Patents

Literature

147results about How to "Safe operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

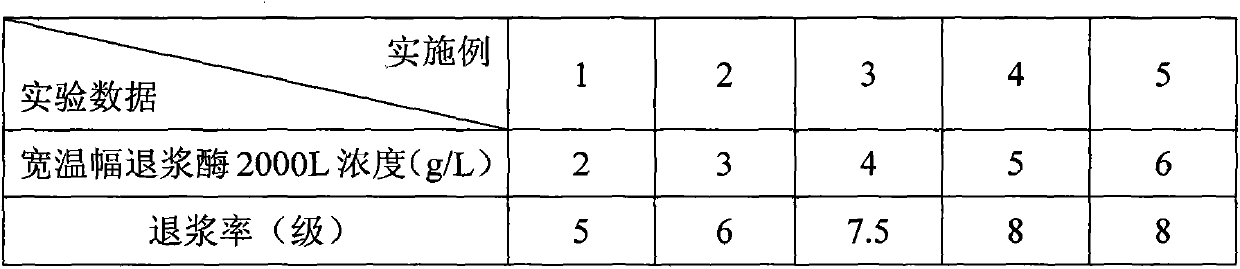

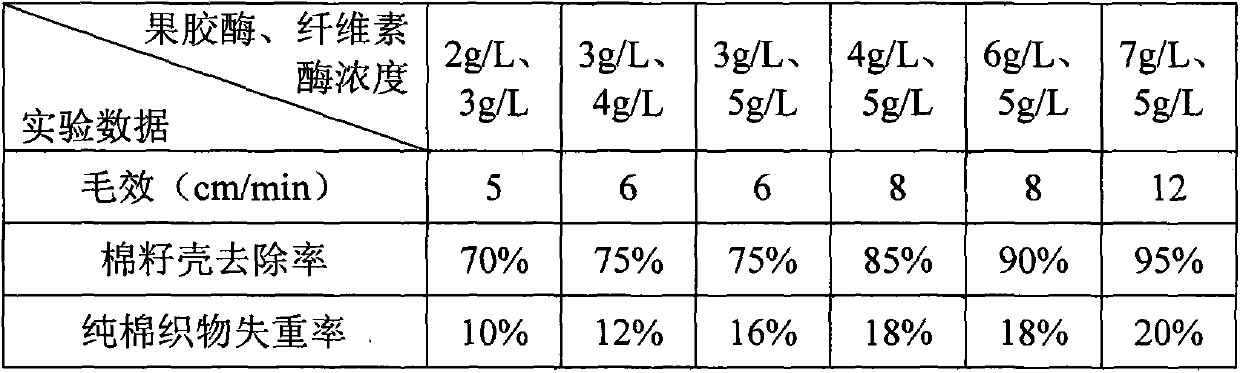

Dyeing treatment process for pure cotton fabrics based on pure natural biological preparations

ActiveCN103437141AHarm reductionEasy to operateShrinkingFabric breaking/softeningWastewaterEngineering

The invention discloses a dyeing treatment process for pure cotton fabrics based on pure natural biological preparations, which is designed for solving the technical problems that the environment is seriously harmed in an existing pure cotton fabric dyeing treatment process, and the human health is harmed in an application process. The adopted technical scheme is as follows: the dyeing treatment process comprises the steps of singeing, desizing, boiling-out, bleaching, dyeing, softening treatment and preshrinking treatment, and the key point is that biological preparations, which are respectively a desizing enzyme solution, a boiling-out enzyme solution, glucose oxidase solution and a plant dye, are respectively adopted in the steps of desizing, boiling-out, bleaching and dyeing. The dyeing treatment process has the technical effects that the operation is simple; the pure natural biological preparations almost do not contain any toxic substance, and wastewater produced in the treatment process is less and biodegradable, so that under the premise of keeping the characteristics such as softness, sweat absorption, comfortableness and naturalness and the like of pure cotton fabrics, the harm to the environment is alleviated, and the harm to human body is avoided, and therefore, the process has a zero-pollution environmental friendliness characteristic.

Owner:HEBEI NINGFANG GRP

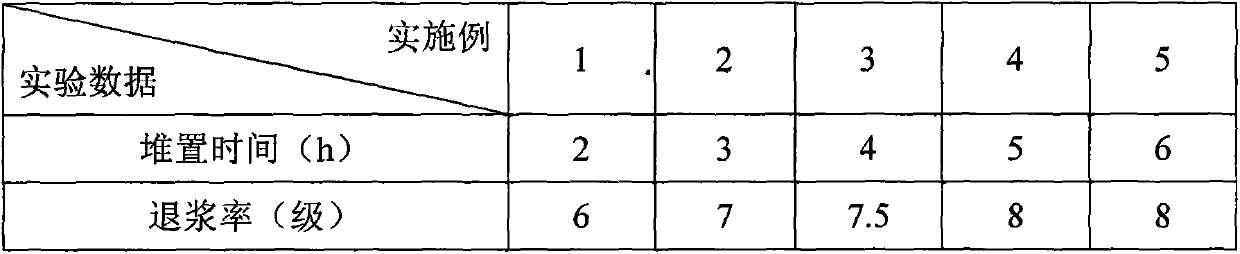

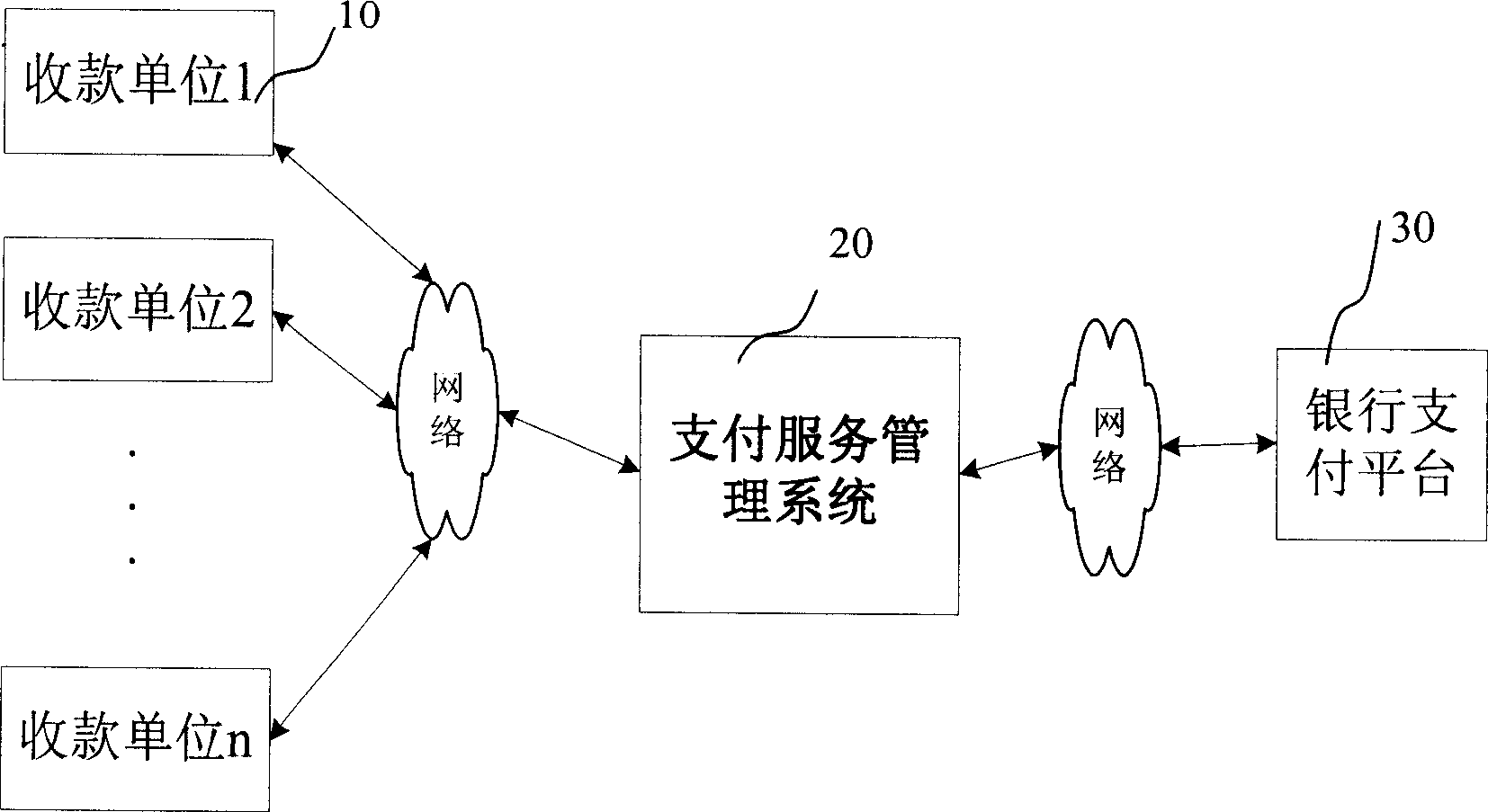

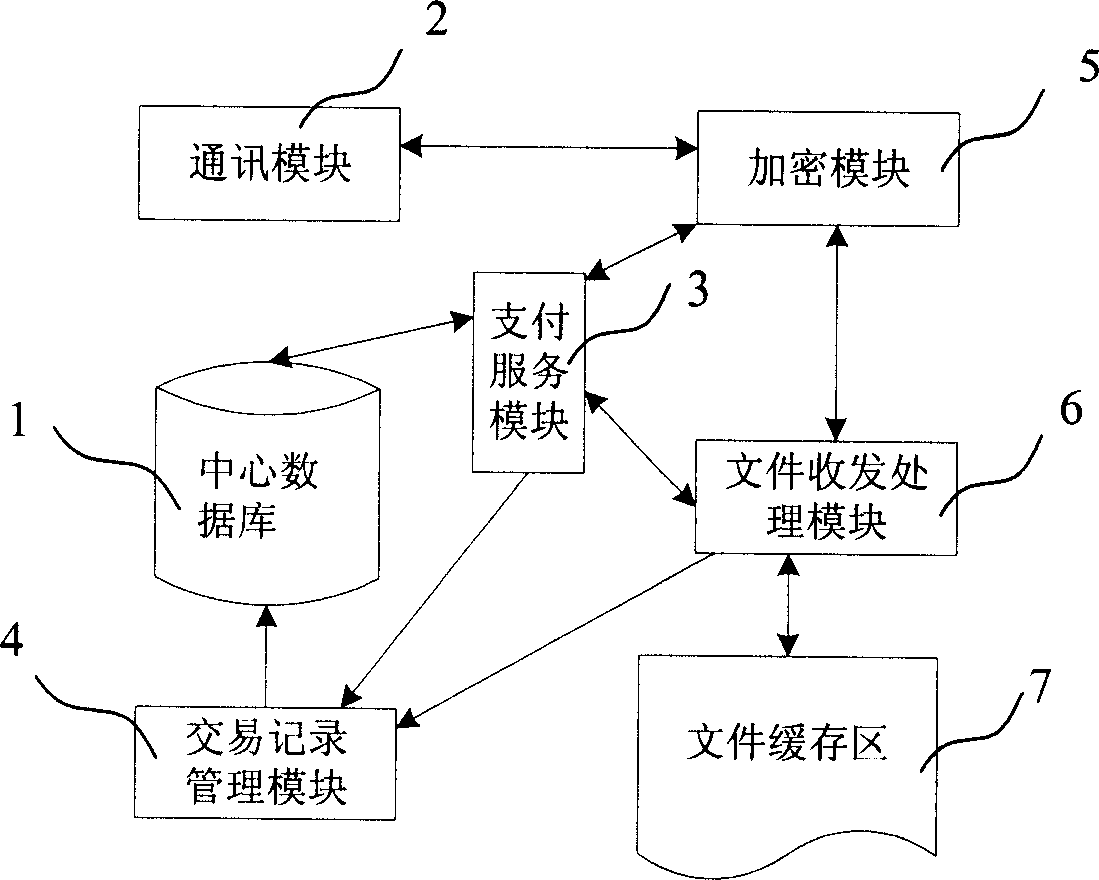

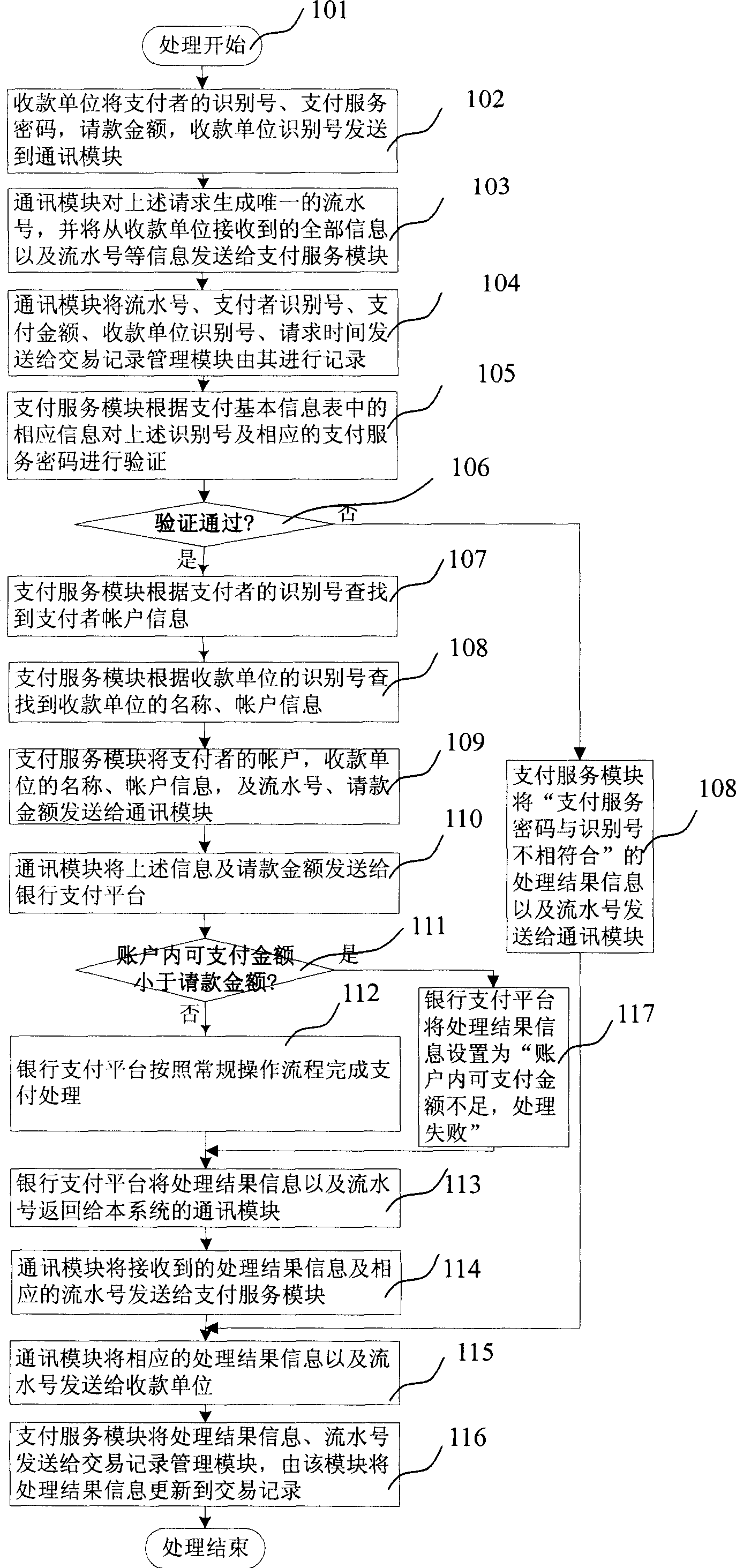

Payoff service management system and method

InactiveCN1758276AConvenient paymentEasy to operateFinancePayment architectureMultiple formsBank account

This invention relates to a payment management system used in providing payment service to the gathering units and bank payment platforms including: a central database, a communication module, a cipher module, a payment service module and a business recording management module, in which, a payer provides a payer identifying number different from the bank account information to the gathering unit, which sends a request for the money to the platform via the system and the platform processes the request then feeds back the information about if the payment is successful. When a payer pays the money or transfers accounts, it can finish them smoothly and safely by providing the identification number of the payer to the gathering unit only without inputting the bank accounts information, the system can provide different kinds of identification numbers according to the needs of payers and multiple gathering units can accept multiple payment ways of the payers after connecting with this system platform.

Owner:CHINA UNIONPAY

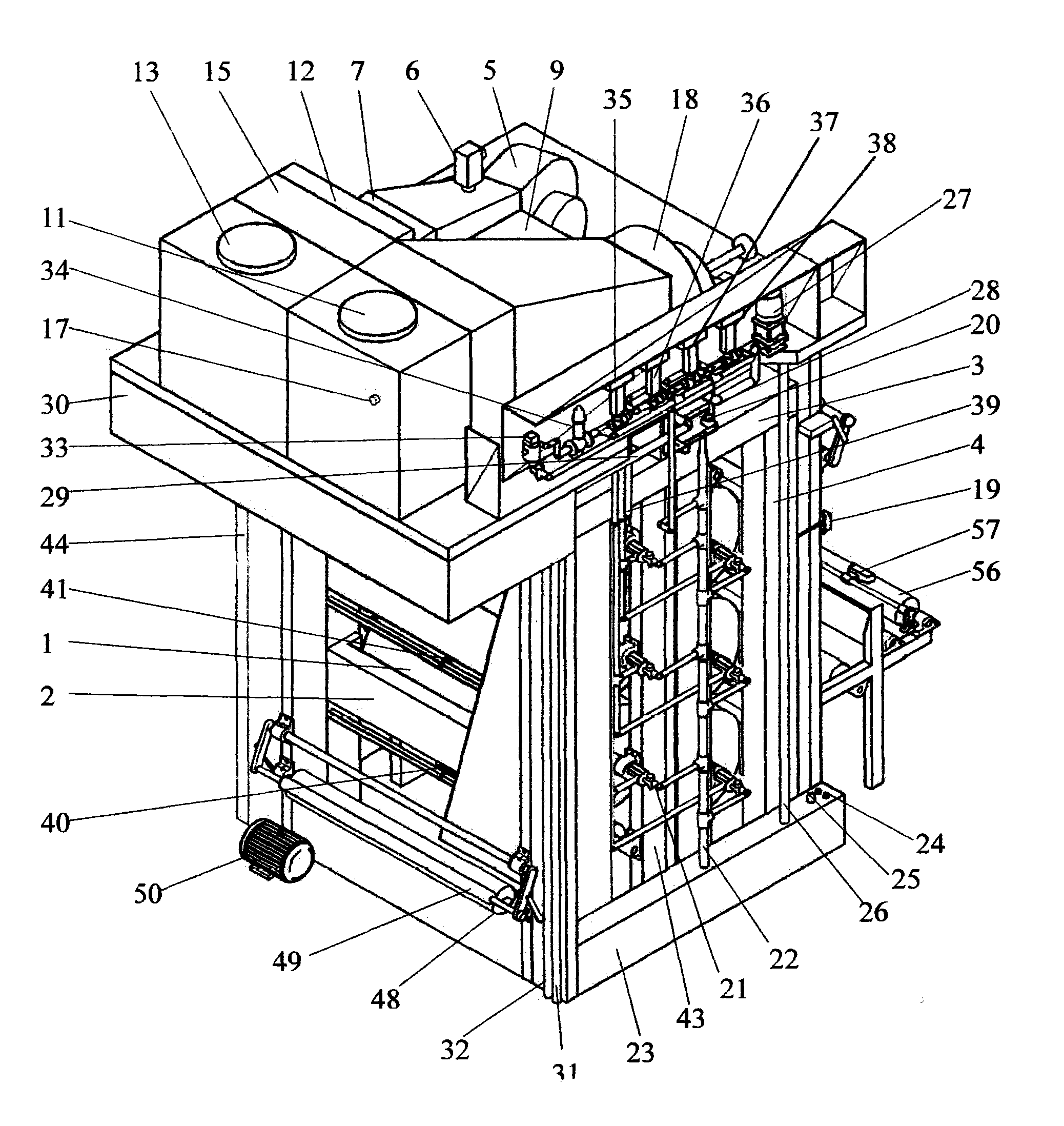

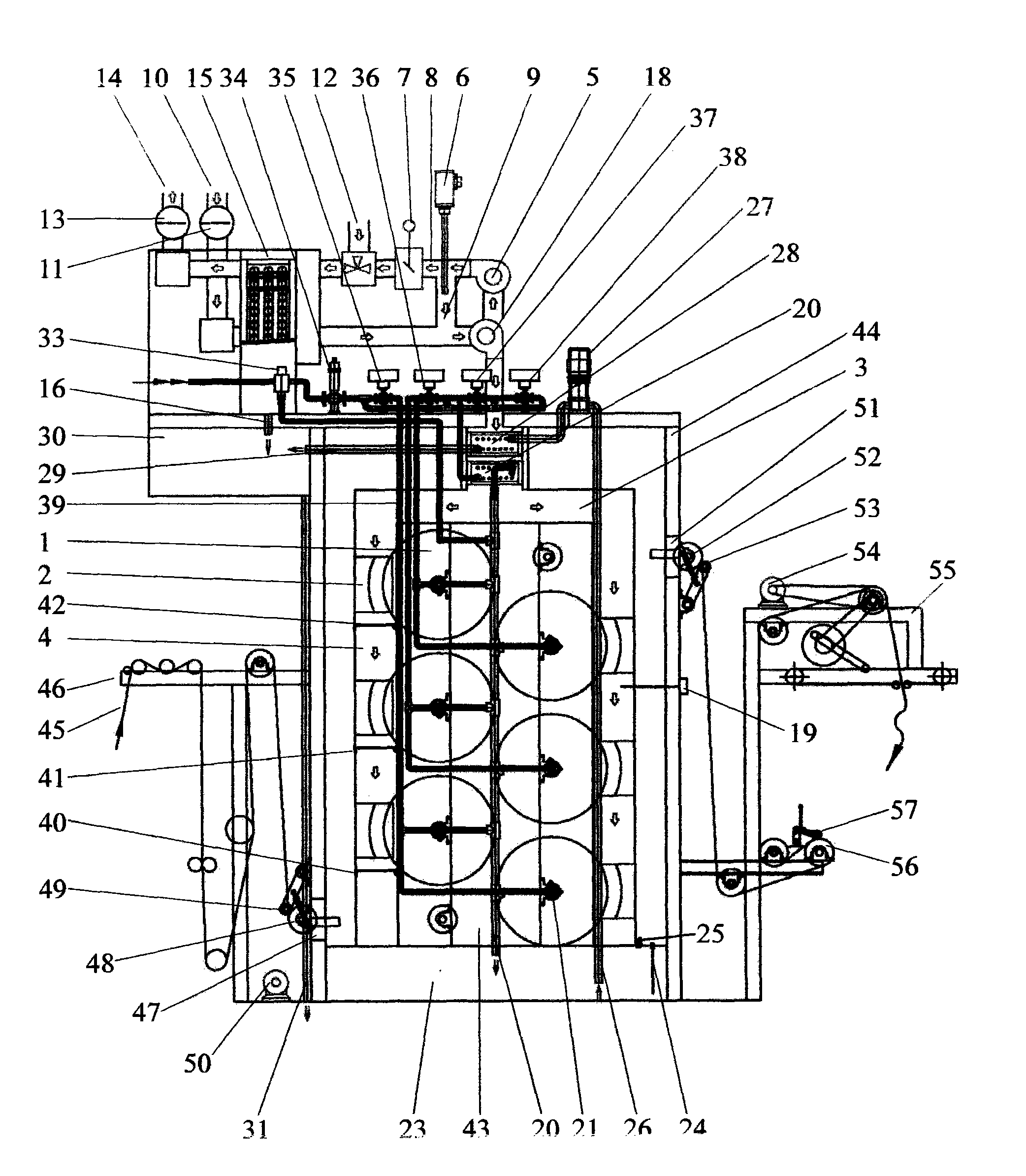

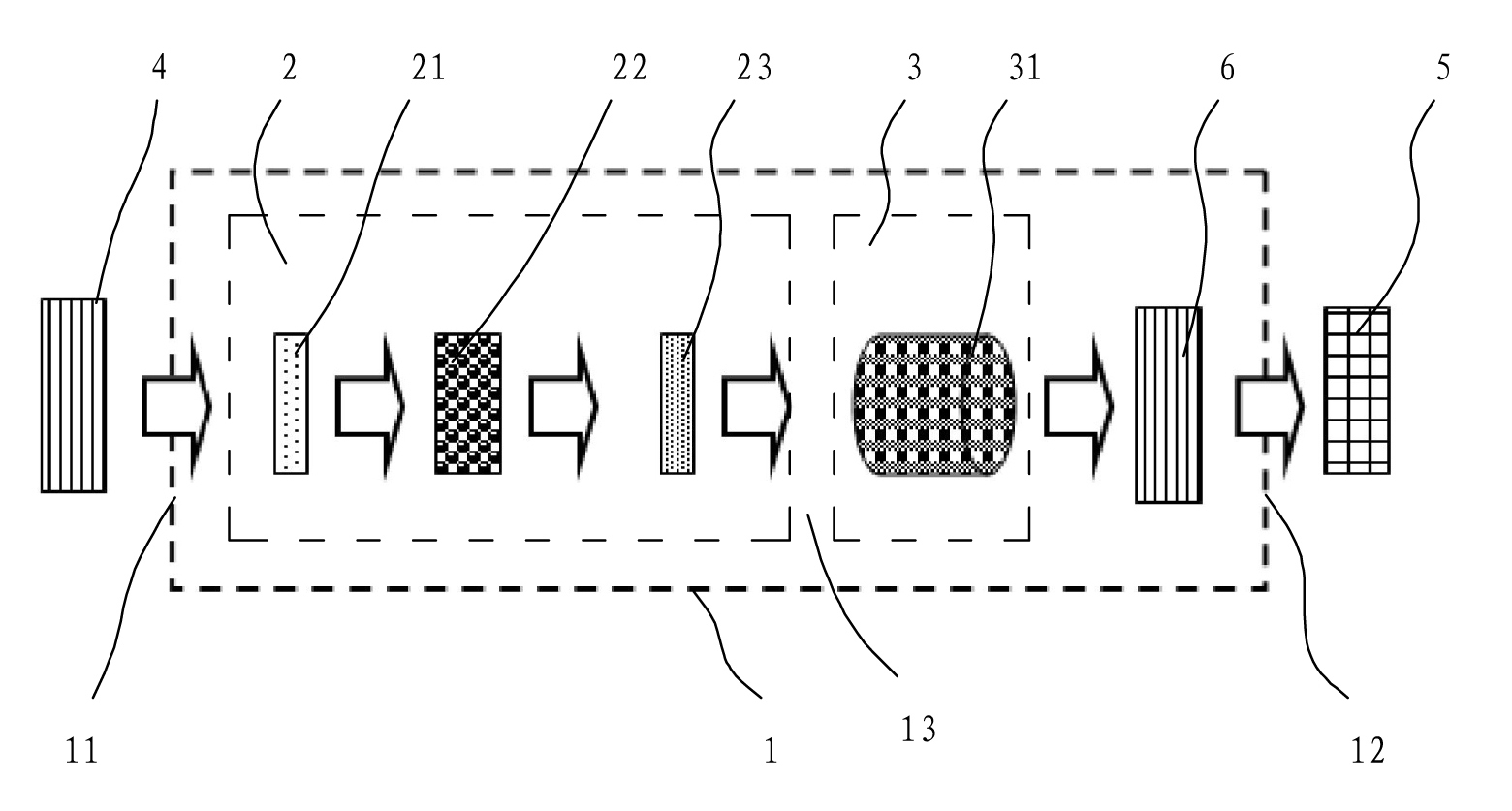

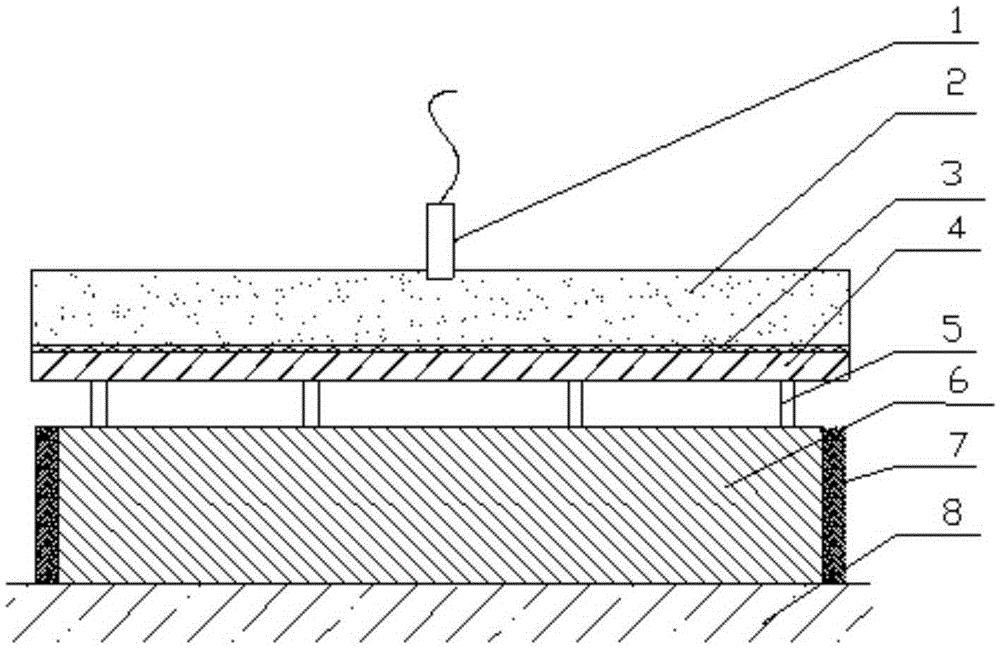

Electronic jet drying cylinder dryer

InactiveCN102183128AMeet production needsSatisfy productivityDrying gas arrangementsLiquid/gas/vapor removalTextile printerWaste heat recovery unit

The invention discloses a textile printing and dyeing electronic jet drying cylinder dryer and a jet drying cylinder, waste gas heat recovery and condensate water recovery thereof and a method for setting a moisture regain reference roller. The electronic jet drying cylinder dryer consists of a heat insulating and preserving drying room, the jet drying cylinder, a heat recovery and jet system and an electronic information system, wherein exhaust air is divided into exhausted air and circulating air according to humidity of the exhaust air; heat of the exhausted air is recovered by fresh air; the fresh air is mixed with the circulating air; the heat of condensate water is then recovered and the condensate water is sprayed to a textile; heating is performed and drying conditions are improved; complete on-line detection and control are performed on temperature, tension and moisture regain of the textile and humidity, temperature and speed of an air flow; therefore, heat application efficiency and drying efficiency are increased, production cost is reduced and production requirement of high-grade textiles is met in a scientific, strict, careful and reliable drying mode. The electronic jet drying cylinder dryer can be used for substituting a drying cylinder dryer or is made by modifying the drying cylinder dryer; a waste gas heat recovery system and a condensate water recovery system are suitable for various heating production occasions; and by the method for setting the moisture regain reference roller, reliability and validity of moisture regain control are solved.

