Liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device

A technology of liquid filling and fire-extinguishing equipment, applied in fire rescue and other directions, can solve the problems of low fire-extinguishing efficiency, short storage period, unsuitable fire-extinguishing agent, etc., and achieve the effect of convenient transportation and operation, suitable for transportation and storage, and targeted fire-extinguishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The spherical fire extinguishing equipment will be clearly and completely described below in conjunction with the accompanying drawings, and the embodiments are only used to explain the present invention, not to limit the protection scope of the present invention.

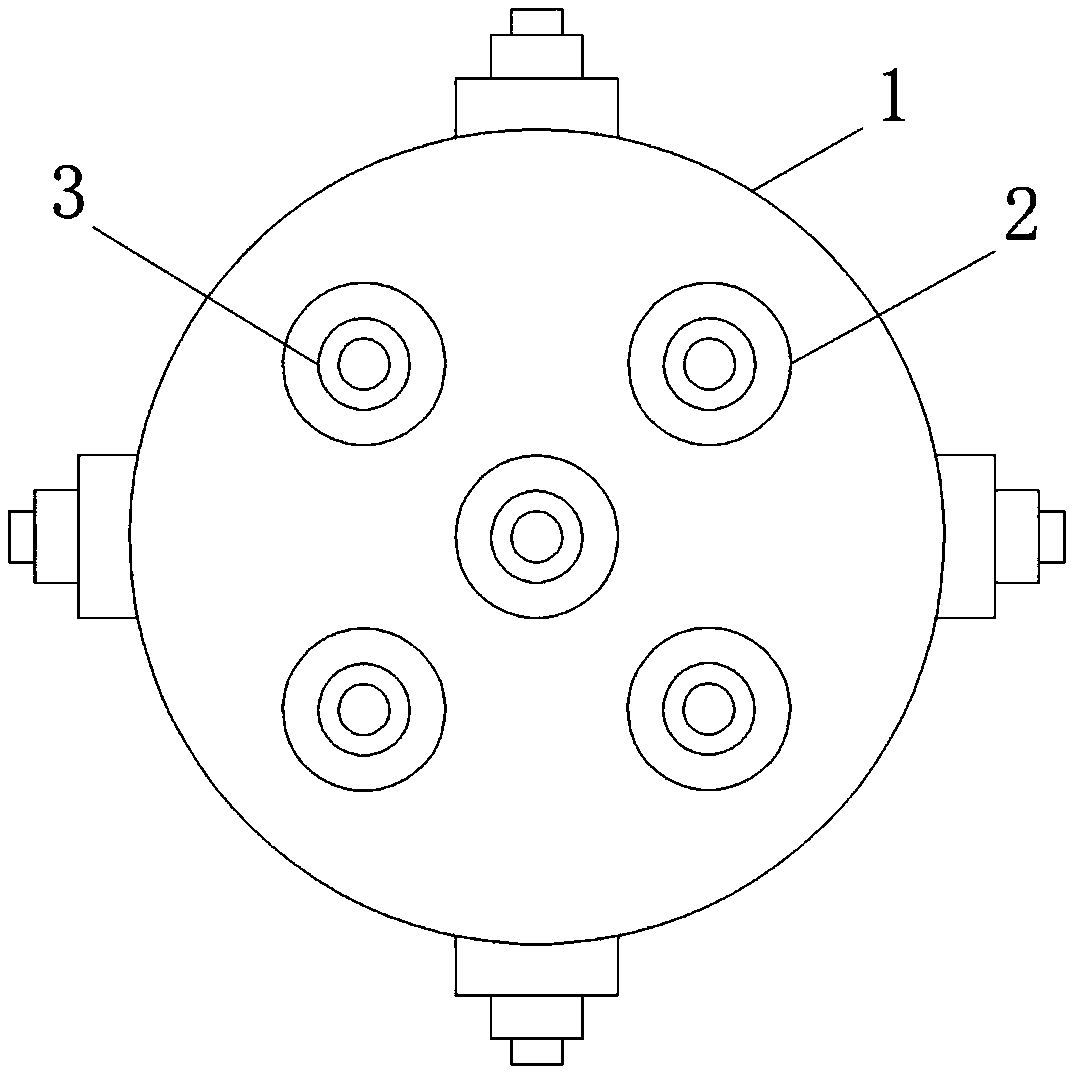

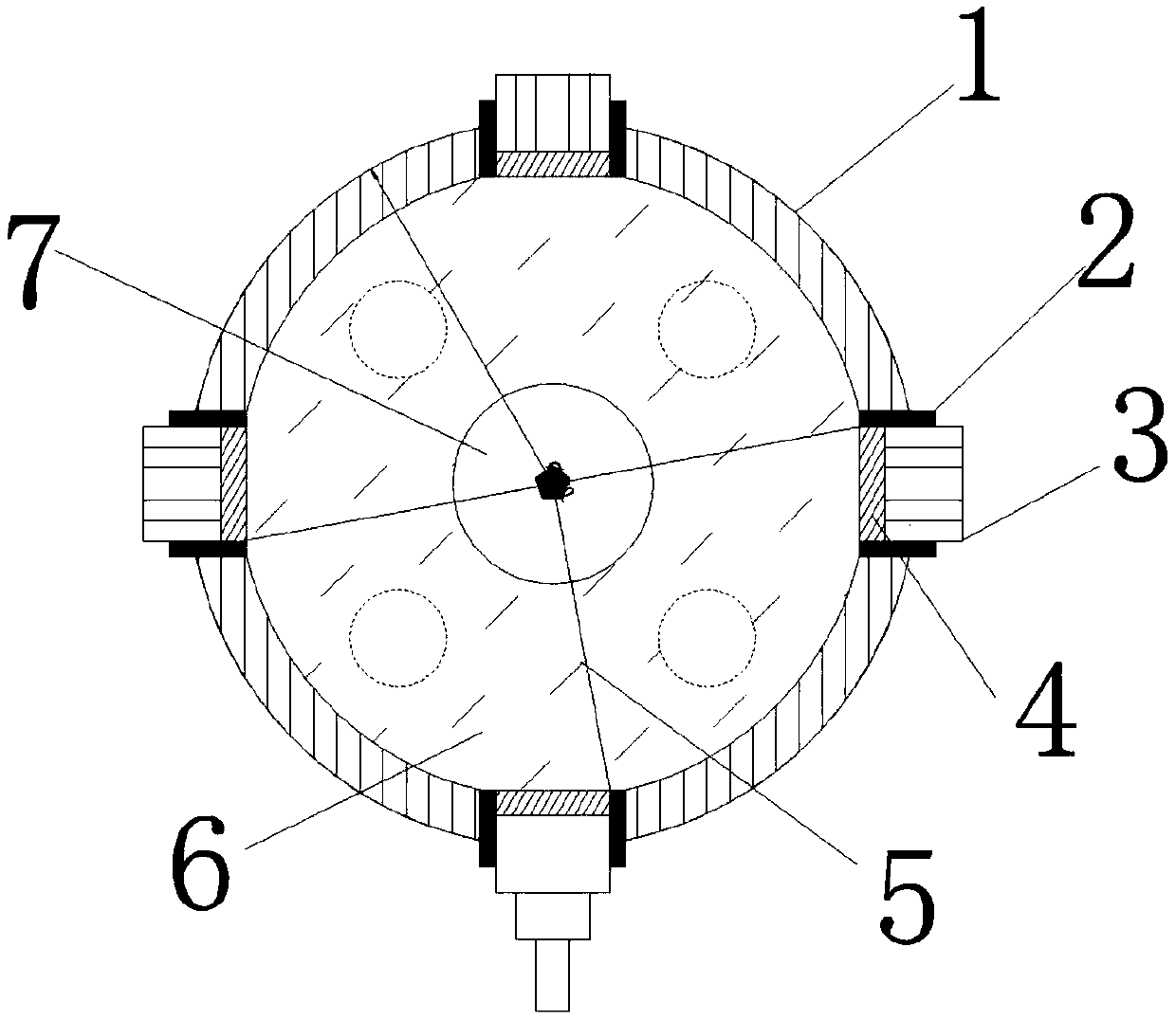

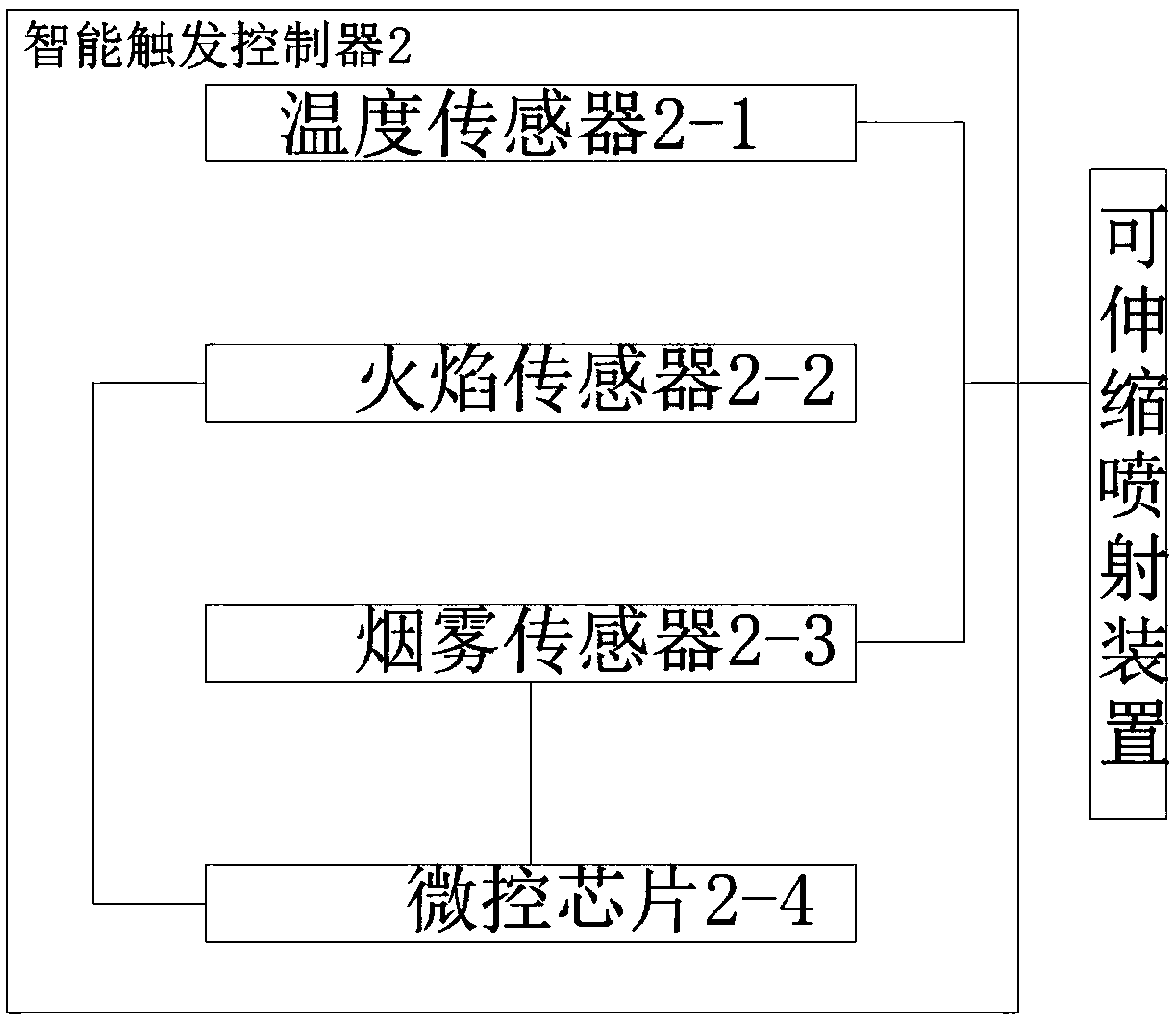

[0030] See attached figure 1 , 2 3. A liquid-filled intelligent multi-directional injection spherical fire extinguishing equipment, including a spherical housing 1, an intelligent trigger controller 2, a retractable injection device (composed of 3 and 4), a perfluorohexanone fire extinguishing agent 7 and a gas generator Agent 8.

[0031] There are multiple injection devices evenly distributed on the spherical shell 1, and the injection ports are sealed by aluminum foil; in this example, the spherical shell 1 is made of explosion-proof carbon steel material, and the thickness is enough to withstand the high pressure generated by the fire extinguishing agent injection process without obvious deformation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com