Patents

Literature

39results about How to "Increase net efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

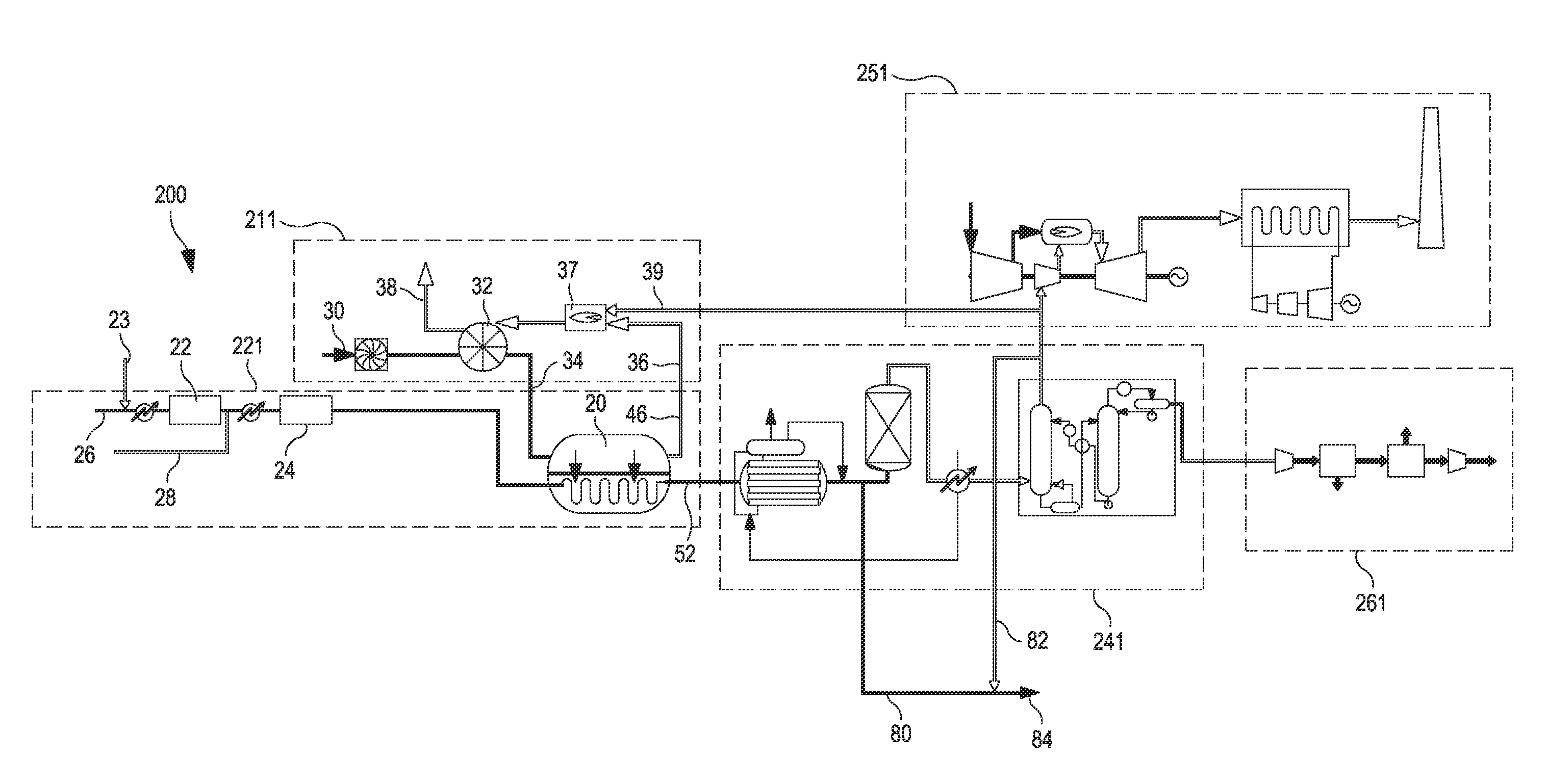

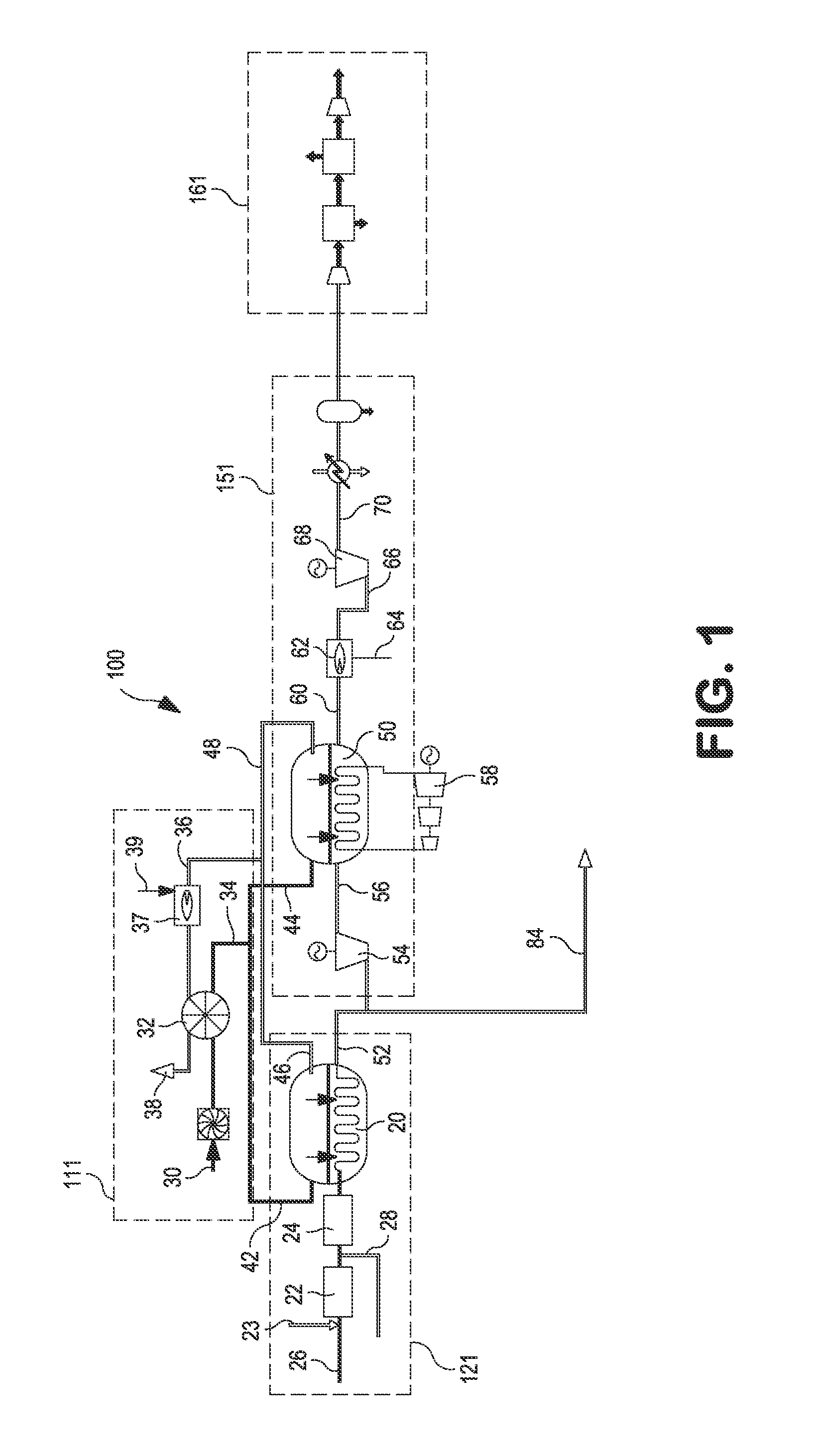

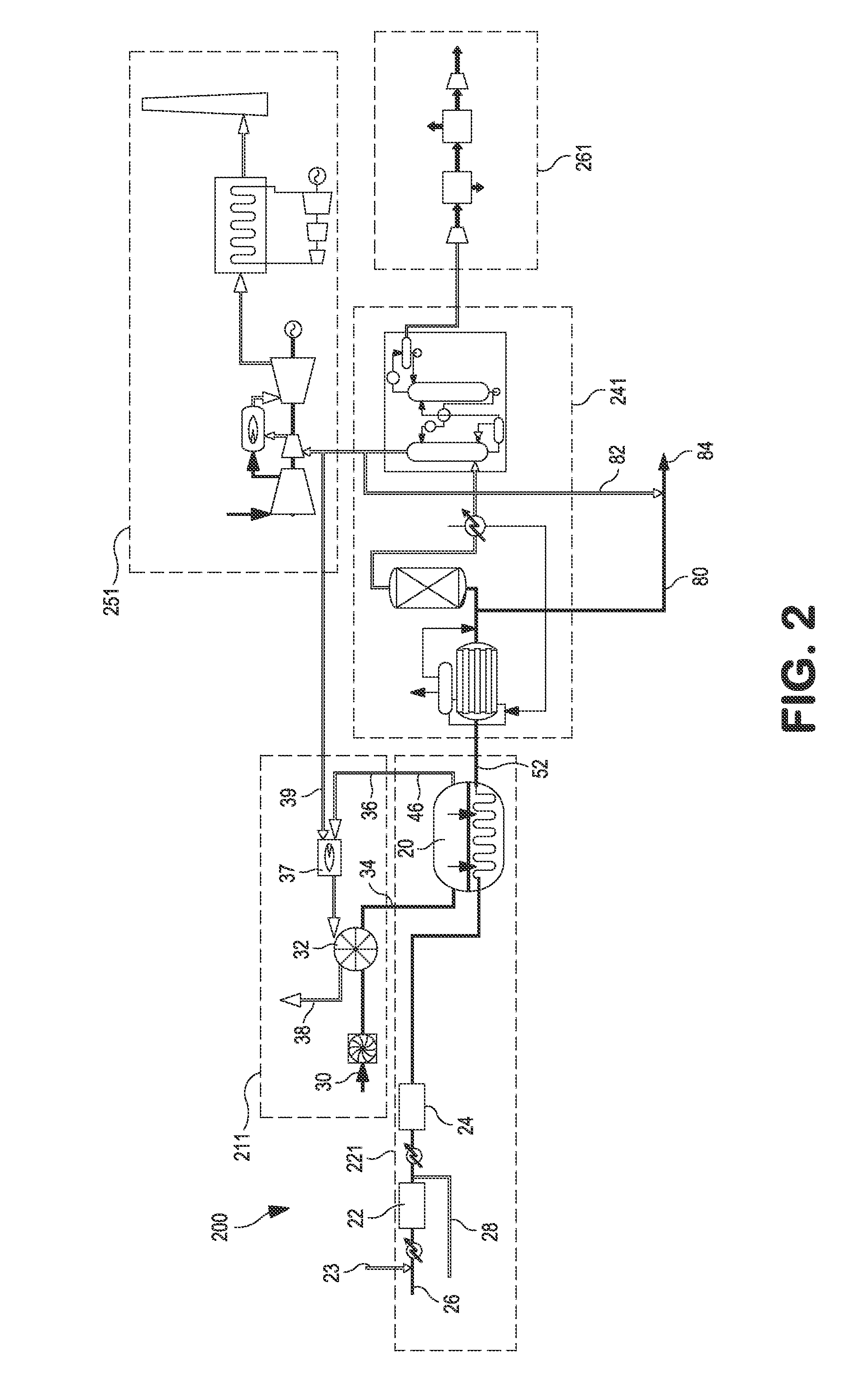

Oxygen transport membrane reactor based method and system for generating electric power

ActiveUS20150226118A1Increase net efficiencyLess cryogenic oxygenTurbinesTurbine/propulsion fuel supply systemsOxygen transportChemistry

Owner:PRAXAIR TECH INC

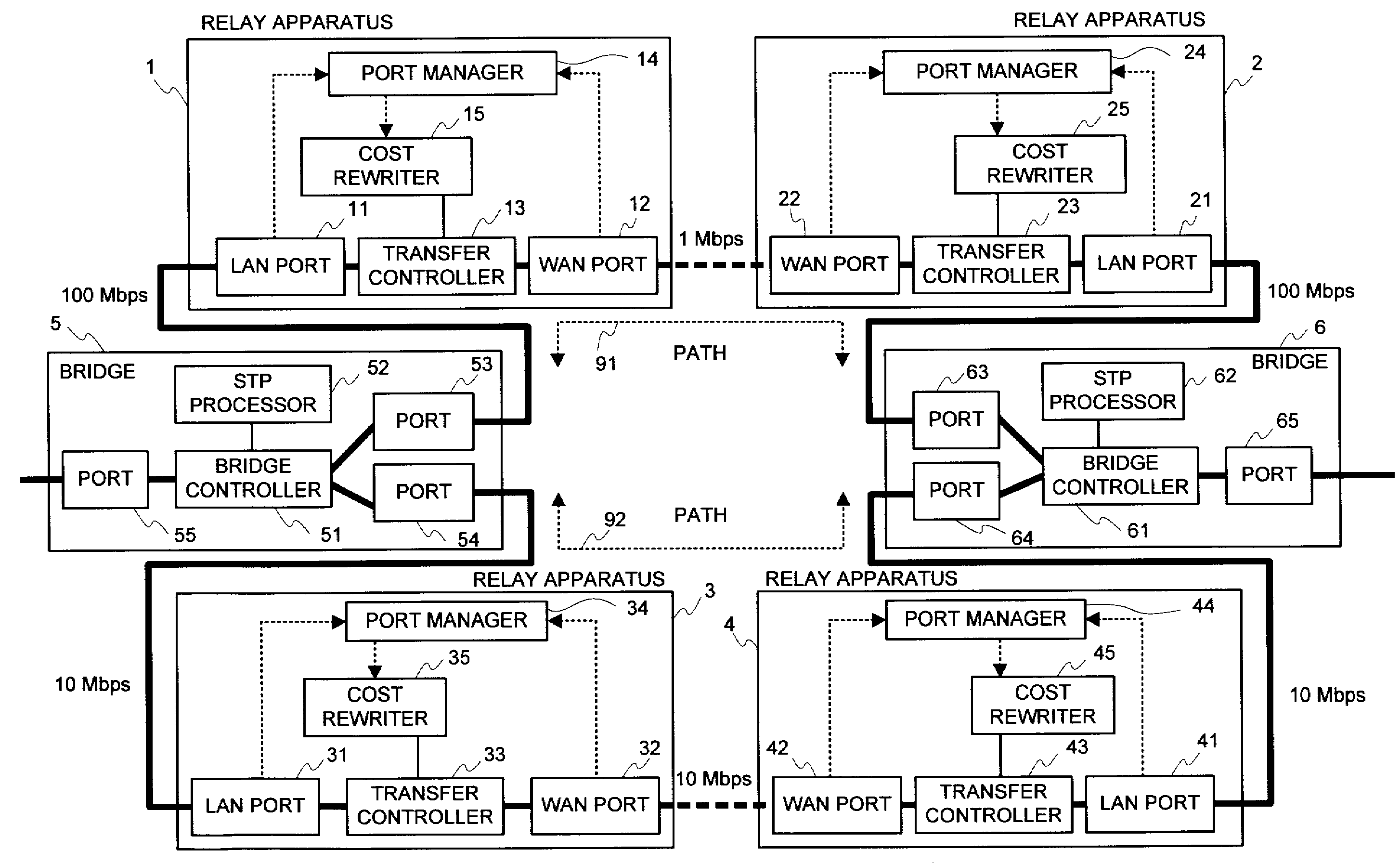

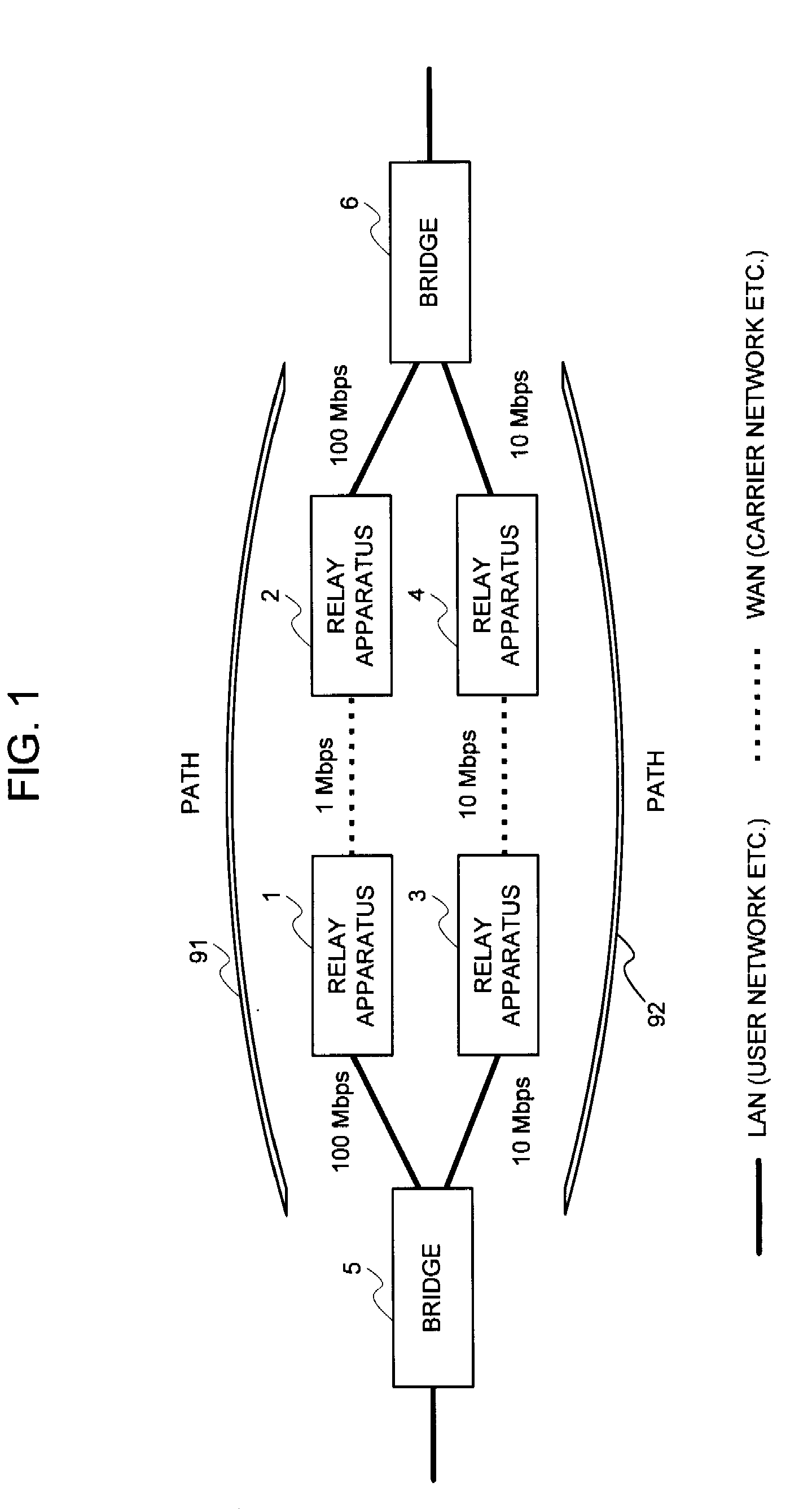

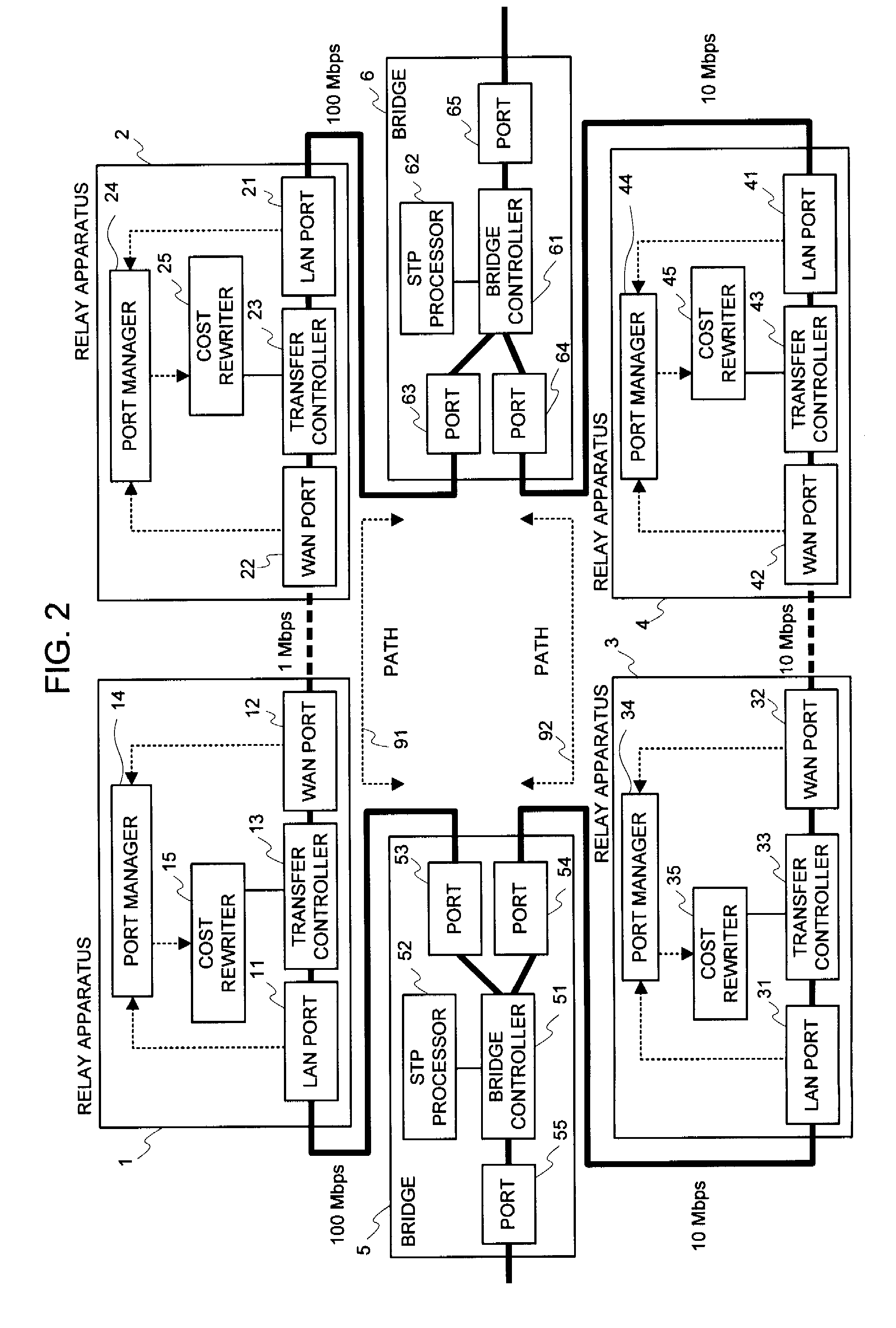

Relay apparatus, path selection system, path selection method and program

InactiveUS20080219168A1Improve efficiencyIncrease net efficiencyError preventionTransmission systemsSelection systemPath cost

An object of the present invention is to reflect a band of the bottleneck into the cost, to select an optimal path, and to enhance an efficiency of the net utilization without making a setting or a modification to the apparatus (bridge etc.) in which the path control protocol operates in a case where a difference exists between an actually utilizable rate (a band of the bottleneck) in the path between the bridges etc. and a link rate of the connection link such as the bridge etc. in a net in which the apparatus (bridge etc.), in which the path control protocol (STP etc.) for automatically computing a cost of a link by a physical band of the connection link operates, exists. In the system of the present invention, the port manager within the relay apparatus, upon receipt of a notification of the link rate from the port, investigates which side, out of the WAN side and the LAN side, becomes a bottleneck, and the cost rewriter within the relay apparatus rewrites the root path cost field within the BPDU in conformity to the rate of the bottleneck.