Owner:段新顺 +1

Method for establishing equipment secure access

InactiveCN101754190ASecure InterconnectionSafe operabilitySecurity arrangementSecuring communicationThe InternetInterconnection

The invention belongs to the field of Internet applications and relates to a method for establishing device secure access, which comprises the following steps: a client device carries out the on-line declaration; a server selects the client device, generates a corresponding token according to the granted access authority and sends to a client; the client receives the token, and adds the token in a service call request message; the server checks the service call request of the client, and compares the token with a token access authority control table maintained by the token, judges the access authority of the client owning the token, and responding to an operation request of the client. The method transfer the complicated secure algorithm realized by relying on machine to people to control the secure access, and the mechanism is more applicable to being realized on consumable electronic equipment. Different equipment can carry out interconnection and interoperability more securely through the simple extension of IGRS protocol.

Owner:TCL CORPORATION

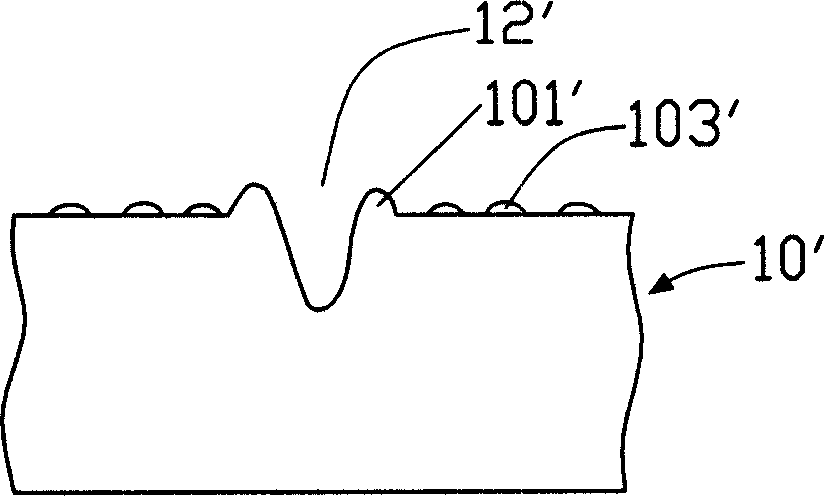

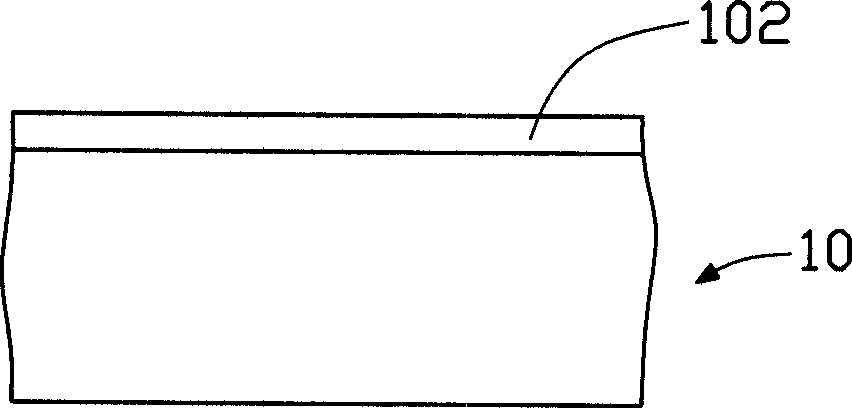

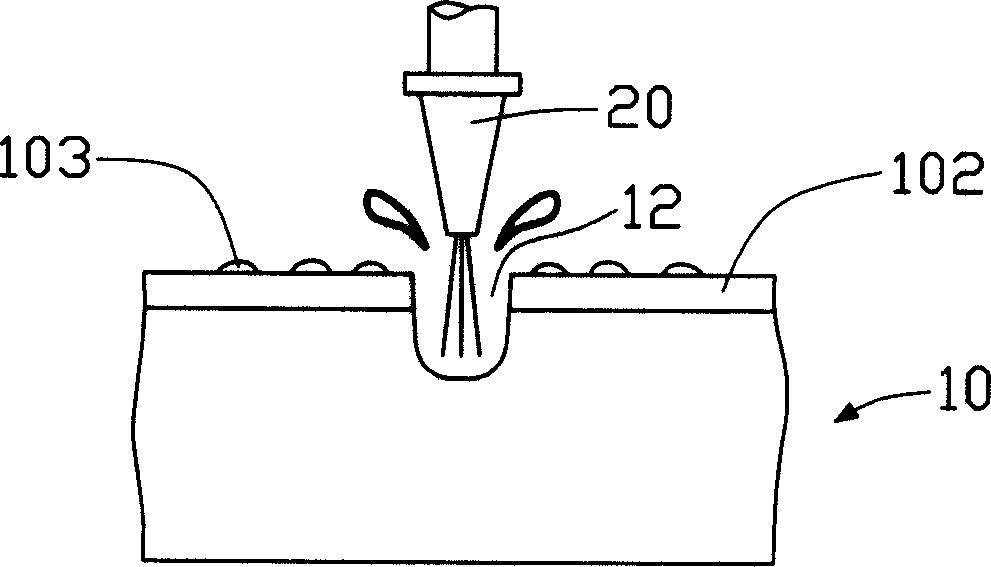

Laser working method

InactiveCN1579697ALow priceExcellent workpiece surfaceOrganic chemistryLaser beam welding apparatusLaser processingSolvent

The invention refers to a kind of laser processing method. At first a protecting coat which is polyimide layer is laid on the surface of the workpiece. And then the work such as stiletto is carried out at the workpiece, after which scour off the polyimide layer with acetone or phenols solutions. Because of the protection of the polyimide layer, the particles and dusts produced in the laser processing will sediment at the surface of the protection layer but the workpiece. We can get perfect workpiece surface after wipe off the protection layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

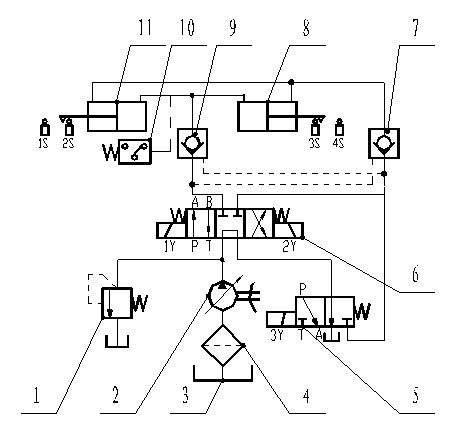

Horizontal pinned hydraulic system of crawler crane counterweight

The invention discloses a horizontal pinned hydraulic system of a crawler crane counterweight. The system comprises two pinned cylinders which are arranged symmetrically, a travel switch for controlling the travel of each piston rod is arranged on one side of the piston rod of each of the two pinned cylinders, rod cavity inlet pipelines of the two pinned cylinders are connected, rod-free cavity inlet pipelines of the two pinned cylinders are connected, a hydraulic control one-way valve is arranged on each of the rod cavity inlet pipelines, a hydraulic control one-way valve is arranged on each of the rod-free cavity inlet pipelines, each hydraulic control one-way valve is connected with a three-station four-way electromagnetic reversing valve through a pipeline, the oil inlet of the three-station four-way electromagnetic reversing valve is connected with a variable pump connected with an oil tank through a pipeline, a safety valve is connected to the outlet of the variable pump, and the oil outlet of the three-station four-way electromagnetic reversing valve is connected with a two-station three-way electromagnetic reversing valve connected with the oil tank through a pipeline. Stretching of the piston rods of the pinned cylinders is controlled through the hydraulic system, so that the piston rods of the pinned cylinders stretch, and the effect of horizontally locking the counterweight is achieved; and the system is simple in structure, time-saving, labor-saving, safe and high in reliability.

Owner:CHINA UNIV OF MINING & TECH

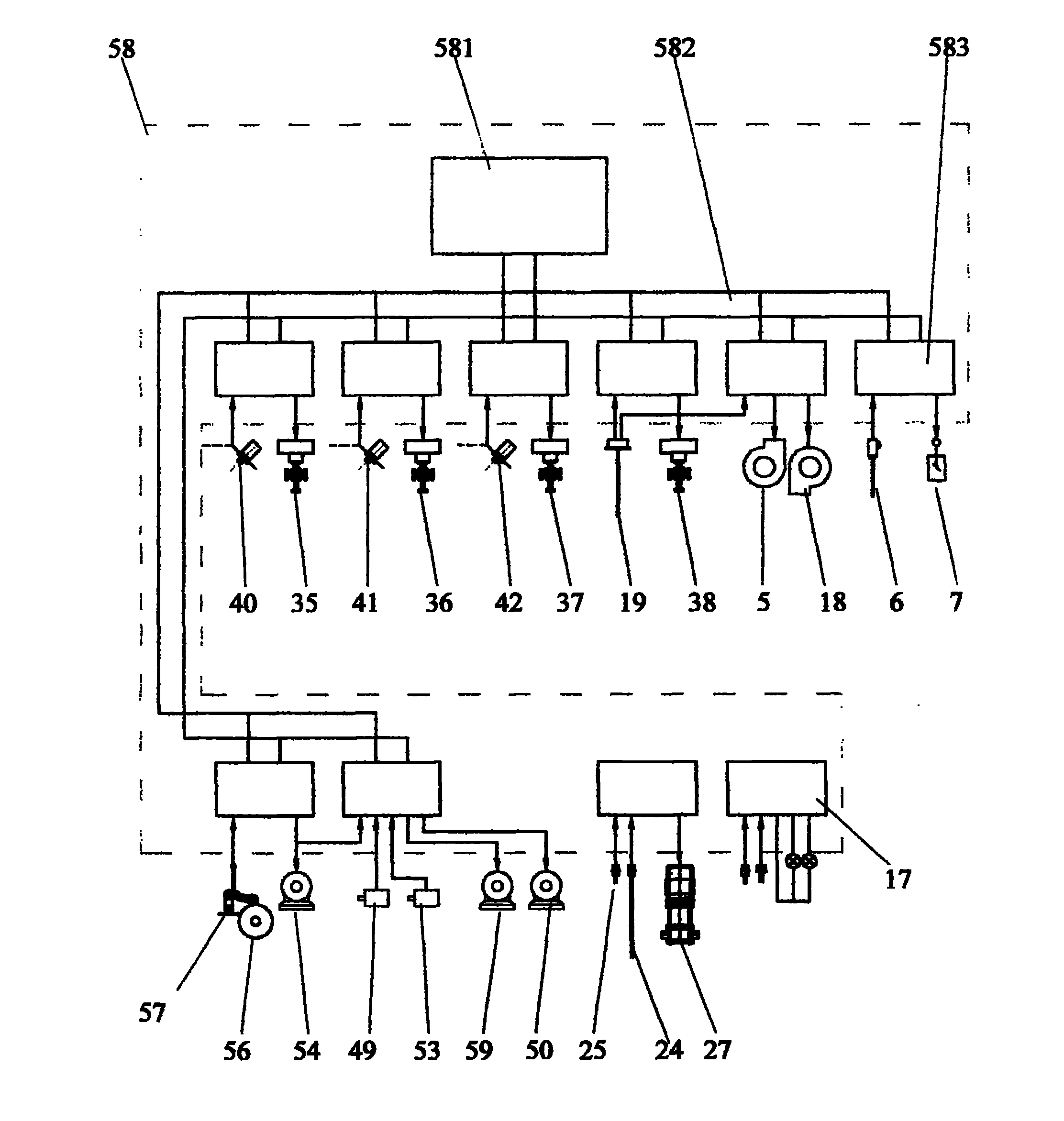

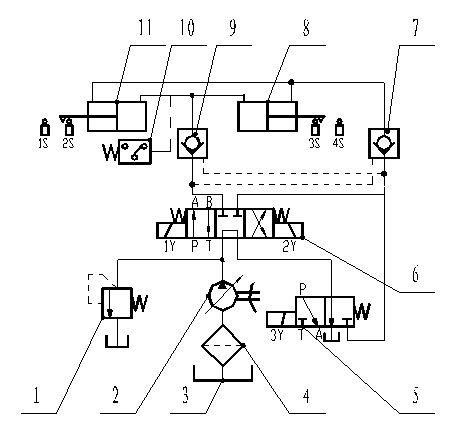

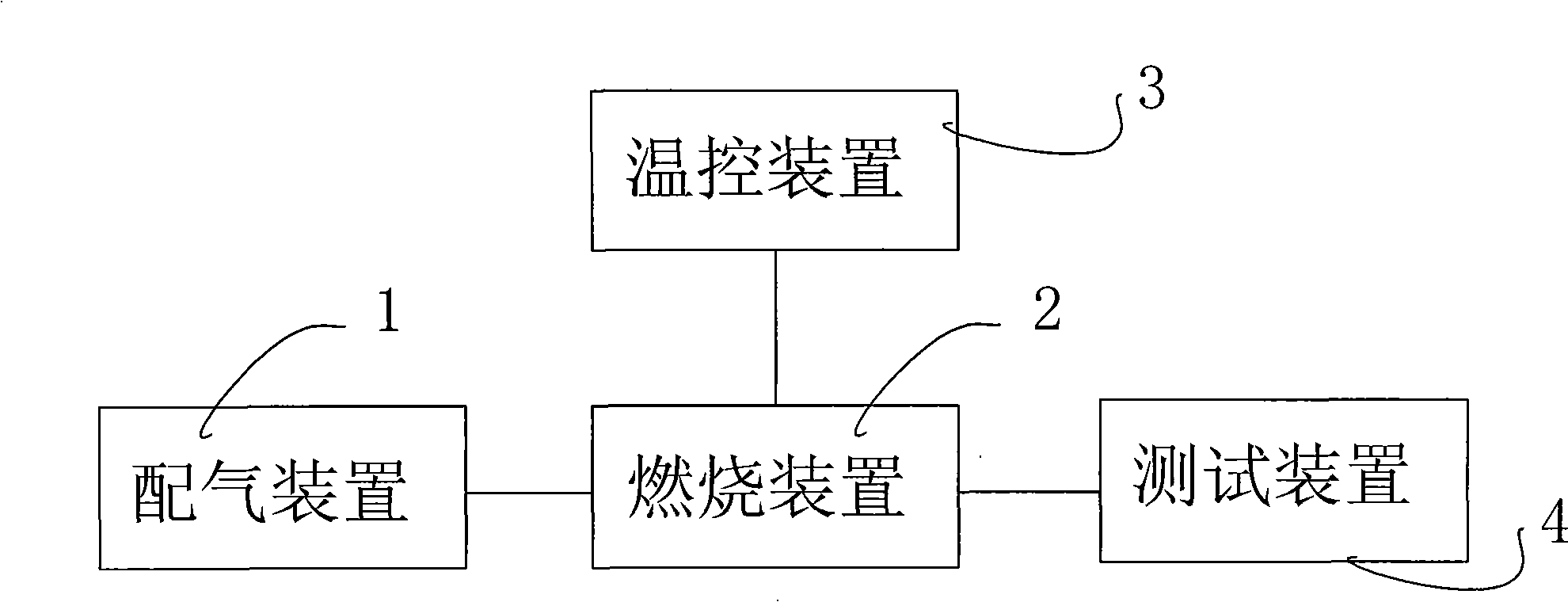

Air/fuel ratio oxygen sensor performance measuring system

InactiveCN101281153AMixing and other links are simplifiedConvenience in thick and thinMaterial analysis by electric/magnetic meansTemperature controlCombustion chamber

The invention discloses a performance testing system for oxygen sensors of air-fuel delivery ratio, which comprises a make-up gas device, a combustion device, a temperature control device and a testing device. Wherein, the combustion device is provided a heating furnace; one end of the heating furnace is connected with a combustion chamber; the other end of the heating furnace is connected with a measuring chamber; the measuring chamber is connected with the testing device which can measure the oxygen concentration in the combustion device, the combustion chamber is connected with the temperature control device which can measure and control the lumen temperature of the heating furnace; and the inlet end of the combustion chamber is connected with the make-up gas device. The make-up gas device realizes the reasonable ratio of CxHy combustible gas to air; the combustion device is composed of the combustion chamber, the heating furnace and the measuring chamber, wherein the heating furnace is used to generate tail gas of different combustion states, the heating furnace heats the tail gas to the temperature required by measurement, and the measuring chamber provides placing and measuring location for the tested oxygen sensors; the temperature control device realizes the temperature control of the tested tail gas. The invention has the advantage of realizing that the variance of the dilute concentrated situation of the combustion tail gas is quick and stable, the measurement, control and conversion of each performance are free and smooth, and the record is convenient, etc.

