Semiconductor device and manufacturing method thereof

a semiconductor and semiconductor technology, applied in non-linear optics, instruments, optics, etc., can solve problems such as the difference between the stoichiometric composition of an oxide semiconductor and the stoichiometric composition, and achieve the effect of easy breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

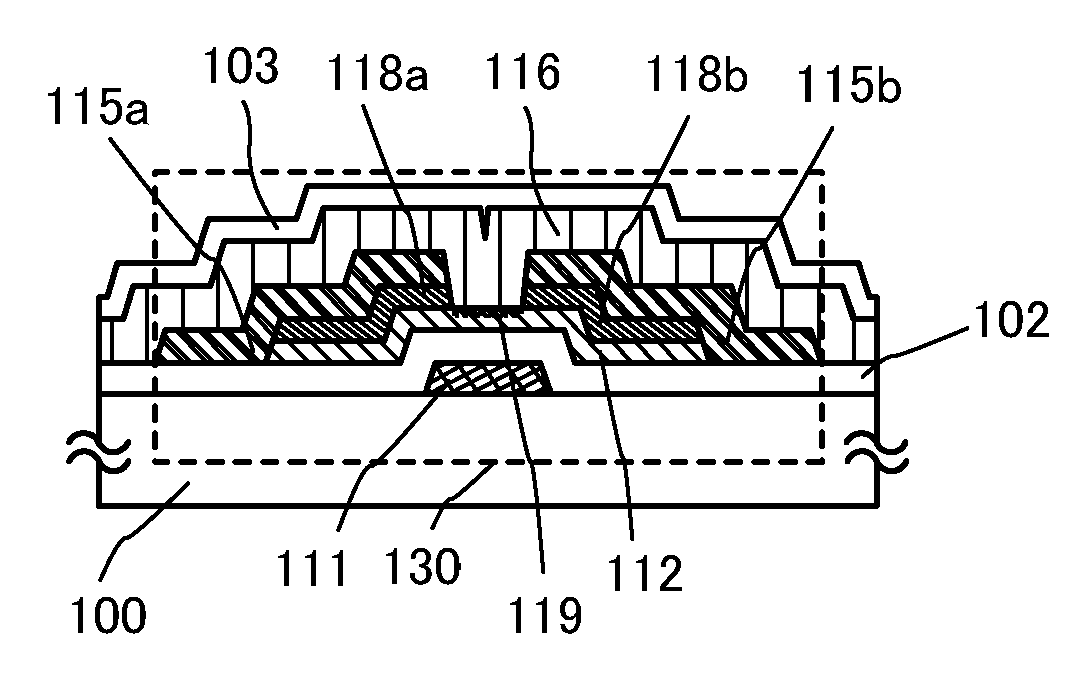

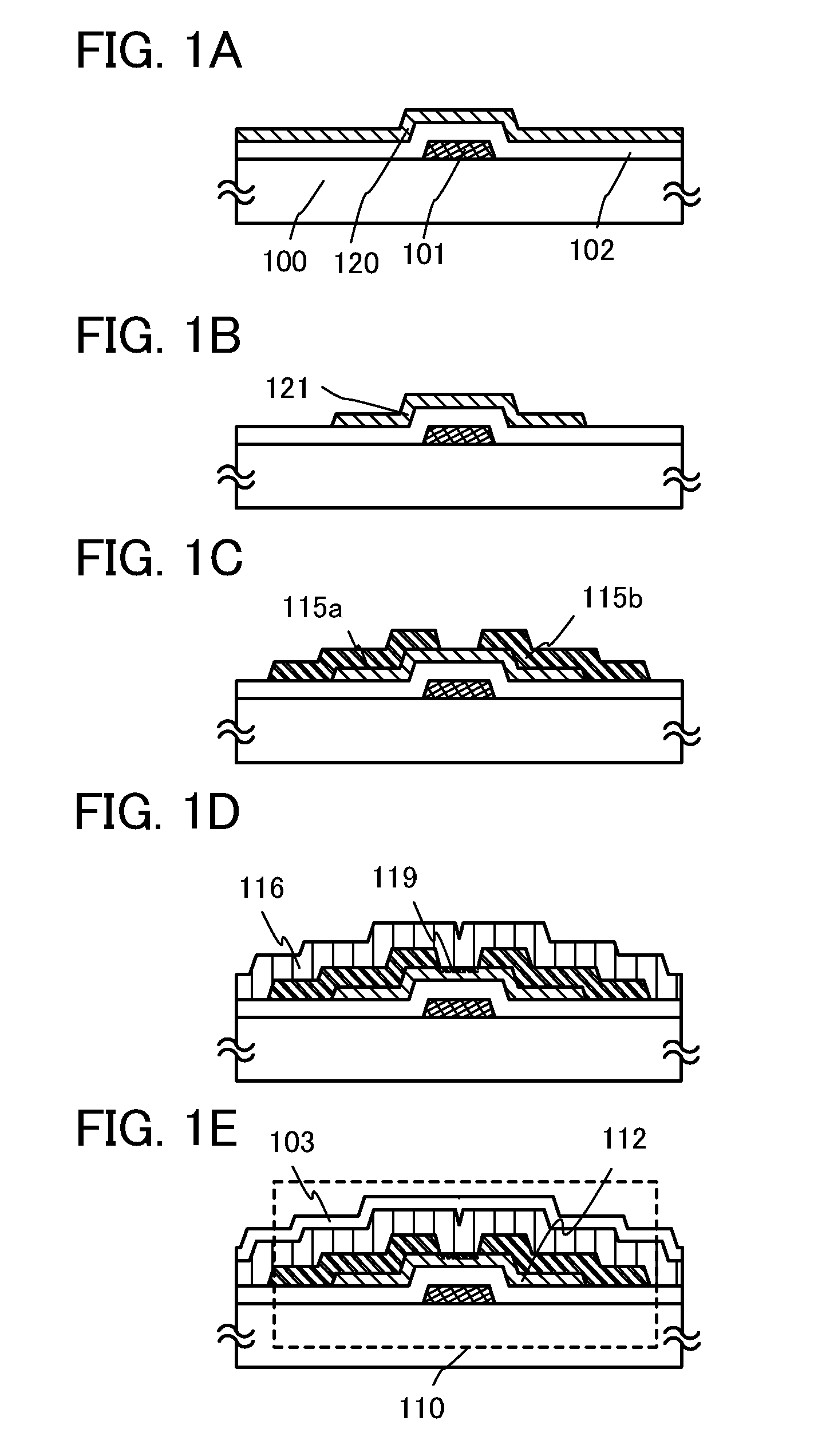

[0055]In this embodiment, an embodiment of a semiconductor device and a manufacturing method of the semiconductor device will be described with reference to FIGS. 1A to 1E. The semiconductor device described in this embodiment is a thin film transistor.

[0056]FIGS. 1A to 1E illustrate an example of a cross-sectional structure of a semiconductor device. A thin film transistor 110 illustrated in FIGS. 1A to 1E has a bottom-gate structure called a channel-etched structure and is also referred to as an inverted staggered thin film transistor.

[0057]The thin film transistor 110 is described using a single-gate thin film transistor; however, a multi-gate thin film transistor including a plurality of channel formation regions can be formed as necessary.

[0058]Hereinafter, a process for manufacturing the thin film transistor 110 over a substrate 100 is described with reference to FIGS. 1A to 1E.

[0059]First, a conductive film is formed over the substrate 100 having an insulating surface, and th...

embodiment 2

[0175]In this embodiment, another example of a thin film transistor which can be applied to a semiconductor device disclosed in this specification will be described.

[0176]In this embodiment, an embodiment of a semiconductor device and a manufacturing method of the semiconductor device will be described with reference to FIGS. 5A to 5E.