Owner:NEC CORP

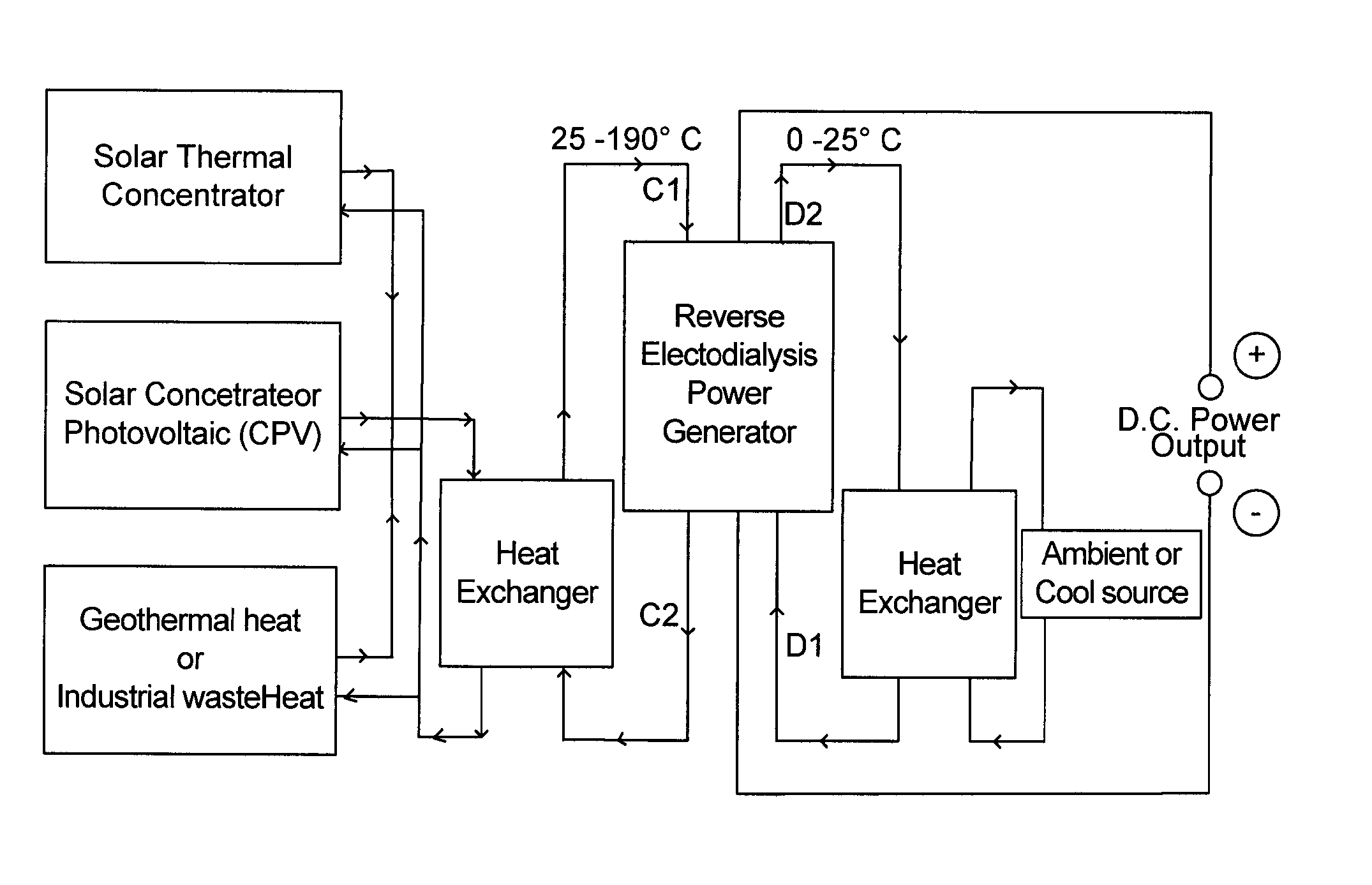

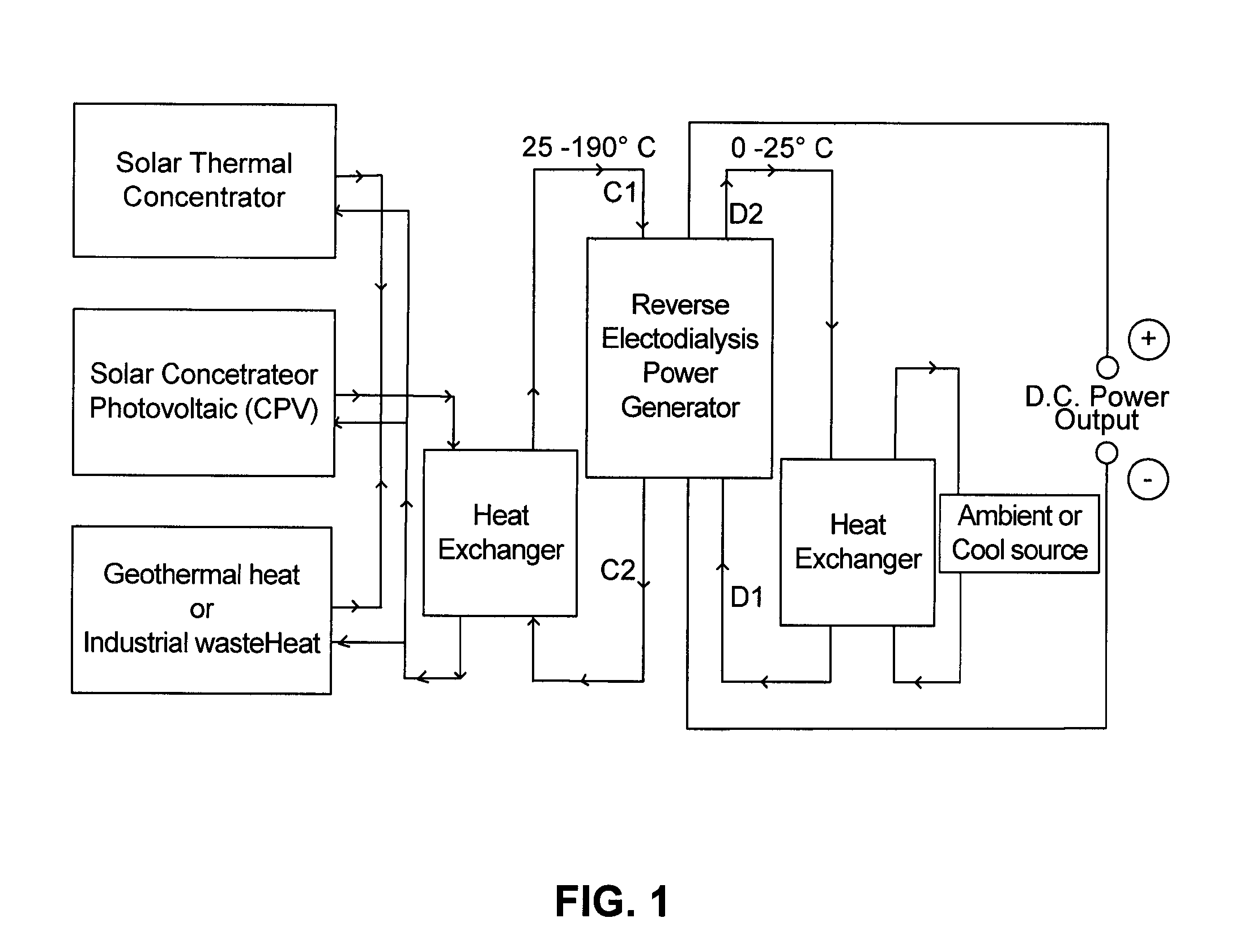

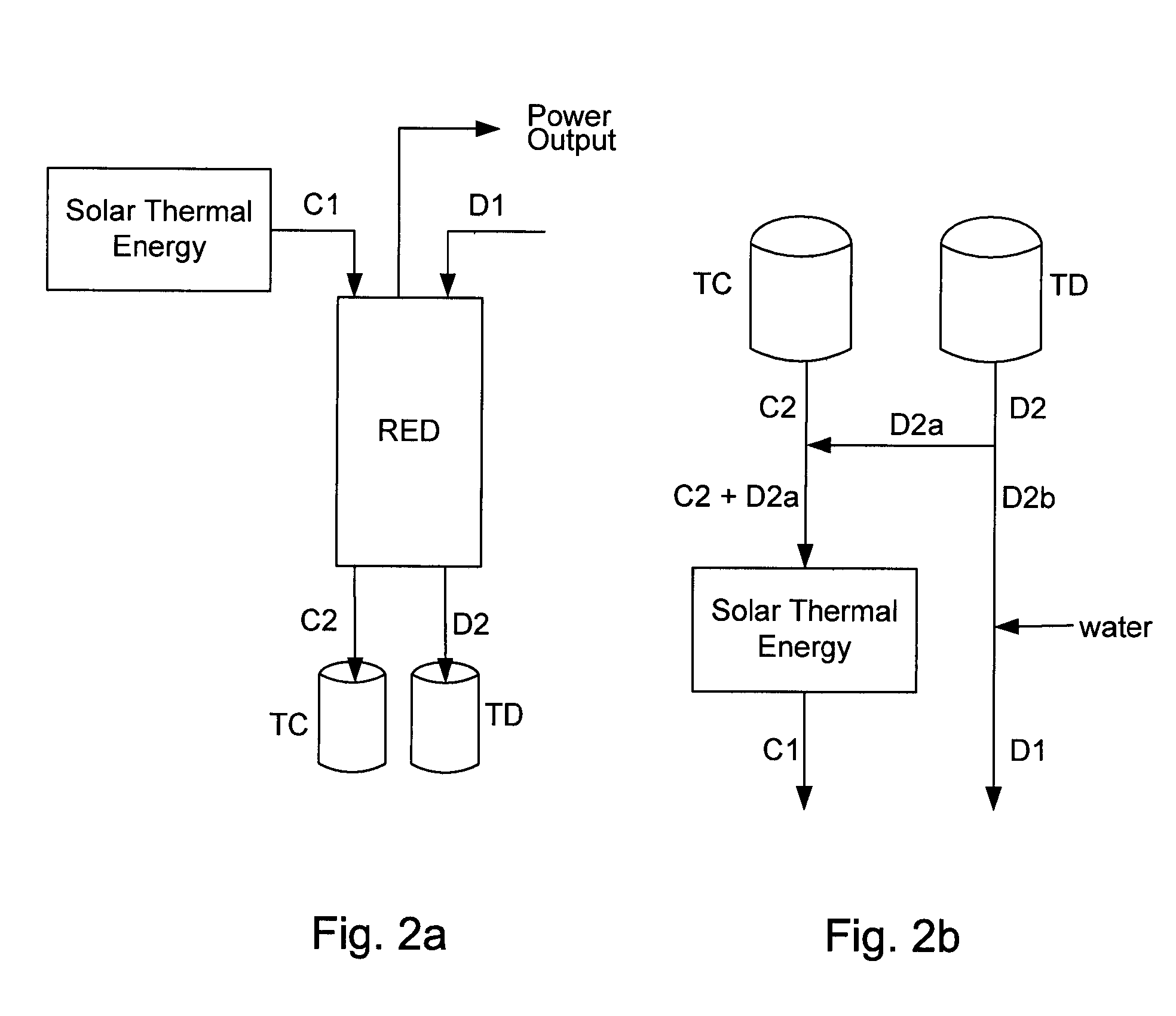

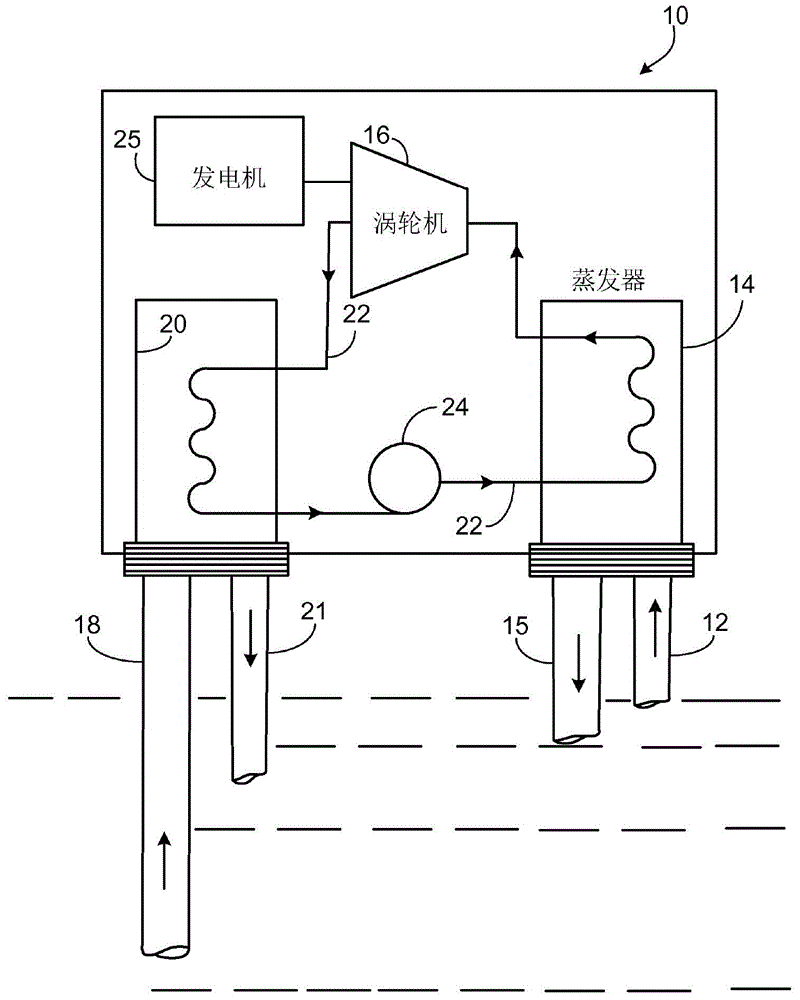

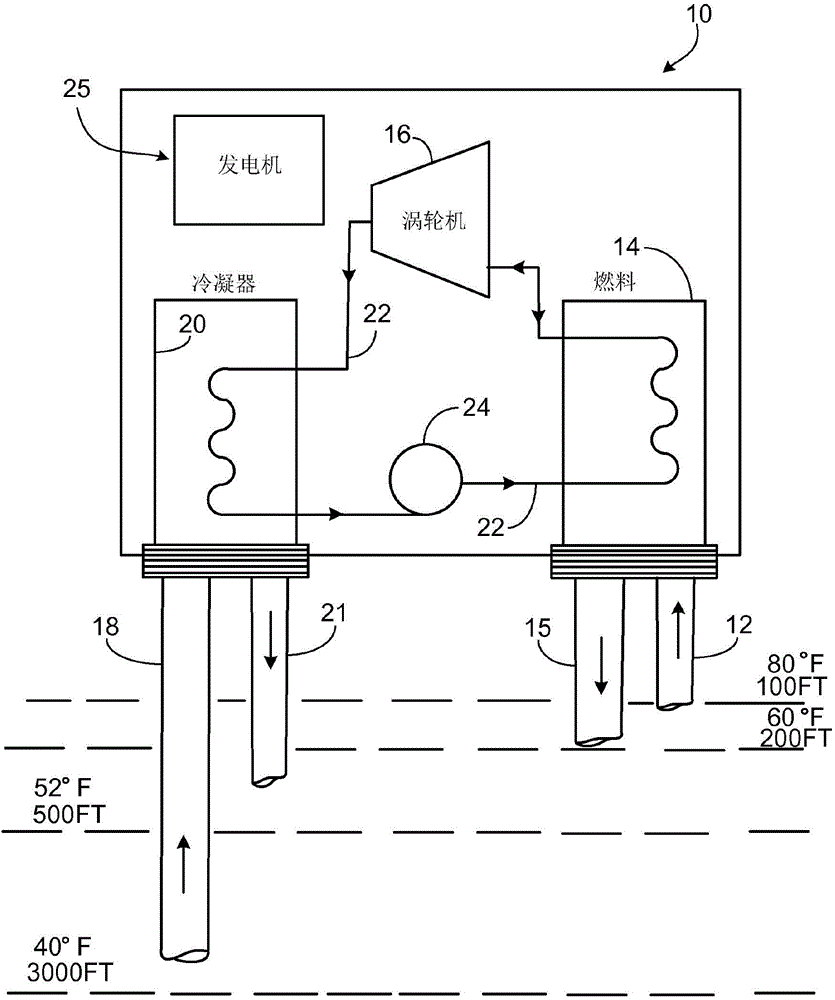

Thermal energy conversion to electricity

ActiveUS9297366B2Improve processing efficiencyIncrease net efficiencyAuxillary drivesFrom solar energyThermal energyOcean thermal energy conversion

A system or methodology for converting thermal energy obtained from solar thermal, photovoltaic, geothermal or industrial waste heat into electrical power is disclosed. The energy efficient way of transferring two steams of liquid solutions containing different concentrations of ionic species is disclosed. The combination of thermal gradient in addition to concentration gradient to improve efficiency, reduce or avoid fouling is disclosed. This invention describes a method of efficient ion migration from concentrated stream to dilute stream thereby improving DC power generation process. The utilization of solar thermal energy from solar collector or concentrating photovoltaic (CPV) generator system or solar thermal power generation (CSP) system provides the additional driving force for ions transport from concentrated stream to dilute stream, apart from the concentration grading to generating power. The thermal power is also used to bring back the diluted steam to original concentration in the reverse Electro dialysis system. The utilization of CPV process heat or solar or waste heat for bringing back the dilute stream into the concentrated stream for next operation of ions gradient power generation is also disclosed in this invention.

Owner:SUGANIT SYSTEMS INC +1

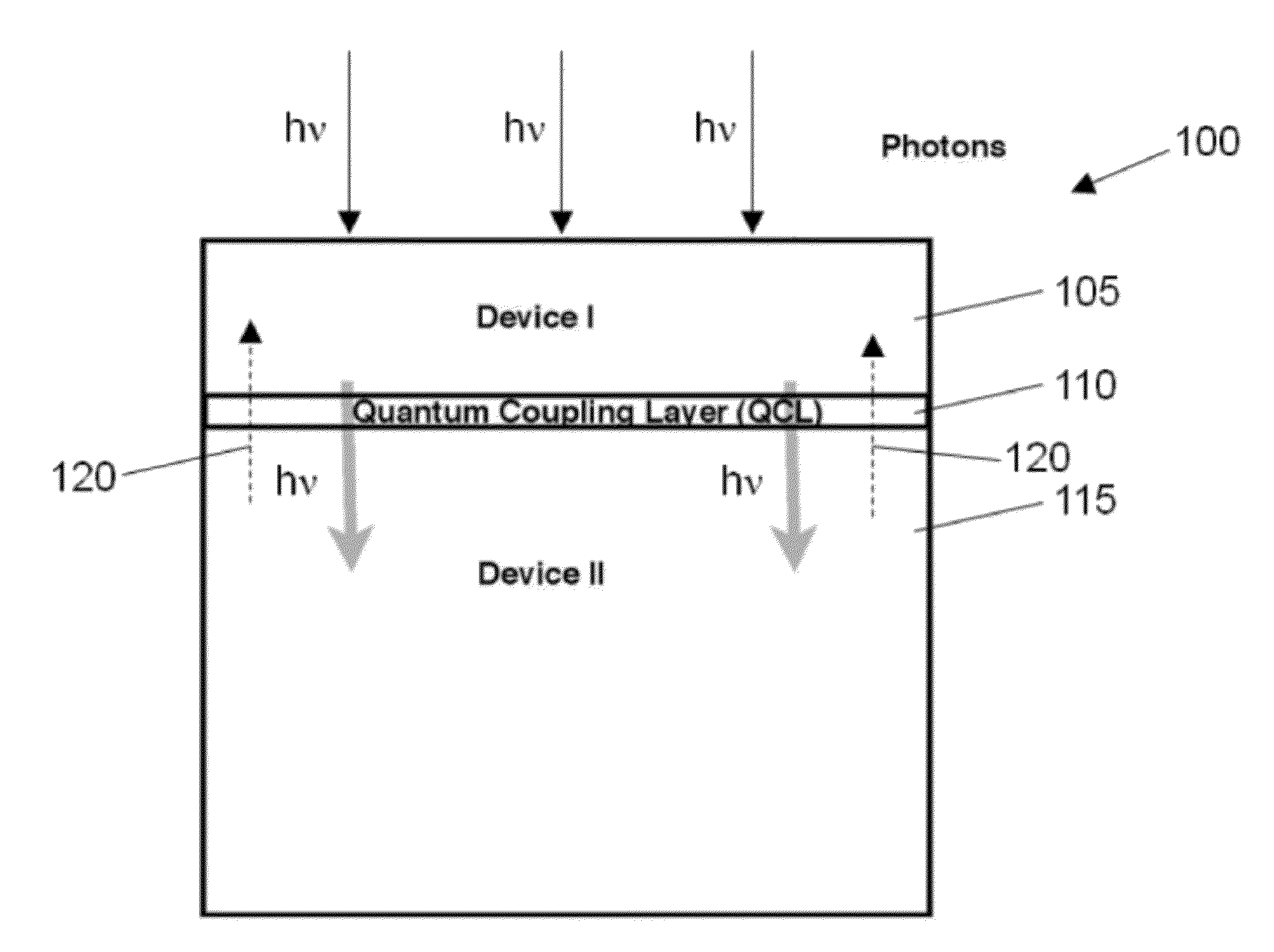

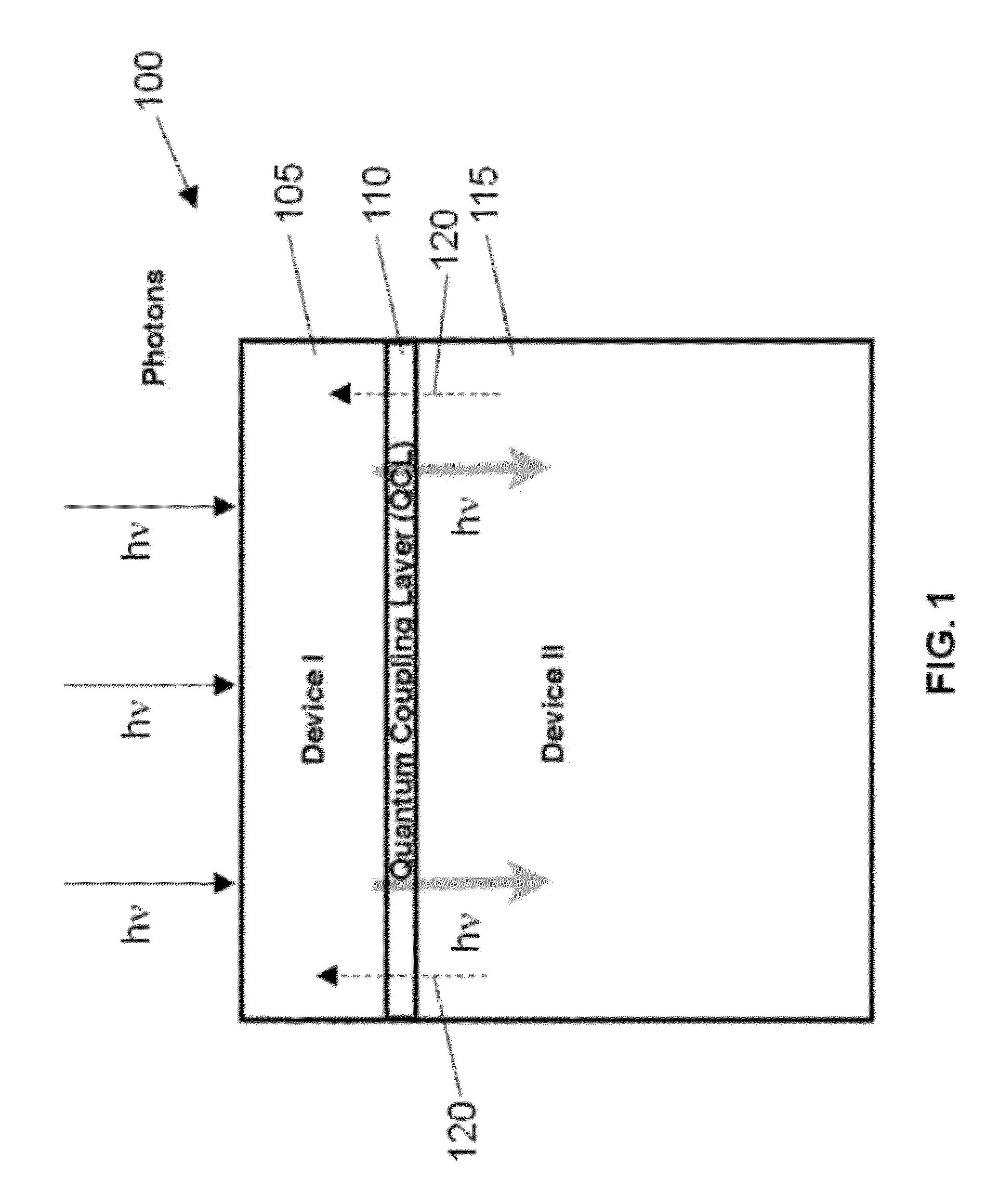

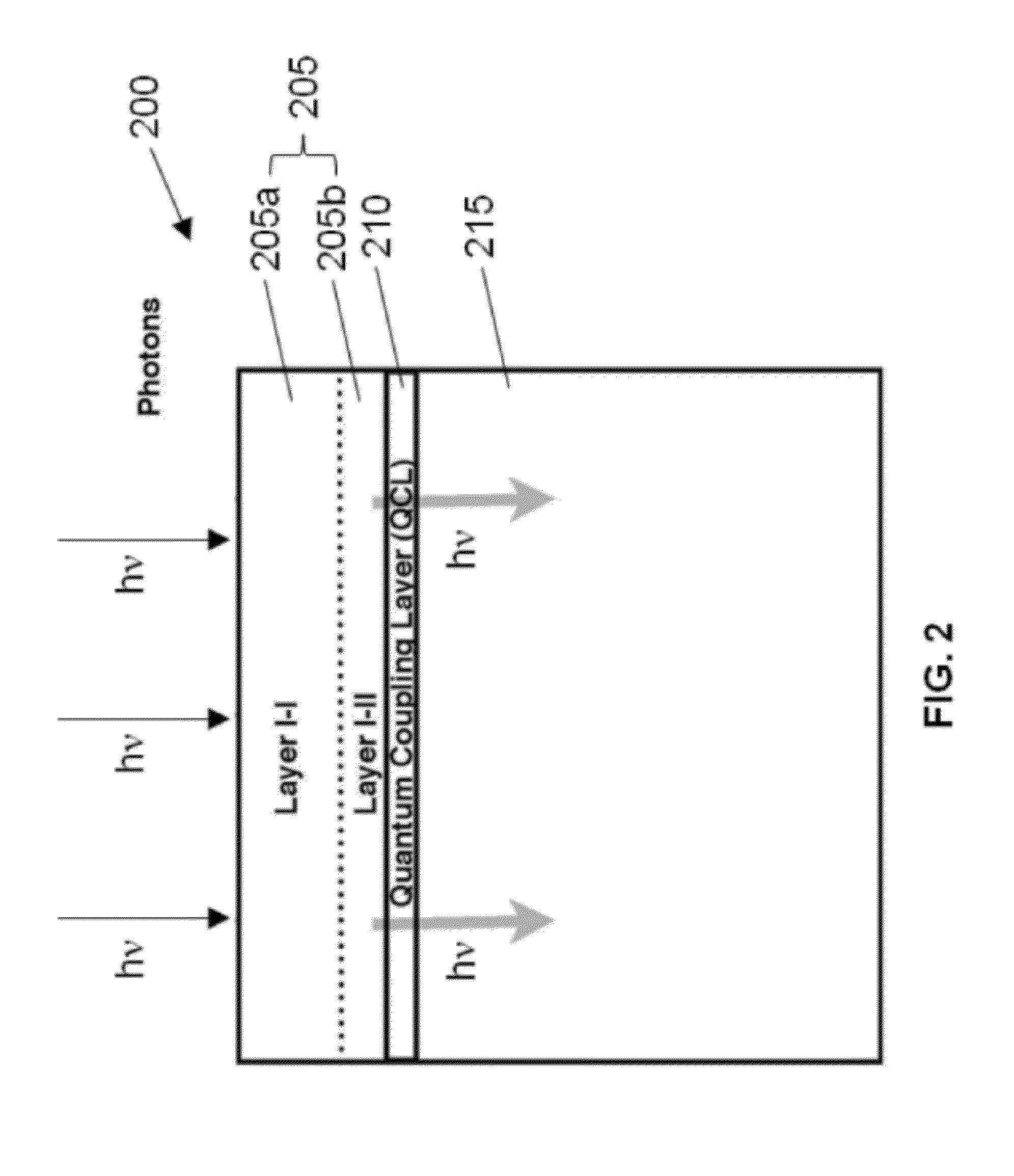

Charge-coupled photovoltaic devices

InactiveUS20120048329A1Reduce lossesHigh generationPV power plantsFinal product manufactureHigh energyHigh energy photon

A photovoltaic (solar) cell comprises two photovoltaic devices that are quantum mechanically coupled via a charge-coupling layer. One of the PV devices may have an energy band gap that is larger than or equal to an energy band gap of the other of the PV devices. The effective electron barrier heights or electron affinity on side portions of the quantum coupling layer are higher than the maximum energy of photo-generated electrons in the photovoltaic devices. The photovoltaic device with larger band gap may include an electron and / or hole transport layer and photon absorbing layer. Photons are transmitted through the transport layer to the absorbing layer. Some high energy photons are absorbed by the absorbing layer. The absorbing layer may function as an absorber of high energy photons and generator of electrons / holes (or excitons). Holes generated in the absorbing layer may be quenched by electrons from the second photovoltaic device.

