Dimethyl ether engine efficient, ultra-low emission combustion system

A technology for combustion systems and engines, applied in engine components, combustion engines, machines/engines, etc., to solve problems such as being unsuitable for practical motor vehicle applications, high nitrogen oxide emissions, and inoperable engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

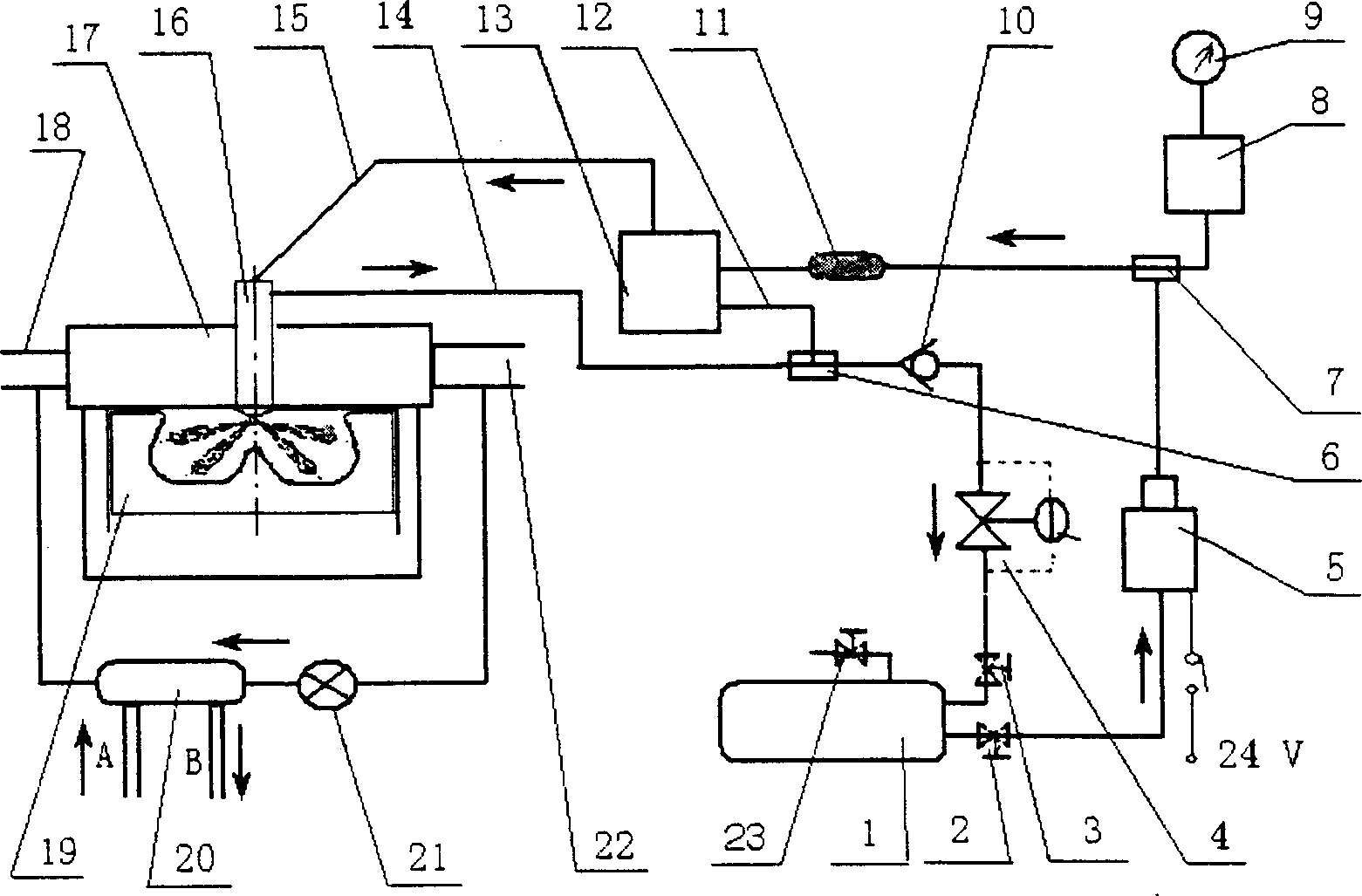

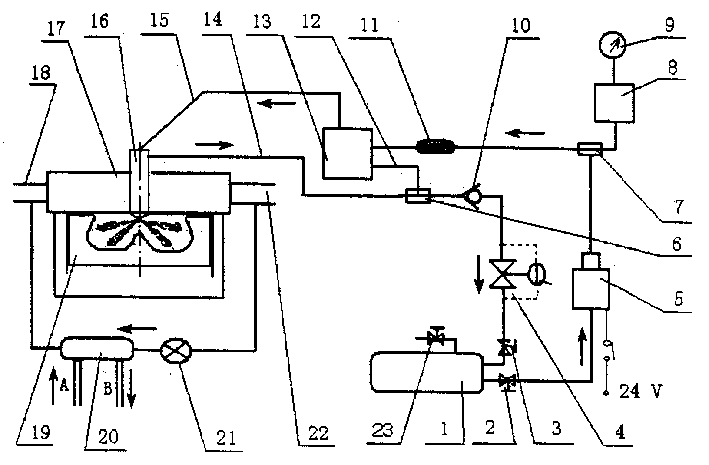

[0009] like figure 1 As shown, the present invention includes: DME storage tank 1, liquid outlet valve 2, return valve 3, pressure control valve 4, low-pressure fuel delivery pump 5, oil return tee joint 6, tee joint 7, pressure accumulator 8, pressure Table 9. Check valve 10, fuel filter 11, fuel injection pump return pipe 12, enhanced fuel injection pump 13, fuel injector return pipe 14, high-pressure fuel pipe 15, super multi-hole injector 16, cylinder head 17, inlet Gas pipe 18, combustion chamber 19, exhaust gas recirculation cooler 20, exhaust gas recirculation control valve 21, exhaust pipe 22, liquid filling valve 23, the connection method is: DME storage tank 1 passes liquid outlet valve 2 and low-pressure fuel delivery pump 5, the outlet of the low-pressure fuel delivery pump 5 is connected with the fuel filter 11 and the enhanced fuel injection pump 13 through the tee joint 7 to form a low-pressure fuel delivery system. The fuel injectors 16 are connected to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com