Owner:NINGBO UNIV

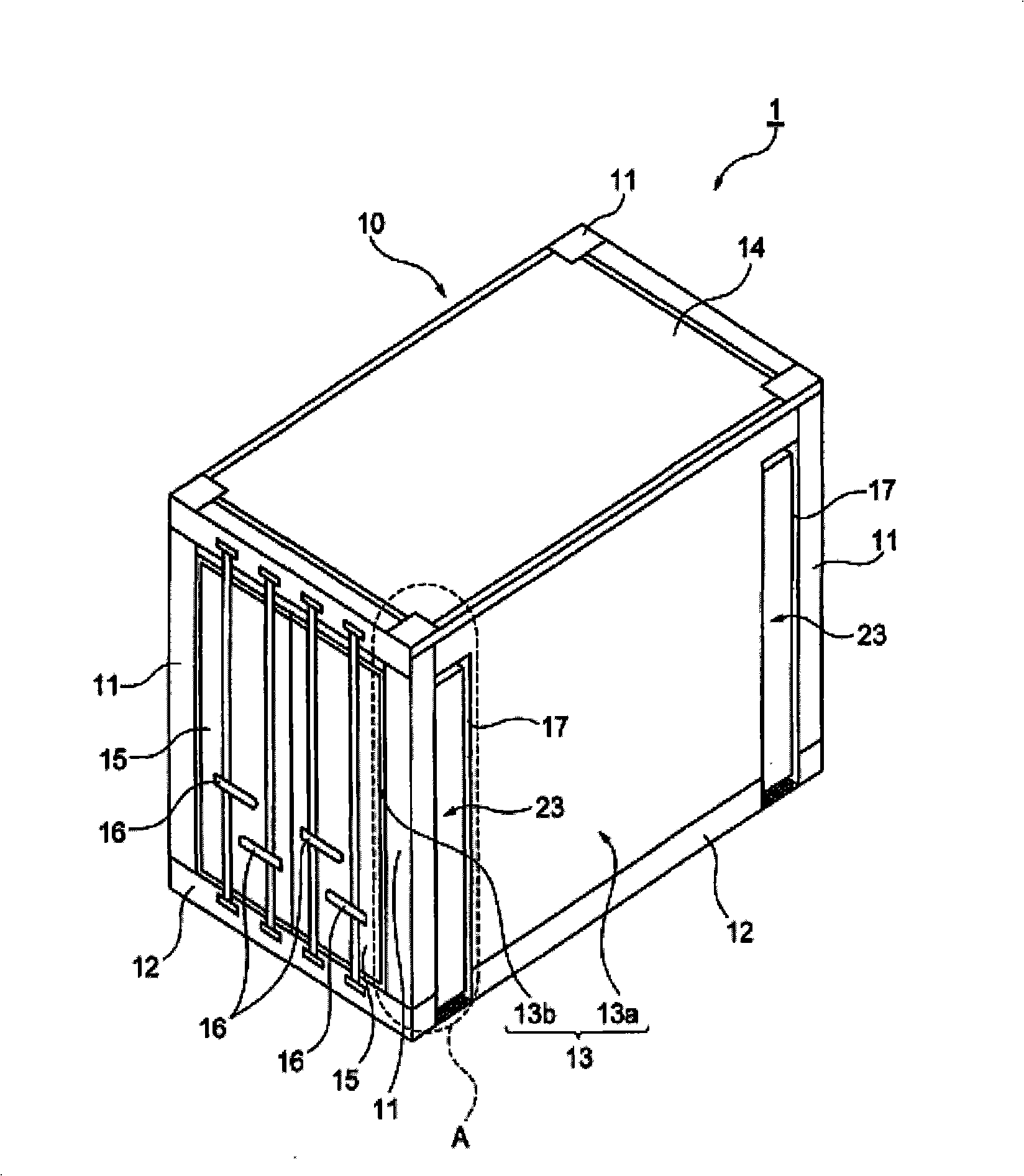

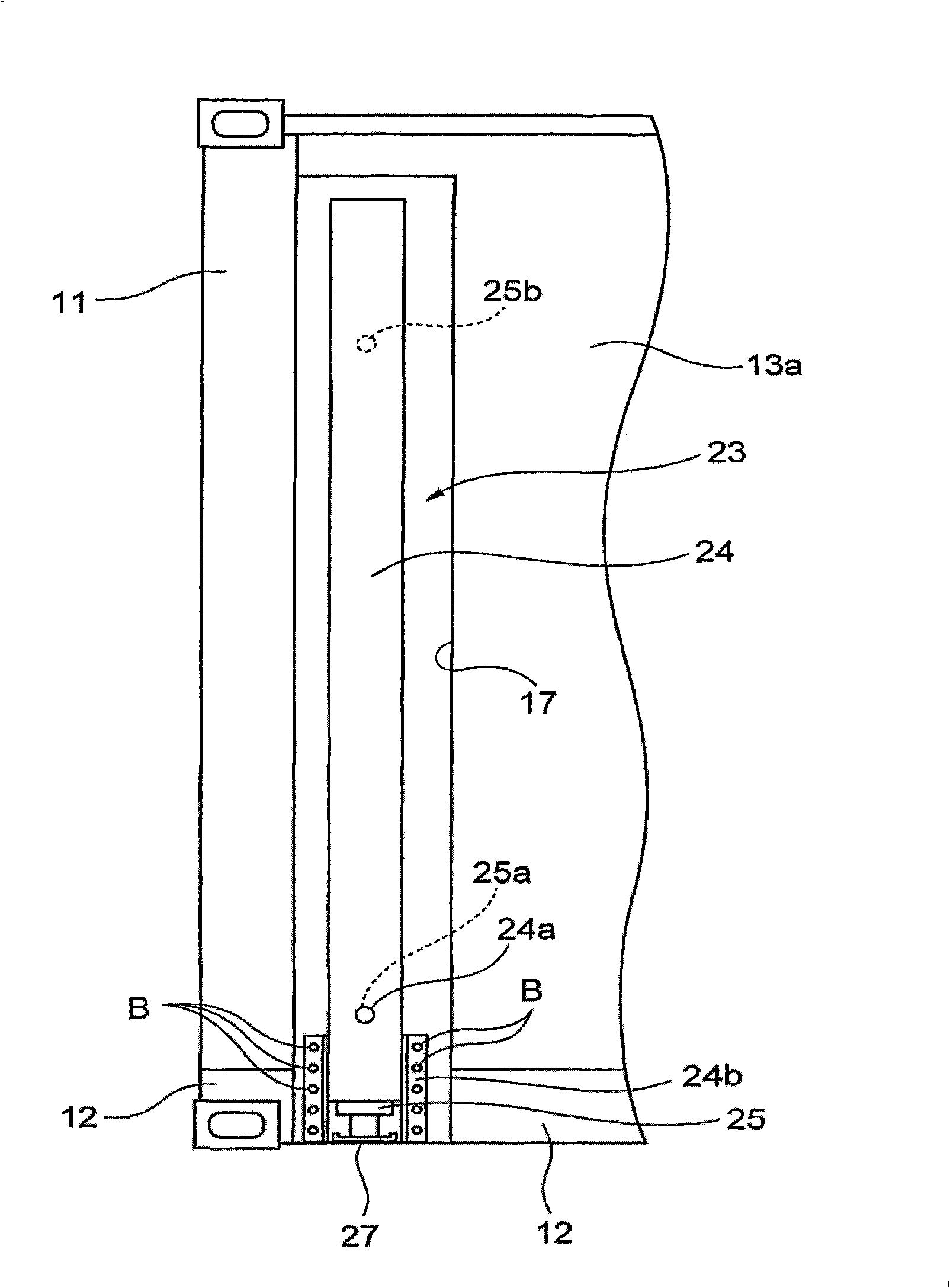

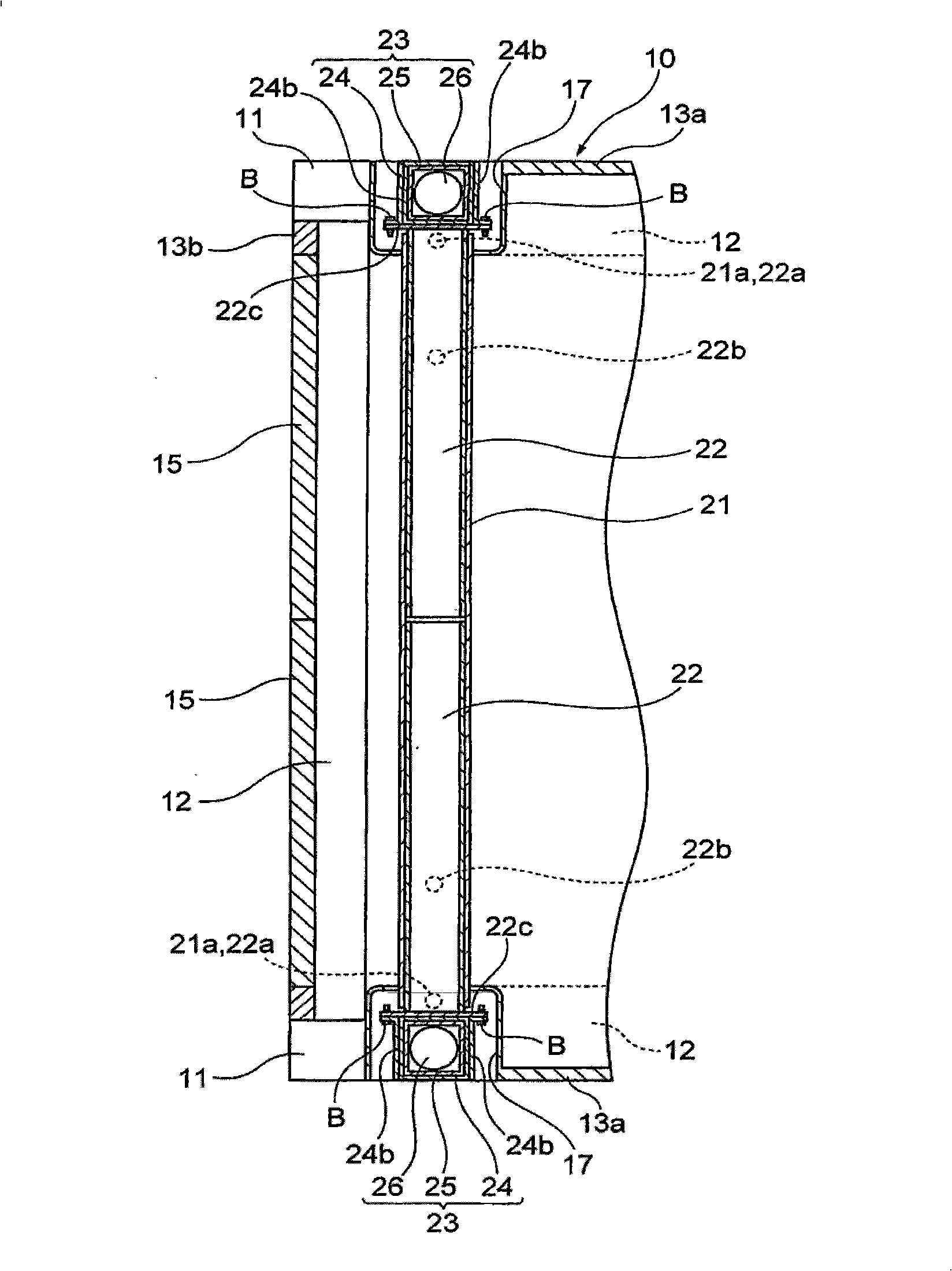

Self-lifting/lowering transport container

Owner:TATSUMI

Ultraviolet (UV) automobile air sterilization purifier

ActiveCN102018988AGuaranteed uptimeOperational securityAir-treating devicesDeodrantsMolecular sieveUltraviolet

The invention discloses an ultraviolet (UV) automobile air sterilization purifier. The purifier comprises a shell, wherein the two ends of the shell are provided with an air inlet and an air outlet; the shell between the air inlet and the air outlet and staggered convex reinforcing ribs in the shell form an air duct in which a filter device and a UV sterilization device are also arranged; the filter device comprises one or more layers of coarse-efficiency filter screens, molecular sieves and medium-efficiency filter screens which are hermetically arranged in the air duct in turn; and the UV sterilization device comprises a short wave UV lamp tube. By using short wave UV and combining the filter device such as the molecular sieves and the like, the device filters circularly flowing air at the air outlet of an air conditioner in an automobile, removes peculiar smell, sterilizes the flowing air and the like, so the device has good sterilization and purification effect, can be safely used, has long service life, and is convenient and reliable.

Owner:钟练

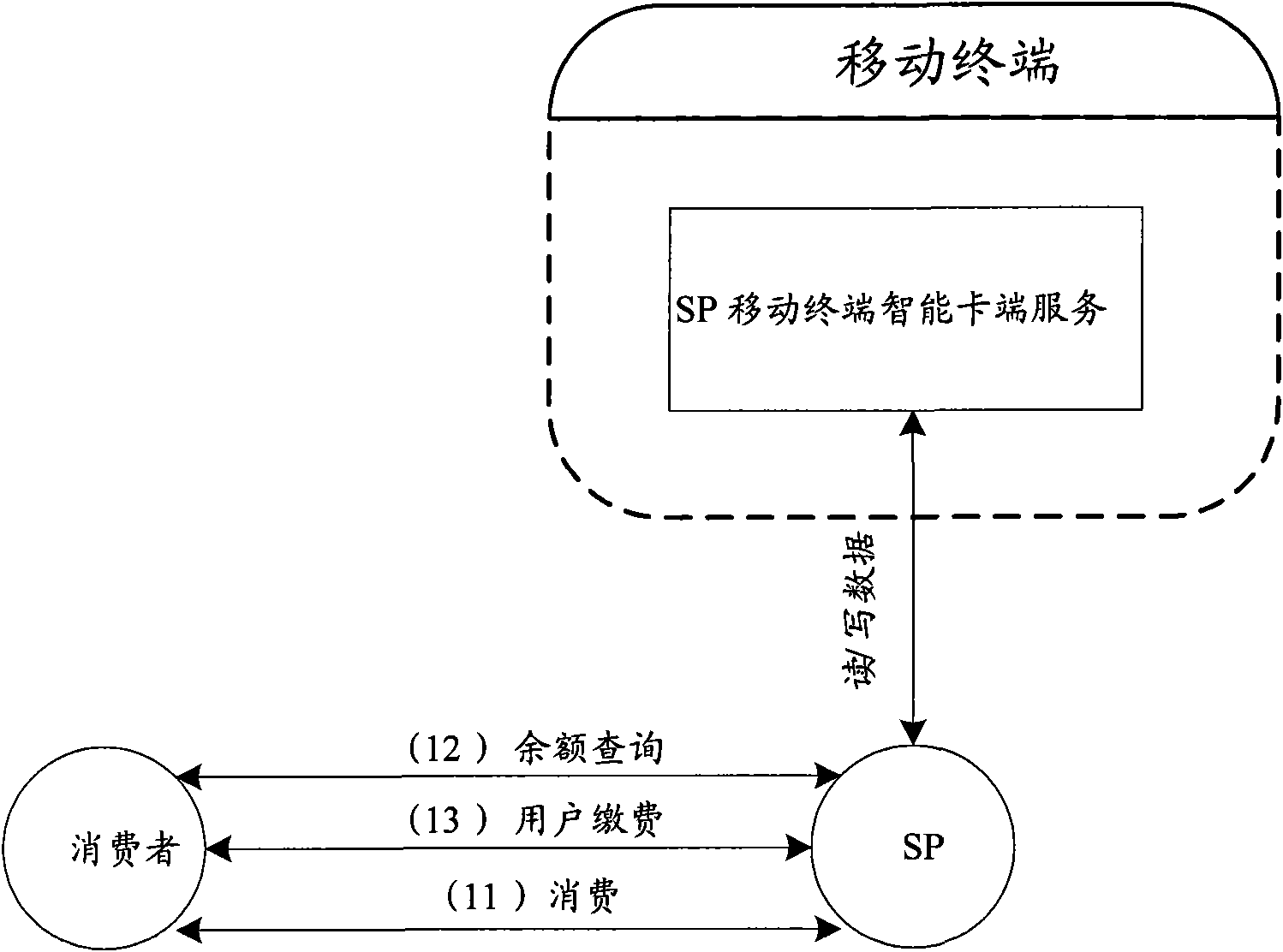

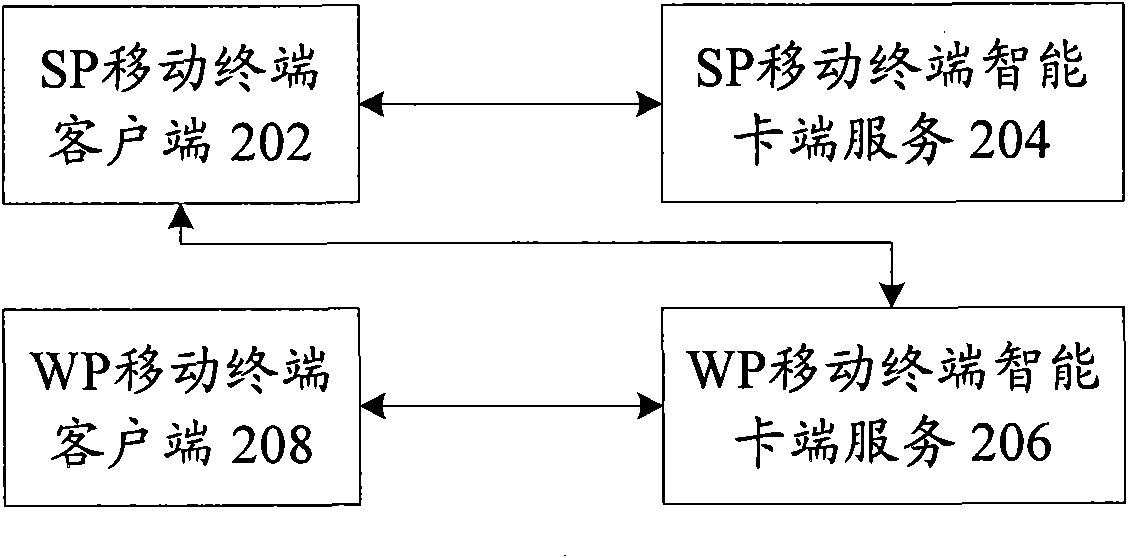

Terminal payment method and terminal based on near field communication

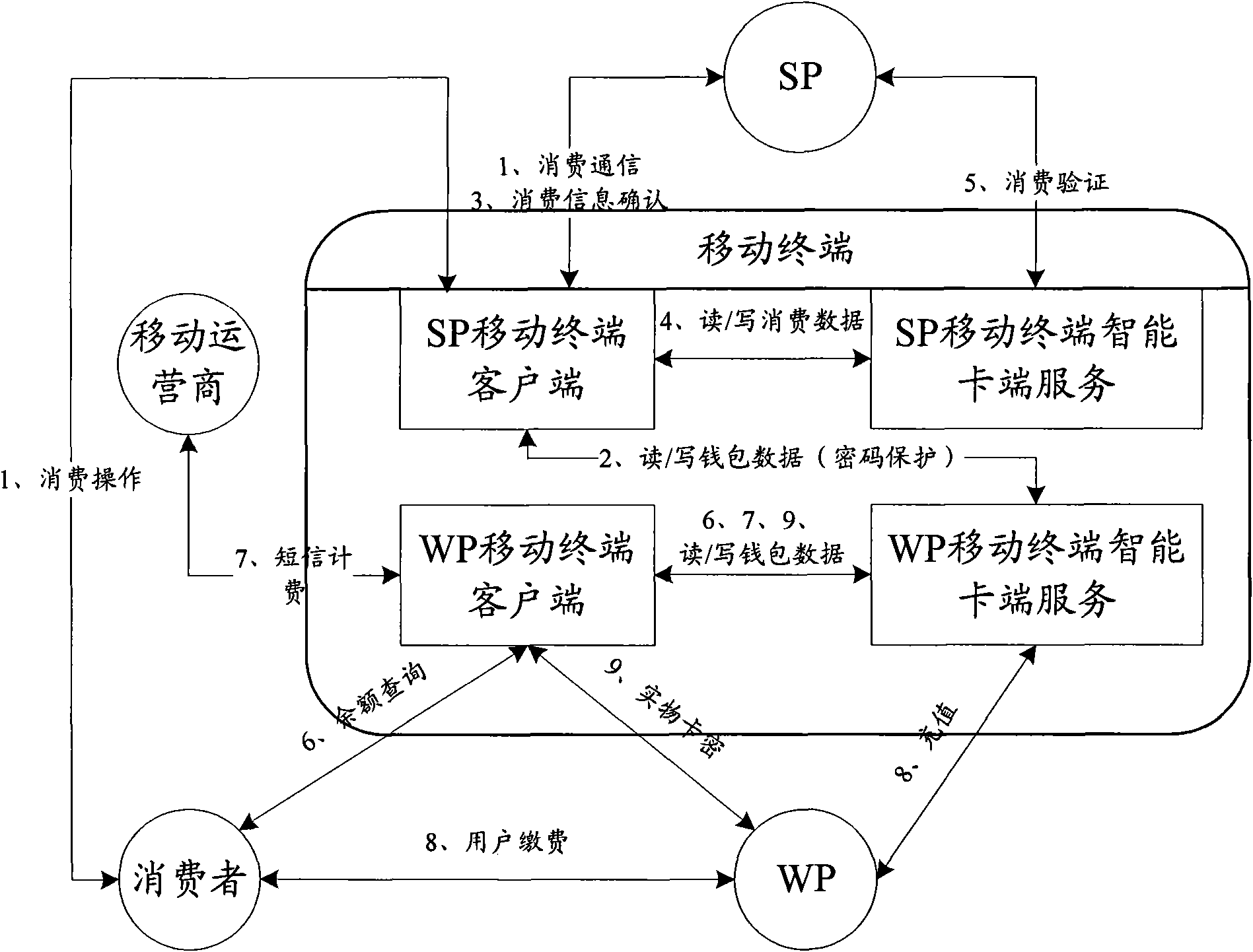

InactiveCN101685511AAddress flexibilityFix security issuesPayment architectureTransmissionComputer moduleSmart card

The invention discloses a terminal payment method and a terminal based on near field communication, wherein the method comprises the following steps: a content service provider mobile terminal clientwhich is an SP mobile terminal client carries out service negotiation with an SP through wireless air communication to determine service information and writes the service information to an intelligent card end service of the SP mobile terminal; the intelligent card end service of the SP mobile terminal carries out near field communication with the SP and provides the service information for the SP; and the SP mobile terminal client communicates with a wallet service provider mobile terminal intelligent card service which is a WP mobile terminal intelligent card service and pays for the SP. Bythe invention, the problems of limited consumption kinds, inflexible operations and low safety existing in near field communication mobile payment of the relevant art can be solved by fully utilizingthe payment and operation flexibility of various modules and safe protection of the interaction among the modules and the aim for realizing safe and flexible payment can be achieved.

Owner:ZTE CORP

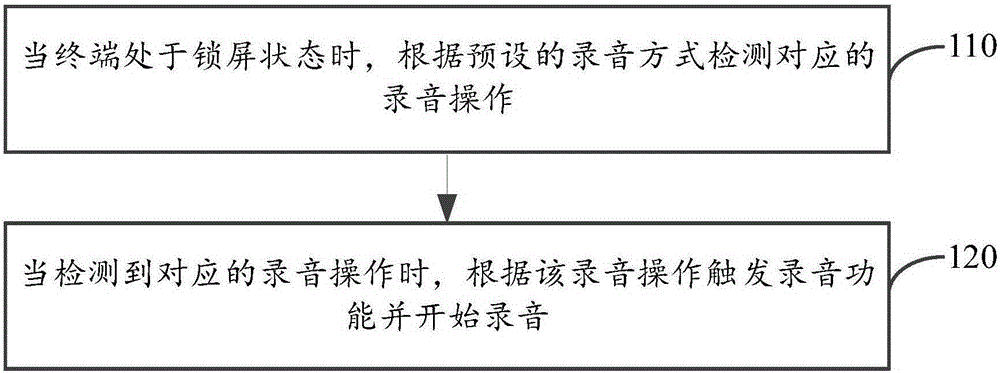

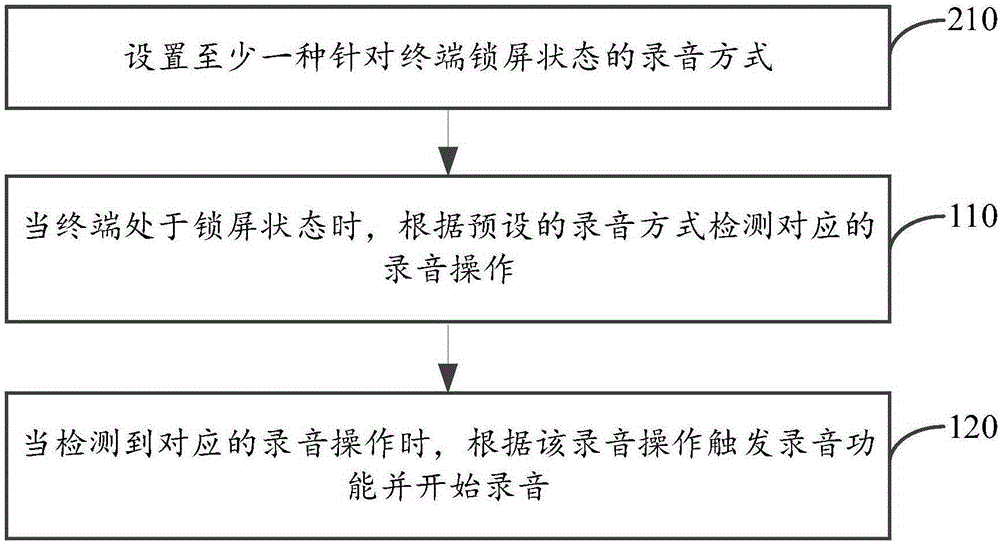

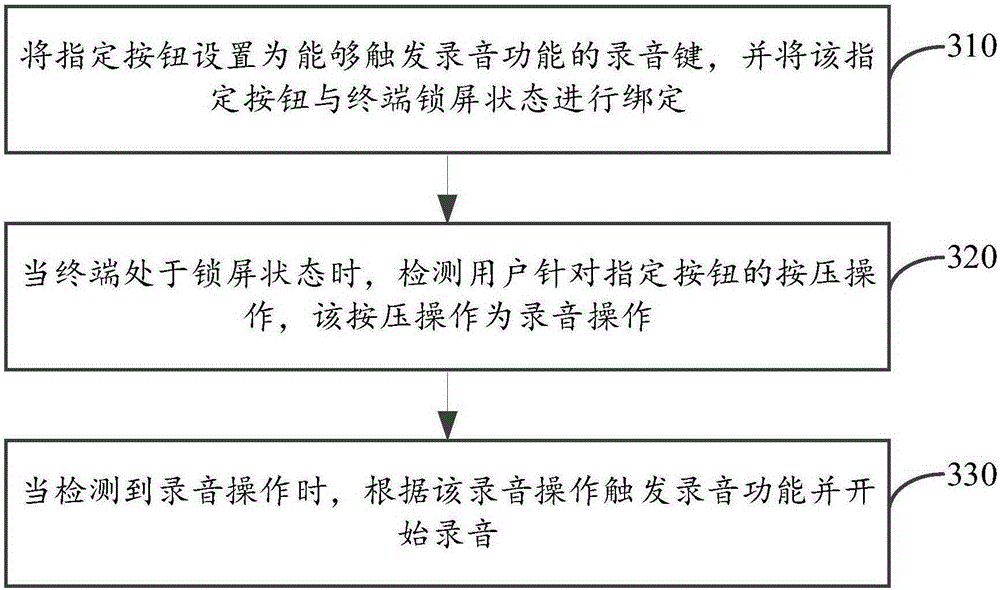

Recording method and device

InactiveCN105187671AImprove experienceMeet individual recording needsSubstation equipmentComputer hardwareRecording duration

The invention relates to a recording method and a device. The method comprises the following steps: when a terminal is at a screen locking state, detecting corresponding recording operation according to a pre-set recording manner; and when detecting the recording operation, triggering a recording function according to the recording operation and starting to record. Therefore, the terminal can trigger the recording function according to the recording operation of a user under the screen locking state, so that an application range of terminal recording is expanded and user experience is also improved.

Owner:XIAOMI INC

Solid-plastic compound heavy-duty anti-corrosion epoxy powder and application thereof

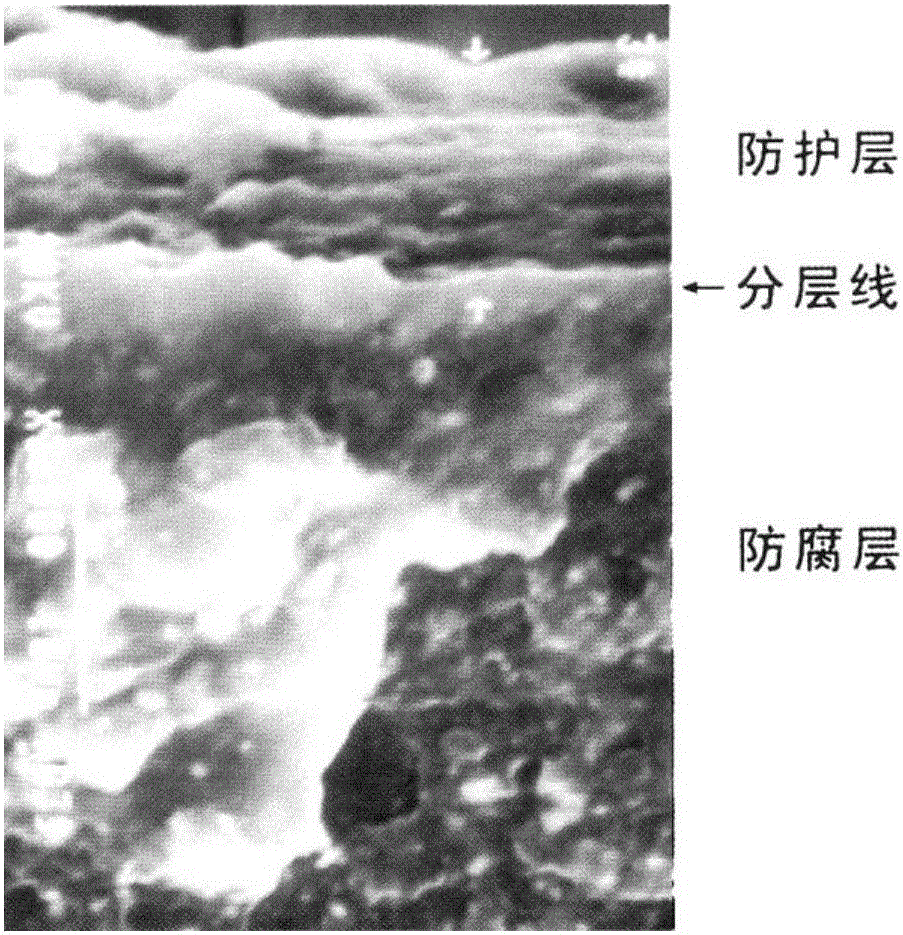

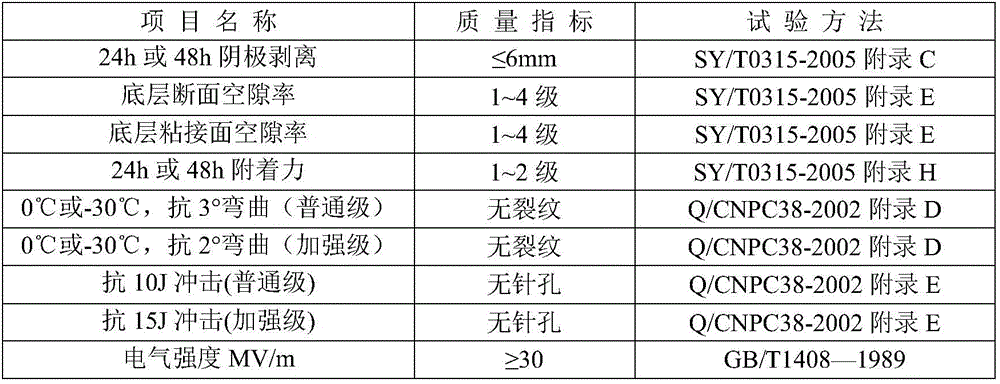

ActiveCN105754445AStrong adhesionHigh impact strengthLiquid surface applicatorsAnti-corrosive paintsSteel tubeThermoplastic

The invention discloses a solid-plastic compound heavy-duty anti-corrosion epoxy powder.The solid-plastic compound heavy-duty anti-corrosion epoxy powder is prepared from epoxy resin, modified thermoplastic resin, a curing agent, a toughening agent, a flatting agent, pigment, an antioxidant and filler.With epoxy resin and modified thermoplastic resin used and compounded, the solid-plastic compound heavy-duty anti-corrosion epoxy powder is an organic and perfect combination of thermoset powder and thermoplastic powder.According to the solid-plastic compound heavy-duty anti-corrosion epoxy powder, electrostatic spraying is omitted, a compact interpenetrating network form structure is formed by compounding epoxy resin and modified thermoplastic resin in cooperation with a specific curing system in the heating fusing and curing process, and an anti-corrosion protecting layer of an overall network form structure on the outer surface of a steel tube is formed.The invention further discloses application of the solid-plastic compound heavy-duty anti-corrosion epoxy powder in preparing an anti-corrosion tube.

Owner:HEILONGJIANG KEFA TONGYE TECH

Bridge facility

InactiveCN107171103AImprove stability and securityThe overall structure is simpleLive contact access preventionEngineeringElectric shock

The invention discloses a facility for a bridge, which includes a frame body and an electrical connector mated with the frame body. Between the electrical connection slots with the port facing forward, the rear end of the electrical connection slot is provided with an electrical contact piece connected to the external power, and the rear ends of the two slots are connected with sliding slots. A sliding block that can be slid back and forth is provided in the sliding joint groove. The overall structure of the present invention is simple, the production cost is low, the power supply is safe and stable, and the operation steps of power on and off are relatively simple, which effectively reduces the electric shock accidents in the existing life. , to ensure the safety of people's lives, and to avoid the occurrence of bridge equipment power failure accidents caused by accidental kicking and collision, and reduce the burnout rate of bridge equipment, which is suitable for popularization and use.