Owner:MANCHANDA LALITA

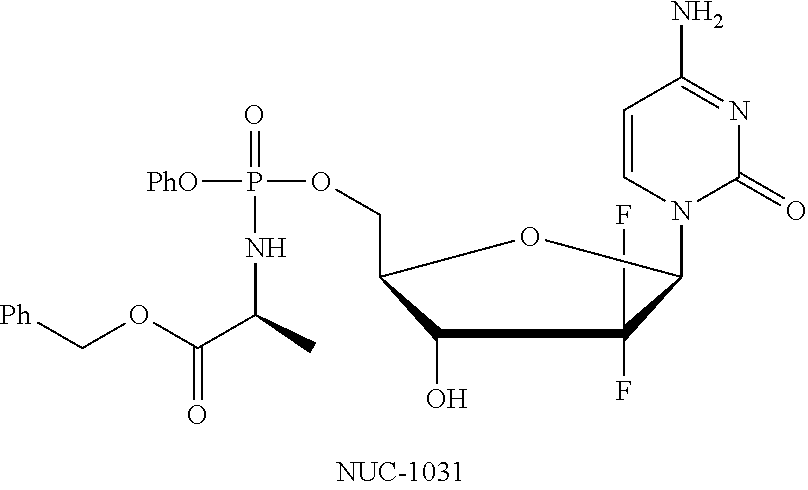

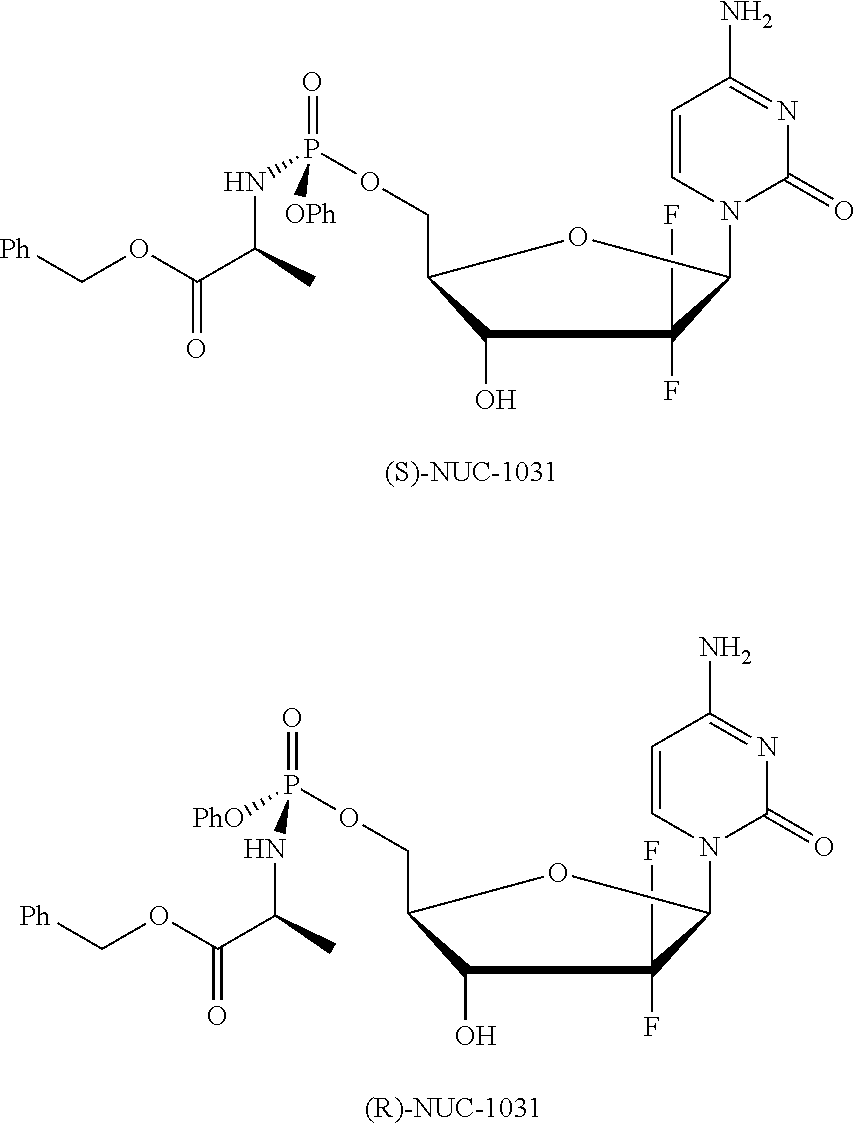

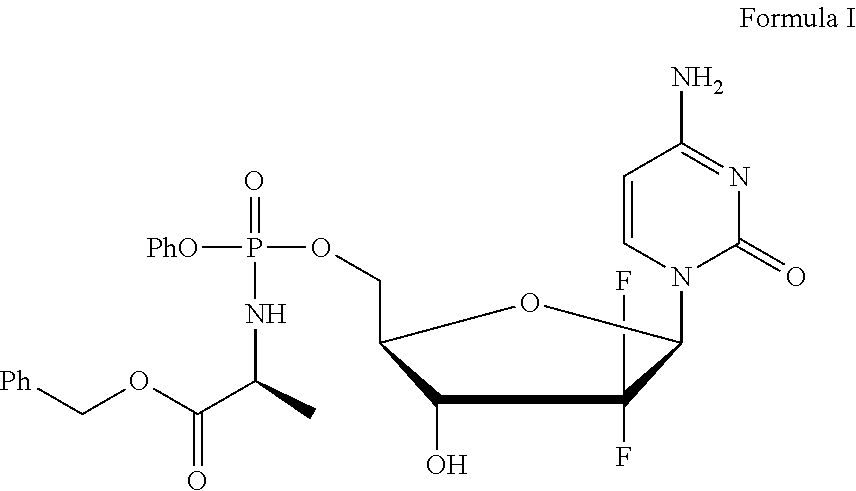

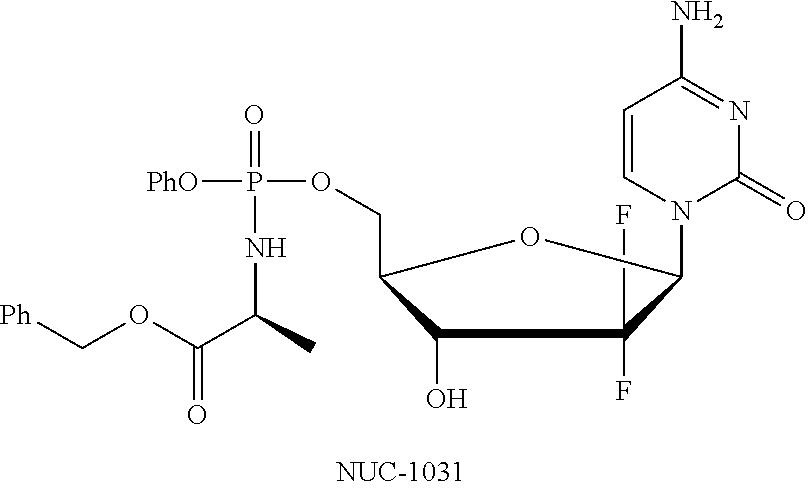

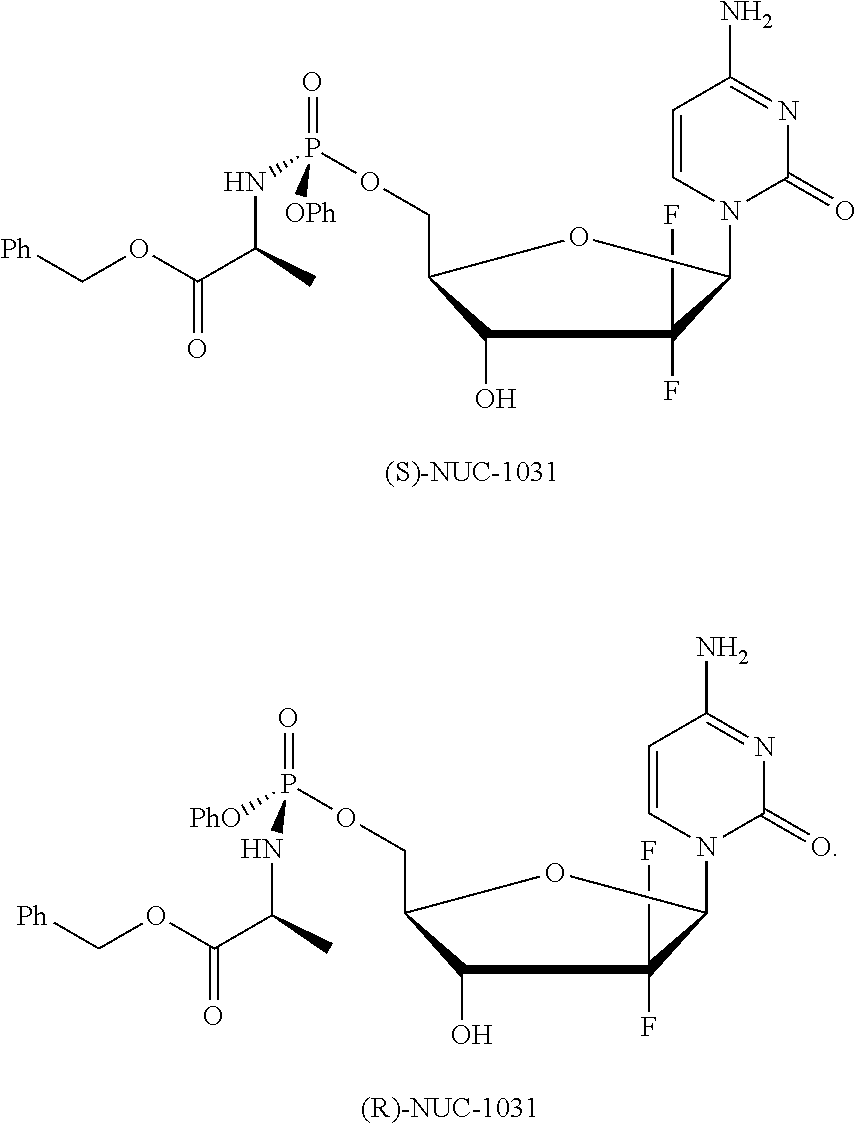

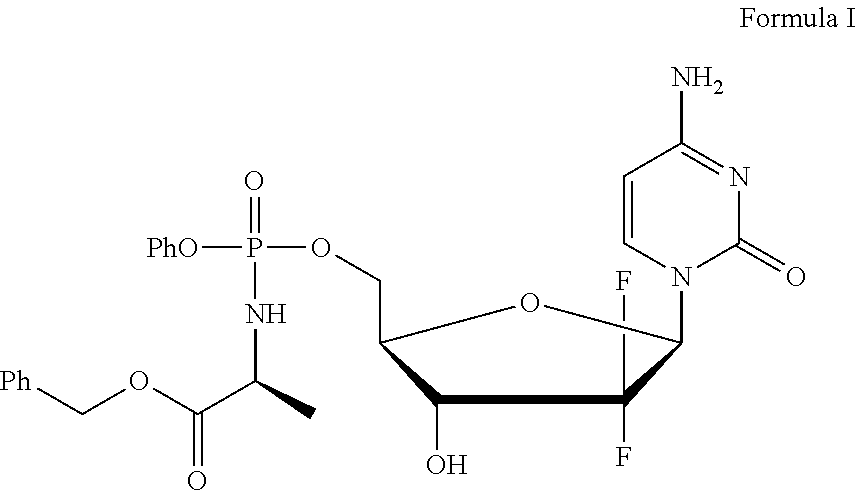

Diastereoselective synthesis of phosphate derivatives

ActiveUS20180362571A1Increase net efficiencySugar derivativesOrganic chemistry methodsPhosphateMedicinal chemistry

Disclosed is a method for the preparation of intermediates useful in the synthesis of gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate. Also disclosed is a method of preparing gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate.

Owner:NUCANA PLC

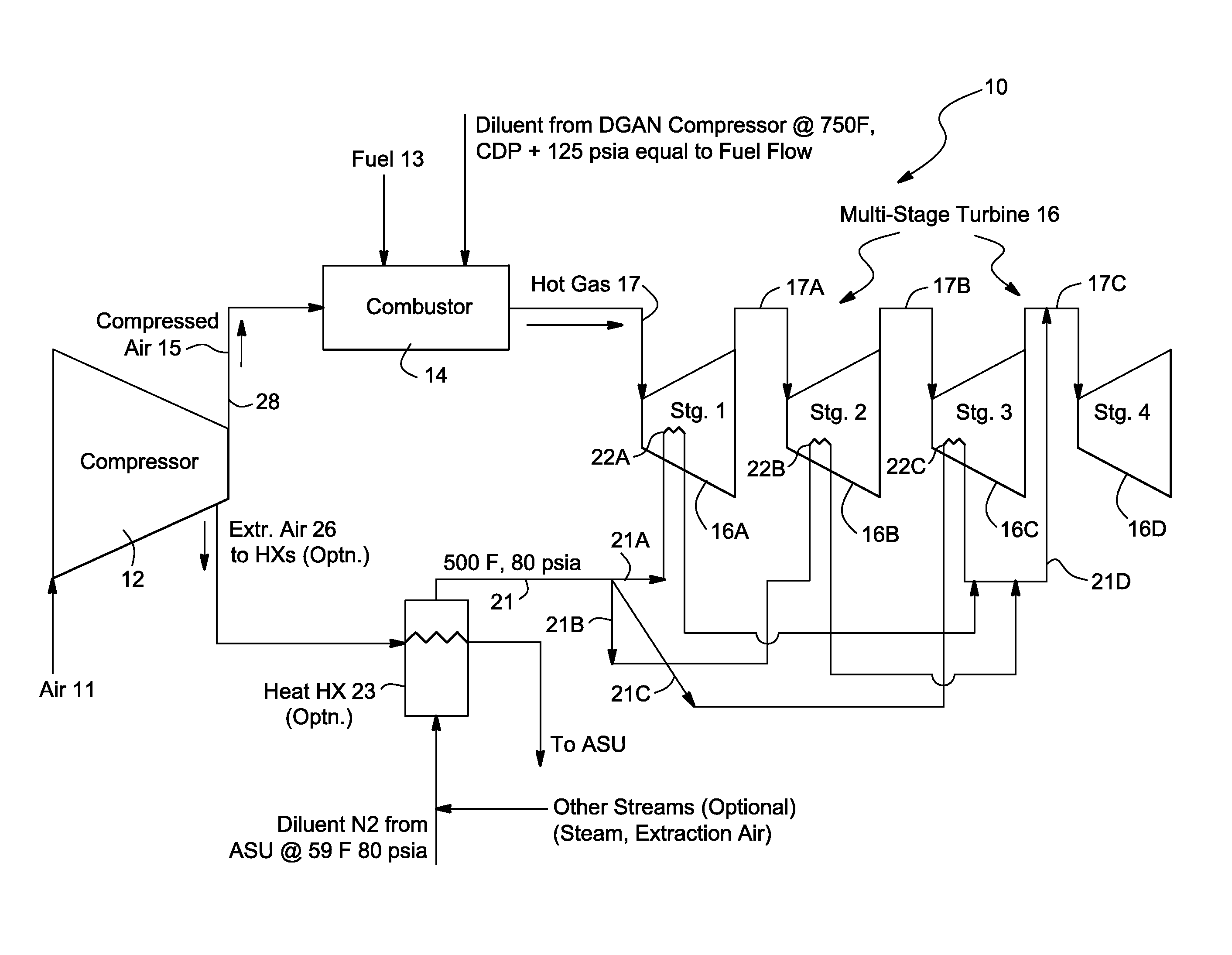

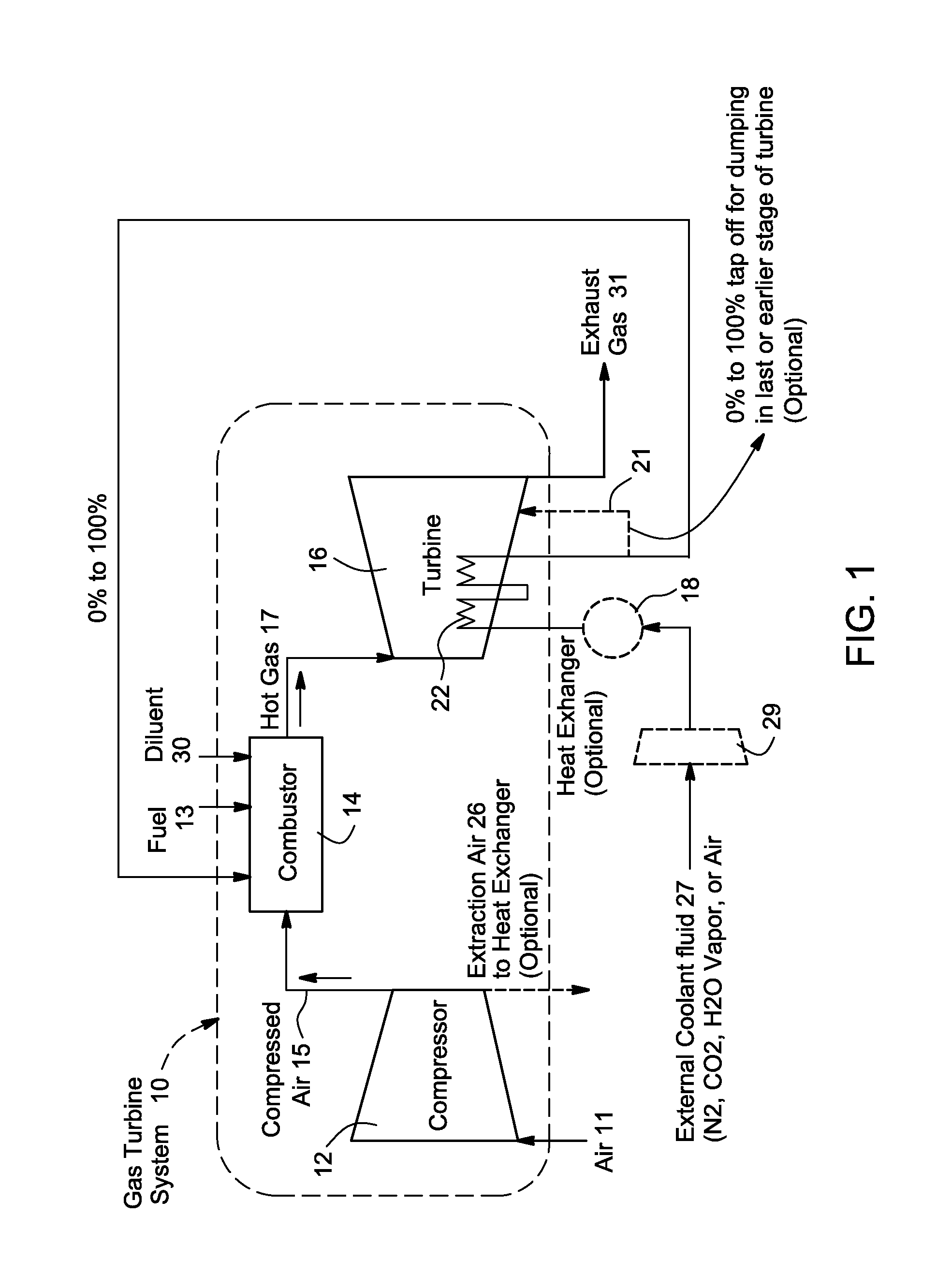

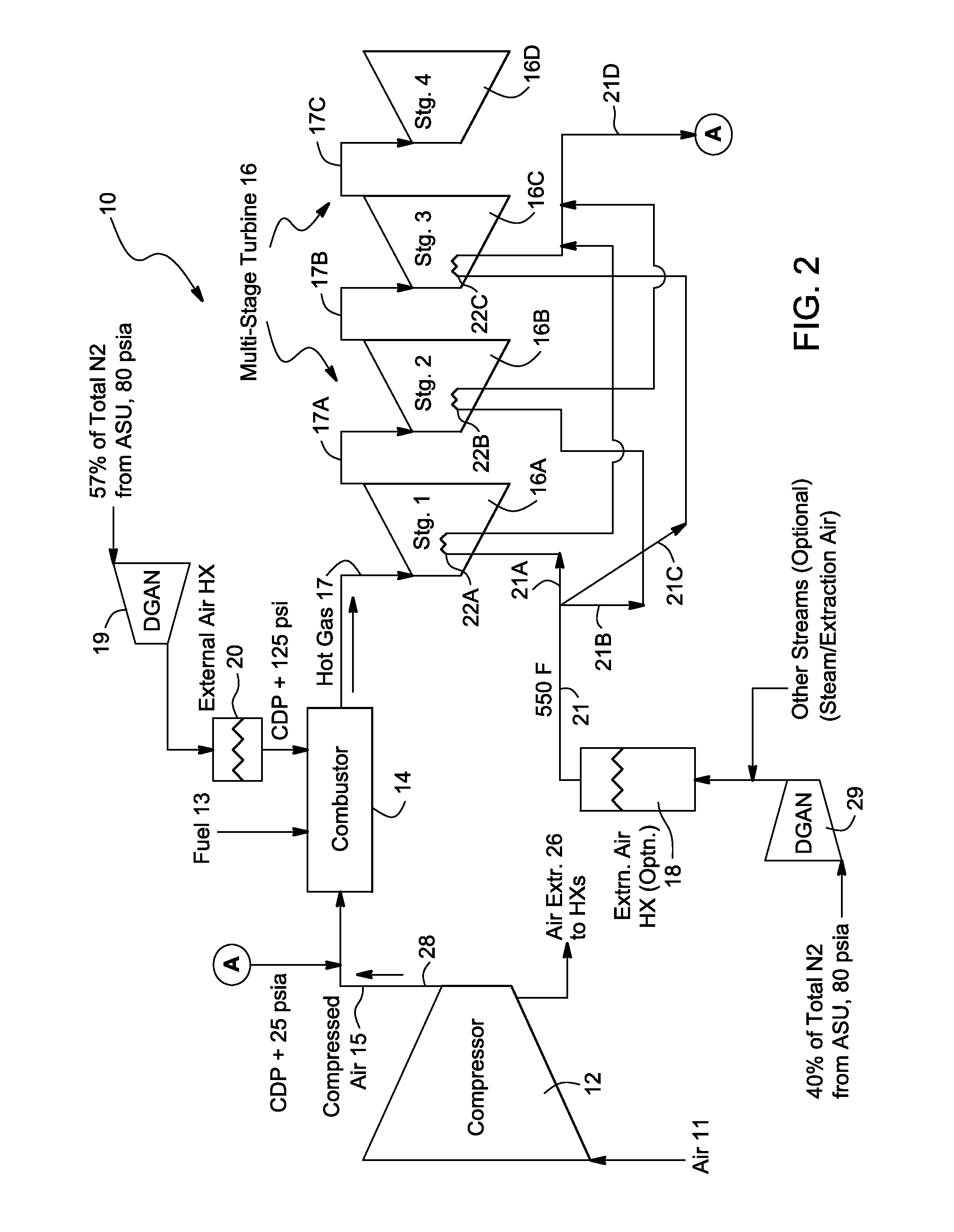

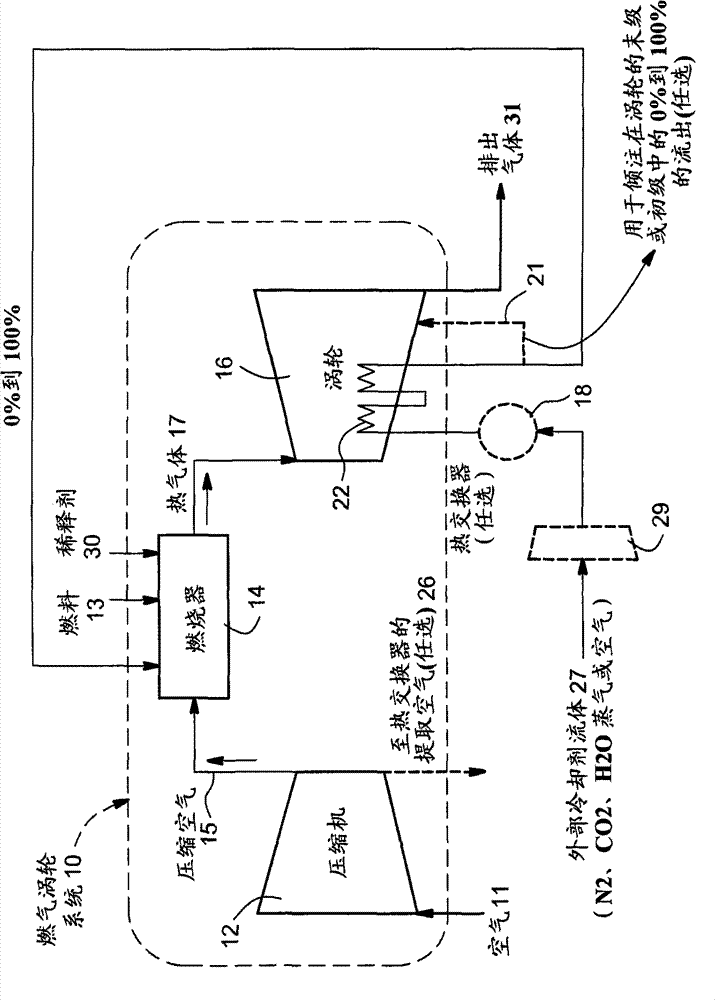

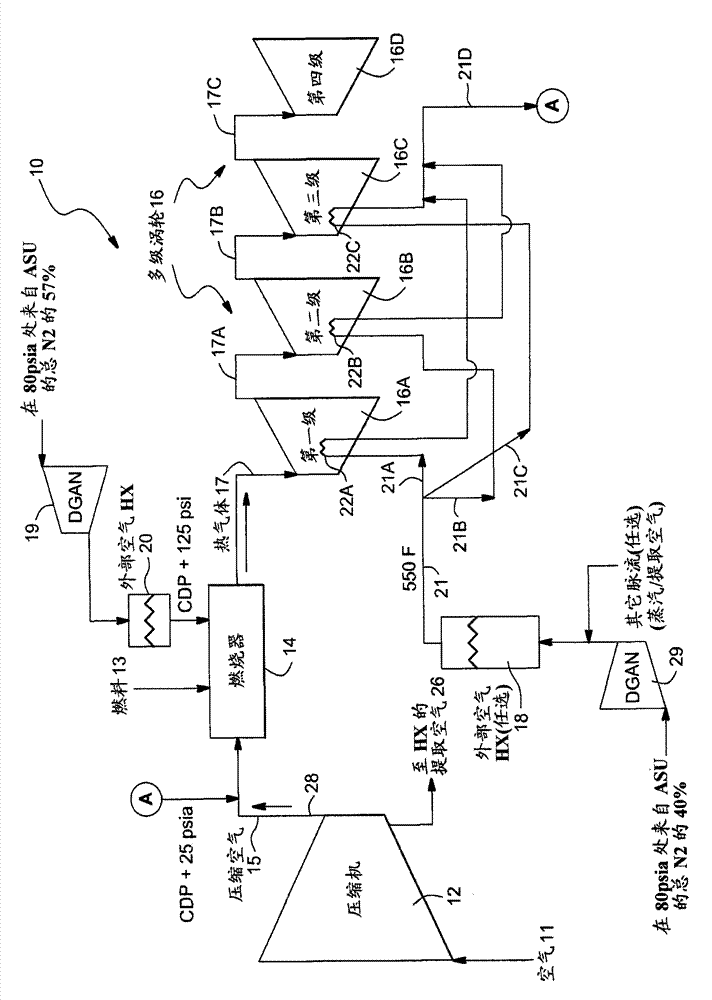

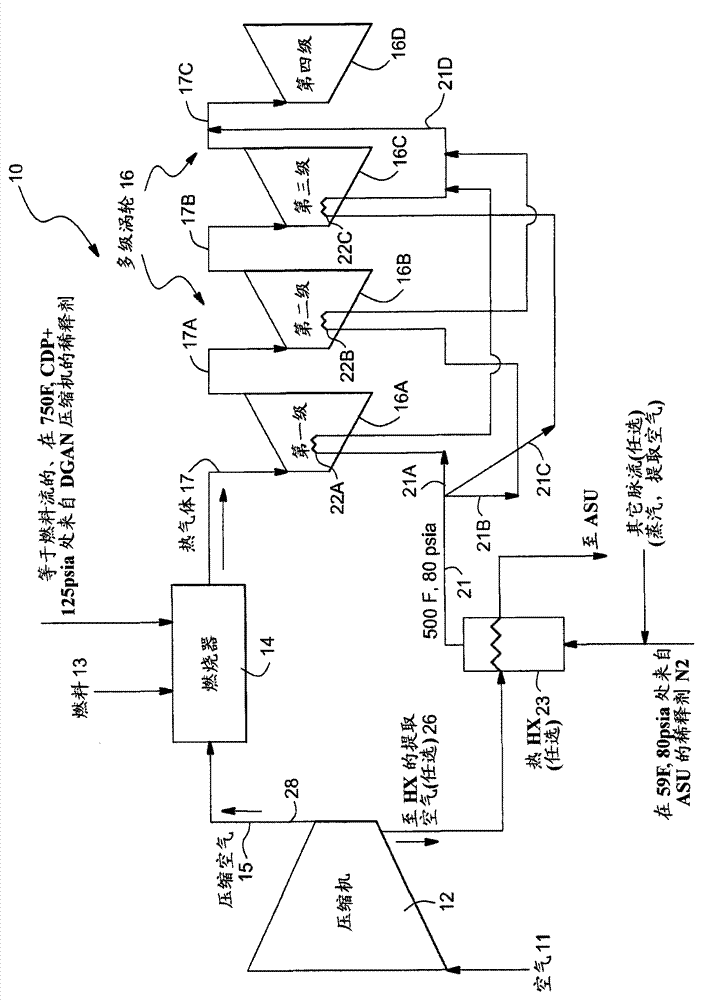

Method of using external fluid for cooling high temperature components of gas turbine for a process power plant

InactiveUS20130186101A1Increase net outputIncrease net efficiencyTurbine/propulsion engine coolingGas turbine plantsPower stationTurbine blade

An external fluid in a closed loop is used to cool hot gas path components of gas turbine. After cooling the turbine components, the heated external fluid is dumped either in the compressor discharge casing or in the one of the turbine's stages. Where the external fluid is nitrogen to be dumped in the turbine compressor's discharge casing, the nitrogen is compressed using diluent nitrogen compressors. Alternatively, where the external fluid is nitrogen to be dumped in one of the stages of the turbine, the nitrogen is not compressed at all. The turbine blade heat exchangers in the turbine stages through which the nitrogen passes can be connected in parallel or in series for cooling the hot gas path components in the turbine stages. The nitrogen can optionally be mixed with air or steam or not mixed at all.

