Industrial ocean thermal energy conversion processes

A technology of hot water and working fluid, applied in the field of OTEC power stations, can solve problems such as the impact of marine environment, impact of fish schools and coral reef systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

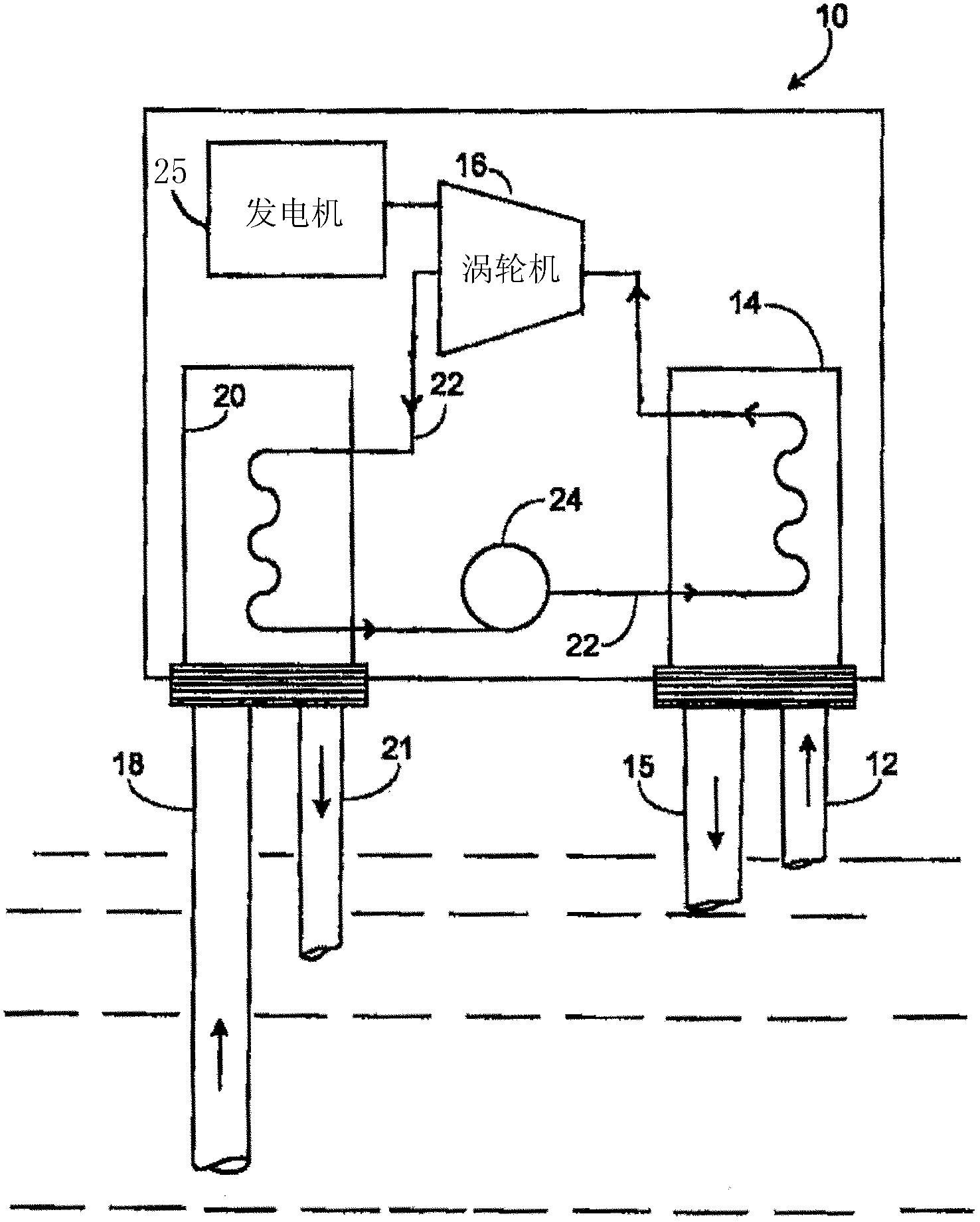

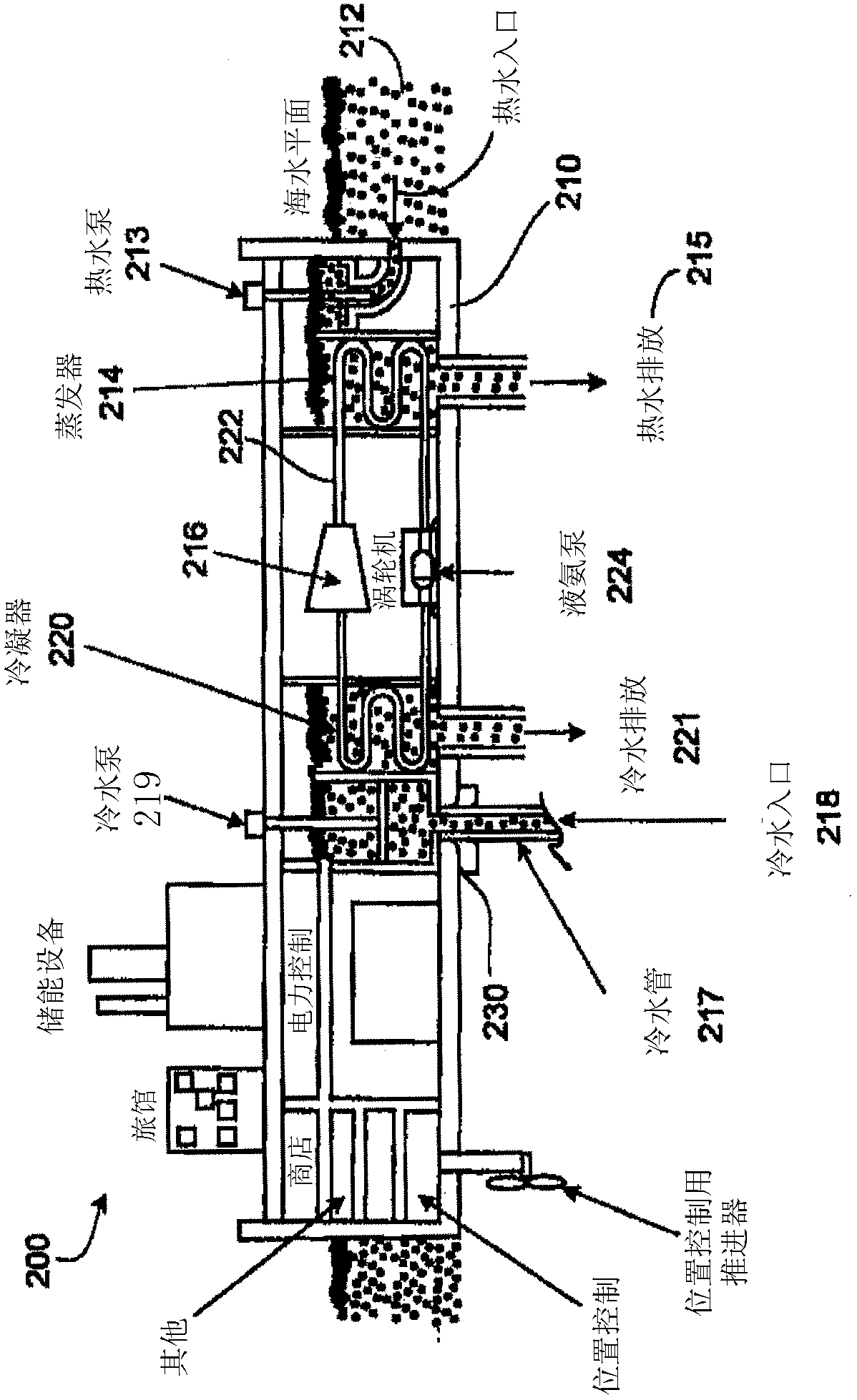

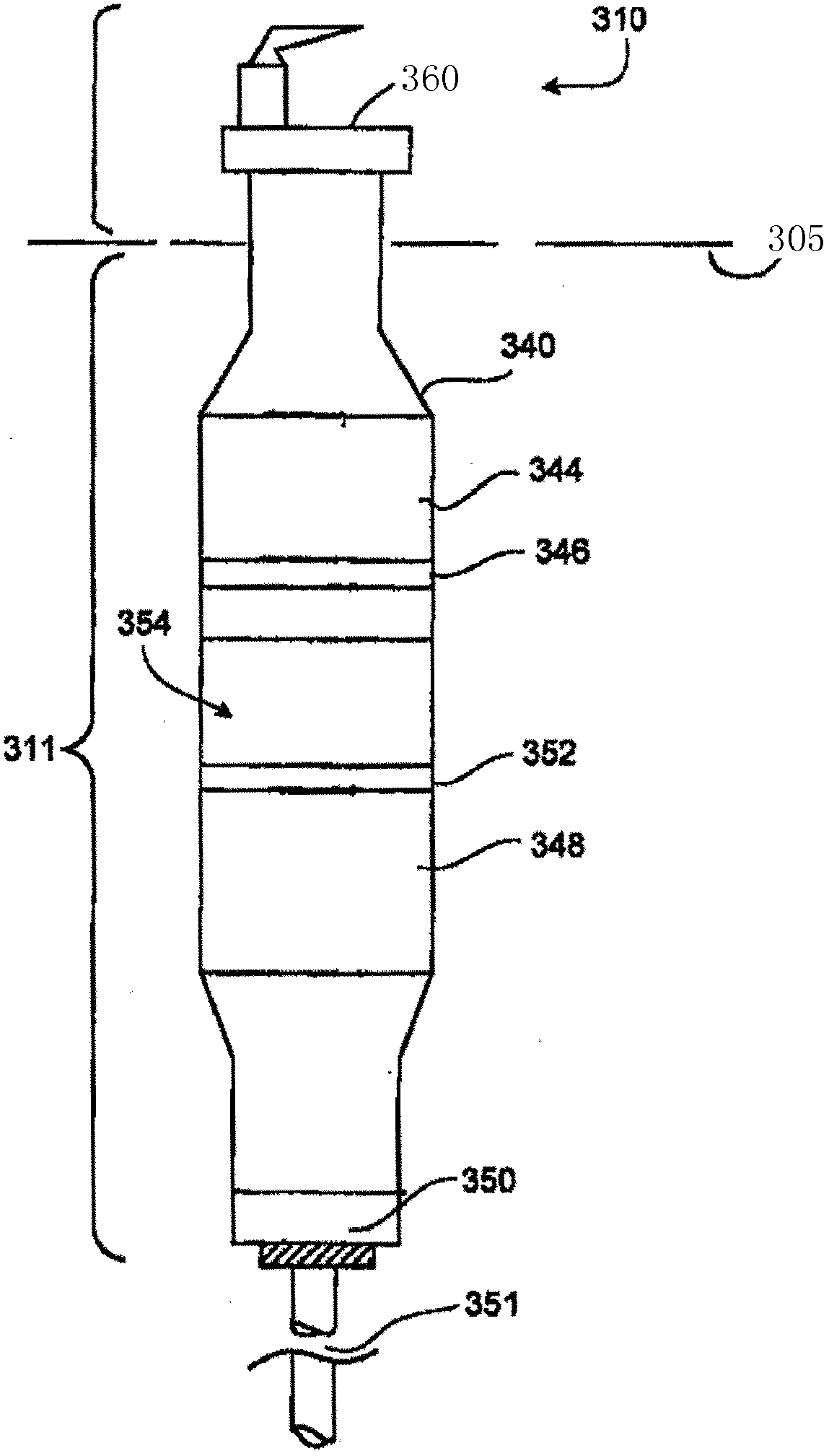

[0096] Aspects of the present invention provide an integrated multi-stage OTEC power plant that utilizes the temperature difference between surface water and deep seawater in tropical and subtropical regions to generate electricity. These aspects eliminate traditional piping routes for seawater by using the structure of the offshore vessel or platform as the conduit or flow channel. Alternatively, the hot and cold seawater pipeline routes may use pipes or tubes of sufficient size and strength to provide vertical or other structural support for the vessel or platform. These integrated seawater pipe sections or channels serve as structural members of the vessel, reducing the need for additional steel. As part of the integrated seawater channel, the multi-stage cabinet heat exchanger provides multi-stage evaporation of the working fluid without external water nozzles or piping connections. The integrated multi-stage OTEC plant allows hot and cold seawater to flow in their natura...

Embodiment 2

[0117] The offshore OTEC column platform includes four independent power modules, and each power module generates about 25MW of net power under rated design conditions. Each power module includes four independent power cycles or cascaded thermodynamic stages operating at different pressure and temperature levels and extracting heat from seawater in four different stages . Four different stages operate in series. The approximate pressure and temperature levels of the four stages under rated design conditions (full load - summer conditions) are as follows:

[0118]

[0119] The working fluid is heated to boil in multiple evaporators by extracting heat from hot sea water (WSW). Saturated steam is separated in the steam separator and directed to the ammonia turbine through STD schedule seamless carbon steel pipes. Liquid condensed in the condenser is pumped back to the evaporator by two 100% motor driven constant speed feed pumps. Cycle 1 and cycle 4 turbines drive a common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com