[0177]FIGS. 5A to 5E illustrate an example of a cross-sectional structure of a semiconductor device. A thin film transistor 160 illustrated in FIGS. 5A to 5E has a bottom-gate structure called a channel-protective structure (also referred to as a channel-stop structure) and is also referred to as an inverted staggered thin film transistor.

[0178]Although the thin film transistor 160 is described using a single-gate thin film transistor; a multi-gate thin film transistor including a plurality of channel formation regions can be formed as necessary.

[0179]Hereinafter, a process for manufacturing the thin film transistor 160 over a substrate 150 is describe...

embodiment 3

[0212]In this embodiment, another example of a thin film transistor which can be applied to a semiconductor device disclosed in this specification will be described.

[0213]In this embodiment, an embodiment of a semiconductor device and a manufacturing method of the semiconductor device will be described with reference to FIGS. 6A to 6C.

[0214]Although a thin film transistor 190 is described using a single-gate thin film transistor; a multi-gate thin film transistor including a plurality of channel formation regions can be formed as necessary.

[0215]Hereinafter, a process for manufacturing the thin film transistor 190 over a substrate 140 is described with reference to FIGS. 6A to 6C.

[0216]First, a conductive film is formed over the substrate 140 having an insulating surface, and then, a gate electrode layer 181 is formed through a first photolithography step. In this embodiment, a tungsten film with a thickness of 150 nm is formed using a sputtering method as the gate electrode layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com