Owner:GENERAL ELECTRIC CO

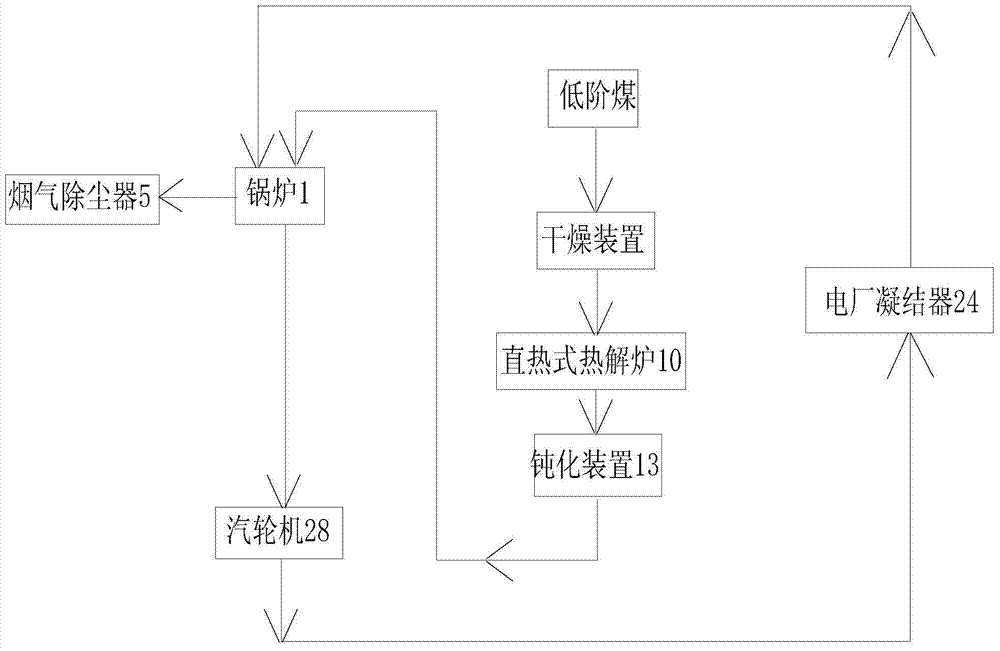

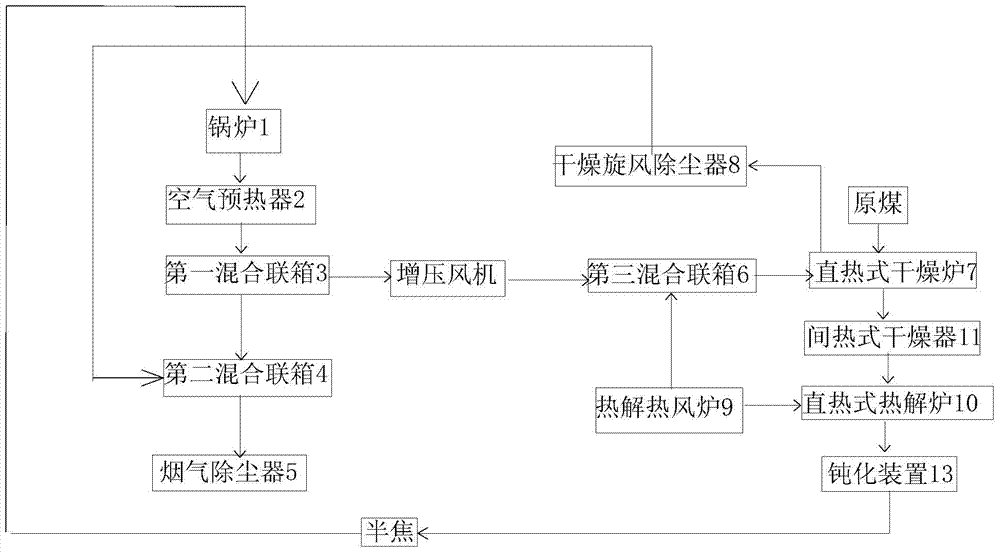

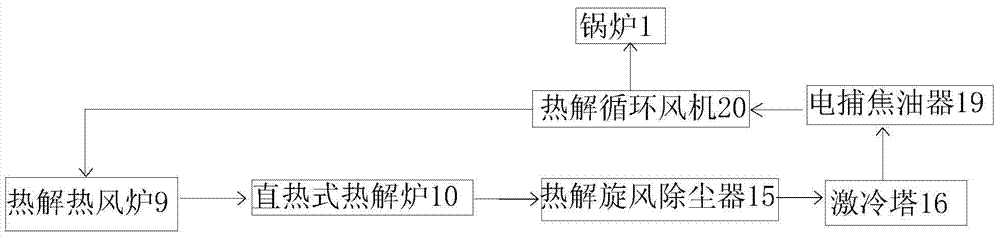

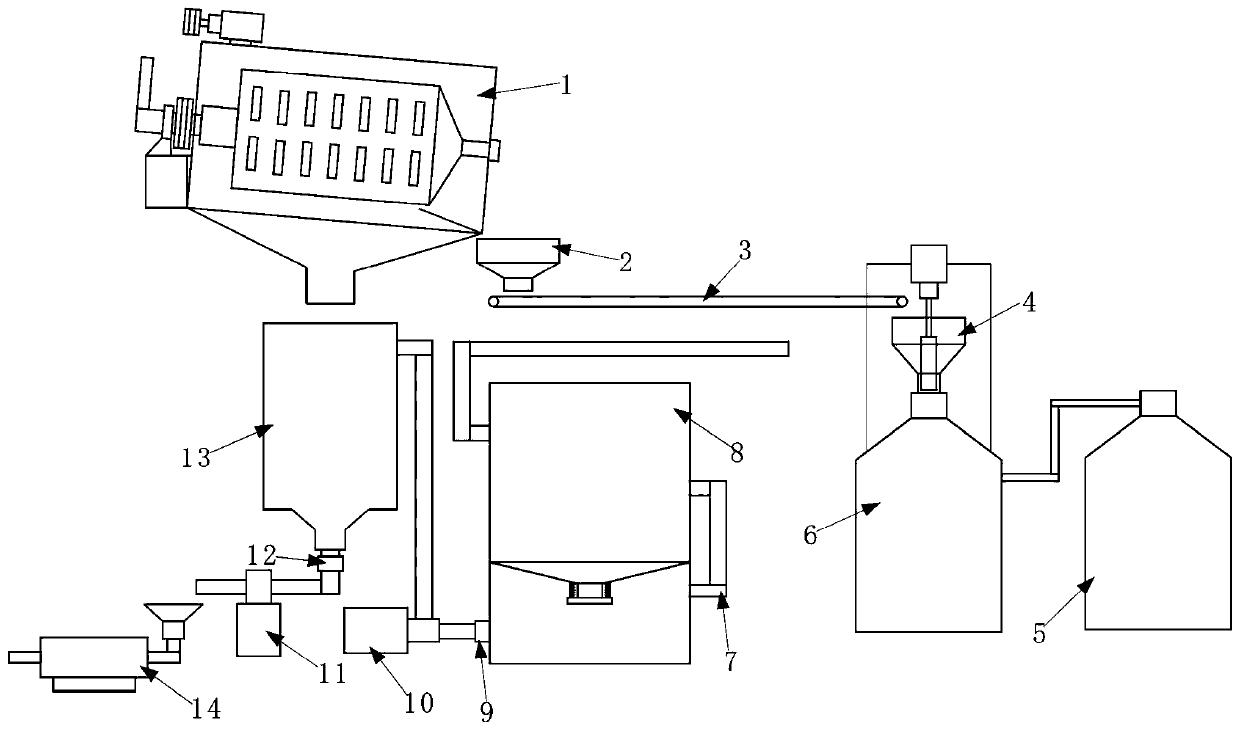

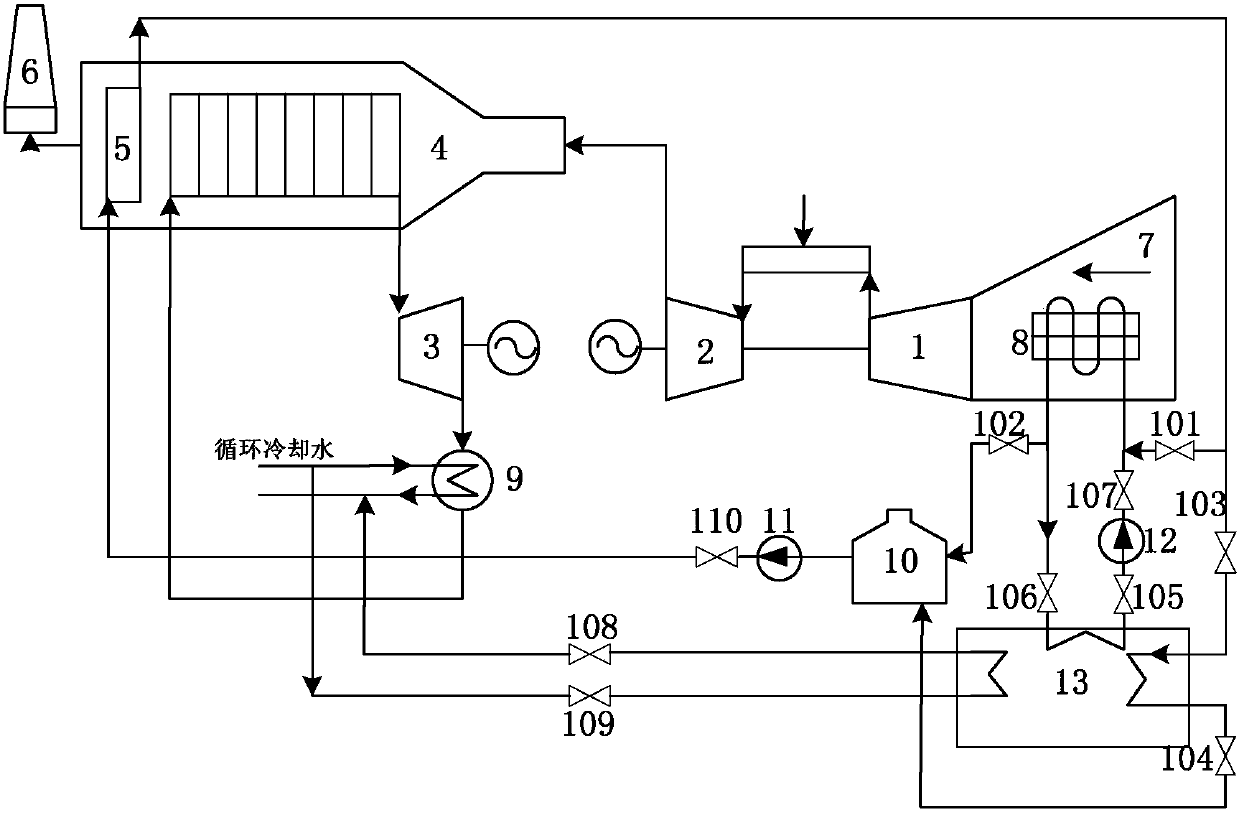

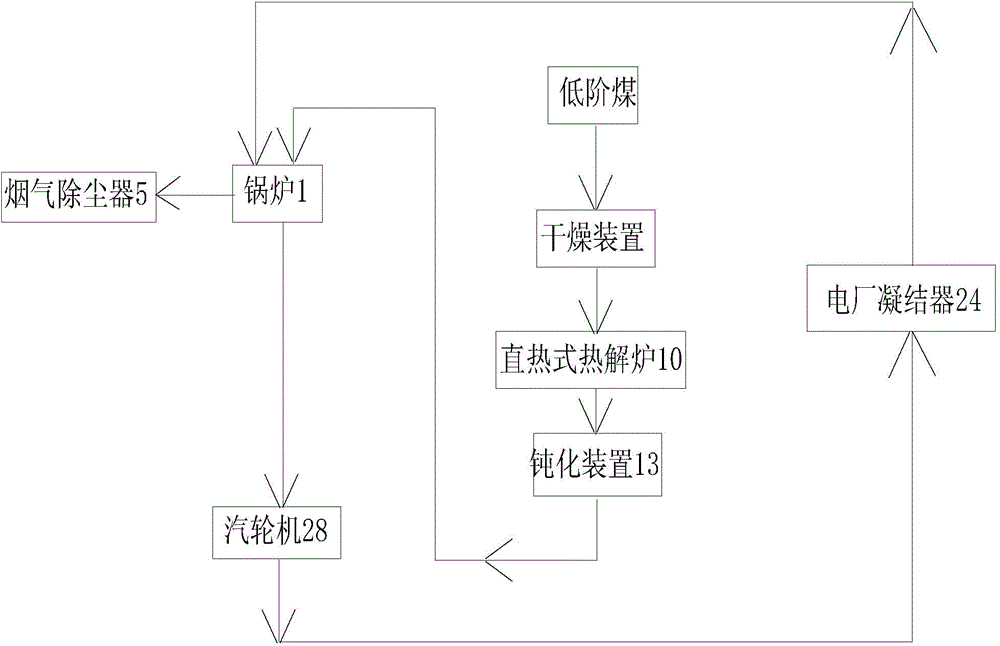

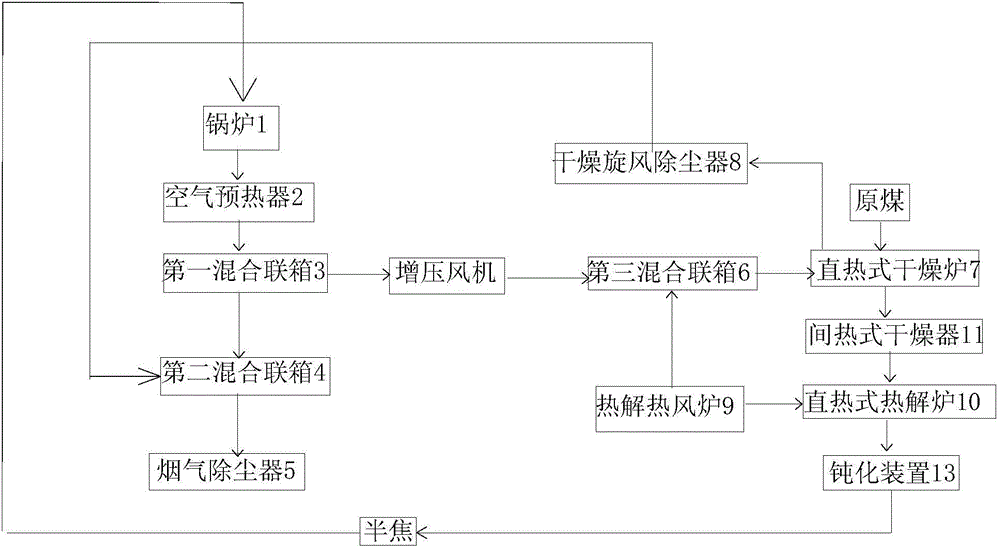

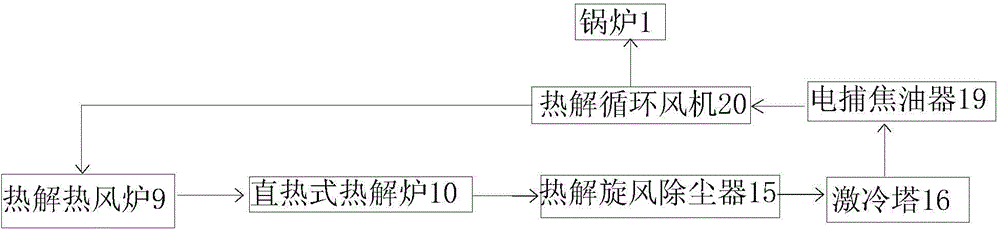

Low-rank coal purification power generation system

InactiveCN103939158AEfficient use ofFix security issuesSteam useLump/pulverulent fuel preparationEngineeringCoal

The invention provides a low-rank coal purification power generation system. The low-rank coal purification power generation system comprises a boiler, a steam turbine used for power generation and a power plant coagulator enabling steam to be coagulated into water. A steam exhaust port of the boiler is connected with a gas inlet of the steam turbine, an exhaust port of the steam turbine is connected with a gas inlet of the power plant coagulator, a liquid outlet of the power plant coagulator is connected with a liquid inlet of the boiler, a fuel inlet of the boiler is provided with a drying device used for drying low-rank coal and a directly-heated-type thermal decomposition furnace which can conduct thermal decomposition on the dried low-rank coal to generate semi-coke is installed between the boiler and the drying device. The semi-coke generated after the low-rank coal in the low-rank coal purification power generation system is purified is used for burning in the boiler, therefore, the boiler burning efficiency is directly increased and the investment is lowered.

Owner:HUNAN HUAYIN ENERGY TECH

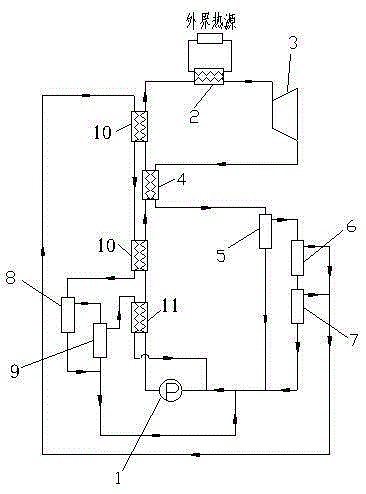

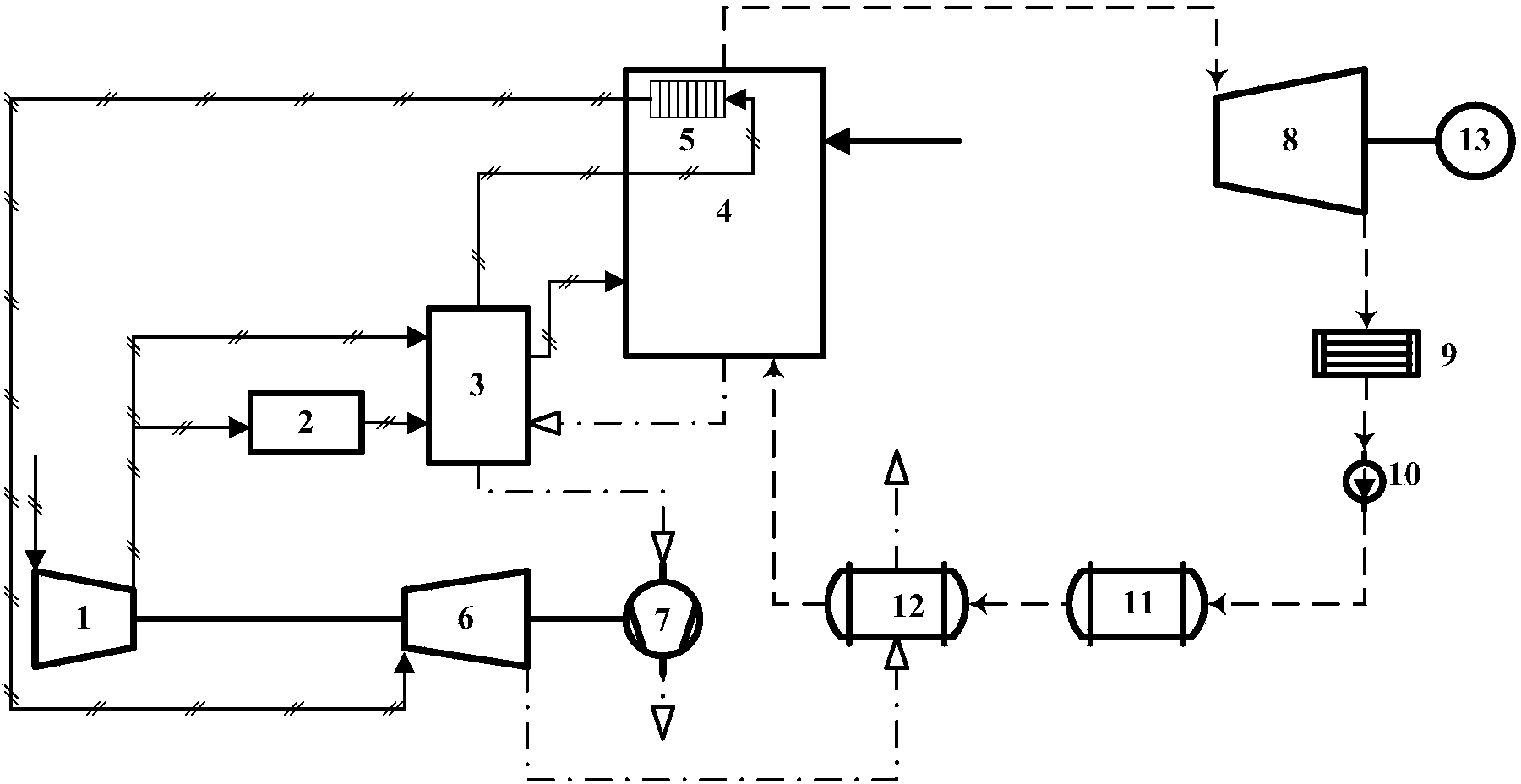

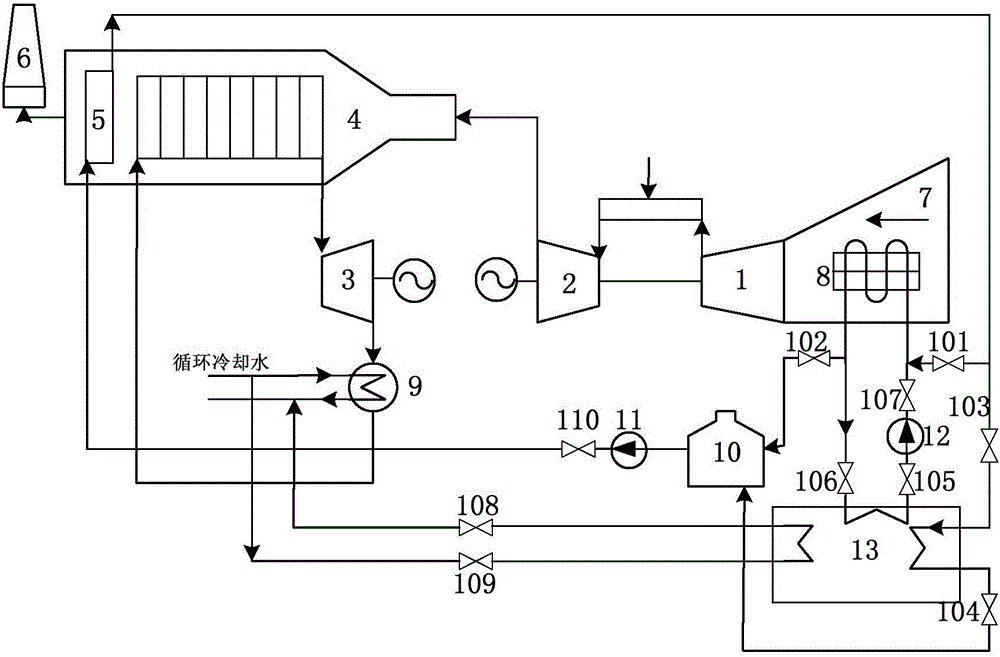

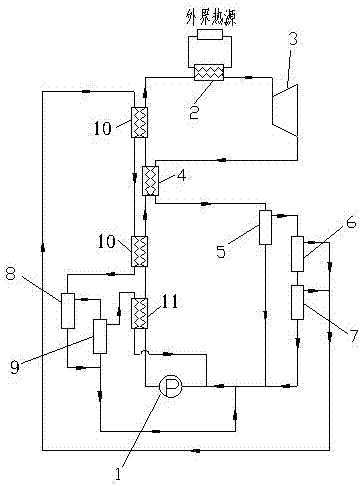

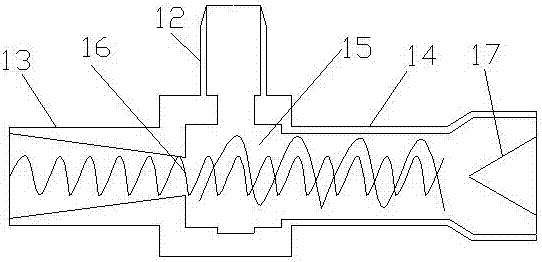

Efficient thermodynamic cycle system utilizing vortex tubes

ActiveCN105401988ASave compression workIncrease net efficiencyCompression machinesSteam regenerationThermodynamic cycleCooling Units

An efficient thermodynamic cycle system utilizing vortex tubes is mainly composed of a work medium pump, a heat exchanger, an expanding machine and a vortex tube flow dividing and cooling unit. The vortex tube flow dividing and cooling unit is formed by combining the multiple vortex tubes. Liquid working media separated from the vortex tubes directly enter a working medium pump inlet. Gaseous working media enter the heat exchanger to exchange heat with low-temperature working media on the high-pressure side of the cycle system. The cooled working media enter the vortex tubes again to be subjected to flow dividing and cooling; liquid working media enter the working medium pump inlet; and gaseous working media enter the heat exchanger to exchange heat with low-temperature working media on the high-pressure side of the cycle system again. Due to flow dividing and cooling of the multi-stage vortex tubes and many times of heat exchange with the low-temperature working media, most of the working media enter the working medium pump inlet in the form of liquid, only an extremely small part of working media are not liquefied, the proportion of the working media entering the working medium pump inlet to the non-liquefied working media is proper, and it can be guaranteed that all the working media on the working medium pump inlet are liquid working media by combining the working media entering the working medium pump inlet and the non-liquefied working media. A liquid working medium pump is used for pressurizing working media, power consumption of the pump is reduced, heat in the cycle system is recycled, and thermal efficiency is high.