Owner:周一戈

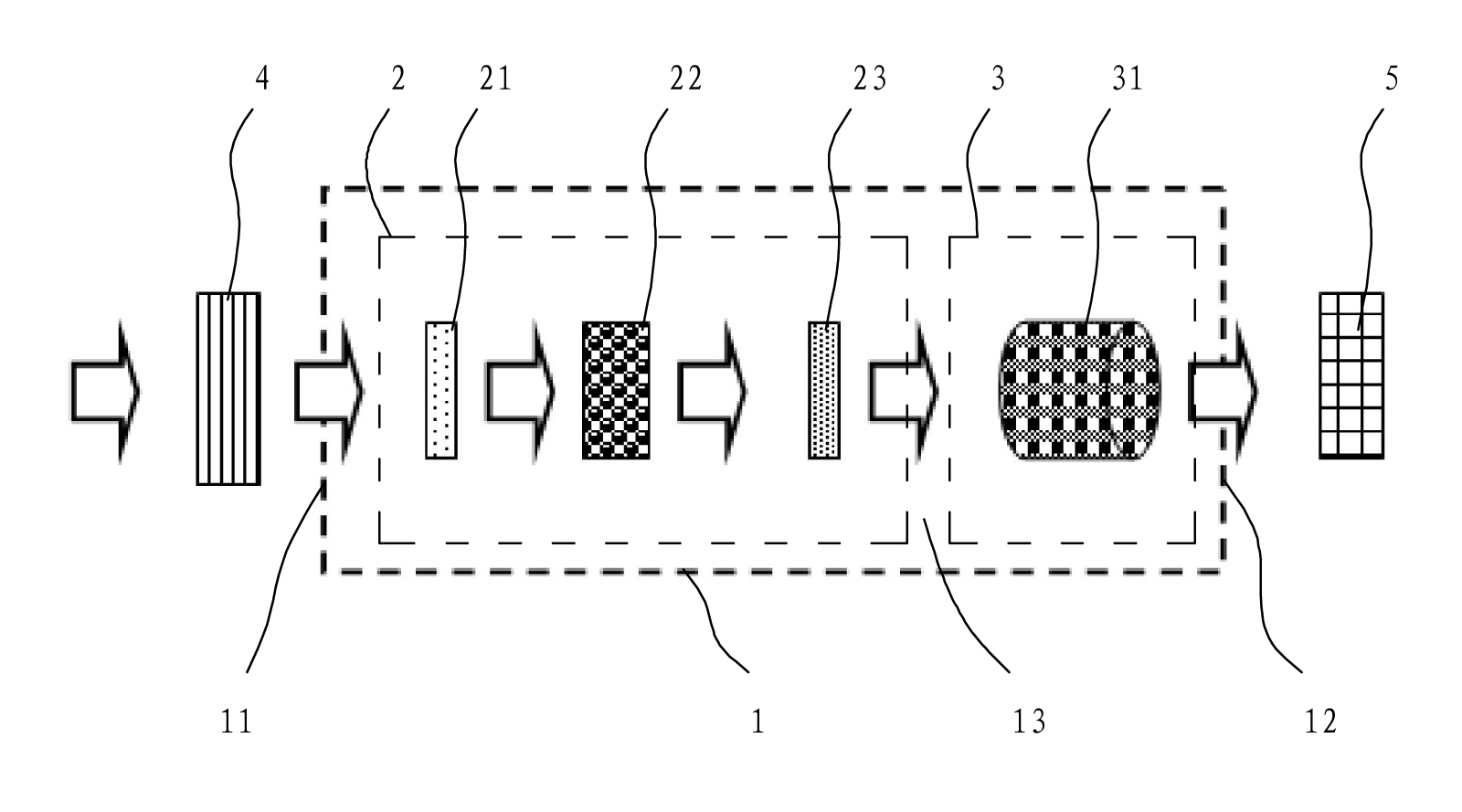

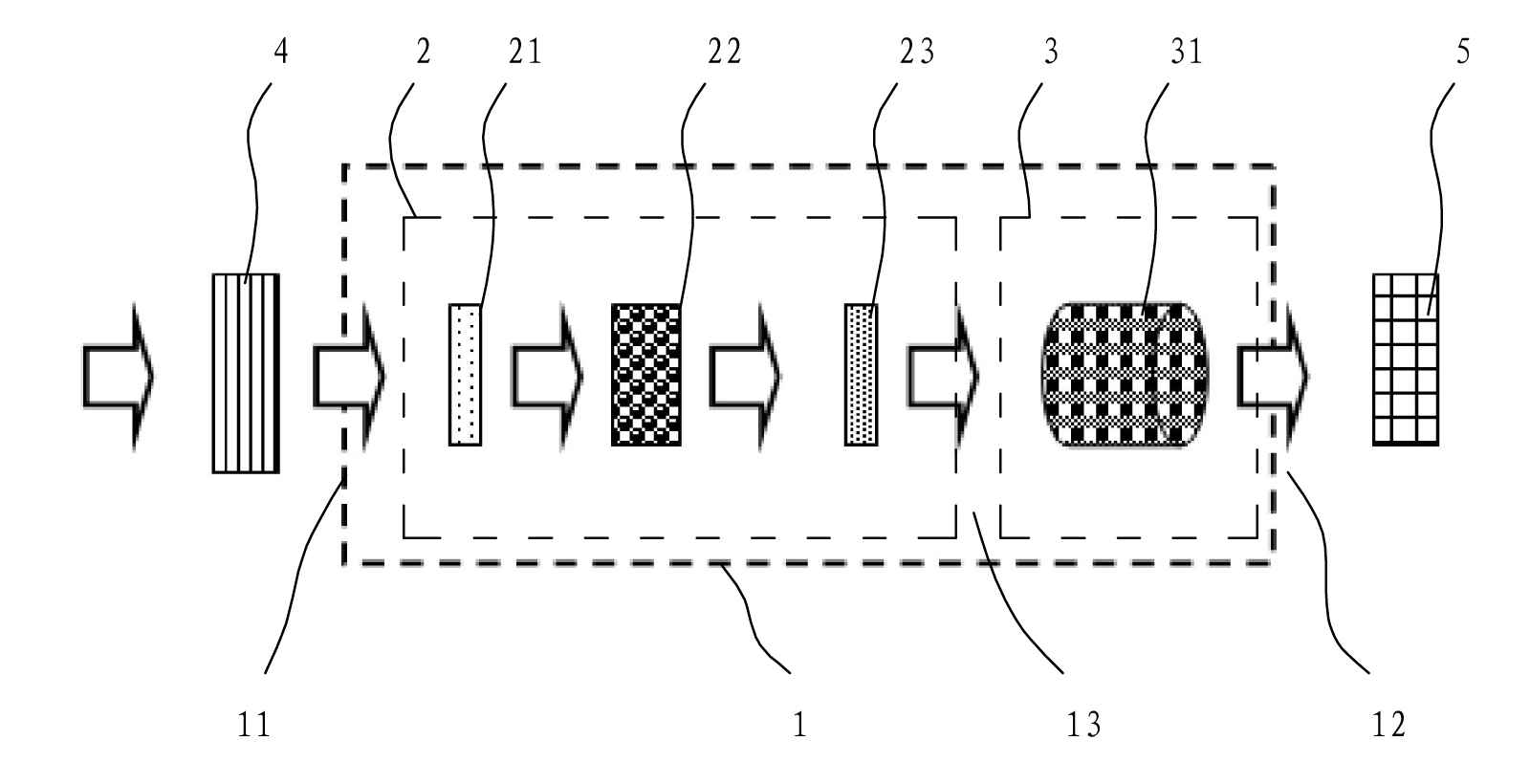

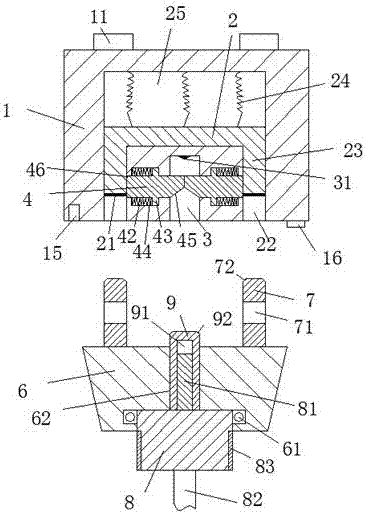

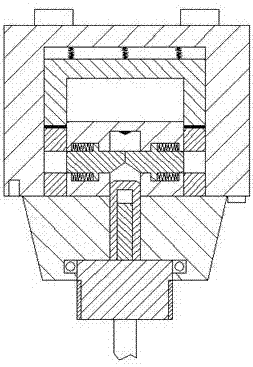

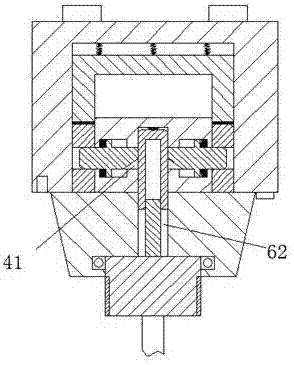

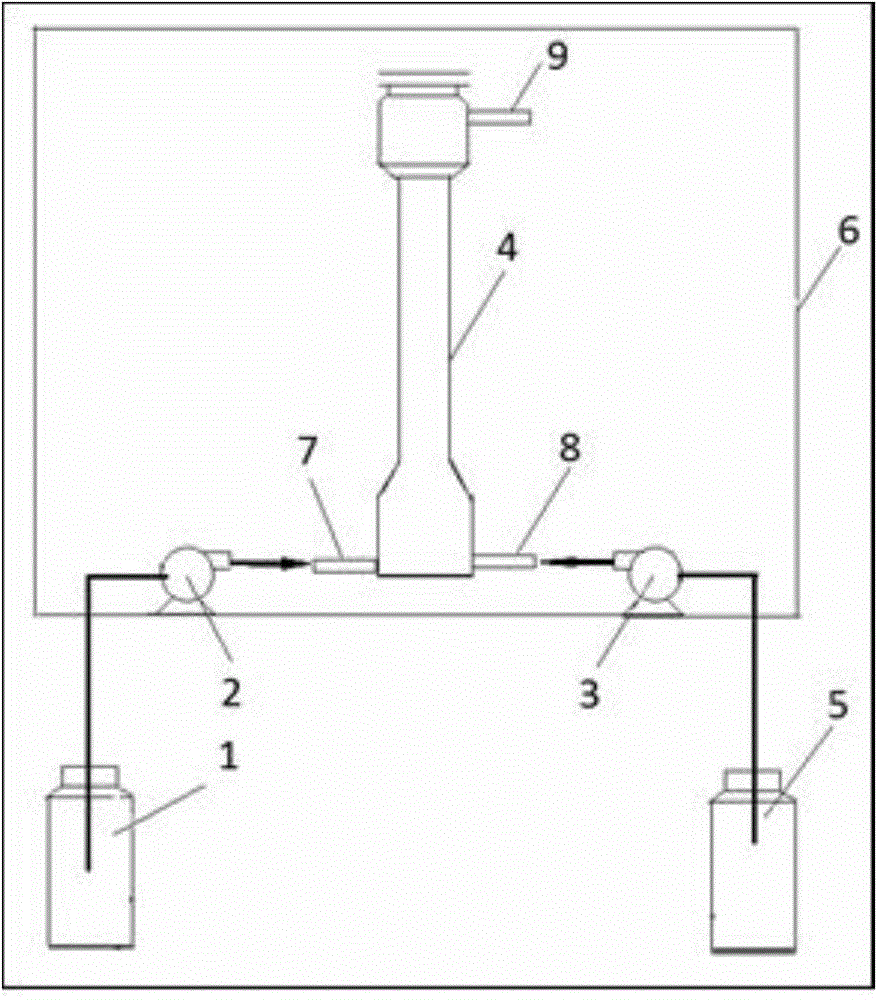

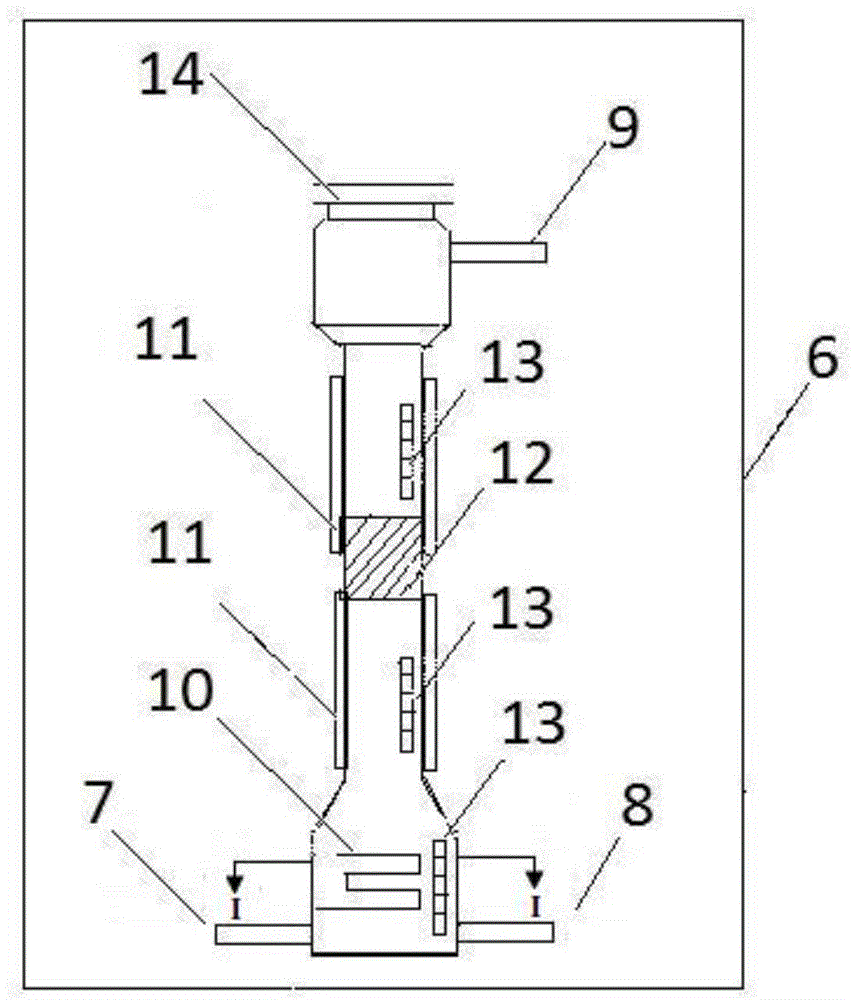

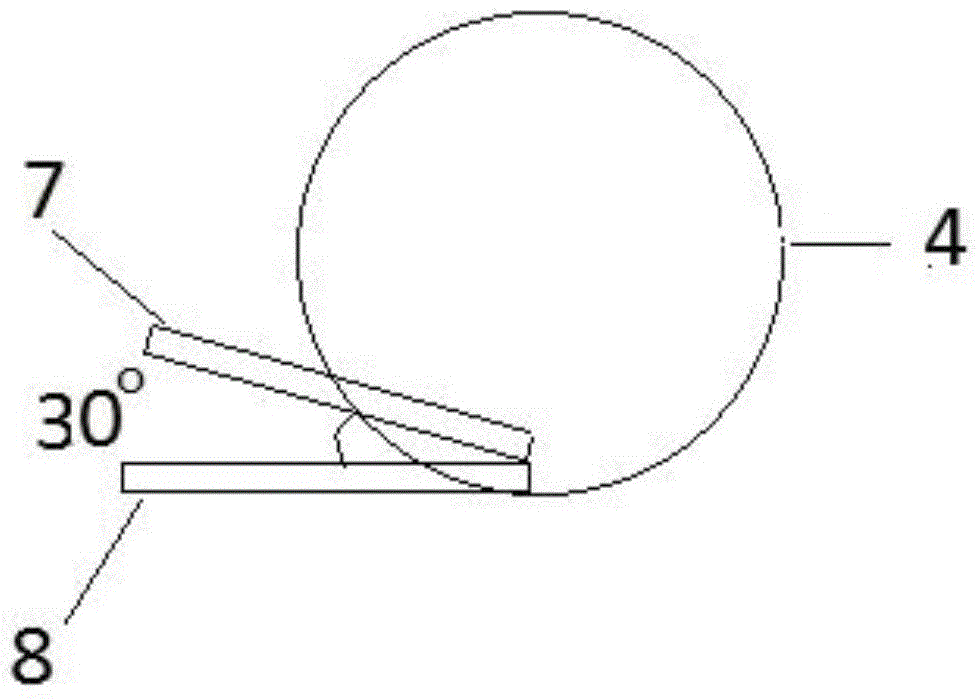

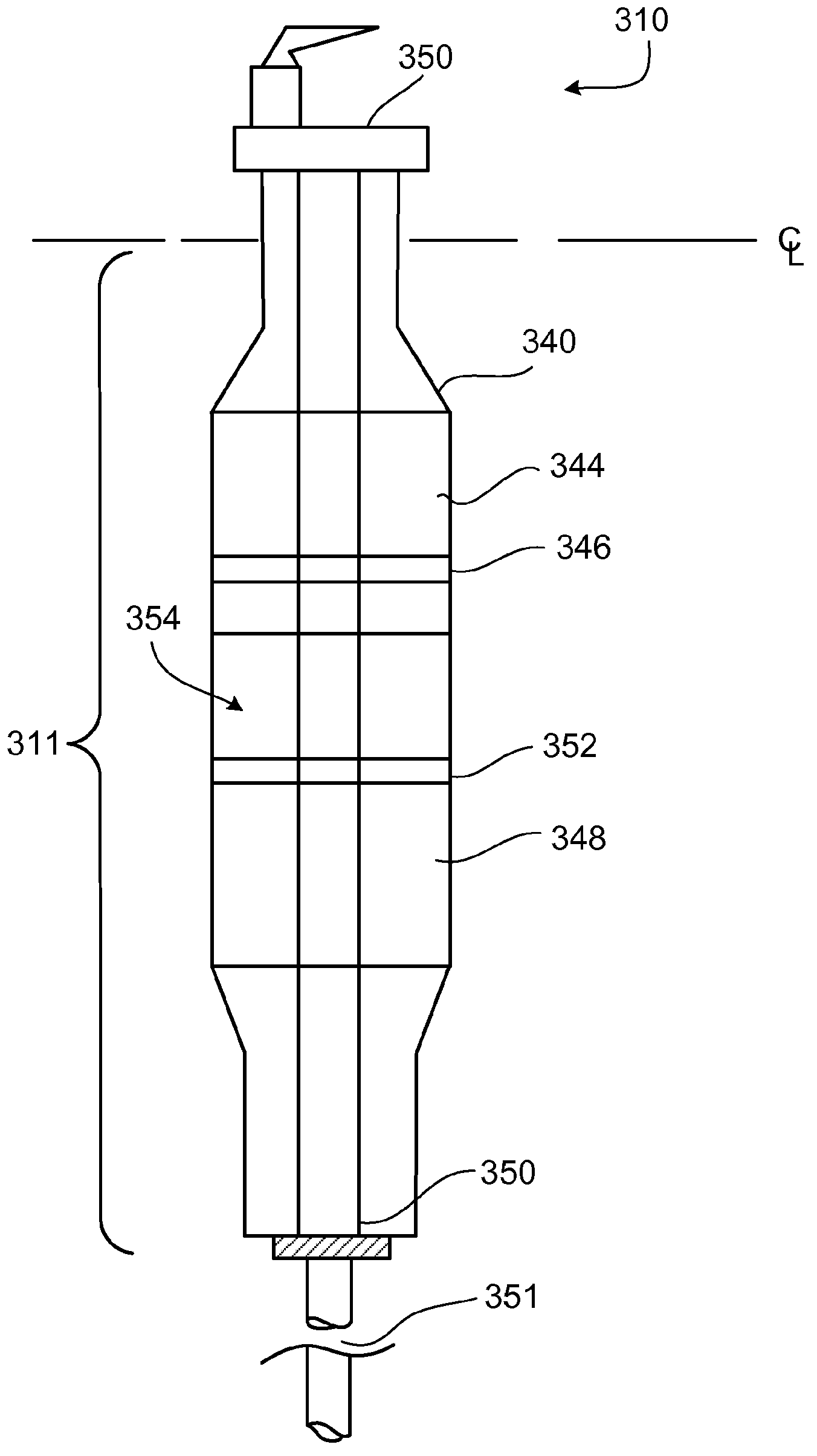

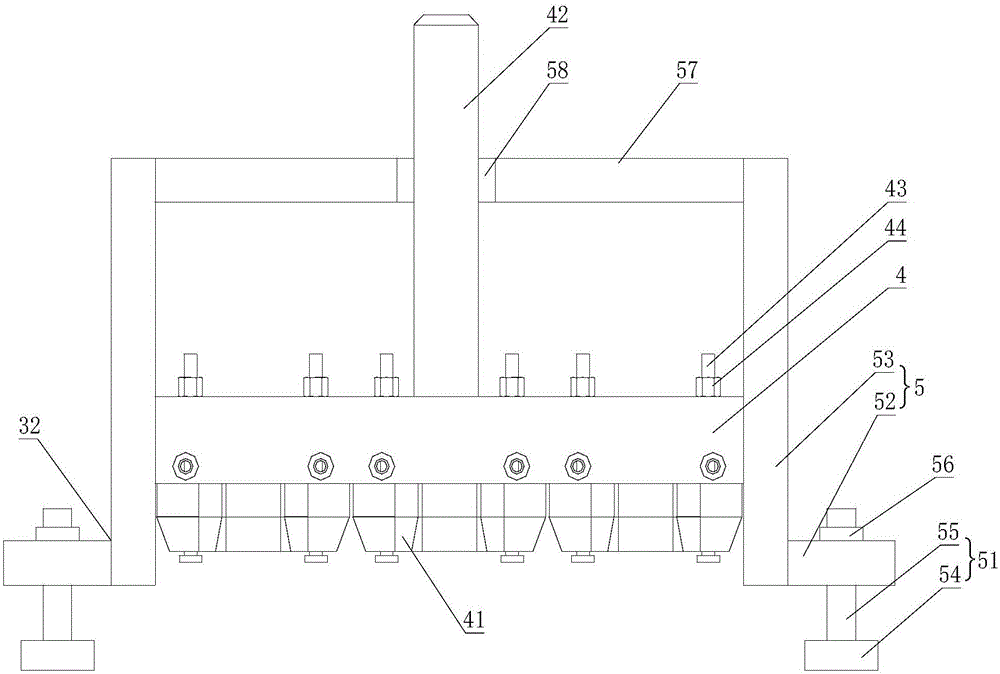

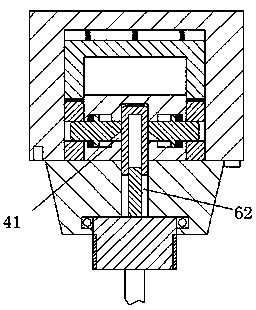

Portable universal type chlorine dioxide generator and its application

The invention discloses a portable universal type chlorine dioxide generator and its application. The generator includes a first raw material supply unit (1), a first raw material pump (2), a second raw material pump (3), a reactor (4) and a second raw material supply unit (5). The lower part of the reactor (4) is provided with a first material inlet pipe (7) and a second raw material inlet pipe (8). The first raw material supply unit (1), the first raw material pump (2), and the first raw material inlet pipe (7) are connected in order through a pipeline. The second raw material supply unit (5), the second raw material pump (3), and the second raw material inlet pipe (8) are connected in order through a pipeline. The upper part of the reactor (4) is equipped with an outlet pipe (9). The raw materials adopted by the device provided by the invention are all salts, do not contain highly corrosive hydrochloric acid or sulfuric acid, have low corrosivity, and are safe to transport and operate. Also, the reaction rate is fast and the raw material conversion rate is high. The device provided by the invention has the advantages of small volume, simple structure, light weight, and easy carry.

Owner:DALIAN JIAOTONG UNIVERSITY

Dual-phase steel/titanium composite board explosive welding forming method

InactiveCN105345249AFix stability issuesSolve quality problemsWelding/soldering/cutting articlesNon-electric welding apparatusDetonationSheet steel

The invention discloses a dual-phase steel / titanium composite board explosive welding forming method. The forming method comprises the following steps of: before explosion cladding, heating a dual-phase steel plate to certain temperature, adopting asbestos to preserve heat for the dual-phase steel plate, transporting the dual-phase steel plate to a working site, putting the steel plate at an interval, placing a titanium plate, adding a protective layer at the same time, fixing a heating belt at a proper position of the plate to ensure that the strength of the dual-phase steel plate in the high-temperature state decreases, finally, paving explosive according to the technological requirements, taking away the heating belt before explosion, ensuring the plate temperature, and flattening after detonation. With adoption of the method, the fitting quality of a dual-phase steel / titanium composite board is greatly improved, and the produced dual-phase steel / titanium composite board can meet the developmental demand of the petroleum technology.

