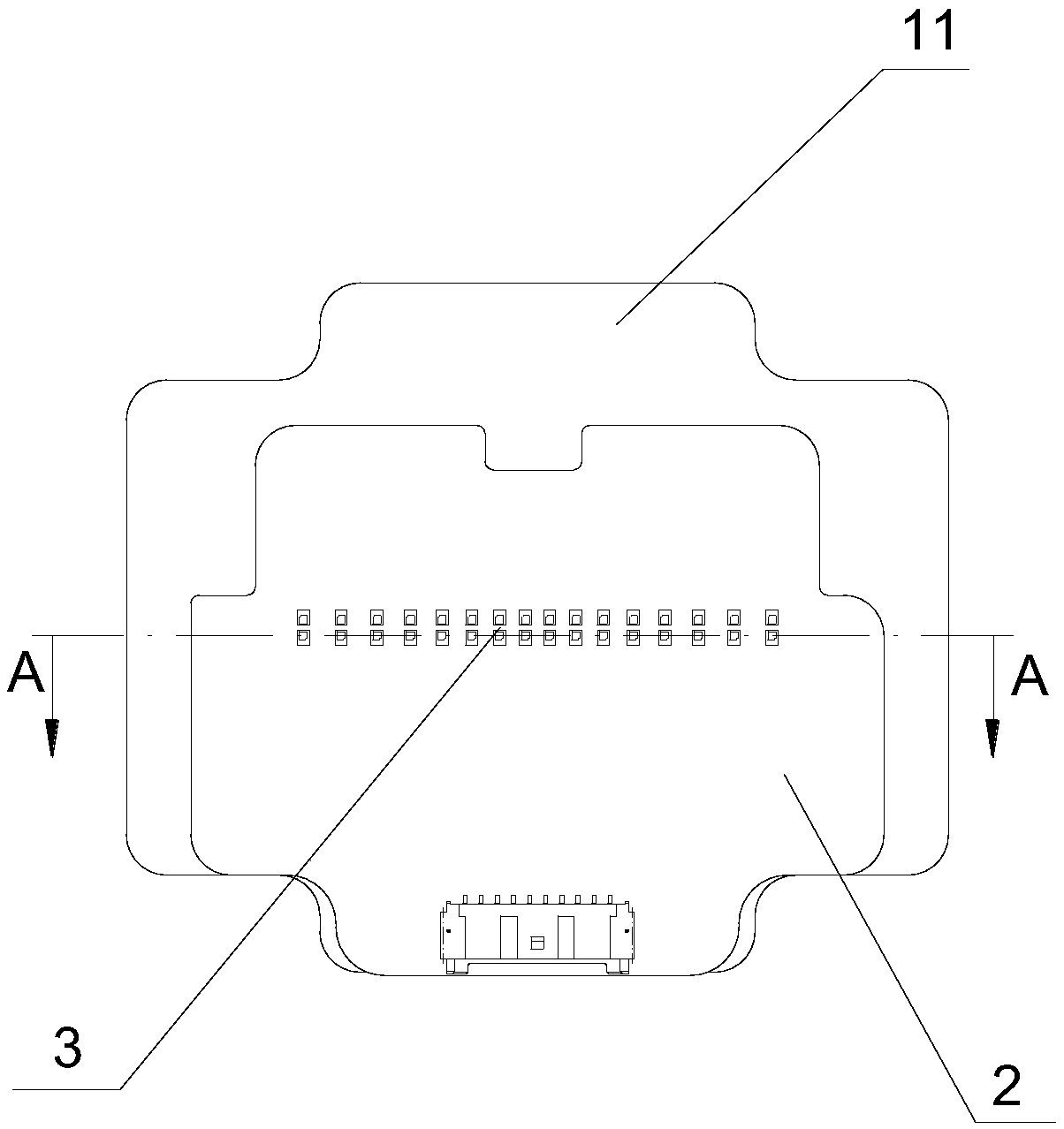

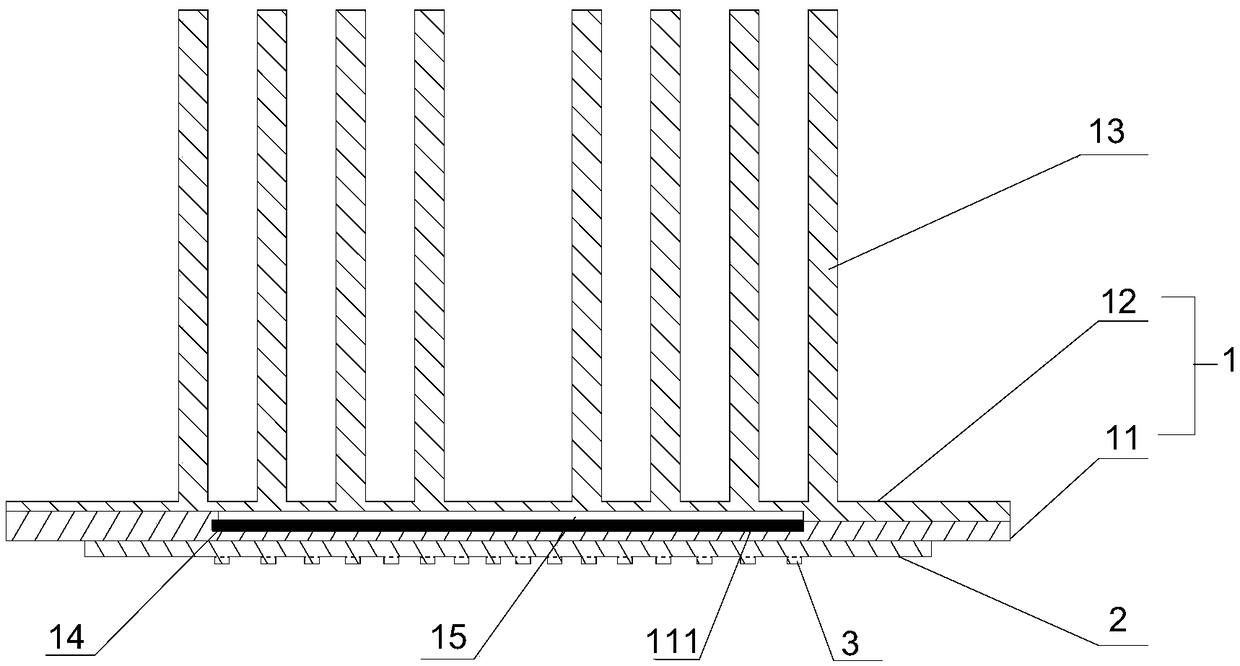

Car lamp and car lamp cooling device

PendingCN108758556ASimple structureGood cooling effectLighting heating/cooling arrangementsSignalling/lighting devicesHeat sinkEngineering

The invention relates to the field of cars, in particular to a car lamp and a car lamp cooling device. The car lamp cooling device comprises a cooling body, wherein a sealed containing cavity is formed in the cooling body, the containing cavity is used for containing condensing media, and a cooling fin is arranged on one side of the cooling body. The containing cavity is formed in the cooling body, the containing cavity contains the condensing media, and the condensing media are heated to vaporize and are cooled to liquefy so as to assist to cool; the structure is simple, and the cooling effect is good. The problems of complex cooling structure and bad cooling effect of the car lamp in the prior art are solved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com