Owner:DEZHOU GAOKELI HYDRAULIC

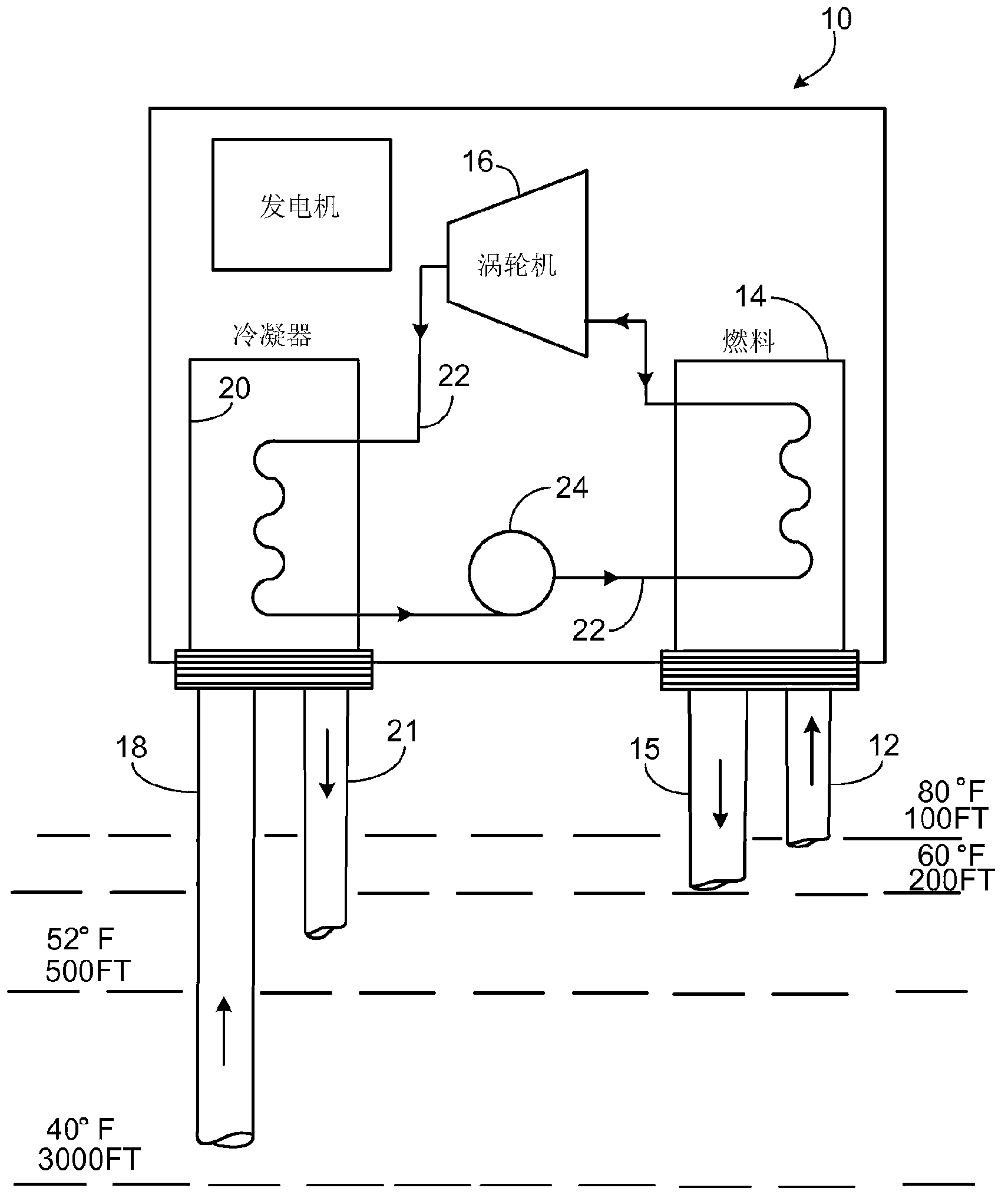

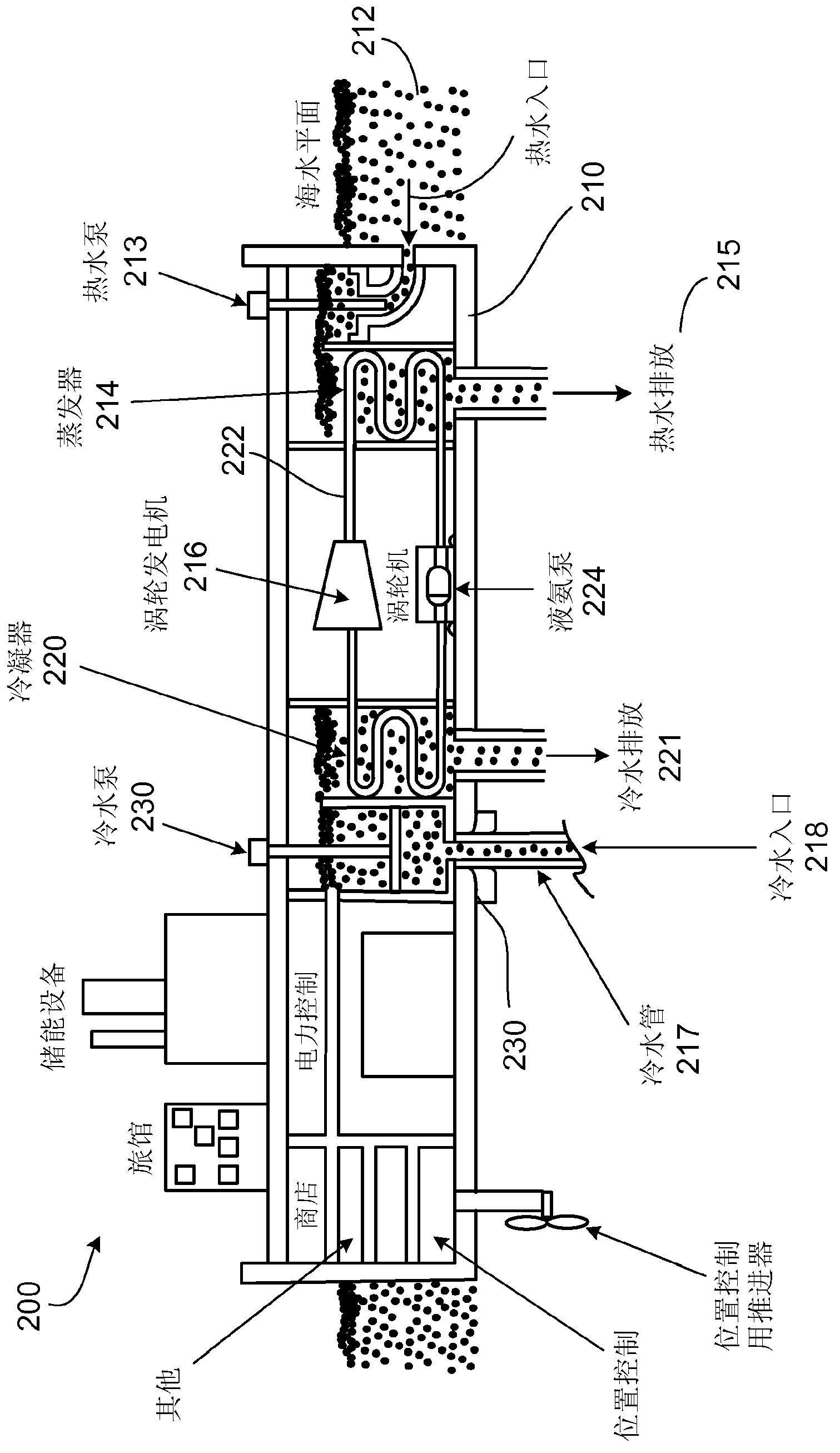

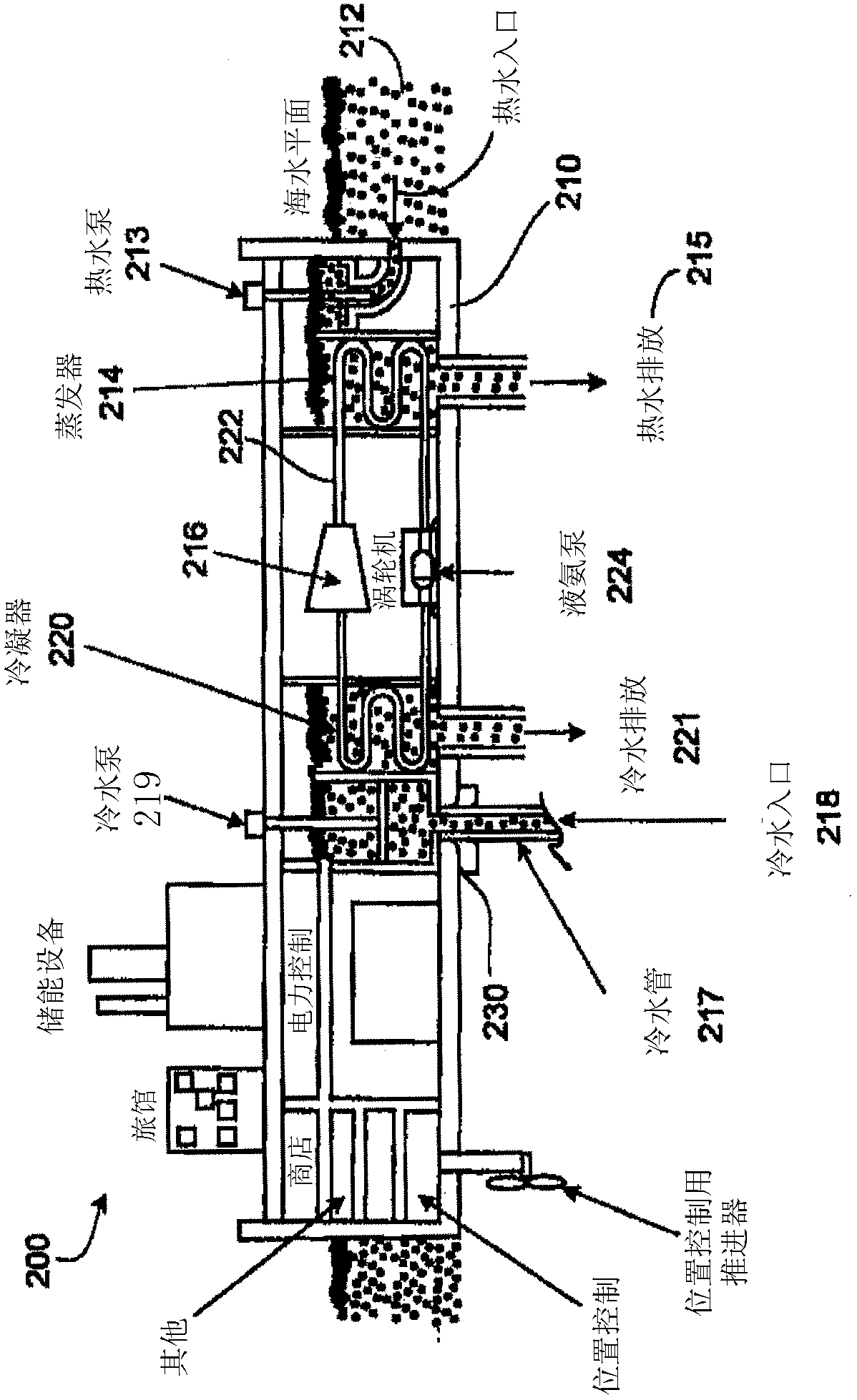

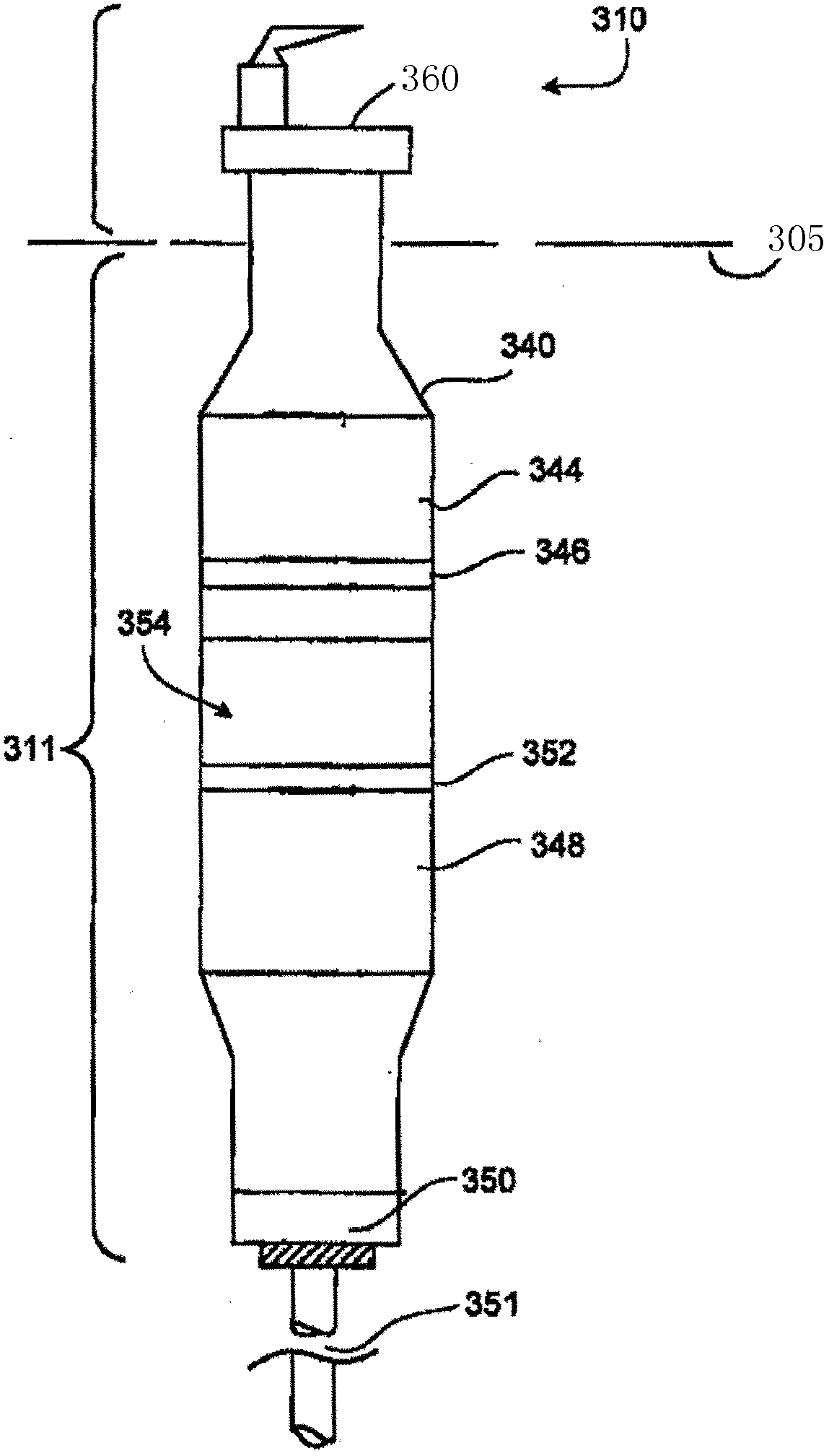

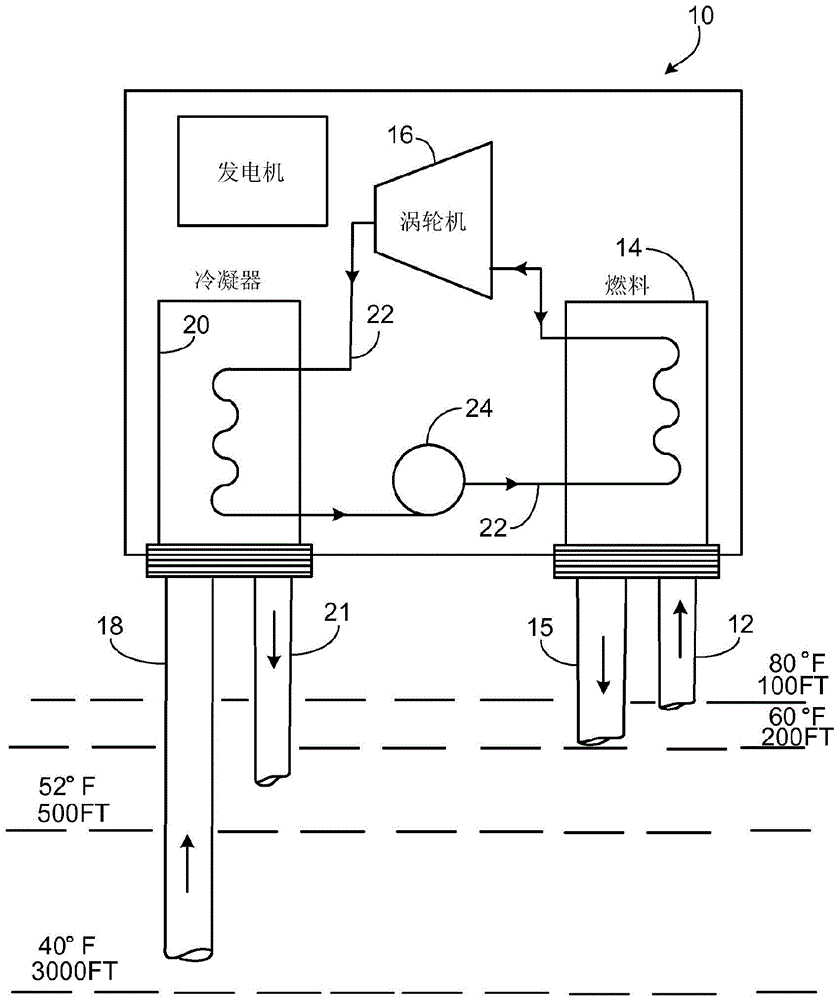

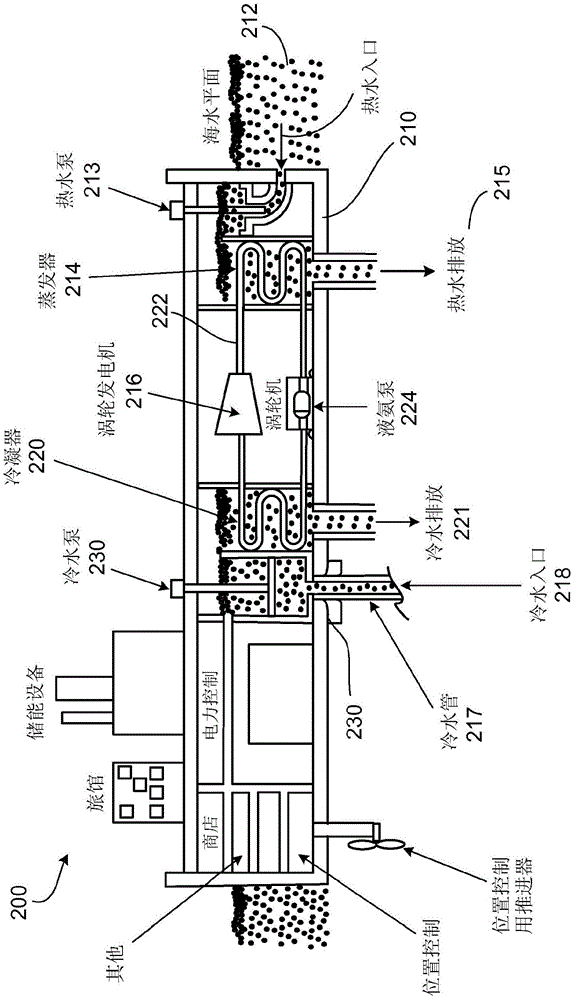

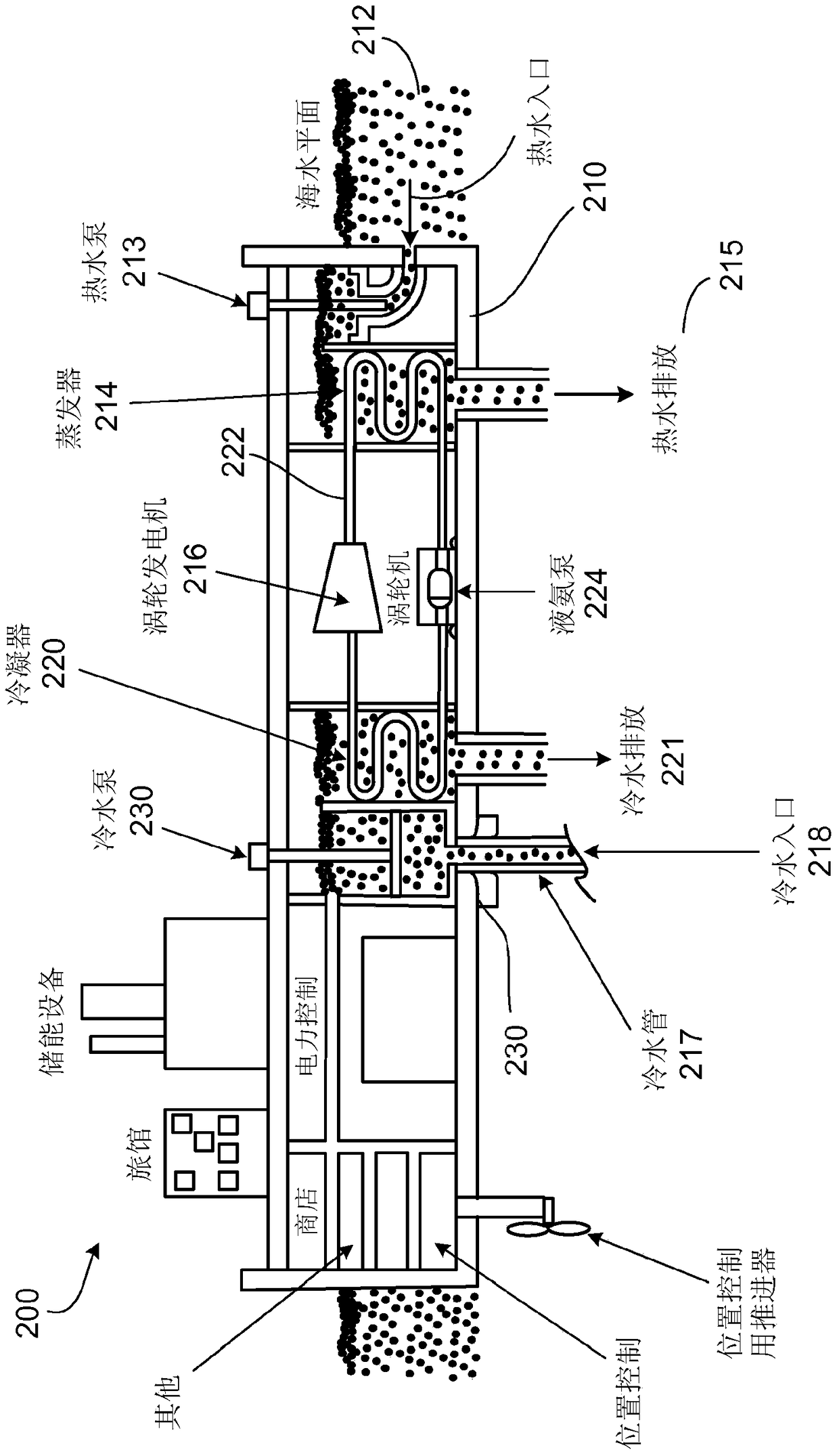

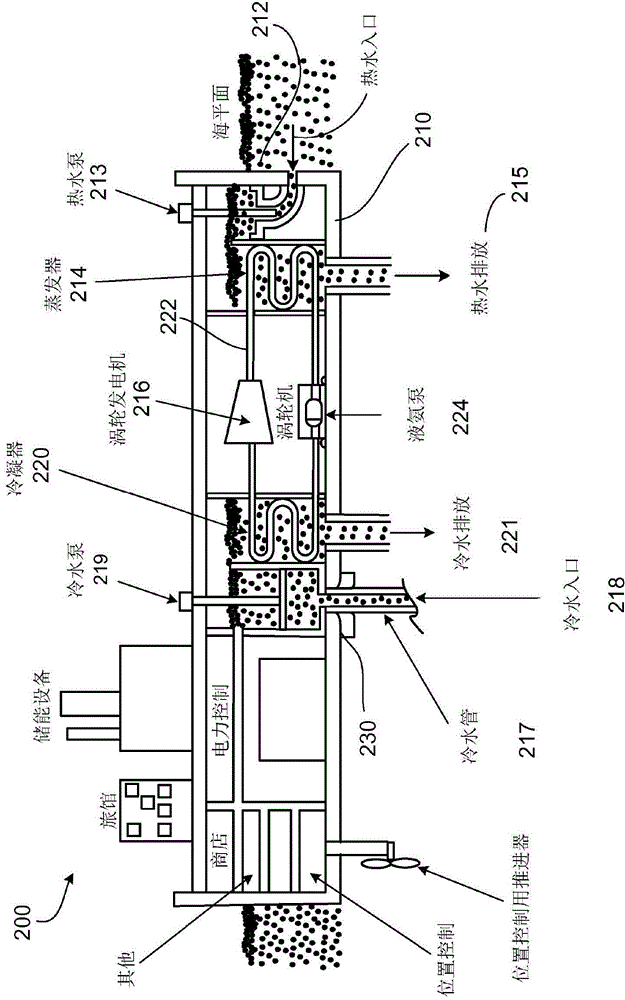

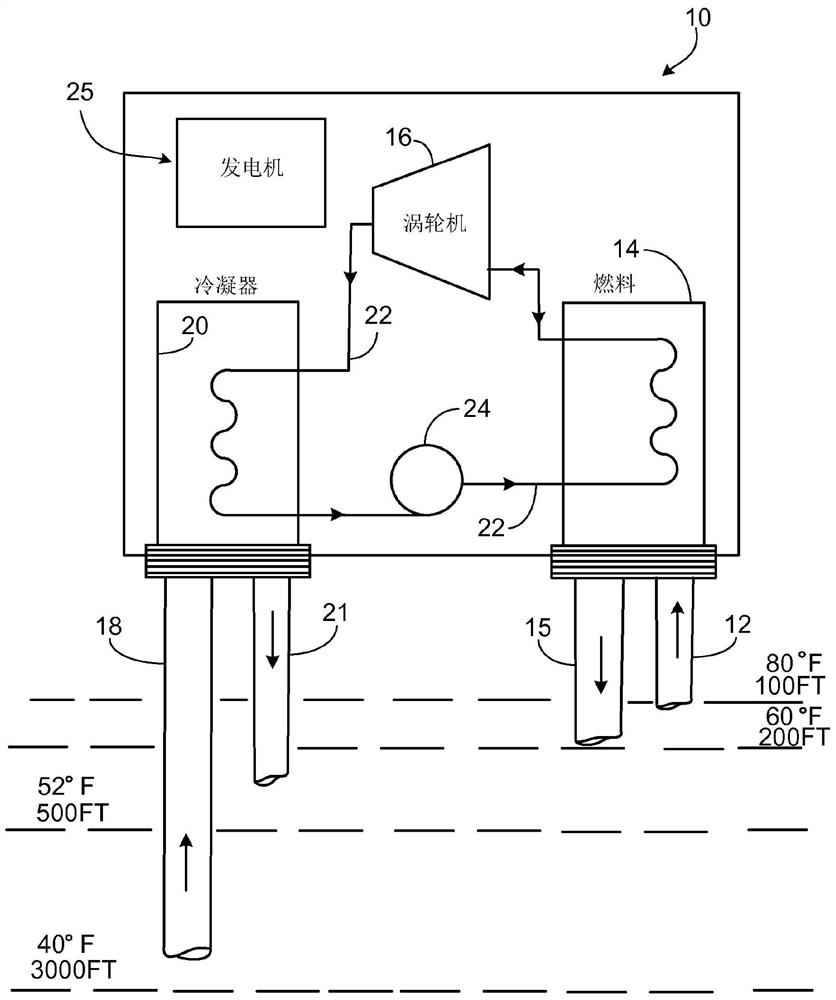

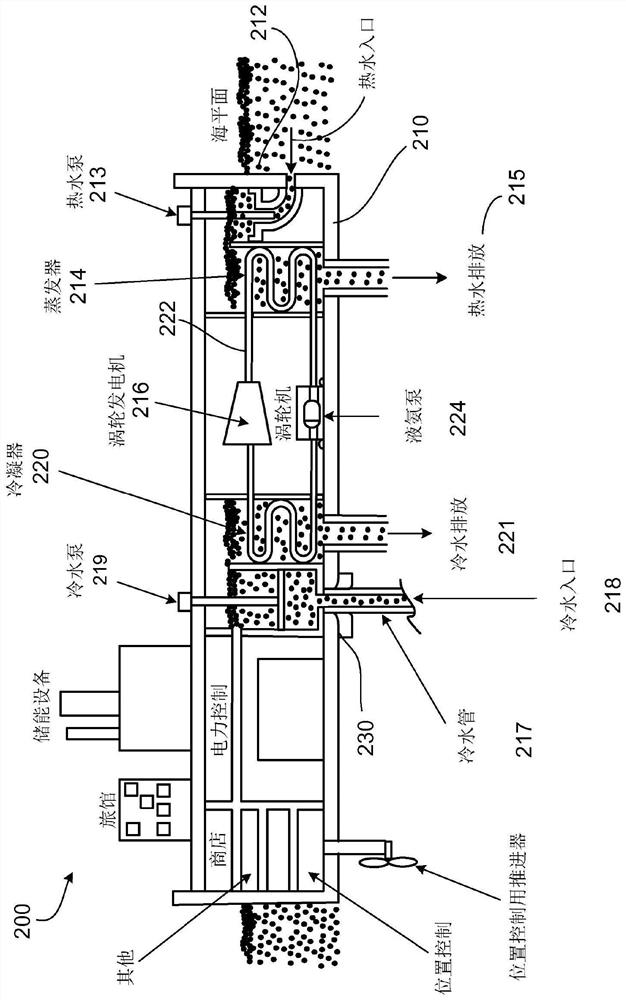

Ocean thermal energy conversion power plant

ActiveCN102844566ALightweight structureReduce friction lossPipe supportsPipe laying and repairThermal energyOcean thermal energy conversion

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection.