Owner:安徽宝泰特种材料有限公司

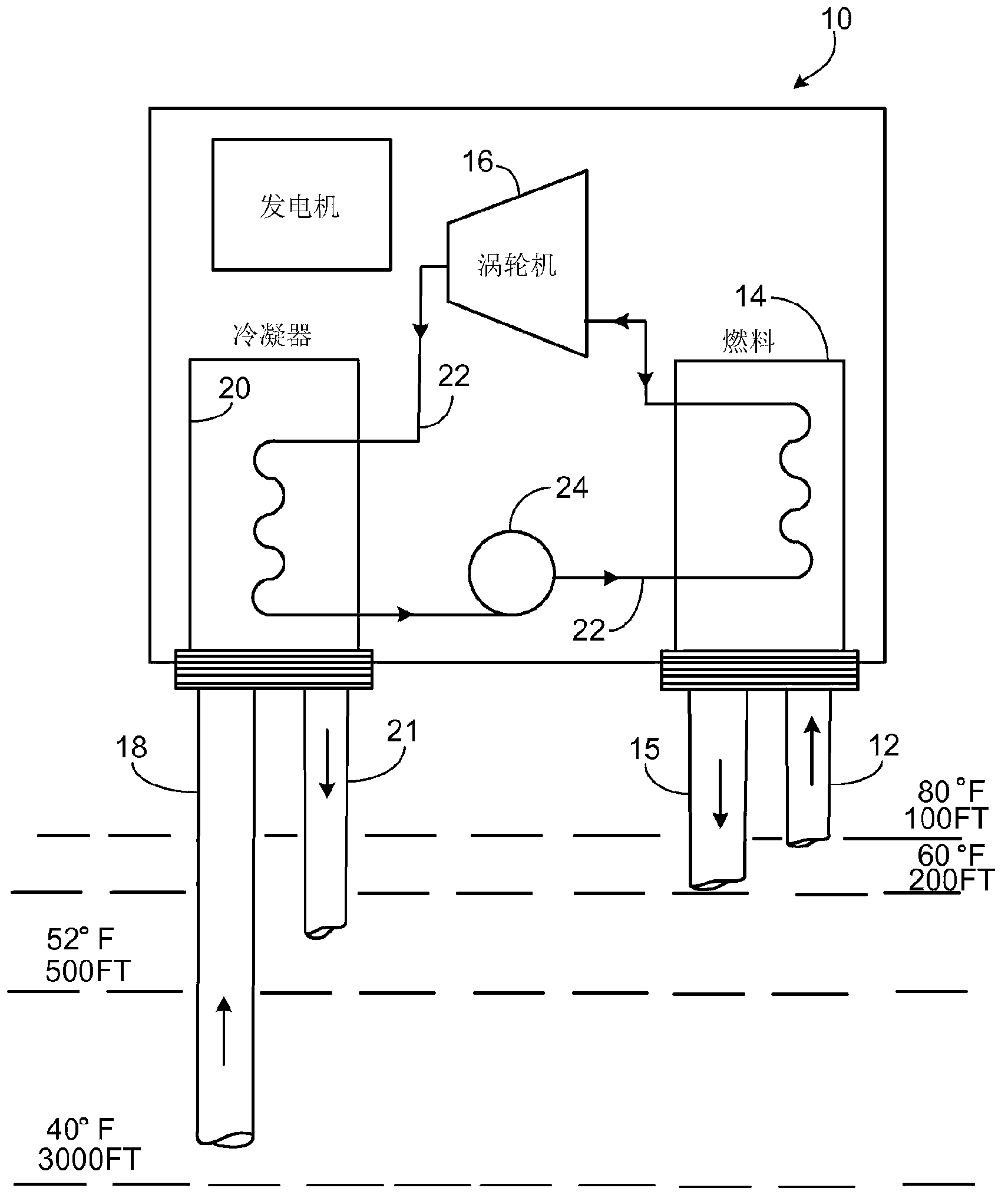

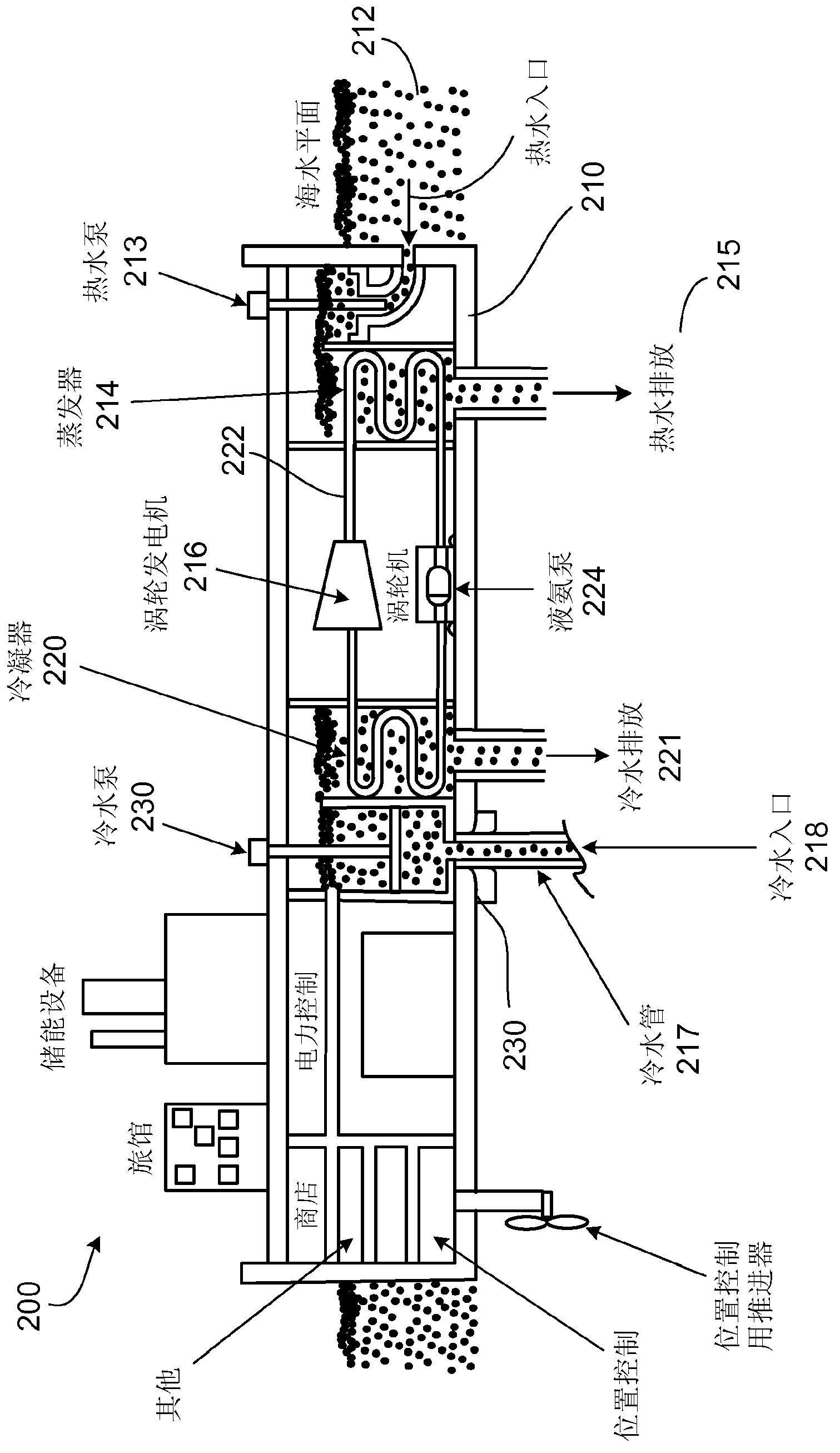

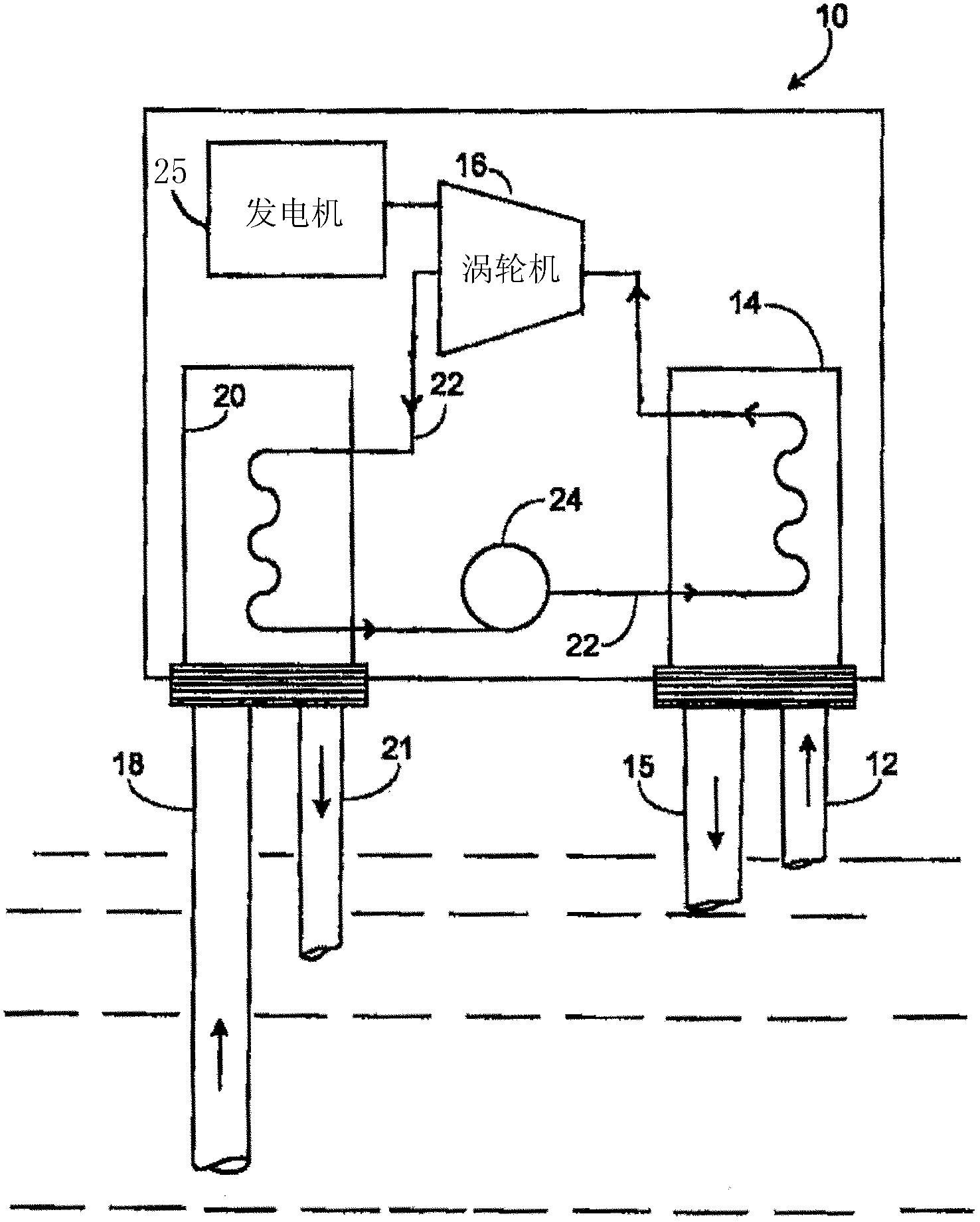

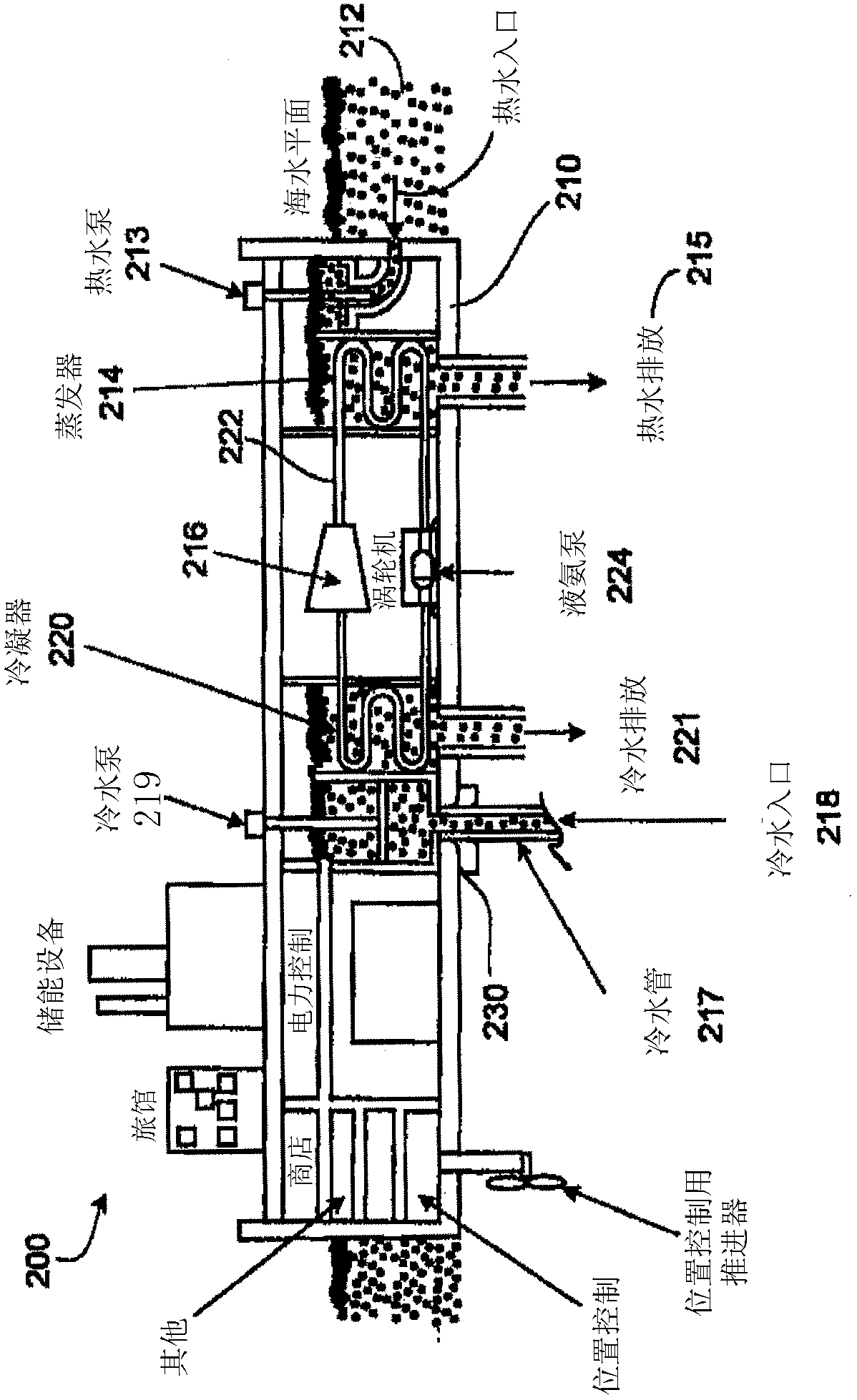

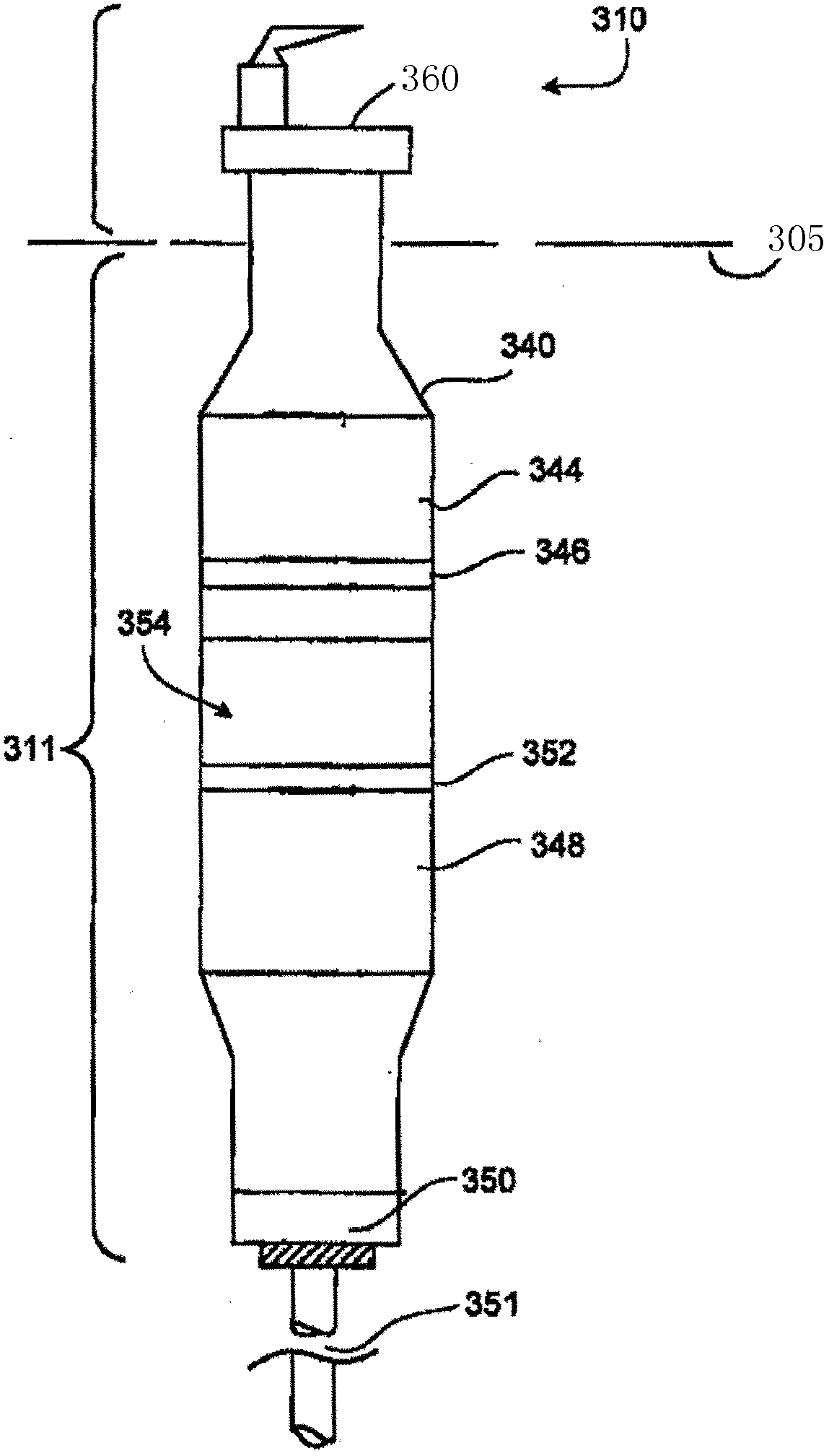

Ocean thermal energy conversion power plant

ActiveCN102844566ALightweight structureReduce friction lossPipe supportsPipe laying and repairThermal energyOcean thermal energy conversion

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection.

Owner:THE ABELL FOUND INC

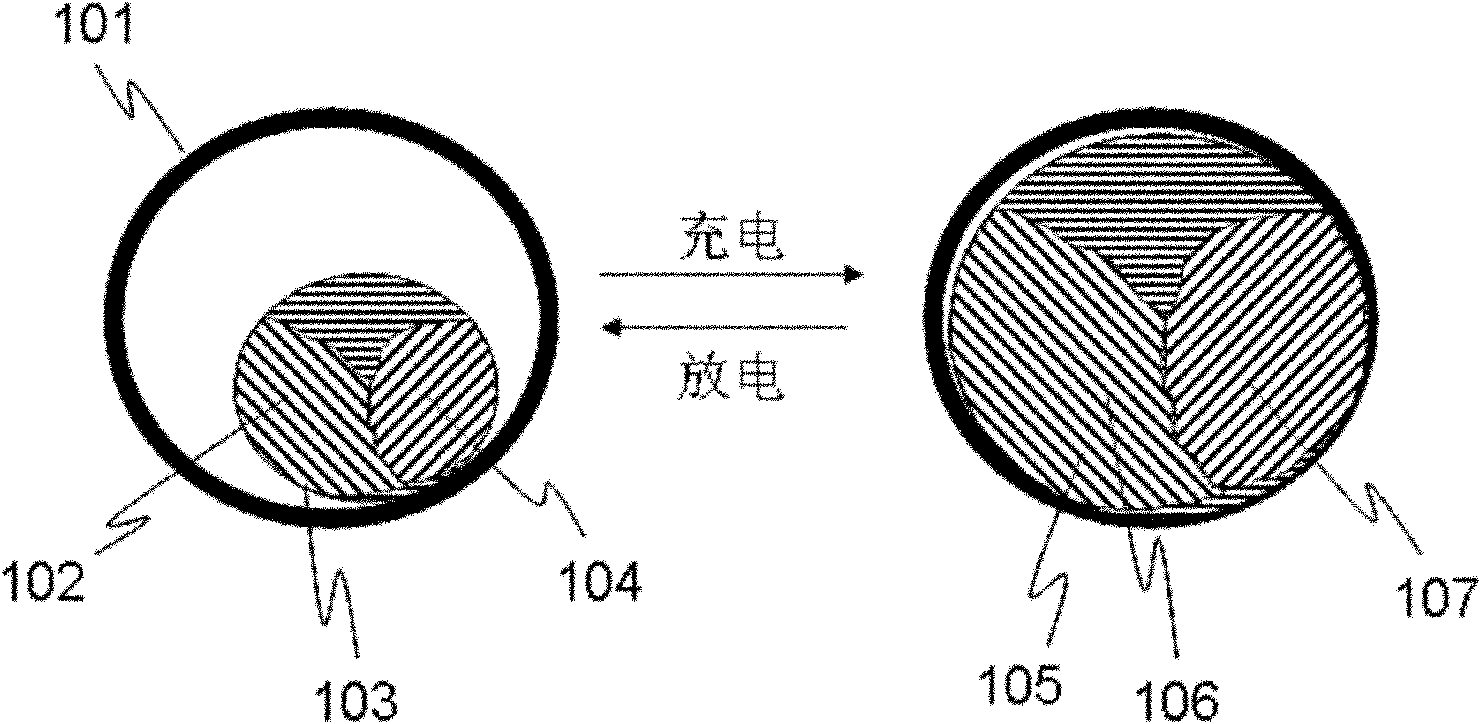

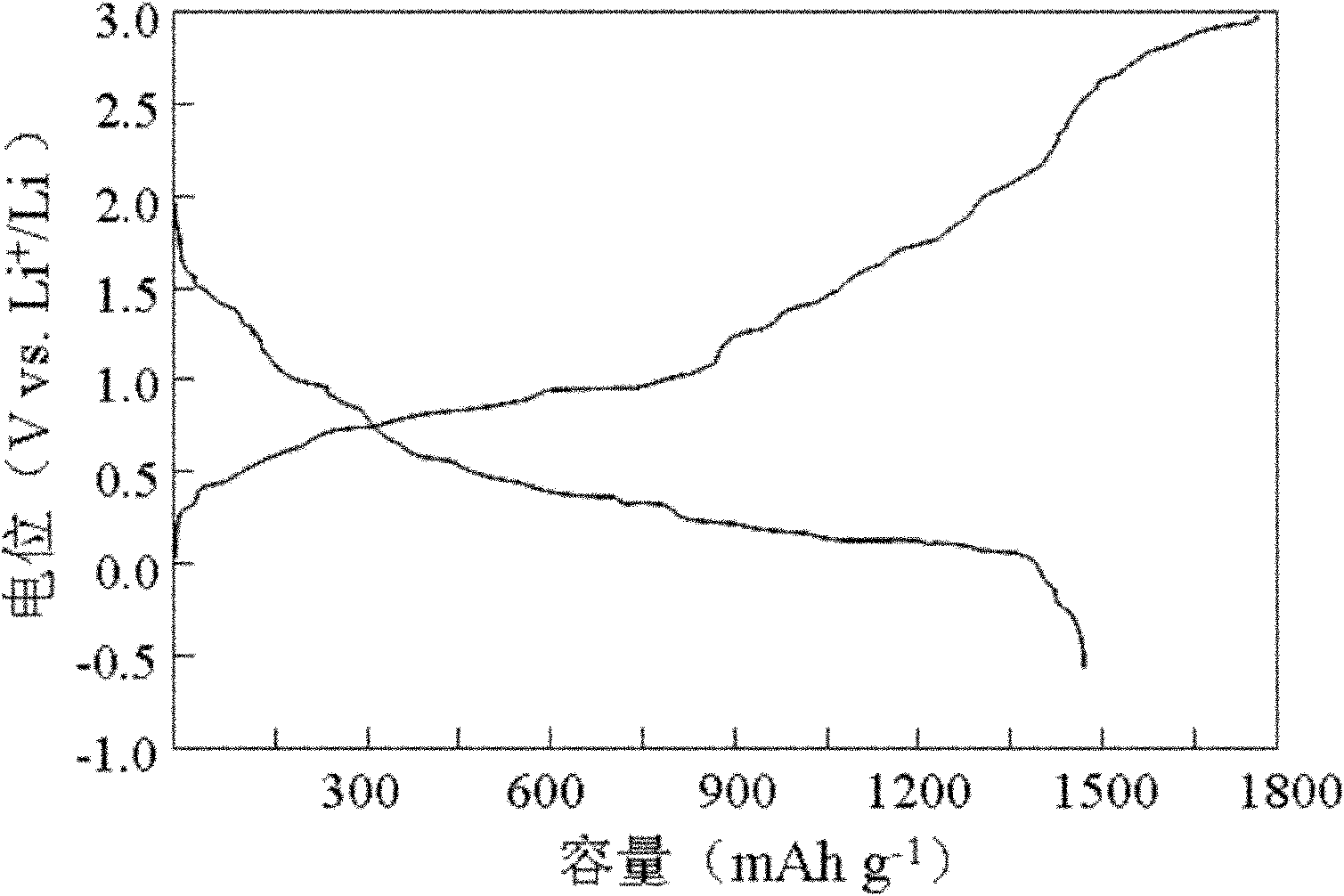

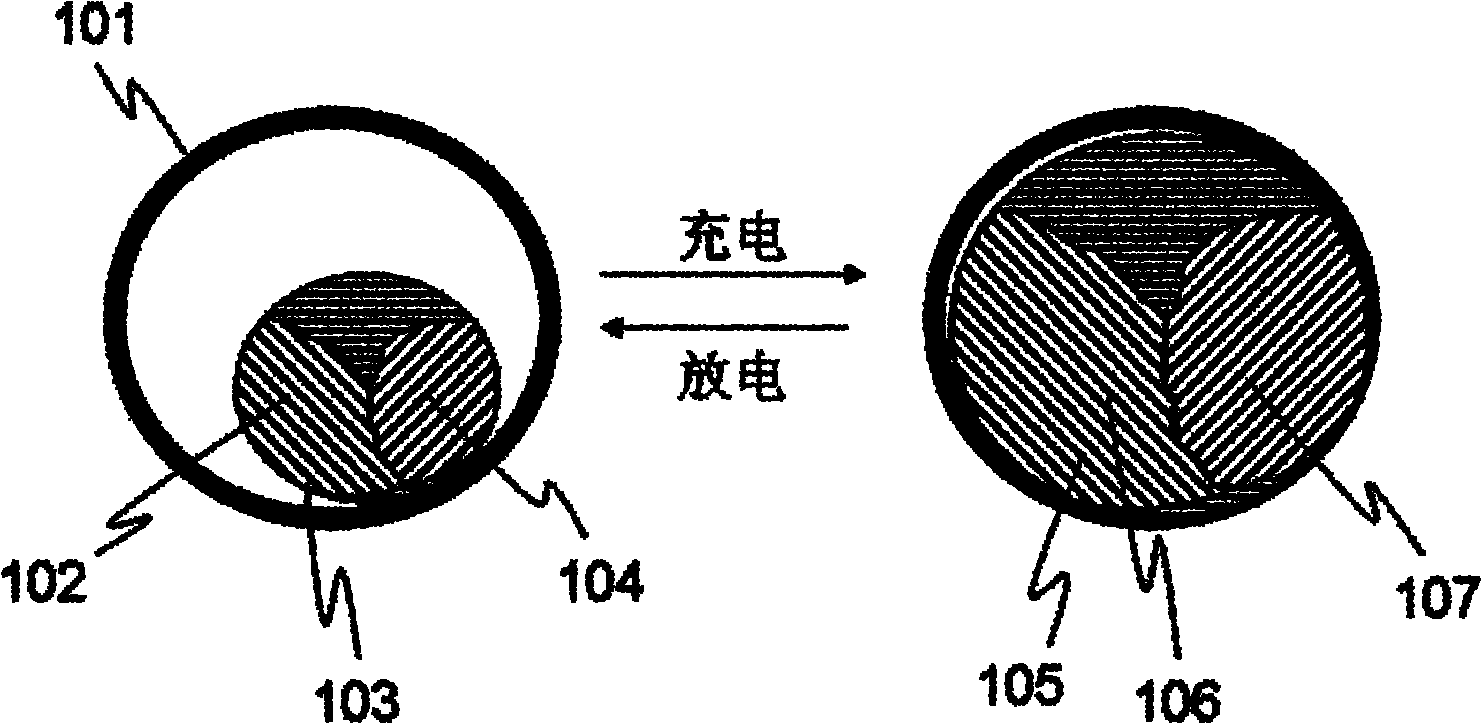

Method for preparing conductive carbon film-coated calcium or calcium-tin alloy serving as anode material of lithium battery

InactiveCN102082263AIncrease speed capacityUniform thicknessCell electrodesLi-accumulatorsCarbon filmPolyethylene glycol

The invention relates to a method for preparing an anode material of a lithium battery and aims to provide a method for preparing a conductive carbon film-coated calcium or calcium-tin alloy serving as the anode material of the lithium battery. The method comprises the following steps of: melting high-purity calcium metal or calcium metal and tin metal, spraying into polyethylene glycol liquid byusing high purity argon, and cooling fog drops in the polyethylene glycol liquid to obtain spherical powder; carbonizing polyethylene glycol to obtain a carbon coated calcium material; filtering out the carbon coated calcium material; calcining again in vacuum or high purity nitrogen atmosphere at the temperature of below 700 DEG C; further carbonizing to remove residual polyethylene glycol on the carbon coated calcium material; and cooling to obtain the conductive carbon film-coated calcium serving as the anode material for preparing the lithium battery. A conductive carbon film is formed onthe surfaces of the calcium or calcium-tin alloy particles and is favorable for the stability of an electrode structure. A gas spraying method for preparing the carbon coated material is favorable for scale production and cost reduction.