Owner:THE ABELL FOUND INC

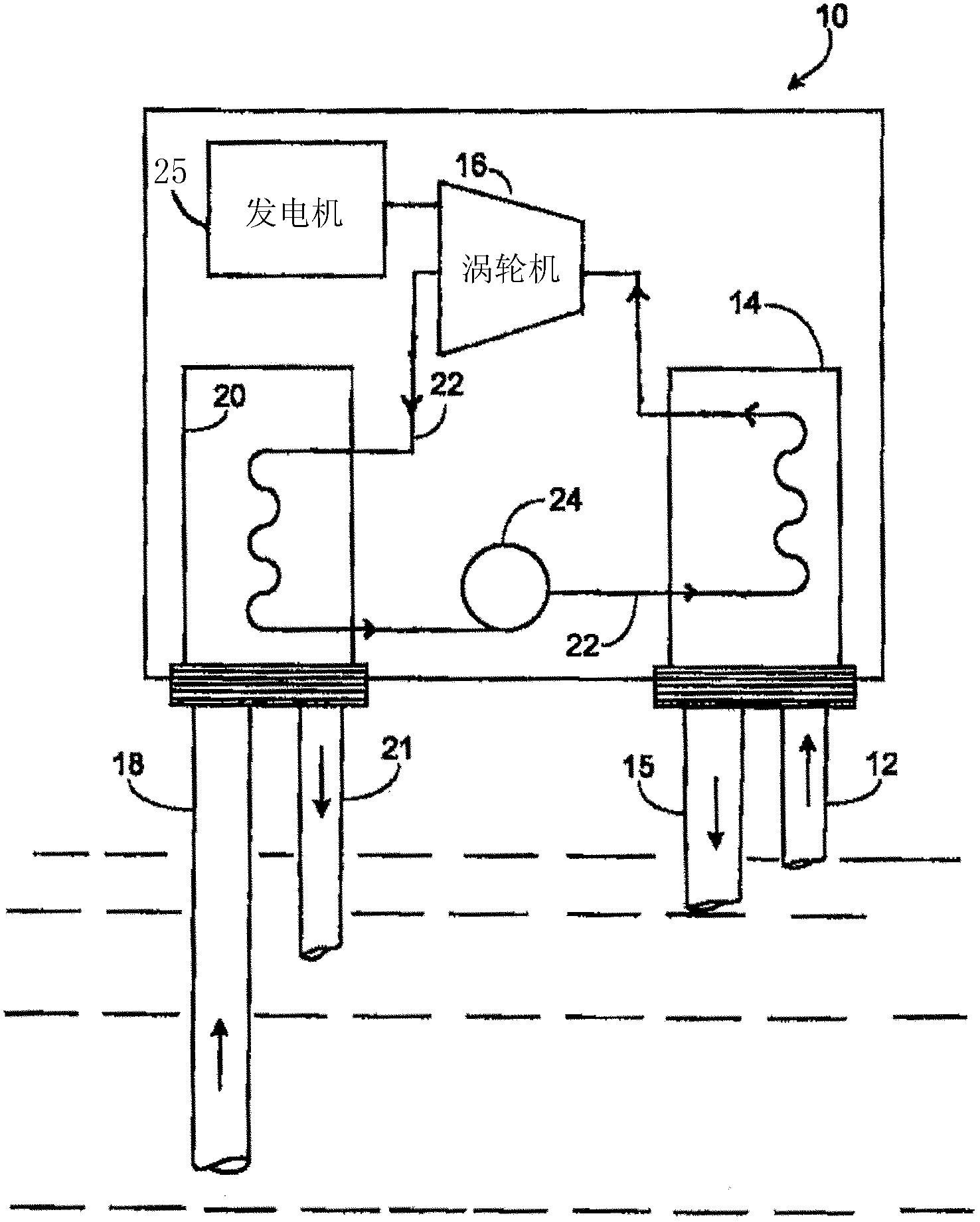

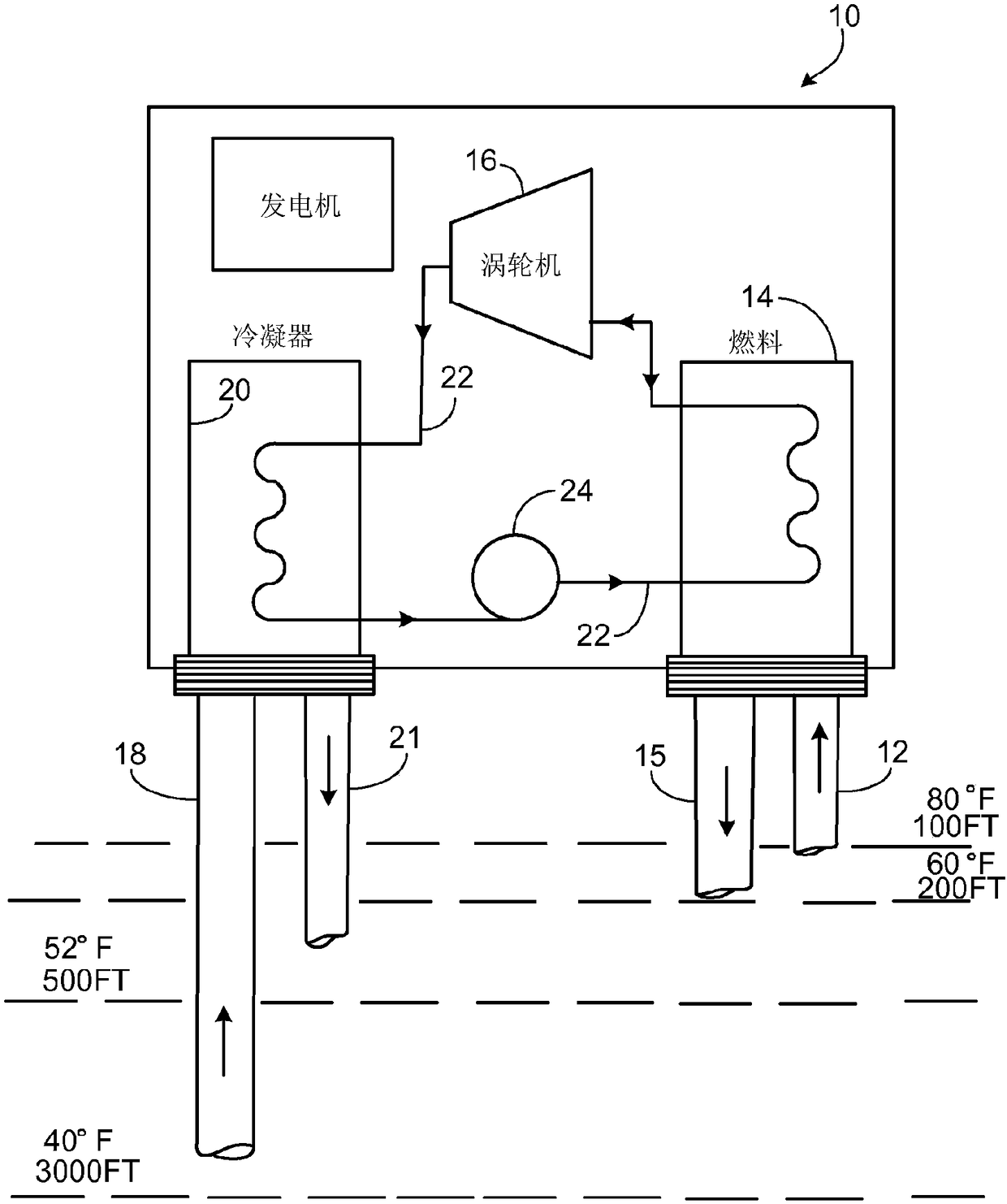

Industrial ocean thermal energy conversion processes

InactiveCN103154511ALow costSmall pressure lossSteam generation plantsSteam engine plantsThermal energyOcean thermal energy conversion

Owner:THE ABELL FOUND INC

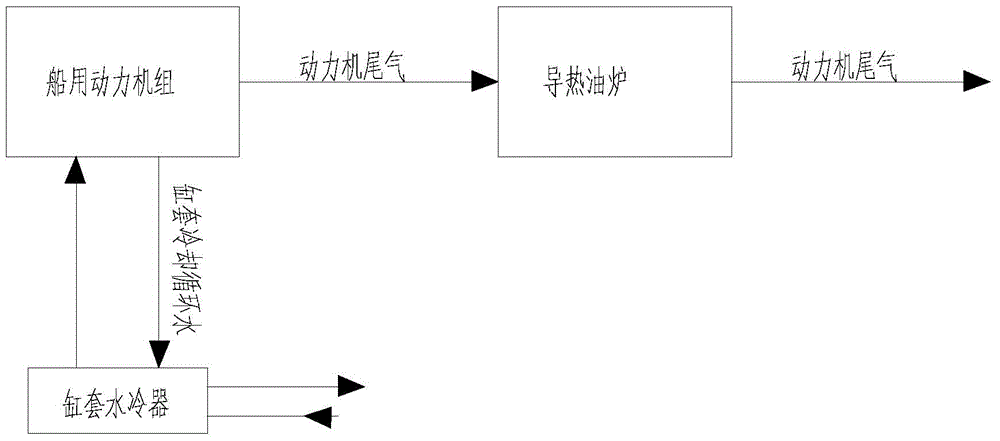

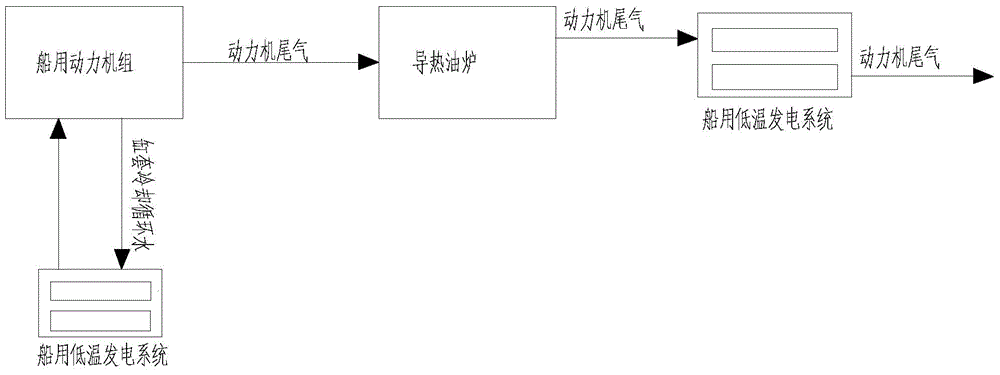

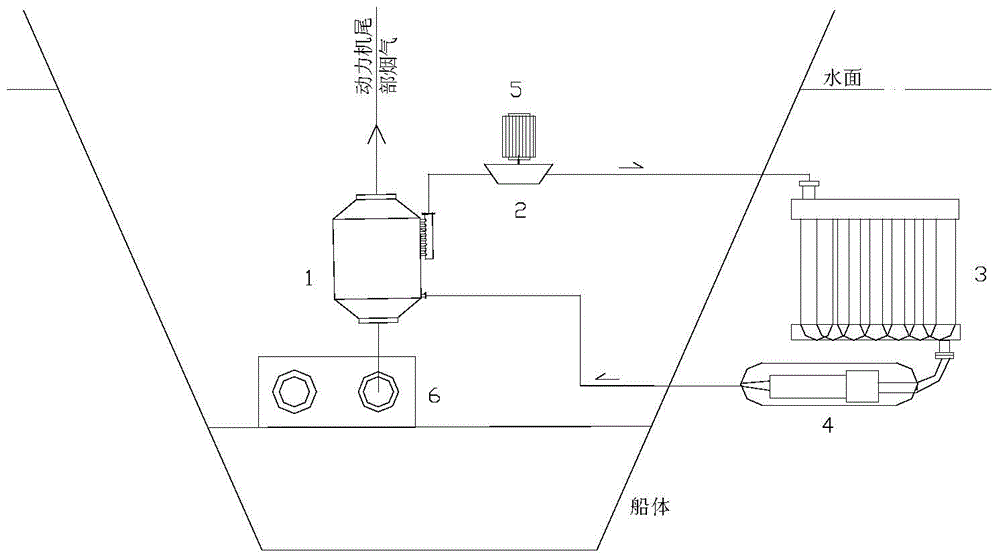

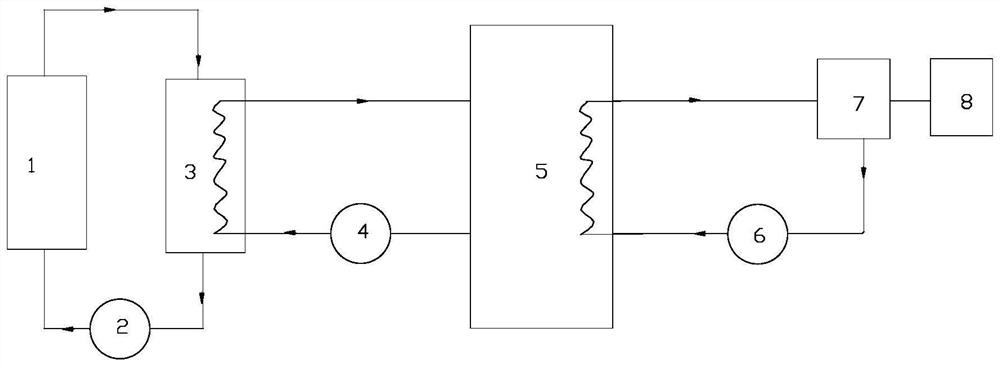

Ship engine waste heat power generation comprehensive utilization method

InactiveCN104806333AEliminate temperature fluctuationsEliminates the effects of temperature fluctuationsInternal combustion piston enginesExhaust apparatusFlue gasThree phase asynchronous motor

The invention discloses a ship engine waste heat power generation comprehensive utilization method. The ship engine waste heat power generation comprehensive utilization method comprises the following steps: (1) a flue gas evaporator is arranged on a flue gas exhausting channel of a ship heat-conduction oil furnace, and high-temperature flue gas passes through a shell pass of the flue gas evaporator; a power generation medium of a waste heat power generation system passes through the shell pass of the flue gas evaporator, and the power generation medium is subjected to heat exchange and heat suction with the high-temperature flue gas; meanwhile, cylinder sleeve cooling circulating water of a ship engine set enters a shell pass of a pipe shell type evaporator and is subjected to heat exchange with the power generation medium entering the shell pass of the pipe shell type evaporator of the waste heat power generation system; (2) after the power generation medium is evaporated, the power generation medium is changed into high-temperature and high-pressure steam and is conveyed into an expansion machine, and the expansion machine is propelled to output mechanical power so as to drive a three-phase asynchronous motor to generate power; (3) then the power generation medium enters an underwater condenser outside a board; (4) the condensed power generation medium passes through a fully-closed underwater medium pressurizer to be divided into two paths, namely one path is returned back to the flue gas evaporator, and the other path is returned back to the pipe shell type evaporator. With the adoption of the method, the purification efficiency of a power generation system is improved.

Owner:TIANJIN UNIV

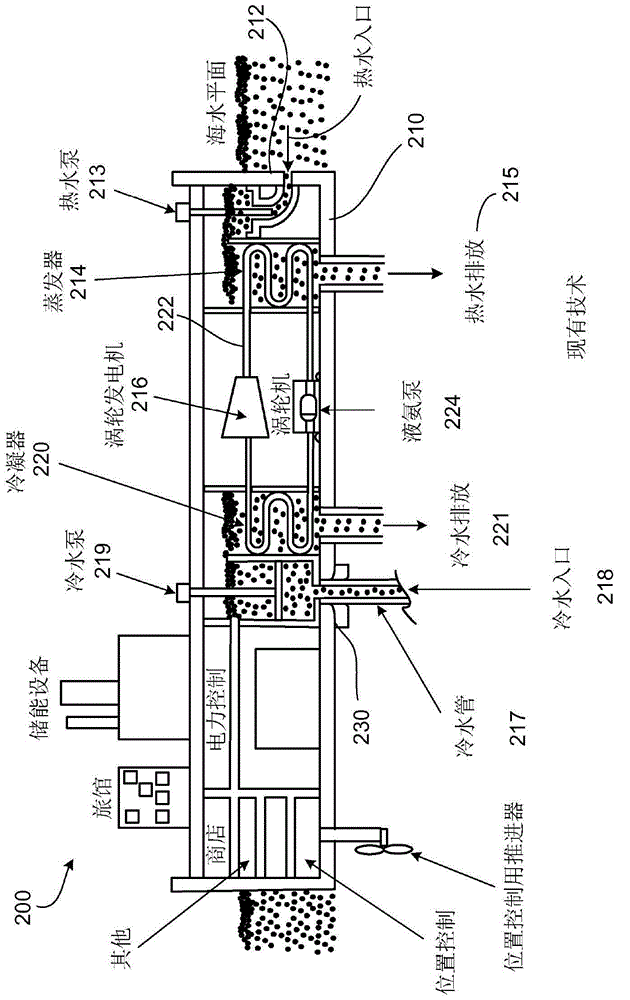

Ocean thermal energy conversion power plant

ActiveCN105464915ALightweight structureReduce friction lossSteam useMechanical power devicesThermal energyOcean thermal energy conversion

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection.

Owner:THE ABELL FOUND INC

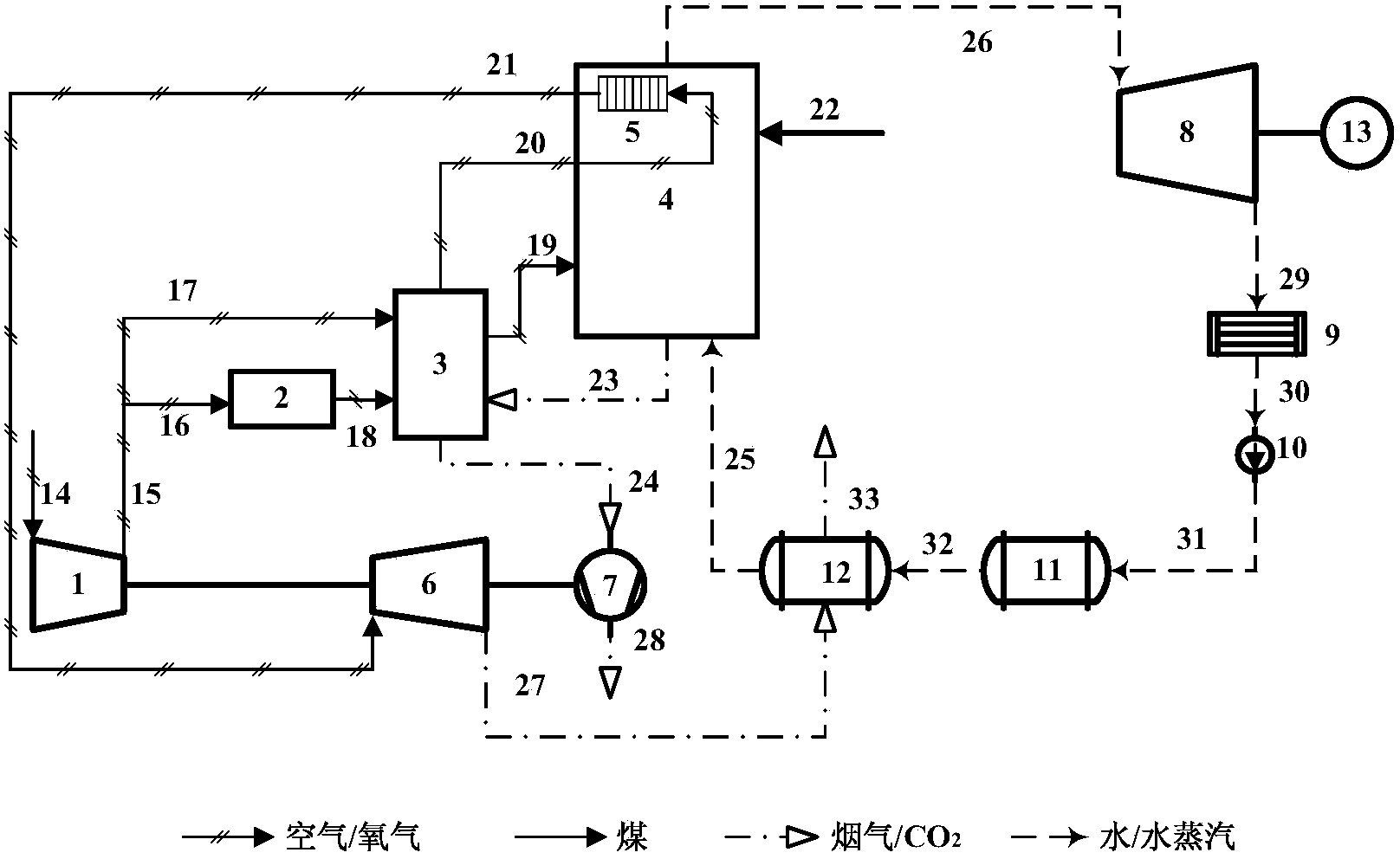

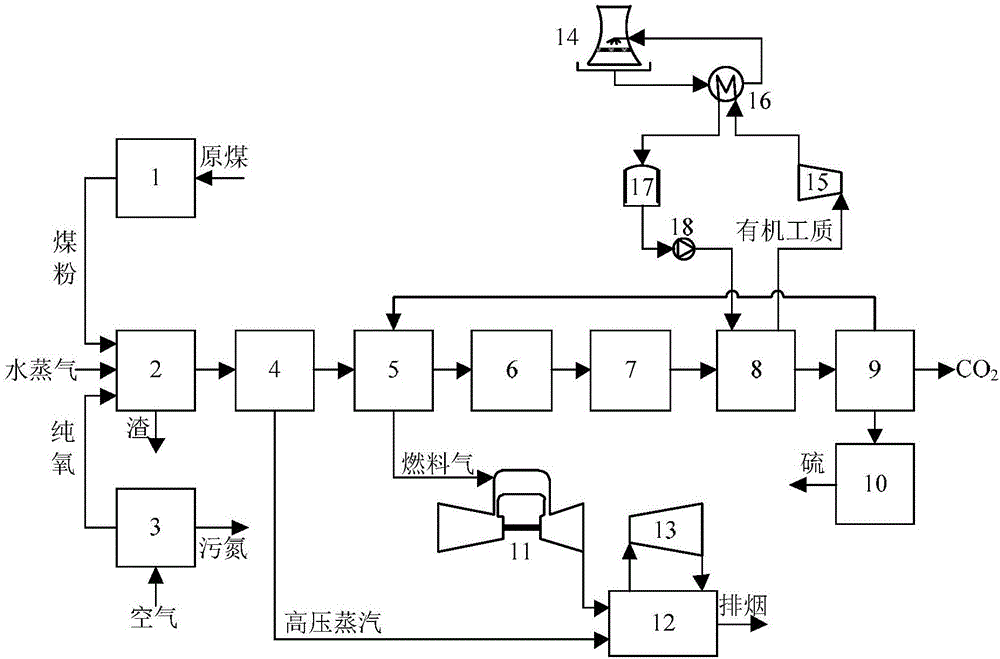

Integrated oxygen-enriched combustion power system

InactiveCN104033250AAchieve economical operationTake advantage ofAir heatersGas turbine plantsGas compressorEngineering

The invention relates to an integrated oxygen-enriched combustion power system which comprises an oxygen-enriched combustion boiler for combusting coal powder, wherein a high-temperature heating surface is additionally arranged in the oxygen-enriched combustion boiler and is used for heating compressed air for driving a gas turbine; the oxygen-enriched combustion boiler is communicated with a gas-gas heat exchanger and is used for receiving heated oxygen and the heated compressed air which are output by the gas-gas heat exchanger and outputting smoke to the gas-gas heat exchanger; furthermore, the high-temperature heating surface of the oxygen-enriched combustion boiler is communicated with the gas turbine and outputs the compressed air heated by the high-temperature heating surface of the oxygen-enriched combustion boiler so as to drive the gas turbine to do work; the gas turbine drives a gas compressor and a CO2 compressor; high-temperature exhaust gas discharged from the gas turbine is conveyed into the highest stage of a generalized backheating heater for further heating water fed by the boiler. According to the integrated oxygen-enriched combustion power system provided by the embodiment of the invention, safe, environment-friendly and economical running of the oxygen-enriched combustion power system can be realized.

Owner:TAIYUAN UNIV OF TECH +1

Diastereoselective synthesis of phosphate derivatives

ActiveUS10774104B2Increase net efficiencySugar derivativesGroup 5/15 element organic compoundsPhosphoric Acid EstersEnantioselective synthesis

Disclosed is a method for the preparation of intermediates useful in the synthesis of gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate. Also disclosed is a method of preparing gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate.

Owner:NUCANA PLC

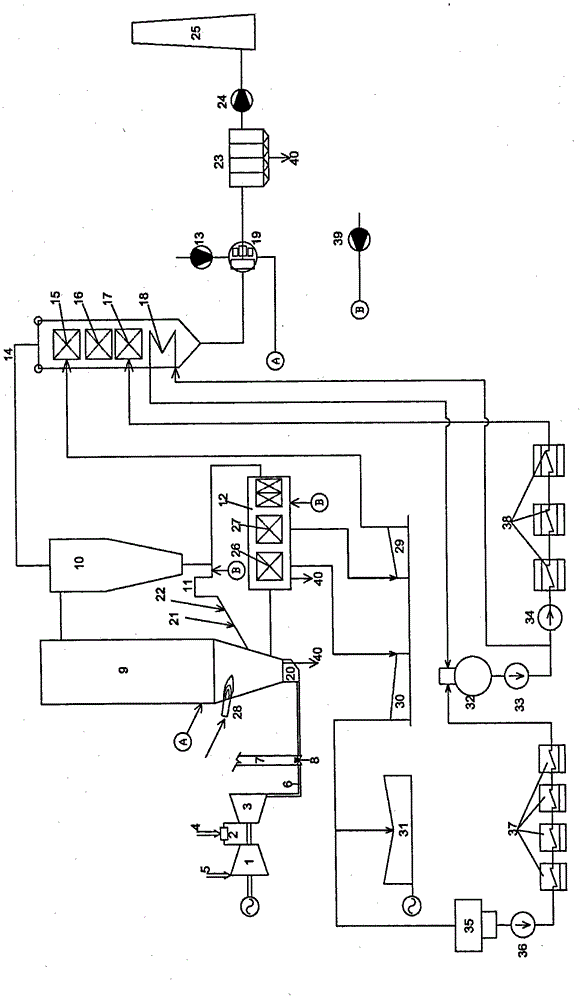

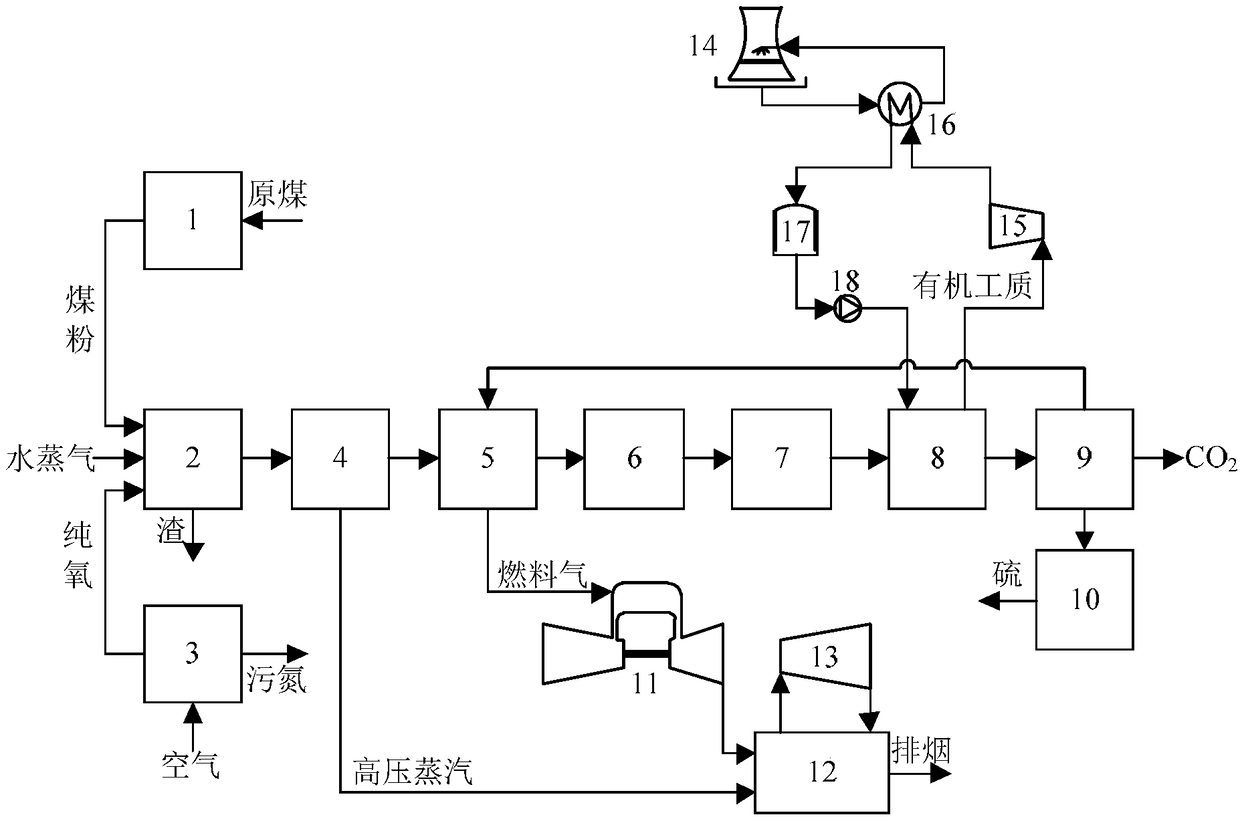

Device and method for achieving low-grade cogeneration by means of IGCC

ActiveCN106761990AImprove power generation efficiencyReduce coal consumptionSteam generation using pressureEnergy industryCooling towerLiquid state

The invention discloses a device and method for achieving low-grade cogeneration by means of an IGCC. The method comprises the steps that saturated synthesis gas is adopted as a heat source for heating a pressurized organic working medium into the superheated steam state from the liquid state, expansion working electricity generation is performed inside an expansion machine, then, the organic working medium enters a condenser to become liquid, and the liquid organic working medium is boosted through a pump, so that an organic working medium Rankine cycle is formed. The device and method are used for reducing heat losses inside a gasification island cooling tower, and the system electricity generation efficiency is improved by means of low temperature exhaust heat in a gasification island.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

Combined cycle waste heat utilization system capable of stabilizing high/low inlet air temperature of compressor

ActiveCN105822431AThreat to safe operationHigh outputGas turbine plantsJet propulsion plantsExpansion tankLithium bromide

The invention discloses a combined cycle waste heat utilization system capable of stabilizing the high / low inlet air temperature of a compressor. The combined cycle waste water heat utilization system comprises a smoke-hot water heat exchanger, an air-water heat exchanger, an expansion water tank, a pipeline pump, a low-temperature heat source hot water type lithium bromide refrigerator and a valve. A heat source used by the low-temperature heat source hot water type lithium bromide refrigerator and a heat source used by the air-water heat exchanger are waste heat of smoke at the tail portion of a waste heat boiler. In the low-temperature weather, the system can heat the inlet air of the compressor to prevent water drops in the air from being frozen, and the running safety and the heat economical efficiency of a unit are improved; in the high-temperature weather, the system can cool the inlet air of the compressor to improve the peak shaving capability and the heat economical efficiency of the unit; and waste heat of the discharged smoke of the waste heat boiler is used as the heat source of the system, the function of stabilizing the temperature of the inlet air of the compressor is achieved, switching of a compressor inlet air heating function and a compressor inlet air cooling function can be achieved through opening and closing of the valve, and double benefits of improving the safety and the economical efficiency of the unit are achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

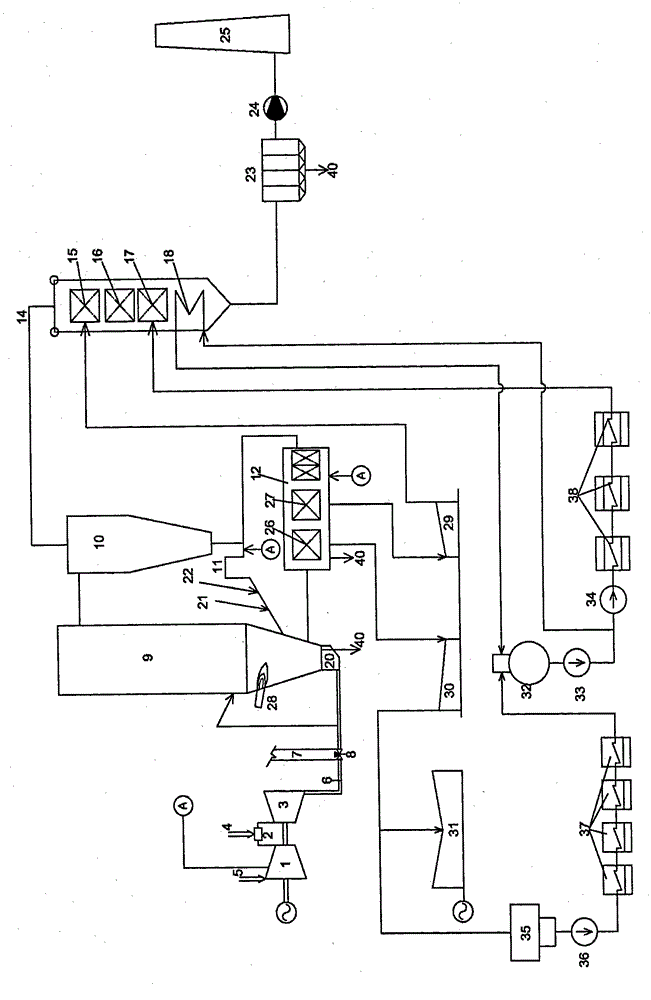

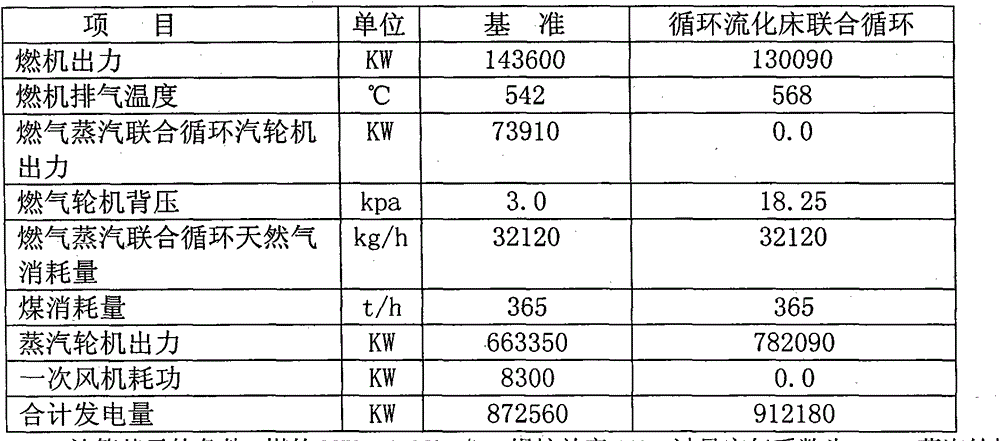

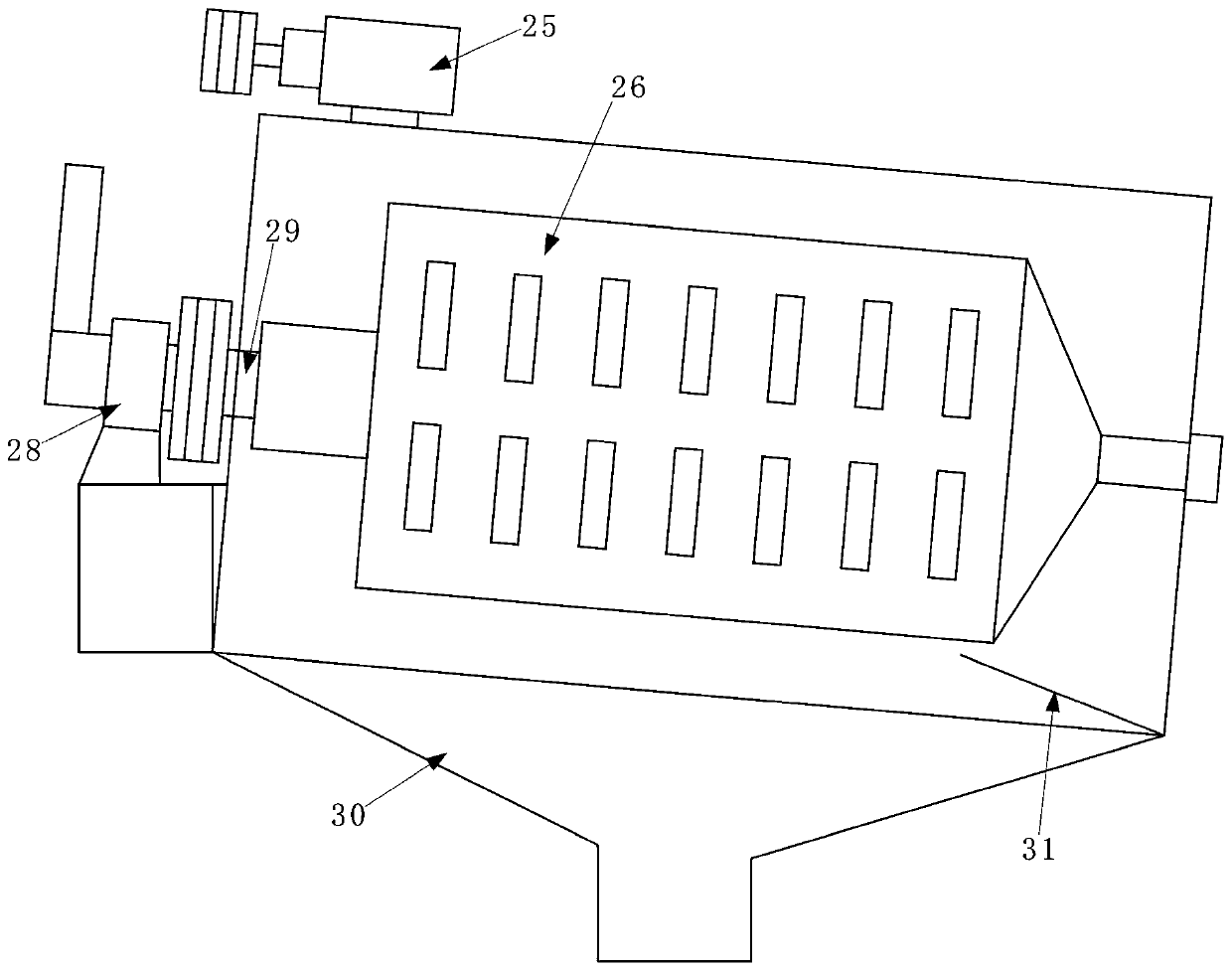

Novel circulating fluidized bed combined cycle

InactiveCN104482530AImprove heat radiation heat transfer capacityRecovery of exhaust energyFluidized bed combustionCombustion technology mitigationCoalDust collector

The invention discloses a novel circulating fluidized bed combined cycle comprising a gas turbine device, a circulating fluidized bed boiler, a steam turbine device, a piping system and a bypass chimney connected with gas turbine exhaust gas and boiler first and secondary wind systems, an air piping system connected with a gas compressor intermediate-grade gas suction port and a boiler high-pressure tuyere, and a flue gas waste heat recovery oxygen-removing heating system; a tail end smoke flue of the circulating fluidized bed boiler is communicated with atmospheric air through a dust collector and a chimney, a high-temperature superheater and a high-temperature reheater of the circulating fluidized bed are respectively communicated with a high-pressure steam turbine and an intermediate-pressure steam turbine, the intermediate-pressure steam turbine is communicated with a low-pressure steam turbine, and an exhaust gas condensate of the low-pressure steam turbine is communicated with a coal economizer through a condensate water pump, low-pressure heaters, a deaerator, a pre-feawater pump, a water-feeding pump and high-pressure heaters. The combined cycle has the advantages of high thermal efficiency, less NOx emission, short starting time, low fuel consumption and station service power consumption rate, less auxiliary equipment, and remarkable energy-saving and emission-reduction effects.

Owner:徐进峰

Method of using external fluid for cooling high temperature components of gas turbine

InactiveCN103485840AIncrease net outputIncrease net efficiencyTurbine/propulsion engine coolingBlade accessoriesTurbine bladeClosed loop

An external fluid (27) in a closed loop is used to cool hot gas path components of gas turbine (16). After cooling the turbine components, the heated external fluid (27) is dumped either in the compressor discharge casing (28) or in the one of the turbine's stages (16A-C). Where the external fluid (27) is nitrogen to be dumped in the turbine compressor's discharge casing (28), the nitrogen is compressed using diluent nitrogen compressors (17). Alternatively, where the external fluid (27) is nitrogen to be dumped in one of the stages (16A-C) of the turbine (16), the nitrogen is not compressed at all. The turbine blade heat exchangers (22) in the turbine stages (16A-C) through which the nitrogen passes can be connected in parallel or in series for cooling the hot gas path components in the turbine stages (16A-C). The nitrogen can optionally be mixed with air or steam or not mixed at all.

Owner:GENERAL ELECTRIC CO

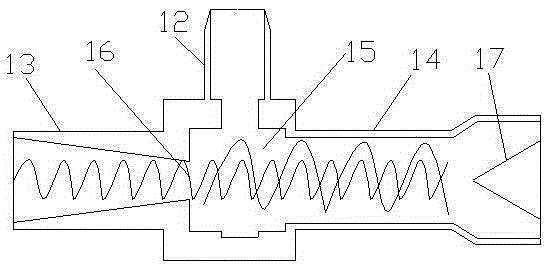

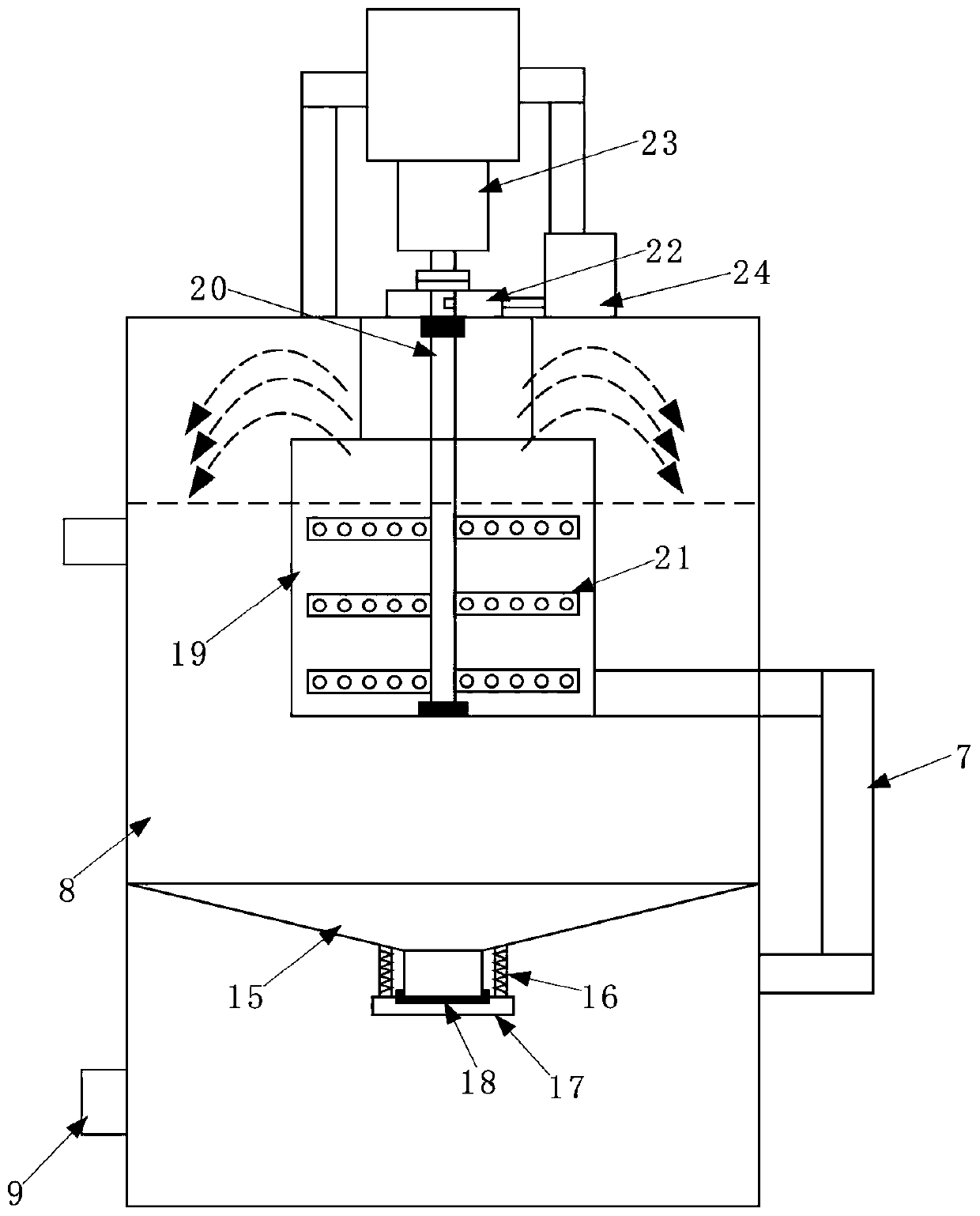

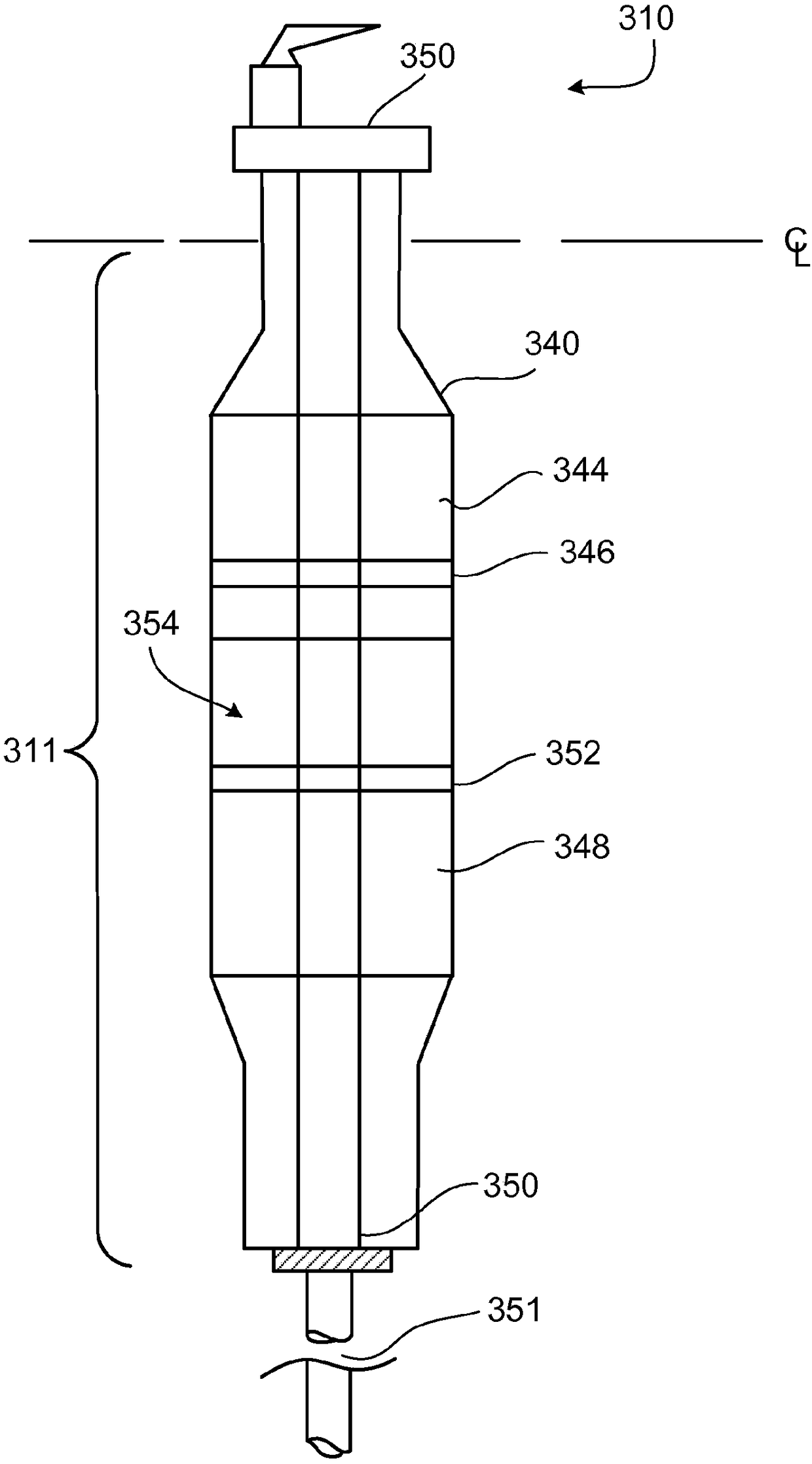

Ultramicro power sewage treatment equipment

PendingCN111333278AWon't pile upAvoid re-entrySludge treatment by de-watering/drying/thickeningWater contaminantsSewage outfallSewage treatment

The invention discloses ultramicro power sewage treatment equipment comprising a solid-liquid separator. The solid-liquid separator comprises an outer box body; a roller is transversely and obliquelyarranged in the outer box body, the roller has a hollow structure, one end of the roller is open, a sewage pipe is connected to the other end of the roller, and a plurality of through holes are formedin the roller. A funnel-shaped sewage outlet is formed in the lower end of the outer box body, and a sedimentation tank is arranged below the sewage outlet; a first receiving hopper is arranged belowthe impurity drain outlet, and the lower end of a second receiving hopper is connected with a fermentation tank. The scheme is used for agricultural sewage treatment, sewage discharged from an agricultural sewage source firstly enters the roller through a transfer box, impurities in the sewage are screened out, a problem that the impurities are slowly decomposed in the sewage purification processis solved, the sewage purification efficiency is improved; meanwhile, the impurities can be utilized to generate biogas to be utilized. Impurities are discharged by utilizing self weight in the roller, so that the power used by the device is far less than that used by a conventional solid-liquid separation device, and the sewage purification cost is saved.