Owner:ZHEJIANG UNIV

Industrial ocean thermal energy conversion processes

InactiveCN103154511ALow costSmall pressure lossSteam generation plantsSteam engine plantsThermal energyOcean thermal energy conversion

Owner:THE ABELL FOUND INC

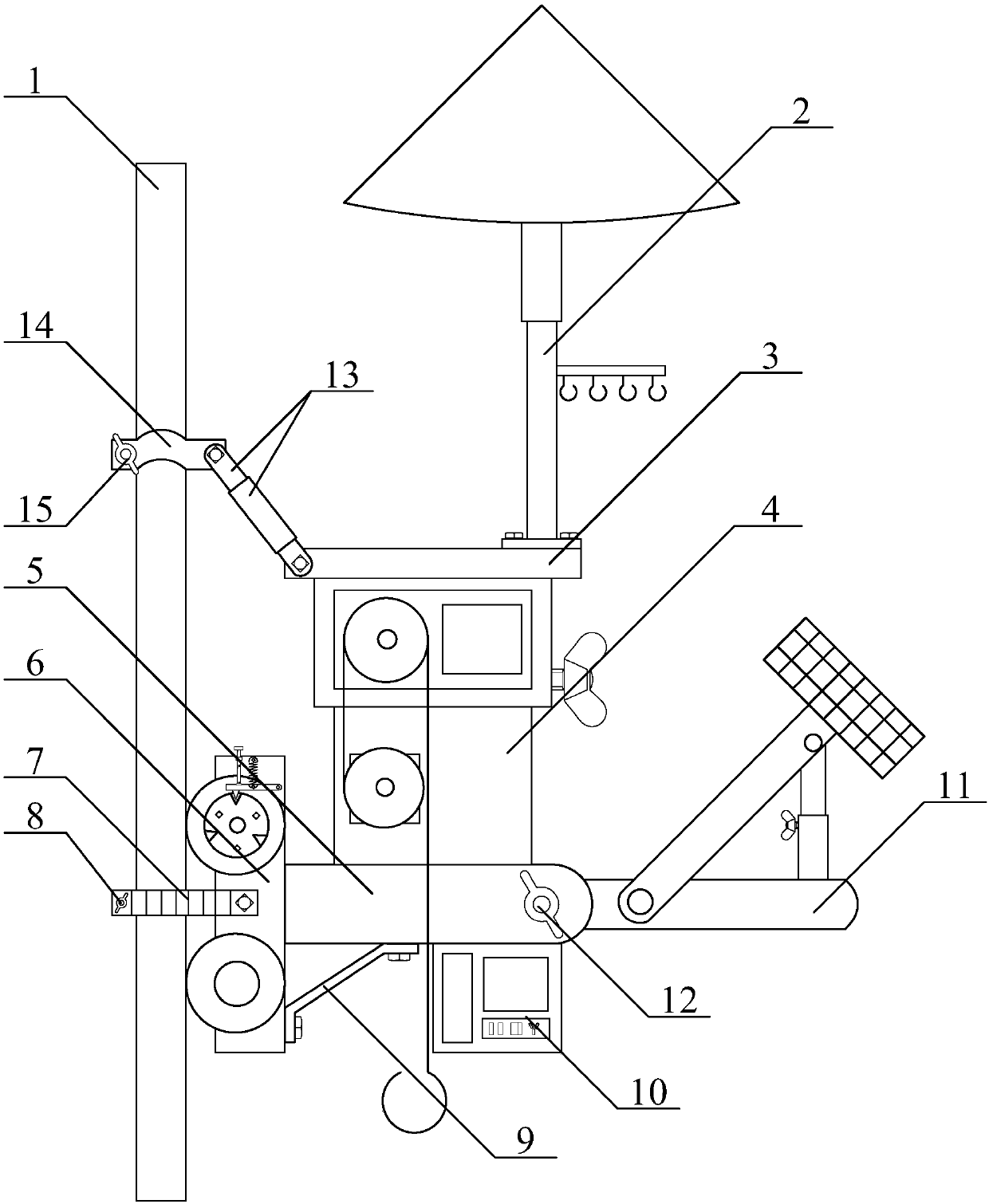

Multifunctional electric power repair operation platform

ActiveCN107724660AImprove scalabilityEasy to useBatteries circuit arrangementsElectric powerVehicle frameThree stage

The invention provides a multifunctional electric power repair operation platform, which comprises a telegraph pole, a dismountable sun umbrella, a station, a regulating table, a cross beam sleeve pipe, a slideable regulating car and a safety belt. Through the arrangement of a rectangular table pipe, a center frame, a fixed wheel, a fixed shaft, a placing box, a four-stage regulating screw bolt, atable plate, a reeling wheel, a reeling motor, a cable rope and a hook, an operator can conveniently lift other repair tools through the device so that the use is more convenient; the work intensitycan be reduced; the use is more convenient; through the arrangement of a stop wheel, a first stage rubber wheel, a first stage axle, a clamp groove, a regulating brake block device, a movable screw bolt, a tension spring, a vehicle frame, a second stage rubber wheel and a second stage axle, the convenient matching with a load bearing plate by the operator is facilitated; through the arrangement ofa hoop and a three-stage regulating screw bolt, the operator can conveniently perform downward slide work on the electric power repair operation platform from the telegraph pole, so that the use andthe operation are safer.

Owner:BEIHAI POWER SUPPLY BUREAU OF GUANGXI GRID +1

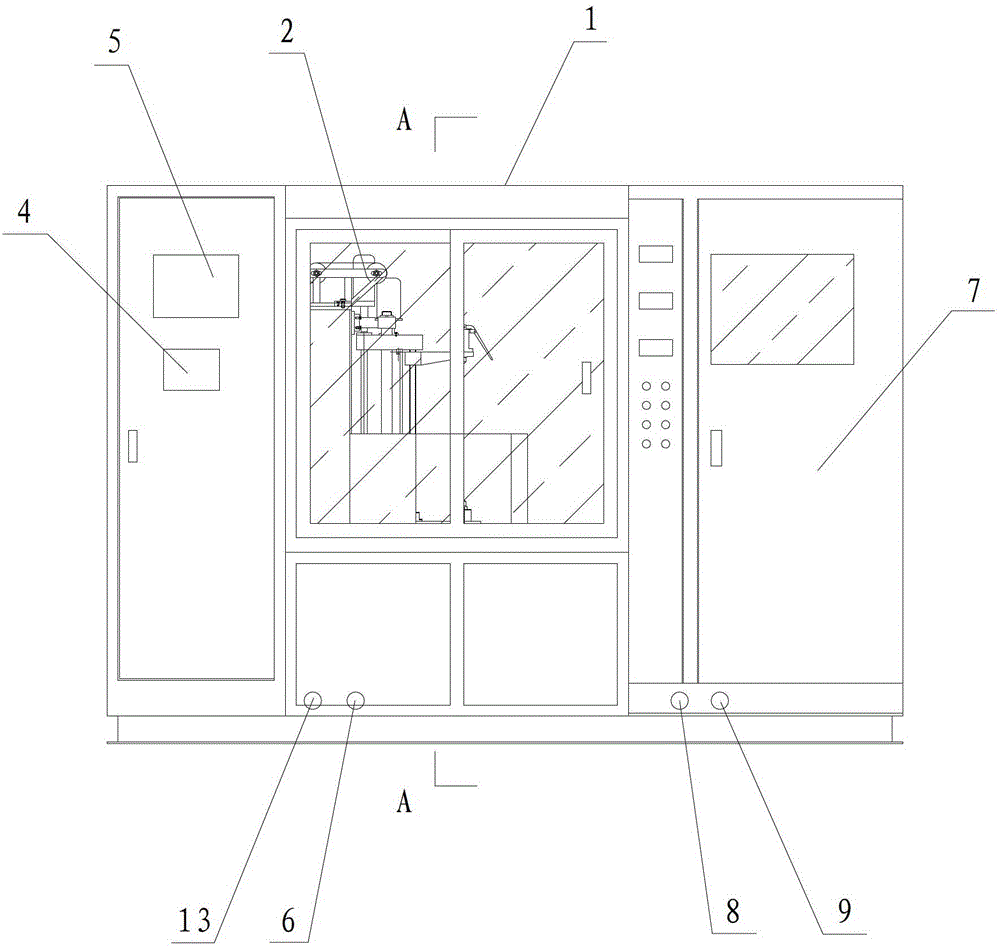

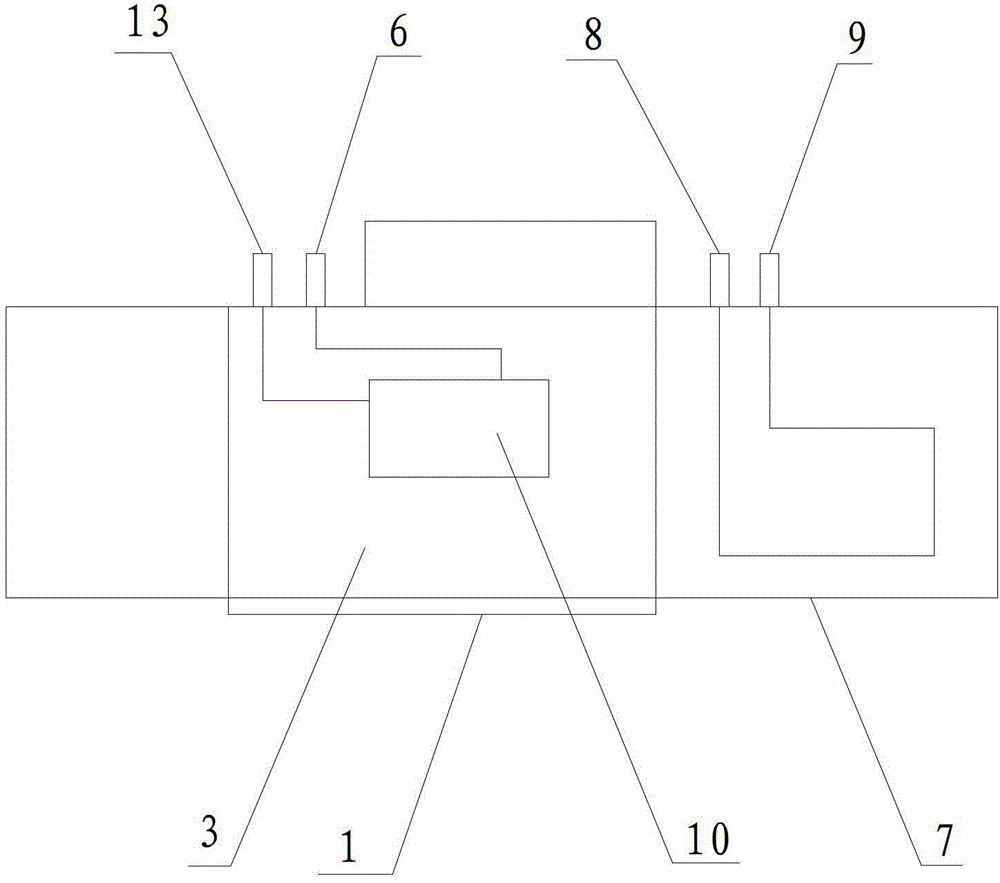

High-frequency induction heat-treatment system with IGBT (Insulated Gate Bipolar Translator)

InactiveCN103146897AReduce lossHigh electrothermal efficiencyIncreasing energy efficiencyOvervoltageSoft switching

The invention relates to a high-frequency induction heat-treatment system with an IGBT (Insulated Gate Bipolar Translator). The high-frequency induction heat-treatment system comprises an engine body, wherein a mechanical transmission system and a cooling water circulating system are arranged in the engine body, a working condition management system is arranged on the left side of the engine body, a touch screen control system is arranged on the working condition management system, a workpiece cooling liquid inlet and a workpiece cooling liquid outlet are arranged at the bottom of the working condition management system, an IGBT induction heating power supply is arranged on the right side of the engine body, and a power supply cooling liquid inlet and a power supply cooling liquid outlet are arranged at the bottom of the IGBT induction heating power supply. The high-frequency induction heat-treatment system has the beneficial effects that effects of high efficiency and energy saving are achieved, an IGBT power device is used as a power supply device, the switching loss of the IGBT is greatly reduced due to the adoption of a zero-passage soft switching IGBT inverter technology, the electrothermal efficiency is high, the frequency range is wide, the process adjustment is simple, the protective system is complete, multiple reliable protection functions such as overvoltage, overcurrent and overheating are arranged for monitoring the machining process, and the high-frequency induction heat-treatment system is safe to use and convenient to maintain.

Owner:WUXI ELECTRIC FURNACE CO LTD

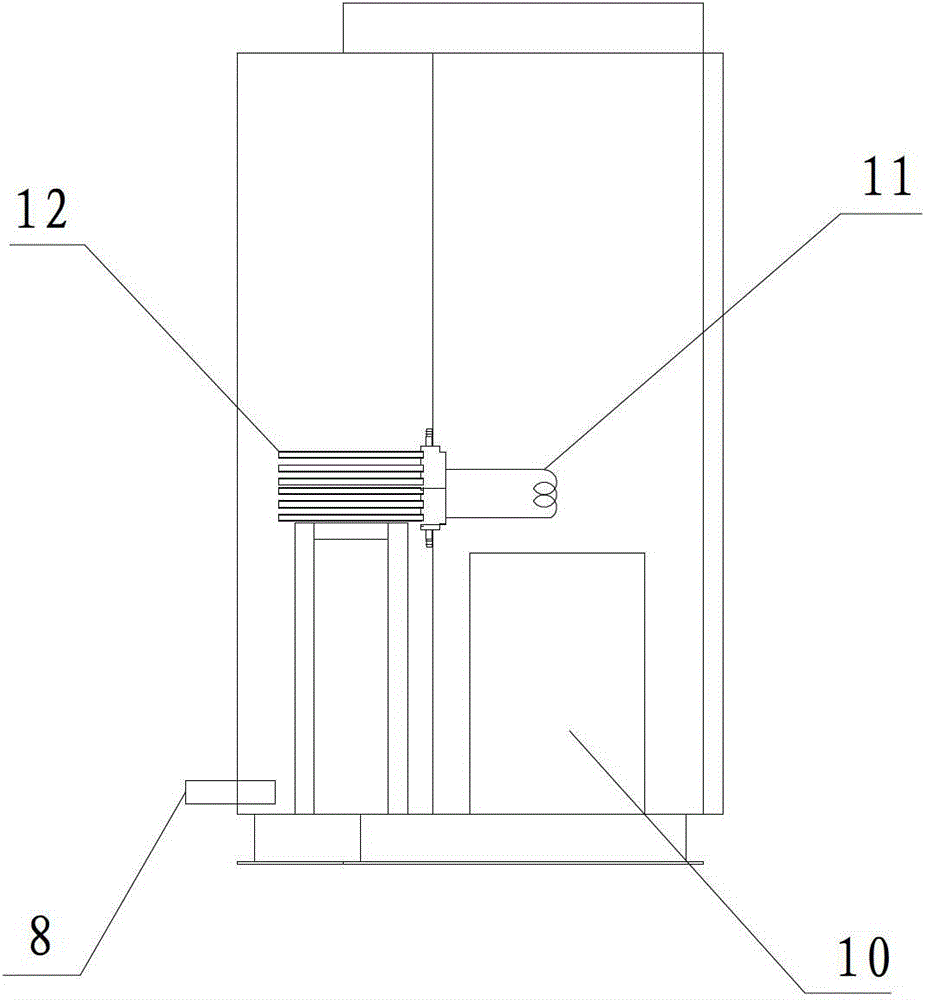

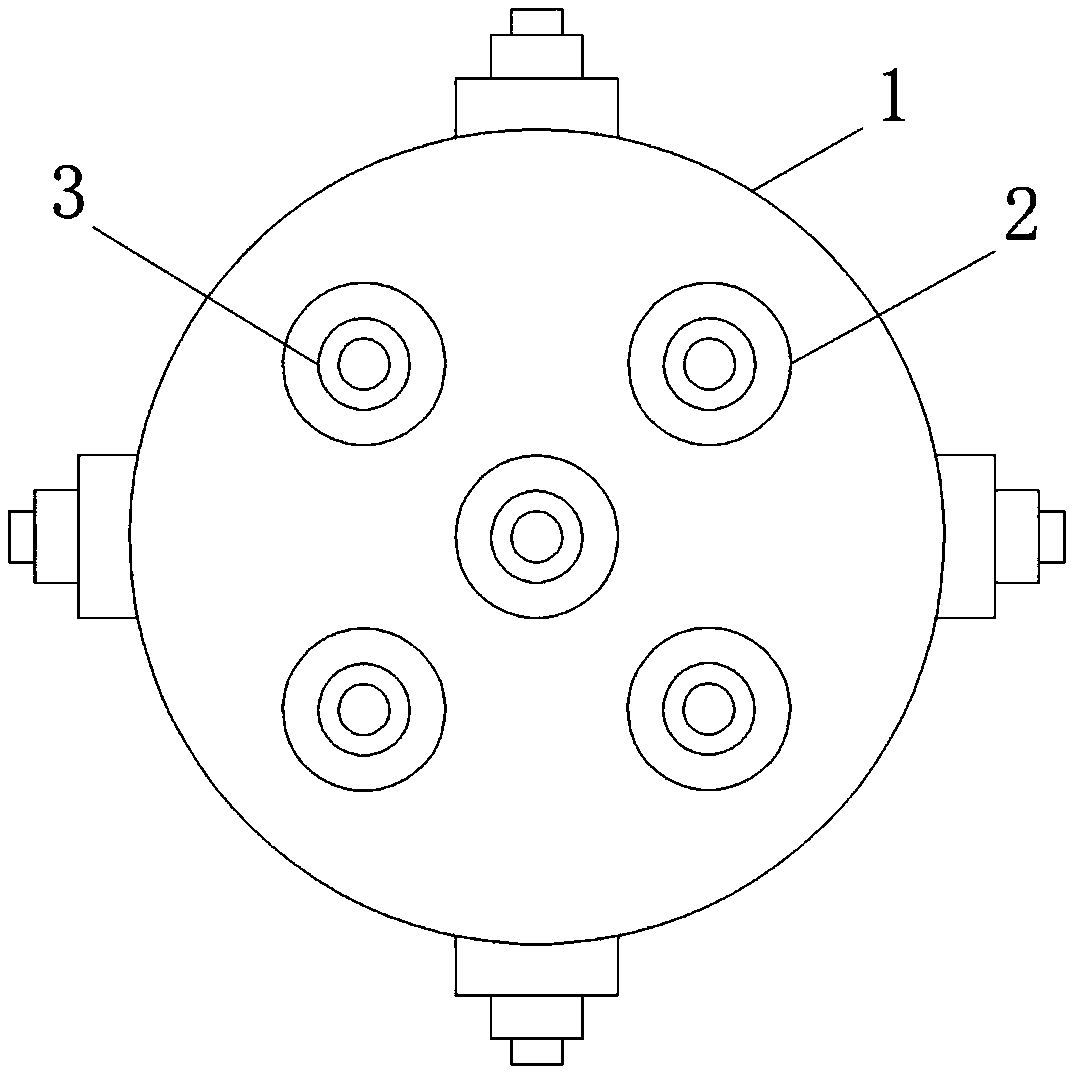

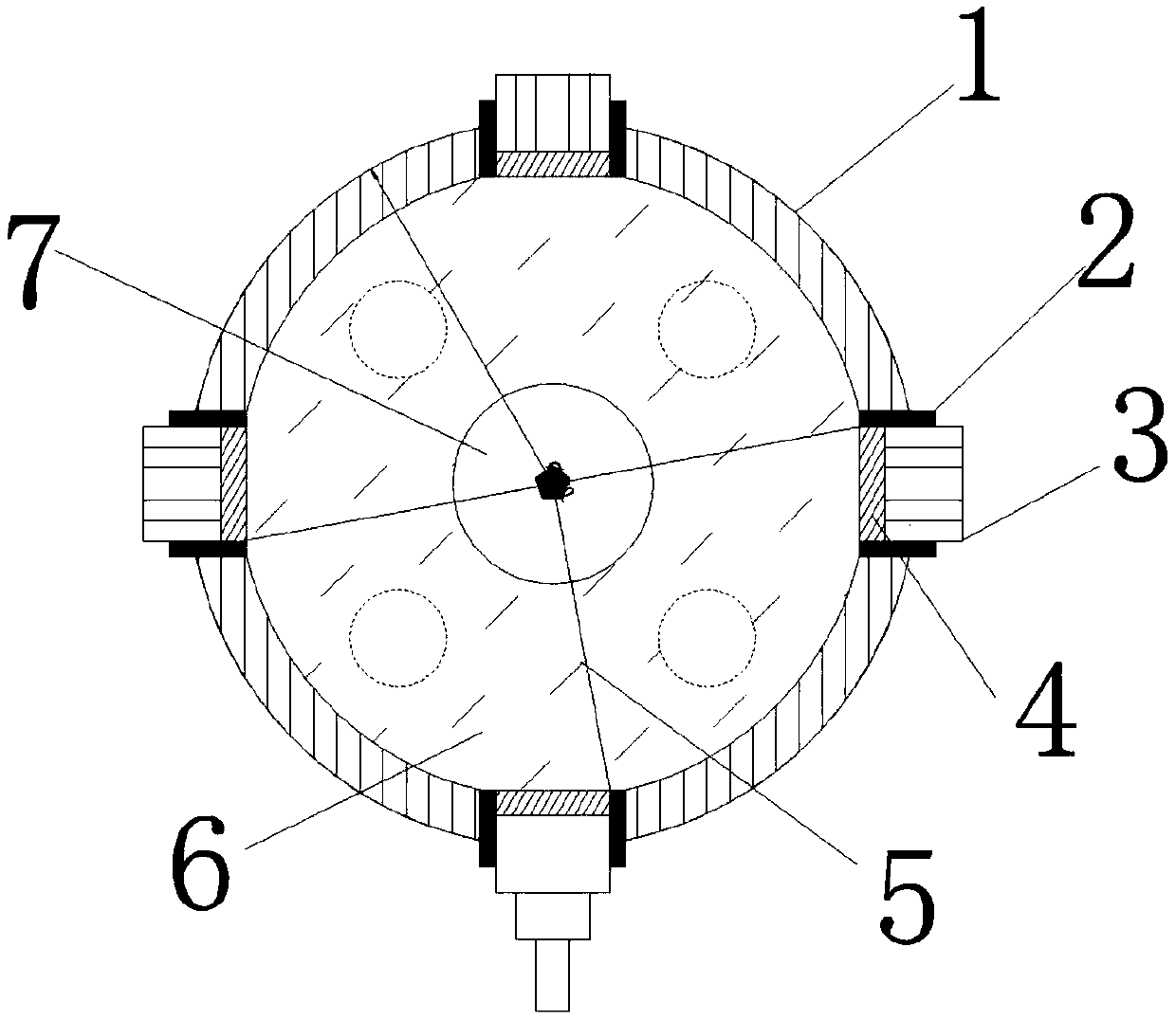

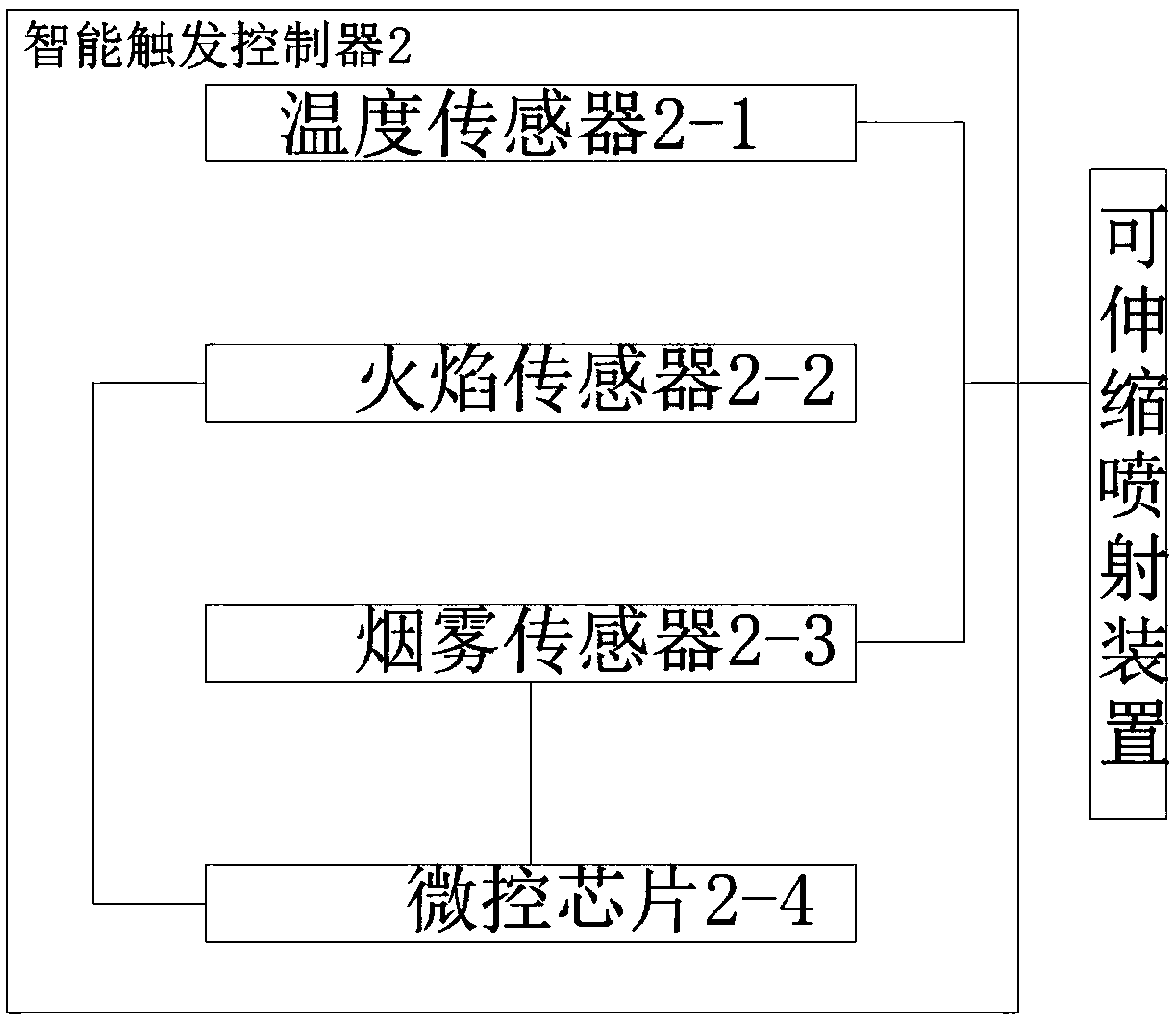

Liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device

The invention relates to a liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device and belongs to the technical field of fire protection and fire extinguishing machinery. The liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device comprises a spherical shell, intelligent trigger controllers, a perfluoro-hexanone fire extinguishing agent and a gas generating agent. The spherical shell is uniformly provided with telescopic jetting devices, and jet orifices of the telescopic jetting devices are sealed through aluminum foil. The intelligent trigger controllers are mounted on the outer portions of the telescopic jetting devices on the spherical shell. Each intelligent trigger controller comprises a fire detection sensor and a microcontrol chip connected with the fire detection sensor. The microcontrol chips judge whether a fire occurs or not according to signals transmitted from the fire detection sensors. The gas generating agent is located at the sphere center position of the spherical shell. The spherical shell is filled with the perfluoro-hexanone fire extinguishing agent. The perfluoro-hexanone fire extinguishing agent is isolated from the gas generating agent. The microcontrol chips of the intelligent trigger controllers are connected to the gas generating agent through electric ignitionwires. When judging that the fire occurs, the microcontrol chips trigger the electric ignition wires to ignite the gas generating agent. The liquid filling type portable intelligent multi-direction jetting spherical fire extinguishing device conducts fire extinguishing in a total flooding heat absorbing physical manner and is intelligent, safe, friendly to environment, convenient to use and high in efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