Owner:四川逸名环保科技有限公司

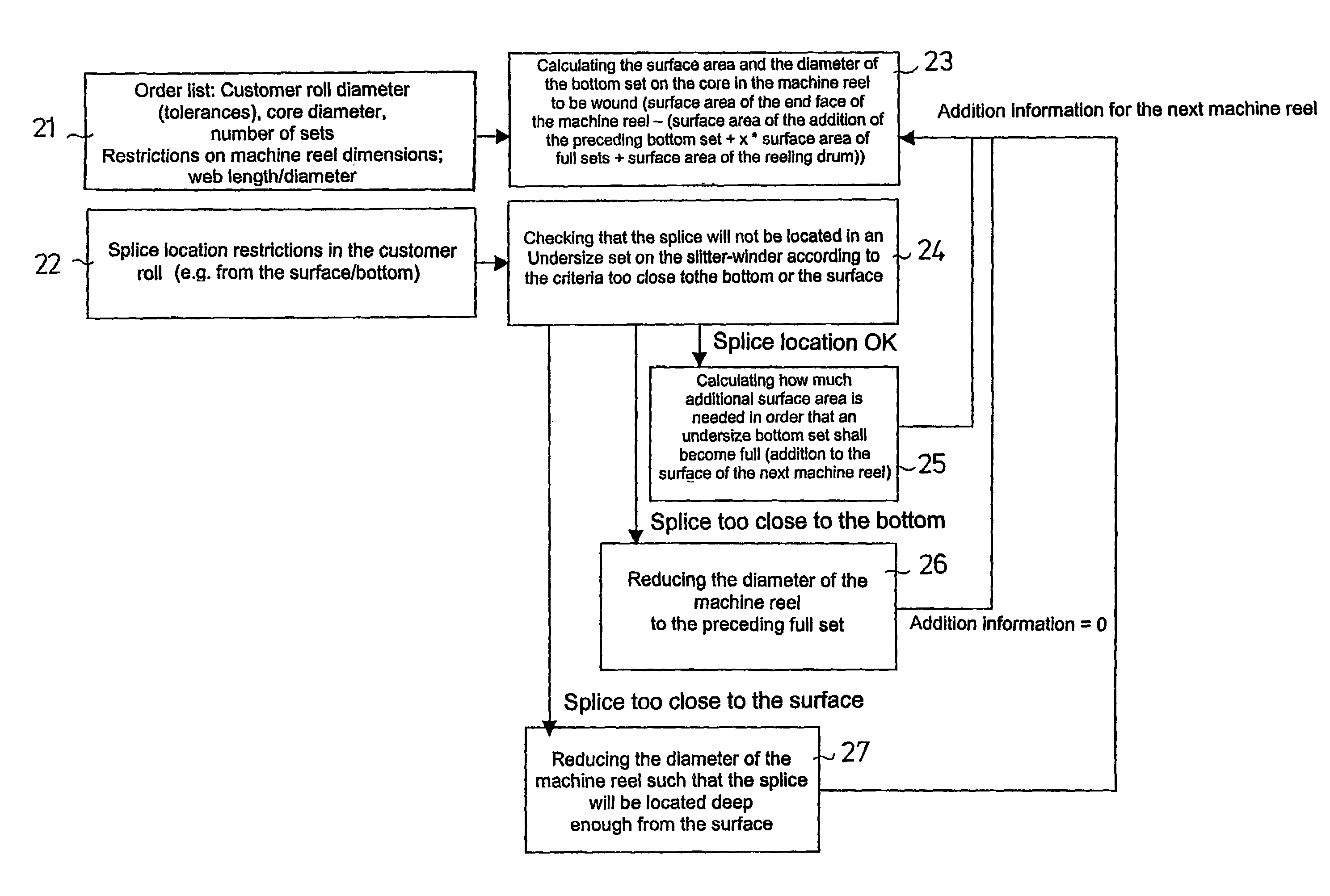

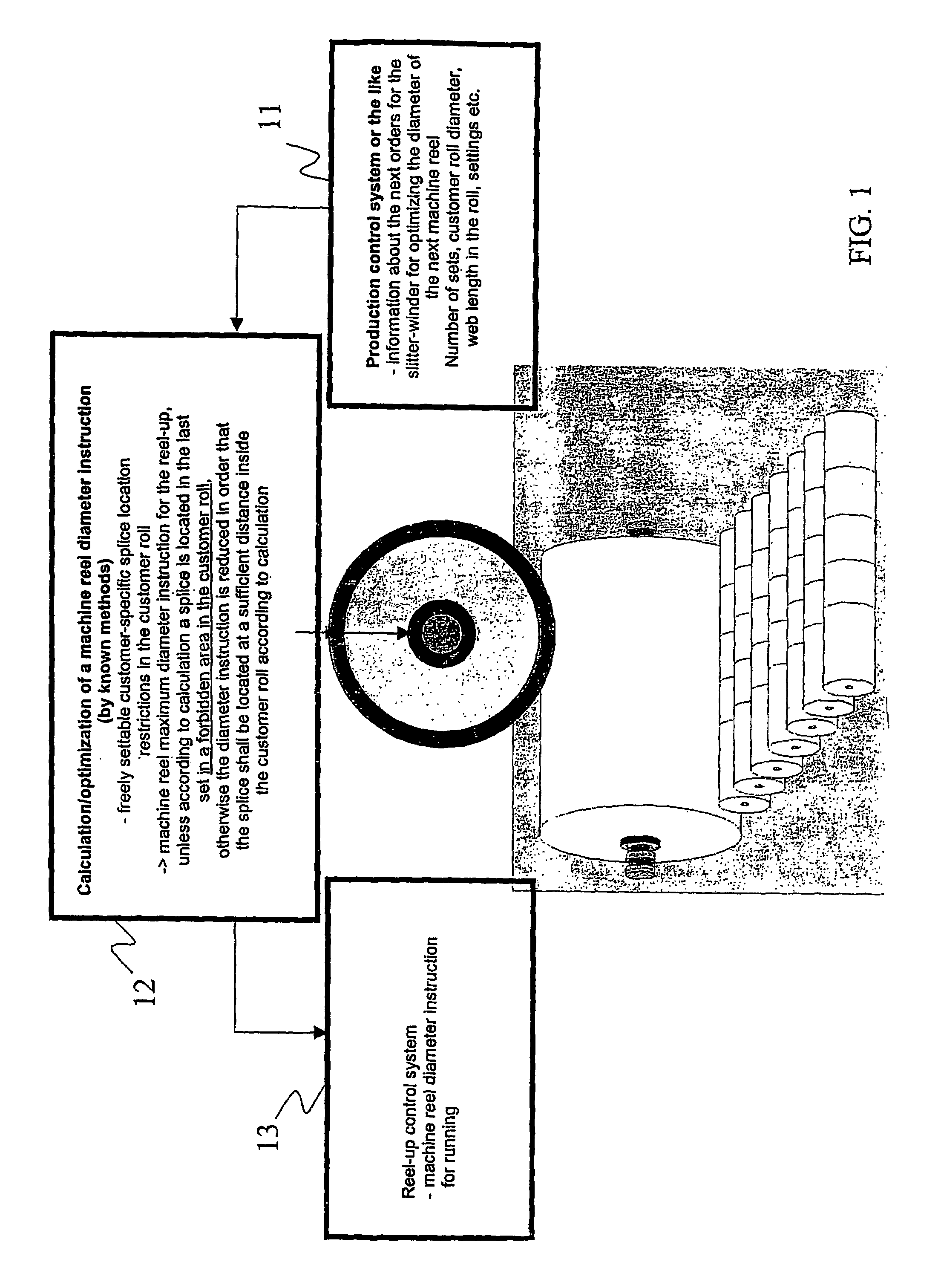

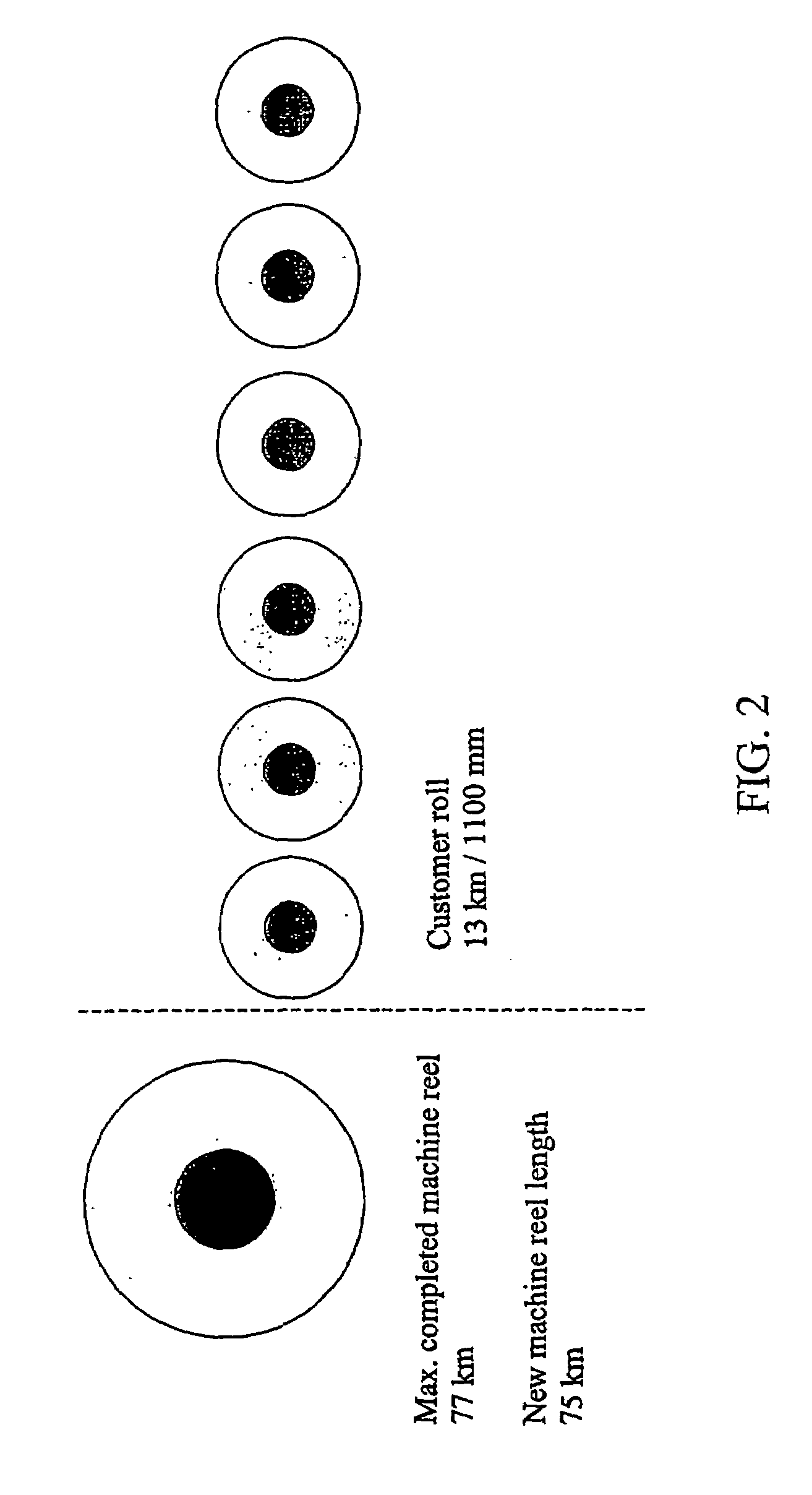

Method for calculating and optimizing the diameter of a paper or board web reel based on customer splice location restrictions

InactiveUS7502661B2Improve material efficiencyIncrease net efficiencyFunction indicatorsDigital differential analysersCardboardControl system

A web is wound in a paper or board machine into machine reels, which are run on a slitter-winder to form customer rolls, whose desired diameter and width are determined according to customer need. A continuous-trimming running mode is used in which a desired amount of web is run into a machine reel and, when needed, splicing is performed on the slitter-winder to produce customer rolls with a desired diameter size. The machine reel diameter is determined based on restrictions set on the location of a splice in the customer roll and the amount of broke produced from the machine reel is optimized. Information about the customer rolls to be slit is obtained from a production control system for calculating / optimizing a machine reel diameter instruction for optimizing the diameter of the next machine reel, and the calculated / optimized machine reel diameter instruction is set in the control system of a reel-up.

Owner:VALMET TECH INC

A device and method for generating electricity using igcc low-grade waste heat

ActiveCN106761990BImprove power generation efficiencyReduce coal consumptionSteam generation using pressureEnergy industryCooling towerLiquid state

The invention discloses a device and method for achieving low-grade cogeneration by means of an IGCC. The method comprises the steps that saturated synthesis gas is adopted as a heat source for heating a pressurized organic working medium into the superheated steam state from the liquid state, expansion working electricity generation is performed inside an expansion machine, then, the organic working medium enters a condenser to become liquid, and the liquid organic working medium is boosted through a pump, so that an organic working medium Rankine cycle is formed. The device and method are used for reducing heat losses inside a gasification island cooling tower, and the system electricity generation efficiency is improved by means of low temperature exhaust heat in a gasification island.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

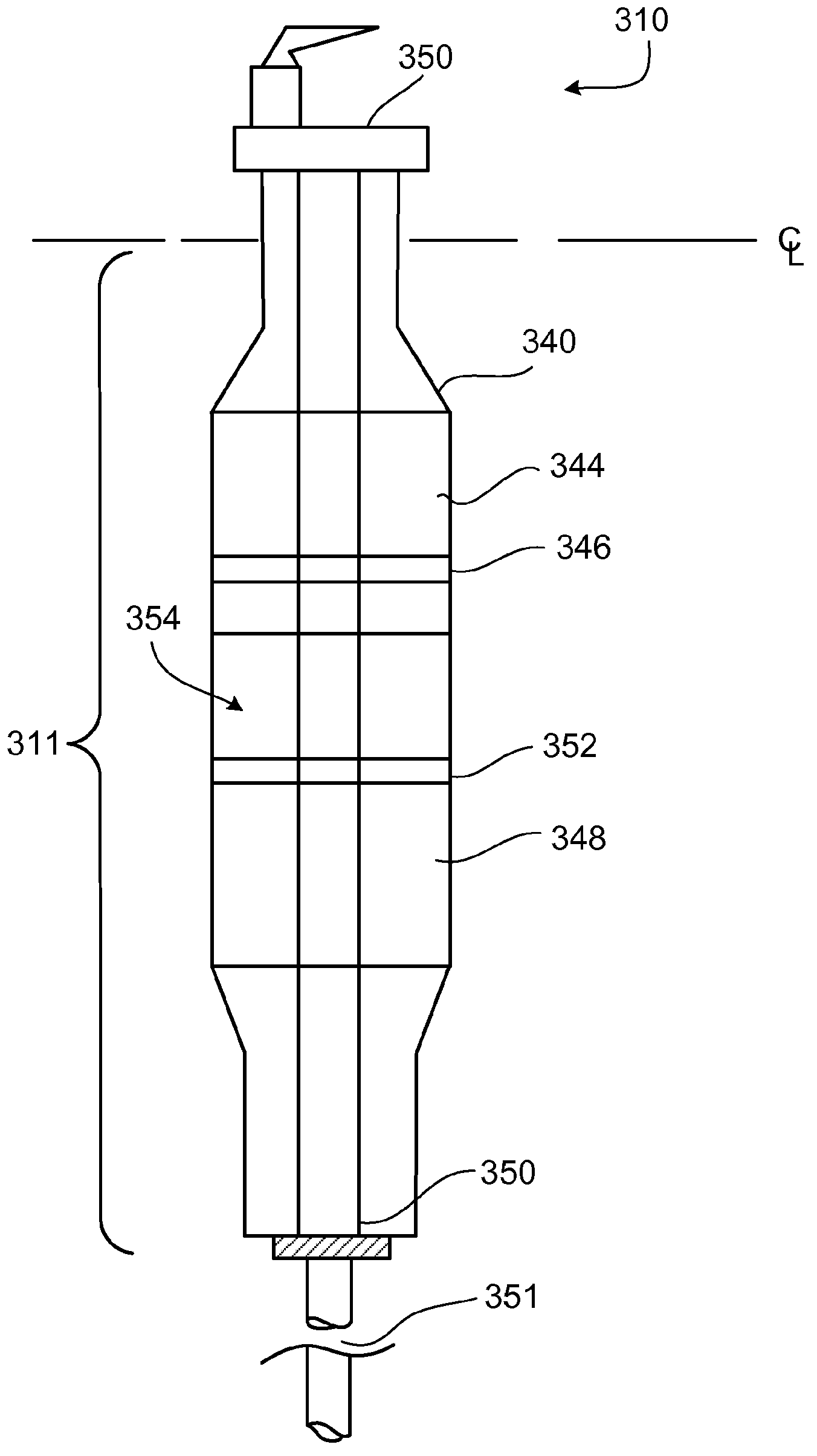

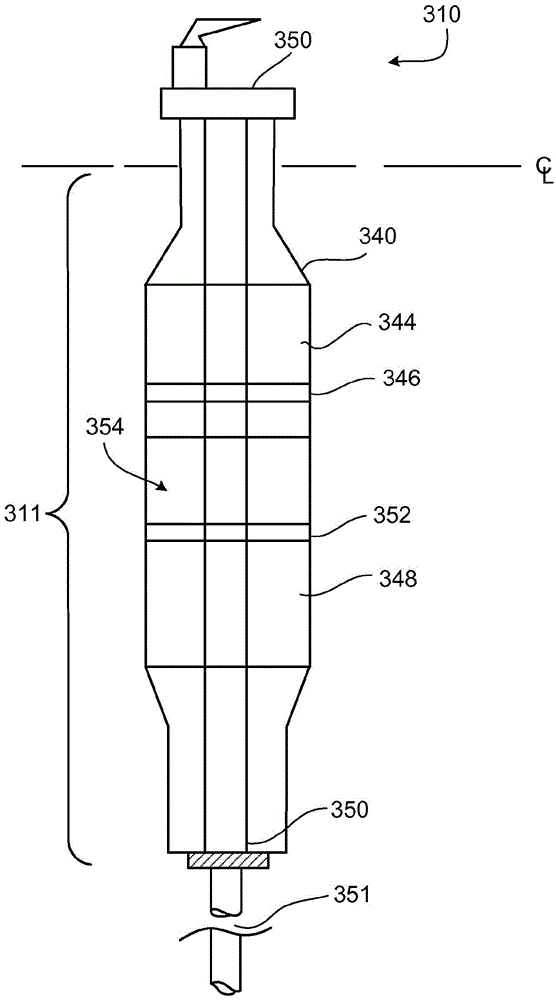

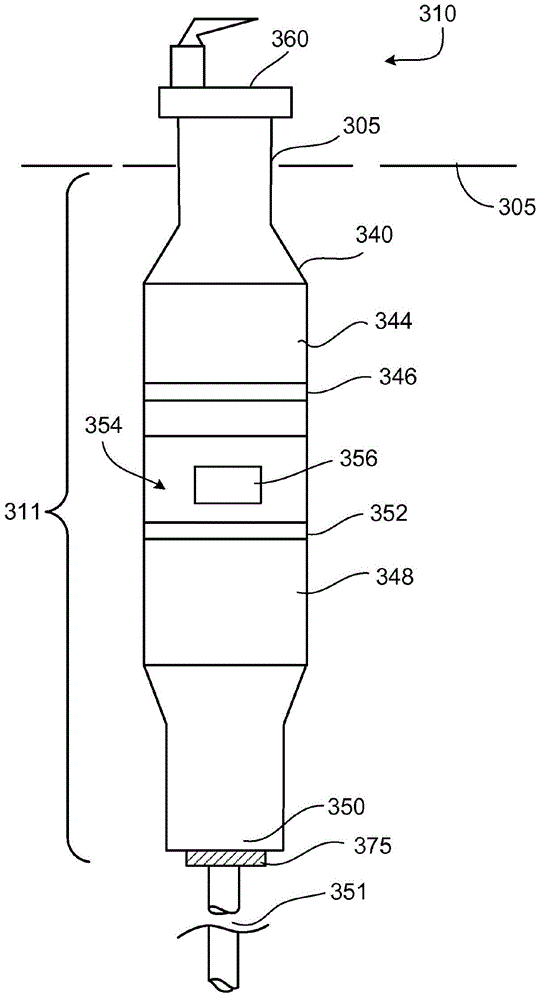

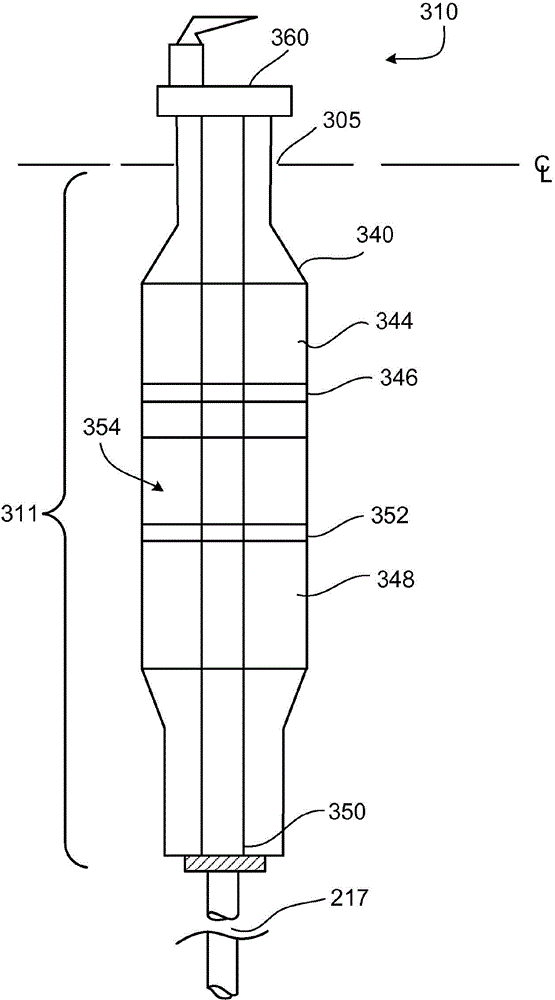

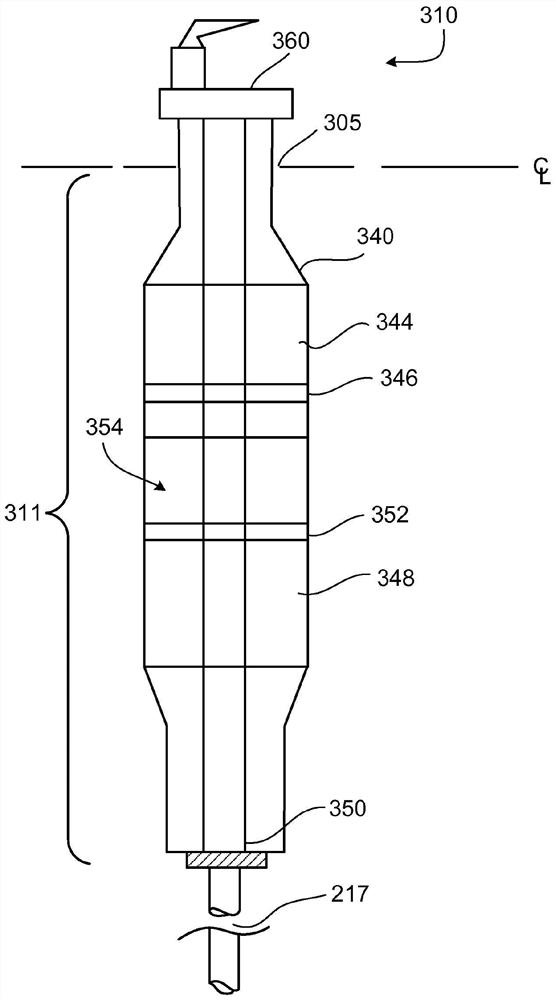

Ocean thermal energy conversion pipe connection

ActiveCN104956077AReduce construction costsReduce maintenance costsPipe laying and repairWaterborne vesselsInterior spaceThermal energy

A method of assembling a pipe on a water-supported floating platform is provided. The platform includes an open central bay, and a gantry on the platform is arranged so as to surround at least a portion of the bay. The method includes providing a pipe intake assembly and staves on the platform; transferring the pipe intake assembly to the interior space of the bay; assembling the individual staves on the pipe intake assembly in an offset construction; lowering the pipe portion within the bay and into the water until the upper ends of the staves reside within a lower portion of the gantry; increasing the length of the pipe portion by assembling additional staves to the upper ends of the assembled staves; and repeating the step of increasing the length of the portion of the pipe until the pipe has a desired length.

Owner:THE ABELL FOUND INC

Ocean thermal energy conversion power station

ActiveCN105464915BLightweight structureReduce friction lossSteam useMechanical power devicesThermal energyPower station

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection.

Owner:THE ABELL FOUND INC

Combined cycle waste heat utilization system that can stabilize high/low intake air temperature of the compressor

ActiveCN105822431BThreat to safe operationHigh outputGas turbine plantsJet propulsion plantsExpansion tankLithium bromide

The invention discloses a combined cycle waste heat utilization system capable of stabilizing the high / low inlet air temperature of a compressor. The combined cycle waste water heat utilization system comprises a smoke-hot water heat exchanger, an air-water heat exchanger, an expansion water tank, a pipeline pump, a low-temperature heat source hot water type lithium bromide refrigerator and a valve. A heat source used by the low-temperature heat source hot water type lithium bromide refrigerator and a heat source used by the air-water heat exchanger are waste heat of smoke at the tail portion of a waste heat boiler. In the low-temperature weather, the system can heat the inlet air of the compressor to prevent water drops in the air from being frozen, and the running safety and the heat economical efficiency of a unit are improved; in the high-temperature weather, the system can cool the inlet air of the compressor to improve the peak shaving capability and the heat economical efficiency of the unit; and waste heat of the discharged smoke of the waste heat boiler is used as the heat source of the system, the function of stabilizing the temperature of the inlet air of the compressor is achieved, switching of a compressor inlet air heating function and a compressor inlet air cooling function can be achieved through opening and closing of the valve, and double benefits of improving the safety and the economical efficiency of the unit are achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

A low-rank coal purification power generation system

InactiveCN103939158BImprove combustion efficiencyLess investmentSteam useLump/pulverulent fuel preparationEngineeringCoal

The invention provides a low-rank coal purification power generation system. The low-rank coal purification power generation system comprises a boiler, a steam turbine used for power generation and a power plant coagulator enabling steam to be coagulated into water. A steam exhaust port of the boiler is connected with a gas inlet of the steam turbine, an exhaust port of the steam turbine is connected with a gas inlet of the power plant coagulator, a liquid outlet of the power plant coagulator is connected with a liquid inlet of the boiler, a fuel inlet of the boiler is provided with a drying device used for drying low-rank coal and a directly-heated-type thermal decomposition furnace which can conduct thermal decomposition on the dried low-rank coal to generate semi-coke is installed between the boiler and the drying device. The semi-coke generated after the low-rank coal in the low-rank coal purification power generation system is purified is used for burning in the boiler, therefore, the boiler burning efficiency is directly increased and the investment is lowered.

Owner:HUNAN HUAYIN ENERGY TECH

Ocean thermal energy conversion power plant

ActiveCN104903573ASmall pressure lossReduce friction lossPipe supportsPipe laying and repairThermal energyOcean thermal energy conversion

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection.

Owner:THE ABELL FOUND INC

High-efficiency thermodynamic cycle system using vortex tubes

ActiveCN105401988BSave compression workIncrease net efficiencySteam regenerationCompression machinesEngineeringHigh pressure

The high-efficiency thermodynamic cycle system using vortex tubes is mainly composed of working fluid pumps, heat exchangers, expanders and vortex tube split cooling units. The vortex tube split cooling unit is composed of several vortex tubes. The liquid working medium separated by the vortex tube directly enters the inlet of the working medium pump, and the gaseous working medium enters the heat exchanger to exchange heat with the low-temperature working medium on the high-pressure side of the circulation system. The working medium enters the vortex tube again for split cooling, the liquid working medium enters the inlet of the working medium pump, and the gaseous working medium enters the heat exchanger again to exchange heat with the low-temperature working medium on the high-pressure side of the circulation system. After multi-stage vortex tube split cooling and multiple heat exchanges with low-temperature working fluid, most of the working fluid enters the inlet of the working fluid pump in liquid form, and only a very small part of the working fluid is not liquefied. The ratio of the two is appropriate, and the two The combination can ensure that all the working fluid at the inlet of the working fluid pump is in liquid state. The invention uses a liquid working medium pump to pressurize the working medium, the power consumption of the pump is reduced, and the heat in the circulation system is recovered and utilized, and the thermal efficiency is high.

Owner:DEZHOU GAOKELI HYDRAULIC

Fast reactor carbon dioxide power generation system and method

PendingCN114718661ANo chemical reactionWill not cause a nuclear accidentNuclear energy generationSteam engine plantsChemical reactionProcess engineering

The invention discloses a fast reactor carbon dioxide power generation system and method. The system comprises a fast reactor core, a sodium pump and a sodium helium heat exchanger, the sodium-helium heat exchanger is a shell-and-tube heat exchanger, sodium is located on the shell side of the heat exchanger, helium is located on the tube side of the heat exchanger, a fast reactor core, a sodium pump, the shell side of the sodium-helium heat exchanger and a pipeline connected with the shell side of the sodium-helium heat exchanger form a primary loop of the fast reactor carbon dioxide power generation system, an electric heating device is arranged in the primary loop, and the medium of the primary loop is sodium. The electric heating device can heat the medium to 200 DEG C or above. According to the method, helium belongs to inert gas and does not chemically react with sodium in a primary loop, and after the sodium-helium heat exchanger leaks, even if helium enters the sodium in the primary loop, chemical reaction does not occur, and nuclear safety accidents cannot be caused; under the condition of high temperature parameters, the supercritical carbon dioxide power generation cycle is more remarkable in efficiency advantage and better matched with fast reactor positioning, and the net efficiency can be improved by 2-4% compared with that of water working medium cycle at the 500 DEG C.

Owner:XIAN THERMAL POWER RES INST CO LTD

Ocean thermal energy conversion power station

ActiveCN104903573BSmall pressure lossReduce friction lossPipe supportsPipe laying and repairOcean thermal energy conversionPower station

Owner:THE ABELL FOUND INC

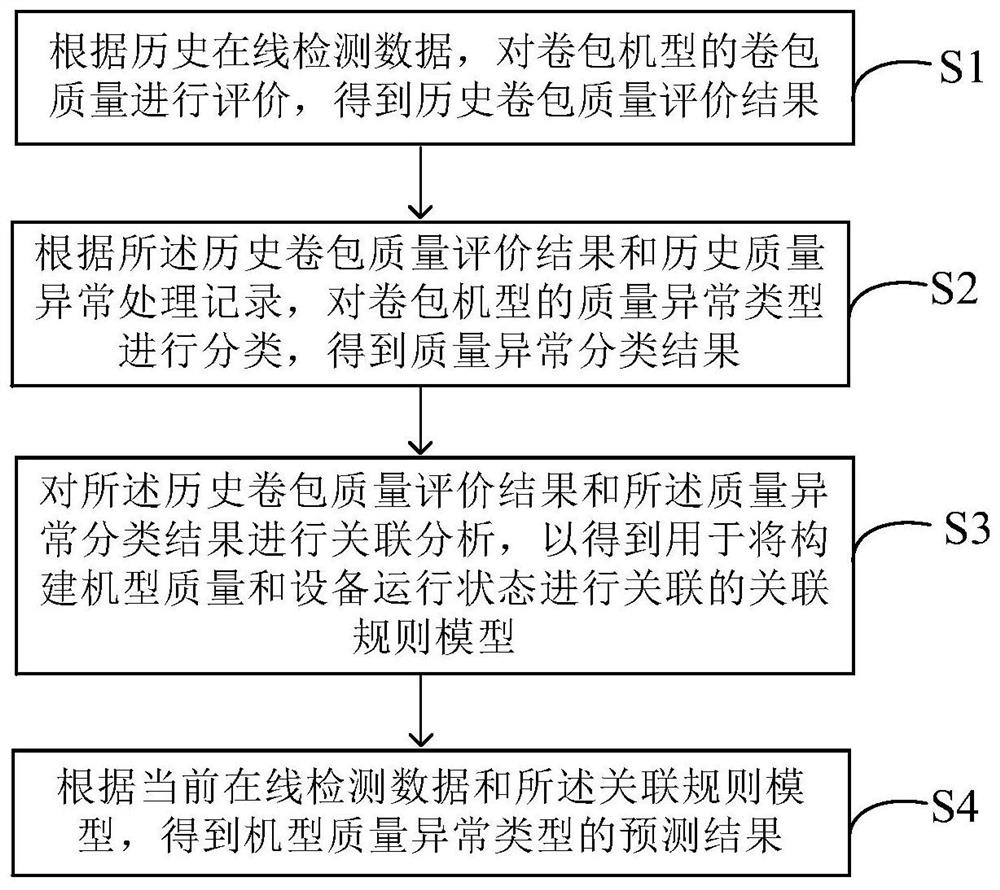

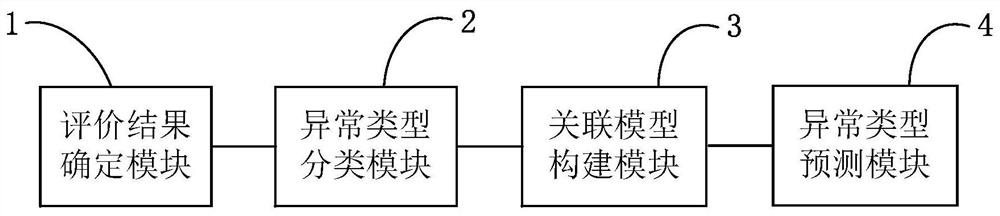

Method and system for dynamic correlation between quality and equipment management of roll-packing machine

ActiveCN113361939BAvoid repairsIncrease net efficiencyDigital data information retrievalCharacter and pattern recognitionEvaluation resultModel quality

The invention discloses a method and system for dynamically associating the quality of a wrapping machine type with equipment management. The method includes: evaluating the wrapping quality of a wrapping machine type according to historical online detection data, and obtaining the historical wrapping quality evaluation Results: According to the historical package quality evaluation results and historical quality anomaly processing records, the quality anomaly types of the package machine were classified to obtain the quality anomaly classification results; the correlation analysis was carried out on the historical reel quality evaluation results and quality anomaly classification results, In order to obtain an association rule model for associating the quality of the built model with the operating state of the equipment; according to the current online detection data and the association rule model, the prediction result of the abnormal type of the model quality is obtained. The dynamic association method of quality and equipment management provided by the present invention can monitor and predict the abnormality of quality and equipment in the production process of the package through the association rule model, which is beneficial to realize the in-process management and control of the package production process.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com