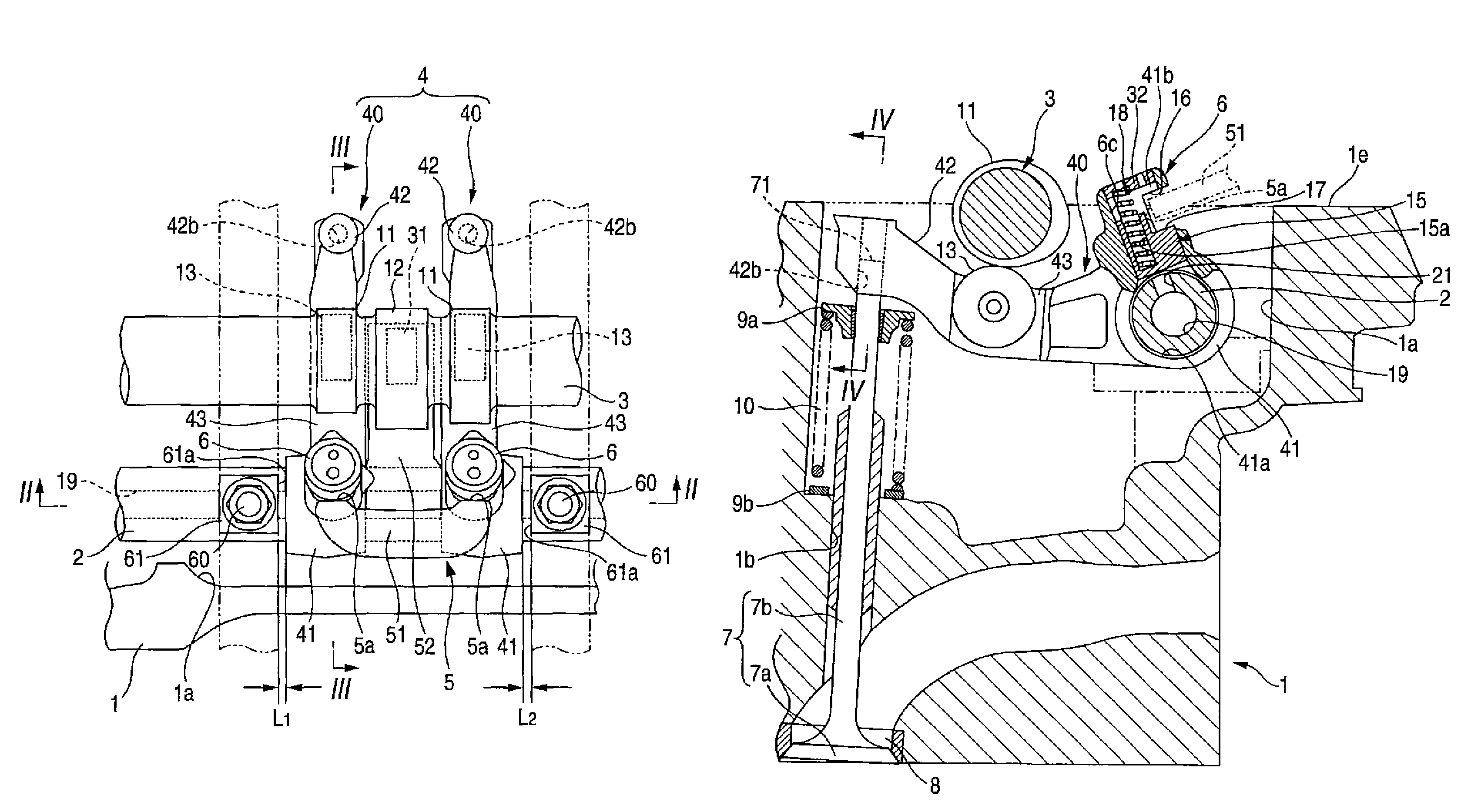

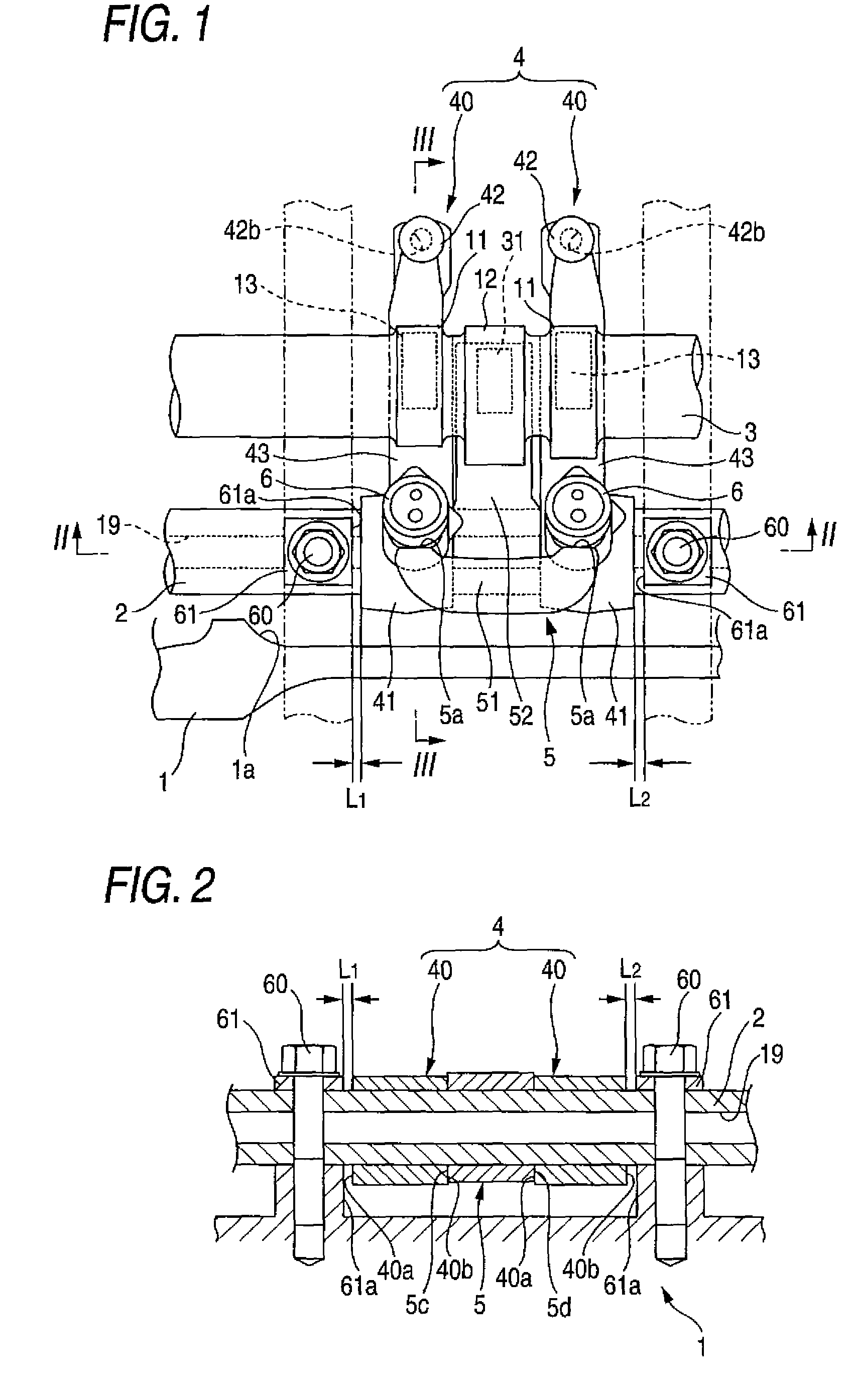

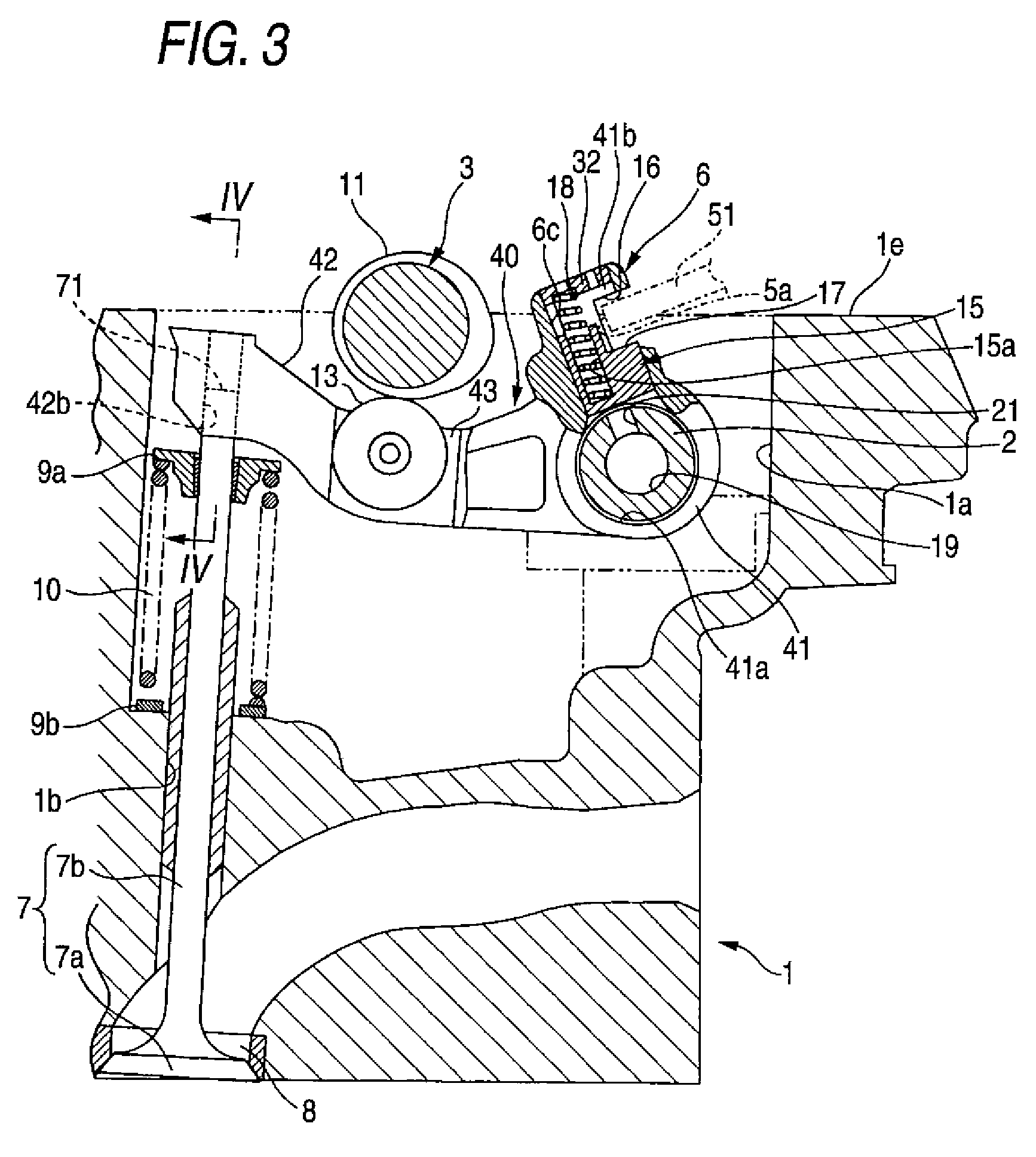

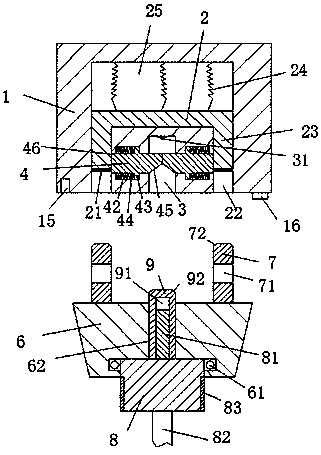

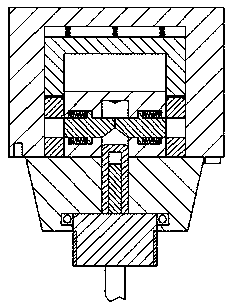

Variable valve mechanism for engine

ActiveUS7918201B2Safe operabilityDownsizing of the engineControlling membersValve arrangementsEngineeringCam

A variable valve mechanism for an engine includes: a rocker shaft; a first rocker arm rotatably supported by the rocker shaft, for transmitting displacement of a first cam to a valve; a second rocker arm rotatably supported by the rocker shaft, for transmitting a displacement of a second cam to the valve; and a switching mechanism for switching a transmitting state and a non-transmitting state. The first rocker arm has a pair of first arm portions and a recess portion in which an upper end of the valve is inserted at an end portion of each of the first arm portions. The second rocker arm has a second arm portion disposed between the first arm portions. The first rocker arm is restricted from movement in an axis direction of the rocker shaft when an inner sidewall of the recess portion is in contact with the upper end of the valve. The second rocker arm is restricted from movement in the axis direction when the second arm portion is in contact with the first rocker arm.

Owner:MITSUBISHI MOTORS CORP

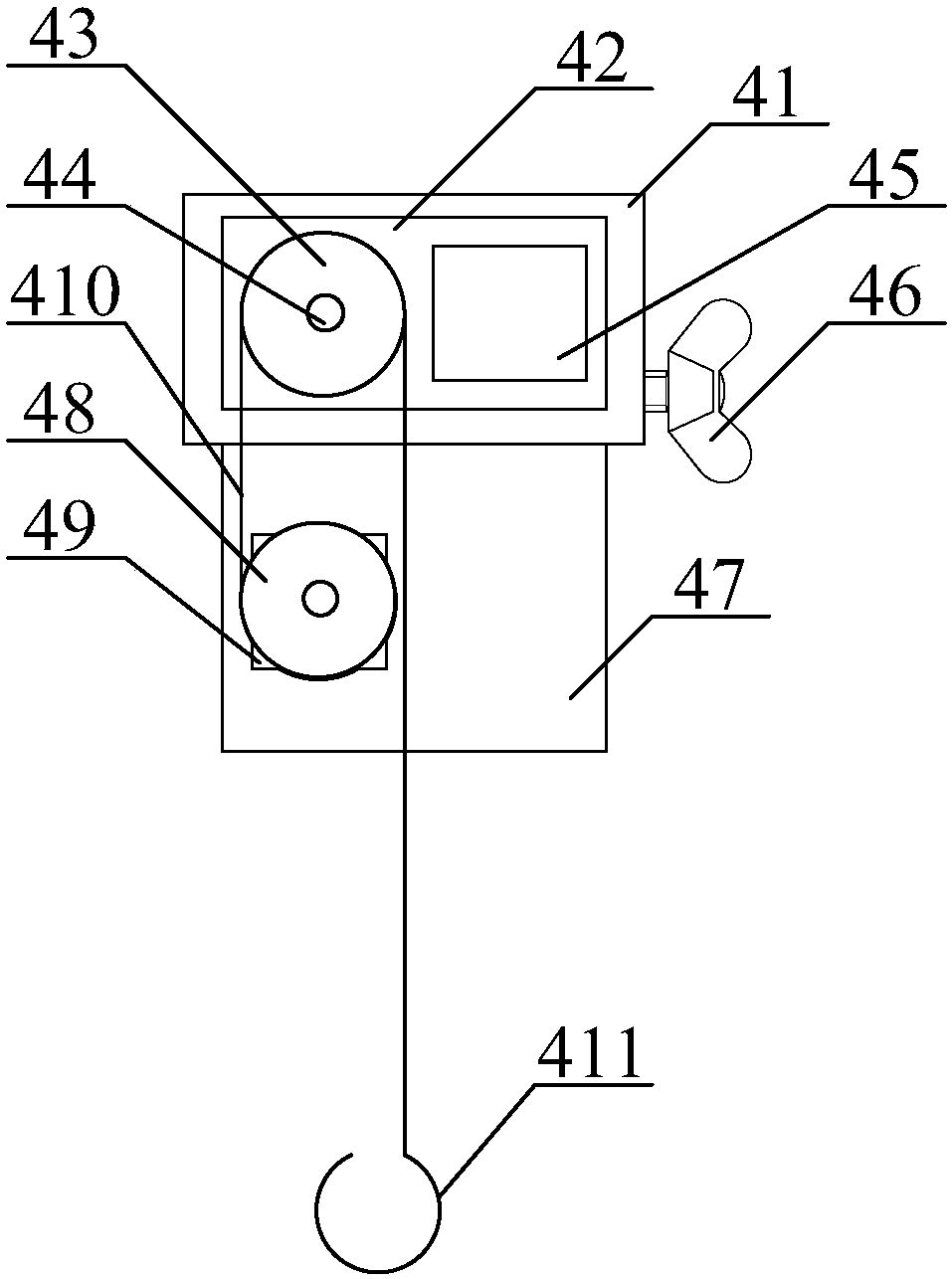

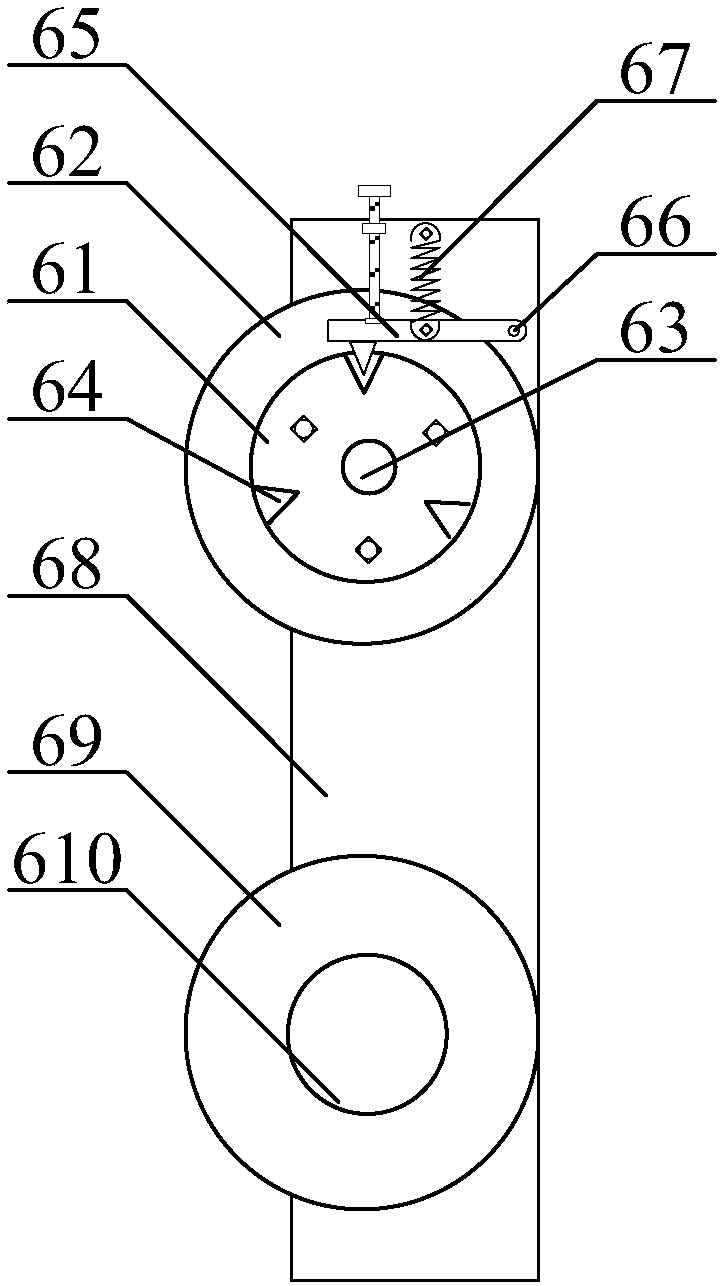

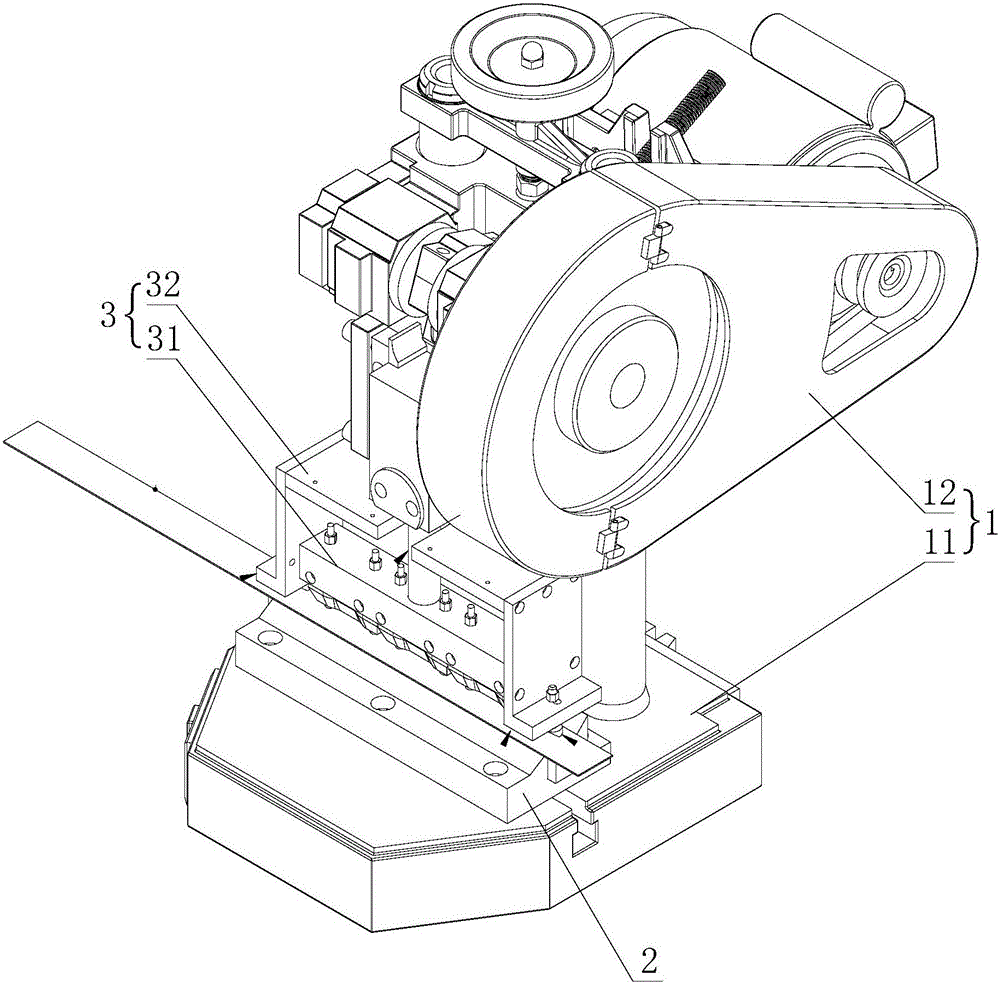

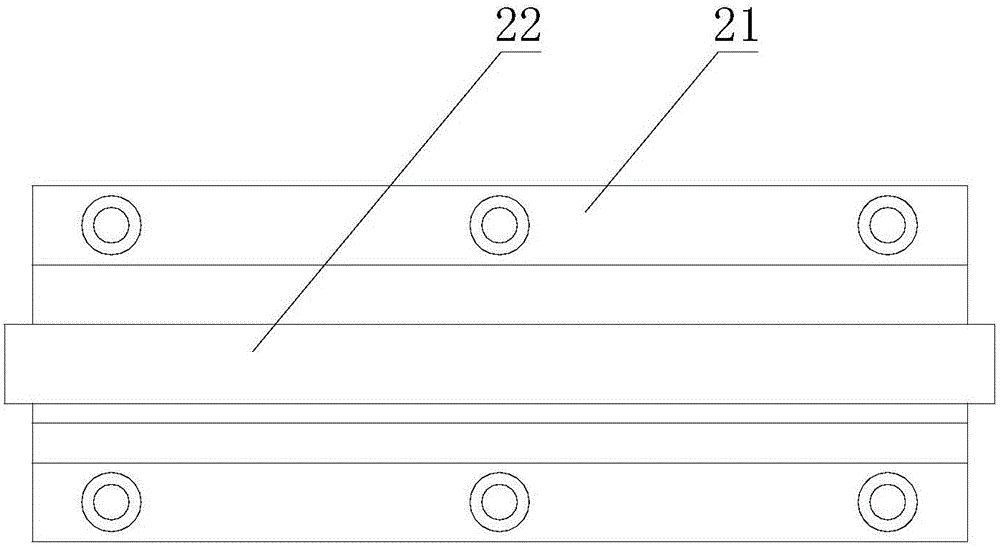

Device for quickly preparing dumbbell from cable insulation material

InactiveCN106079208AReliable operationImprove efficiencyPreparing sample for investigationEngineeringOperability

The invention relates to a device for quickly preparing a dumbbell from a cable insulation material. The device comprises a punching machine body, wherein the punching machine body comprises a rack and a driving part, wherein a base for fixing the cable insulation material is arranged on the rack; the driving part is connected with a punching head; the punching head punches the cable insulation material to form a sample plate which is dumbbell-shaped. The device disclosed by the invention has the advantages that the punching head connected with the driving part of the punching machine body punches the cable insulation material; by the use of the impact force generated by the punching machine, quick punching on the cable insulation material is realized, so that the cable insulation material can be punched into the sample plate with a dumbbell-shaped cross section; the device is reliable and safe in operability, and automatic for production, labor-saving and high in efficiency; furthermore, the punched sample plate is stable in accuracy; the base realizes fixing of the cable insulation material, so that the stability of the cable insulation material during punching is effectively guaranteed, sliding of the cable insulation material is prevented, and the punching efficiency is improved.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST

Method for producing ferronickel through reduction smelting of laterite-nickel ore flash furnace

The invention relates to the technical field of pyrometallurgy, in particular to a method for producing ferronickel through reduction smelting of a laterite-nickel ore flash furnace, which is short inflash reduction smelting time, high in speed, high in production efficiency, energy-saving and environment-friendly, and the reduction time is within one minute. Iron in the slag is reduced to prepare the iron-containing semi-steel alloy; remelting of said alloy is carried out to form qualified molten steel, meanwhile, submerged arc furnace slag is also obtained; the submerged arc furnace slag can serve as cement clinker to be conveyed to a cement plant to produce high-quality cement. The process is simple, the flow is short, qualified molten steel can be smelted and recycled, cement can be manufactured, economic benefits are good, environmental protection is facilitated, and hot materials subjected to multi-stage cyclone drying and pre-reduction directly enter a rotary kiln to be roasted; on one hand, the material buffering effect is achieved, and the material blocking problem caused when the hot materials directly enter the rotary kiln can be avoided; and on the other hand, throughfurther pre-reduction roasting of the rotary kiln, agglomeration of the materials can be achieved, and equipment and operation safety problems caused by direct feeding of the powdery materials into the furnace is avoided.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

Power supply plug device

InactiveCN107706592AImprove stability and securityAvoid Electric Shock AccidentsCoupling device detailsElectricityElectric shock

The invention discloses a power supply plug-in device, which comprises a power supply body and a plug cooperating with the power supply body. Between the power supply slots with opening forward, the rear end wall of the power supply slots is provided with power supply contacts connected with the power supply, and the rear ends of the two slots are connected with sliding slots, in the sliding slots The sliding block that can slide back and forth is provided, the overall structure of the present invention is simple, the production cost is low, the power supply is safe and stable, and the operation steps of power connection and power off are relatively simple, which effectively reduces the electric shock accidents in the existing life and guarantees the safety of people's lives , It can also avoid the occurrence of power failure accidents of electrical equipment caused by accidental kicking and bumping, and reduce the burnout rate of electrical equipment, which is suitable for popularization and use.

Owner:罗亚香

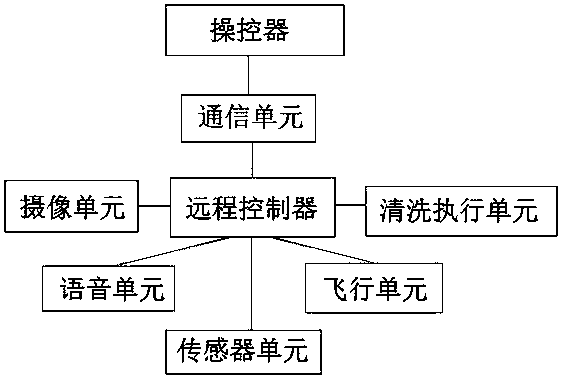

Window cleaning robot control system and method

InactiveCN111374585AEasy to operateControl safetyProgramme-controlled manipulatorWindow cleanersComputer hardwareCommunication unit

The invention relates to a window cleaning robot control system and method. The system comprises a remote controller, a communication unit, a manipulator, a cleaning execution unit, a camera shootingunit and a sensor unit. The remote controller is in communication connection with the manipulator through the communication unit; the remote controller is further connected with the cleaning executionunit, the camera shooting unit and the sensor unit. The manipulator is used for remotely controlling the window cleaning robot; the communication unit is used for communication signal transmission between the manipulator and the remote controller; the camera shooting unit is used for shooting the working environment of the window cleaning robot to obtain a cleaning image; the sensor unit is usedfor collecting environment information of the window cleaning robot. The cleaning execution unit is used for receiving an execution signal of the remote controller so as to perform window cleaning work; and the remote controller is used for receiving a control signal of the manipulator or controlling the cleaning execution unit to wipe the window according to the cleaning image. Therefore, the robot can work high above the ground more safely, and the cleaning efficiency is improved.

Owner:AMICRO SEMICON CORP

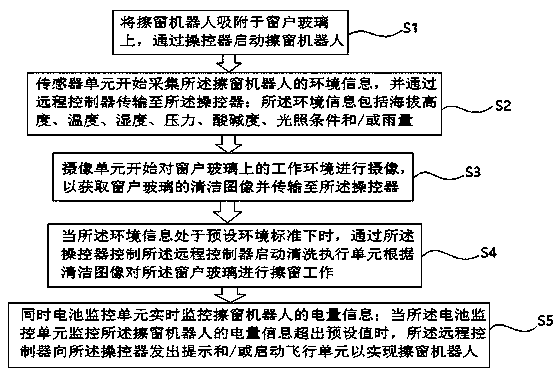

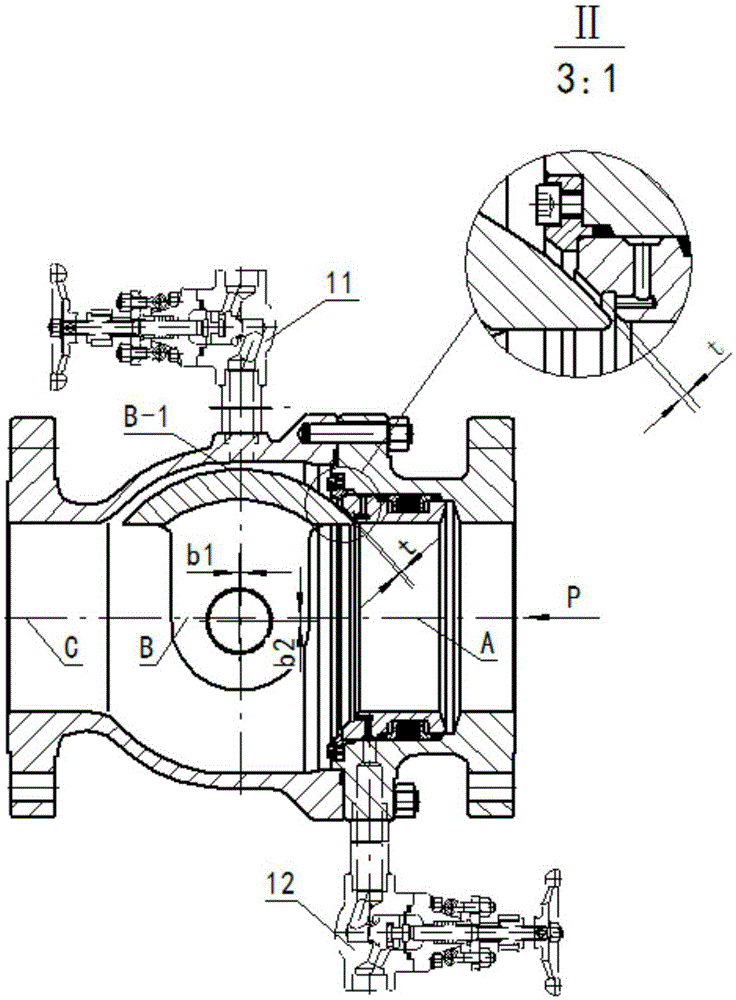

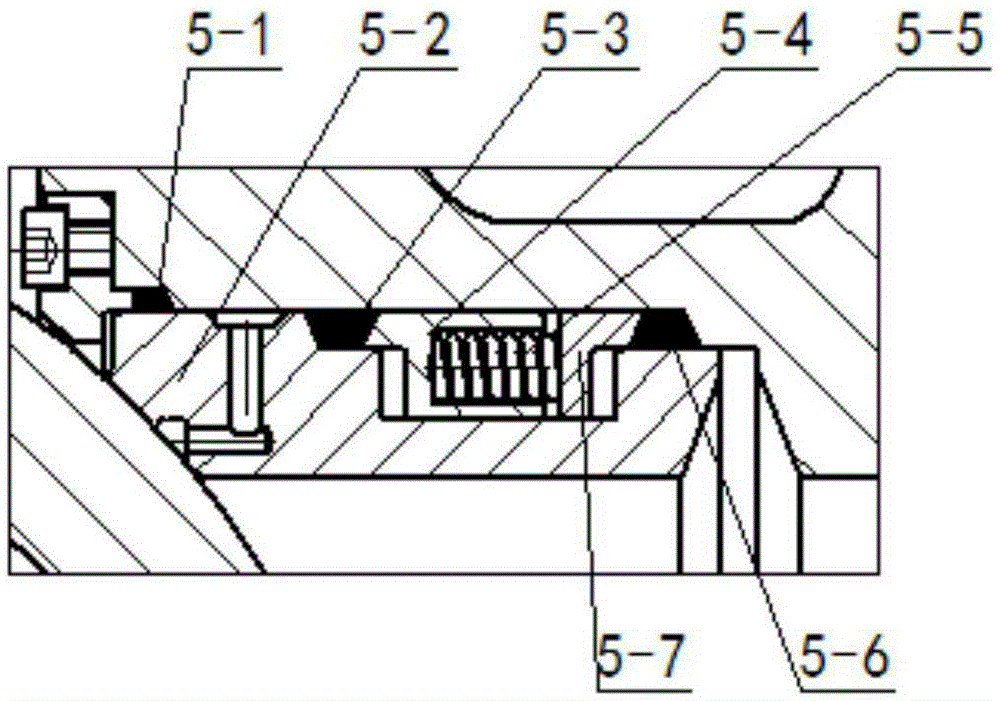

Anti-jammed and anti-blocking wearproof ball valve

The invention discloses an anti-jammed and anti-blocking wearproof ball valve which comprises a valve body, a valve element, a valve seat and a valve rod, wherein the valve body comprises a valve main body and a valve body side cover; the valve main body and the valve body side cover can be detached and assembled in a left-right manner; a medium inlet cavity (A), a valve cavity (B) and a medium outlet cavity (C) communicated with each other are arranged in the valve body; the medium inlet cavity (A) is arranged in the valve body side cover; the valve element is of U-shaped non-integral spherical structure composed of an integral valve ball with part of the side wall cut off; a side ball panel is in seal fit with the valve seat when the valve element is in a closed state; the central axis of the valve rod is eccentrically arranged relative to the spherical center of the side ball panel of the valve element, so that the maximum medium circulating clearance exists between the side ball panel and the valve seat when the valve element is in the full open state. The anti-jammed and anti-blocking wearproof ball valve has the advantage that the problems that the middle cavity of the valve is deposited and blocked and the switch of the valve is blocked can be solved during application of a solid particle medium, a solid-containing liquid medium, a solid-containing gas medium and a multiphase complex medium.

Owner:CHAODA VALVE GRP

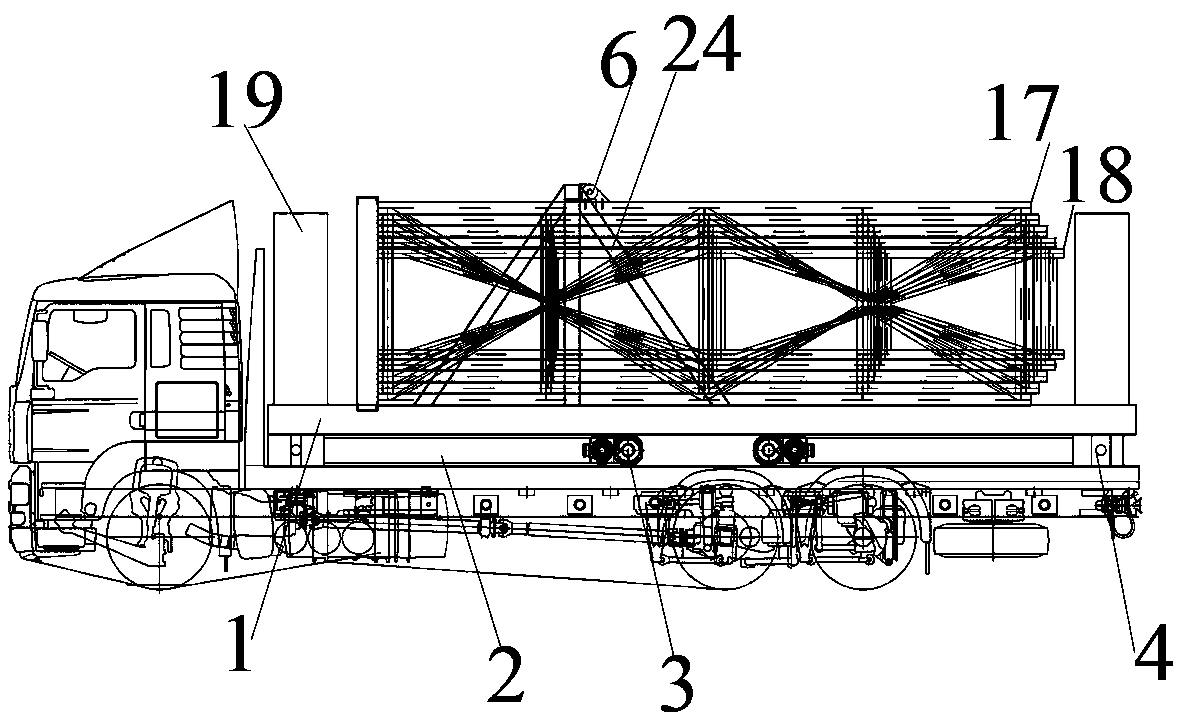

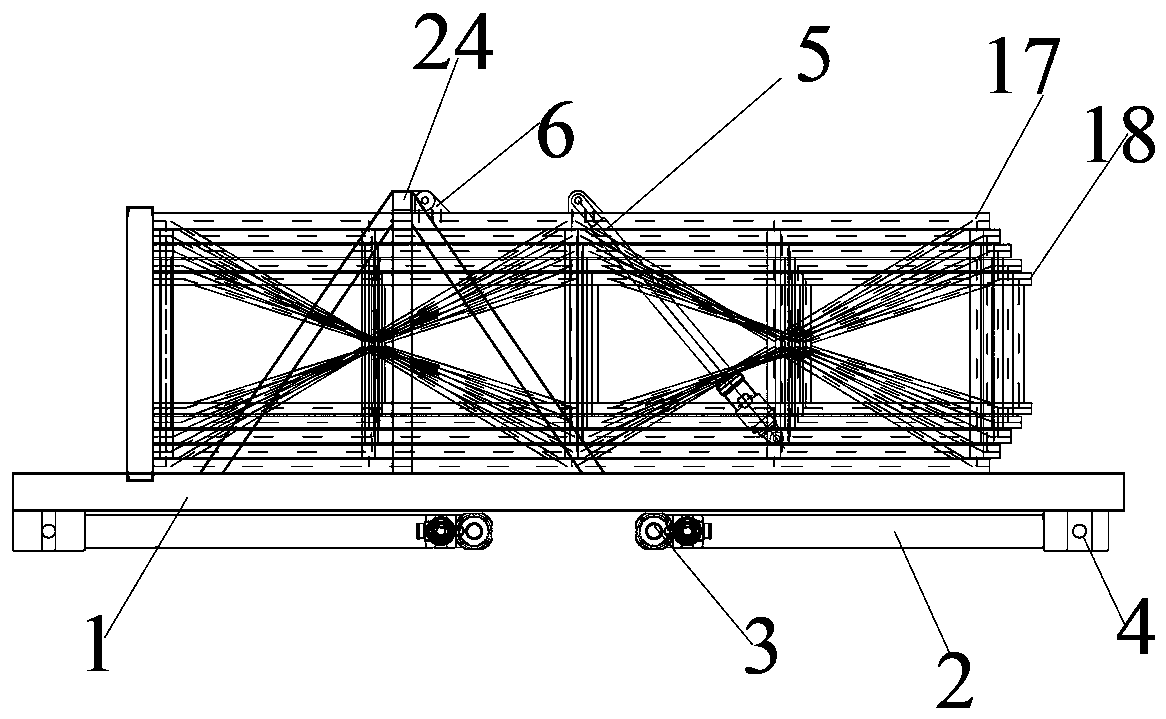

Movable intelligent lifting radar tower and mounting method thereof

The invention provides a movable intelligent lifting radar tower and a mounting method thereof. The movable intelligent lifting radar tower is transversely loaded to a transport vehicle and comprisesa tower body base, a tower body, a tower body rotating device, a jacking device and a working platform, wherein the tower body base is fixed at the bottom of the tower body and used for supporting thetower body to be separated from the transport vehicle; the tower body comprises a plurality of standard tower body sections which are all retracted in a tail standard tower body section, and a jacking fulcrum is arranged on the standard tower body sections; the tower body rotating device is used for rotating the tower body to a vertical state perpendicular to the ground from a horizontal state; the jacking device is used for jacking the standard tower body sections; the working platform is used for providing a site for construction. The tower body is convenient and safe to erect and collect and stable and reliable in repeated erection and long-term working performance, the antenna tower has sufficient rigidity and strength and anti-overturning capacity, and all-weather continuous safe work of a radar system can be guaranteed.

Owner:衡水通广通信导航设备有限公司

Rubber regeneration method

InactiveCN106750515ANo pollution in the processSave resourcesPlastic recyclingCooling towerWaste rubber

The invention discloses a rubber regeneration method. The rubber regeneration method comprises the following steps: firstly selecting waste rubber, and carrying out the steps of washing, drying, slicing and smashing in sequence; then putting the smashed rubber in a reaction kettle, adding a desulfurizing agent, uniformly stirring so as to react completely; then putting and cooling the rubber in a cooling tower; pressing and tabletting the cooled rubber through a refining mill and an open mill in rubber pressing equipment, thus preparing a regenerated rubber finished product. Compared with the prior art, the rubber regeneration method disclosed by the invention has the following advantages that a linear molecular chain of the rubber cannot be damaged, material taking and operation are both safe, environment protection is realized, no smell exists, the petroleum resource is saved, the rubber quality is increased, the environment is not polluted, equipment requirements on production are reduced, and the production cost is reduced.

Owner:俞杨许

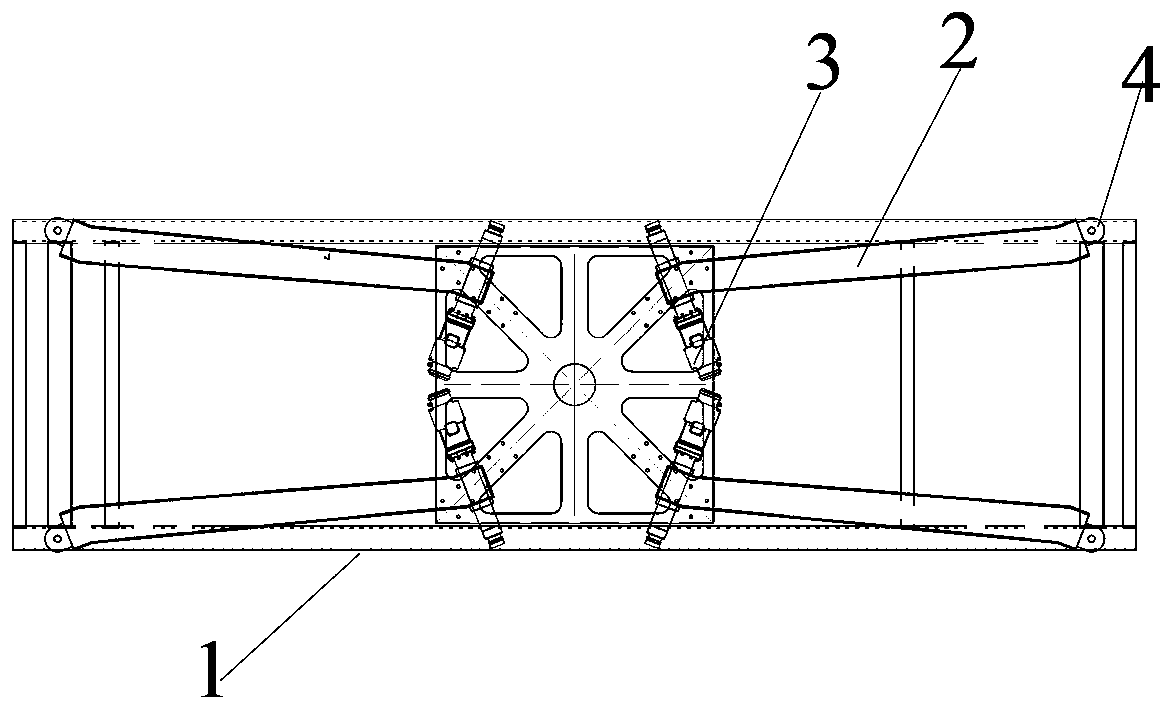

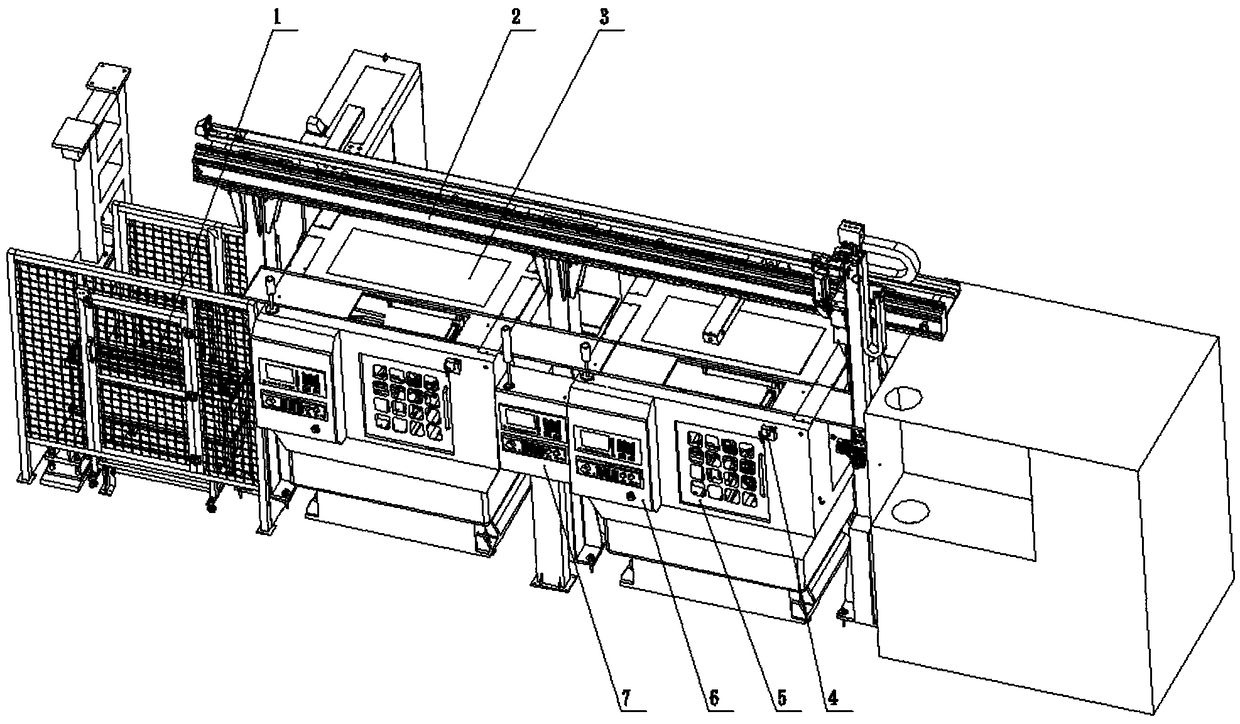

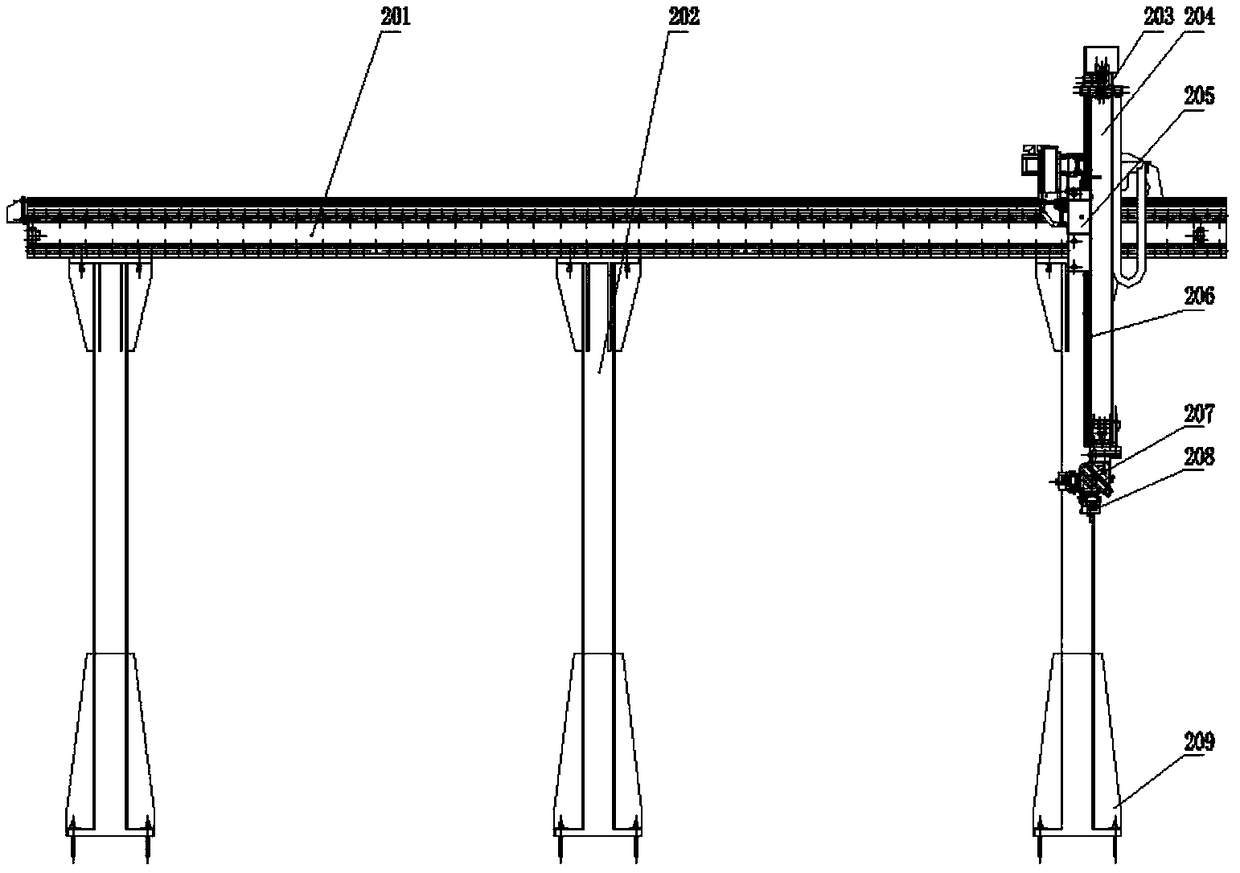

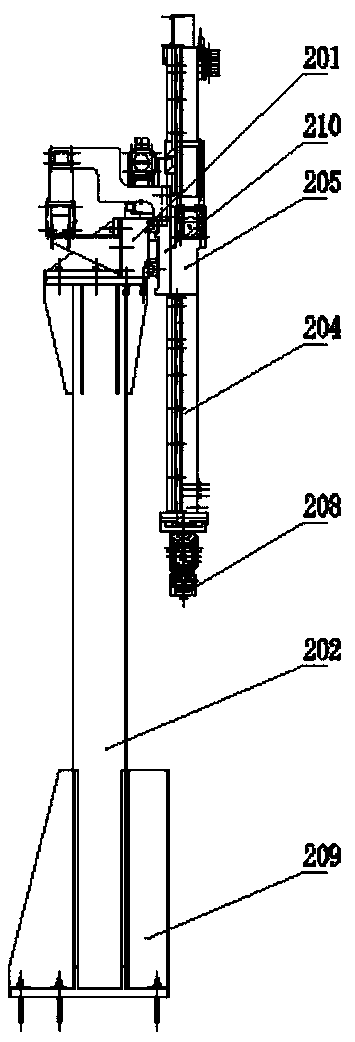

Automatic production line of chamfering machine

PendingCN109290613ASmooth runningSimple operation and maintenanceMilling equipment detailsMaintainance and safety accessoriesManipulatorProduction line

The invention relates to an automatic production line of a chamfering machine. The automatic production line of the chamfering machine comprises three-axis chamfering machines, an automatic line truss, a horizontal workpiece moving sliding platform and an automatic line control box, wherein the horizontal workpiece moving sliding platform and the automatic line truss are coaxially sequentially arranged at the left and right; two three-axis chamfering machines are arranged in parallel at the inner left and right of the automatic line truss; and the automatic line control box is mounted at the rear end of the automatic line truss. Workpieces are fed to the horizontal workpiece moving sliding platform; after the workpiece feeding is finished, the workpieces are moved to the right end of the sliding platform through the horizontal workpiece moving sliding platform; a truss manipulator is controlled to grab the workpieces through the automatic line truss; the workpieces are moved to one three-axis chamfering machine through the automatic line truss, and the workpieces are mounted in the three-axis chamfering machine; and meanwhile, the processed workpieces are grabbed from the three-axis chamfering machine and are conveyed to equipment in the next process. According to the automatic production line of the chamfering machine, a single tool is adopted for continuous processing under three-axis numerical control; and the automatic production line is high in efficiency, stable in performance, convenient to adjust and operate, wide in applicable scope, simple in cutting tools, and high in processing quality.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com